#Eva Footwear Manufacturers

Text

Kids Shoes Manufacturers & Suppliers in India | mlqshoes

MLQ Shoes is a reputable manufacturer and supplier of kids' shoes in India, offering a wide range of high-quality footwear for children. With a focus on both style and comfort, their shoes are designed to meet the needs of active kids while ensuring durability and support. From trendy sneakers to classic sandals, MLQ Shoes provides options for every occasion and preference, making them a go-to choice for parents looking for reliable footwear for their little ones.

#airwash#Eva Footwear Manufacturers#Suppliers In New Delhi#EVA Shoe Sole Manufacturers#Suppliers In Delhi#pvc shoes manufacturers in delhi#Top Pvc Shoe Manufacturers in Delhi#PVC Footwear Manufacturers & Suppliers in India#Kids Shoes#boys Shoes#gents shoes#Eva sandals#vschool#FOAMA shoes#Kids Shoes Manufacturers & Suppliers in India#Kids Shoes Manufacturers in india#Kids Shoes Manufacturers & Suppliers in Delhi#Top Kids Shoe Manufacturers in Delhi#Gent and Ladies Shoes Manufacturer in India#ladies shoes manufacturers in india#Ladies Shoes Manufacturers & Suppliers in India#Shoes Manufacturer in India#boys Shoes manufacturers in india#Top boys Shoe Manufacturers in Delhi#boys Shoes manufacturers in delhi#best boys shoes manufacturers in india#delhi#Gents Shoes Manufacturers & Suppliers in India#Gents Shoe Manufacturers In India#Mens Shoes Manufacturers & Suppliers in Delhi

0 notes

Text

Masterbatchin: Unleashing the Power of Additives Masterbatches

Elevate the quality of your plastics with Masterbatchin's premium additives masterbatches. Our comprehensive range of masterbatches is engineered to enhance the performance and aesthetics of various plastic applications. Whether you need UV protection, flame retardancy, or color consistency, we have the perfect solution for you.

Click Here: https://www.masterbatchin.com/

#additives masterbatches#colour masterbatch manufacturers#black & white masterbatches#phthalate free colour masterbatch#eva masterbatches manufacturers#eva compound manufacturers for footwear#light weight pvc compound for footwear#pvc compound manufacturers#phthalate free pvc compound for footwear

0 notes

Text

Women Slippers Manufacturers – Aygo Footwear

We, Aygo Footwear are the renowned Women Slippers Manufacturers, suppliers, and exporters of an exclusive array of Women's slippers that include Ladies' slippers, women's fancy slippers, and fashionable upper girl's slippers. These are open-back casual slip-on footwear that are made by utilizing top-quality rubber foam (EVA, PU, TPR) for the sole and polypropylene & leather for the upper wrap. These slippers are widely used by ladies in homes and also when going outside to different places to protect their feet from the dirt. Furthermore, these slippers are available in a variety of styles and sizes.

Contact Us Today.

#top 10 footwear manufacturers in india#trendy sports shoes manufacturers#Women Slippers Manufacturers#Kids School Shoes Manufacturers in India#Women Sandals Manufacturers in Delhi#Men Slippers Manufacturers#sneakers manufacturers#trendy sports footwear manufacturers#footwear manufacturers in delhi#comfortable sport shoes manufacturers

0 notes

Link

Check out this listing I just added to my Poshmark closet: BIRKENSTOCK Madrid Big Buckle (Washed Metallic Rose Gold) Sandals Size 3….

0 notes

Text

Decoding the Manufacturing Process of Ethylene Vinyl Acetate (EVA): Technologies Adopted by Industry Leaders

Ready to dive into the world of cutting-edge polymers? Today, we're shining the spotlight on Ethylene Vinyl Acetate, or EVA – the superhero of polymers! So, what's the deal with EVA? Well, it's not your average resin – oh no! It's a super-special copolymer of vinyl acetate and ethylene, packed with some seriously awesome properties. We're talking flexibility that'll make your jaw drop, the ability to brave even the chilliest temperatures, and toughness that can stand up to any chemical thrown its way. In this blog, we will read more about EVA and unleash the secrets this material holds along with its manufacturing process in detail. So, what are we waiting for? Let’s dive into it!

Introduction

EVA, a polymer blend of ethylene and vinyl acetate, stands out among plastics due to its distinctive properties. Its composition grants it a range of advantages that distinguish it in various applications. Regarding production, EVA boasts ease of processing. It lends itself well to molding, extrusion, or foaming, enabling diverse shapes and configurations and enhancing design possibilities. This versatility renders it indispensable across industries, spanning from packaging to healthcare.

EVA has the following characteristics:

Flexibility: EVA remains pliable and doesn't become stiff or brittle. For example, in cold weather conditions, materials like EVA can still bend and stretch without breaking, making them ideal for applications where flexibility is crucial, such as in footwear or packaging.

Resilient: Resilience refers to the ability of a material to return to its original shape or form after being stretched, compressed, or deformed. In the case of EVA, its resilience means that it can withstand pressure or impact without permanently deforming. This property makes it suitable for products that undergo repetitive stress or impact, like athletic gear or cushioning materials.

Tough at low and moderate temperatures: EVA maintains its strength and durability even when exposed to low or moderate temperatures. It can withstand external forces or impacts without breaking or cracking, ensuring the integrity of the material. This toughness makes it suitable for various applications, including outdoor equipment, automotive parts, or industrial components.

Crack resistant: EVA's crack resistance means that it can endure bending, stretching, or impact without developing cracks or fractures. This property is crucial for ensuring the longevity and reliability of products made from EVA, such as footwear, toys, or packaging materials.

Manufacturing Process

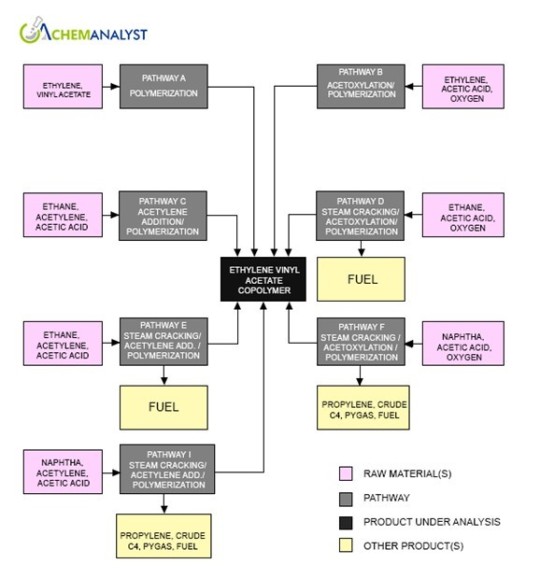

There are several ways to create EVA through the copolymerization of ethylene and vinyl acetate, including solution polymerization, suspension polymerization, bulk polymerization, and emulsion polymerization.

In solution polymerization, a solvent is used alongside a catalyst to facilitate the reaction between ethylene and vinyl acetate. The preferred solvents are alcohols with four or fewer carbon atoms, or mixtures where these alcohols are the main component. Examples include methanol, ethanol, and propanol, with methanol being the most favorable choice. While any radical initiator can technically be used as a catalyst in EVA production, some options are more favorable. This invention particularly highlights azo compounds as preferred catalysts. Two specific examples of suitable azo compounds are 2,2'-azobis-(2,4-dimethylvaleronitrile) and 2,2'-azobis-(2,4,4-trimethylvaleronitrile).

There are several options for feeding vinyl acetate and the catalyst into the reaction vessel:

Pre-mix: Combine all three (vinyl acetate, solvent, and catalyst) beforehand and feed them together.

Separate Feed 1: Dissolve the catalyst in the solvent, then feed the vinyl acetate and solvent separately.

Separate Feed 2: Feed the vinyl acetate separately from a pre-mixed liquid containing the catalyst and solvent.

Separate Feeds (Preferred): Introduce separate streams of a pre-mixed liquid containing vinyl acetate and solvent, and another pre-mixed liquid containing the catalyst and solvent.

The ideal polymerization temperature falls within a range of 40°C to 80°C. Temperatures below 40°C require a longer reaction time, necessitating an increased amount of catalyst, which can complicate control of the process. Conversely, exceeding 80°C makes controlling the polymerization difficult.

The average time the reaction mixture spends within the vessel (residence time) is preferably between 2 and 8 hours, with a narrower preference of 2 to 6 hours. A residence time shorter than 2 hours requires adjustments like increasing the reaction temperature or catalyst amount, both of which can make control of the polymerization more challenging. After the EVA copolymerization process, the resulting product undergoes further processing to create usable forms.

The first step involves using an alcohol solution (or an alcohol-water solution) of the EVA copolymer that has been saponified (a chemical treatment). This solution serves as the base for creating strands. These strands are then formed by extruding the alcohol solution into a solidifying liquid, typically water or a water-alcohol mix. The solidified strands are cut into pellets and rinsed with water.

Following rinsing, the pellets can optionally undergo a chemical treatment. This may involve immersing them in a water-based solution containing acids or their salts. Examples of suitable chemicals include formic acid, acetic acid (preferred choice), adipic acid, other carboxylic acids, phosphoric acid, boric acid, or their salts.

Finally, the dried pellets are ready for melt-molding into various desired products. The preferred temperature range for melt-molding is between 160°C and 260°C. During molding, various additives can be incorporated as needed. Additionally, the EVA copolymer can be blended with other thermoplastic resins for further modification. There are numerous melt-molding methods available, including injection molding, compression molding, and extrusion molding. Extrusion molding offers even more possibilities, with techniques like T-die, blow molding, pipe extrusion, wire extrusion, irregularly shaped die extrusion, inflation, and more. The processed EVA can be molded into various final products, either by itself (films, sheets, tapes, bottles, pipes, filaments, irregularly shaped extrusions) or through co-extrusion with other thermoplastic resins.

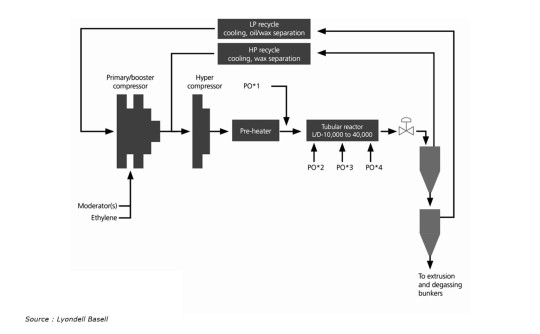

Lyondell Basell uses the Lupotech process to produce EVA. The overall EVA production process can be segmented into several distinct process units: Pre-compression of ethylene, compression to reach reaction conditions, the polymerization reaction itself, separation of polymer from gas, recycling of unreacted gases, extrusion, pelletizing, degassing, storage, and packaging.

In the Lupotech T tubular reactor, the entire flow of ethylene is received from the hyper compressor, entering the first reaction zone preheated to temperatures ranging between 150–170°C and under pressures ranging from 2000 to 3100 bar. For the synthesis of copolymers, specific comonomers like vinyl acetate or acrylic-based monomers are introduced. The reaction is initiated by injecting organic peroxides into the reactor at various points following each reaction peak, which optimizes the temperature profile of the reaction mixture.

On the other hand, in the Lupotech A autoclave reactor, compressed ethylene from the secondary compressor is directed through flow splitters to designated points within the reactor. An organic liquid peroxide initiator is introduced to sustain a continuous polymerization reaction within controlled temperature zones. Additionally, a comonomer modifier is injected to regulate product properties. The effluent from the reactor is then discharged through a product cooler into the high-pressure separator.

Applications of Ethylene Vinyl Acetate (EVA):

Footwear

Ethylene Vinyl Acetate (EVA) is a superstar material in the footwear industry. Thanks to its impressive cushioning, shock absorption, and flexibility, EVA is a go-to material for crafting comfortable and supportive insoles, midsoles, and outsoles. This makes it a popular pick for a wide range of footwear, from athletic shoes that help you conquer your workout to comfy sandals and casual shoes for everyday wear.

Sports Goods

EVA shines in the world of sports and recreation due to its exceptional cushioning and impact resistance. This makes it a hero material for various equipment, including sports padding, helmet liners, yoga mats, exercise mats, and protective gear like knee pads and shin guards. By absorbing shock and blows, EVA helps athletes of all levels train and perform safely and comfortably.

Automotive

Cars are another place where EVA shows off its versatility. Inside the vehicle, EVA contributes to comfort and functionality. Floor mats made from EVA are a common sight, and it's also used to create supportive headrests, attractive door panels, and even instrument panels. Beyond comfort, EVA's presence extends to essential car parts like gaskets, seals, and insulation materials.

Packaging

Because EVA plastic is lightweight, flexible, and great at absorbing shock, it's a champion in the world of packaging. Commonly found as foam inserts, protective packaging for delicate items, and padding materials for electronics, EVA helps keep your valuable products safe and sound during transport.

Solar Panels

Ethylene vinyl acetate is a key player in solar panel technology. This material boasts excellent properties for solar applications. It allows sunlight to pass through easily (good radiation transmission) and resists degradation from sunlight over time (low degradability). In the solar panel manufacturing process, EVA acts as a glue (encapsulating agent). When heated and applied, it forms a protective layer (sealing and insulating film) that encases the delicate solar cells within the panel. This layer safeguards the cells and keeps them functioning optimally.

Market Outlook:

The footwear industry reigns as the main driver of the global market for Ethylene Vinyl Acetate (EVA). This dominance is expected to continue due to the ever-growing global population. EVA's winning formula for footwear lies in its impressive combination of properties: high resistance, excellent grip, crack resistance, thermal insulation, shock absorption, chemical resistance, vibration dampening, and low water absorption. Beyond footwear, EVA finds another key application in the solar energy sector. Here, it serves as an adhesive that encapsulates photovoltaic (PV) modules within solar panels. This not only provides structural support but also ensures electrical isolation, further fueling the demand for EVA.

Ethylene Vinyl Acetate (EVA) Major Manufacturers

Significant companies in the Global Ethylene Vinyl Acetate (EVA) market are ExxonMobil Corporation, Sinopec, Hanwha Total Petrochemical, Formosa Plastics Corporation, BASF-YPC, The Dow Chemical Company, Celanese, Shaanxi Yanchang Zhongmei Yulin Energy Chemical Co., Ltd, Asia Polymer Corporation, PJSC Kazanorgsintez, and Others.

Conclusion:

Ethylene Vinyl Acetate (EVA) is a versatile polymer with numerous useful applications. EVA is a material that can morph into many shapes and structures. It is great when it comes to resisting water and moisture, providing cushioning and shock absorption, insulating against heat, and lasting a long time. This winning combination, especially its lightweight design with shock-absorbing capabilities, makes it a superstar in the world of sports footwear. You'll find EVA in various parts of athletic shoes, from outsoles and midsoles to insoles. But its popularity goes beyond just sports shoes; it's become a common element in all types of footwear. EVA's versatility extends beyond shoes as well, finding use as padding and interfacing in various applications. The increasing popularity of Ethylene Vinyl Acetate (EVA), propelled by its exceptional friction coefficient and long-lasting nature, is fueling its utilization in the production of footwear. This trend is anticipated to significantly boost the global Ethylene Vinyl Acetate (EVA) demand.

0 notes

Text

Fashion and sustainability meet in the Adidas Yeezy Foam Runner

Adidas' Yeezy Foam Runner has become an industry-leading sneaker, captivating fashion enthusiasts with its futuristic design and sustainable materials. In this article, we delve into the world of Adidas Yeezy Foam Runner, exploring its unique features, eco-friendly construction, and the cultural impact it has made since its debut.

Adidas Yeezy Foam Runner introduction

The fake foam runners represents a departure from traditional sneaker design, featuring a sculpted silhouette crafted entirely from a proprietary foam material. A collaboration between Kanye West and Adidas, the Foam Runner is a model of innovation and sustainability that redefines footwear design boundaries.

A distinctive cutout design and minimalist construction separate the Foam Runner from conventional sneakers at first glance. A lightweight, eco-friendly shoe that leaves a smaller environmental footprint, the Foam Runner is made from EVA foam and algae, which is unlike traditional sneakers, which are made from synthetic materials such as rubber and leather.

Algae as an eco-friendly building material

As a key component of its construction, the Adidas Yeezy Foam Runner utilizes algae, one of the most innovative aspects of the shoe. In order to create a foam material that serves as the foundation of the Foam Runner, algae, a renewable resource abundant in nature, is harvested and processed.

Adidas and Kanye West have demonstrated a commitment to sustainability and environmental stewardship by using algae in their production process. An eco-friendly alternative to traditional manufacturing methods that rely on fossil fuels and synthetic materials, algae cultivation requires minimal resources and produces little waste.

By capturing carbon dioxide and purifying water during the cultivation process, algae not only reduce the shoe's carbon footprint, but also contribute to cleaner air and waterways. Therefore, the Foam Runner represents a paradigm shift in footwear design, highlighting the possibility of sustainable materials revolutionizing the footwear industry as a whole.

A Foam Runner's Appeal: Fashion and Function

Adidas Yeezy Foam Runner offers more than just eco-friendly construction; it is a unique blend of fashion and functionality that resonates with consumers everywhere. Whether worn casually or incorporated into more avant-garde fashion ensembles, the shoe's futuristic design and futuristic aesthetic makes it a statement piece in any wardrobe.

With its ergonomic fit and breathable construction, the Foam Runner prioritizes comfort and performance without sacrificing style. With its custom fit and enhanced support, the foam material molds to the wearer's foot. Moreover, the shoe's lightweight design and durable construction allow it to be worn for a variety of activities, from running errands to working out.

Foam runners' cultural impact

Fashion critics and sneaker enthusiasts have consistently praised the Adidas Yeezy Foam Runner since its debut, cementing its status as a cultural icon. A conversation about sustainability and innovation has sparked around its distinctive design and eco-friendly construction, inspiring other brands to explore alternative methods of production.

The Foam Runner is also highly sought after due to its limited availability and high demand, with secondary market resale prices often exceeding retail value. In addition to its popularity among celebrities and influencers, it appears on red carpets, magazine covers, and social media feeds worldwide, solidifying its status as an essential fashion accessory.

The Foam Runner: Practical Considerations

For consumers considering investing in the Adidas Yeezy Foam Runner, practical considerations play a crucial role in the decision-making process. Although the shoe's innovative design and sustainable materials make it an attractive choice for fashion-forward individuals, the price point may deter budget-conscious shoppers. Get more info about fake shoes.

Despite its environmental responsibility and superior performance, many consumers consider the Foam Runner to be a worthwhile investment for both style and sustainability, recognizing the long-term value of a shoe that prioritizes sustainability. It is possible for consumers to contribute to positive change within the fashion industry by aligning their purchasing decisions with their values by supporting brands like Adidas and Kanye West that champion innovation and ethical production practices.

Finally, the Adidas Yeezy Foam Runner embodies the Yeezy brand's spirit of innovation and creativity with its groundbreaking fusion of fashion and sustainability. The Foam Runner offers a glimpse into the future of footwear, where style and sustainability go hand in hand thanks to its eco-friendly construction and futuristic design. Fashion can be both innovative and responsible as consumers increasingly prioritize ethical consumption and environmental stewardship, inspiring positive change within the industry and beyond with the Foam Runner.

0 notes

Text

Carbon Footwear are deal in Hawai Slipper for Men & Women form Rajasthan

Carbon Footwear is a renowned manufacturer and supplier of high-quality footwear in Rajasthan. Specializing in Hawai slippers Carbon Footwear are deal And Manufacturing in Hawai Slipper for both men and women, Carbon Footwear is dedicated to providing comfortable and durable footwear options for all. The Hawai slipper, also known as flip-flops, has a rich history dating back to ancient Egypt. Originally made from papyrus and palm leaves, these simple yet versatile sandals have evolved over the years to become a staple in footwear fashion. Carbon Footwear uses high-quality materials such as rubber, EVA, and PVC to manufacture its Hawai slippers. These materials are chosen for their durability, flexibility, and comfort, making them ideal for everyday wear.

#pu footwear manufacturer in rajasthan#best quality gents and ladies shoes in india#stylish footwear for kids in rajasthan#best sandal for ladies in india#gents shoes manufacturer in india

0 notes

Text

What's the Best Material for Sneaker Sole?

Sneaker soles, often overlooked, are a critical component of footwear, providing the necessary support, cushioning, and traction for everyday use. They impact not only the shoe's functionality and comfort but also contribute to its overall aesthetic and environmental footprint.

Historical Evolution of Sneaker Soles

The evolution of sneaker soles is a fascinating journey. Initially, soles were made from simple materials like leather and wood. However, with the advent of vulcanized rubber in the 19th century, the sneaker industry underwent a transformation. This innovation led to the creation of more durable and flexible soles, paving the way for modern sneaker designs.

Types of Materials Used in Sneaker Soles

Modern sneaker soles are crafted from a variety of materials, each offering unique benefits. Rubber, polyurethane (PU), ethylene vinyl acetate (EVA), and thermoplastic rubber (TPR) are among the most popular choices.

Rubber Soles

Rubber is the traditional choice for sneaker soles. Its key advantages include excellent traction and high durability, making it ideal for outdoor and athletic footwear. However, rubber soles can be heavy and offer less shock absorption compared to newer materials.

Polyurethane (PU) Soles

PU soles are known for their resilience and resistance to wear and tear. They provide good stability and are often used in work and safety shoes. On the downside, PU soles can be stiff and less comfortable for prolonged wear.

Ethylene Vinyl Acetate (EVA) Soles

EVA is a lightweight and flexible material, popular in running and casual shoes. It provides good cushioning, which helps in reducing impact on the joints. However, EVA soles may wear down faster than rubber or PU, especially under heavy use.

Thermoplastic Rubber (TPR) Soles

TPR is a blend of rubber and plastic, offering a balance between flexibility, comfort, and durability. It's commonly used in various types of footwear, including children's shoes, due to its versatile properties.

Comparison of Materials

When comparing these materials, factors like durability, comfort, cost, and environmental impact must be considered. Rubber and PU are typically more durable, while EVA and TPR offer greater comfort and flexibility. The choice of material often depends on the specific needs of the wearer and the intended use of the sneaker.

The Best Material for Performance Sneakers

For athletes and sports enthusiasts, the sole material must provide excellent grip, flexibility, and durability. Rubber, with its superior traction, is often the preferred choice for outdoor sports shoes, while EVA is favored for its lightweight properties in running shoes.

The Best Material for Casual Sneakers

In casual sneakers, comfort and style take precedence. EVA and TPR are popular choices due to their lightweight and flexible nature, providing comfort for everyday wear.

The Best Material for Eco-Friendly Sneakers

With growing environmental concerns, the demand for eco-friendly sneaker soles has risen. Materials like recycled rubber, organic cotton, and bioplastics are being explored to reduce the carbon footprint of footwear.

The Role of Design in Sneaker Soles

The design of sneaker soles, including the pattern and thickness, also plays a crucial role in the shoe's overall performance. Innovative designs can enhance grip, provide better shock absorption, and improve the shoe's aesthetic appeal.

Consumer Preferences and Trends

Consumer preferences in sneaker soles are influenced by a blend of factors including fashion trends, brand loyalty, and awareness of environmental issues. Manufacturers must stay attuned to these trends to meet the evolving demands of consumers.

Future of Sneaker Sole Materials

The future of sneaker soles lies in the ongoing research and development of new materials and technologies. Advances in material science promise the emergence of more sustainable, durable, and comfortable sole options.

Conclusion

Choosing the best material for a sneaker sole involves considering the shoe’s purpose, wearer's needs, and environmental impact. As technology progresses, we can expect more innovative and sustainable options in sneaker sole materials.

FAQs

What is the most durable material for sneaker soles?

Rubber and PU are generally the most durable options.

Are EVA soles suitable for running shoes?

Yes, EVA is preferred for running shoes due to its lightweight and cushioning properties.

Can sneaker sole materials impact athletic performance?

Definitely, the right sole material can significantly affect traction, comfort, and agility.

Are there eco-friendly sneaker sole options available?

Yes, materials like recycled rubber and bio-based plastics are becoming more common.

Do sneaker sole materials vary based on shoe style?

Yes, performance, casual, and eco-friendly sneakers often use different materials to meet specific requirements.

1 note

·

View note

Video

youtube

HTN540 8 Inches Lightweight Tactical Boots

Our HTN540 S3S lightweight tactical Boots, are the ultimate outdoor adventure and tactical operations companion, combining performance with the utmost safety and comfort. Lightweight yet durable, they are designed for any challenge.

Firstly, our boots feature an 8-inch black thermos-cut mesh combined with microfiber, ingeniously providing water resistance, breathable, and comfortable wear. This innovative material selection keeps your feet dry, ensuring endurance in all weather conditions.

Secondly, integrated moisture-wicking lining promotes air circulation, maintaining dry, comfortable feet even during the toughest treks or tactical missions.

Thirdly, safety is paramount in our design. The boots meet the EN ISO 20345:2022 S3S safety standard, ensuring top protection for your feet in any setting against hazards.

Moreover, we incorporate a composite material toe cap and TPU toe protection. This combination offers robust protection without added weight, enabling swift and safe movement.

Additionally, our soft Kevlar midsoles offer exceptional anti-penetration qualities. Complying with EN ISO 20345:2012, they can effectively defend against nails and other sharp objects.

The lightweight tactical boots use an EVA model sole with cement construction. The design includes triple-protection features: slip-resistant, oil-resistant, and abrasion-resistant, securing your footing on any terrain.

Furthermore, we focus not only on product excellence but on quality as manufacturers. We are committed to offering superior service, including tailored OEM/ODM and customization services based on your needs.

We also guarantee a 12-month warranty period, assuring quality. Keeping our MOQ competitive at 600 pairs, we ensure we can cater to bulk wholesalers and boutique retailers.

Additionally, we ensure timely delivery within 30 days. We understand the importance of consistently meeting your inventory needs on time.

Finally, our payment terms are as flexible as our footwear. We offer 90-day T/T, L/C, and OA options to suit your financial planning.

In conclusion, our HTN540 S3S Tactical Boots provide durable, safe, and comfortable footwear, complemented by customer-centric manufacturing and exporting services, all aimed at your complete satisfaction.

https://www.htech-footwear.com/product/lightweight-tactical-boots-s3s-htn540/

0 notes

Link

Check out this listing I just added to my Poshmark closet: BRAND NEW Men’s Hoka Anacapa Low GTX / CSHR.

0 notes

Text

Ethylene Vinyl Acetate Market Poised to Grow on Back of High Demand from Solar Panel Manufacturing Industry

Ethylene vinyl acetate (EVA) is a copolymer of ethylene and vinyl acetate which finds extensive usage as an encapsulant in photovoltaic (PV) module manufacturing. As an encapsulant, EVA protects PV cells from moisture and helps in improving their performance. It provides excellent adhesion to both front glass as well as back sheet. The global solar panel market has been growing rapidly over the past few years owing to supportive government policies and initiatives encouraging the adoption of renewable energy. With increasing deployment of solar panels worldwide, demand for EVA from this application segment is projected to surge substantially.

The global ethylene vinyl acetate market is estimated to be valued at US$ 1710.66 Mn in 2024 and is expected to exhibit a CAGR of 3.4% over the forecast period 2024 to 2031, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

The high demand from solar panel manufacturing is one of the major drivers propelling the growth of ethylene vinyl acetate market. Solar panel encapsulants account for over 40% of the overall EVA consumption. The government targets to increase usage of renewable sources of energy along with falling prices of solar panels have boosted the solar energy market size significantly. According to the International Renewable Energy Agency (IRENA), globally over 100 GW of solar PV was added in 2021 alone. This rising deployment of solar panels directly translates to increased consumption of EVA. Apart from this, EVA finds wide applications in hot melt adhesives, packaging, and cables. The growth in end-use industries is further augmenting demand.

SWOT Analysis

Strength: Ethylene Vinyl Acetate (EVA) is used as an effective polymer in several end use industries such as solar panels, medical devices, and footwear. EVA provides excellent flexibility, transparency, and reliability in production processes. EVA products show consistent performance even in extreme temperatures due to their durable nature.

Weakness: Fluctuating raw material prices impact the cost of EVA production. Rising crude oil prices increase the commodity prices of ethylene and vinyl acetate, making EVA slightly expensive. EVA has poor mechanical properties and low melting point in comparison to other polymers.

Opportunity: Surging demand for renewable energy sources is driving the solar PV industry. EVA encapsulants protect photovoltaic cells from moisture and UV damage, thereby enhancing module efficiency. Growing medical devices market especially for implants and prosthetics boosts EVA usage.

Threats: Strict regulations regarding toxic emissions can adversely impact manufacturing units. Intense competition from substitute polymers may reduce EVA consumption gradually.

Key Takeaways

The global ethylene vinyl acetate market size is expected to witness high growth backed by increasing solar installations and growing medical device industry. The global ethylene vinyl acetate market is estimated to be valued at US$ 1710.66 million in 2024 and is expected to exhibit a CAGR of 3.4% over the forecast period 2024 to 2031.

Asia Pacific dominates the global market due to large solar PV sector and rapidly expanding construction industry in China and India. Key regional players are expanding their production capacities to meet local demand.

Key players operating in the ethylene vinyl acetate market are DuPont, ExxonMobil, FPC, Hanwha Group, LyondellBasell, Sipchem, and Formosa Plastics. They are focusing on developing novel EVA grades with enhanced properties to strengthen their market position. Technological innovation and partnerships remain crucial for gaining competitive edge. New product launches with optimized performance characteristics could boost revenues. Collaboration with end users aids in developing customized polymer solutions.Get more insights on this topic:https://www.newswirestats.com/ethylene-vinyl-acetate-market-size-and-outlook/

#Ethylene Vinyl Acetate#Ethylene Vinyl Acetate Market#Ethylene Vinyl Acetate Market size#Ethylene Vinyl Acetate Market share#Coherent Market Insights

0 notes

Text

Ladies Shoes Manufacturers & Suppliers in India | mlqshoes

MLQ Shoes is a reputable manufacturer and supplier of ladies shoes in India, offering a wide range of stylish and high-quality footwear options for women. With a focus on both fashion and comfort, MLQ Shoes ensures that their products are not only trendy but also durable and comfortable to wear. From casual flats to elegant heels, MLQ Shoes caters to the diverse needs and preferences of modern women, making it a go-to destination for those looking for fashionable footwear options.

#Ladies Shoes Manufacturers & Suppliers in India#ladies shoes manufacturers in india#Shoes Manufacturer in India#boys Shoes manufacturers in india#Top boys Shoe Manufacturers in Delhi#delhi#best boys shoes manufacturers in india#Gents Shoes Manufacturers & Suppliers in India#Gents Shoe Manufacturers In India#Mens Shoes Manufacturers & Suppliers in Delhi#Gents Shoes Manufacturer in Delhi#EVA Sandals Manufacturers & Suppliers in India#EVA Sandals manufacturer in Delhi#Ladies EVA Sandals manufacturer in Delhi#Eva Footwear Manufacturers#Suppliers In New Delhi#EVA Shoe Sole Manufacturers#Suppliers In Delhi#pvc shoes manufacturers in delhi#Top Pvc Shoe Manufacturers in Delhi#PVC Footwear Manufacturers & Suppliers in India#Kids Shoes#boys Shoes#gents shoes#Eva sandals#Airwash#vschool

0 notes

Text

Masterbatchin: Inside the World of Leading PVC Compound Manufacturers

Masterbatchin offers high-quality masterbatch solutions for pvc compound manufacturers looking to enhance the color, strength, and durability of their products. Our custom formulations are designed to meet the specific needs of your compounding process, resulting in a uniform and consistent end product.

Click Here: https://www.masterbatchin.com/

#pvc compound manufacturers#black & white masterbatches#eva compound manufacturers for footwear#phthalate free colour masterbatch#light weight pvc compound for footwear#colour masterbatch manufacturers#additives masterbatches#eva masterbatches manufacturers#phthalate free pvc compound for footwear

0 notes

Text

EVA Sole Manufacturers In India

Uttam Polyrubs, a renowned name in the Indian manufacturing industry, stands tall as one of the leading EVA sole manufacturers in India. With a commitment to excellence and a rich legacy spanning several years, Uttam Polyrubs has established itself as a trusted provider of high-quality EVA soles, catering to diverse industries and customer needs.

EVA, or Ethylene Vinyl Acetate, is a versatile and durable material widely used in the production of footwear soles. Uttam Polyrubs excels in harnessing the potential of EVA to create soles that not only offer superior comfort but also boast excellent shock absorption and durability. The company's manufacturing process incorporates cutting-edge technology and adheres to stringent quality standards, ensuring that each pair of EVA soles meets or exceeds customer expectations.

One of the key strengths of Uttam Polyrubs lies in its commitment to innovation. The company continuously invests in research and development to stay ahead of industry trends and deliver products that align with the evolving needs of the market. This dedication to innovation has enabled Uttam Polyrubs to offer a diverse range of EVA soles, customizable to meet specific design requirements and performance criteria.

Uttam Polyrubs' state-of-the-art manufacturing facilities, coupled with a skilled workforce, enable the company to scale production to meet the demands of both domestic and international markets. The EVA soles produced by Uttam Polyrubs find applications in various footwear segments, including sports shoes, casual footwear, and industrial safety shoes.

In addition to its commitment to quality and innovation, Uttam Polyrubs places a strong emphasis on sustainability. The company is dedicated to environmentally friendly manufacturing practices, ensuring that its EVA soles are not only high-performing but also produced with a minimal ecological footprint.

As customers seek reliable and high-performance EVA sole manufacturers in India, Uttam Polyrubs emerges as a top choice. With a legacy of excellence, a commitment to innovation, and a focus on sustainability, Uttam Polyrubs continues to set benchmarks in the industry, delivering EVA soles that combine comfort, durability, and style. Choose Uttam Polyrubs for EVA soles that elevate your footwear to new heights.

Uttam Polyrubs India Pvt. Ltd.

Corporate Office: 1002, Tower B, Millennium Plaza, Sector 27, Gurgaon 122009, Haryana, India

Tel: +91-9351722277, +91-1244286902

Email: [email protected]

Visit - https://www.uttampolyrubs.com/eva-soles.php

0 notes

Link

Check out this listing I just added to my Poshmark closet: BIRKENSTOCK Madrid Big Buckle (Washed Metallic Rose Gold) Sandals Size 3….

0 notes

Text

Ethylene Vinyl Acetate Prices, Trend, Supply and Demand & Forecast | ChemAnalyst

Ethylene Vinyl Acetate (EVA) Prices is a versatile polymer widely used in various industries due to its exceptional properties and affordability. As a copolymer of ethylene and vinyl acetate, EVA finds applications in industries ranging from footwear to packaging, automotive, and even solar energy. Understanding the dynamics of EVA prices is crucial for businesses reliant on this material for their operations.

Several factors influence the pricing of EVA, with raw material costs being one of the primary determinants. Ethylene, derived from crude oil or natural gas, and vinyl acetate monomer (VAM), synthesized from ethylene and acetic acid, form the basis of EVA production. Fluctuations in crude oil prices, geopolitical tensions, and supply-demand imbalances directly impact the cost of ethylene and, consequently, EVA prices. Similarly, disruptions in the production or availability of acetic acid affect VAM costs, further influencing EVA pricing trends.

Market demand plays a pivotal role in determining EVA prices. The versatility of EVA renders it indispensable in various industries, leading to consistent demand. In sectors like footwear, where EVA is extensively used in midsoles and outsoles due to its lightweight and shock-absorbing properties, seasonal fluctuations and fashion trends can significantly influence demand and, subsequently, prices. Similarly, the packaging industry's demand for EVA films and sheets fluctuates based on consumer preferences, environmental regulations, and economic conditions.

Get Real Time Prices of Ethylene Vinyl Acetate (EVA) Prices: https://www.chemanalyst.com/Pricing-data/ethylene-vinyl-acetate-74

Global economic factors also impact EVA prices. Economic downturns or recessions tend to suppress demand across industries, leading to a downward pressure on prices. Conversely, during periods of economic growth, increased industrial activity and consumer spending bolster demand for EVA, thereby driving prices upwards. Moreover, currency fluctuations, trade policies, and tariffs affect the cost of imported raw materials and finished EVA products, further adding to pricing volatility.

Technological advancements and innovations in EVA production processes can influence pricing dynamics. Manufacturers continuously strive to enhance production efficiency, reduce energy consumption, and develop novel formulations to meet evolving industry requirements. Investments in research and development aimed at improving EVA quality, durability, and sustainability may impact production costs, subsequently affecting prices in the market.

Environmental regulations and sustainability initiatives also shape EVA pricing trends. As concerns over plastic pollution and carbon emissions intensify, industries are under pressure to adopt eco-friendly materials and manufacturing practices. EVA manufacturers may incur additional costs in compliance with stringent environmental standards or implementing sustainable initiatives such as recycling programs or utilizing bio-based feedstocks. These factors contribute to the overall cost structure and, consequently, influence EVA prices.

Supply chain disruptions, including natural disasters, transportation bottlenecks, or labor strikes, can cause temporary shortages or delays in EVA production, leading to price fluctuations. Such disruptions highlight the importance of supply chain resilience and contingency planning for businesses reliant on EVA as a critical input.

In summary, EVA prices are subject to a myriad of factors encompassing raw material costs, market demand, economic conditions, technological advancements, regulatory requirements, and supply chain dynamics. Businesses must stay abreast of these factors and adopt proactive strategies such as hedging, inventory management, and supplier diversification to mitigate risks associated with EVA price volatility. By understanding the multifaceted nature of EVA pricing dynamics, businesses can make informed decisions to optimize their operations and remain competitive in the market.

Get Real Time Prices of Ethylene Vinyl Acetate (EVA) Prices: https://www.chemanalyst.com/Pricing-data/ethylene-vinyl-acetate-74

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes