#Foam Tape for Construction Projects

Explore tagged Tumblr posts

Text

youtube

"Discover the Strength of 25 mil, 47 mil & 0.016 Acrylic Foam Tapes for Your Projects"

Looking for durable, high-performance adhesive tapes? Whether you need 25 mil gray AFTC acrylic foam tape, 47 mil for heavy-duty bonding, or 0.016 acrylic foam tape for lighter applications, we've got you covered. These tapes provide excellent adhesion, flexibility, and weather resistance, perfect for automotive, construction, and electronics use.

Learn more about our options:

0.016 Gray Acrylic Foam Tape

0.025 Gray Acrylic Foam Tape

#Adhesive Tapes for Automotive Applications#Acrylic Foam Tape Uses#High-Strength Double Sided Tapes#Heavy Duty Bonding Solutions#Weather-Resistant Adhesive Tape#Foam Tape for Construction Projects#Durable Foam Tape for Electronics#Bonding and Sealing with Acrylic Foam Tape#Best Acrylic Foam Tape for Outdoor Use#Foam Tape for Industrial Applications#Youtube

0 notes

Text

reveal of my gordon hlvrai costume project, now that about half of it is done! this is cardstock and glue and tape and more glue and paint and velcro. and 2 gloves (one hand-sewn)

i got started sometime in early-mid fall, but i committed to making it work with cardstock in january- it was originally meant to be a sizing test before construction with eva foam over the summer. then i realized how expensive thatd be, too much pressure for a form of craft ive never practiced. im pretty amazed with how its come together, even with the large seams! during that whole time when it was unpainted (started painting two weeks ago) there was no way to tell

#thank you sketchfab thank you blender thank you pepakura#school library printer… you were necessary but i dont appreciate that i had to pay per page despite my tuition#i started this because theres a tradition of wearing whatever you want to graduation at my college. ive thought abt how cool itd be to wear#an hev suit like gordon hlvrai.. hlvrai has been important throughout my whole time at college. that plus the stem degree im going for makes#hlvrai the most fitting thing to homage with my outfit#*so important to me#the support of my friends was the last push i needed before research#i havent seen anyone else go for the in-game low poly look for the hev suit! multiple tutorials out there (as expected)#but all i saw involve eva foam and molding. most of them were based on the half life 2 suit which. yeah. that one seems more desirable for#cosplay#lucky that this way was much more simple because its also the most in-theme!#hlvrai#half life vr but the ai is self aware

2K notes

·

View notes

Text

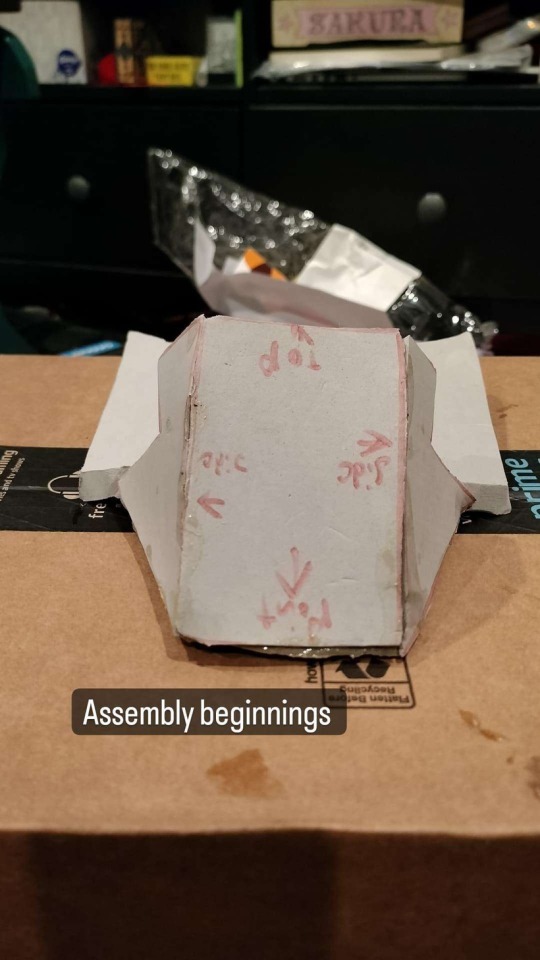

Recently I built a model of Metal Gear mk II, the robot sidekick from Snatcher. I used cardboard and duct tape, partially out of nostalgia for the materials I used to use but mostly since I was on a pretty short timeline since I wanted a visual aid for a panel I was presenting at an anime convention. It was fun to put Metal together!

I used a cheap handheld mirror from the hardware store for his neck, so it can extend and rotate just like in the game.

The compartment opens up, too.

I made a couple of the paper inventory items from the game (trawled a couple thrift stores but couldn't find a chess queen to toss in). Would be fun to try and get more things, like making Gillian's JUNKER identification card!

Metal Gear's size is a little odd... the Japanese PC manual puts him at around three feet tall with his neck contracted, though in all the ingame art across the versions he's depicted as closer to half that (approximately knee-high to Gillian) so I adapted that size for my model.

It would be great fun to make a more accurate model someday, even just out of foam, but it would be pretty difficult! Metal is made up of a lot of smooth, organic curves that are very difficult to model (you can see that I definitely made him more rectangular). The asymmetry of the screen/chest upper body make weight distribution very tricky on his two legs - even anchoring feet to a base platform and adding supports, he feels very wobbly (to say nothing of how un/loading the storage would affect that)! Finally, because the character only exists as drawings and was never actually modeled or sculpted, the details of his construction are really inconsistent! Perhaps it's no surprise that Metal Gear Mark 2 from MGS4 seems more popular for people to recreate...

Anyways! Metal went over well at the con and I like having this little guy hanging around my work area. A fun little project.

youtube

7 notes

·

View notes

Text

How I Made my V2 Cosplay

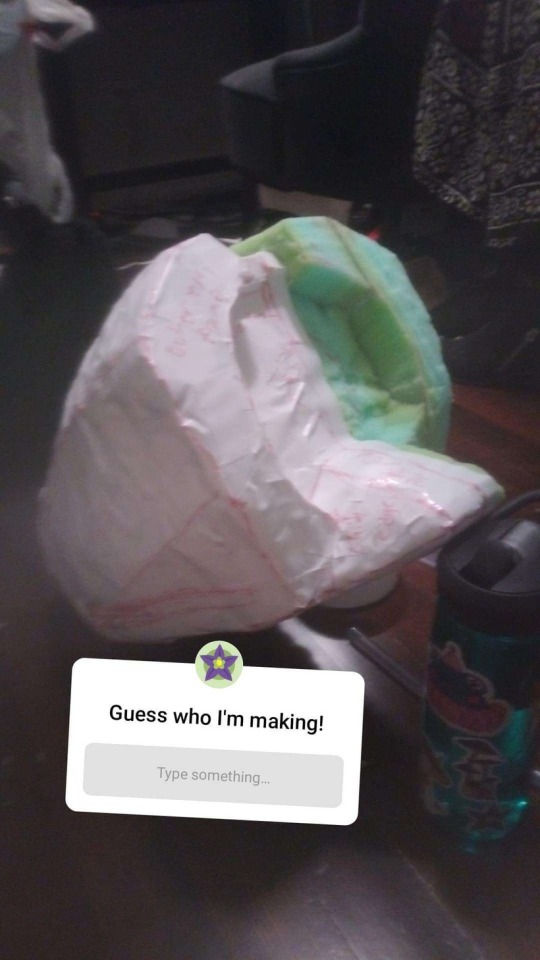

Oh boy! This right here is about how I make my cosplay head of V2. Some of the stages don't have photos, but i'll do my best to explain what I did. I also have no WIPs of the gloves, but those were super straight forward. Some photos are very low quality due to my phone having a damaged camera at the time, and other photos were taken from my instagram story as they're the only photos I have from that stage. Please note that this is not a tutorial! This is more of a story of a disastrous (but ultimately successful) project done by someone with no idea what they were doing. Please find actual tutorials by more experienced people!

The Modeling Base

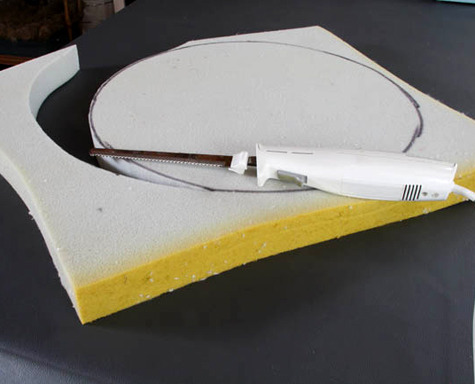

This right hear is a big chunk of upholstery foam! I own a ton of this stuff, so i decided the best way to start this was a foam blank. Well, this was a bad idea in retrospect, but hey it technically worked. Kinda. I started by drawing the basic shape, then cutting out thick sheets. From there, I glued them together and began shaping with scissors to get the desired shape. Honestly a 3D modeled blank may have been better, or a base made of foam board pieces used instead. Live and learn I suppose.

After I got the shape to something i was happy with, I began the transition to EVA foam. To do this, I mummified the thing in duct tape and marked seam lines in sharpie. I then cut out these duct tape pieces, and stuck them to paper to act as a backing.

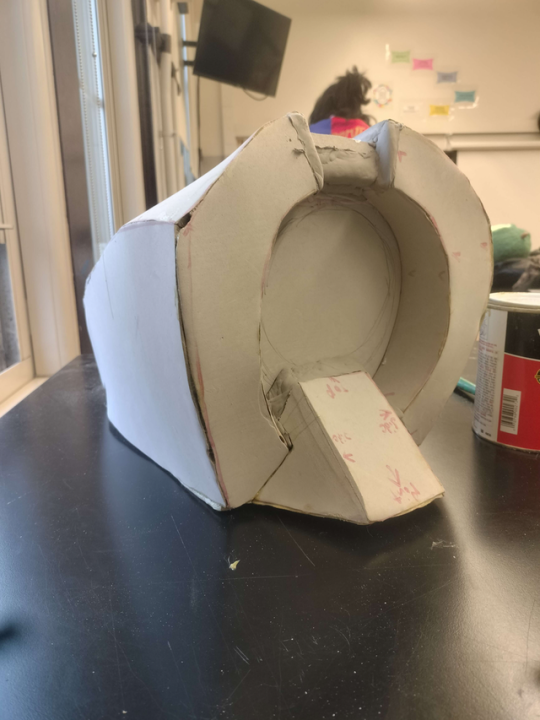

Foam Shell Construction

Once I had a pattern, I began making the actual head. To do this, I traced the pattern onto sheets of EVA foam (I believe 4mm or 6mm) and cut them out. Lots of these pieces needed bevels, some of which i had to dremel as shown below due to them not cutting correctly. Bevels are important as they make the foam crease as desired for angular shapes. I'm still pretty amateur with it though, and frequently got bevels wrong.

As I cut pieces, I began gluing them together with an awful gunk called contact cement. This stuff is a special glue that you let dry before sticking the pieces together, and it pretty cool. Unfortunately it's flammable and a carcinogen. As stated before, I'm pretty new to armor, so lots of the seams have weird gaps I had to fix farther down the line. After quite awhile, I had the basic shell assembled. However, the shell had numerous gaps and pieces that didn't fit correctly. Enter the foam clay.

Foam clay is a substance similar to model magic, and was honestly a life saver here. This thing has a second shell basically made of the stuff. I had to fill gaps primarily around the eye socket, but the entire thing honestly barely fit together.

After some filling and sanding, I made a test optic. And the head looked preeeety bad. There was something just incredibly off about it. This began the massive amounts of revising and reshaping I had to do. And fixing of awful symmetry. The head required a massive amount of sanding around the sides of the face and the chin. Between initial construction and when I began painting, I completely reshaped these areas. I made the chin significantly smaller, and added the indents or whatever (fins?) on the side of the head. However, doing all of this required me to fill in chunks of the interior with large wads of foam clay. If I hadn't done so, then I would've sanded through it in places. I also made the awful decision to gap fill with hot glue. If you've not dremeled hot glue, I don't recommend trying it. It melts the glue and sends globs of it flying, and those things are hot and really hurt.

After even more sanding, gap filling, and re-sanding, I finally got the shape to something i was happy with. Unfortunately I don't have any photos from just before painting.

Priming and Painting

The next step was for me to slather this thing in primer so it could be painted. I use Plastidip, as a tutorial i saw years ago said it was the best primer. Why does it need primed? I'm not actually entirely sure, but it's what I've heard needs done, so that's what I do.

Plastidip is a spray, so I of course did this outside. After a ton of coats, I was left with a shiny surface ready for the paint. Not much to say on primer.

Due to not currently having a functional airbrush, V2 is entirely hand painted. I coated this guy in red paint, and i mean coated the entire thing. Even areas I'd later paint black. Quick tip: Don't do that. It's a waste of paint. But i did it anyway cause I'm a dumbass. I also had issues when doing the black with getting it to stick, and when removing tape it caused some paint to peal off too. I originally had painted a barcode on the side of the head, but removing the tape took the black paint off too. Sooooo no bar code.

Once I got the shell painted, I did the optic. The test optic I used was marker on unicorn buckram, but that stuff is really hard to see through, the markers looked bad, and I couldn't pain it without clogging the mesh (due to not having an airbrush and having to do it by hand.) So, I got different mesh: a larger weave black mesh. This stuff I was actually able to hand paint, thus how I got the iris I did.

The Gloves

The gloves were, frankly, rushed. I bought a pair of cheap black costume gloves online, and then glued foam to em. For the gloves, I just used paper patterns to make the foam pieces. No fancy patterning here, just drawing shapes. After cutting the foam, I hot glued it, and then painted them. No priming on these, cause I was lazy and had a con coming up.

Conclusion

So that's about it! Thank you for reading this monster of a post! I'm hoping to eventually do a V1 head, so I'll be repatterning the V unit head soon. When I do, I'll probably make an actual tutorial. I dunno. We'll see.

54 notes

·

View notes

Text

Happy Critmas 2024 Everyone!

I guess is it really Critmas, if there's no game...eh, the first Critmas was imaginary (that was sort of the point, I started this in 2020 BECAUSE I missed playing with my friends, so I started making game supplies for my dolls so they could play). Usually I set this post to air the day of my Critmas game, but since it's not happening I picked a date; and I noticed that over the last 3 years (since '20 was a daily advent) the day had been going down by one, I figured today would be the perfect date. (Maybe next year it will be the 16th lol)

ANYWHOS y'all're here for the printables, not my rambling right? well good news! I have far more printables than I thought I would, so everybody wins! (I actually thought I had maybe 3 things, so I was ready to skip Critmas all together this year actually

D&D Stuff:

AD&D Pink Box Starter Set (this is based upon the box set that I inherited from my late grandmother's house, and belonged to my father and/or uncle back in the day)

Dragonlance Set

Lego One-Shot Adventure

Critical Role Sheet #10

Critical Role Sheet #11

Critical Role Sheet #12

Critical Role Folder Set #1

Critical Role Folder Set #2

Other Stuff:

Barbie Holiday Sheet

Xmen TAS VHS Tapes (USA)

Xmen TAS VHS Tapes (UK)

Nickmas VHS Tapes

Fazbear Frights Book Series (these are Mini Brands Books compatible)

Fazbear Frights Books Pages

And now, the biggest project I came up with year, and am most proud of the execution of; 1:6 scaled boxes of TCG Cards. That's right, your dolls can collect TCG boxes and do pack openings now. (I mean, mine have a game and hobby store, of course they'd need boxes of cards). Each box type has a sealed version, an opened version, and packs to go in said open box. Sealed box is fairly simple, just construct a box. Opened, you construct a box without a top and put the top flap (that is separate) in as well as make an insert by wrapping the cover with several pack pictures on it, onto an insert of foam board or stacked paperboard (template included) so the box will look filled. But there's also loose backs, that are made by folding the pack in half over a tiny rectangle (to be the cards inside) and then you can fill your open box with the loose packs too. The are fun, they are tiny (and very easy to loose ^^; ) I also laminate all parts with packing tape before cutting to five the shiny box look, but that's up to you. Each sheet has 2 boxes on them for maximized variety.

Set 1 (Pokemon)

Set 2 (Pokemon)

Set 3 (YGO)

Set 4 (YGO)

Set 5 (KH and HP)

Set 6 (MTG)

And as always links to the collected folders of my previous printables, if you don't feel like checking out my #printables and #papercraft tags

RPG Printables

Critical Role Printables

Comic Book Printables

As always, stay safe out there folks. Stay safe, stay warm, and have fun crafting nerd supplies for your doll friends. Have a Happy Holidays.

#happy holidays#free printables#printables#printable#paper craft#papercraft#free stuff#barbie#dolls#dnd stuff#pathfinderstuff#dungeon dice dolls

4 notes

·

View notes

Text

In the last week I've made cosplay progress by:

Taping together and fully cutting out the coat sewing pattern

Received the package with the coat's fabric and given it a pre-wash

Ordered some EVA foam to make the prop gun (arriving this upcoming weeks)

Ordered a base wig and extra wefts to style (should arrive by the end of March depending on how the shipping goes)

In the next week I'm hoping to iron the fabric (possibly this evening), cut out the coat pattern pieces, take a swatch to the fabric store to pick up some matching thread, and start on constructing the coat.

I also need to keep in mind that I can't just leave all the foam work until the end of the project, because I can only do the gluing outside in the sunshine which effectively will limit me to weekends just considering the work commute times

Also technically the wings are not fully fully finished since I need to glue on the last of the feathers, swap out all the regular nuts for nylon-insert locknuts, and just finalise how the electronic parts will be tied down inside the thing, but none of those steps area really depending on getting other steps done, so I'll only really do that if I don't have anything else to progress on that day

4 notes

·

View notes

Text

DIY Salvaged Spool Ottoman

Project by Shelly:

i know ottomans aren’t the most indispensable piece of furniture in the house, but is it criminal to say they bring me the most joy? i think upholstery maven shelly (aka ModHomeEcTeacher) would agree with me; she’s made a whole collection of smart looking ottomans using a range of found fabrics and materials. i am so excited to follow her instructions and craft an adorable plaid ottoman of my very own, just in time to welcome fall. click here to see more of shelly’s amazing work, including her tutorials on everything from upholstering with rugs to aligning atomic legs. thanks, shelly! –kate

When Lowes stopped selling the pre-cut wood circles I used to construct my ottoman frames, it was a dark day. I soon discovered that cutting perfect circles with a hand-held jigsaw wasn’t easy, or even really possible. Weeks later, while roaming the store searching for an alternative, I discovered the empty electrical spools that are routinely discarded. Two perfectly cut round pieces of 5/8” plywood with a removable cardboard cylinder in the middle? Now we’re talking. With a tiny bit of carpentry, I came up with a way to easily re-work these into frames for my upholstered ottomans. I would label this as a mid-level DIY project that you could complete in a weekend. Once you get the hang of it, you these would make fantastic handmade gifts for friends and family. –Shelly

Materials:

-1 20” diameter empty electrical wire spool (hardware stores usually throw these out, so ask about picking them up instead) -8 pre cut 1”x 2”x 6” pieces of wood (a hardware store will cut these for you) -Wood glue -32 1 ¾” screws -A piece of foam (anywhere from 3” to 6” thick and at least ½” larger all around than the wood) -Spray adhesive (Elmers makes a spray adhesive available at the craft store) -Scrap fabric ( this to attach around the ottoman frame measuring about 8” x 65”. An option would be to use a bendable piece of cardboard) -1 ½ yard of cotton or dacron batting -1 ½ yard of 54” wide fabric -¾” yard of scrap fabric to cover the bottom of the finished ottoman -Thread and straight pins -Staples -4 screw on leg plates (hardware store) -4 fabulous ottoman legs (look around for good legs on cruddy, inexpensive Goodwill furniture)

Tools:

-Big marker -Drill -3/32” drill bit and a 3/8” drill bit -Electric knife -Electric stapler -Scissors -Measuring tape -Flat head screwdriver -Pliers (crescent or needle nose) -Sewing machine

Instructions:

Making the frame:

1. Take the spool apart and make a pattern by tracing the circle on a large piece of paper, adding ½” all around for the seam allowance. The pattern will be used for cutting out the foam, batting, fabric and a dustcover for the bottom. Lay aside.

2. Glue and screw 6-8 posts evenly around the outside edge of one wooden circle, then add the other piece of wood on top of the posts and attach. Be sure to keep the wood circles aligned.

Padding:

1. Use the staple gun to attach the long piece of cotton muslin around the outside edges of the top and bottom circles. Keep fabric pulled taut. The fabric serves to fill in the open spaces between the support posts. Cut off excess fabric. (Option: use bendable cardboard)

2. Trace the pattern onto the foam and cut the foam using the electric knife. Keep the knife blades perpendicular to the foam to get a crisp, even cut.

3. Use spray adhesive to glue the foam to the top of the ottoman frame.

4. Trace the pattern onto the batting, cut out. Also, cut out a long strip of batting equal to the total height of the ottoman, from the top of the foam to the bottom edge, plus two extra inches.

5. Pin the batting strip to the batting circle, starting 1” from the short end of the strip and ending 1” from the other end. Stitch in place.

6. Remove from under the sewing machine and stitch the open seam closed and go back and complete stitching that section of the band to the batting top.

7. Trim off the excess seam allowance, turn the batting covering right side out and pull it down on top of the ottoman frame.

8. Measure and mark the batting band (all the way around the covering ) so that it will be stapled evenly from the top seam to the bottom EDGE of the frame. Do not attach the batting to the underneath side of the wood. Attach it to the edge and cut off the excess batting.

Sewing and Upholstering:

1. To make the fabric covering, which is a bit like a snug slipcover, trace the pattern onto the fabric and cut it out. You’ll need to cut a band of fabric 3” longer than the height of the ottoman and 5” wider than the circumference. If you need to stitch two pieces together to get a long enough piece for the band, split the circumference measurement in two and add 3 extra inches to each piece.

2. To prepare the fabric covering for stitching, fold one short end of the cut fabric band over 1” with wrong sides together. With the right side of the band to the right side of the fabric circle, patterns matching, pin and begin stitching at the folded short edge all the way around to the other short end. Overlap the excess fabric 2” past the folded short end. Cut off any excess fabric beyond the 2”. Pin and stitch the overlapping fabric to the seam.

3. Turn the fabric covering right side out and topstitch the folded seam closed from the bottom of the band to the top seam.

4. Pull the fabric covering down over the dacron covered ottoman. Adjust the fabric pattern and straighten so the pattern or plaid is aligned.

5. Pull the fabric down firmly and staple in place evenly and snugly.

Upholstery Tip: It works best to start with one section and attach with a few staples, move to the opposite side and do the same. Then repeat for the other sides. Attach the fabric between the set staples by smoothing and easing in the fabric.

Attach Legs:

1. Measure and mark the bottom of the ottoman base for leg attachment. Place the leg plates on the marks to make sure they are equidistant from each other. Mark the center hole of the plates. Use the 3/8”drill bit to drill out the center hole. You can also do this step prior to putting the fabric on (as shown below).

2. Cut out a dustcover from scrap fabric and attach it to the bottom of the ottoman by folding the edge under ½”.

3. Locate the drilled holes, line the leg plates up, screw the leg plates on using a Phillips head screwdriver or the drill. Attach the legs to the plates.

VOILA!

4 notes

·

View notes

Text

Cosplay 2010 - Sakura Con

Oh man! I was going through my computer and found a bunch of old cosplay photos that I thought was lost! Back in my wee cosplay days of 2010 me and my friends did a .Hack//G.U. cosplay group at Sakura Con here in Seattle, WA. So many people brought fabulous costumes and it was a ton of fun! For that shoot I made four costumes: Silabus, Ovan, Haseo (2nd form), and Endrance (I was Endrance). I was so proud of those costumes, though I would not use the same materials or techniques today at all! This was in the early days where I used materials that looked right even if it wouldn't function right, be too hot, too fragile, not structurally sound, etc. As such, ended up making Haseo out of upholstery vinyl. Don't envy them at all 'cus I imagine it was pretty hot and constrictive!

Not posting their faces because I lost contact with these guys years ago and don't believe in posting faces online other than mine without permission, even if it's a cosplay in a public sphere.

Sylabus is first! I made the majority of the costume mainly because my friend didn't have the time to do so between school and other projects (they are/were an amazing artist!!). I was particularly proud of how this one came out looking considering I had only been doing cosplay for around 3-ish years at the time. The lines look great! They did the wig and the sword. We lost contact years ago after graduating high school so I hope they're doing well for themselves (I miss you if you're out there!).

Next is Ovan! I am so proud of not only how the costume looked but that damn arm of his! I spent so long cutting cardboard and foam core and painting.... ug! But it looked incredible! He paid me $300 for the entire costume including materials at the time. Def would not do that again, ever. But again it was in my younger days where I didn't value my time or effort as much... also it's pretty but, you know, don't look at the seams or the construction lol. Not pictured: the glasses. His face was perfect for the costume but since I lost contact with them years ago I don't want to post their face without permission.

Then Haseo, 2nd form. We saw a hack online about using reflective tape to make costume parts glow when flash is used. It worked so well! As said above, this is all vinyl with puff paint and foam, so it was HOT to wear. Bless this guy for being a good sport, especially since it took me something like 2-ish years to actually put it together...

Finally, myself as Endrance. Once again, a whole lot of work for a costume that I would not at all make in the same way. I bought a cording foot for my machine and carefully pieced together a Jet Set material and sewed the cording on.... the cording did not stretch. So I used a stretch material with a non-stretch cord for what is essentially a body suit.... yiiikkkess! Looks great, don't look inside cus it is not remotely clean. But that's what the early days are about! I had fun, they had fun, tried and learned a lot, so it was all worth it! All the all-nighters and, at times, multiple days of not sleeping. Literally can't do that anymore cus I'm not built like I was at 20. :)

2 notes

·

View notes

Text

How To Choose the Best Acrylic Foam Tape For Your Projects?

The best option for bonding strength, durability, and clean aesthetics are acrylic foamtapes. They are proven to be a wise as well as reliable choice across several industries-from automotive assembly to signage installation and home improvements, acrylic double sided tape will replace mechanical fasteners. Vibrations are absorbed while moisture is resisted, and adhesion is maintained long-term with these tapes.

What is Acrylic Foam Tape?

Acrylic foam tape is unlike ordinary tapes; this material is designed for high performance exposure to UV light, high and low temperature extremes, and humidity conditions. Because of its ability to conform with irregular surfaces, it is also ideal for similar-material bonding, including glass, metal, and plastic.

The prime advantage of acrylic double sided tape leaves an absolutely neat and invisible appearance. The tape bonds through or behind the surfaces, making it useful for modern design applications. With such tapes, one enjoys:

High bond strength: both light and heavy applications will benefit from its high bond strength.

Long-lasting effects: does not deteriorate in weather, chemical or age; such properties make this tape applicable outdoors without restrictions.

Absorption of shock and vibration: when movement or impact is expected, this is where this type of tape comes handy.

Flexibility: easily adapts to intricate surfaces and accommodates minor gaps between materials.

Acrylic Foam Tape

Saves time and money: eliminates the cost of drilling, welding, or other types of fastening.

Applications Across Different Industries

Automotive: For the attachment of trims, emblems, mirrors, and paneling without any surface damage.

Electronics: In any device or component where reliable bonding in space-saving applications is a must.

Construction and Architecture: For applications such as glass façades, partitions, and sign installations.

Home and DIY Projects: For all intents and purposes, from hanging picture frames to mounting hooks to fixing small appliances.

How to Choose the Right Tape

When you're looking at an acrylic foam tape, consider the surface materials, the weight of the components being attached, and environmental exposure. Some tapes may be customized to be heat resistant or with added thickness for gap-filling properties. In all cases, however, ensure that a suitable class quality product is chosen to meet your specific needs.

Final Thoughts

If you're looking for a reliable, mess-free, and highly effective bonding solution, acrylic foam tapes and acrylic double sided tapeare well worth considering. Whether you're securing automotive parts or mounting signage, this tape delivers a powerful hold without the hardware.

0 notes

Text

Construction Materials Delivered On Time: Streamlining Your Projects with Supply Ontime

Construction Materials Delivered On Time: Streamlining Your Projects with Supply Ontime

In the dynamic world of construction, timely access to quality construction materials is crucial. Delays can escalate costs and disrupt project timelines. Enter Supply Ontime, your reliable partner in ensuring that your building materials arrive precisely when and where you need them.

Why Choose Supply Ontime for Your Construction Materials?

Supply Ontime specializes in delivering a comprehensive range of construction materials directly to job sites across the Greater Los Angeles area. Whether you're a contractor, builder, or DIY enthusiast, our services are designed to keep your projects on schedule and within budget.

Extensive Product Catalog

Our inventory includes:

Drywall & Accessories: Drywall sheets, DensGlass, cement boards, steel studs, joint compounds, drywall tape, corner beads, screws, and tools.

Insulation: Fiberglass, foam, mineral wool, spray foam, housewrap, radiant barriers, and pipe insulation.

Lumber & Composites: Dimensional lumber, pressure-treated lumber, redwood, cedar, composite decking, moulding, casing, siding, and fascia.

Plywood & OSB: OSB, plywood, MDF, and small format panels.

Mortars & Aggregates: Concrete mix, aggregates, mortar mix, stucco, floor levelers, and tile setting materials.

Masonry: Bricks, blocks, rebar, concrete forms, wire mesh, and pavers.

Roofing & Facade: Roofing shingles, panels, underlayment, flashing, coatings, gutter systems, and James Hardie siding.

Building Hardware: Joist hangers, metal straps, corner braces, post brackets, mending plates, wood connectors, and nail plates.

Fasteners: Various screws (drywall, wood, sheet metal), nails, nuts, bolts, anchors, and fastening tools.

Electrical: Wires, electrical boxes, conduits, fittings, power distribution components, outlets, and switches.

Plumbing: Pipes and fittings (ABS, brass, copper, CPVC, PVC), valves, and plumbing accessories.

Paint Tools & Primers: Primers, caulks, sealants, adhesives, paint rollers, brushes, tapes, and sanding supplies.

Tools: Cutting tools, wrenches, screwdrivers, pliers, hammers, drill bits, shovels, and wheelbarrows.

Landscaping & Gardening: Fencing, landscape rocks, fabric, soil, soil amendments, and wood mulch.

Builders Fuel: Liquid and solid fuels.

Flexible Delivery Options

Same-Day Delivery: Place your order, and we'll deliver within hours.

Scheduled Delivery: Plan ahead and choose a delivery time that aligns with your project timeline.

Our delivery services are designed to be:

Fast: Minimizing downtime on your projects.

Reliable: Ensuring materials arrive in excellent condition.

Convenient: Delivering directly to your job site.

How to Order Supply Ontime

Browse our extensive online catalog.

Select the materials you need.

Choose your preferred delivery option.

Place your order and let us handle the rest!

For bulk orders or special requests, feel free to contact us directly.

0 notes

Text

Foil Tape Insulation: The Ultimate Solution for Sealing and Energy Efficiency.

Foil tape insulation is an essential product in both residential and commercial settings for enhancing thermal performance and ensuring air-tight seals.

Known for its durability and resistance to heat, moisture, and chemicals, foil tape insulation offers an efficient and long-lasting solution for various insulation applications. Whether you’re installing HVAC systems, ductwork, or sealing aluminum foil-faced insulation materials, foil tape is your go-to companion.

Why Choose Foil Tape Insulation?

Foil tape insulation is engineered to deliver unmatched performance in extreme conditions. Its design ensures seamless bonding and protection, making it a versatile choice across multiple applications. Here’s why professionals and DIYers alike prefer it:

Thermal Efficiency: Reflects heat and light, enhancing insulation properties.

Moisture Resistance: Prevents condensation and water ingress.

Strong Adhesion: Adheres to metal, plastic, and insulation surfaces with ease.

Durability: Resistant to weather, UV, and flame, making it ideal for long-term use.

Versatility: Suitable for HVAC, duct sealing, insulation joints, and vapor barrier repairs.

Applications of Foil Tape Insulation

Foil tape insulation can be used in a wide range of environments due to its adaptability and performance:

HVAC Systems: Sealing duct joints and insulation seams.

Construction Projects: Wrapping and sealing foil-faced fiberglass and foam board.

Roof and Wall Insulation: Enhancing the R-value and creating a vapor barrier.

Automotive and Marine Use: Heat shielding and vibration dampening.

DIY Home Repairs: Attic sealing, pipe wrapping, and more.

In situations that require extra support, Hanging Tape can be used in conjunction to provide structural reinforcement and additional stability for suspended insulation materials.

Key Benefits

Improves energy efficiency by reducing heat loss or gain.

Enhances the life of insulation materials by protecting edges and seams.

Creates a clean, professional finish with high-tack adhesion.

Easy to apply and conforms to irregular surfaces.

Frequently Asked Questions (FAQ)

Q: Can foil tape insulation be used outdoors? A: Yes, high-quality foil tape is UV and weather-resistant, making it suitable for outdoor applications.

Q: Is foil tape insulation fire-resistant? A: Most foil tapes are designed to meet flame resistance standards. Always check the product specifications to ensure compliance.

Q: How long does foil tape insulation last? A: When properly applied, it can last for many years without peeling or deteriorating.

Q: Can I use foil tape on plastic surfaces? A: Yes, foil tape adheres well to a variety of surfaces, including plastics, metals, and insulation boards.

Testimonial

"We used foil tape insulation during our attic renovation, and the results were fantastic. It sealed every corner perfectly and added an extra layer of insulation. Combined with hanging tape for support, everything stayed in place—even during summer heatwaves. Highly recommended!" — Emily R., Homeowner, Texas

Conclusion

Foil tape insulation is a cost-effective and highly reliable solution for enhancing thermal insulation and sealing performance. Its strength, durability, and ease of use make it a top choice for professionals and homeowners alike. When paired with hanging tape, it provides complete, secure, and energy-efficient insulation systems.

1 note

·

View note

Text

Spacer Tapes Market: Key Growth Drivers Across Construction, Automotive, Electronics, and Emerging Industrial Applications

Spacer Tapes Market Drivers

The global spacer tapes market is experiencing robust growth, propelled by a confluence of factors across various industries. These tapes, known for their adhesive and cushioning properties, are integral in applications ranging from construction to electronics. Below, we delve into the primary drivers fueling this market expansion.

1. Construction and Green Building Initiatives

Spacer tapes are pivotal in modern construction, especially in the assembly of Insulating Glass Units (IGUs). They enhance thermal insulation, reduce energy loss, and bolster the durability of structures. With the global push towards sustainable construction, the demand for spacer tapes is surging. Green buildings, which aim for energy efficiency and minimal environmental impact, frequently rely on these tapes to meet performance standards. As the construction industry embraces eco-friendly designs and materials, the usage of spacer tapes is expected to grow in tandem.

2. Automotive Industry Evolution

The automotive sector’s transition toward electric vehicles (EVs) and lightweight, high-efficiency designs is significantly boosting the demand for spacer tapes. These tapes provide excellent vibration absorption, noise reduction, and thermal stability, making them ideal for applications such as battery enclosures, dashboards, and structural bonding. As EV adoption increases globally, spacer tapes play a critical role in maintaining safety, comfort, and energy efficiency. Furthermore, stringent regulations around vehicle emissions and safety standards also drive innovation and increased utilization of spacer tapes.

3. Electronics and High-Tech Applications

Spacer tapes are essential in the electronics sector for functions such as cushioning, gap filling, vibration dampening, and thermal insulation. Their use extends to smartphones, tablets, televisions, and various smart devices. These tapes help protect sensitive components while enhancing the durability and performance of electronic gadgets. As technological advancements continue and the demand for miniaturized, lightweight devices grows, the use of high-performance spacer tapes will become even more critical.

4. Sustainability and Eco-Friendly Materials

Rising environmental concerns and increasing regulatory scrutiny are pushing manufacturers toward sustainable practices. In the spacer tapes industry, this has led to the development of eco-friendly adhesives and bio-based materials that reduce environmental impact without sacrificing performance. Companies are also adopting recycling and waste-reduction initiatives, aligning with broader circular economy goals. The shift toward sustainable manufacturing is not only meeting regulatory compliance but also becoming a selling point for environmentally conscious consumers and industries.

5. Emerging Markets and Infrastructure Development

Developing countries, particularly in Asia-Pacific regions such as India and China, are witnessing rapid urbanization and industrial growth. Massive infrastructure projects, along with rising demand for energy-efficient buildings, are fueling the consumption of spacer tapes. Government initiatives focused on affordable housing, smart cities, and renewable energy integration further bolster demand. The increasing use of spacer tapes in both residential and commercial construction highlights their growing relevance in these markets.

6. Technological Advancements and Innovation

Ongoing research and development efforts are leading to spacer tapes with improved thermal resistance, longer lifespan, enhanced adhesion, and weatherproof qualities. Innovations like UV-curable adhesives, advanced foam substrates, and precision die-cutting techniques are enabling manufacturers to produce high-performance products tailored for specialized applications. These advancements not only expand the range of uses but also improve cost-efficiency and environmental impact, giving manufacturers a competitive edge.

7. Integration in Renewable Energy Solutions

The renewable energy industry, particularly the solar power sector, is emerging as a significant user of spacer tapes. In solar panel manufacturing, spacer tapes are used to maintain structural integrity and protect sensitive components during installation and operation. As solar energy becomes a mainstream power source globally, spacer tapes are increasingly employed to improve panel durability and efficiency. This application segment is poised for significant growth due to the accelerating global transition to clean energy.

8. Challenges and Opportunities

Despite the optimistic outlook, the spacer tapes market faces certain challenges, such as limited awareness in some developing regions and intense price competition among suppliers. However, these obstacles also present growth opportunities. Educating end-users, expanding into untapped markets, and leveraging strategic partnerships can help overcome these barriers. Moreover, companies investing in sustainable innovation, automation, and digital marketing are better positioned to differentiate themselves and capture emerging demand.

Conclusion

The spacer tapes market is being driven by a dynamic mix of construction demands, automotive innovations, technological progress, and sustainability initiatives. Industries are increasingly relying on these tapes to enhance product performance, reduce environmental impact, and meet evolving regulatory standards. With continuous innovation and growing awareness, spacer tapes are becoming a vital component across a variety of sectors. As global markets evolve, the demand for high-performance, environmentally responsible spacer tapes is set to grow significantly, offering abundant opportunities for manufacturers, suppliers, and investors.

0 notes

Text

Specialty Tape Market Growth Forecast Highlights Emerging Trends and Key Drivers Shaping Industry Expansion Globally

The specialty tape market is witnessing robust growth globally, fueled by a range of factors from technological advancements to increasing demand across various industries. As companies seek innovative solutions for packaging, automotive, electronics, healthcare, and construction applications, specialty tapes have become indispensable. This article explores the Specialty Tape Market Growth Forecast by highlighting emerging trends and key drivers shaping industry expansion worldwide.

Market Overview

Specialty tapes are adhesive tapes designed to meet specific application requirements beyond conventional tapes. These include double-sided tapes, foam tapes, electrical insulation tapes, high-temperature tapes, and many others tailored for unique uses. The increasing industrialization and growing focus on efficiency and safety are pushing demand for high-performance specialty tapes globally.

Market Drivers

One of the primary market drivers is the rapid growth in end-use industries such as automotive and electronics. Specialty tapes are critical in automotive manufacturing for bonding, insulation, and vibration dampening. With the rise of electric vehicles (EVs), the demand for specialized tapes that can withstand high temperatures and electrical stress is accelerating.

Similarly, the electronics industry requires ultra-thin, heat-resistant tapes for devices like smartphones, laptops, and wearable tech. As consumer electronics continue to evolve, the demand for advanced specialty tapes that offer precision and reliability is increasing.

The packaging sector also plays a vital role in boosting the market. Specialty tapes with moisture resistance, durability, and strong adhesion properties are essential for protecting goods during transit. Growth in e-commerce and logistics has further intensified the need for effective packaging solutions, thereby driving the specialty tape market.

Emerging Trends

Several emerging trends are shaping the specialty tape market's future:

Sustainability Focus: There is a rising emphasis on eco-friendly and biodegradable specialty tapes as companies aim to reduce their environmental impact. Innovations in materials and adhesives that are recyclable and non-toxic are gaining traction.

Smart Tapes: Integration of smart technology into tapes, such as tapes with sensors for monitoring conditions like temperature and pressure, is an exciting development. This trend is especially relevant in healthcare and industrial applications.

Customization and Innovation: Manufacturers are investing in R&D to develop tapes tailored to specific applications with enhanced properties like UV resistance, flame retardance, and conductivity. This customization is expanding the scope of specialty tape applications.

Digital Manufacturing: Adoption of automated and digital manufacturing techniques enables the production of high-quality tapes at scale, ensuring consistency and efficiency.

Market Insights and Dynamics

The market dynamics include both opportunities and challenges. On the opportunity side, emerging economies are investing heavily in infrastructure, automotive, and electronics, which bodes well for specialty tape demand. The rise in renewable energy projects, such as solar panel installations, also requires specialized adhesive tapes, opening new avenues for market growth.

However, challenges such as raw material price volatility and stringent regulatory standards for chemical use can inhibit market expansion. Companies are focusing on overcoming these market restraints by adopting cost-effective manufacturing processes and adhering to environmental regulations.

The market landscape is highly competitive, with key players focusing on strategic partnerships, mergers, and acquisitions to enhance their product portfolios and global presence. Innovation remains a critical factor in gaining a competitive edge.

Market Forecast and Future Outlook

The market forecast indicates a promising CAGR over the next five to seven years, driven by continuous product innovation and expanding application areas. Growth in sectors such as automotive, electronics, healthcare, and packaging will be pivotal.

Looking ahead, the market future trends point towards increased digital integration, sustainability-driven products, and customized solutions. These trends will not only shape the competitive environment but also define the long-term growth trajectory of the specialty tape market.

Conclusion

In summary, the specialty tape market is set for dynamic growth globally, powered by key industry drivers and emerging trends. Technological advancements, sustainability efforts, and expanding end-use industries are creating vast opportunities. Companies that innovate and adapt to evolving market needs will lead the industry’s expansion, tapping into a broad spectrum of applications and geographies.

0 notes

Text

How To Choose The Best PTFE Adhesive Tapes?

For industrial or commercial bonding solutions, there is no better place than Double Sided Polyethylene Foam Tapes and PTFE Adhesive Tapes. They are unique and versatile. All these tapes are individually designed for high-performance adhesion in many different environments and used in various industries like automotive, construction, electronics, and general manufacturing.

What Is Double Sided PE Foam Tapes?

Double Sided Polyethylene Foam Tapes are a soft foam polyethylene double adhesive tape--the polyethylene foam carrier is soft, flexible, and has strong adhesive on both sides. Its structural factor enables it to form a good and permanent bond between any two surfaces thus rendering it especially valuable for bonding uneven or textured surfaces.

PTFE Adhesive Tapes

Key Benefits:

Shock Absorbing: Foam base absorbs vibrations, suitable for automotive appliances and other applications.

Weather Resistant: PE foam tapes are moisture- and UV-resistant so they can be used responsibly in indoor and outdoor applications.

Strong Bonding: The adhesive on both sides makes them stick to surfaces well, without the need for mechanical fasteners.

Clean Application: Will deliver a clean and professional finish without mess and residue.

Common applications include mounting mirrors, nameplates, decorative trims, and panels, as well as bonding glass to metal and plastic surfaces.

What are PTFE Adhesive Tapes?

PTFE Adhesive Tapes (commonly referred to as Teflon® tapes) offer non-stick, heat-resistant, and low-friction properties. These consist of a PTFE-coated fiberglass backing with a silicone adhesive on one side.

Main Features:

Heat Resistance: Capable of withstanding extreme temperature ranges, PTFE tape works from -70 degree Celsius up to +260 degree Celsius.

Non-Stick Surface: This feature makes it suitable for applications where materials have to be released cleanly, such as heat sealing or packaging lines.

Chemical Resistant: Resistant to most chemicals, acids, and solvents, therefore suitable for a harsh environment.

Low Friction: A high low-friction property will reduce wear and tear on surfaces from continuous usage.

They find extensive application in food processing, packaging, aerospace, and electronics industries, where heat and chemical resistance are of high importance.

Selecting the Proper Tape for Your Requirements

Double Sided Polyethylene Foam Tapes and PTFE Adhesive Tapes both have a firm standing in modern applications, whether it is strong adhesion to rough surfaces or not gluing under extremely harsh conditions. You will come to understand the exact requirements of your project-temperature range, surface texture, environmental exposure-which will guide you in the choice of your tape.

With regard to reliable performance in demanding situations, these tapes ensure dependable and efficient bonding solutions.

0 notes

Text

Global Construction Adhesive Tapes Market Analysis: Opportunities & Challenges

Growing Infrastructure and Sustainable Building Practices Propel the Construction Adhesive Tapes Market Forward.

The Construction Adhesive Tapes market size was valued at USD 2.60 billion in 2023 and is expected to reach USD 4.11 billion by 2032 and grow at a CAGR of 5.21% over the forecast period 2024-2032.

The Construction Adhesive Tapes Market is driven by increasing demand in residential, commercial, and industrial construction projects. These tapes provide high bonding strength, durability, and resistance to extreme conditions, making them essential for flooring, roofing, insulation, and structural applications. The surge in urbanization, infrastructure development, and energy-efficient building construction has fueled the demand for advanced adhesive tape solutions.

Key Players in the Construction Adhesive Tapes Market

Nitto Denko Corporation (No.500, EPTSEALER)

Tesa SE (tesa 60412, tesa ACXplus)

Scapa Group Ltd (Scapa 3309, Scapa 2501)

Intertape Polymer Group (IPG ULTRA, ALF)

Berry Global Inc. (Polyken 225, Nashua 557)

Nichiban Co., Ltd. (Nichiban CT405, Nichiban Gaffa)

Sika AG (SikaTack, SikaBond)

Shurtape Technologies (Shurtape VP 410, Shurtape PC 857)

Lohmann (DuploCOLL 911, DuploCOLL 376)

HiCube Coating (HiCube 5000, HiCube 7000)

Future Scope of the Market

The Construction Adhesive Tapes Market is expected to expand due to:

Increasing adoption of high-performance adhesive tapes for sustainable construction.

Growing demand for lightweight and eco-friendly construction materials.

Rising infrastructure development, particularly in emerging economies.

Technological advancements in pressure-sensitive adhesive (PSA) tapes.

Expanding applications in HVAC, electrical insulation, and glazing systems.

Emerging Trends in the Construction Adhesive Tapes Market

The construction industry is shifting toward sustainable and energy-efficient materials, driving the demand for eco-friendly and low-VOC (volatile organic compound) adhesive tapes. Smart tapes with thermal resistance, waterproofing properties, and enhanced flexibility are gaining popularity, especially in modular and prefabricated construction. The growing emphasis on fire-resistant and weatherproof adhesive tapes is also shaping market trends. Additionally, advancements in double-sided and foam-based adhesive tapes are providing stronger bonding solutions for glass, metal, and composite materials.

Key Points:

Increasing demand for high-performance adhesive tapes in infrastructure projects.

Rising preference for eco-friendly and low-VOC adhesive solutions.

Technological innovations in pressure-sensitive and fire-resistant tapes.

Growing applications in HVAC, electrical, and roofing industries.

Expanding market opportunities in prefabricated and modular construction.

Conclusion

The Construction Adhesive Tapes Market is on an upward trajectory, fueled by technological advancements, urbanization, and sustainability trends. As smart cities, green buildings, and infrastructure projects continue to expand, the demand for high-quality adhesive tapes will surge. Market players are focusing on innovation and product diversification to cater to the evolving needs of the construction and building materials industry.

Read Full Report: https://www.snsinsider.com/reports/construction-adhesive-tapes-market-1694

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Construction Adhesive Tapes Market#Construction Adhesive Tapes Market Size#Construction Adhesive Tapes Market Share#Construction Adhesive Tapes Market Report#Construction Adhesive Tapes Market Forecast

0 notes

Text

Industrial Strength Tape Market, Global Outlook and Forecast 2025-2032

Industrial tapes are used for binding purposes in various industrial operations, offering a high level of adhesive strength compared to normal tapes used in everyday life. They are essential for attaching components like cushions, foams, and lighting fixtures, and are used in operations such as concrete bonding, glass bonding, and packaging. Industrial tapes have applications in automotive, construction, electronics, and more.

Market Size

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/288188/global-industrial-strength-tape-forecast-market-2025-2032-121

The global Industrial Strength Tape market size was estimated at USD 42,590 million in 2023 and is projected to reach USD 66,071.07 million by 2032, with a CAGR of 5.00% during the forecast period.

North America's market size was estimated at USD 12,069.36 million in 2023, exhibiting a CAGR of 4.29%.

Market Dynamics

Drivers:

Growing demand for high-strength adhesive bonding in industrial processes.

Increasing adoption of industrial tapes in automotive and construction industries.

Advancements in tape technology leading to improved performance and durability.

Restraints:

High initial investment costs associated with industrial tape applications.

Regulatory challenges in certain regions regarding the use of specific tape materials.

Competition from alternative bonding methods impacting market growth.

Opportunities:

Emerging applications of industrial tapes in the electrical and electronics sector.

Growth opportunities in developing regions with expanding manufacturing sectors.

Increasing focus on eco-friendly and sustainable tape materials driving market growth.

Challenges:

Fluctuating raw material prices affecting manufacturing costs.

Limited awareness about the benefits of industrial tapes in certain industries.

Rising competition from local manufacturers and counterfeit products impacting market share.

Regional Analysis

North America:

The industrial strength tape market in North America has shown steady growth, with major players like 3M and Nitto dominating the region. Demand is being primarily driven by the automotive and construction sectors, which require high-quality adhesive solutions for various applications. The market share of key players in this region is substantial, with strategic pricing and product innovation being key growth strategies.

Europe:

Europe has a well-established industrial tape market, with companies like Avery Dennison and Tesa leading the way. The region benefits from a strong manufacturing base and stringent quality standards. Market growth is influenced by factors such as technological advancements and a focus on sustainable adhesive solutions. The competitive landscape is characterized by a mix of global and regional players vying for market share.

Asia-Pacific:

The Asia-Pacific region presents significant growth opportunities for industrial strength tapes, driven by the expanding automotive and electronics industries. Companies like Intertape Polymer Group and Henkel are focusing on expanding their presence in this region through strategic partnerships and investments. Economic growth, coupled with rising infrastructure development, is fueling market expansion in countries like China and India.

Middle East & Africa:

Industrial tape usage in the Middle East and Africa region is growing steadily, supported by infrastructure development projects and investments in the construction sector. Key players like Scapa and Achem are targeting this region for market expansion. Factors such as increasing urbanization and industrialization are driving demand for industrial strength tapes in this region.

South & Central America:

South and Central America present a growing market for industrial tapes, with companies like ORAFOL Europe and Luxking Group expanding their presence in the region. The market is influenced by factors such as increasing investment in manufacturing facilities and growth in the packaging sector. Competitive pricing and product differentiation strategies are key focus areas for players in this region.

Competitor Analysis

Major Competitors:

The industrial strength tape market is highly competitive, with key players like 3M, Nitto, and Avery DennisonCorporation leading the industry. These companies have established a strong market presence through product innovation and strategic partnerships.

Market Share & Influence:

3M holds a significant market share globally, with a wide product portfolio and strong brand recognition. Nitto and Avery DennisonCorporation also have considerable influence in specific regions, with a focus on tailored adhesive solutions.

Strategies:

Market leaders like 3M focus on continuous product development and innovation to meet changing customer demands. Nitto emphasizes strategic partnerships with manufacturers to enhance its distribution network. Avery DennisonCorporation leverages its strong R&D capabilities to introduce sustainable adhesive solutions.

Competitive Positioning:

Each major player in the industrial strength tape market has a unique positioning strategy to differentiate themselves from competitors. While 3M focuses on technology-driven solutions, Nitto emphasizes customization for specific industries, and Avery DennisonCorporation prioritizes sustainability and environmental stewardship.

Market Segmentation (by Application)

Automotive

Building and Construction

Packing

Electrical and Electronics

Others

Market Segmentation (by Type)

Non-Adhesive Industrial Tape

Single-Sided Adhesive Tapes

Double-Sided Adhesive Tape

Transfer Tape

Others

Key Company

3M

Nitto

Avery Dennison Corporation

Tesa (Beiersdorf AG)

Lintec

Berry Plastics

Intertape Polymer Group

Saint Gobin

Henkel

Tremco illbruck(Adhere Industrial Tapes)

Scapa

Shurtape Technologies

Achem (YC Group)

Luxking Group

ORAFOL Europe

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

FAQ

01. What is the current market size of Industrial Strength Tape Market?

The global Industrial Strength Tape market size was estimated at USD 42590 million in 2023 and is projected to reach USD 66071.07 million by 2032, exhibiting a CAGR of 5.00% during the forecast period. North America Industrial Strength Tape market size was estimated at USD 12069.36 million in 2023, at a CAGR of 4.29% during the forecast period of 2025 through 2032.

02. Which key companies operate in the Industrial Strength Tape Market?

The major players in the market include 3M, Nitto, Avery Dennison Corporation, Tesa (Beiersdorf AG), Lintec, Berry Plastics, Intertape Polymer Group, Saint Gobin, Henkel, Tremco illbruck(Adhere Industrial Tapes), Scapa, Shurtape Technologies, Achem (YC Group), Luxking Group, ORAFOL Europe.

03. What are the key growth drivers in the Industrial Strength Tape Market?

The key growth drivers in the Industrial Strength Tape Market include the high adhesive strength offered by industrial tapes, the increasing adoption in various applications like automotive, building and construction, packing, electrical and electronics, and others, and the water and shock resistance features for specific operations.

04. Which regions dominate the Industrial Strength Tape Market?

The market is dominated by regions like North America, Europe, Asia-Pacific, South America, and The Middle East and Africa, based on factors like demand, supply, and market share.

05. What are the emerging trends in the Industrial Strength Tape Market?

The emerging trends in the Industrial Strength Tape Market include technological advancements in adhesive tapes, innovations in product offerings, and the growing demand in various industries for permanent or temporary assembly and fabrication.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/288188/global-industrial-strength-tape-forecast-market-2025-2032-121 Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Industrial Strength Tape 1.2 Key Market Segments 1.2.1 Industrial Strength Tape Segment by Type 1.2.2 Industrial Strength Tape Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Industrial Strength Tape Market Overview 2.1 Global Market Overview 2.1.1 Global Industrial Strength Tape Market Size (M USD) Estimates and Forecasts (2019-2032) 2.1.2 Global Industrial Strength Tape Sales Estimates and Forecasts (2019-2032) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Industrial Strength Tape Market Competitive Landscape 3.1 Global Industrial Strength Tape Sales by Manufacturers (2019-2025) 3.2 Global Industrial Strength Tape Revenue Market Share by Manufacturers (2019-2025) 3.3 Industrial Strength Tape Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Industrial Strength Tape Average Price by Manufacturers (2019-2025) 3.5 Manufacturers Industrial Strength Tape Sales Sites, Area Served, Product Type 3.6 Industrial Strength Tape Market Competitive Situation and Trends 3.6.1 Industrial Strength Tape Market Concentration Rate 3.6.2 Global 5 and 10 Largest Industrial Strength Tape Players Market Share by Revenue 3.6.3 Mergers & Acquisitions, Expansion 4 Industrial Strength TaCONTACT US: North Main Road Koregaon Park, Pune, India - 411001. International: +1(646)-781-7170 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes