#flanges manufacturer

Text

Metalica Forging Inc, a prominent Flanges Manufacturer in India, offers a wide selection of flanges ranging from 12 inches to 48 inches. These flanges are crucial components that connect pipes to vital accessories like tees, elbows, reducers, and valves, enabling seamless integration within piping systems.

As one of the largest Flange Suppliers in India. is recognized for meeting the global demands of its clients, serving customers across five continents and nearly 80 countries. This achievement reflects the company's dedication to providing high-quality and durable products.

Metalica Forging Inc. is a trusted name in the Indian flanges market, supplying ASTM A105 flanges known for their ability to withstand high-pressure and high-temperature environments. As a leading provider of JIS Flanges, the company continues to expand its range of services to cater to the growing needs of its diverse customer base.

We Lead flanges in several Indian cities.

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Ahmedabad

Flange Manufacturer In Surat

Flange Manufacturer In Bhavnagar

For more details, please visit: metalicaforginginc.com

Product Information: Flange manufacturer

#flanges#flanges manufacturer in india#flanges manufacturer#jis flanges#jis flanges manufacturer#jis flanges manufacturer in india

0 notes

Text

Top Quality Flanges Manufacturer in USA

Pipingprojects.us is a widely known Flanges Manufacturer in USA. We produce and sell a broad range of flanges, such as lap joint, weld neck, orifice, slip-on, and more. We employ a range of materials to make high-quality flanges. Nickel, molybdenum, and chromium are common alloy steel flange materials. Chrome moly flanges are well-known for their high corrosion and oxidation resistance. We are one of the leading flange supplier in USA.

We are the best flange manufacturer. These flanges can be manufactured by forging or casting. These components, available from renowned stainless steel flange manufacturers, are used to strengthen or connect beams and columns. When installing stainless steel pipe flanges, a certain flange type is necessary to provide a precise and secure fit and seamless integration into the piping system. We provide Flanges in a number of cities like Flanges Supplier in Texas, Flanges Supplier in California and Flanges Supplier in Florida.

#Flanges Manufacturer in USA#Flanges Supplier in USA#Flanges Manufacturer#Flanges Supplier in Texas#Flanges Supplier in California#Flanges Supplier in Florida

0 notes

Text

“Vendemos productos, entregamos confianza”

#brigamex#acero#aceroalcarbono#conexion#conexionesindustriales#flanges#conexión#flanges manufacturer

0 notes

Text

Factors to Consider When Choosing Flanges for Your Project

Flanges play a pivotal feature inside the seamless functioning of numerous enterprise projects. Whether you are running in creation, oil and gasoline, or manufacturing, selecting the right flanges is critical for ensuring efficiency, protection, and sturdiness.

However, with a plethora of alternatives to be had within the market, deciding on the first-class flanges may be overwhelming. In this whole manual, we are going to delve into the essential component factors you want to consider even when choosing flanges for your project, empowering you to make informed options.

Understanding Your Requirements

Before diving into the specifics of flange selection, it's crucial to evaluate your venture's specific necessities. Consider factors which include stress, temperature, media type, and environmental situations. By gaining an easy knowledge of those variables, you could narrow down your alternatives and discover flanges which may be tailor-made to satisfy your mission's needs.

Material Selection

The cloth composition of flanges is a critical determinant in their standard overall performance and sturdiness. As a main flanges producer, Bu-Lok offers a diverse variety of materials, such as stainless steel, high nickel metallic, alloy steel, and carbon metallic. Each material has remarkable houses that make it suitable for particular applications. For example, stainless-steel flanges are renowned for their corrosion resistance, making them ideal for environments exposed to moisture or chemicals. Conversely, carbon steel flanges boast wonderful strength and affordability, making them a famous choice for excessive-pressure programs. By carefully comparing your challenge's necessities, you may select the perfect fabric that aligns with your overall performance expectations and rate variety constraints.

Pressure Ratings

Flanges are subjected to diverse tiers of pressure relying on the nature of the gadget they are protected into. It's vital to select out flanges with stress scores which are probably well perfect with the running conditions of your challenge. Failure to achieve this could bring about catastrophic outcomes, consisting of leaks, ruptures, and tool harm. Their significant form of flanges encompasses particular stress classes, making sure that you could locate suitable alternatives tailor-made for your unique pressure requirements. Whether you're handling low-pressure systems or immoderate-strain applications, they have you covered with dependable and strong flange solutions.

Dimensional Accuracy

Achieving a particular match is paramount in terms of flange set up. Any discrepancies in dimensions can compromise the integrity of the device and result in leaks or inefficiencies. Therefore, it is imperative to pick flanges that adhere to standardized dimensions and tolerances. Their flanges are artificial with meticulous hobby to detail, ensuring superb dimensional accuracy and compatibility with corporation requirements. Whether you require ANSI, ASME, or DIN compliant flanges, they offer you products that meet stringent awesome requirements, making sure seamless integration into your undertaking.

Corrosion Resistance

In corrosive environments, the sturdiness of flanges is contingent on their potential to face up to chemical degradation and oxidation. Choosing corrosion-resistant flanges is vital for stopping untimely deterioration and making sure prolonged carrier existence. Their stainless steel and immoderate nickel steel flanges display off superior corrosion resistance homes, making them nicely-suited for programs exposed to corrosive materials or harsh jogging situations. By prioritizing corrosion resistance in your flange choice system, you can safeguard your funding and mitigate the chance of expensive safety and replacements down the road.

Temperature Considerations

Flanges are uncovered to a wide type of temperatures, starting from excessive bloodless to excessive warmness, depending on the strolling surroundings. It's essential to choose flanges which can face up to those temperature fluctuations without compromising their structural integrity or average overall performance.Their comprehensive variety of flanges is engineered to withstand a diverse array of temperature situations, making sure reliability and stability underneath challenging thermal environments. Whether you are operating in sub-0 temperatures or high-temperature programs, they offer flange answers that supply ordinary overall performance and durability.

End Connection Type

The approach of becoming a member of flanges to piping structures can range relying on the unique requirements of the undertaking. Common end connection sorts encompass welding, threading, and flanged connections. Each connection technique gives awesome blessings and boundaries in phrases of installation ease, upkeep flexibility, and leak prevention. They give flanges with flexible cease connection alternatives, allowing you to select the maximum suitable method based totally to your task's needs and alternatives. Whether you pick the convenience of welding or the flexibility of threaded connections, they offer flanges that facilitate seamless integration into your piping system.

Quality Assurance and Certification

When sourcing flanges for your undertaking, it's critical to prioritize pleasant assurance and certification to make sure compliance with enterprise requirements and rules. They are dedicated to upholding the best exceptional requirements inside the production of flanges, adhering to rigorous fine manipulation measures and acquiring applicable certifications which include ISO 9001 and PED certification. By selecting Bu-Lok as your flange supplier, you could believe in the reliability, consistency, and compliance of the goods, thereby mitigating risks and ensuring regulatory compliance for your assignment.

Conclusion

In the end, selecting the proper flanges in your challenge includes careful attention to different factors, together with material choice, stress scores, dimensional accuracy, corrosion resistance, temperature concerns, end connection kind, and nice guarantee. By partnering with a good flanges manufacturer and flanges supplier like Bu-Lok, you can get right of entry to a comprehensive range of outstanding flange solutions tailor-made to fulfill your undertaking's precise necessities.

With their massive understanding, impeccable craftsmanship, and commitment to patron delight, you can embark in your undertaking with confidence, knowing that you have dependable flange solutions helping your endeavors. Contact them today to find out how we can empower your project's success with our premium flange services and products.

0 notes

Text

Flanges Manufacturer & Supplier by SPP Metal & Alloys

SPP Metal & Alloys emerges as a trusted Flanges Manufacturer & Supplier, catering to diverse industrial needs. Our comprehensive range includes high-quality flanges crafted with precision and expertise, ensuring durability and performance. Backed by innovation and excellence, we deliver solutions that meet stringent standards and exceed expectations in every project.

0 notes

Text

Top-Quality Flanges Manufacturer in USA

Piping Project is a well-known Flange Manufacturers in USA. Flanges have various features, and the type of stainless steel used determines their features. These flanges can be cast or forged during the manufacturing process.

As a globally recognized Flanges Manufacturer, we produce flanges using stringent quality control techniques and standards to provide good surface and near-dimensional tolerances. We are a primary global provider of carbon steel, alloy steel, and stainless steel flange solutions, having obtained ASME Quality and ISO 9001:2015 Certifications. We are also a leading Flanges Supplier in USA.

A flange is crucial in many production processes since it is available in various specifications. The properties of the Flange material, such as its resistance to chemicals, temperatures (or temperature changes), pressures, acids, gasses, and occasionally electromagnetic or electrical forces, are considered when choosing the material for installation. We are also known as a prominent Fasteners Manufacturer in USA.

For more Details Visit: Flange Weight Chart

Website: pipingprojects.us

0 notes

Text

Inconel 600 Flanges Manufacturers

0 notes

Text

Flanges - Uses & Types | Arcellor controller

Flanges play a essential function in connecting pipes and making sure a steady, leak-unfastened seal in diverse industries. There are unique sorts of flanges, every serving unique functions. Arcellor Controller, a good flanges manufacturer in India, makes a speciality of crafting terrific flanges to satisfy diverse industrial needs. From preferred flanges to custom designs, they offer dependable answers for connecting pipes correctly. Whether you're in need of weld neck, slip-on, or blind flanges, Arcellor Controller gives quite a number alternatives to suit your requirements. As a trusted flanges manufacturer,, they prioritize first-class and precision of their merchandise, ensuring durability and top-quality performance. If you're in search of top-notch flanges and exploring different flange kinds, Arcellor Controller stands proud as a dependable companion, presenting understanding and excellence in the area.

0 notes

Text

Which industries use flanges?

Flanges are pivotal components within the intricate web of industrial connectivity, seamlessly linking diverse sectors. At Bullion Pipes & Tubes LLP, we take great pride in our role as a premier flanges manufacturer, supplier, stockist, and exporter, serving a vast global clientele. As a leading player in the industry, we acknowledge the diverse flanges uses by providing an extensive range that encompasses various sizes, specifications, standards, materials, grades, and types. This commitment ensures that we not only meet but exceed the unique requirements of every project as a reliable flanges supplier.

In this blog post, we'll delve into the diverse array of industries that heavily rely on flanges for their day-to-day operations.

Understanding Flanges

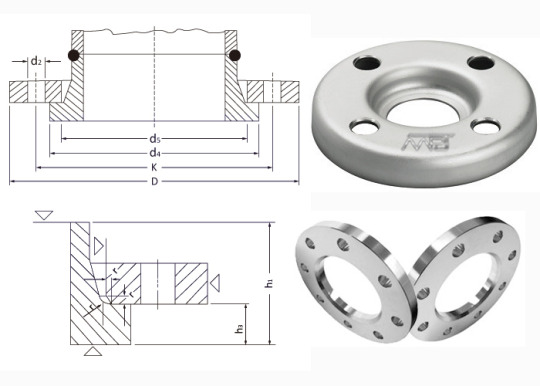

Flanges are flat, circular components with evenly spaced holes that are used to connect or join pipes, valves, pumps, and other equipment in various industrial applications. They provide a means for easy assembly and disassembly, facilitating maintenance and repairs. By creating a secure and leak-proof connection, flanges help ensure the integrity of fluid or gas systems. The bolts passing through the holes in the flange create a tight seal, preventing leaks and promoting the efficient flow of materials within a piping system.

Industries That Rely on Flanges:

Numerous industries flanges uses to enhance the performance and reliability of their piping systems. From traditional applications to cutting-edge projects, flanges find their utility in a wide array of sectors. Let's delve into some of the key industries that extensively flanges uses:

Oil and Gas Industry:

Flanges are indispensable in the oil and gas sector, where they are utilized for connecting pipes and valves in drilling rigs, refineries, and pipelines. The demanding and high-pressure environments in this industry necessitate the use of sturdy and reliable flanges to prevent leaks and ensure safety.

Chemical Industry:

In chemical processing plants, the compatibility of materials is of utmost importance. Flanges are employed to create secure connections that withstand the corrosive nature of various chemicals. From transporting raw materials to processing final products, flanges play a critical role in maintaining the integrity of the system.

Power Generation:

Power plants, whether thermal, nuclear, or renewable, rely on flanges to connect piping systems that transport steam, water, or other fluids. The efficiency and safety of power generation facilities hinge on the proper functioning of flanges, making them a fundamental component in this industry.

Water and Wastewater Treatment:

Flanges find extensive use in water treatment plants for connecting pipes and valves in both potable water distribution systems and wastewater treatment facilities. The robustness of flange connections ensures the reliability of the infrastructure that delivers clean water and manages wastewater.

Aerospace Industry:

Even in the aerospace sector, where precision and reliability are paramount, flanges are utilized. Aircraft engines, fuel systems, and hydraulic systems all incorporate flanges to ensure secure connections that can withstand the demanding conditions of flight.

Shipbuilding and Marine Industry:

Flanges play a crucial role in shipbuilding, providing watertight connections in piping systems on vessels. Whether for cargo ships, cruise liners, or naval vessels, the maritime industry relies on flanges to maintain the structural integrity of the ship's systems.

Construction and Infrastructure:

In construction projects, flanges are used to connect structural components, pipes, and other elements. They find applications in building infrastructure such as bridges, tunnels, and high-rise buildings, contributing to the stability and durability of these structures.

Food and Beverage Industry:

Hygiene is paramount in the food and beverage industry, and flanges help maintain sanitary conditions by providing secure connections in processing and packaging equipment. Stainless steel flanges, in particular, are popular in this industry due to their corrosion resistance.

Diverse Flange Types for Varied Applications:

At Bullion Pipes & Tubes LLP, we offer a wide range of flange types to meet the specific requirements of different industries:

Weld Neck Flanges:

Ideal for high-pressure applications, providing a strong and durable connection.

Threaded Flanges:

Convenient for low-pressure applications, offering ease of installation and maintenance.

Slip-on Flanges:

Easy to align and weld, suitable for applications with lower pressure and temperature demands.

Lap Joint Flanges:

Used in systems where frequent dismantling is required, providing flexibility in maintenance.

Socket Weld Flanges:

Well-suited for small-diameter pipes and high-pressure applications.

Ring Type Joint Flanges:

Commonly used in high-pressure and high-temperature applications, ensuring a tight seal.

Blind Pipe Flanges:

Used to close the end of pipes, preventing the flow of fluids and gases.

Advantages of Using Flanges

Flanges offer several advantages that make them indispensable in various industries:

Improved Structural Integrity:

Flanges enhance the stability and durability of structures, especially in high-pressure environments.

Ease of Maintenance and Repairs:

The modular nature of flanges makes maintenance and repairs more accessible, minimizing downtime.

Cost-Effectiveness:

Over the long term, the use of flanges proves cost-effective, contributing to the overall efficiency of industrial operations.

Challenges and Considerations - Flanges

Despite their benefits, it's crucial to be aware of potential challenges:

Maintenance Practices:

Regular inspection and maintenance are essential to prevent issues related to wear and tear.

Proper Selection:

Choosing the right type of flange for specific applications is critical to ensure optimal performance.

Final Words!

Industry dynamics continue to demand reliable and flanges uses. Bullion Pipes & Tubes LLP takes center stage as a leading flanges Manufacturer and Supplier, offering a comprehensive range that caters to diverse needs across various global regions. Our flanges find applications in numerous countries, including India, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Italy, Romania, Chile, Australia, Brazil, Russia, Uganda, Algeria, Egypt, and Tanzania, showcasing their widespread utility and adaptability.

0 notes

Text

Loose Flanges Stockists in India

ASME B16.5 Free Flanges types to fit elbows, valves and on a very basic level such a pipeline part being utilized. Carbon Steel Free Flanges is a contraption that is welded onto the completing of a hint of line to make half of a flanged coupling. Containing level steel passing on with astonish openings around the edge and an opening in the center the size of the line that is should have been welded onto solidified steel free Flanges, the part can be made of carbon steel or Stainless Steel to meet the proposed application.

ASME B16.5 Free Flanges manufacturers in India. We are dispatching SS Free Flanges, Free Exhaust Flanges, EN 1092-2 PN16 Free plate flanges and Free Plate flanges at bound costs mulling over reasonable master hours in India and crucial wellspring of first in class ASME B16.47 Series a Free Flanges, most ideal situation, cost open in Mumbai, India.

Nutech Overseas We have worked with store of Noise 2642 Free Flanges, PN10 Free Flanges, EN1092-1 Free Flanges and jis 10k Free Flanges, Best case scenario, worth once-over in India. Stainless Steel Free Flanges affirmed by Saudi Aramco. We keep up beast ably of MSS SP-44 SS Free Line Flange.Nutech Overseas is scientist and transporter of Duplex Steel Free hubbed Flanges, Noise 86029 PN10 Free hubbed Flanges in various sizes.

Loose Flanges Manufacturers, Loose Flanges Suppliers, Loose Flanges Stockists, Loose Flanges Exporters

Stacking huge level of ASTM A350 Gr LF2 Free Flanges to buy, most ideal situation, cost in India, enquire our expense of Carbon Steel Free Flanges including Level Face Free flanges, AWWA C207 Free steel flanges and ASME B16.5 Class 300 Free Flanges. Free Line Flanges to Thailand, Russia, Kuwait, France, Australia, Malaysia, USA, Iran, Italy, Sweden, Egypt, Bahrain, Turkey, UAE, Germany, Qatar, Singapore, Indonesia, UK, Israel, Oman,Canada, Sri Lanka and Saudi Arabia.

We are most conspicuous giving relationship of ASTM A105 Free flanges, most ideal situation, cost as we are one of the most surprising supplier and carrier of Nutech Overseas steel Free Flanges in India. We have our stocking wholesalers in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our ASTM B381 F5 Free Flanges cost going prior to buying Produced Free Water powered Flanges from India or China. other than mail for our live deftly of Hastelloy Free Sae Flanges to check types and sizes with our set up stock we can give you best expense of EN 1092-1 Sort 02 Carbon Steel Free Flanges.

We can also give free occasion of ASME B16.5 Free Flange,Nutech Overseas is having our Vendor and Merchant in Aurangabad, Kolkata, Faridabad, Ludhiana, Chennai (Madras), Chhattisgarh, Vadodara, Tamil Nadu, Pune, Ahmedabad, Maharashtra, Nagpur,Bangalore, Punjab, Rajkot, Delhi, West-Bengal, Khopoli, Raipur, Indore, Haryana, Gujarat, Uttar Pradesh, Jaipur, Rajasthan, Karnataka, Ghaziabad, Gurgaon, Kolhapur, Bhosari, Madhya Pradesh, Karnataka. So in case you are looking for best expense of BS 4504 PN10 Split free or ASME B16.47 Series b Free Flanges, Stainless Steel Free Flanges near you with briefest time improvement or free occasion of ANSI b16 5 Free Flanges.

0 notes

Text

High-Quality Flange Manufacturer India - Metalica Forging Inc

Metalica Forging Inc. is a leading Flanges Manufacturers in India. We make Industrial Pipe, Flanges that are widely used to connect pipes to other plumbing systems, including tees, elbows, reducers, valves, and other piping components.

We are the largest Flange Supplier In India. We provide various flanges, including socket weld, slip-on, threaded, and blind flanges. The ANSI B16.5 Carbon Steel Blind Flange and the ANSI B16.48 Carbon Steel Long Weld Neck Flange are designed and manufactured by the International Quality Standards (IQS). We also provide customized flanges based on the customer's requirements.

We are the top Flange Manufacturer in India. Our clients from all over the world, spanning five continents and approximately 80 countries, have a strong need for our services. Our BS 4504 Carbon Steel Forged Flanges are well-known around the world for their durability and quality.

Also offering them our products and services.as being a Flange Manufacturer also leading in several areas of India. ASTM A105 Flange suppliers in India are constantly enhancing their market offerings.

We Lead flanges in several Indian cities.

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Ahmedabad

Flange Manufacturer In Surat

Flange Manufacturer In Bhavnagar

For More Detail

Website: metalicaforginginc.com

0 notes

Text

Understanding Flanges: Essential Components in Piping Systems

Pipingprojects.us is a well-known Flanges Manufacturer in USA. We manufacture and supply a wide variety of flanges, including lap joint, weld neck, orifice, slip-on, and more. We use a variety of materials to produce high-quality flanges. Common alloy steel flange materials include chromium, molybdenum, and nickel. Chrome Moly flanges are well-known for their superior corrosion and oxidation resistance. We are one of the leading flange supplier in USA.

What Are Flanges?

A flange is a protruding rim, edge, or collar used to connect two sections of piping, allowing for easy assembly, disassembly, and maintenance of the piping system. They are typically round and feature bolt holes around the perimeter, enabling secure connections. Flanges can also join piping to other equipment, such as pumps and valves, making them versatile components in any piping infrastructure.

Types of Flanges

Flanges come in various designs, each suited to specific applications. The most common types include:

Weld Neck Flange: Known for its long tapered hub, this flange is ideal for high-pressure applications. It is welded to the pipe, ensuring a strong connection that can withstand extreme conditions.

Slip-On Flange: As the name suggests, this flange slips over the pipe and is then welded in place. It is easier to install than weld neck flanges but is typically used for lower pressure applications.

Blind Flange: This flange is used to close off the end of a piping system or a pressure vessel opening. It can be easily removed, making it ideal for maintenance and inspection.

Socket Weld Flange: Designed for smaller pipes, this flange has a socket in which the pipe is inserted and then welded around the outside. It is often used in high-pressure, small-diameter piping systems.

Threaded Flange: This flange has internal threads that match the external threads of the pipe. It is typically used in low-pressure applications and systems where welding is not possible or practical.

Lap Joint Flange: Used with a stub end, this flange is not welded or fixed to the pipe, making it easy to assemble and disassemble. It is often used in systems that require frequent maintenance.

We are Flanges Supplier In:

Flanges Supplier in Texas

Flanges Supplier in California

Flanges Supplier in Florida

Flanges Supplier in New York

Flanges Supplier in Los Angeles

Materials of Construction

Flanges are made from a variety of materials, each chosen based on the requirements of the application. Common materials include:

Carbon Steel: Widely used due to its strength and affordability, carbon steel flanges are suitable for high-temperature and high-pressure applications.

Stainless Steel: Known for its corrosion resistance, stainless steel is ideal for applications involving corrosive environments, such as chemical processing and offshore oil and gas.

Alloy Steel: These flanges are used in high-temperature environments, such as in power plants and refineries, due to their enhanced mechanical properties.

Plastic: In situations where weight and corrosion are concerns, plastic flanges offer a lightweight and corrosion-resistant option, commonly used in water treatment and chemical handling.

Applications of Flanges

Flanges are ubiquitous in industries that rely on extensive piping systems. Their applications include:

Oil and Gas: Used extensively in pipelines, refineries, and offshore platforms to connect pipes, valves, and equipment.

Chemical Processing: Essential for handling corrosive substances and ensuring leak-proof connections in chemical plants.

Power Generation: Used in boilers, turbines, and cooling systems to maintain the integrity of high-temperature and high-pressure piping.

Water Treatment: Flanges connect pipes and equipment in water filtration and distribution systems, ensuring reliable and easy-to-maintain connections.

Flanges Manufacturer In USA

We are the top flange manufacturer. These flanges can be made by forging or casting. These components, available from reputable stainless steel flange manufacturers, are used to reinforce or connect beams and columns. When installing stainless steel pipe flanges, a certain flange type is required to provide a precise and secure fit and seamless integration into the piping system.

#Flanges Manufacturer in USA#Flanges Supplier in USA#Flanges Manufacturer#Flanges Supplier in Texas#Flanges Supplier in California#Flanges Supplier in Florida

0 notes

Text

“Vendemos productos, entregamos confianza”

0 notes

Text

What Flanges are used in the Oil and Gas Industry?

Flanges play a pivotal role in numerous commercial sectors, and one enterprise where their significance cannot be overstated is the oil and gas region. These critical additives serve multiple purposes, ensuring the safe and efficient operation of pipelines, valves, and other critical gadgets. In this blog, we will delve into the sorts and uses of flanges in the oil and fuel enterprise, highlighting their significance in retaining the integrity of the infrastructure.

Flanges uses in the oil and gas industry:

Weld Neck Flanges:

These flanges are recognized for their high structural energy and resistance to deformation under stress.

Commonly used at factors where high pressure is expected, inclusive of high-strain packages inside the oil and gasoline region.

Slip-On Flanges:

Easy to install and price-powerful, slip-on flanges are broadly utilized in low-pressure and non-critical applications.

Commonly discovered in structures where common maintenance and inspection are required.

Blind Flanges:

Used to shut the ends of pipes, valves, or pressure vessel openings.

It is essential for isolating sections of a pipeline throughout renovation or maintenance.

Socket Weld Flanges:

Suitable for smaller diameter pipes and excessive-strain programs.

The smooth bore and counter-bore offer wonderful glide traits.

Threaded Flanges:

Ideal for low-pressure applications where welding isn't feasible.

Commonly used in small diameter piping structures.

Lap Joint Flanges:

It is designed to be used in structures that require common dismantling for inspection and cleansing.

Useful in corrosive environments.

Flanges in Critical Applications:

In the oil and gas industry, flanges serve essential functions in ensuring the protection, reliability, and efficiency of the infrastructure. Some key applications include:

Pipeline Connections:

Flanges are used to attach exceptional sections of pipelines, taking into account clean installation, preservation, and upkeep.

Valve Connections:

Flanges play an important role in connecting valves to the pipeline, facilitating control and the law of fluid glide.

Pressure Vessels:

Flanges are fundamental in connecting strain vessels, ensuring the structural integrity and protection of the vessels under high pressure.

Pump Connections:

Flanges are used to attach pumps to the pipeline, allowing for the green switch of fluids.

Global Flanges Manufacturers and Flanges Suppliers:

In the oil and fuel industry, reliability and precision are non-negotiable. It is crucial to associate with legit flange producers and flanges suppliers who adhere to international requirements. Aside from BU-LOK, different globally identified producers, including Weldbend, Texas Flange, and Coastal Flange, provide a wide range of flanges designed to fulfill the unique wishes of the oil and gas sector.

Future Trends in Flange Technology:

As generation keeps increasing, so does the innovation in flange design and production. The industry is witnessing the development of smart flanges with sensors to reveal factors like temperature, stress, and corrosion in real time. This proactive method of upkeep and monitoring can appreciably improve the performance and protection of oil and gasoline operations.

Conclusion:

In the end, the oil and fuel enterprise relies closely on quite a few flanges to maintain the integrity and functionality of its infrastructure. From weld neck flanges for excessive-strain packages to slip-on flanges for clean setup, each kind serves a particular purpose in making sure the clean operation of pipelines, valves, and different crucial gadgets.

When it comes to acquiring super flanges, deciding on a reliable Flanges manufacturer and flanges supplier is critical. One such enterprise chief is BU-LOK, specializing no longer only in flanges but also in Tube Clamps and Dairy Pharma Fittings. With an understanding of Hydraulic Pipe Tube Clamps, Heavy Duty Tube Clamps, and Light Duty Tube Clamps, BU-LOK is dedicated to presenting pinnacle products and sharing their extensive knowledge of the subject. Whether you are in need of reliable flanges or professional recommendations on Tube Clamps, BU-LOK sticks out as a depended-on accomplice within the oil and fuel industry.

0 notes

Text

Flanges Manufacturer: Connecting Pipes with Precision and Strength

When you turn on your tap to get water or drive your car, you may not think about the numerous components working together to make these everyday tasks possible. One crucial element involved in ensuring the seamless functioning of various industrial applications and systems is the humble flange. Flanges are essential components that connect pipes and equipment, providing a secure and leak-proof joint. In this article, we will explore the world of flanges, their manufacturing process, and their significance in a wide range of industries.

What are Flanges?

Flanges are flat, circular discs with holes in the center, designed to connect pipes, valves, pumps, and other equipment together. They act as connectors, joining different parts of a piping system, creating a strong, sealed joint. The flange's circular shape allows for even distribution of pressure, preventing leakage and ensuring the safety and efficiency of industrial processes.

Types of Flanges:

Flanges come in various shapes and sizes to suit different applications. Some common types of flanges include:

Slip-On Flanges: These flanges slide over the pipe end and are then welded in place. They are easy to install and widely used in low-pressure systems.

Weld Neck Flanges: These flanges have a long tapered neck that provides excellent support to the pipe. They are ideal for high-pressure applications.

Blind Flanges: Blind flanges are solid plates used to close the end of a pipe or vessel, making them perfect for inspection and maintenance purposes.

Socket Weld Flanges: These flanges are designed for small-sized high-pressure pipes and are attached using socket welds.

Lap Joint Flanges: Lap joint flanges are used in conjunction with a stub end, allowing easy alignment of bolt holes in the joint.

Flanges Manufacturing Process:

Flanges are manufactured through a series of steps to ensure their precision and durability:

Material Selection: Flanges are commonly made from materials like carbon steel, stainless steel, and alloy steel, depending on the application's requirements.

Cutting: The selected material is cut into circular discs of the desired size.

Forming: The disc is then heated and shaped using pressing or rolling techniques.

Boring: The center hole and bolt holes are drilled into the formed disc.

Machining: The flange is subjected to machining processes to achieve smooth surfaces and precise dimensions.

Quality Control: Each flange undergoes rigorous testing to check for defects and ensure adherence to industry standards.

Applications of Flanges:

Flanges play a crucial role in various industries, including:

Oil and Gas: Flanges are widely used in oil and gas pipelines, connecting sections of the network and facilitating the transportation of resources.

Petrochemicals: Flanges are essential in petrochemical plants, where they connect different equipment to create a seamless process flow.

Water and Sewage: Flanges are used in water treatment plants and sewage systems, ensuring a reliable and leak-free supply.

Construction: Flanges are employed in construction projects, such as bridges and skyscrapers, where they connect structural elements with precision.

Shipbuilding: Flanges are utilized in shipbuilding, connecting pipes and equipment aboard vessels.

Frequently Asked Questions (FAQs):

What are flanges made of?

Flanges are commonly made of materials like carbon steel, stainless steel, and alloy steel.

How do flanges work?

Flanges connect pipes and equipment, creating a secure, leak-proof joint that allows the smooth flow of fluids or gases.

Can flanges be reused?

Yes, flanges can be reused if they are in good condition and meet safety standards.

What types of flanges are there?

Some common types of flanges include slip-on flanges, weld neck flanges, blind flanges, socket weld flanges, and lap joint flanges.

How are flanges manufactured?

Flanges are manufactured through a process involving material selection, cutting, forming, boring, machining, and quality control.

Are flanges only used in industrial applications?

No, flanges are also used in everyday applications like plumbing and automotive systems.

Can flanges handle high-pressure systems?

Yes, certain types of flanges, like weld neck flanges, are designed for high-pressure applications.

What is the purpose of a blind flange?

A blind flange is used to close the end of a pipe or vessel, allowing for inspection and maintenance.

How are flanges installed?

Flanges are either slipped onto the pipe end and then welded or bolted in place, depending on the type of flange.

Are flanges the same as gaskets?

No, flanges and gaskets are different components. Flanges connect pipes, while gaskets are used between flanges to create a seal.

Can flanges prevent leaks?

Yes, flanges create a tight joint that prevents leaks in the piping system.

Can flanges be custom-made?

Yes, manufacturers can create flanges in custom sizes and materials to meet specific requirements.

Are there standards for flange manufacturing?

Yes, various organizations set standards for flange manufacturing to ensure quality and safety.

Can flanges withstand extreme temperatures?

Yes, some flange materials are designed to withstand high and low temperatures.

Are flanges suitable for corrosive environments?

Yes, certain materials like stainless steel and alloy steel are resistant to corrosion and are used in such environments.

Are flanges used in renewable energy systems?

Yes, flanges are used in renewable energy systems, such as wind turbines and solar power plants.

Can flanges be painted or coated?

Yes, flanges can be painted or coated to protect them from corrosion or enhance their appearance.

Can flanges be used for both liquids and gases?

Yes, flanges are versatile and can be used to handle both liquids and gases.

Do flanges come with warranties?

Warranties on flanges may vary depending on the manufacturer and specific application.

Can flanges be recycled?

Yes, most flange materials are recyclable, contributing to sustainability efforts.

How often should flanges be inspected?

Flanges should be regularly inspected as part of a maintenance routine to identify any potential issues.

Are flanges suitable for underground piping?

Yes, flanges are used in underground piping systems to connect pipes securely.

Can I install flanges myself?

While some flanges are easy to install, it is recommended to have a professional perform the installation to ensure proper alignment and tightness.

Can flanges be used in hazardous environments?

Yes, flanges can be used in hazardous environments with the appropriate material selection and safety measures.

Do flanges require regular maintenance?

Flanges require regular maintenance to ensure their proper functioning and prevent leaks.

Conclusion:

Flanges may seem like small components, but they are vital in various industries, providing the connections that keep our world running smoothly. From oil and gas pipelines to water supply systems, flanges play an essential role in ensuring the safety and efficiency of industrial processes. Their versatility and durability make them indispensable in a wide range of applications, making the world a better-connected place.

0 notes