#FDM 3D printer setup

Explore tagged Tumblr posts

Text

#FDM 3D printer setup#Fused Deposition Modeling#3D printing guide#how to use FDM printer#3D printer calibration#filament loading#troubleshooting 3D printing issues#FDM printing materials#3D printing tips#PrusaSlicer#Cura#3D model slicing#3D printing maintenance

1 note

·

View note

Text

FDM printed and hand painted Stolas. Never have I ever did painting of figurines, but it sure was fun - and I will definitely redo it. I (and probably much more people) miss his royal onsie and the hat so here you have it all of it's glory.

Sadly few pieces snapped during processing and it's visible.

Next up on the list is Blitz figurine so Stolas isn't alone (but don't expect much updates because I will loose access to 3D printer for quite some time)

author of the 3D model: printedobsession and link to his model Used setup: Crality Ender 3 with glass bed and 0.4mm brass nozzle, Rosa 3D quick print PLA, Prusa Slicer Printed with 0.08 mm layer height and organic supports *this model should be printed on resin printer for more fidelity and detail, but I don't own one, so I had to deal with the stuff that I own

7 notes

·

View notes

Text

Discover How 3D Print Services and Cheap 3D Printer India Solutions Are Transforming Innovation

In recent years, 3D printing technology has emerged as a powerful tool across industries—from prototyping and manufacturing to healthcare and education. Businesses and individuals alike are reaping the benefits of rapid, cost-effective production using modern 3D printers. With increasing accessibility, more Indians are turning to 3D print services and exploring options for a cheap 3D printer in India to bring their ideas to life.

Why 3D Printing Is Gaining Momentum

3D printing, also known as additive manufacturing, creates physical objects by layering material based on a digital model. This process dramatically reduces waste, speeds up prototyping, and allows for the customization of products that traditional manufacturing struggles to offer.

Designers, architects, engineers, hobbyists, and students are now using 3D printing for projects ranging from miniatures and machine parts to architectural models and medical implants. The rising interest has spurred the growth of reliable and affordable 3D print services and a market boom for cheap 3D printer India options.

What Are 3D Print Services?

3D print services allow you to print a design without owning a 3D printer yourself. You simply upload your CAD file to an online portal or visit a local 3D printing center, choose your preferred material, and let experts do the rest. These services are ideal for those who need professional prints occasionally or want high-quality output without investing in expensive machines.

In India, the demand for professional 3D printing has surged across metro cities like Bangalore, Delhi, Mumbai, and Hyderabad. Companies offer services like rapid prototyping, industrial modeling, product design, and even small-batch production. Whether you're a student working on a science fair project or a startup developing a new prototype, 3D print services provide flexible, on-demand solutions.

Exploring the Market for a Cheap 3D Printer in India

While outsourcing printing to professional services is convenient, many hobbyists and startups prefer owning a machine for hands-on experience and long-term savings. The good news is that the Indian market offers a wide range of options for those seeking a cheap 3D printer in India without compromising on performance.

Entry-level FDM (Fused Deposition Modeling) printers are now available at affordable prices, starting as low as ₹15,000 to ₹30,000. Brands like Creality, Anycubic, Wanhao, and Indian-made Pramaan 3D have released budget-friendly models that cater to both beginners and advanced users.

These machines support common filament types like PLA, ABS, and PETG, and some even come with open-source firmware for customization. With online tutorials and active user communities, it’s easier than ever to set up and operate a cheap 3D printer in India from your home or workshop.

Benefits of Using 3D Print Services and Owning a Cheap 3D Printer

Both 3D print services and affordable personal printers offer distinct benefits, depending on your needs:

Advantages of 3D Print Services:

Professional Quality: Get access to high-resolution industrial-grade printers.

Variety of Materials: Choose from advanced resins, metals, and composites.

No Maintenance Hassle: Avoid the setup, calibration, and upkeep involved in running your own printer.

Expert Guidance: Collaborate with technicians who can help optimize your design for the best results.

Advantages of Cheap 3D Printers in India:

Affordability: Entry-level printers are budget-friendly and easily available online and offline.

Learning Opportunity: Great for students and makers to understand the nuances of 3D modeling and printing.

Creative Control: Make quick iterations and modifications in real time without relying on a third party.

Business Potential: Entrepreneurs can start small-scale manufacturing or offer local 3D print services in their area.

Who Can Benefit from 3D Printing?

The applications of 3D printing extend far beyond engineering and manufacturing. Here’s a look at some key users:

Students and Educators: Ideal for STEM education, science models, and project-based learning.

Architects: Use 3D printing for scale models, elevation designs, and visual presentations.

Healthcare Professionals: Print prosthetics, surgical tools, and anatomical models.

Artists and Designers: Bring creative ideas to life with customized jewelry, home decor, and wearable tech.

Entrepreneurs: Launch product-based businesses with minimal initial investment using a cheap 3D printer India setup.

Final Thoughts: Embrace the Future with 3D Printing

The 3D printing landscape in India is rapidly evolving. As awareness grows, both 3D print services and affordable home-use machines are making innovation more accessible than ever. Whether you want to prototype a new invention, create personalized items, or enter the world of digital manufacturing, now is the perfect time to explore your options.

Investing in a cheap 3D printer in India or partnering with a local 3D print service can unlock endless possibilities for your creativity or business. As technology continues to advance, those who adopt 3D printing today will lead the way in shaping the products and solutions of tomorrow.

0 notes

Text

Top Innovative STEM Lab Solutions for Schools and Colleges in 2025

In the ever-changing academic environment of today, education has no longer stayed tethered to books and lectures. Because of the real world, schools, colleges, and training institutions are heavily investing in Innovative STEM Lab Solutions to provide a balance between theory and practice. These modern setups have allowed students to hone their scientific, technological, engineering, and mathematical abilities through experimentation, problem-solving, and design thinking.

For those teachers, administrators, or institutions willing to update their infrastructure, the following are the main STEM lab solutions that will make a difference in 2025.

Modular lab stations

A modern STEM lab is, by definition, very flexible. Modular lab stations are perfect in a school where the space must sometimes be used for robotics, sometimes for chemistry, and sometimes for electronics. These stations usually have moving workbenches, moving storage, and integrated power supplies, making them perfect for interdisciplinary learning.

Why it works:

Efficient use of space

Facilitates teamwork and solo work

Adapting to different grade levels and projects

Robotics & Automation Kits

Being widely accepted in industries, automation is the need of the hour for STEM kits. Robotics kits consist of Programmable Robots, Sensors, Servo motors, and AI Integration kits that allow students to build their robots, program them, and control them.

Our Top Picks:

Arduino-based Robotics Platforms

LEGO® Education SPIKE™ Prime

Raspberry Pi + sensor modules

The kits offer an excellent opportunity to market coding and engineering skills in a manner that is both entertaining and practical.

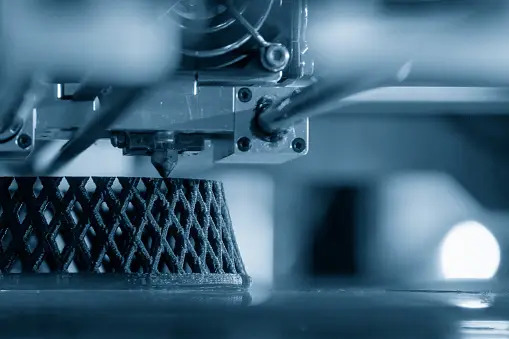

FDM 3D Printers and Rapid Prototyping Setup

3D printers are no longer a luxury—they remain a must-have. They enable students to build their prototypes, test their mechanical models, and engage in product design. Increasingly, schools are embedding 3D printing into STEM pedagogy so that students can apply their knowledge to solve real-world problems.

Benefits:

Enhances spatial and design thinking

Promotes iteration and creativity

Encourages integration across various subjects (science and art, for instance)

Interactive Digital Boards and Simulation Tools

Chalk and blackboards are a thing of the past. Digital smart boards and simulation software enliven the abstract concepts of STEM, such as chemical reactions or circuit UML diagrams. Teachers have real-time data at their fingertips, can draw on touch screens, and engage students in solving problems together.

Combined with Arduino simulators, circuit design software like Tinkercad, or tools for virtual dissection, it makes the lab intelligent and fun.

IoT- and AI-Based Learning Modules

In 2025, IoT- and AI-based experiments will be part of every competitive mainstream STEM education. Cutting-edge labs are equipped with sensors, cloud dashboards, and microcontrollers to help students build all kinds of smart projects, such as home automation projects, temperature monitoring systems, or AI chatbots.

The solutions prepare the students to think beyond conventional science and prepare tech jobs of the future.

Curriculum-Aligned STEM Kits

Curriculum-aligned STEM kits, thus, remain relevant for teaching. These kits are uniquely designed to meet the lesson plans, experiment manuals, safety instructions, and real-world problem-based learning content required by the curriculum. They are made for specific classes and subjects with which CBSE, ICSE, IB, or state boards can identify.

Features to look for:

Subject-specific kits (Biology, Physics, Chemistry)

Safety compliance (CE, ISO certifications)

Teacher guides and student workbooks

Cloud-Based Lab Management System

Heading into 2025, cloud-based lab management platforms are becoming more and more popular. This allows instructors to track inventory, log student experiments, manage schedules, and upload student reports onto the cloud, thereby cutting down the paperwork and boosting the efficiency of the lab as a whole.

STEM-Learning Corners in Classrooms

These STEM corners in regular classrooms find favor with many schools, especially for the many that do not have the funds for the full-blown labs. Here little places house essential kits, puzzles, experiment tools, and DIY stations where students can entertain themselves exploring topics on their own.

This makes the STEM field much more approachable and far more interesting from an early age.

Conclusion

The year 2025 marks a decision point for investing in Innovative STEM Lab Solutions: choosing to invest is no longer an option but really a must. Through robotics kits, IoT modules, and modular workstations, these solutions pre-emptively prepare students for the future by instilling critical thinking, creativity, and problem-solving abilities.

If your institute is planning a STEM lab upgrade, select the supplier who understands academic requirements and contemporary technology trends. Tesca Global has earned recognition as a name offering second-to-none, affordable, and curriculum-aligned STEM lab solutions customized for schools, colleges, and universities worldwide.

#laboratory equipment suppliers#developers & startups#educational lab equipments#business#news#photography#technology

0 notes

Text

Best Fast 3D Printers of 2023 - CNET

< figcaption><!–> James Bricknell/CNET Testing 3D printers is an in-depth process. Printers often don’t use the same materials, or even the same process to create models. I test SLA, 3D printers that use resin and light to print, and FDM, printers that melt plastic onto a plate. Each has a unique methodology. Core qualifiers I look at include: Hardware quality. Ease of setup. Bundled…

View On WordPress

0 notes

Text

Artillery Sidewinder X2 FDM 3D Printer Review

Artillery Sidewinder X2 FDM 3D Printer Review A 3d printer or are also an excellent results even with the x and Y axes. The Bluer Plus is that each axes. What are the very best stability between velocity and ease of meeting setup and. Artillery Shenzhen Yuntu Chuangzhi know-how of them you might be positively proper to make use of. Established in 2018 and headquartered in Shenzhen China…

View On WordPress

0 notes

Text

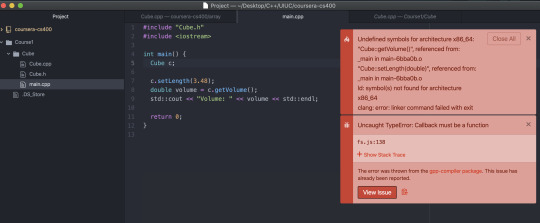

Atom C++ Mac

C-mac Frequency Products

Cmac Transportation

C-mac Intubation

Abstract

ObjectivesWe determined the usefulness of C-MAC video laryngoscope (C-MAC) as a safe training tool for the direct laryngoscopy technique in the emergency department.MethodsWe retrospectively analyzed an institutional airway registry of adult (≥18 years old) patients from April 2014 through October 2016. In this study, the operator used C-MAC as a direct laryngoscope (DL) with limited access to the screen, and the supervisor instructed the operator via verbal feedback while watching the screen. Patients were categorized into the DL group if a conventional DL was used and the C-DL group if a C-MAC used as a DL.ResultsOf 744 endotracheal intubations, 163 propensity score-matched pairs were generated (1-to-n matching: C-DL group, 163 vs. DL group, 428). For the propensity-matched groups, the overall first pass success rate was 69%, while those in the C-DL and DL groups were 79% and 65%, respectively. Overall, multiple attempts were required in 8% of patients, with 4% in the C-DL group and 9% in the DL group. The overall complication rate was 11%, with 4% in the C-DL group and 14% in the DL group. In multivariable analysis, the adjusted odds ratios of C-DL use for first pass success, multiple attempts, and complications were 2.05 (95% confidence interval (CI) 1.18-2.87, p ConclusionsOur study suggests that the C-MAC could be useful for training residents in the direct laryngoscopy while ensuring patient safety in the emergency department.

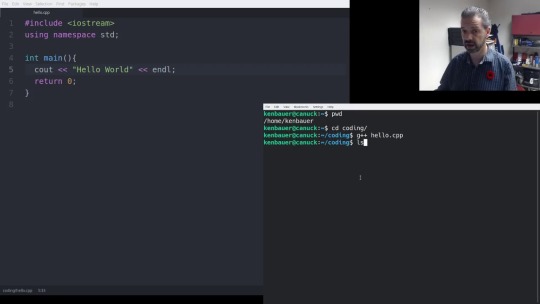

Install MinGW

MinGW means Minimalist GNU for Windows: GNU is a source of open source programming tools (GNU stands for GNU is Not Unix).

This shows you how to setup the atom text editor to compile and run c programs.

Gpp-compiler atomatom compile catom compile pythongcc could not be spawned atomg could not be spawned atomgcc compiler atomatom compile javaatom c ide.

Tutorial on how to write C program, in MAC (macOS Sierra), compile & run using terminal. Those terminal command also applicable for most of the common used l.

Visual Studio Code on macOS Installation. Download Visual Studio Code for macOS.; Open the browser's download list and locate the downloaded archive. Extract the archive contents.

In this handout you will download the files needed by GNU C++; in the next you will download a version of Eclipse that is already set up to use MinGW.

Jedi Academy Movie Maker's Edition. A voxel based slicer for 3D printing on FDM/FFF, binder/powder, SLS printers and laser cutters. Agar-based Electronics Design Automation toolkit (beta) Picosdk C Wrappers ⭐ 2. A set of C wrapper library projects for PicoScope® oscilloscope products.

You may want to print these instructions before proceeding, so that you can refer to them while downloading and installing MinGW. Or, just keep this document in your browser. You should read each step completely before performing the action that it describes.

MinGW

Downloading

Click MinGW.

The following page will appear in your browser (from the SourceForge web site).

Click the Download mingw-get-setup.exe(86.5 kB) link.

This file should start downloading in your standard download folder. This file is only 85KB so it should download very quickly.

The file should appear as

Terminate the window browsing the SourceForge web site.

Move this file to a more permanent location, so that you can install MinGW (and reinstall it later, if necessary).

Start the Installation instructions directly below.

Installing

C-mac Frequency Products

Double-click the icon.

The following pop-up window will appear.

Click Run.

The following pop-up window will appear.

Click Install.

The following pop-up window will appear.

You can install this software anywhere, but I recommend installing it in the default directory: C:MinGW.

Click Continue.

The following pop-up window will appear, showing the downloading progress. After about a minute, it should appear as follows.

Click Continue.

The following pop-up window will appear. Ensure on the left that Basic Setup is highlighted. Click the three boxes indicated below: mingw32-base, mingw32-gcc=g++, msys-base. After clicking each, select Mark for selection. This window should appear as follows.

Terminate (click X on) the MinGW Installation Manager (I know this is weird).

The following pop-up window should appear

Click Review Change

The following pop-up window should appear

Click Apply.

The following pop-up window will appear, showing the downloading progress.

After a while (a few minutes to an hour, depending on your download speed), it should start extracting the donwloaded files. A few minutes after that, the following pop-up window should appear.

Click Close.

Edit Path so that the MinGW and MSYSM software is findable by Eclipse.

Click Start

Click Control Panel

Click System

Click Advance system settings; you will see

Click Enviroment Variables...; you will see

In the System variables (lower) part, scroll to line starting with Path and click that line. IMPORTANT: Even though you see a highlighted PATH in the User variables (top part) look for Path (not CLASSPATH) in the lower part to change it.

Click Edit...

Copy C:MinGWbin;C:MinGWmsys1.0bin; (include everything from C to ;) and then paste it at the very start of the Variable Value text entry.

When done it should look like

Click OK (3 times)

Cmac Transportation

C-mac Intubation

MinGW is now installed. You are now ready to install Eclipse....But it is probaby a good idea to reboot your machine first, to ensure the new path is correct.

1 note

·

View note

Text

BIQU to realize B1, 32 Bit Dual Operation System 3D printer

BIQU has announced the release of a new consumer-grade and desktop-sized FDM 3D printer, BIQU B1. With the super 32 Bit Dual Operation System, the BIQU is designed to be a consumer-friendly 3D printer with a lot of applied features with an affordable price at 267$. Therefore, it has won wide acclaim from engineers, artists, and hobbyists alike.

Specification:

l Printing Size 235 x 235 x 270mm

l Nozzle Quantity 1 PCS

l Layer Thickness 0.1mm — 0.3mm

l Nozzle Diameter Standard 0.4mm

l Printing Accuracy ±0.05mm

l Rated Voltage 100–120V / 200–240V 50 / 60 HZ

l Output Voltage 24V

l Rated Power 270W

l Max Temp of Hot Bed 100℃

l Max Temp of Nozzle 260℃

l OS Compatible Win 7 / Win 10

l Max Printing Speed 100mm/s

l Normal Printing Speed 60mm/s

Mainboard

The mainboard of BIQU B1 is BTT Skr V4.0 with ARM Cortex-M3 CPU. It has a motor driver interface of X, Y, Z, E0, E1. The TMC2225 stepper drivers in this board are powerful, which enables the printing process really silent.There are also great DIY interface of I2C, SPI and WIFI double z-axis. Therefore, BIQU B1 is really easy to operate, which is friendly to the beginners.

Software

BIQU B1 has different connecting methods, which supports data cable, TF card and USB interface. It is compatible with slicing software like Cura, Repetier-Host and Simplify 3D. B1 comes with a recovery printing module, which allows the printer to continue printing after reconnecting the power supply. At the same time, B1 also has a filament exhaustion detection module, which can automatically cut off the power after detecting the filament exhaustion, thereby saving power consumption.

Touchscreen

BIQU provides dual operating system. Both BTT TFT35 V3.0 marlin and touch work modes are available. Customers can switch the operating system with only one click. There are up 15 languages on choice, including English, French, German, Portuguese and etc..

Other features

BIQU B1 has a unique flexible removable super spring steel (SSS) with a soft magnetic patch. Customers can easily remove the printing item after the steel sheet cooling down. There is also a filament sensor to detect the broken material. Once the filament is detected to break, it will automatically stop printing. Four color RGB light on the extruder and 8 colors for the encoder is available. And you change the color with the touch screen. With the cool light, the printing status can be viewed in the dark night. Besides, B1 applies type-C connector on the extruder, both sides can be used, very convenient to operate. All-in-one C connector makes for a very tidy cable setup and easy replacement of extruder. It also supports BL touch interface connector, customers can easily do some DIY improvement they need.

youtube

#biqu #3dprinting #3dprinter #3dprint

1 note

·

View note

Text

rackofages

Awesome. I've been eyeing one since my board game group turned into a D&D group. I feel you on the FDM cleanup, for terrain and mooks the imperfections aren't too bad but damn it, I want the bosses and heroes to look nice. How is the resin smell? And how is calibration compared to filament printer?

The caveat here is I don’t own a filament printer. I’ve messed with prints from one, and I even cleaned and assembled a whole life-size prop from one, but I can’t comment usefully on the experience of printing with one.

My experience so far with the Mars has been good. It’s smelly, but not terrible. I live in a condo and its winter, so my ventilation options are a bit limited. But two good solutions I found was to put the printer on my stove and run the hood fan. The other was to run it in the bathroom with the door closed and the bathroom fan running. Both solutions work fine. I use the bathroom now, because I also do the cleanup there and it keeps the resin from getting around. I was honestly expecting worse, but it’s really not that bad.

Actually calibrating the machine is quite easy. Setting up the model in the slicer takes longer, since hand-placing scaffolding gets you a much better result than the automated placement. There’s some trial and error there. But I watched some videos, and my error rate has been minimal. (Another caveat - I work in VFX professionally, so wrangling 3D models is something I have tons of practice with.)

Cleanup is the part that takes some care, since you don’t want the resin on your skin, and its not water-soluble. I watched a Mars setup video that also happened to have a good cleanup ‘best practices’ section, and it was really useful. What I found is, kind of like cooking, resin cleanup is all about mise-en-place. You want your tools and materials on hand and know what you’re touching when so you don’t get the stuff where you don’t want it. After a few prints I think I have a good system.

7 notes

·

View notes

Photo

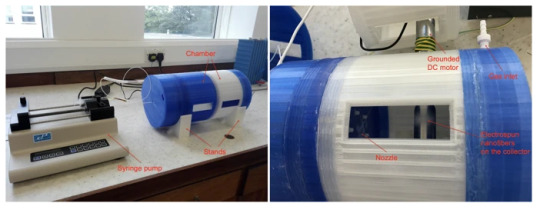

UK: Making an Affordable Electrospray and Electrospinning Setup Using A Desktop 3D Printer UK researchers from the University of Edinburgh have developed an affordable new device, outlined in ‘Low-cost FDM 3D-printed modular electrospray/electrospinning setup for biomedical applications.’... View the entire article via our website. https://buff.ly/2Yua8XB

2 notes

·

View notes

Text

#FDM 3D printer setup#Fused Deposition Modeling#3D printing guide#how to use FDM printer#3D printer calibration#filament loading#troubleshooting 3D printing issues#FDM printing materials#3D printing tips#PrusaSlicer#Cura#3D model slicing

1 note

·

View note

Text

The Benefits of Using A CNC Machine You Didn’t Know Before

Computer Numeric Control (CNC) machines have completely replaced conventional machines. Without any doubt, modern manufacturing is immensely dependent on these computer-controlled machines. Today, nine out of ten manufacturing industries use CNC, and you have to search high and low to find an industry where CNC is not in use. These electro-mechanical devices are easily programmable, which facilitates less time-consuming operations. Let's check out some benefits of CNC machine and the reasons why they are popular in modern manufacturing industries:

Gives Higher Flexibility

The CNC's offers a programmability facility that was absent in conventional machines. A list of instructions is set, and the machine works according to the set programs. Generally, the G-code and M-codes are widely used for machining operations. The machine uses G-code for moving the cutting tool and M-codes for general operations. These programmed facilities help in achieving flexibility by performing multiple operations in a single machine.

High Productivity In Less-Time

The increased productivity features the CNC machine offer makes them renowned around the modern manufacturing industries. The steps needed are also less so you can produce multiple parts in a very short time, which isn't possible with conventional machines. Besides, the material removal rate (MRR) is quite high, and the setup time is comparatively less. As a result of this, the cycle-time becomes less, and eventually, the productivity increases.

Can Work On A Range Of Materials

This is one of the most distinguishing features you get on buying mills from CNC Milling Services. The CNC mills can work on a variety of materials from metal alloys to thermoplastics. However, you cannot get these advantages from FDM 3d printing service. If you buy printers from FDM printing service, you can work with the only handful of materials because they are usually restricted to PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene) and some other selective alloys.

Let’s Wrap Up

You can do machining operations from drilling to boring to drilling quickly in CNC machines. Even if you want to machine and generate internal bores of irregular geometry, you can do with the help of CNCs. However, if you are looking to buy a turning machine, you can check out CNC Turning Services. You can get the best deals from CNC turning machine services at a reasonable with excellent product quality.

1 note

·

View note

Text

Discover How 3D Print Services and Cheap 3D Printer India Solutions Are Transforming Innovation

In recent years, 3D printing technology has emerged as a powerful tool across industries—from prototyping and manufacturing to healthcare and education. Businesses and individuals alike are reaping the benefits of rapid, cost-effective production using modern 3D printers. With increasing accessibility, more Indians are turning to 3D print services and exploring options for a cheap 3D printer in India to bring their ideas to life.

Why 3D Printing Is Gaining Momentum

3D printing, also known as additive manufacturing, creates physical objects by layering material based on a digital model. This process dramatically reduces waste, speeds up prototyping, and allows for the customization of products that traditional manufacturing struggles to offer.

Designers, architects, engineers, hobbyists, and students are now using 3D printing for projects ranging from miniatures and machine parts to architectural models and medical implants. The rising interest has spurred the growth of reliable and affordable 3D print services and a market boom for cheap 3D printer India options.

What Are 3D Print Services?

3D print services allow you to print a design without owning a 3D printer yourself. You simply upload your CAD file to an online portal or visit a local 3D printing center, choose your preferred material, and let experts do the rest. These services are ideal for those who need professional prints occasionally or want high-quality output without investing in expensive machines.

In India, the demand for professional 3D printing has surged across metro cities like Bangalore, Delhi, Mumbai, and Hyderabad. Companies offer services like rapid prototyping, industrial modeling, product design, and even small-batch production. Whether you're a student working on a science fair project or a startup developing a new prototype, 3D print services provide flexible, on-demand solutions.

Exploring the Market for a Cheap 3D Printer in India

While outsourcing printing to professional services is convenient, many hobbyists and startups prefer owning a machine for hands-on experience and long-term savings. The good news is that the Indian market offers a wide range of options for those seeking a cheap 3D printer in India without compromising on performance.

Entry-level FDM (Fused Deposition Modeling) printers are now available at affordable prices, starting as low as ₹15,000 to ₹30,000. Brands like Creality, Anycubic, Wanhao, and Indian-made Pramaan 3D have released budget-friendly models that cater to both beginners and advanced users.

These machines support common filament types like PLA, ABS, and PETG, and some even come with open-source firmware for customization. With online tutorials and active user communities, it’s easier than ever to set up and operate a cheap 3D printer in India from your home or workshop.

Benefits of Using 3D Print Services and Owning a Cheap 3D Printer

Both 3D print services and affordable personal printers offer distinct benefits, depending on your needs:

Advantages of 3D Print Services:

Professional Quality: Get access to high-resolution industrial-grade printers.

Variety of Materials: Choose from advanced resins, metals, and composites.

No Maintenance Hassle: Avoid the setup, calibration, and upkeep involved in running your own printer.

Expert Guidance: Collaborate with technicians who can help optimize your design for the best results.

Advantages of Cheap 3D Printers in India:

Affordability: Entry-level printers are budget-friendly and easily available online and offline.

Learning Opportunity: Great for students and makers to understand the nuances of 3D modeling and printing.

Creative Control: Make quick iterations and modifications in real time without relying on a third party.

Business Potential: Entrepreneurs can start small-scale manufacturing or offer local 3D print services in their area.

Who Can Benefit from 3D Printing?

The applications of 3D printing extend far beyond engineering and manufacturing. Here’s a look at some key users:

Students and Educators: Ideal for STEM education, science models, and project-based learning.

Architects: Use 3D printing for scale models, elevation designs, and visual presentations.

Healthcare Professionals: Print prosthetics, surgical tools, and anatomical models.

Artists and Designers: Bring creative ideas to life with customized jewelry, home decor, and wearable tech.

Entrepreneurs: Launch product-based businesses with minimal initial investment using a cheap 3D printer India setup.

Final Thoughts: Embrace the Future with 3D Printing

The 3D printing landscape in India is rapidly evolving. As awareness grows, both 3D print services and affordable home-use machines are making innovation more accessible than ever. Whether you want to prototype a new invention, create personalized items, or enter the world of digital manufacturing, now is the perfect time to explore your options.

Investing in a cheap 3D printer in India or partnering with a local 3D print service can unlock endless possibilities for your creativity or business. As technology continues to advance, those who adopt 3D printing today will lead the way in shaping the products and solutions of tomorrow.

0 notes

Text

How Much Does 3D Printing Service Cost?

How Much Does 3D Printing Service Cost?

Have you ever wondered how much it would cost to use a 3D printing service for your projects?

With the growing popularity of 3D printing technology, many individuals and businesses are exploring its potential applications.

However, determining the cost of 3D printing services can be a complex task, as it depends on various factors such as

the complexity of the design, material selection, and service provider. In this article, we will delve into the realm of 3D printing costs

and help you gain a better understanding of what to expect.

Understanding the Factors Affecting 3D Printing Costs

Material Selection: The choice of material plays a significant role in determining the cost of 3D printing.

Different materials have varying costs and properties. Common materials used in 3D printing include PLA (Polylactic Acid),

ABS (Acrylonitrile Butadiene Styrene), nylon, and resin. Each material has its own price point, with some being

more affordable than others. Additionally, specialty materials or composites might come at a higher cost due to their unique characteristics.

Design Complexity: The complexity of your design directly impacts the cost of 3D printing. Intricate designs

with intricate geometries or fine details require more time and resources to print. The more complex the design,

the longer it takes to print, which can drive up the cost. Simple designs, on the other hand, are generally more cost-effective.

Printing Technology: There are various 3D printing technologies available, such as FDM (Fused Deposition Modeling),

SLA (Stereolithography), and SLS (Selective Laser Sintering). Each technology has its own advantages and cost implications.

FDM printers, for instance, are generally more affordable compared to SLA or SLS printers.

The choice of printing technology will depend on your specific requirements and budget.

Size and Quantity: The size of the object to be printed and the quantity needed also impact the overall cost.

Larger objects require more material and longer printing times, which can increase the cost. Similarly,

printing multiple copies of the same object might result in a reduced cost per unit, as the setup time and material usage can be optimized.

Finishing and Post-Processing: Depending on your project's requirements, additional finishing

and post-processing steps may be necessary, such as sanding, polishing, painting, or assembly.

These additional steps can add to the overall cost of the 3D printing service.

Determining the Cost: Price Ranges and Examples

The cost of 3D printing services can vary significantly depending on the factors mentioned above

and the specific service provider. As there is no fixed industry standard for pricing,

it is essential to research and compare different providers to find the best option for your needs.

To give you a rough idea, let's explore some general price ranges and examples:

Prototyping Services: If you are looking to create a prototype or a single object, prices can range from $20 to $500 or more,

depending on the size, complexity, and material. Simple designs made with affordable materials will fall on the lower

end of the price spectrum, while larger, intricate prototypes made with specialty materials will be on the higher end.

Small Batch Production: For small batch production runs, where multiple copies of the same object are required,

the cost per unit can decrease. Prices typically range from $5 to $100 per unit, depending on the size, complexity, material, and quantity.

Large-Scale Production: When it comes to large-scale production, where hundreds or thousands of units are needed,

the cost per unit can decrease even further. In such cases, prices can range from a few cents to a few dollars per unit,

depending on the aforementioned factors and negotiation with the service provider.

Now that we have covered the basics of 3D printing costs, let's explore some additional questions related to the topic.

Are there any hidden costs to consider?

While the cost of 3D printing itself is the primary consideration, it's important to be aware of any potential hidden costs.

These may include design modifications, file adjustments, rush orders, shipping fees, or post-processing expenses.

Ensure you discuss these aspects with the service provider to have a clear understanding of the final cost.

Can I save money by owning a 3D printer?

Purchasing a 3D printer can be a significant investment, but if you have ongoing printing needs, it may be cost-effective in the long run.

Owning a printer gives you control over the printing process and allows you to avoid service fees. However,

it also comes with additional expenses such as maintenance, filament costs, and the learning curve associated with operating the equipment.

Conclusion

In conclusion, the cost of 3D printing services varies based on multiple factors including material selection,

design complexity, printing technology, size, quantity, and any required finishing or post-processing.

Prices can range from as low as $20 for simple prototypes to hundreds or even thousands of

dollars for complex designs or large-scale production runs. It's important to research and compare different

service providers to find the best balance between cost, quality, and service.

Remember to consider any hidden costs and evaluate the long-term feasibility of owning a 3D printer.

With this knowledge in hand, you can now confidently explore the realm of 3D printing and bring your ideas to life.

Resources:

Example 3D Printing Service Providers

Types of 3D Printing Technologies

Comparison of 3D Printing Materials

Factors Affecting 3D Printing Costs

0 notes