#DrytechEngineeringSystem

Explore tagged Tumblr posts

Text

Exporter of Flash Dryer in Gabon

Drytech Engineering System is a prominent Manufacturer, Supplier, and Exporter of Flash Dryer in Gabon. Our Manufacturing unit is based in Ahmedabad, Gujarat, India. A Flash Dryer is a type of industrial dryer used to rapidly dry materials by using a stream of hot air. The material is fed into a high-velocity airstream, which instantly evaporates the moisture content. Flash dryers suit granular, powdery, or crystalline materials that need quick and efficient drying. Industries commonly use these dryers where drying speed, energy efficiency, and product quality are critical. Flash dryers work with various materials, including food, chemicals, minerals, and pharmaceuticals, ensuring minimal degradation and a high-quality finish. Features: High-Speed Drying: The flash dryer offers a fast-drying process, reducing moisture content in a short amount of time. Efficient Airflow System: The advanced airflow system ensures even distribution of hot air for uniform drying of materials. Adjustable Settings: You can easily adjust the temperature and airflow to optimize drying conditions based on material type and desired moisture levels. Low Energy Consumption: Drytech designs Flash Dryers to operate efficiently, ensuring minimal energy use and reducing operational costs. Compact Design: These dryers fit into various production lines and factory layouts, saving space without compromising performance. Durability: Built with high-quality, corrosion-resistant materials to withstand harsh operating conditions and ensure long-term reliability. Applications: Food Industry Pharmaceutical Industry Chemical Industry Mineral Processing Cosmetic Industry Agriculture FAQs: How does a Flash Dryer work? Flash dryers work by rapidly evaporating moisture from materials using a high-velocity airstream of hot air. The material is fed into the chamber, where it is suspended in the air and quickly dried. What types of materials can be dried using a Flash Dryer? Flash dryers are suitable for drying granular, powdery, or crystalline materials. Common materials include food products, pharmaceuticals, chemicals, minerals, and pigments. Can flash dryers handle heat-sensitive materials? Flash dryers suit drying heat-sensitive materials, using rapid drying techniques that minimize heat exposure time and preserve quality. Drytech Engineering System is an Exporter of Flash Dryer in Gabon and including other locations Libreville, Port-Gentil, Franceville, Oyem, Moanda, Mouila, Lambaréné, Tchibanga, Koulamoutou, Makokou, Bitam, Gamba, Mounana, Ntoum, Lastoursville, Okondja, Ndendé, Booué, Fougamou, Ndjolé, Mbigou, Mayumba, Mitzic, Lékoni, Mimongo, Omboué, Cocobeach. For more information, please visit www.drytechengg.com or reach out to our team at [email protected]. View Product: Click Here Read the full article

#Ahmedabad#Bitam#Booué#Cocobeach#DrytechEngineeringSystem#Exporter#ExporterofFlashDryer#ExporterofFlashDryerinGabon#FlashDryer#FlashDryerExporter#FlashDryerinAhmedabad#FlashDryerinGabon#FlashDryerinGujarat#FlashDryerinIndia#FlashDryerManufacturer#FlashDryerSupplier#FlashDryers#Fougamou#Franceville#Gabon#Gamba#Gujarat#India#Koulamoutou#Lambaréné#Lastoursville#Lékoni#Libreville#Makokou#Manufacturer

0 notes

Text

Exporter of Spray Dryer in Rwanda

Drytech Engineering System is a reliable Manufacturer, Supplier, and Exporter of Spray Dryer in Rwanda. We are based in Ahmedabad, Gujarat, India. A spray dryer converts liquid or slurry into dry powder by evaporating moisture using hot air. Drytech Engineering System manufactures spray dryers that adhere to international standards for performance and safety. Our spray dryers deliver high ROI with energy-efficient operations and low maintenance. We export spray dryers from top manufacturers, ensuring reliability and durability. Working Process of Spray Dryers: Atomization: A nozzle or rotary atomizer atomizes the liquid feed into fine droplets. Drying Chamber: The chamber introduces hot air, which evaporates moisture from the droplets. Drying Process: The droplets transform into dry powder particles as they travel through the chamber. Separation: The dried particles are separated from the air using cyclones or bag filters. Collection: The final product is collected for packaging or further processing. Uses and Applications of Spray Dryers: Food Industry: For drying milk, coffee, tea, and other food products. Pharmaceuticals: For producing powdered medicines, vitamins, and excipients. Chemicals: For drying dyes, pigments, and specialty chemicals. Dairy Industry: For producing milk powder, whey, and other dairy products. Ceramics: For drying ceramic slurries into fine powders. Environmental Applications: For drying wastewater sludge and other waste materials. FAQs: Q: What after-sales support do you provide? A: We offer installation, training, maintenance, and technical support to ensure smooth operation. Q: How do I place an order for a spray dryer in Rwanda? A: Contact Drytech Engineering Systems via phone, email, or our website to discuss your requirements. Q: What makes Drytech’s spray dryers stand out? A: Our spray dryers are known for their advanced technology, energy efficiency, and reliable performance. Drytech Engineering System is an Exporter of Spray Dryer in Rwanda including locations Kigali, Gisenyi, Ruhengeri, Butare, Muhanga, Byumba, Cyangugu, Nyanza, Bugarama, Kayonza, Rwamagana, Nyamata, Ruhango, Gikongoro, Nyagatare, Busogo, Kibuye, Kibungo, Rubengera. For more information, please visit www.drytechengg.com or reach out to our team at [email protected]. View Product: Click here Read the full article

#after-salessupport#Ahmedabad#Atomization#bagfilters#Bugarama#Busogo#Butare#Byumba#ceramics#chemicals#Cyangugu#cyclones#dairyindustry#dryingchamber#dryingprocess#DrytechEngineeringSystem#DrytechEngineeringSystemRwanda#EnergyEfficiency#Environmentalapplications#Exporter#ExporterofSprayDryerinRwanda#foodindustry#Gikongoro#Gisenyi#Gujarat#India#installation#Kayonza#Kibungo#Kibuye

0 notes

Text

Supplier of Spray Dryer in Kerala

Drytech Engineering Systems is a Manufacturer, Exporter, and Supplier of Spray Dryer in Kerala. Drytech Engineering System specializes in a range of drying equipment including Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, and Dust Collector Systems. we offer premium quality Spray Dryer Manufacturers in India at the international standards level. We are manufacturers and suppliers of various kinds of Spray dryers as per customer requirements. Various configurations of spray dryers, such as nozzle atomizers, rotary atomizers, and fluidized bed dryers, cater to specific applications and requirements. Spray drying involves transforming feed from a fluid state into a dried particulate form by spraying it into a hot drying medium. How does our Spray Dryer Work? The spray drying method employs a single process to convert a liquid solution/slurry into a powder. In a specially designed Drying Chamber, the liquid/slurry is atomized at high velocity into a stream of hot air, evaporating the solvent. We custom design Spray Dryers to suit the product quality, feed conditions, heating source available, and the local environment norms. Spray drying is a process of dehydrating fluids, solutions, and thin slurries, into powder form. The liquid or slurry undergoing dehydration sprays as fine droplet dispersion into a hot air stream. Both air and material either travel in parallel or counterflow. Drying in a spray dryer occurs at a very fast rate so that the contact of material to heat is not for a longer time hence it does not damage the heat selectivity materials and becomes ideal for drying such materials. Drytech Engineering System is a Supplier of Spray Dryer in Kerala, covering locations like Chennai and places like Alappuzha, Vatakara, Idukki, Kannur, Kochi, Kollam, Kottayam, Kozhikode, Mattancheri, Palakkad, Thalassery, Thiruvananthapuram, Thrissur. For detailed information and inquiries, please feel free to contact us. Read the full article

#Alappuzha#atomizedathighvelocity#CentrifugalBlowers#dehydratingfluids#designedDryingChamber#Dryinginspraydryer#DrytechEngineeringSystem#DrytechEngineeringSystems#DustCollectorSystems#EvaporatorDryers#Exporter#feedconditions#FlashDryers#FluidBedDryers#fluidizedbeddryers#heatingsource#HotAirGenerators#Idukki#Kannur#Kerala#Kochi#Kollam#Kottayam#Kozhikode#Manufacturer#Mattancheri#Palakkad#parallelorcounterflow#premiumqualitySprayDryerManufacturers#quality

0 notes

Text

Exporter of Spin Flash Dryer in Bangladesh

Drytech Engineering System is a Manufacturer, Supplier, and Exporter of Spin Flash Dryer in Bangladesh. We are Certified with ISO 9001:2015 since 2017, Ahmedabad, Gujarat, India. Drytech Engineering System specialize in a range of drying equipment including Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, and Dust Collector Systems. A spin flash dryer is an industrial drying equipment utilizing hot air and mechanical agitation for rapid drying of various materials. It comprises a cylindrical drying chamber with a high-speed rotor. Materials are introduced through a feed mechanism, encountering hot air for swift drying. This dryer is ideal for processing filter press wet cake, fluids with high viscosity, and thick pastes. Operating at 440V/50Hz, this stainless steel system ensures energy-efficient operation and high output. By creating a rotating wind area with hot air, it accelerates the drying process for pastes and fluids. Features: Accomplished with bag filter and cyclone separator for collecting dry powder Free from deposits Superiorly dry cohesive and non-cohesive pastes, cakes and highly viscous products Chemical and thermal resistant No sticking and accumulation Drytech Engineering System is Exporter of Spin Flash Dryer in Bangladesh, covering locations like Dhaka, Chattogram, Mymensingh, Sylhet, Khulna, Gazipur, Bogura, Narsingdi, Rajshahi, Sirajganj, Narayanganj, Faridpur, Pabna, Bhairab, Tangail, Chuadanga, Kishoreganj, Jhenaidah, Lakshmipur, Sreepur Upazila, Gournadi, Rangpur, and more. For detailed information and inquiries, please feel free to contact us. Read the full article

#Balngadesh#Bhairab#Bogura#CentrifugalBlowers#Chattogram#Chemicalandthermalresistant#Chuadanga#Dhaka#DrytechEngineeringSystem#DustCollectorSystems#EvaporatorDryers#ExporterofSpinFlashDryer#ExporterofSpinFlashDryerinBalngadesh#ExporterofSpinFlashDryersinBangladesh#Faridpur#feedmechanism#filterpresswetcake#FlashDryers#FluidBedDryers#Freefromdeposits#Gazipur#Gournadi#high-speedrotor#HotAirGenerators#Jhenaidah#Khulna#Kishoreganj#Lakshmipur#Manufacturer#Mymensingh

0 notes

Text

Supplier of Flash Dryer in Karnataka

We are Manufacturers, Suppliers, and Supplier of Flash Dryer in Karnataka. Drytech Engineering System, an ISO 9001:2015-certified company since 2017, based in Ahmedabad, Gujarat, India. Our expertise spans various industrial equipment, including Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems, and more. Drytech Engineering System has enabled us to address the needs of our clients by providing a wide selection of Flash Dryers. We design our dryers to facilitate cohesive and continuous drying of various types of pastes and viscous liquids. We manufacture our entire range of Flash Dryers from high-quality raw materials sourced from reputable suppliers. Professionals evaluate our dryers for quality, considering various characteristics like structure, durability, and performance. The flash dryer is a continuous drying facility that disintegrates wet cakes into fine powder and then dries them with hot air. The entire process is totally automated, requiring no handling or human intervention. The system automatically adjusts the feed rate based on moisture content variations in the wet cake, ensuring consistent product quality. We go beyond product delivery by actively promoting customer satisfaction through great after-sales services, end-to-end solutions, and project management. The Flash Dryer has various advantages, including adjustable designs, the ability to remove rough edges while drying, and efficient handling of huge materials. Drytech Engineering System serves as an Supplier of Flash Dryer in Karnataka, covering locations like Badami, Bengaluru, Belagavi, Bhadravati, Bidar, Chikkamagaluru, Chitradurga, Davangere, Halebid, Hassan, Hubballi-Dharwad, Kalaburagi, Kolar, Madikeri, Mandya, Mangaluru, Mysuru, Raichur, Shivamogga, Shravanabelagola, Shrirangapattana, Tumakuru, Vijayapura. For detailed information and inquiries, please feel free to contact us. Read the full article

#Ahmedabad#Badami#Belagavi#Bengaluru#Bhadravati#Bidar#CentrifugalBlowers#Chikkamagaluru#Chitradurga#Davangere#DrytechEngineeringSystem#durability#DustCollectorSystems#end-to-endsolutions#EvaporatorDryers#Exporter#ExporterofFlashDryer#ExporterofFlashDryerinKarnataka#FlashDryerInKarnataka#FlashDryers#FluidBedDryers#greatafter-salesservices#Gujarat#Halebid#handlingorhumanintervention#Hassan#high-qualityrawmaterials#HotAirGenerators#Hubballi-Dharwad#India

0 notes

Text

Supplier of Flash Dryer In Karnataka

Drytech Engineering System, founded in 2017, is an ISO 9001:2015 certified firm situated in Ahmedabad, Gujarat, India and Supplier of Flash Dryer In Karnataka. Drytech Engineering System Is a Manufacturer and Supplier of Multi Effect Evaporator, Spray Dryer, Flash Dryer, Spin Flash Dryer, Fluid Bled Dryer and etc. Flash dryers, frequently referred to as 'pneumatic dryers,' provide the most cost-effective means of drying solids with low moisture content or dewatered. They are the most basic gas suspension dryers with the smallest footprint. A single process provides mixing, heat transmission, and mass transfer to dry a solid. The residence time in the dryer is often less than three seconds, resulting in nearly immediate surface drying. A flash dryer's operation consists of three critical stages: drying, separation, and collection. We are manufacture and supplier of two types of Flsh Dryer Fully Automatic Flash Dryer Semi Automatic Flash Dryer Features Low dwell duration, minimum heat exposure, and preservation of original product quality An excellent substitute for drying wet cakes on a tray. An highly sticky/pasty wet cake can be treated. High-quality cyclone and baghouse for powder recovery The Fully Automatic Plant The insignificant sprinkling of products Instrumentation and controls to ensure consistent performance Applications Food Industry Pharmaceutical Industry Chemical Industry Minerals and Aggregates Industry Drytech Engineering System is a Manufacturer and Supplier of Flash Dryer In Karnataka and various locations, including Badami, Ballari, Bengaluru, Belagavi, Bhadravati, Bidar, Chikkamagaluru, Chitradurga, Davangere, Halebid, Hassan, Hubballi-Dharwad, Kalaburagi, Kolar, Madikeri, Mandya, Mangaluru, Mysuru, Raichur, Shivamogga, Shravanabelagola, Shrirangapattana, Tumakuru, Vijayapura. For a more in-depth understanding of our products and engaging discussions, we invite you to connect with our dedicated team. Read the full article

#Ahmedabad#Badami#Ballari#Belagavi#Bengaluru#Bhadravati#Bidar#Chikkamagaluru#Chitradurga#cost-effective#Davangere#dryingsolids#DrytechEngineeringSystem#FlashDryer#FlashDryerInKarnataka#FluidBledDryer#FullyAutomaticFlashDryer#Gujarat#Halebid#Hassan#Hubballi-Dharwad#India#Kalaburagi#Karnataka#Kolar#Lowdwellduration#Madikeri#Mandya#Mangaluru#Manufacturer

0 notes

Text

Supplier of Spray Dryer In Mumbai

Supplier of Spray Dryer In Mumbai Drytech Engineering System, founded in 2017, is an ISO 9001:2015 certified firm situated in Ahmedabad, Gujarat, India. Drytech Engineering System Is a Manufacturer and Supplier of Multi Effect Evaporator, Spray Dryer, Flash Dryer, Spin Flash Dryer, Fluid Bled Dryer and etc. Spray drying is a process of dehydrating fluids, solutions, and thin slurries, converting them to powder form. Spraying a thin dispersion of the liquid or slurry material into a heated airstream dries it effectively. The drying process involves using spray dryers to convert liquids and slurries into powder form. Each Drytech Engineering System Spray Dryer is custom-built to fit your exact specifications. Our comprehensive drying knowledge, expertise, and technology are available to you, allowing us to transform your ideas into high-quality powders customized to fit your unique features and characteristics. Features High aspirator rate that decreases residual moisture from the product Yield high performance with proper control on temperature and other functions. Require low maintenance for great functional life Assured reliability for long run Spray dryers are broadly classified into two types based on the method of atomization. Nozzle Spray Dryers Rotary Atomiser Spray Dryers Sub Types Of Spray Dryers: Co-current Spray Dryer Counter-current Spray Dryer Mixed flow Spray Dryer We are offering plants for a variety of applications ranging from heat-sensitive products like enzymes, blood, flavors, regular products like plant and animal extracts, milk, food and pharmaceutical applications, dyes, and chemicals, detergents. Drytech Engineering System is a Manufacturer and Supplier of Spray Dryer In Mumbai, Maharashtra serving locations including Ahmednagar, Akola, Amravati, Aurangabad, Bhandara, Bhusawal, Buldhana, Chandrapur, Daulatabad, Dhule, Jalgaon, Kalyan, Karli, Kolhapur, Mahabaleshwar, Malegaon, Matheran, Mumbai, Nagpur, Nanded, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal. For a more in-depth understanding of our products and engaging discussions, we invite you to connect with our dedicated team. Read the full article

#Ahmedabad#Ahmednagar#Akola#Amravati#Aurangabad#Bhandara#Bhusawal#Buldhana#Chandrapur#Co-currentSprayDryer#Counter-currentSprayDryer#Daulatabad#Dhule#DrytechEngineeringSystem#FlashDryer#FluidBledDryer#Gujarat#high-qualitypowders#High-QualitySprayDryers#India#Jalgaon#Kalyan#Karli#Kolhapur#Mahabaleshwar#Maharashtra#Malegaon#Manufacturer#Matheran#MixedflowSprayDryer

0 notes

Text

Supplier of Spray Dryer In Telangana

Drytech Engineering System is an ISO 9001:2015 certified company based in Ahmedabad, Gujarat, India, established in 2017.Supplier of Spray Dryer In Telangana. We are a major manufacturer and supplier of a wide range of products, including Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems, and more. Spray dryers primarily serve the purpose of drying solutions and slurries into powders. Each Drytech Engineering System Spray Dryer is individually designed to meet your specific requirements. Our extensive knowledge in drying, expertise, and technology are at your disposal, allowing us to turn your ideas into high-quality powders engineered to match your specific properties and characteristics. We offer unparalleled project management from start to finish, providing plants for various applications, from heat-sensitive products like enzymes, blood, flavors, to regular products like plant and animal extracts, milk, food, pharmaceuticals, dyes, and chemicals, as well as heat-resistant products like ceramics, inorganic salts, glass, and metals, and more. Key Features: High aspirator rate reduces residual moisture. High performance with precise temperature control. Low maintenance for extended functional life. Reliable for long-term use. Continuous drying in spray dryers enables higher production speeds. Control and maintain product quality during the drying process. Drytech Engineering System is a manufacturer and supplier of Spray Dryers in Telangana, serving locations including Hyderabad, Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, and Wanaparthy. For a more in-depth understanding of our products and engaging discussions, we invite you to connect with our dedicated team. Read the full article

#Ahmedabad#Bhongir#DrytechEngineeringSystem#Gujarat#Highperformance#Hyderabad#India#Jagtial#Kamareddy#Karimnagar#Khammam#Mahbubnagar#Mancherial#Miryalaguda#Nalgonda#Nizamabad#Ramagundam#Siddipet#SpinFlashDryers#SprayDryer#SprayDryerInTelangana#Supplier#SupplierofSprayDryer#SupplierofSprayDryerInTelangana#Suryapet#Telangana#Wanaparthy#Warangal

0 notes

Text

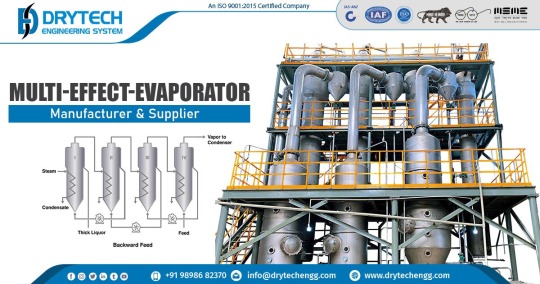

Supplier of Multi Effect Evaporator In Haydrabad

Drytech Engineering System is a 2017 ISO 9001:2015 certified company situated in Ahmedabad, Gujarat, India and Supplier of Multi Effect Evaporator In Haydrabad. We are a major manufacturer and supplier of a wide range of products such as Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems, and many more. A multi-effect evaporator is a type of evaporator system that consists of a succession of evaporation stages. Each stage operates at a lower pressure than the previous one, allowing for more energy-efficient liquid evaporation. Steam provides the heat required for evaporation, making it a cost-effective alternative for concentrating liquids and recovering valuable goods. Features Oily emulsions, coolant fluids, mold release agents Purging of compressors, water from washing floors Water from washing tanks and reactors Working and washing baths in galvanic processes and surface treatments Penetrating liquids Water treatment plant rejection Multi-Effect-Evaporator Working Principle : Liquid Introduction Heat Transfer Vapor Recompression Concentrated Liquid Collection Types of Multi Effect Evaporator Fully Automatic Multi-Effect-Evaporator Semi Automatic Multi-Effect-Evaporator Application Food and Beverage Pharmaceuticals Chemicals Wastewater Treatment Desalination Drytech Engineering System is a Manufacturer and Supplier of Multi Effect Evaporator In Haydrabad, Telangana and various locations, including Hyderabad, Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, Jangaon. Read the full article

#Ahmedabad#Bhongir#DrytechEngineeringSystem#FullyAutomaticMulti-Effect-Evaporator#Gujarat#Haydrabad#India#Jagtial#Jangaon#Kamareddy#Karimnagar#Khammam#Mahbubnagar#Mancherial#Miryalaguda#MultiEffectEvaporator#MultiEffectEvaporatorInHaydrabad#Nalgonda#Nizamabad#Ramagundam#SemiAutomaticMulti-Effect-Evaporator#Siddipet#Supplier#SupplierofMultiEffectEvaporator#SupplierofMultiEffectEvaporatorInHaydrabad#Suryapet#Wanaparthy#Warangal

0 notes

Text

Supplier of Spin Flash Dryer In Sri Lanka

Drytech Engineering System is a 2017 ISO 9001:2015 certified company situated in Ahmedabad, Gujarat, India and Supplier of Spin Flash Dryer In Sri Lanka. We are a major manufacturer and supplier of a wide range of products such as Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems, and many more. Our spin flash dryer is a sort of industrial drying equipment that uses hot air and mechanical agitation to speedily dry a variety of materials. It consists of a cylindrical drying chamber with a high-speed rotor. The feed mechanism of the drying chamber introduces and swiftly dries the material upon contact with hot air. Its raw materials include filter press wet cake, fluids with high viscosity levels, and thick paste. This stainless steel drying system is popular for its energy-efficient operation and high output level, known for its 440V/50HZ voltage. It generates a revolving wind region with hot air to deliver paste or fluid-based ingredients. The fast rotation of the inserted paste and fluid aids the rapid drying of these substances. Two Types of Spin Flash Dryer Machine Available Fully Automatic Spin Flash Dryer Semi Automatic Spin Flash Dryer Features of Spin Flash Dryer Accomplished with bag filter and cyclone separator for collecting dry powder Free from deposits Superiorly dry cohesive and non-cohesive pastes, cakes and highly viscous products Chemical and thermal resistant No sticking and accumulation Drytech Engineering System is a Manufacturer and Supplier Of Spin Flash Dryer In Sri Lanka and various locations, including Colombo, Galle, Negombo, Nuwara Eliya, Ratnapura, Dehiwala-Mount Lavinia, Hambantota, Moratuwa, Kandy, Jaffna, Trincomalee, Bentota, Kotte, Sigiriya, Hikkaduwa, Kalutara, Anuradhapura, Dambulla, Polonnaruwa, Batticaloa, Tangalle, Kurunegala, Matara, Mirissa. Read the full article

#Ahmedabad#Bentota#CentrifugalBlowers#Colombo#Dehiwala-MountLavinia#DrytechEngineeringSystem#DustCollectorSystems#EvaporatorDryers#FlashDryers#FluidBedDryers#FullyAutomaticSpinFlashDryer#Galle#Gujarat#Hambantota#Hikkaduwa#HotAirGenerators#Manufacturer#Moratuwa#Negombo#NuwaraEliya.#otaryAtomizers#Ratnapura#RotaryAtomizers#RotaryValves#SemiAutomaticSpinFlashDryer#SpinFlashDryers#SprayDryers#SriLanka#Supplier#SupplierofSpinFlashDryerInSriLanka

0 notes

Text

Supplier of Multi Effect Evaporator In Madhya Pradesh

Drytech Engineering System is an ISO 9001:2015 certified firm based in Ahmedabad, Gujarat, India, that was created in 2017 and Supplier of Multi Effect Evaporator In Madhya Pradesh. We are a leading manufacturer and supplier of a comprehensive range of goods, including Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems, and others. A multi-effect evaporator is a type of evaporator system that consists of a succession of evaporation stages. Each stage operates at a lower pressure than the previous one, allowing for more energy-efficient liquid evaporation. Steam provides the heat required for evaporation, making it a cost-effective alternative for concentrating liquids and recovering valuable goods. We manufacture two types of Multi Effect Evaporators. Fully Automatic Multi-Effect-Evaporator Semi Automatic Multi-Effect-Evaporator Multi-Effect-Evaporator Features: Coolant fluids, oily emulsions, mold releasing agents Compressor purge, water from washing floors Washing tank and reactor water Galvanic processes and surface treatments require working and cleaning baths. Permeable liquids Rejection of a water treatment plant Drytech Engineering System is a Manufacturer and Supplier of Multi Effect Evaporator In Madhya Pradesh and various locations, including Balaghat, Barwani, Betul, Bharhut, Bhind, Bhojpur, Bhopal, Burhanpur, Chhatarpur, Chhindwara, Damoh, Datia, Dewas, Dhar, Guna, Gwalior, Hoshangabad, Indore, Itarsi, Jabalpur, Jhabua, Khajuraho, Khandwa, Khargone, Maheshwar, Mandla, Mandsaur, Morena, Murwara, Narsimhapur, Narsinghgarh, Narwar, Neemuch, Nowgong, Orchha, Panna, Raisen, Rajgarh, Ratlam, Rewa, Sagar, Sarangpur, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri, Ujjain, Vidisha. Read the full article

#Ahmedabad#Balaghat#Barwani#Betul#Bharhut#Bhind#Bhojpur#Bhopal#Burhanpur#CentrifugalBlowers#Chhatarpur#Chhindwara#Damoh#Datia#Dewas#Dhar#DrytechEngineeringSystem#DustCollectorSystems#EvaporatorDryers#FlashDryers#FluidBedDryers#FullyAutomaticMulti-Effect-Evaporator#Gujarat#Guna#Gwalior#Hoshangabad#HotAirGenerators#India#Indore#Itarsi

0 notes

Text

Welcome To Drytech Engineering System

Drytech Engineering System is an ISO 9001:2015 Certified Company and Founded in 2017 in Ahmedabad, Gujarat, India.We rank among the leading manufacturers and suppliers of a wide range of products, including Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, Dust Collector Systems, and more.We can also customize these products according to our cherished clients' exact requirements.Our offered array is widely demanded for its fine finish, sturdy construction, enhanced durability, and corrosion resistance.We have categorized our infrastructure into different divisions, including manufacturing, production, procurement, testing, R & D, quality control, sales, and marketing. This segmentation helps us manage all business processes systematically.We are supported by well developed infrastructural setup, which is spread across a sprawling area and has large installation capacity.The unit is installed with requisite machines and equipment that are updated timely to develop quality products.For more details on our products/catalog, please contact us using the following information:Contact number: +91 9898682370Email: [email protected] Read the full article

#Ahmedabad#CentrifugalBlowers#DrytechEngineeringSystem#DustCollectorSystems#EvaporatorDryers#FlashDryers#FluidBedDryers#Gujarat#HotAirGenerators#India#Manufacturer#QualityControl#RotaryAtomizers#RotaryValves#Sales#SpinFlashDryers#Supplier#Welcome

1 note

·

View note

Text

Exporter of Spray Dryer in Guinea

Drytech Engineering Systems is a leading Manufacturer and Exporter of Spray Dryer in Guinea. We are a spray dryer manufacturer in Ahmedabad, Gujarat, India. Drytech Engineering Systems uses spray dryers to rapidly dry liquid feed in hot air, converting it into powder. Drytech Engineering Systems atomizes liquid into droplets, exposes them to hot air, evaporating moisture to create powder. Various industries, including food and beverages, pharmaceuticals, chemicals, cosmetics, and more, use spray dryers. Why Choose Drytech Engineering Systems for Spray Dryers? Superior Quality: We use top materials and strict quality control to ensure each spray dryer meets the highest performance standards. Energy Efficiency: Drytech spray dryers are designed to minimize energy consumption while maximizing productivity, helping businesses save on operational costs. Easy Maintenance: Our spray dryers are designed for easy installation, operation, and maintenance, ensuring long-lasting performance and minimal downtime. Technical Support: We offer ongoing technical support and service to our clients in Guinea, ensuring your equipment continues to perform at its best. Benefits of Spray Dryers for Export to Guinea: Efficient and Scalable Production: Spray dryers offer an efficient way to convert liquids into powders, enabling scalability for large production volumes. Preservation of Product Quality: Spray drying helps retain the nutritional and sensory properties of the product, making it suitable for food and pharmaceutical applications. Improved Storage and Transport: Powdered products are easier to store, handle, and transport, ensuring better preservation during shipment to Guinea. Applications of Spray Dryers in Guinea: Food and Beverages Pharmaceuticals Chemical Industry Cosmetics FAQs. Do you provide after-sales support for spray dryers in Guinea? Yes, Drytech Engineering Systems offers comprehensive after-sales support, including installation, maintenance, and troubleshooting services for clients in Guinea. How do I order a spray dryer from Drytech Engineering Systems? You can contact us directly through our website or contact our sales team for more information about placing an order. Drytech Engineering Systems is an Exporter of Spray Dryer in Guinea and including locations Conakry, Nzérékoré, Kankan, Manéah, Dubréka, Kindia, Siguiri, Kissidougou, Labé, and Kamsar. For more information about our spray dryers or to get a quote, feel free to reach out to Drytech Engineering Systems. View Product: Click here Read the full article

#Ahmedabad#Conakry#DrytechEngineeringSystems#Dubréka#Exporter#ExporterofSprayDryer#ExporterofSprayDryerinGuinea#Gujarat#India#Kamsar#Kankan#Kindia#Kissidougou#Labé#Manéah#Manufacturer#ManufacturerandExporterofSprayDryer#Nzérékoré#Siguiri#SprayDryerinGuinea#SprayDryerManufacturerinAhmedabad#Supplier

0 notes

Text

Exporter of Multi Effect Evaporator in Mauritius

Drytech Engineering Systems is a Prominent Manufacturer and Exporter of Multi Effect Evaporator in Mauritius. Our Manufacturing unit is based in Ahmedabad, Gujarat, India. What is a Multi Effect Evaporator? A Multi Effect Evaporator (MEE) is a sophisticated system that concentrates liquid solutions through multiple stages, also called "effects." Each effect uses the vapor from the previous stage to heat the next stage, dramatically increasing energy efficiency. This technology reduces the need for external heating sources, lowering energy consumption and operational costs. How Does a Multi Effect Evaporator Work? Feed Introduction: The liquid feed enters the first effect where it is heated using an external heat source, typically steam. This causes the liquid to evaporate. Vapor Utilization: The vapor generated in the first effect is used as a heating medium in the second effect. This energy-saving process continues in the following stages, with each effect relying on the vapor from the previous one. Sequential Evaporation: The liquid becomes more concentrated as it passes through each stage. As the process moves forward, each stage operates at progressively lower pressures and temperatures, which improves energy efficiency. Condensation and Collection: The vapor from the last effect condenses, and the concentrated liquid is collected. The entire system minimizes the need for extra external energy. Benefits of Multi Effect Evaporators: Energy Efficiency: By reusing vapor for heating, these evaporators significantly lower energy consumption. Cost Savings: Reduced energy consumption leads to lower operational costs, providing substantial savings. Scalability: Easily scalable, these evaporators can be adjusted to meet varying production needs, offering flexibility for different industries. Versatility: Multi-effect evaporators can handle a broad range of liquids and concentrations, making them ideal for diverse applications. FAQs about Multi Effect Evaporators: Q1: How much energy can a Multi Effect Evaporator save? A1: Multi Effect Evaporators can save up to 80% of the energy required in traditional evaporation methods due to their ability to reuse vapor across multiple stages. Q2: What support do you provide after installation? A2: We offer comprehensive post-installation support, including regular maintenance, troubleshooting, and any required upgrades to keep your evaporator running efficiently. Drytech Engineering Systems is an Exporter of Multi Effect Evaporator in Mauritius including locations Port Louis, Plaines Wilhems, Vacoas-Phoenix, Beau Bassin-Rose Hill, Curepipe, Quatre Bornes, Rivière Noire, Pamplemousses, Savanne, Grand Port and Flacq. Contact us for detailed information and inquiries, please feel free to contact us. Read the full article

#Ahmedabad#BeauBassin-RoseHill#Curepipe#DrytechEngineeringSystems#Exporter#ExporterofMultiEffectEvaporator#ExporterofMultiEffectEvaporatorinMauritius#GrandPortandFlacq#Gujarat#India#Manufacturer#ManufacturerandExporterofMultiEffectEvaporator#ManufacturingunitisbasedinAhmedabad#Mauritius#MultiEffectEvaporatorinMauritius#Pamplemousses#PlainesWilhems#PortLouis#ProminentManufacturerandExporterofMultiEffectEvaporator#QuatreBornes#RivièreNoire#Savanne#Supplier#Vacoas-Phoenix

0 notes

Text

Exporter of Spin Flash Dryer in Somalia

Drytech Engineering Systems is a trusted Manufacturer and Exporter of Spin Flash Dryer in Somalia. We are located in Ahmedabad, Gujarat, India. Our Spin Flash Dryers are designed for rapid and efficient drying, offering reduced processing times and lower energy consumption. Drytech Engineering Systems' dryers are made from high-quality materials, ensuring long-lasting performance in demanding industrial environments. From installation to ongoing maintenance, our expert team is always available to support and troubleshoot, ensuring seamless operations. We offer the best value for money without compromising on the quality of our equipment. Features of Spin Flash Dryers from Drytech Engineering Systems: Uniform Drying: Consistent moisture removal without any damage to the material. Low Energy Consumption: Energy-efficient design reduces operational costs. Compact Design: The dryer’s space-saving design is ideal for facilities with limited space. Temperature Control: Precise temperature control to protect sensitive materials. High Throughput: Capable of handling large quantities of material efficiently. Applications of Spin Flash Dryers: Food Processing Pharmaceuticals Chemicals Agriculture Environmental Solutions Drytech Engineering Systems is an Exporter of Spin Flash Dryer in Somalia and including locations Mogadishu, Kismaayo, Hargeysa, Baidoa, Gaalkacyo, Marka, Boosaaso, Garoowe, Burco, Buurhakaba, Bu’aale, Jawhar, Xuddur, Afgooye, Beledweyne, Qoryooley, Garbahaarrey, Hobyo, Laasqoray, Dhuusamarreeb, Boorama, Laascaanood, Ceerigaabo, and Lughaye. Contact us for detailed information and inquiries, please feel free to contact us. Read the full article

#Afgooye#Ahmedabad#Baidoa#Beledweyne#Boorama#Boosaaso#Bu’aale#Burco#Buurhakaba#Ceerigaabo#Dhuusamarreeb#DrytechEngineeringSystems#efficientdrying#Exporter#ExporterofSpinFlashDryer#ExporterofSpinFlashDryerinSomalia#Gaalkacyo#Garbahaarrey#Garoowe#Gujarat#Hargeysa#Hobyo#India#Jawhar#Kismaayo#Laascaanood#Laasqoray#Lughaye#Manufacturer#Marka

0 notes

Text

Exporter of Flash Dryer in Libya

Drytech Engineering Systems is a trusted Manufacturer and Exporter of Flash Dryer in Libya. Our Flash Dryer Manufacturing Unit is based in Ahmedabad, Gujarat, India. A Flash Dryer is a highly efficient industrial drying system designed to quickly dry granular, powdered, or liquid materials. Flash dryers consume less energy compared to traditional drying methods, making them known for their energy efficiency. We offer fully customizable Flash Dryers, including adjustments for airflow speed, temperature range, and drying chamber size to suit your particular application needs. Drytech Engineering Systems designs Flash Dryers with minimal moving parts and robust components, making them easy to maintain and service. Features of Flash Dryer: Rapid Drying: Flash dryers can quickly dry materials in a matter of seconds to minutes. Adjustable Temperature and Airflow: Precise control over temperature and airflow, ensuring the drying process meets the material's requirements. Compact Design: Saves space while offering high efficiency. Low Energy Consumption: Optimized to reduce energy use, making it a cost-effective choice for continuous drying operations. Minimal Maintenance: Built with robust components, requiring minimal maintenance and offering long-term reliability. Applications of Flash Dryer: Food Processing: Drying fruits, vegetables, spices, and other food products. Pharmaceuticals: Drying active ingredients, powders, and granules. Chemical Industry: Drying chemical powders and slurry. Mineral Processing: Drying minerals and ores before further processing. Petrochemicals: Drying slurry-like materials in various production processes. FAQs: What is the ideal material for a Flash Dryer? Flash dryers are best suited for drying powders, granules, and slurries. They work effectively with materials that can be dispersed in a stream of hot air, such as food products, chemicals, and minerals. How long does it take to dry materials using a Flash Dryer? The drying time varies depending on the material and its moisture content. Typically, flash drying can be completed in a matter of seconds to minutes. Drytech Engineering Systems is an Exporter of Flash Dryer in Libya including locations Tripoli, Benghazi, Ajdabiya, Misrata, Al Bayda, Al Khums, Az Zawiya, Gharyan, Al Marj, Tobruk, Sabratha, Al Jumail, Derna, Janzur, Zuwara, Masallata, Sirte, Yafran, Nalut, Bani Walid, Tajura, Birak, Shaahat, Murzuq, Awbari, Qasr al Qarabulli, Waddan, Al Qubbah, Al Aziziyah, Mizdah, Toukra, Ghat, Az Zuwaitina, Hun, Qaryat al Qiyan, Al Jawf, Zaltan, Az Zintan, Qaryat Suluq, Tarhuna, Umm ar Rizam, Qaminis, Kiklah, Ghadamis, Sukhna, As Sidrah, Al Bardiyah, Al Abraq, Bin Jawwad, Sousa, Martubah, Al Qayqab, Musaid, Taknis, Al Burayqah, Awjilah, Farzughah, Bir al Ashhab, Qaryat al Faidiya, Jardas al Abid, Qandulah, Kambut, Daryanah, Marawah, Jikharrah, Zawilah, Wazin, Qirnadah, Bir al Ghanam, Ar Rajmah, Al Jaghbub, Sabha. Contact Us For detailed information and inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Ajdabiya#AlAbraq#AlAziziyah#AlBardiyah#AlBayda#AlBurayqah#AlJaghbub#AlJawf#AlJumail#AlKhums#AlMarj#AlQayqab#AlQubbah#ArRajmah#AsSidrah#Awbari#Awjilah#AzZawiya#AzZintan#AzZuwaitina#BaniWalid#Benghazi#BinJawwad#BiralAshhab#BiralGhanam#Birak#Daryanah#Derna#DrytechEngineeringSystems

0 notes