#FullyAutomaticMulti-Effect-Evaporator

Explore tagged Tumblr posts

Text

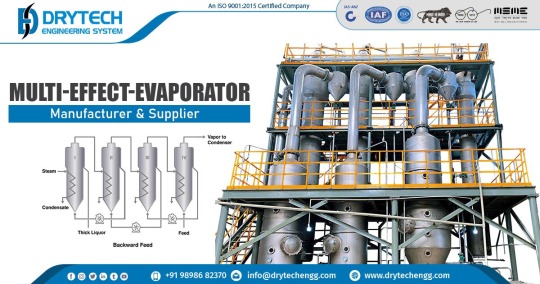

Supplier of Multi Effect Evaporator In Haydrabad

Drytech Engineering System is a 2017 ISO 9001:2015 certified company situated in Ahmedabad, Gujarat, India and Supplier of Multi Effect Evaporator In Haydrabad. We are a major manufacturer and supplier of a wide range of products such as Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems, and many more. A multi-effect evaporator is a type of evaporator system that consists of a succession of evaporation stages. Each stage operates at a lower pressure than the previous one, allowing for more energy-efficient liquid evaporation. Steam provides the heat required for evaporation, making it a cost-effective alternative for concentrating liquids and recovering valuable goods. Features Oily emulsions, coolant fluids, mold release agents Purging of compressors, water from washing floors Water from washing tanks and reactors Working and washing baths in galvanic processes and surface treatments Penetrating liquids Water treatment plant rejection Multi-Effect-Evaporator Working Principle : Liquid Introduction Heat Transfer Vapor Recompression Concentrated Liquid Collection Types of Multi Effect Evaporator Fully Automatic Multi-Effect-Evaporator Semi Automatic Multi-Effect-Evaporator Application Food and Beverage Pharmaceuticals Chemicals Wastewater Treatment Desalination Drytech Engineering System is a Manufacturer and Supplier of Multi Effect Evaporator In Haydrabad, Telangana and various locations, including Hyderabad, Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, Jangaon. Read the full article

#Ahmedabad#Bhongir#DrytechEngineeringSystem#FullyAutomaticMulti-Effect-Evaporator#Gujarat#Haydrabad#India#Jagtial#Jangaon#Kamareddy#Karimnagar#Khammam#Mahbubnagar#Mancherial#Miryalaguda#MultiEffectEvaporator#MultiEffectEvaporatorInHaydrabad#Nalgonda#Nizamabad#Ramagundam#SemiAutomaticMulti-Effect-Evaporator#Siddipet#Supplier#SupplierofMultiEffectEvaporator#SupplierofMultiEffectEvaporatorInHaydrabad#Suryapet#Wanaparthy#Warangal

0 notes