#Equipmentmonitoring

Explore tagged Tumblr posts

Text

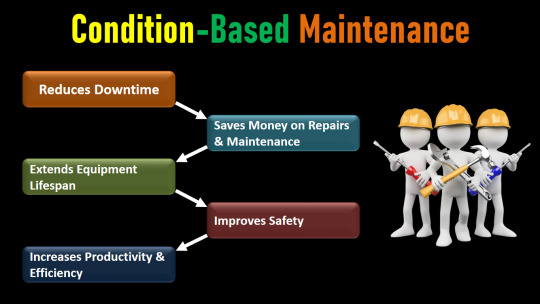

Everything You Need to Know About Condition-Based Maintenance

Discover the essentials of condition-based maintenance (CBM), its benefits, best practices, and how to implement it for improved asset management, cost efficiency, and operational performance in industries. Learn why CBM is the future of maintenance strategies.

For more details read our blog :

#Conditionbasedmaintenance#Predictivemaintenance#Maintenancestrategy#Preventivemaintenance#Maintenancemanagement#CBM#Equipmentmonitoring#Assetmanagement#Industrialmaintenance#Performancemonitoring

0 notes

Text

Electrical Thermography Inspection

The Smart Way to Prevent Failures | Thermo Elite Introduction: Why Electrical Thermography Inspection is a Game Changer Electrical failures can be costly, dangerous, and disruptive to any industrial or commercial operation in today's fast-moving world. A small fault in an electrical component could easily lead to a significant fire hazard or equipment failure, resulting in downtime and expense. What if you had a means to identify potential issues before they turn into a failure? That is where Electrical Thermography Inspection comes into play. Thermo Elite performs infrared inspections providing advanced energy diagnostics that allow business and property owners to identify hidden electrical issues before they negatively impact the asset.

What is Electrical Thermography Inspection?

Electrical thermography inspection is a type of predictive maintenance that does not affect the function of the electrical equipment. Thermography inspection detects abnormal heat patterns in electrical systems using infrared cameras. When electrical systems start to overheat, the components release infrared radiation. This radiation is not visible to the naked eye but is visible on thermal imaging photographs. When Thermo Elite captures the images, we will be able to draw attention to the potential electrical faults below:

✅ Loose connections

✅ Overloaded circuits

✅ Failing breakers or fuses

✅ Faulty electrical panels

✅ Unbalanced loads

✅ Insulation breakdown

✅ Wiring defects

The Importance of Electrical Thermography for BusinessesMany businesses are reactive in dealing with electrical failures and outages. However, with Thermal Imaging Inspections, you can make the switch to being proactive in your maintenance. Here's why it's important:

1️⃣ Prevention of Electrical Fires 🔥Overheated electrical components are one of the main reasons for electrical fires. Thermal inspections help identify this risk before the fire occurs.

2️⃣ Reduction of Downtime and Costly Repairs 💰Electrical failure can happen at any time and stop your operation, cost you money, time, and resources. A planned thermographic inspection can help to avoid unexpected failures and the expensive costs associated with emergency repairs.

3️⃣ Safety for Employees ⚡A faulty electrical system can expose employees to possible hazards. Regular thermal inspections provide a safer working environment.

4️⃣ Meeting Industry Standards 📜Many industries require electrical inspection for insurance, certifications, and to comply with regulations. Our inspections can assist businesses in meeting those requirements.

5️⃣ Increase Equipment Lifespan ⏳If an electrical fault goes unnoticed, it can shorten the life of motors, panels, wiring, and other components. Identifying issues early on and fixing them can help ensure the longevity of your equipment.

Thermo Elite’s Electrical Thermography ProcessAt Thermo Elite,

we employ a structured and methodical procedure to carry out our electrical thermography inspections so you can receive accurate and dependable inspections:

🔹 Step 1: Pre-Inspection Assessment – We arrive onsite to talk with you about the layout of your electrical system and any important areas you would like to monitor.

🔹 Step 2: Infrared Scanning – Our infrared thermal cameras allow our team to scan the electrical panels, switchgear, circuit breakers and other possible places of concern.

🔹 Step 3: Data Analysis – Our qualified professionals analyze the thermal data that is captured to examine the heat signatures and discover any areas of abnormal temperature, which may signify an issue.

🔹 Step 4: Comprehensive Report & Recommendations – You will receive a report that outlines the information from the thermal images; any recommended remedies for the issues and any recommendations we have for ongoing maintenance moving forward.

🔹 Step 5: Ongoing Support – We are available to assist with actions to remedy the issues discovered in your thermographic inspection and can help with scheduling future thermographic inspections as part of an ongoing support agreement or routine maintenance.

Industries That Electrical Thermographic Inspection Benefits:

🔸 Manufacturing & Industrial Facilities – Regular, preventive thermographic inspection means your operation continues and minimizes the risk of electrical failure in the operation of machinery and controls in a manufacturing environment.

🔸 Commercial Buildings & Offices – Thermographic inspections of your electrical systems, HVAC systems, or critical server space help avoid interruptions to power, and reduce risk of fire

🔸 Hospitals & Healthcare Facilities – It is imperative for life-saving medical devices to have a continuous electrical power supply.

🔸 Retail Stores & Malls – Periodic, scheduled thermography will help to observe electrical hazards in lighting, refrigeration, and other power systems.

🔸 Data Centers & IT Hubs – Servers and infrastructure require constant monitoring from electrical failure.

🔸 Residential Buildings & Condos – Where residents live and sleep, thermographic scans will identify any wiring faults, electrical panel problems, and thermal abuse that may lead to deteriorating electrical meets the safety policies associated to that dwelling.

Why Select Thermo Elite for Electrical Thermography Inspection?

✔ Expert Certified Inspectors – Our crew of infrared thermographers are highly trained with years of experience.

✔ State-of-the-Art Infrared Technology – We utilize the most up to date thermal imaging cameras to ensure accuracy and instantaneous results.

✔ Non-Intrusive & Quick Process – No more shutdowns! Our inspections are quick, safe, reliable, and do not disrupt your operation.

✔ Easy to Read Reporting & Actionable Solutions – We can provide you with written reports that are easy to read with solutions to the problems we find.

✔ Affordable & Cost Effective – Our service is an investment in thermal imaging to protect from potential costly repairs and downtime.Schedule your Electrical Thermography Inspection Service!There's no need to wait for an electrical failure, electrical fire, or some unexpected breakdown to impact your business! Thermo Elite can help you stay ahead of potential electrical issues with our professional thermal imaging inspections.

#ElectricalThermography#ThermalImagingInspection#InfraredInspection#ElectricalSafety#PreventElectricalFires#PredictiveMaintenance#IndustrialSafety#ElectricalTesting#InfraredThermography#EquipmentMonitoring#ThermalInspection#ElectricalMaintenance#ElectricalRiskAssessment#NonDestructiveTesting#ThermoElite

0 notes

Text

Condition-Based Maintenance: How It Works & Why It Matters

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

0 notes

Text

Vibration Meter R Tek RK63A

Measurement Range : Acceleration: 0.1~199.9m/s2 Velocity: 0.1~199.9m/s Displacement: 0.001-1.999mm P.P

Accuracy : +5%

LCD Display : 3.5 digits display

Operation Condition : 0~40°C

Unit Size : 183*67*30mm,

Standard Carton Size : 51.7*40.5*32CM

Power : 9V Battery

Buy : https://vegabazaar.com/product/Vibration-Meter-R-Tek-RK63A/

#VibrationMeter#vibrationanalysis#conditionmonitoring#predictivemaintenance#industrialtools#machineryhealth#EquipmentMonitoring#Manufacturing#factoryautomation

0 notes

Text

Optimizing Operations: Equipment Performance Monitoring Services

Maximize equipment efficiency with our comprehensive monitoring services. Real-time tracking and analysis ensure optimal performance, minimize downtime, and extend equipment lifespan for enhanced operational productivity.

1 note

·

View note

Text

Why Calculating ROI for Your Construction Operation is a Game-Changer

Hey Team Construction! 🏗️✨

Ever sat down with your cup of coffee, looking at the hustle of your construction site, and wondered, 'What's the real impact of all this on our budget?' Well, let’s chat about something that might just be the key to turning those thoughts into solid project wins – Return on Investment (ROI).

Why Should We Care About ROI? So, it's not just about spending money; it's about spending it wisely. ROI is that cool friend who guides your spending decisions, making sure every penny you put in contributes to the success of your project. It's like having a financial GPS for your construction journey.

What's the Deal with FUPO's Calculator? Imagine having a tool that takes all those complex finance numbers and turns them into something we can all understand. Well, that’s FUPO's ROI Calculator for you. It’s like having a financial superhero in your corner, helping you decode the language of construction finance.

Let’s Talk Numbers – 71.67 to be Exact: Here's the scoop – for every rupee you toss into FUPO, it throws back 71.67 rupees your way. That’s not just a return; that’s a celebration! It's not just software; it's like having a financial wizard on your team.

Tailored Just for You: FUPO gets it. Your project is unique – a bit like your favorite playlist. So, the calculator is designed to let you tailor it to your project's rhythm. Those blue fields? Your customization playground.

Efficiency – Let’s Keep it Real: With FUPO, it’s not just about software; it's about making things run smoother. Picture this – less wastage, smarter hiring, and getting the most out of your equipment. It's like the secret sauce for a successful project recipe.

Let’s Have a Chat:

Ever done the ROI dance with your construction gear?

What's your go-to way of figuring out if your equipment is hitting all the right notes?

Ever checked out FUPO's ROI Calculator symphony?

Share your thoughts below! Let’s create a community vibe where every construction story is a unique tale of success.

#equipmentmonitoring#constructionsoftware#constructiontechnology#construction projects#project management#assettracking#constructionequipment#projectmanagement

0 notes

Text

Maximize Efficiency with Equipment Performance Monitoring

Real-time equipment performance monitoring helps detect inefficiencies, reduce downtime, and optimize productivity. With IoT sensors and AI-driven analytics, you can track machine health, predict failures, and cut maintenance costs.

Stay ahead with: *Predictive maintenance . * Reduced operational costs . * Enhanced productivity.

Is your equipment running at peak performance? #Manufacturing #Efficiency #EquipmentMonitoring #IoT

0 notes

Text

0 notes

Photo

Equipment Monitoring System predicts failures & helps manage operations by monitoring real-time equipment data.

0 notes

Photo

Global Equipment Monitoring Market is expected to reach USD 5.26 Billion by 2024 from USD 3.16 Billion in 2016 at a CAGR of 6.6 %

https://www.maximizemarketresearch.com/market-report/global-equipment-monitoring-market/8369/

0 notes

Text

Empowering Equipment Health with Shop Floor Data Collection Software Boost equipment health with Shop Floor Data Collection Software for real-time insights, enhanced efficiency, and reduced downtime

For more details read our blog :

#machinemonitoring#machinemonitoringsystem#EquipmentHealthMonitoring#machinemonitoringsoftware#productionmonitoringsystem#oeemonitoringsystem#productionmonitoringsoftware#equipmentmonitoring#oeemanufacturing#smartmanufacturing#factorymonitoringsystem#datacollection#dataautomation#dataanalysistools

0 notes

Text

Chief Engineer

Chief Engineer A Chief Engineer will manage the Engineering Team to efficiently maintain all hotel operations such that safety security conversation and compliance are ensured at the highest levels.What will I be doing?As Chief Engineer you are responsible for the effective management of all engineering and maintenance operations within the hotel including energy conservation. You are also responsible for the development of the Engineering Team and staying abreast of compliance regulations and procedures in the field of Engineering as required for hotel standards. Specifically a Chief Engineer will perform the following tasks to the highest standards Lead the Engineering Team in the day to day engineering and maintenance operations of the hotel including service standards equipment schedules and work schedulesCommunicate with Housekeeping to coordinate and prioritize maintenance activities for Guest rooms and public areasDevelop systems and procedures to ensure the health and safety of Guests and Team Members as well as the proper conditions for plants machinery and propertyCommunicate with Government agencies to ensure full compliance with statutory regulationsPrepare Capital and Repairs and Maintenance budgets for EngineeringPerform daily checks around the hotelConduct lift emergency release procedures as requiredDiagnose maintain and repair mechanical equipment within the hotelEnsure good relationships are built with internal and external customersMaintenance of all hotel fixtures and fittings to ensure they are in safe condition and take action when any unsafe situations ariseDevelop implement and direct all emergency programsDevelop implement and manage energy conservation programs for the property to minimize expensesCoordinate renovation bidding define the cost and scope of the project and oversee the general contractor and subcontractors to ensure quality work is performed cost effectivelyPerform special projects and other responsibilities as assignedIdentify and introduce environmentally friendly systems and equipmentMonitor Key Performance Indicators for the Engineering Department and take corrective action as required to improve equipment inventory quality audit productivity and other objectivesManage all Team Member related activities including recruitment performance management training career planning disciplinary matters and team motivationWhat are we looking for?A Chief Engineer serving Hilton brands is always working on behalf of our Guests and working with other Team Members. To successfully fill this role you should maintain the attitude behaviours skills and values that follow Advanced knowledge of building management engineeringA degree in Engineering or similarExposure to budgeting and basic accountingPositive attitudeGood communication skillsCommitted to delivering a high level of customer serviceStrong leadership skills and previous experience of managing a teamExcellent grooming standardsFlexibility to respond to a range of different work situationsAbility to work under pressureAbility to work on their ownPrevious experience of facilities managementProficient at an advanced level with computers and relevant computer programs It would be advantageous in this position for you to demonstrate the following capabilities and distinctions First AidQualification in engineering fieldWhat will it be like to work for Hilton?Hilton is the leading global hospitality company spanning the lodging sector from luxurious full service hotels and resorts to extended stay suites and mid priced hotels. For nearly a century Hilton has offered business and leisure travelers the finest in accommodations service amenities and value. Hilton is dedicated to continuing its tradition of providing exceptional guest experiences across its global brands. Our vision to fill the earth with the light and warmth of hospitality unites us as a team to create remarkable hospitality experiences around the world every day. And our amazing Team Members are at the heart of it all! EOE AA Disabled Veterans En savoir plusTout afficher * راتب مجزي جداً. * مكافأت و حوافز متنوعة. * توفير سكن مؤثث أو بدل سكن. * أنتقالات أو توفير بدل عنها. * توفير تذاكر السفر لمن يشغل الوظيفة و عائلته. * نسبة من الأرباح الربع سنوية. * أجازات سنوية مدفوعة الراتب بالكامل. * مسار وظيفي واضح للترقيات. * بيئة عمل محفزة و مناسبة لحالة الموظف. * تأمين طبي للموظيف و عائلته. * تأمينات أجتماعية. التقدم و التواصل مباشرة دون و سطاء عند توافر الألتزام و الجدية التامة و المؤهلات المطلوبة علي: [email protected]

0 notes

Text

Condition-Based Maintenance: How It Works & Why It Matters

Imagine if your car could tell you exactly when it needs an oil change rather than following a fixed schedule. Instead of guessing or changing the oil too early, you’d only do it when it’s actually necessary, saving time and money while keeping your engine in top shape. That’s the core idea behind Condition-Based Maintenance (CBM) in industries.

CBM is a smart maintenance strategy that monitors the real-time condition of machines and equipment. Instead of performing maintenance on a fixed schedule (like every three months), CBM uses sensors and data analysis to determine when maintenance is truly needed. This approach helps prevent unnecessary servicing while avoiding unexpected breakdowns.

➥ How Does Condition-Based Maintenance Work?

CBM relies on real-time monitoring and data-driven decision-making. Here’s a simple breakdown of how it works:

✅ 1. Sensors Collect Real-Time Data

Machines are equipped with sensors that track critical performance indicators such as:

Temperature – Helps detect overheating issues.

Vibration – Identifies misalignments or wear in rotating equipment.

Pressure Levels – Ensures pumps, compressors, and hydraulic systems are working properly.

Oil Quality – Measures contamination or degradation in lubricants.

✅ 2. Data Is Analyzed to Detect Problems

The collected sensor data is continuously monitored and compared to normal operating conditions. If the system detects unusual behavior, like excessive vibration or rising temperature, it signals a potential issue.

For example, if a motor starts vibrating abnormally, it could indicate a misalignment, loose parts, or an upcoming failure. Maintenance teams receive an alert, allowing them to inspect and fix the issue before the motor breaks down.

✅ 3. Maintenance Is Performed When Needed

Instead of following a fixed maintenance schedule (which can either be too frequent or too late), CBM ensures maintenance is done only when the data suggests it's necessary. This reduces unnecessary downtime and repair costs while keeping machines running efficiently.

Read in detail: https://www.knowledgewale.com/2025/03/condition-based-maintenance.html

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

1 note

·

View note

Text

Effortless Site Equipment Management with FUPO's Precision

FUPO simplifies site equipment management, offering a centralized solution for planning, allocation, engagement, and tracking. Achieve operational excellence, minimize costs, and ensure projects are completed on time with FUPO's advanced features.

#constructionequipment#projectmanagement#project management#constructionsoftware#equipmentmonitoring#constructiontechnology#assettracking#construction projects

0 notes

Text

Construction Equipment Tracking System by FUPO: Stay in Control!

Take control of your construction projects with FUPO's tracking system. Ensure real-time visibility, prevent mishandling, and optimize fleet utilization for on-time and on-budget project completion.

#constructionequipment#projectmanagement#constructionsoftware#assettracking#construction projects#equipmentmonitoring#constructiontechnology#project management

0 notes

Link

Equipment Monitoring System is a comprehensive solution for equipment manufacturers company. It enhances the overall performance of the business by reducing operating and maintenance expenses.

0 notes