#Extruded Plastics Market

Text

Extruded Plastics Market Size & Share to Surpass USD 356.1 billion by 2031

The global extruded plastics market is set to witness significant growth from 2024 to 2031, driven by the increasing demand for lightweight, durable, and cost-effective materials across various industries. Extruded plastics, produced through the extrusion process, find extensive applications in packaging, construction, automotive, and consumer goods sectors, among others.

The global extruded plastics market was projected to attain US$ 210.2 billion in 2022. It is anticipated to garner a 6% CAGR from 2023 to 2031. The market is likely to attain US$ 356.1 billion by 2031.

Extruded plastic objects may be made in a variety of lengths and shapes. Numerous industries, including the automotive and building and construction sectors, employ these items. Market development is being aided by the expansion of the building and construction, as well as packaging sectors, particularly in emerging nations.

Grab Exclusive Sample PDF: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=20687

Market Segmentation:

By Service Type: Profile Extrusion, Sheet Extrusion, Tubing Extrusion, Film Extrusion, Others

By Sourcing Type: Virgin Plastics, Recycled Plastics

By Application: Packaging, Building & Construction, Automotive, Electrical & Electronics, Consumer Goods, Others

By Industry Vertical: Food & Beverage, Healthcare, Automotive, Construction, Aerospace, Others

By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa

Regional Analysis:

North America: Leading the market with a strong presence of key industry players and high demand from the packaging and construction sectors.

Europe: Witnessing significant growth driven by stringent regulations promoting sustainable packaging solutions and increasing investments in construction activities.

Asia Pacific: Emerging as a key market with rapid industrialization, urbanization, and expanding manufacturing sector.

Latin America, Middle East & Africa: Showing promising growth potential fueled by infrastructure development and rising consumer spending.

Market Drivers and Challenges:

Drivers: Increasing demand from end-use industries, rapid urbanization, lightweight and cost-effective properties of extruded plastics, and technological advancements in extrusion processes.

Challenges: Environmental concerns associated with plastic usage, fluctuating raw material prices, and stringent regulations regarding plastic waste management.

Market Trends:

Growing adoption of recycled plastics for sustainable packaging solutions.

Development of bio-based and biodegradable polymers to address environmental concerns.

Integration of advanced additives and fillers for enhancing the performance and properties of extruded plastics.

Future Outlook:

The extruded plastics market is poised for substantial growth in the coming years, driven by the versatility and efficiency of extrusion technology in manufacturing a wide range of plastic products. The market will witness increasing demand for customized extruded plastic solutions catering to diverse applications and industries.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=20687

Key Market Study Points:

Market size and growth projections.

Regional analysis and market dynamics.

Segmentation by service type, sourcing type, application, industry vertical, and region.

Market drivers, challenges, and trends shaping the industry.

Future outlook and growth opportunities.

Competitive landscape and recent developments.

Competitive Landscape: Key players operating in the extruded plastics market include:

The Dow Chemical Company

ExxonMobil Corporation

SABIC

BASF SE

Berry Global Inc.

Sealed Air Corporation

Bemis Company Inc.

Saint-Gobain S.A.

Sonoco Products Company

LyondellBasell Industries N.V.

Recent Developments:

Launch of innovative extrusion technologies improving production efficiency and product quality.

Expansion of manufacturing facilities to meet growing demand from various industries.

Strategic partnerships and collaborations to develop sustainable plastic solutions.

Investments in research and development for advancing extrusion processes and materials.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTERS DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll-Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

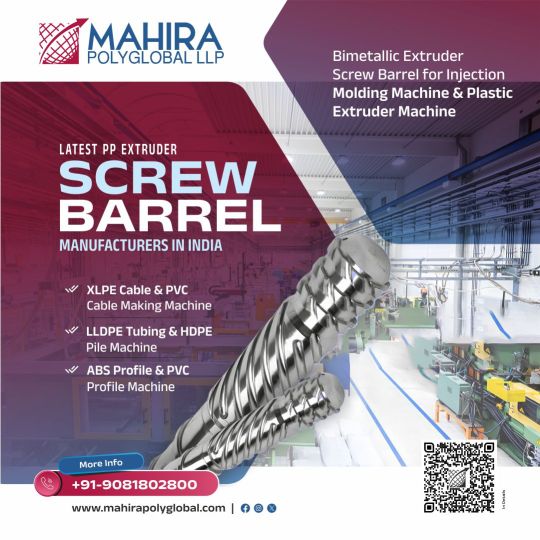

Extruder Screw Barrel

we are leading manufacturer and supplier of Extruder Screw Barrel in india & worldwide, we assure the finest quality, robustness, and accuracy in our extruder screw barrels, facilitating smooth plastic processing for various kinds of industries. Our extruder screw barrel, which effectively melts and shapes raw materials, is an essential part of the plastics manufacturing process.

For more information, please contact us : +91- 9081802800, email : [email protected]

https://www.mahirapolyglobal.com/product/screw-barrel-extruder-screw-barrel

#extruder screw barrel#plastic extruder screw barrel#hs code for extruder screw barrel#extruder screw and barrel#extruder screw barrel manufacturer#screw barrel#extruder screw barrel for plastic extrusion machine#mahira#mahirapolyglobal#commercial#marketing#sales#ecommerce#manufacturingexcellence

0 notes

Text

#Extruded Plastics Market Share#Extruded Plastics Market Scope#Extruded Plastics Market Size#Extruded Plastics Market Price#Extruded Plastics Market Research#Extruded Plastics Market Revenue#Extruded Plastics Market Report#Extruded Plastics Market Demand#Extruded Plastics Market Value#Extruded Plastics Market Estimation#Extruded Plastics Market Segmentation#Extruded Plastics Market Growth#Extruded Plastics Market Analysis#Extruded Plastics Market Insight#Extruded Plastics Market Forecast#Extruded Plastics Market Index#Extruded Plastics Market Trends#Extruded Plastics Market Opportunities#Extruded Plastics Market Scenario#Extruded Plastics Market Valuation#Extruded Plastics Market Outlook#Extruded Plastics Market Overview#Extruded Plastics Market Statistics#Extruded Plastics Market Investment Analysis#Extruded Plastics Market Intelligence Report#Extruded Plastics Market Market Research Future#Extruded Plastics Market Types#Extruded Plastics Market Growth Rate#Extruded Plastics Market Satistics#Extruded Plastics Market Development

0 notes

Text

Blow Molding: Transforming Plastic into Innovative Products

Blow molding is a manufacturing technique for producing hollow plastic items. It is a flexible process capable of producing a wide range of plastic containers, bottles, automobile components, toys, and other items. The method is extremely cost-effective and efficient, making it a popular choice in a variety of sectors.

What Is the Process of Blow Molding?

Blow molding usually entails the following steps:

Extrusion is the process of melting plastic pellets and extruding them into a hollow tube, commonly known as a parison.

Mold Cavity: The parison is put in a mold cavity, which is frequently custom-designed to match the shape of the object.

Inflation: When air is introduced into the parison, it expands and takes on the shape of the mold.

Cooling: The plastic within the mold is allowed to cool and solidify.

The molded item is ejected from the mold.

Variations in Blow Molding

Blow molding from blow molding manufacturer comes in a variety of forms, including:

Extrusion Blow Molding (EBM) is the most prevalent form, and it is used to make bottles and containers.

Injection Blow Molding (IBM): This process is best suited for tiny, precise items like medical vials and some automotive components.

Stretch Blow Molding (SBM): A popular method for producing PET bottles, it provides better control over the finished product's properties.

Continuous Extrusion Blow Molding (CEBM): This technique is mostly utilized for the high-volume manufacture of smaller goods such as milk jugs.

Blow Molding Manufacturers' Role

The heart of this business is made up of blow molding producers. They take raw materials and turn them into a diverse range of products that fulfill the demands of many sectors. Here's a deeper look at their key responsibilities:

Design on Demand: Blow molding manufacturers collaborate closely with clients to create unique molds that meet the product specifications.

Material Expertise: They have an extensive understanding of various plastic materials, ensuring that the appropriate material is selected for the intended use.

Precision Manufacturing: Blow molding companies use cutting-edge technology to accurately regulate factors like temperature, pressure, and cooling, resulting in consistent product quality.

Quality Control: Strict quality control methods guarantee that each product fulfills industry standards as well as customer specifications.

To keep ahead of market expectations, Blow molding manufacturer China continually innovates in terms of materials, processes, and designs.

2 notes

·

View notes

Text

Pro tools 101 an introduction to pro tools 10 pdf

#PRO TOOLS 101 AN INTRODUCTION TO PRO TOOLS 10 PDF PDF#

#PRO TOOLS 101 AN INTRODUCTION TO PRO TOOLS 10 PDF PRO#

#PRO TOOLS 101 AN INTRODUCTION TO PRO TOOLS 10 PDF SOFTWARE#

#PRO TOOLS 101 AN INTRODUCTION TO PRO TOOLS 10 PDF WINDOWS#

Whether your project involves multi-track recordings.

#PRO TOOLS 101 AN INTRODUCTION TO PRO TOOLS 10 PDF PRO#

Learn the basic principles you'll need to complete a Pro Tools project using Pro Tools, from initial setup to mixdown. The hands-on exercises provide experience setting up sessions, importing media, working with digital video, spotting sound effects, using loop recording and MIDI Merge techniques, working with virtual instruments, warping with Elastic Audio, applying Real-Time Properties, creating clip loops, applying signal processing, using automation, and using submixes and track groups to simplify a final mix. Berklee Online is the exclusive online provider of the Pro Tools 101 curriculum by Avid, and this course constitutes the first stage of their Pro Tools certification program. Lecture slides for Pro Tools 101, An Introduction to Pro Tools 11 by Frank D. Students learn to build sessions designed for commercial purposes and improve the results of their recording, editing, and mixing efforts. (.pdf), Text File (.txt) or view presentation slides online. This course expands upon the basic principles taught in the Pro Tools Fundamentals I (PT101) course and introduces the core concepts and techniques students need to competently operate a Pro Tools system running mid-sized sessions. The second course, Pro Tools 110: Pro Tools Production I, is available exclusively through Avid Learning Partners. Completion of the Pro Tools Fundamentals I (ED-PT101) course PRO TOOLS 101 AN INTRODUCTION TO PRO TOOLS 11 is the first of two courses designed to prepare users for the Avid Pro Tools 11 Certified User exam.The output is the same fidelity, at only half the file size.

#PRO TOOLS 101 AN INTRODUCTION TO PRO TOOLS 10 PDF PDF#

Plotting out a PDF is also quicker, because you have more control over the vector raster and image quality of PDF output.

$655.00 CAD (Save 5% Bundled with ED-PT101) Text is searchable in your PDF, and if you create sheet sets with hyperlinks to drawings, those links are now maintained.

Strangely, at that time, it did not make big announcements, hold conferences, or undertake a big marketing campaign for it. Hands-on exercises and projects introduce essential techniques for creating sessions, recording and importing audio and MIDI, editing session media, navigating sessions and arranging media on tracks, and using basic processing and mixing techniques to finalise a production. viii Introduction Introduction Microsoft introduced the idea of Self-Service Business Intelligence (BI) back in 2009, announcing Power Pivot for Microsoft Excel 2010. Students also learn to build sessions that include multi-track recordings of MIDI sequences and virtual instruments. This course introduces fundamental Pro Tools concepts and principles, covering everything needed to complete a basic Pro Tools project, from initial setup to final mix-down. Course Description: Introduction to recording, editing, and mixing MIDI and digital audio using a computer based.

Basic audio recording knowledge is recommended but not necessary.

It typically contains 70 fat, 20 protein, and only 10 carbs ( 9. Plastic extrusion is a manufacturing process. Standard ketogenic diet (SKD): This is a very low carb, moderate protein and high fat diet.

#PRO TOOLS 101 AN INTRODUCTION TO PRO TOOLS 10 PDF WINDOWS#

A working knowledge of Windows or macOS operating systems Utilizing the extruding tool to pull or push out a 2D sketch is a crucial step toward becoming an Inventor pro.

#PRO TOOLS 101 AN INTRODUCTION TO PRO TOOLS 10 PDF SOFTWARE#

No experience with Avid Pro Tools software is required Pro Tools 101: An Introduction to Pro Tools 10 is the official training package used in first-level certification courses.

Assemblers, compilers, and inter-preters are examples of programs that fall into this category. Learn to build sessions that include multitrack recordings of live instruments. Now updated for Pro Tools 10 software, this new edition from the definitive authority on Pro Tools covers everything you need to know to complete a Pro Tools project.

Location: ED (Exchange District) Campus - 245 McDermot Ave. Pro Tools Ultimate Software with Pro Tools HD Native Hardware. Software Development Tools Software development toolsare the programs that pro-grammers use to create, modify, and test software. PRO TOOLS 101: AN INTRODUCTION TO PRO TOOLS 10 takes a comprehensive approach to learning the fundamentals of Pro Tools systems.

Next Start Date: Monday, OctoNovember 21, 2022.

2 notes

·

View notes

Text

Extruded Plastics Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The extruded plastics global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Extruded Plastics Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size -

The extruded plastics market size has grown strongly in recent years. It will grow from $232.87 billion in 2023 to $246.52 billion in 2024 at a compound annual growth rate (CAGR) of 5.9%. The growth in the historic period can be attributed to industrialization and manufacturing growth, lightweighting in automotive, construction and infrastructure development, sustainable practices, consumer goods and packaging.

The extruded plastics market size is expected to see strong growth in the next few years. It will grow to $315.92 billion in 2028 at a compound annual growth rate (CAGR) of 6.4%. The growth in the forecast period can be attributed to eco-friendly extruded plastics, electric and autonomous vehicles, infrastructure modernization, medical device manufacturing, advanced extrusion processes. Major trends in the forecast period include high-performance extruded plastics, 3d printing with extruded plastics, smart extruded products, co-extrusion technology, foam extrusion.

Order your report now for swift delivery @

https://www.thebusinessresearchcompany.com/report/extruded-plastics-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers -

The rise of the packaging industry is significantly contributing to the growth of the extruded plastics market going forward. Packaging refers to enclosing or protecting products for distribution, storage, sale, and use. Extruded plastics are helpful in creating highly durable and effective packaging solutions. As a result, the rise of the packaging industry increases the demand for the extruded plastics market. For instance, in 2021, according to the India Brand Equity Foundation, an Indian government export promotion agency, packaging demand and consumption in India increased by 200%, which increased from 4.3 kgs per person per annum (PPPA) to 8.6 kgs PPPA. Therefore, the rise of the packaging industry is driving the growth of the extruded plastics market.

The extruded plastics market covered in this report is segmented –

1) By Type: Low Density Polyethylene, High Density Polyethylene, Polypropylene, Polystyrene, Polyvinyl Chloride, Other Types

2) By Form: Films, Pipes, Sheets, Tubes, Wires and Cables

3) By End-User: Packaging, Building and Construction, Automotive, Consumer Goods, Electrical and Electronics, Other End Users

Get an inside scoop of the extruded plastics market, Request now for Sample Report @

https://www.thebusinessresearchcompany.com/sample.aspx?id=6589&type=smp

Regional Insights -

Asia-Pacific was the largest region in the extruded plastics market in 2023. Asia-Pacific is expected to be the fastest-growing region in the extruded plastics market during the forecast period. The regions covered in the extruded plastics market report include Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East and Africa.

Key Companies -

Major companies operating in the extruded plastics market include Apogee Enterprises Inc., Olsen Doors and Windows Limited, Fletcher Building Limited, YKK AP Inc., Bradnam's Windows & Doors, Fenesta Building Systems, PGT Innovations Inc., Geeta Aluminium Co. Pvt. Ltd., Ply Gem Holdings Inc., Andersen Corporation, Sapa Group, Alupure, Alteza Healthcare Private Limited, Reynaers Aluminium, Schuco International Group, Bemis Company Inc., LyondellBasell Industries N.V., Trex Company Inc., Teijin Limited, Borealis AG, Westlake Corporation, NOVA Chemicals Corporation, Mitsubishi Chemical Group Corporation, Plastipak Holdings Inc., Sigma Plastics Group of FL, Bunzl Extrusions Inc., Avient Corporation, The Ensinger Group, REHAU Polymers Pvt Ltd, Primex Plastics Private Limited

Table of Contents

1. Executive Summary

2. Extruded Plastics Market Report Structure

3. Extruded Plastics Market Trends And Strategies

4. Extruded Plastics Market – Macro Economic Scenario

5. Extruded Plastics Market Size And Growth

…..

27. Extruded Plastics Market Competitor Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Small-Scale Plastic Recycling: Innovative Solutions for Individuals and Communities

Plastic pollution is one of the most pressing environmental issues of our time. With over 300 million tons of plastic produced annually worldwide, much of it ends up in landfills, oceans, and other natural environments, causing significant harm to ecosystems and human health. Large-scale industrial recycling plays a crucial role in managing plastic waste, but small-scale plastic recycling can also offer powerful, community-driven solutions to this global problem.

Small-scale plastic recycling is essential for communities, businesses, and individuals looking to make a meaningful impact on reducing plastic waste. Whether it’s reducing your own waste footprint, supporting local businesses, or creating innovative products from recycled materials, small-scale recycling offers numerous opportunities for people to participate in the circular economy. In this blog, we will explore some of the best solutions for small-scale plastic recycling, how these methods work, and how they can be implemented in everyday life.

1. Home-Based Recycling Solutions

Home-based plastic recycling is an accessible way for individuals to reduce plastic waste and contribute to recycling efforts directly from their homes. While traditional recycling programs managed by municipalities may not recycle all types of plastics, home-based systems give people the ability to recycle different kinds of plastics, like bottle caps, bags, and packaging, that often aren't accepted in curbside programs.

a. Manual Sorting and Cleaning

Before any plastic can be recycled at home, it must be sorted and cleaned. Sorting plastic by type (e.g., PET, HDPE, PP, etc.) is crucial since different types of plastics require different processing methods. Washing the plastic is also essential to remove any food residue or contaminants that could interfere with the recycling process. While this method is labor-intensive, it is a fundamental step in any recycling process.

b. Shredding Plastic at Home

Shredding plastic is a critical step in home recycling. Small, affordable plastic shredders are available in the market that allow you to break plastic items into smaller, more manageable pieces. Shredded plastic is easier to melt or mold into new products. Shredding machines for home use vary in size and price, making it a viable option for households looking to reduce their plastic waste footprint.

c. Melting and Repurposing Plastic

Once plastic is shredded, it can be melted down and repurposed into new items. Small-scale plastic extruders and injection molding machines are available for home use, allowing individuals to melt shredded plastic and turn it into new products such as containers, tools, and household items. Some systems are specifically designed to work with DIY molds, making it easier to create custom products.

2. Community-Based Recycling Initiatives

While individual efforts are essential, collective action in the form of community-based recycling can have an even broader impact. Community recycling initiatives bring people together to work towards reducing plastic waste on a local level. These initiatives often involve education, workshops, and shared recycling equipment to allow for more efficient processing.

a. Precious Plastic: A Global Movement

One of the most well-known community-based small-scale recycling projects is Precious Plastic, a global initiative that empowers individuals and communities to start their own small-scale recycling workshops. Precious Plastic offers open-source blueprints for building plastic recycling machines, including shredders, extrusion machines, and injection molders, which can be built using locally available materials.

Precious Plastic workshops can be set up in community centers, schools, or even garages, allowing people to recycle plastic waste into new products such as furniture, building materials, and decorative items. The initiative encourages the creation of local businesses based on recycling, providing economic opportunities while promoting sustainability.

b. Collection Hubs and Drop-Off Points

Another effective community-based solution is setting up plastic collection hubs where individuals can drop off their plastic waste for recycling. These hubs can be located at community centers, schools, or local businesses. Once the plastic is collected, it can be sorted and sent to local recycling facilities or processed at community workshops using shredders and extruders.

c. Recycling Co-ops

Recycling co-ops are organizations where members pool resources to set up small-scale recycling operations. These co-ops can invest in shared equipment, such as shredders and extruders, which members use to process plastic waste. The co-op can then sell the recycled plastic or products made from it, with profits reinvested into the co-op to support further recycling efforts.

3. Plastic Recycling for Small Businesses

Small businesses can play a crucial role in reducing plastic waste by integrating recycling into their operations. There are several ways that small-scale plastic recycling can benefit businesses, from reducing waste management costs to creating new revenue streams through the sale of recycled plastic products.

a. In-House Recycling Systems

Small-scale plastic recycling systems, such as shredders and extruders, can be integrated directly into business operations. For example, businesses that generate a lot of plastic waste, such as packaging or plastic bottles, can set up an in-house recycling system to process that waste into reusable materials. These recycled materials can then be used to manufacture new products, reducing the need for virgin plastics and cutting down on waste disposal costs.

b. Creating Recycled Plastic Products

Many small businesses are using recycled plastic to create innovative products. For instance, companies are producing everything from eco-friendly furniture to fashion accessories using recycled plastic. Businesses can take advantage of small-scale recycling machinery to turn plastic waste into raw material for new products, allowing them to reduce their environmental impact while tapping into the growing demand for sustainable products.

c. Partnerships with Local Recycling Workshops

Small businesses that may not have the resources to set up their own recycling systems can partner with local recycling workshops, such as Precious Plastic workspaces, to handle their plastic waste. This can be a mutually beneficial relationship, as businesses can reduce their waste management costs while supporting local recycling initiatives, and workshops gain access to more plastic material to process.

4. Innovative Technologies for Small-Scale Plastic Recycling

Technology is playing an increasingly important role in small-scale plastic recycling, with innovative solutions emerging that make it easier, more efficient, and more accessible to individuals and communities.

a. Desktop Recycling Machines

Desktop plastic recycling machines, such as the ProtoCycler, are compact systems designed for home or office use. These machines can shred, melt, and extrude plastic, turning it into filament for 3D printers. The ability to recycle plastic waste into 3D printing filament opens up opportunities for individuals, hobbyists, and small businesses to create custom products, prototypes, or tools from their plastic waste.

b. Plastic-to-Fuel Systems

Another emerging technology in small-scale plastic recycling is plastic-to-fuel systems. These systems use pyrolysis to break down plastic waste into liquid fuel, which can then be used as an energy source. While these systems are still in the early stages of development, they hold promise as a way for individuals and communities to reduce plastic waste while producing renewable energy.

c. Micro Recycling Factories

Micro recycling factories, like those pioneered by researchers at the University of New South Wales in Australia, aim to turn plastic waste into valuable materials using small, portable systems. These modular, scalable recycling systems can be deployed in local communities or even remote areas to recycle plastic waste into usable raw materials like plastic filaments, pellets, or other industrial inputs.

5. Education and Awareness Initiatives

Education and awareness are vital components of small-scale recycling efforts. Many people are still unsure of how to recycle plastic correctly or are unaware of the possibilities for small-scale recycling. Educational initiatives, workshops, and outreach programs can help empower individuals and communities to take action.

a. Workshops and Training Programs

Hosting workshops on small-scale recycling methods can teach people how to sort, clean, and recycle plastic effectively. These workshops can include hands-on demonstrations of shredding, melting, and repurposing plastic into new products. Training programs can also teach individuals how to build and operate small-scale recycling machines, such as those designed by Precious Plastic.

b. Awareness Campaigns

Local governments, businesses, and community organizations can launch awareness campaigns to encourage more people to get involved in plastic recycling. These campaigns can provide practical tips on reducing plastic waste, information on local recycling options, and details on how individuals can start their own small-scale recycling projects.

Conclusion

Small-scale plastic recycling offers a range of solutions for individuals, businesses, and communities to reduce plastic waste and promote sustainability. From home-based recycling systems and community workshops to innovative technologies and educational programs, there are many ways to get involved in the circular economy and make a positive impact on the environment.

As the world continues to grapple with the challenge of plastic pollution, small-scale recycling represents a powerful tool for reducing waste, conserving resources, and fostering a culture of sustainability. By embracing these solutions, we can all contribute to a cleaner, greener future.

0 notes

Text

Multilayer Packaging Market Future Trends to Look at | BIS Research

Multilayer Packaging refers to a type of packaging that consists of multiple layers of different materials, each chosen for its specific functional properties, such as barrier protection, strength, flexibility, and durability. These layers often include plastics, paper, aluminum, and adhesives, which are laminated or co-extruded to create a single, cohesive structure.

The Multilayer Packaging Market was valued at $88.26 billion in 2022, and it is expected to grow at a CAGR of 8.03% and reach $199.71 billion by 2032

At BIS Research, we focus exclusively on technologies related to precision medicine, medical devices, life sciences, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), big data, blockchain technology, Multilayer Packaging Material , advanced materials and chemicals, agriculture and FoodTech, mobility, robotics, and aerospace and defense, among others.

Multilayer Packaging Overview

Multilayer Packaging is a rapidly emerging field at the intersection of materials science, data science, and artificial intelligence. Its primary objective is to accelerate the discovery, design, and optimization of materials by leveraging advanced computational tools and data-driven approaches.

The core concept of Multilayer Packaging is to treat materials and their characteristics as data. By analyzing vast amounts of material-related data—such as chemical compositions, structural properties, and performance metrics—researchers can identify patterns, correlations, and trends that would be difficult or impossible to detect through traditional experimentation alone.

Grab a look at the report page click here !

Key Techniques

Machine Learning

Data Mining

Open Quantum Material Database

Typically, the materials used in multilayer packaging include combinations of plastics, paper, aluminum, and adhesives. Each layer serves a specific purpose: plastic layers may offer flexibility and scalability, aluminum layers provide barrier protection against oxygen, light, and moisture, and paper layers add rigidity and printability

Market Segmentation

By End User Industry

By Product Type

By Region

Market Drivers

Growing demand for packaged food

Increased use in pharmaceutical industry

Rising focus on product shelf life

Consumer awareness of sustainability

Have a look at the free sample click here !

Key Companies

Constantia Flexibles

Berry Global Inc.

Amcor plc

Mondi

Sonoco Products Company

Sealed Air

Visit our Next Generation Fuel/ Energy Storage Solutions

Conclusion

Multilayer packaging plays a vital role in modern industries by offering enhanced protection, extended shelf life, and improved product quality. Its ability to combine the best properties of various materials makes it indispensable, especially in sectors like food, pharmaceuticals, and e-commerce.

0 notes

Text

Why PP Corrugated Sheets Are a Game-Changer for Packaging Solutions

In the ever-evolving world of packaging, businesses are constantly seeking innovative materials that combine durability, versatility, and cost-effectiveness. Among the many options available, PP corrugated sheets have emerged as a game-changer, revolutionizing packaging solutions across various industries. This blog explores why PP corrugated sheets are a superior choice, pp corrugated sheet uses, benefits, and how they compare in terms of cost and quality.

What Is PP Corrugated Sheets?

PP (polypropylene) corrugated sheets are made from a type of plastic known for its robustness and flexibility. These sheets are created by extruding polypropylene into a corrugated structure, which provides them with an excellent balance of strength and lightweight properties. This corrugated structure, with its parallel fluting sandwiched between two liner sheets, enhances the sheet's ability to withstand impact and stress, making it ideal for various packaging applications.

Advantages of PP Corrugated Sheets

1. Durability and Strength

One of the primary advantages of PP corrugated sheets is their durability. The corrugated design significantly increases the sheet's strength, allowing it to endure heavy loads and rough handling without breaking. This makes them perfect for packaging and transporting fragile or heavy items. Their resistance to impact and compression ensures that the contents remain protected throughout the supply chain.

2. Lightweight

Despite their strength, PP corrugated sheets are remarkably lightweight. This characteristic reduces shipping costs and makes them easier to handle and transport. The reduced weight of packaging materials also contributes to overall cost savings for businesses, making them a practical choice for both small and large-scale operations.

3. Weather Resistance

PP corrugated sheets are resistant to moisture and various weather conditions, including UV rays. Unlike traditional cardboard, which can weaken when exposed to water or extreme temperatures, PP corrugated sheets maintain their integrity and performance. This weather resistance makes them suitable for outdoor use and storage, providing reliable protection in diverse environments.

4. Recyclability

Environmental sustainability is a growing concern in packaging, and PP corrugated sheets offer an eco-friendly solution. Polypropylene is a recyclable material, and PP corrugated sheets can be recycled and repurposed, reducing their environmental footprint. Businesses can benefit from using recyclable materials, aligning with green initiatives, and appealing to eco-conscious consumers.

5. Customizability

PP corrugated sheets can be easily customized to meet specific requirements. They come in various sizes, colors, and thicknesses, allowing businesses to tailor their packaging solutions to their needs. Custom printing options are also available, enabling companies to brand their products and enhance their market presence through attractive and functional packaging.

Key Uses of PP Corrugated Sheets

Here are some pp corrugated sheet uses;

1. Retail Packaging

In retail, presentation is key, and PP corrugated sheets offer an aesthetically pleasing and practical solution. They are used for creating durable and attractive packaging for products ranging from electronics to clothing. Their ability to be printed with high-quality graphics helps in brand promotion and improves the overall shopping experience.

2. Industrial Packaging

For industrial applications, PP corrugated sheets are invaluable. They are used to package and transport heavy machinery, automotive parts, and other bulky items. Their strength and durability ensure that these items are securely packaged and protected during transit.

3. Agricultural Packaging

In agriculture, PP corrugated sheets are used for packaging fruits, vegetables, and other produce. Their resistance to moisture and ability to maintain structural integrity make them suitable for storing and transporting fresh produce, minimizing spoilage and waste.

4. Construction and Building

The construction industry also benefits from PP corrugated sheets. They are used for protective barriers, temporary structures, and as insulation materials. Their resistance to the elements and easy handling makes them a versatile choice for various construction needs.

5. Office and Storage Solutions

PP corrugated sheets are used in creating storage boxes, file organizers, and office dividers. Their lightweight nature and strength make them ideal for organizing and protecting office supplies and documents.

Corrugated Sheet Price and Cost Efficiency

When considering packaging solutions, cost is a crucial factor. PP corrugated sheets offer excellent value for money. While the initial cost of these sheets may be higher than traditional cardboard, their durability and longevity often result in long-term savings. They are less prone to damage, reducing the need for replacements and minimizing waste.

Moreover, their lightweight nature contributes to lower shipping costs. Businesses can enjoy both immediate and long-term savings by investing in PP corrugated sheets. To get the best deal, it's advisable to compare prices from different suppliers and manufacturers. Checking for bulk purchase discounts and evaluating the overall cost-effectiveness of PP corrugated sheets can help businesses make an informed decision.

Choosing the Right PP Corrugated Sheet Manufacturer

Selecting the right PP corrugated sheet manufacturer is crucial for ensuring the quality and reliability of PP corrugated sheets. Look for manufacturers with a proven track record in producing high-quality products. Consider factors such as:

Reputation and Experience: Choose manufacturers with a strong reputation and years of experience in the industry.

Product Range and Customization: Ensure that the manufacturer offers a wide range of options and customization to meet your specific needs.

Quality Assurance: Verify that the manufacturer adheres to strict quality control standards and uses high-quality raw materials.

Customer Support: Good customer service and support are essential for addressing any issues and ensuring a smooth purchasing experience.

In India, numerous PP corrugated sheet manufacturers offer a range of products catering to different industries. Researching and selecting a reliable manufacturer can significantly impact the effectiveness and efficiency of your packaging solutions.

Conclusion

PP corrugated sheets are undoubtedly a game-changer in the packaging industry. Their strength, lightweight nature, weather resistance, and recyclability make them a superior choice for a wide range of applications. By understanding their benefits and applications, businesses can leverage PP corrugated sheets to enhance their packaging solutions, reduce costs, and contribute to environmental sustainability. Investing in high-quality PP corrugated sheets from a reputable manufacturer ensures that you receive a product that meets your needs and exceeds your expectations.

Frequently Asked Questions (FAQs)

Q1. What are PP corrugated sheets made of?

PP corrugated sheets are made from polypropylene, a durable and flexible plastic material, which is extruded into a corrugated structure for added strength.

Q2. How do PP corrugated sheets compare in price to other packaging materials?

While PP corrugated sheets may have a higher initial cost compared to materials like cardboard, their durability and long lifespan often result in cost savings over time.

Q3. Can PP corrugated sheets be customized?

Yes, PP corrugated sheets can be customized in terms of size, color, thickness, and printing, making them suitable for various packaging needs.

Q4. Are PP corrugated sheets recyclable?

Yes, PP corrugated sheets are made from recyclable polypropylene, contributing to environmental sustainability.

0 notes

Text

Types of 3D Printers, Materials, and Applications

What is 3D Printing?

3D Printing or additive manufacturing technologies manufacture three-dimensional parts from computer-aided design (CAD) models by adding material layer by layer until the final physical part is produced. It can be done through a variety of processes where material is deposited, joined, or solidified with the aid of computer control. Materials in the form include plastics, liquids, or powder grains.

3D printing has been around since the 1980’s where it was only suitable for aesthetic protypes considered rapid prototyping but today, especially since 2019, these technologies are considered industrial- production technology, due to the precision, repeatability, and material range.

Today, professional, low-cost desktop and applications of 3D printing aid in creating geometries that were once even impossible by hand and push innovative boundaries in various industries including, jewelry, engineering, dentistry, healthcare, education, and entertainment and more. According to an article published on Statista, “the worldwide market for 3D printing products and services was valued at 12.6 Billion U.S Dollars in 2020 and the industry is expected to grow at a CAGR of 20% between 2020 and 2026.”

How does 3D printing Work?

Every 3D Printer starts with a CAD design file, that is sliced (converted into machine language) and sent to the Printer. Depending on the technology of your printer, the final piece might be produced layer by layer, by solidifying liquid resin or sintering powder. The final parts usually go through post-processing depending on the application.

Design

3D printable models are created with use of CAD software, 3D scanner or other. Models created with CAD software result in the fewest errors. The manual modeling process of preparing geometric data for 3D printing is like plastic arts such as sculpting. CAD models can be saved in stereolithography file format (STL), a de facto CAD file format for additive manufacturing that stores data based on triangulations of the surface of models. Other CAD formats also exist, each with different features and application such as OBJ, 3MF, AMF and more.

Slice

A Slicer software is an important part of the additive manufacturing process. Slicer algorithms convert a 3d printable model into layers that are sent to the 3D printer in machine language called G-code. A G-code file is a series on instructions that machines can understand and move the extruder in ways that prints a model layer by layer. G-code file formats are de-facto for FDM 3D printers, but Resin or SLA, MSLA printers use other formats such as photon file which are images of each layer that a laser cures the resin liquid.

3D Print

Some 3D printers use a roll of filament through a hot extruder to fuse layers into a final piece, others use a laser to cure liquid resin into hardened plastic, others fuse small particles of polymer powder at high temperatures to build parts. Most 3D printers run unattended until the print is complete, and modern systems automatically refill the material required for the parts from cartridges.

Post-Process

Depending on the technology and the material, printed parts may require rinsing in isopropyl alcohol (IPA) to remove any uncured resin from their surface, post-curing to stabilize mechanical properties, manual work to remove support structures, or cleaning with compressed air or a media blaster to remove excess powder.

Types of 3D Printers

The three most common and established 3D printer types for plastic or metal parts are SLA, SLS and FDM. Mintcad supports all these technologies and offers a free slicer software (Jullienne) that allows encrypted 3D printing.

Stereolithography (SLA)

Stereolithography was the first kind of 3D printing technology invented in the 1980’s. and is still one of the most efficient and popular technologies for professionals. SLA 3D printers use lasers to sure liquid resin into a hardened plastic, through the photopolymerizations process.

3D Printing Materials used : Liquid Resin

Fused Deposition Modeling (FDM)

Fused deposition modeling (FDM) is the most widely used type of 3D printing at the consumer level. FDM 3D printers work by extruding thermoplastic filaments, such as ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), through a heated nozzle, melting the material and applying the plastic layer by layer to a build platform. Each layer is laid down one at a time until the part is complete.

FDM 3D printers are well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, FDM has the lowest resolution and accuracy when compared to SLA or SLS.

3D Printing Materials used: Plastics (ABS, PLA, PVA, PET), Carbon Fiber, Steel, Silver

Selective Laser Sintering (SLS)

elective laser sintering (SLS) 3D printers use a high-power laser to sinter small particles of polymer powder into a solid structure. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

3D Printing Materials used: Metals (Gold, Silver, Platinum, Titanium, Steel and Aluminum), Ceramic.

The Benefits of 3D printing

Speed

With traditional manufacturing methods it can take weeks or months to receive a part or final product of a consumable item. With 3D printing technology this time has been cut out by at least 80%. Some designs can even be printed in just a few hours for prototyping and experimentation to make time to market faster than ever before.

Cost

With 3D printing there is no requirement of expensive setups and machinery required by injection molding or machining. The same equipment can be used for prototyping and even production in some industries. As 3D printing becomes more capable of producing full function end products, it may compliment or even replace traditional manufacturing processes in low or high volumes.

Customization

From shoes to sports equipment and jewelry, we are surrounded by products made in limited uniform sizes and styles as businesses strive to standardize things to make it more economical to manufacture. With 3D printing and CAD, only the digital design needs to be changed to tailor products for consumer preferences. The concept first took to industries such as medicine and dentistry and has now entered many other industries and is beginning to grow.

New Age Design

3D printing can create complex shapes and parts, such as overhangs, microchannels, and organic shapes, that would be costly or even impossible to produce with traditional manufacturing methods. This provides the opportunity to consolidate assemblies into less individual parts to reduce weight, alleviate weak joints, and cut down on assembly time, unleashing new possibilities for design and engineering.

Applications of 3D printing

3D printing accelerates innovation and supports startups and small businesses in a range of industries, like engineering, jewelry, dentistry, healthcare, education, entertainment, and each have their own use of 3D printer applications.

Engineering

Rapid prototyping through 3D printing technologies empowers designers in engineering to ideate and produce proof of concept and advance these concepts into production. Prototypes that are visual and functional are close to final product ideology and guides designers through a series of validation stages and finalize go to market.

Jewelry

The Jewelry industry uses CAD and 3D Printing to rapidly prototype designs, fill bespoke client needs, and produce large batches of ready to cast pieces. Digital tools allow for the creation of consistent, sharply detailed pieces without the time consuming and low finish hand wax carving.

Education

For immersive learning and advanced research, 3D printers are the go-to multifunctional tools, they encourage creativity and expose students to professional technologies supporting STEM learning and manufacturing.

Healthcare

Affordable, professional-grade desktop 3D printing helps doctors deliver treatments and devices customized healthcare to better serve each unique individual, opening the door to high-impact medical applications while saving organizations significant time and costs from the lab to the operating room.

Entertainment

High-definition physical models are widely used in sculpting, character modeling, and prop making. 3D printed parts have starred in stop-motion films, video games, bespoke costumes, and even special effects for blockbuster movies. Not only that 3D printers can print at home all kinds of toys and board-games for children and adult entertainment.

If you found this article helpful support designers on Mintcad and print your first 3D printable design file using Mintcad’s free slicer software today. Share this 3D printing guide on your social media or with your friends and colleagues who want to get started today.

This content is originally published on Mintcad's Website: Types of 3D Printers, Materials, and Applications

0 notes

Text

0 notes

Text

What is non woven bag

Non-woven bags have become a popular choice for both consumers and businesses looking for sustainable and practical alternatives to traditional plastic bags. But what exactly is a non-woven bag, and why is it gaining so much attention? In this post, we'll explore the concept of non-woven bags, their manufacturing process, benefits, and common uses.

Understanding Non-Woven Bags

Non-woven bags are made from non-woven fabric, a material that is produced using a unique process of bonding fibers together without weaving them. Unlike traditional woven fabrics, where threads are interlaced, non-woven fabrics are created by mechanically, chemically, or thermally bonding the fibers. This process results in a fabric that is soft, flexible, and durable.

The most commonly used material for making non-woven bags is polypropylene (PP), a type of plastic that is both lightweight and strong. Polypropylene is melted and then spun into fine threads, which are then pressed and bonded together to form a sheet of non-woven fabric. This fabric is then cut and sewn into various shapes and sizes to create bags.

Key Features of Non-Woven Bags

Durability

Non-woven bags are known for their strength and durability. They can carry heavy loads without tearing, making them a reliable choice for everyday use.

Lightweight

Despite their durability, non-woven bags are lightweight, making them easy to carry around and store.

Eco-Friendly

Non-woven bags are often touted as eco-friendly because they are reusable and recyclable. They are a more sustainable option compared to single-use plastic bags.

Water-Resistant

The polypropylene material used in non-woven bags is naturally water-resistant, protecting the contents inside from moisture.

Customizability

Non-woven bags can be easily customized with logos, designs, and colors, making them an excellent choice for promotional purposes.

Cost-Effective

These bags are relatively inexpensive to produce, especially in large quantities, making them a cost-effective option for businesses.

Manufacturing Process of Non-Woven Bags

The process of manufacturing non-woven bags involves several steps:

Spinning: Polypropylene granules are melted and extruded into fine fibers.

Web Formation: The fibers are laid down in a web-like structure, either randomly or in a specific pattern.

Bonding: The web is bonded together using heat, pressure, or chemical agents to create a stable fabric.

Cutting and Sewing: The non-woven fabric is cut into the desired shapes and sizes, and the pieces are sewn together to form bags.

Common Uses of Non-Woven Bags

Non-woven bags are versatile and can be used in a variety of settings:

Shopping Bags: Widely used in retail stores as an eco-friendly alternative to plastic shopping bags.

Promotional Bags: Customized with company logos and used for marketing purposes at events and trade shows.

Grocery Bags: Durable enough to carry groceries and other heavy items.

Gift Bags: An attractive and reusable option for packaging gifts.

Tote Bags: Used as everyday carry bags for personal belongings.

Why Choose Non-Woven Bags?

Non-woven bags offer several advantages over traditional plastic and even some fabric bags:

Environmentally Friendly: Reusable and recyclable, they help reduce plastic waste and promote sustainability.

Versatile: Suitable for a wide range of applications, from shopping to branding.

Affordable: Cost-effective, especially when produced in bulk, making them accessible for businesses of all sizes.

Customizable: Can be easily printed with designs, logos, or slogans, providing an excellent branding opportunity.

Conclusion

Non-woven bags are more than just a trend; they represent a shift towards more sustainable and practical alternatives in everyday life. Their unique manufacturing process, coupled with their durability and eco-friendly properties, make them an ideal choice for both consumers and businesses. Whether you’re looking for a reliable shopping bag or a customizable promotional item, non-woven bags offer a solution that is both functional and environmentally responsible.

https://favouritehub.com/what-is-non-woven-bag/

0 notes

Text

Thermoplastic Tapes Market Share, Trends, and Growth Reports | Global Insight Services

“Global Insight Services company has recently revised its global market reports, now incorporating the most current data for 2024 along with projections extending up to 2033.

Thermoplastic Tapes are tapes composed of plastic materials that can be repeatedly softened and hardened by the application of heat. They are commonly used in a variety of industrial and consumer applications. They are well suited for applications requiring good electrical insulation, chemical resistance, and a wide range of temperature performance.

Thermoplastic tapes can be divided into two broad categories: thermoplastic elastomers (TPEs) and thermoplastic films (TPFs). TPEs are generally softer and more flexible than TPFs. TPEs are generally used in applications where flexibility and conformability are needed, such as electrical insulation, sealing, splicing, and gaskets. TPFs are generally stiffer and more rigid than TPEs and are used in applications where strength and dimensional stability are important, such as protective packaging, labeling, and insulation.

To Know More@ https://www.globalinsightservices.com/reports/thermoplastic-tapes-market/?utm_id=Pranalip

Thermoplastic tapes are available in a wide variety of materials including polypropylene, polyethylene, polyvinyl chloride (PVC), polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE), and many others. Each material has its own unique properties and characteristics, and each can be tailored to meet the specific requirements of the application.

Thermoplastic tapes can be fabricated in a variety of ways. They can be extruded, cast, or laminated. Extrusion is the most common method and involves pushing the material through a die to form a continuous sheet or strip. Cast tapes are created by pouring the material into a mold and then curing it. Laminated tapes are created by bonding multiple layers of material together.

Thermoplastic tapes are widely used in a variety of industries and applications. They are used for electrical insulation, sealing, splicing, gaskets, and protective packaging. They are also used in medical and food packaging, labeling, and insulation.

Thermoplastic tapes are a versatile and cost-effective solution for a variety of applications. They offer good electrical insulation, chemical resistance, and a wide range of temperature performance. They are available in a variety of materials and can be tailored to meet specific application requirements.

Key Trends

Thermoplastic tapes are a type of adhesive tape that is heat-activated and used for a variety of applications. These tapes are made of a variety of materials such as polyethylene, polypropylene, polyvinyl chloride, polyester, and nylon. They are used in a variety of industries and applications, from medical and automotive to industrial and consumer products.

Request Sample@ https://www.globalinsightservices.com/request-sample/GIS24880/?utm_id=Pranalip

The thermoplastic tape market has seen significant growth in recent years due to the increasing demand for lightweight, durable, and cost-effective solutions. This growth is driven by the rising demand for energy-efficient and sustainable products. As such, manufacturers are striving to develop products with improved performance and optimized cost. To meet this demand, manufacturers are exploring the latest trends in thermoplastic tapes technology.

One of the key trends in thermoplastic tapes technology is the development of advanced adhesive systems. Traditional thermoplastic tapes rely on solvent-based adhesives, which can be difficult to use and can have a negative environmental impact. To address this issue, manufacturers are developing new adhesive systems that are more user-friendly and environmentally friendly. These advanced adhesives are designed to provide superior adhesion and durability while also minimizing environmental impacts.

Another key trend in thermoplastic tapes technology is the development of new materials. Traditional thermoplastic tapes are made from polyethylene and polypropylene. However, manufacturers are now exploring the use of new materials such as polyvinyl chloride, polyester, and nylon. These materials offer improved performance characteristics and are more durable than traditional materials. As such, they are becoming increasingly popular in a variety of applications.

A third key trend in thermoplastic tapes technology is the development of self-adhesive tapes. Self-adhesive tapes are designed to be easily applied without the need for an adhesive. This makes them ideal for use in applications where an adhesive would be difficult to apply. In addition, self-adhesive tapes are also less expensive than traditional tapes, making them a more cost-effective solution.

Finally, manufacturers are also exploring the use of smart thermoplastic tapes. Smart thermoplastic tapes are designed to be used with sensors to monitor and control temperature and humidity levels. This technology can be used in a variety of applications, from packaging to medical devices. Smart thermoplastic tapes are also becoming increasingly popular in the automotive industry due to their ability to monitor and control temperature and humidity levels in vehicles.

In conclusion, the thermoplastic tape market is rapidly evolving, and manufacturers are exploring a variety of new trends in order to meet the growing demand for energy-efficient and sustainable solutions. Advanced adhesive systems, new materials, self-adhesive tapes, and smart thermoplastic tapes are some of the most important trends in thermoplastic tapes technology. These trends are helping to improve performance and optimize cost, making thermoplastic tapes an attractive solution for a variety of applications.

Key Drivers

The thermoplastic tapes market is driven by a number of factors. These include the increasing demand for thermoplastic tapes in a variety of industries, the growing use of thermoplastic tapes for packaging and labeling, the rising demand for thermoplastic tapes in medical applications, and the increasing availability of low-cost thermoplastic tapes.

The demand for thermoplastic tapes has increased significantly over the past few years due to their versatile nature and wide range of applications. Thermoplastic tapes can be used in a variety of industries, including automotive, construction, electronics, and medical. For instance, thermoplastic tapes are used for insulation in automotive wiring harnesses, sealing and joining in construction, and for protection against electromagnetic interference in electronics. In medical applications, thermoplastic tapes are used to secure dressings, catheters, and other medical devices.

The increasing use of thermoplastic tapes for packaging and labeling is another key driver of the thermoplastic tapes market. Thermoplastic tapes are used for sealing, labeling, and protecting products during shipping and handling. Additionally, thermoplastic tapes are used in a variety of labeling applications, including bar codes, product identification, and warning labels.

The growing demand for thermoplastic tapes in medical applications is another driver of the thermoplastic tapes market. Thermoplastic tapes are used in medical applications for a variety of reasons, including securing dressings, catheters, and other medical devices. Additionally, thermoplastic tapes are used in wound closure and as a barrier against infection.

The increasing availability of low-cost thermoplastic tapes is also driving the thermoplastic tapes market. Low-cost thermoplastic tapes are becoming increasingly available, which has enabled a wider range of customers to access them. This has increased the demand for thermoplastic tapes, as customers are able to purchase them at a lower cost.

In summary, the thermoplastic tapes market is driven by the increasing demand for thermoplastic tapes in a variety of industries, the growing use of thermoplastic tapes for packaging and labeling, the rising demand for thermoplastic tapes in medical applications, and the increasing availability of low-cost thermoplastic tapes. These drivers are expected to continue to support the growth of the thermoplastic tapes market over the coming years.

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS24880/?utm_id=Pranalip

Market Segmentation:

Thermoplastic Tapes Market is segmented into resin type, application, technology and region. Based on resin type the market is categorized into Polyethylene, Polypropylene, Polyvinyl Chloride, Polyamide and Others. On the basis of application, it is further segmented into Automotive, Aerospace and Defense, Electrical and Electronics, Building and Construction, Sports and Leisure and Others. Based on technology it is segmented into Hot-Melt Extrusion, Solvent Dipping, Pultrusion and Others. Whereas based on region it is divided into North America,Europe,Asia-Pacific and Rest of the World .

Key Players:

The Thermoplastic Tapes Market Report includes players such as 3M Company (U.S), Avery Dennison Corporation (U.S), DuPont de Nemours, Inc. (U.S), Toray Industries, Inc. (U.S), Teijin Limited (Japan), Nitto Denko Corporation (Japan), Sekisui Chemical Co., Ltd. (Japan), Tesa SE (Germany), Saint-Gobain Performance Plastics (France) and BASF SE (Germany), among others.

Buy your copy here@ https://www.globalinsightservices.com/checkout/single_user/GIS24880/?utm_id=Pranalip

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com

About Global Insight Services:

lobal Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

Thermoplastic Vulcanizates Market Outlook, Research, Trends and Forecast to 2030

Thermoplastic Vulcanizates Industry Overview

The global thermoplastic vulcanizates market size was estimated at USD 1.65 billion in 2023 and is projected to grow at a CAGR of 8.7% from 2024 to 2030. The market for thermoplastic vulcanizates (TPV) is expected to grow during the forecast period due to rising demand for lightweight, environmentally friendly solutions that offer exceptional durability as well as increased safety. High-performance elastomers known as thermoplastic vulcanizates (TPV) provide exceptional flexibility, processing ease, durability, and resistance to heat, fluids, and chemicals. Due to these qualities, they may be used to create lightweight automobile parts, including car doors, weather seals, and engine-related elements.

Thermoplastic Vulcanizates (TPV) are now increasingly being used as an alternative to PVC plastic due to several stringent regulations regarding the use of polyvinyl chloride (PVC) in the automotive industry, which in turn is expected to increase market demand in the coming years. In addition, a strong shift towards replacing metals with lightweight materials such as thermoplastic vulcanizates (TPV) to improve fuel efficiency in automobiles is expected to increase demand for thermoplastic vulcanizates (TPV) during the forecast period. TPVs are widely used for making automobiles' interior and exterior components, such as wiper systems, air guides and dams, spoilers and trims, and flappers. The inclination of consumers toward fuel-efficient vehicles across the globe is leading to rising demand for TPV in the automotive application and is expected to drive market growth over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Thermoplastic Vulcanizates Market

Favorable federal regulations set by agencies such as the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) on carbon emissions, along with EU initiatives to develop a TPV app to build light and fuel-efficient vehicles, are likely to boost market growth. The high raw material costs associated with EPDM are expected to hinder profitability.

Favorable government policies for encouraging lightweight and recyclable material applications in various industries including automotive and construction are expected to support the demand for thermoplastic vulcanizates over the forecast period. The investment of USD 2 trillion by the U.S. government as a part of the coronavirus responsible for the development of infrastructure, including hospital building and construction, is expected to further propel the demand for thermoplastic vulcanizates (TPV) in medical and fluid handling applications in the coming years.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

The North America tin cannabis packaging market size was estimated at USD 75.91 million in 2023 and is projected to grow at a CAGR of 12.8% from 2024 to 2030.

The global BOPP dielectric films market size was estimated at USD 1.51 billion in 2023 and is projected to grow at a CAGR of 31.5% from 2024 to 2030.

Key Thermoplastic Vulcanizates Company Insights

Key companies are adopting several organic and inorganic growth strategies, such as new product development, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

In August 2023, Teknor Apex Company, Inc. announced the launch of its new Sarlink RX 3100B Series of TPVs containing up to 40% recycled content. These multi-purpose TPVs are suitable for various automotive applications, such as extruded seals, and offer sustainability benefits by reducing dependency on virgin petroleum-based plastics. The two new grades, with 84 Shore A and 94 Shore A hardness, are based on the existing Sarlink 3100 Series technology but incorporate post-industrial recycled (PIR) content, which provides a more controlled and consistent raw material stream compared to post-consumer recycled (PCR) content.

Key Thermoplastic Vulcanizates Companies:

The following are the leading companies in the thermoplastic vulcanizates market. These companies collectively hold the largest market share and dictate industry trends.

Dawn Polymer

Ravago Manufacturing.

RTP Company

DuPont de Nemours, Inc.

Mitsui Chemicals Inc.

Celanese Corp.

LyondellBasell Industries Holdings B.V.

Mitsubishi Chemical Corp.

KRAIBURG TPE GmbH & Co. KG

Teknor Apex Company, Inc.

Trinseo

Hexpol AB

JSR Corporation

Zeon Corporation.

Order a free sample PDF of the Thermoplastic Vulcanizates Market Study, published by Grand View Research.

0 notes

Text

Cell Phone Signal Boosters Market Analysis, Size, Share, Growth, Trends, and Forecasts by 2031

The Cell Phone Signal Boosters Market, as per the insightful report provided by Metastat Insight, reflects a landscape influenced by the perpetual quest for enhanced connectivity. In a world where seamless communication is non-negotiable, the demand for signal boosters has grown exponentially, addressing the perennial challenge of inconsistent mobile network coverage.

𝐆𝐞𝐭 𝐚 𝐅𝐫𝐞𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭:https://www.metastatinsight.com/request-sample/2553

Top Companies

Wilson Electronics, SureCall, Stella Doradus, SmoothTalker, Comba Telecom Systems Holdings Ltd, Phonetone Technologies, Shenzhen GrenTech RF Communication Limited, Remotek Corporation, Nextivity Inc, Huaptec, CommScope Inc.

In the global market for cell phone signal boosters, geographical distribution plays a crucial role. The market is categorized into North America, Europe, and Asia-Pacific based on location. This segmentation helps analyze and understand the diverse factors influencing the cell phone signal booster industry across different regions. Each geographical sector presents unique challenges and opportunities, shaping the overall landscape of the market.

North America stands out as a significant player in the cell phone signal booster market. Factors like technological advancements, high smartphone penetration, and the demand for seamless connectivity contribute to the region's prominence. The market dynamics in North America are distinct, driven by consumer preferences and regulatory frameworks that impact the adoption of signal booster solutions.

Access Full Report @https://www.metastatinsight.com/report/cell-phone-signal-boosters-market/2553

Meanwhile, the Asia-Pacific region emerges as a dynamic and rapidly evolving market for cell phone signal boosters. The diverse economic landscape, varying levels of technological infrastructure, and the sheer size of the population contribute to the complexity of this market segment. Understanding the unique dynamics within Asia-Pacific is crucial for stakeholders aiming to navigate the opportunities and challenges prevalent in this region.The global cell phone signal boosters' market is intricately linked to geographical nuances. The North American, European, and Asia-Pacific segments showcase distinct characteristics, driven by factors specific to each region. This geographical perspective provides a comprehensive understanding of the market dynamics, helping businesses tailor their strategies to the unique demands of different global regions.

Related Reports -

Extruded Plastics Market - https://www.metastatinsight.com/report/extruded-plastics-market

North America Prefabricated Wall Panel Market - https://www.metastatinsight.com/report/north-america-prefabricated-wall-panel-market

Fluorescence Microscopy Market - https://www.metastatinsight.com/report/fluorescence-microscopy-market

Asia Container Glass Market - https://www.metastatinsight.com/report/asia-container-glass-market

#CellPhoneSignalBoosters#CellPhoneSignalBoostersMarket#CellPhoneSignalBoostersindustry#marketsize#marketgrowth#marketforecast#marketanalysis#marketdemand#marketreport#marketresearch

0 notes