#Fanuc Robots

Explore tagged Tumblr posts

Text

Having an objectum moment. Dyfm

30 notes

·

View notes

Text

god i need to fuck her so bad. like badly. like i’m going to do a poor job of it

5 notes

·

View notes

Text

youtube

The best glass handling robot arm in Vietnam

3 notes

·

View notes

Text

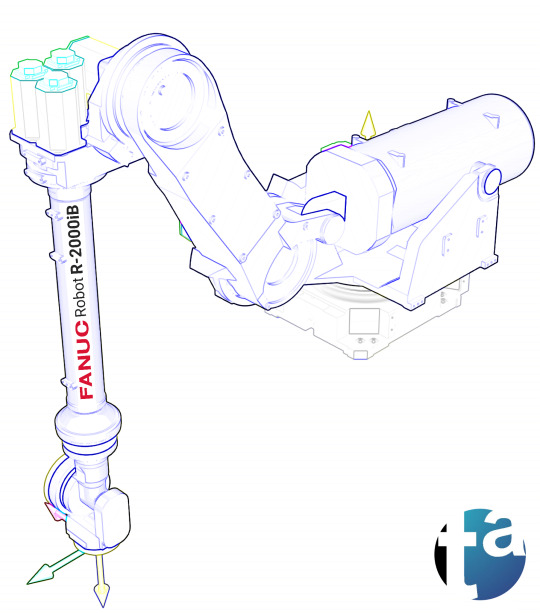

🦾 A010 - Robot FANUC R-2000iB Camshaft Machining Center automotive appl engineparts machining TranTek's Courtesy Robotics RTU Transfer Unit - linear motion track ▸ TAEVision Engineering on Pinterest

Data A010 - Jul 23, 2023

#automation#robot#robotics#FANUC#R-2000iB#FANUC R-2000iB#camshaft machining center#automotive applications#machining center#engineparts machining#TranTek courtesy#RTU#RTU Transfer Unit#transfer unit#TransferUnit#linear motion track#automation linear motion

4 notes

·

View notes

Text

High-Quality FANUC Robot Parts – CNC Tools LLC

Shop premium FANUC robot parts at CNC Tools LLC. We offer a wide selection of reliable, high-performance replacement parts for FANUC robots to keep your automation running smoothly. Trust CNC Tools for fast shipping and expert support on all FANUC robot parts. Visit us today for quality you can count on!

0 notes

Text

Explorando el Universo de la Robótica y la Automatización: Líderes y Tecnologías Clave

¿Qué es la Robótica y la Automatización y Para Qué Sirven? La robótica y la automatización son dos conceptos tecnológicos estrechamente relacionados que están transformando radicalmente industrias enteras y, cada vez más, aspectos de nuestra vida cotidiana. Aunque a menudo se usan indistintamente, tienen matices distintos: Robótica: Se centra específicamente en el diseño, construcción, operación…

#ABB Robotics#automatización#Automatización Industrial#Boston Dynamics#Cobots#Denso Robotics#Fabricación Avanzada#Fanuc Robotics#Festo#Industria 4.0#inteligencia artificial#KUKA Robotics#Logística Automatizada#Mitsubishi Electric Automation#Omron Adept Technologies#robótica#Robotiq#Robots Colaborativos#Robots Industriales#Robots Móviles#Rockwell Automation#Siemens Digital Industries#SoftBank Robotics#Staubli Robotics#tecnología#Universal Robots#Yaskawa Motoman

0 notes

Text

Spot Welding Training Cell | Manufacturer & Supplier in Pune

Hytech Didactic is a trusted manufacturer and supplier of spot welding training cells in Pune. Explore advanced robotic spot welding training, spot welding robocells, and Fanuc spot welding training systems for educational and industrial applications.

#Spot Welding Training Cell Manufacturer Pune#Robotic Spot Welding Training Supplier Pune#Spot Welding Robocell Pune#Fanuc Spot Welding Robocell Pune#Robotics Training Pune#Didactic Robocell Pune#Spot Welding Training Cell Pune#Robotic Spot Welding Training Pune#Educational Robots Pune

0 notes

Text

How Is The Robot Revolution Changing The Manufacturing Industry?

The rapid developments in robotics and automation have led to a tremendous shift in the manufacturing landscape. Companies have started achieving better efficiency, superior quality, and flexibility. Such advanced technologies have become an inescapable requirement for industries to integrate and adapt to evolving market demands. FANUC India paces the process with its efforts toward shaping modern manufacturing processes with the help of robotics and automation. With a legacy of innovation, FANUC India finds itself at the apex of the robot revolution in terms of providing robotic process automation solutions that empower manufacturers to compete better in an increasingly competitive marketplace.

Manufacturing Process Reimagined

Underlying this revolution lie the ideas of robotic process automation (RPA) and industrial robot types and applications. But these are far from just tools; they represent a fundamental transformation in manufacturing processes. With FANUC India leading the way in robotic process automation solutions that not only make operations lean but also agile and reactive to the fast-paced demands of the production world, manufacturing today can look at these lines of integration. This was the march toward full automation—from merely being an idealistic notion to making it a reality. It required a complete rethink about the manufacturing ecosystem.

As we move forward in this blog, let's take a look into how FANUC India is collaborating with manufacturers, from big to small, to reimagine the future of manufacturing through robotic solutions. Let's also look into the significance of RPA, which enhances productivity and efficiency while discussing various applications of industrial robots across a wide variety of industries. This shift is poised to be tremendous because, undoubtedly, the future of manufacturing will become synonymous with breakthroughs in robotics and automation.

Understanding Robotics and Automation

Robotics and automation simply refer to the use of machines and software packages designed to perform rigorous tasks. This technology, which includes solutions from renowned companies like FANUC India, simplifies the manufacturing process. The end results are enhanced productivity and high quality of output. Robotics and automation basically help manufacturers produce larger volumes of the product with a minimal error rate.

From Human to Machine

Work in traditional manufacturing systems is often tedious and time-consuming. Industrial robots allow producers the opportunity to give machines the tasks involving repetition. This shift frees human personnel to engage in other important strategic and creative activities. As a result, efficiency increases, and employee morale improves because workers can focus on more meaningful tasks.

Cost Efficiency Through Automation

Beyond efficiency, more relevant areas have been touched by the benefits of robotics and automation. Solutions provided by FANUC India show great savings in costs over the long run. As manufacturers can cut back on material wastage and avoid expensive rework for more profitability, this enhances their bottom line. As this technology is used in various industries, it is striking to notice how dramatically the effects of robotics and automation will be.

The Rise of Robotic Process Automation Solutions

Key Benefits of RPA

Simplified Work Processes: RPA simplifies tedious processes that have repetitive actions because it allows smooth workflow among departments.

Less Human Error: Since RPA reduces human involvement, the errors that may cause major setbacks are at lower levels as well.

Productivity Improvement: Robots handle repetitive and mundane tasks; hence, it will free human workers to work on high-value activities. All said and done, their productivity will improve.

As the manufacturing field expands, RPA will only be of prime importance for companies seeking the upper hand.

Applications of Industrial Robots in Manufacturing

Industrial robots have become indispensable in the day-to-day manufacturing process in contemporary times. They are applied in many industries such as automotive, electronics, food and beverages, and consumer goods, among other fields. The use of different types of robots makes a particular production process more efficient and has a higher degree of efficiency.

Multifaceted Applications of Industrial Robots

Automobile Manufacturing: They are used for welding, painting, and assembling. This means precision with speed in the production line.

Electronics Assembly: Robots aid in the complex process of assembling electronic parts. This increases accuracy and decreases assembly time.

Food and Beverage Production: Robots are used for packaging, palletizing, and sorting. In such processes, hygiene and efficiency of production are maintained.

Production of Consumer Goods: Robots are applied in handling repetitive tasks in the assembly and packaging of consumer goods. This increases productivity and quality control.

FANUC India is at the forefront of innovative robotic process automation solutions tailored for various industries. That is why, with its range of industrial robots assembled for specific applications, the company empowers manufacturers with customized options that turn out to be an optimized way forward for more productive operations and time, along with added efficiency. It unlocks new levels of productivity and quality in companies by integrating robotic solutions from FANUC.

The Future of Robotics and Automation in Manufacturing

Looking forward, things will look bright and promising for robotics and automation in manufacturing as more advanced technologies are likely to transform the industry even further—IoT, AI, and ML, among others.

Key Developments Driving the Future

Cobots: These robots are designed specifically to work alongside human workers. Cobots will take on tasks that a human would spend too much time on or that may be hazardous. They aim to improve productivity and safety in workplaces by extending human capacity for work.

Advanced Vision Systems: They are used with robots and are basically used for quality checks. They scan all products for defects so that production can maintain good quality with less wastage. This accuracy helps sustain high standards in production.

AI and Machine Learning Integration: With AI algorithms, robots can learn from their environment and adjust in real time. This means production processes can be optimized, making operations with increased real-time decision-making more efficient.

Data Analytics and Predictive Maintenance: The new generation of robots will collect internal operation data from equipment. This data is analyzed and used to predict potential failures. Data analytics will reduce the time spent on any breakdown in equipment. This would make the manufacturing processes very smooth and efficient.

3D Printing Integration: With robotics integrated into 3D printing, product parts are designed quickly during production. This technology allows producers to enjoy flexibility with short lead times for prototypes, allowing product designs to be ready in an instant.

Benefits of the Robot Revolution

The robot revolution has numerous benefits:

More Productivity: Robots can continuously function, thus producing more volume and making production easier.

More Quality: The precision of robot movements and improved inspection systems mean that products will have more consistent quality.

Savings: Automation reduces labor costs and material use. These savings for the producers translate to cheaper products.

Safety: Robots help prevent accidents during dangerous operations by eliminating the need for human workers in a workplace and ensuring safe and healthy conditions.

Flexibility: Robots are easy to reconfigure for other tasks, which translates to product changes faster than what was possible for humans in adapting to changing production needs.

Problems to Consider

There are many pros, but integration with robots and automation is quite difficult:

High Initial Investment Cost: It entails considerable pre-investment, where lots of investment is required to be incurred at the initial stage, which can be difficult to tackle for some manufacturers.

Skill Gap: There is a critical need for training the workforce to operate and maintain high-end robotic systems.

Ease of Integration in the Workplace: To work seamlessly with existing production lines and personnel, robots must be integrated smoothly without any glitches.

Artificial Intelligence and Machine Learning in India's Smart Factories

The primary force behind this change is the growth of Indian manufacturing that progresses with AI and ML solutions. Digital technologies will account for 40% of the total expenditure in manufacturing by 2025, up from just 20% in 2021, as reported by NASSCOM. This change lays heavy emphasis on every stage of factory automation, from sourcing raw materials to finished goods dispatch.

Sector-Wise Changes

Automotive Industry: AI-based robotics shortens the processes in the manufacturing process with higher accuracy and speed. Indian companies have launched a 54% implementation rate of AI and analytics technologies, using machine sensors and cloud technology for the most efficient production.

Electronics Manufacturing: AI-based machine vision triggers the correct assembly of tiny components, propelling India's electronics manufacturing to the much-desired US$ 300 billion by 2026.

Chemicals and Pharmaceuticals: AI makes the monitoring and control of the production cycle precise; therefore, enhancing productivity and also meeting regulatory requirements.

Textile Industry: The textile industry applies CAD while designing textiles for maximum cut optimization and quality inspections; its value adds to India's GDP.

Evolution of Market Dynamics

The industrial robotics market in India is estimated to reach $264.10 million by 2028, at a CAGR of 2.92%. AI-algorithm-driven robots are undergoing this change and transforming manufacturing processes, raising production efficiency, and cutting labor costs. Industry majors like FANUC India are pursuing this growth, providing innovative robotic process automation solutions to empower manufacturers to leverage robotics and automation.

Conclusion With more and more industries adopting industrial robot types and applications, the applications and benefits will only add up. With leading names like FANUC India on their side, manufacturers are confidently investing in robotics and automation, further enhancing their position in the market. Contact FANUC India today and learn how their solutions can transform your manufacturing processes and help you move ahead in the robot revolution.

0 notes

Text

The Future is Automated: How Used Fanuc Robots Can Help Prepare Your Business

In a world where technology evolves at an unprecedented pace, the future of manufacturing and production is inexorably tied to automation. This march towards an automated future is not just about keeping up with trends; it's about economic survival, operational efficiency, and achieving new levels of innovation.

However, one of the significant barriers to automation for many businesses, particularly small and medium-sized enterprises, has been the cost. Enter the solution: used Fanuc robots for sale.

A Cost-Effective Entry to Automation

The primary allure of used Fanuc robots is their cost-effectiveness. New, state-of-the-art robotic systems can run into the hundreds of thousands of dollars – a daunting investment for many. However, used robots often come at a fraction of this cost, making them an accessible option for companies looking to automate without breaking the bank.

Despite their used status, these robots often have much life left in them. With proper maintenance and care, a used Fanuc robot can operate efficiently for many years, offering businesses a high return on investment. The reduced initial expenditure also means companies can recoup their investment quicker, improving their cash flow and financial stability.

Flexibility and Adaptability

One of the strengths of Fanuc robots is their versatility. Whether your business is in packaging, assembly, machining, or welding, there is likely a Fanuc robot configuration that can be adapted to your needs. The broad range of models and sizes available means that regardless of your production scale or industry, integrating a used Fanuc robot into your operations is possible.

Moreover, Fanuc’s commitment to backward compatibility ensures that even older models can be updated or modified with newer software enhancements, improving their functionality and extending their operational life. Businesses can therefore adapt these robots to changing manufacturing requirements without significant additional investments.

Future-Proofing Your Enterprise

Leveraging used Fanuc robots is not just about meeting today's operational needs; it's also an investment in the future. As automation and digital manufacturing technologies advance, having an established robotic infrastructure in place will allow businesses to pivot and scale more easily. This agility is crucial in staying competitive in fast-moving industries.

Additionally, by integrating robotics into their operations, companies can accumulate valuable data on their processes, leading to insights that drive further efficiency improvements, cost reductions, and even product innovations. This learning curve and adjustment period become significantly more accessible and affordable with used robots, ensuring businesses are not left behind as the industry evolves toward more automated futures.

Sustainability Benefits

Choosing used Fanuc robots also reflects an environmentally responsible decision. By extending the life cycle of these machines, businesses contribute to reducing electronic waste and the demand for new raw materials. In an era where consumers and regulatory bodies are increasingly focused on sustainability, this can enhance a company’s green credentials, potentially opening up new markets and improving public perception.

Getting Started

For businesses contemplating this venture into automation with used Fanuc robots, a systematic approach is recommended. Start by identifying processes that could benefit most from automation. These are typically repetitive, high-volume tasks where robots can work continuously without fatigue, ensuring consistency and quality.

Next, consult with experts. Many sellers of used Fanuc robots offer consultancy services to help you select the right model for your needs and plan the integration process. This step is crucial in avoiding common pitfalls and ensuring that the transition to automation is as smooth as possible.

Finally, consider the training needs of your staff. While Fanuc robots are known for their user-friendly interface, ensuring your team is well-prepared to work alongside their new robotic colleagues is essential for maximizing the benefits of automation.

Conclusion:

As we edge closer to the future, where automation becomes the backbone of manufacturing and production, the opportunity to integrate used Fanuc robots into your business operations represents a wise, forward-thinking decision. Not only does it allow for a cost-effective entry into automation, but it also sets the foundation for future growth, innovation, and sustainability.

Whether you're a small startup or a medium-sized enterprise looking to expand, the advantages of investing in used Fanuc robots for sale for your production lines are clear. The future is automated, and with used Fanuc robots, your business can be well-prepared to meet it head-on.

0 notes

Text

ROBOT GẮP KÍNH FANUC R2000iA/165EW

THÔNG SỐ KỸ THUẬT CHÍNH:

Tải trọng tối đa: 165 kg

Tầm với tối đa: 2655 mm

Số trục: 6 trục

Độ lặp lại: ±0,2 mm

Trọng lượng robot: Khoảng 1.600 kg

Phạm vi chuyển động các trục:

Trục 1 (J1): ±360°

Trục 2 (J2): ±245°

Trục 3 (J3): ±360°

Trục 4 (J4): ±720°

Trục 5 (J5): ±250°

Trục 6 (J6): ±720°

Tốc độ trục:

J1: 100°/s

J2: 90°/s

J3: 90°/s

J4: 120°/s

J5: 120°/s

J6: 190°/s

Nhiệt độ hoạt động: 0°C đến 45°C

Cấp bảo vệ: IP67 (chịu được bụi và nước)

Trình trạng của cánh tay robot Fanuc: hàng đã qua sử dụng

Fanuc R-2000iA/165EW là một robot mạnh mẽ, đa năng, được thiết kế để hoạt động bền bỉ trong các môi trường sản xuất yêu cầu cao về độ chính xác và hiệu suất.

0 notes

Video

youtube

Robot gắp kính - Robot nâng hạ kính Fanuc gia công kính HỘP | No.1 Glass...

0 notes

Link

We offer a complete range of products and services for industrial robotics, CNC systems & factory automation solutions.

#manufacturing #automation #robotics @FANUCAmerica

0 notes

Text

Unlocking the Power of the Fanuc Test Simulator: Your Gateway to Testing Fanuc Robots and Components

In the world of industrial automation, precision and reliability are paramount. For businesses that rely on Fanuc robots, ensuring that every component functions flawlessly is crucial. This is where the Fanuc Test Simulator comes into play. In this blog post, we'll dive into how this indispensable tool enables comprehensive testing of Fanuc robots, robot servo amplifiers, spare parts, and teach pendants, ensuring your operations run smoothly and efficiently.

What is the Fanuc Test Simulator?

The Fanuc Test Simulator is a state-of-the-art testing platform designed specifically for Fanuc robotic systems. It provides a controlled environment where you can thoroughly test and diagnose various components of Fanuc robots. This includes everything from the robots themselves to their servo amplifiers, spare parts, and teach pendants.

Comprehensive Testing for Fanuc Robots

One of the standout features of the Fanuc Test Simulator is its ability to test all models of Fanuc robots. This includes:

Articulated Robots: From small, precise models to large, heavy-duty robots, the simulator can handle them all.

Delta Robots: Known for their speed and precision in pick-and-place operations, delta robots can also be tested for optimal performance.

Collaborative Robots (Cobots): Ensuring safety and efficiency in collaborative environments is critical, and the simulator helps verify these aspects.

By simulating real-world conditions, the Fanuc Test Simulator allows you to identify and rectify issues before they impact your production line.

Testing Robot Servo Amplifiers by Cnc-shopping engineers

Servo amplifiers are the heart of any robotic system, controlling the motors that drive the robot's movements. The Fanuc Test Simulator enables you to test these amplifiers thoroughly with dedicated Fanuc Servo motors, ensuring they deliver precise and consistent performance. This is vital for maintaining the accuracy and reliability of your robotic operations. (Such as FANUC A06B-6100, 6102, 6104, 6107 and well know models such as FANUC A06B-6107-H001 which is fully tested on the FANUC Robot Test bench)

Ensuring the Quality of Fanuc Robot Spare Parts

Spare parts are essential for minimizing downtime and maintaining the longevity of your robots. With the Fanuc Test Simulator, you can test these parts before they are integrated into your system. This proactive approach helps prevent potential failures and ensures that every component meets Fanuc's high standards.

Verifying Fanuc Teach Pendants

Teach pendants are the interface between the operator and the robot, making their reliability crucial. The Fanuc Test Simulator allows you to test teach pendants for functionality and durability, ensuring that they provide accurate control and feedback.

Why Choose the Fanuc Test Simulator?

Accuracy: The simulator replicates real-world conditions, providing accurate test results.

Efficiency: Quickly diagnose and address issues, minimizing downtime.

Versatility: Test a wide range of Fanuc robots and components.

Reliability: Ensure all parts meet Fanuc's stringent quality standards.

Linking to Our E-Store

Ready to enhance your testing capabilities with the Fanuc Test Simulator? Visit our e-store at CNC-Shopping.us to explore our range of Fanuc robots, servo amplifiers, spare parts, and teach pendants. Our products are designed to work seamlessly with the Fanuc Test Simulator, ensuring you get the most out of your investment.

Conclusion

The Fanuc Test Simulator is an invaluable tool for any business that relies on Fanuc robotic systems. By enabling comprehensive testing of robots, servo amplifiers, spare parts, and Fanuc teach pendants, it ensures your operations remain efficient and reliable. Don't wait until a problem arises—invest in the Fanuc Test Simulator and keep your production line running smoothly.

Visit CNC-Shopping.us today to learn more and make your purchase.

#cnc-shopping#fanuc robotic#fanuc#Fanuc teach pendant#Fanuc servo amplifiers#machine-tools#industry#automation#A06B-6107-H001

0 notes

Text

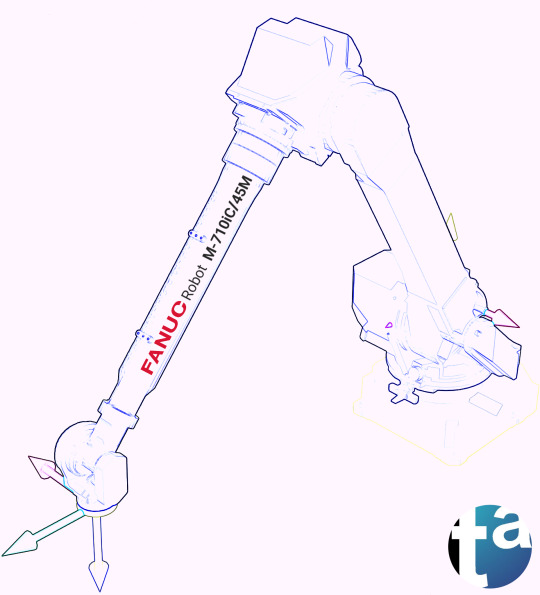

🦾 A007 - Palletizing Robot FANUC M-710iC/45M FanucAmerica Vision Reading QRCodes Automation Manipulator MaterialHandling Robotics ▸ TAEVision Engineering on Pinterest

Data A007 - Jul 17, 2023

#automation#robot#robotics#palletizing#FANUC#FanucAmerica#M-710iC/45M#FANUC M-710iC/45M#Vision Reading QRCodes#manipulator#MaterialHandling

5 notes

·

View notes