#Gasoline Direct Injection Device

Explore tagged Tumblr posts

Text

Gasoline Direct Injection Device Market Anticipated to Expand Owing to Efficiency Regulations

Global Gasoline Direct Injection Device Market is estimated to be valued at US$ 8.26 Bn in 2025 and is expected to exhibit a CAGR of 6.3% over the forecast period 2025 to 2032.

The gasoline direct injection device market encompasses advanced fuel delivery systems designed to inject fuel directly into the combustion chamber, enabling precise atomization and timing. These devices offer significant advantages such as enhanced fuel economy, lower CO₂ and NOₓ emissions, improved engine responsiveness, and optimized power output. As automotive OEMs strive to meet stringent emission norms and consumer demand for better fuel efficiency, gasoline direct injection systems have emerged as a critical technology. Gasoline Direct Injection Device Market Insights support downsizing strategies without compromising performance, facilitate compliance with global emission standards, and align with evolving market trends toward sustainable mobility. Moreover, these systems contribute to lower operating costs over a vehicle’s lifetime and bolster overall engine health. Growing awareness of environmental regulations and the need for cleaner combustion have further amplified demand for direct injection technology in passenger cars, light commercial vehicles, and high-performance engines. Get more insights on,Gasoline Direct Injection Device Market

#Coherent Market Insights#Gasoline Direct Injection Device#Gasoline Direct Injection Device Market#Gasoline Direct Injection Device Market Insights#Solenoid Injectors

0 notes

Text

Upcoming Jaguar Models in Canada: 2025/2026 Lineup Preview

Jaguar has always epitomized luxury, performance, and quintessential craftsmanship. Besides, these cars have long been the object of affection among car enthusiasts worldwide. As the marque looks to the future, there's a thrilling evolution in store--a fusion of advanced technology with Jaguar's classic beauty. With a fresh emphasis on innovation, sustainability, and higher driving dynamics, the next-generation lineup is sure to break new ground without losing sight of the marque's heritage. Drivers in Canada can anticipate change, a fresh design language, and a transformation that embodies Jaguar's vision for a new age.

P250 R-Dynamic S Auto

Engine - Intercooled Turbo Premium Unleaded I-4 Displacement - 2.0 L/122 Fuel System - Gasoline Direct Injection Horsepower - 247 hp @ 5500 rpm Torque - 269 ft-lb @ 1300 rpm Steering - Power Steering Drivetrain - All-Wheel Drive Transmission - 8-Speed Automatic -inc: satin chrome gearshift paddles Smart Device Integration, Apple CarPlay, Android Auto, WiFi Hotspot, Bluetooth Connection

P400 R-Dynamic S Auto

Engine - Intercooled Turbo Gas/Electric I-6 Displacement - 3.0 L/183 Fuel System - Gasoline Direct Injection Horsepower - 395 hp @ 5500 rpm Torque - 406 ft-lb @ 2000 rpm Steering - Power Steering Drivetrain - All-Wheel Drive Transmission - 8-Speed Automatic -inc: satin chrome gearshift paddles Smart Device Integration, Apple CarPlay, Android Auto, WiFi Hotspot, Bluetooth Connection

P575 SVR 575 Edition Auto

Engine - Intercooled Supercharger Premium Unleaded V-8 Displacement - 5.0 L/305 Fuel System - Gasoline Direct Injection Horsepower - 575 hp @ 6250 rpm Torque - 516 ft-lb @ 3500 rpm Steering - Power Steering Drivetrain - All-Wheel Drive Transmission - 8-Speed Automatic -inc: satin chrome gearshift paddles Smart Device Integration Apple CarPlay Android Auto WiFi Hotspot Bluetooth Connection

Jaguar E-PACE

Command respect with Jaguar E-PACE's precisely sculpted design, where each refined touch tells of conviction and determination. Seamless connection is always with you -- experience technology that combines comfort with control.

You will also see that the Pivi Pro is your best friend and comes complete with a stately 11.4-inch curved touchscreen and intuitive voice command using Alexa. Systems updates are performed via software-over-the-air updates. Sync your digital world through wireless Apple CarPlay® and Android Auto™, and charge devices with the built-in wireless charging pad on the centre console.

Get access to important information without any distractions on the 12.3-inch Interactive Driver Display and Head-up Display, which can be personalized. Have clear rear views with the optional ClearSight interior rear-view mirror, providing a live video feed in the cabin. And with a classy interior space and practical cargo room, you can safely stow six cases when you fold down the rear seats--Jaguar E-PACE keeps all that you require conveniently at hand.

Upcoming 2025 Jaguar GT: What to Expect

The world of cars is abuzz with excitement as Jaguar gets ready to launch the eagerly anticipated 2025 Jaguar GT. The new model is going to revolutionize the world of luxury sports cars, and car fans can expect an incredible driving experience.

The 2025 Jaguar GT is shaped to capture the spirit of Jaguar's heritage in luxury and performance while incorporating innovative technology. Its sleek lines and aggressive stance reflect more than beauty; it recognizes both power and elegance. High-performance capabilities, luxury interior, and groundbreaking features come together to rewrite the rules for what you demand from a sports car.

PERFORMANCE AND TECHNOLOGY

With its high-performance engine choices and responsive handling, the Jaguar GT will be a showstopper. The 2025 Jaguar GT is expected to deliver heart-pounding acceleration and responsive handling as the world goes green with more eco-friendly automobiles. This car features the brand's electric car technology innovation. With breathtaking battery life and rapid charging, the Jaguar electric vehicle line is transforming, and the 2025 Jaguar GT will lead the way in this change. It will be fitted with state-of-the-art infotainment systems, driver aids, and connectivity options to meet the needs of modern-day drivers.

JAGUAR TYPE 00

This new Jaguar is here to erase the bland, to go bold, to copy nothing. Every element of Jaguar's new identity reflects this philosophy. Its signature is characterized by symmetry, simplicity, and statement -- the brand finds its inspiration in modernism, with the Jaguar Device Mark. It also reflects their newly imagined design philosophy. The vehicle seems to bridge the past and future--a timeless mark of excellence and forward motion. The Artist's Mark can be visualized as a fresh monogram created from the 'J' and 'r' at the extremities of the vehicle, which stands as an emblem of authenticity, balance, and creative vision. The vehicle is definitely not commonplace, but much isn't known about it. We will keep you informed.

PRICING AND AVAILABILITY

As anticipation mounts for the 2025 Jaguar GT's launch, prospective customers are keen to learn more about the Jaguar GT price. Although official pricing information has not been released, market analysts predict that the GT will be priced competitively in the luxury sports car market.

WHERE TO BUY THE 2025 JAGUAR GT FOR SALE

When the 2025 Jaguar GT officially becomes available, you can see it at local Jaguar dealerships, such as Jaguar London. Our dealership will have the newest models available, so you can view and drive this phenomenal car. If you are a loyal Jaguar fan or a new customer, our experienced staff will help you choose the ideal setup to suit your lifestyle.

Frequently Asked Questions

When is the expected release date for the Jaguar GT in Canada?

The Jaguar GT, the company's first all-electric four-door grand tourer, is expected to arrive in Canada in 2025, with customer deliveries set to begin in 2026. The model represents Jaguar's entry into a fully electric luxury lineup.

What is the anticipated price range for the 2025 Jaguar GT in the Canadian market?

The 2025 Jaguar GT should be competitively priced in Canada within the electric luxury grand tourer market. Although no formal pricing information is available, Jaguar hopes to align this model among other high-end electric cars in terms of being a strong performer, having stylish looks, and good technology.

Will there be a 2025 model year for the Jaguar E-Pace available in Canada?

Yes, the 2025 Jaguar E-PACE will be sold in Canada. The 2025 Jaguar E-PACE is set to arrive soon and dealerships such as Jaguar London and Jaguar Windsor will be ready to take delivery. To know if pre-orders are accepted, reach out to our showroom.

Are there any significant changes or updates expected for the new Jaguar E-Pace model?

Yes, the 2025 Jaguar E-PACE in Canada brings a few updates, including a new exterior design, a more upgraded interior, and technologies -- you might get a new infotainment system with a new touchscreen. The updates focus on improving the driving experience without compromising the model's hallmark luxury and performance.

Discover the new Jaguar today

The new Jaguar E-PACE combines performance, sophistication, and innovation in a compact SUV. With sophisticated styling, cutting-edge features, and a luxurious feel, it's the ideal start to the new Jaguar experience. The Jaguar E-PACE price points are competitive in the luxury market, and value is matched according to its industry standing and style. Ready to discover? Stop by a Jaguar dealership near me and feel the rush of driving a Jaguar for yourself.

1 note

·

View note

Text

0 notes

Text

Diesel Engine

Diesel Engine

Diesel engine, any internal-combustion engine in which air is compressed to a sufficiently high temperature to ignite diesel fuel injected into the cylinder, where combustion and expansion actuate a piston. It converts the chemical energy stored in the fuel into mechanical energy, which can be used to power freight trucks, large tractors, locomotives, and marine vessels. A limited number of automobiles also are diesel-powered, as are some electric-power generator sets.

Diesel combustion

four-stroke diesel engine

The typical sequence of cycle events in a four-stroke diesel engine involves a single intake valve, fuel-injection nozzle, and exhaust valve, as shown here. Injected fuel is ignited by its reaction to compressed hot air in the cylinder, a more efficient process than that of the spark-ignition internal-combustion engine.(more) The diesel engine is an intermittent-combustion piston-cylinder device. It operates on either a two-stroke or four-stroke cycle (see figure); however, unlike the spark-ignition gasoline engine, the diesel engine induces only air into the combustion chamber on its intake stroke. Diesel engines are typically constructed with compression ratios in the range 14:1 to 22:1. Both two-stroke and four-stroke engine designs can be found among engines with bores (cylinder diameters) less than 600 mm (24 inches). Engines with bores of greater than 600 mm are almost exclusively two-stroke cycle systems.

The diesel engine gains its energy by burning fuel injected or sprayed into the compressed, hot air charge within the cylinder. The air must be heated to a temperature greater than the temperature at which the injected fuel can ignite. Fuel sprayed into air that has a temperature higher than the “auto-ignition” temperature of the fuel spontaneously reacts with the oxygen in the air and burns. Air temperatures are typically in excess of 526 °C (979 °F); however, at engine start-up, supplemental heating of the cylinders is sometimes employed, since the temperature of the air within the cylinders is determined by both the engine’s compression ratio and its current operating temperature. Diesel engines are sometimes called compression-ignition engines because initiation of combustion relies on air heated by compression rather than on an electric spark.

In a diesel engine, fuel is introduced as the piston approaches the top dead centre of its stroke. The fuel is introduced under high pressure either into a precombustion chamber or directly into the piston-cylinder combustion chamber. With the exception of small, high-speed systems, diesel engines use direct injection.

Diesel engine fuel-injection systems are typically designed to provide injection pressures in the range of 7 to 70 megapascals (1,000 to 10,000 pounds per square inch). There are, however, a few higher-pressure systems.

Precise control of fuel injection is critical to the performance of a diesel engine. Since the entire combustion process is controlled by fuel injection, injection must begin at the correct piston position (i.e., crank angle). At first the fuel is burned in a nearly constant-volume process while the piston is near top dead centre. As the piston moves away from this position, fuel injection is continued, and the combustion process then appears as a nearly constant-pressure process.

The combustion process in a diesel engine is heterogeneous—that is, the fuel and air are not premixed prior to initiation of combustion. Consequently, rapid vaporization and mixing of fuel in air is very important to thorough burning of the injected fuel. This places much emphasis on injector nozzle design, especially in direct-injection engines.

Engine work is obtained during the power stroke. The power stroke includes both the constant-pressure process during combustion and the expansion of the hot products of combustion after fuel injection ceases.

Diesel engines are often turbocharged and aftercooled. Addition of a turbocharger and after cooler can enhance the performance of a diesel engine in terms of both power and efficiency.

The most outstanding feature of the diesel engine is its efficiency. By compressing air rather than using an air-fuel mixture, the diesel engine is not limited by the preignition problems that plague high-compression spark-ignition engines. Thus, higher compression ratios can be achieved with diesel engines than with the spark-ignition variety; commensurately, higher theoretical cycle efficiencies, when compared with the latter, can often be realized. It should be noted that for a given compression ratio the theoretical efficiency of the spark-ignition engine is greater than that of the compression-ignition engine; however, in practice it is possible to operate compression-ignition engines at compression ratios high enough to produce efficiencies greater than those attainable with spark-ignition systems. Furthermore, diesel engines do not rely on throttling the intake mixture to control power. As such, the idling and reduced-power efficiency of the diesel is far superior to that of the spark-ignition engine.

The principal drawback of diesel engines is their emission of air pollutants. These engines typically discharge high levels of particulate matter (soot), reactive nitrogen compounds (commonly designated NOx), and odour compared with spark-ignition engines. Consequently, in the small-engine category, consumer acceptance is low. A diesel engine is started by driving it from some external power source until conditions have been established under which the engine can run by its own power. The simplest starting method is to admit air from a high-pressure source—about 1.7 to nearly 2.4 megapascals—to each of the cylinders in turn on their normal firing stroke. The compressed air becomes heated sufficiently to ignite the fuel. Other starting methods involve auxiliary equipment and include admitting blasts of compressed air to an air-activated motor geared to rotate a large engine’s flywheel; supplying electric current to an electric starting motor, similarly geared to the engine flywheel; and applying a small gasoline engine geared to the engine flywheel. The selection of the most suitable starting method depends on the physical size of the engine to be started, the nature of the connected load, and whether or not the load can be disconnected during starting.

Major types of diesel engines

Three basic size groups

There are three basic size groups of diesel engines based on power—small, medium, and large. The small engines have power-output values of less than 188 kilowatts, or 252 horsepower. This is the most commonly produced diesel engine type. These engines are used in automobiles, light trucks, and some agricultural and construction applications and as small stationary electrical-power generators (such as those on pleasure craft) and as mechanical drives. They are typically direct-injection, in-line, four- or six-cylinder engines. Many are turbocharged with aftercoolers.

Medium engines have power capacities ranging from 188 to 750 kilowatts, or 252 to 1,006 horsepower. The majority of these engines are used in heavy-duty trucks. They are usually direct-injection, in-line, six-cylinder turbocharged and aftercooled engines. Some V-8 and V-12 engines also belong to this size group.

Large diesel engines have power ratings in excess of 750 kilowatts. These unique engines are used for marine, locomotive, and mechanical drive applications and for electrical-power generation. In most cases they are direct-injection, turbocharged and aftercooled systems. They may operate at as low as 500 revolutions per minute when reliability and durability are critical.

Two-stroke and four-stroke engines

As noted earlier, diesel engines are designed to operate on either the two- or four-stroke cycle. In the typical four-stroke-cycle engine, the intake and exhaust valves and the fuel-injection nozzle are located in the cylinder head (see figure). Often, dual valve arrangements—two intake and two exhaust valves—are employed. Use of the two-stroke cycle can eliminate the need for one or both valves in the engine design. Scavenging and intake air is usually provided through ports in the cylinder liner. Exhaust can be either through valves located in the cylinder head or through ports in the cylinder liner. Engine construction is simplified when using a port design instead of one requiring exhaust valves.

Fuel for diesels

Petroleum products normally used as fuel for diesel engines are distillates composed of heavy hydrocarbons, with at least 12 to 16 carbon atoms per molecule. These heavier distillates are taken from crude oil after the more volatile portions used in gasoline are removed. The boiling points of these heavier distillates range from 177 to 343 °C (351 to 649 °F). Thus, their evaporation temperature is much higher than that of gasoline, which has fewer carbon atoms per molecule. In the United States, specifications for diesel fuels are published by the American Society of Testing and Materials (ASTM). ASTM D975 “Standard Specification for Diesel Fuel Oils” covers specifications for five grades of diesel fuel oils:

Grade Low Sulfur No. 1-D—A special purpose, light distillate fuel for automotive diesel engines requiring low sulfur fuel and requiring higher volatility than that provided by Grade Low Sulfur No. 2-D. Grade Low Sulfur No.

2-D—A general-purpose, middle distillate fuel for automotive diesel engines requiring low sulfur fuel. It is also suitable for use in non-automotive applications, especially in conditions of varying speed and load.

Grade No. 1-D—A special purpose, light distillate fuel for automotive diesel engines in applications requiring higher volatility than that provided by

Grade No. 2-D fuels. Grade No. 2-D—A general-purpose, middle distillate fuel for automotive diesel engines, which is also suitable for use in non-automotive applications, especially in conditions of frequently varying speed and load.

Grade No. 4-D—A heavy distillate fuel, or a blend of distillate and residual oil, for low- and medium-speed diesel engines in non-automotive applications involving predominantly constant speed and load.

Water and sediment in fuels can be harmful to engine operation; clean fuel is essential to efficient injection systems. Fuels with a high carbon residue can be handled best by engines of low-speed rotation. The same applies to those with high ash and sulfur content. The cetane number, which defines the ignition quality of a fuel, is determined using ASTM D613 “Standard Test Method for Cetane Number of Diesel Fuel Oil.”

Development of diesel engines

Early work

Rudolf Diesel, a German engineer, conceived the idea for the engine that now bears his name after he had sought a device to increase the efficiency of the Otto engine (the first four-stroke-cycle engine, built by the 19th-century German engineer Nikolaus Otto). Diesel realized that the electric ignition process of the gasoline engine could be eliminated if, during the compression stroke of a piston-cylinder device, compression could heat air to a temperature higher than the auto-ignition temperature of a given fuel. Diesel proposed such a cycle in his patents of 1892 and 1893.

Originally, either powdered coal or liquid petroleum was proposed as fuel. Diesel saw powdered coal, a by-product of the Saar coal mines, as a readily available fuel. Compressed air was to be used to introduce coal dust into the engine cylinder; however, controlling the rate of coal injection was difficult, and, after the experimental engine was destroyed by an explosion, Diesel turned to liquid petroleum. He continued to introduce the fuel into the engine with compressed air.

The first commercial engine built on Diesel’s patents was installed in St. Louis, Mo., by Adolphus Busch, a brewer who had seen one on display at an exposition in Munich and had purchased a license from Diesel for the manufacture and sale of the engine in the United States and Canada. The engine operated successfully for years and was the forerunner of the Busch-Sulzer engine that powered many submarines of the U.S. Navy in World War I. Another diesel engine used for the same purpose was the Nelseco, built by the New London Ship and Engine Company in Groton, Conn.

The diesel engine became the primary power plant for submarines during World War I. It was not only economical in the use of fuel but also proved reliable under wartime conditions. Diesel fuel, less volatile than gasoline, was more safely stored and handled.

At the end of the war many men who had operated diesels were looking for peacetime jobs. Manufacturers began to adapt diesels for the peacetime economy. One modification was the development of the so-called semidiesel that operated on a two-stroke cycle at a lower compression pressure and made use of a hot bulb or tube to ignite the fuel charge. These changes resulted in an engine less expensive to build and maintain.

Fuel-injection technology

One objectionable feature of the full diesel was the necessity of a high-pressure, injection air compressor. Not only was energy required to drive the air compressor, but a refrigerating effect that delayed ignition occurred when the compressed air, typically at 6.9 megapascals (1,000 pounds per square inch), suddenly expanded into the cylinder, which was at a pressure of about 3.4 to 4 megapascals (493 to 580 pounds per square inch). Diesel had needed high-pressure air with which to introduce powdered coal into the cylinder; when liquid petroleum replaced powdered coal as fuel, a pump could be made to take the place of the high-pressure air compressor.

There were a number of ways in which a pump could be used. In England the Vickers Company used what was called the common-rail method, in which a battery of pumps maintained the fuel under pressure in a pipe running the length of the engine with leads to each cylinder. From this rail (or pipe) fuel-supply line, a series of injection valves admitted the fuel charge to each cylinder at the right point in its cycle. Another method employed cam-operated jerk, or plunger-type, pumps to deliver fuel under momentarily high pressure to the injection valve of each cylinder at the right time.

The elimination of the injection air compressor was a step in the right direction, but there was yet another problem to be solved: the engine exhaust contained an excessive amount of smoke, even at outputs well within the horsepower rating of the engine and even though there was enough air in the cylinder to burn the fuel charge without leaving a discoloured exhaust that normally indicated overload. Engineers finally realized that the problem was that the momentarily high-pressure injection air exploding into the engine cylinder had diffused the fuel charge more efficiently than the substitute mechanical fuel nozzles were able to do, with the result that without the air compressor the fuel had to search out the oxygen atoms to complete the combustion process, and, since oxygen makes up only 20 percent of the air, each atom of fuel had only one chance in five of encountering an atom of oxygen. The result was improper burning of the fuel.

The usual design of a fuel-injection nozzle introduced the fuel into the cylinder in the form of a cone spray, with the vapour radiating from the nozzle, rather than in a stream or jet. Very little could be done to diffuse the fuel more thoroughly. Improved mixing had to be accomplished by imparting additional motion to the air, most commonly by induction-produced air swirls or a radial movement of the air, called squish, or both, from the outer edge of the piston toward the centre. Various methods have been employed to create this swirl and squish. Best results are apparently obtained when the air swirl bears a definite relation to the fuel-injection rate. Efficient utilization of the air within the cylinder demands a rotational velocity that causes the entrapped air to move continuously from one spray to the next during the injection period, without extreme subsidence between cycles.

Price’s engine

In 1914 a young American engineer, William T. Price, began to experiment with an engine that would operate with a lower compression ratio than that of the diesel and at the same time would not require either hot bulbs or tubes. As soon as his experiments began to show promise, he applied for patents.

In Price’s engine the selected compression pressure of nearly 1.4 megapascals (203 pounds per square inch) did not provide a high enough temperature to ignite the fuel charge when starting. Ignition was accomplished by a fine wire coil in the combustion chamber. Nichrome wire was used for this because it could easily be heated to incandescence when an electric current was passed through it. The experimental engine had a single horizontal cylinder with a bore of 43 cm (17 inches) and a stroke (maximum piston movement) of 48 cm (19 inches) and operated at 257 revolutions per minute. Because the nichrome wire required frequent replacement, the compression pressure was raised to 2.4 megapascals (348 pounds per square inch), which did provide a temperature high enough for ignition when starting. Some of the fuel charge was injected before the end of the compression stroke in an effort to increase the cycle timing and to keep the nichrome wire glowing hot.

In the meantime many engines of the two-stroke-cycle, semidiesel type were being installed. Some were used to produce electricity for small municipalities, while others were installed in water-pumping plants. Many provided power for tugs, fishing boats, trawlers, and workboats.

In the early 1920s the General Electric Company suggested to the Ingersoll-Rand Company, for whom Price was working, that they cooperate in the building of a diesel-electric locomotive. At that time many of the locomotives in service were powered by gasoline engines. A diesel-electric locomotive with Price’s engine was completed in 1924 and placed in service for switching purposes in New York City. The success of this locomotive resulted in orders from railroads, factories, and open-pit mines. The engine used in most of these installations was a six-cylinder, 25-cm (10-inch) bore, 30-cm (12-inch) stroke system, rated 300 brake horsepower at 600 revolutions and weighing 6,800 kg (15,000 pounds).

Subsequent developments and applications

Many diesel engines were purchased for marine propulsion. The diesels, however, normally rotated faster than was desirable for the propellers of large ships because the high speeds of the huge propellers tended to create hollowed-out areas within the water around the propeller (cavitation), with resultant loss of thrust. The problem did not exist, however, with smaller propellers, and diesel engines proved especially suitable for yachts, in which speed is desired. The problem was solved by utilizing a diesel-electric installation in which the engines were connected to direct-current generators that furnished the electricity to drive an electric motor connected to the ship’s propeller. There were also many installations in which the diesel was connected either directly or through gears to the propeller. When diesel engines with larger horsepower and slower rotation speeds became available, they were installed in cargo and passenger ships.

The diesel engine became the predominant power plant for military equipment on the ground and at sea during World War II. Since then it has been adopted for use in heavy construction machinery, high-powered farm tractors, and most large trucks and buses. Diesel engines also have been installed in hospitals, telephone exchanges, airports, and various other facilities to provide emergency power during electrical power outages. In addition, they have been used in automobiles, albeit on a limited scale. Although diesels provide better fuel economy than gasoline engines, they do not run as smoothly as the latter and emit higher levels of pollutants.

A diesel engine is an internal-combustion engine where air is compressed to a high temperature, igniting diesel fuel injected into the cylinder, causing combustion and expansion to actuate a piston. This process converts the chemical energy in the fuel into mechanical energy, which powers freight trucks, large tractors, locomotives, marine vessels, and some electric-power generators. A limited number of automobiles also use diesel engines.

In a typical four-stroke diesel engine, there is a sequence involving an intake valve, fuel-injection nozzle, and exhaust valve. Fuel ignites upon reacting with compressed hot air in the cylinder, making this process more efficient than that of a spark-ignition engine. Diesel engines operate on either a two-stroke or four-stroke cycle and have compression ratios between 14:1 and 22:1. Engines with bores less than 600 mm can be either two-stroke or four-stroke, while those with larger bores are typically two-stroke systems.

Diesel engines gain energy by burning fuel injected into the compressed hot air in the cylinder. The air temperature must be higher than the fuel's auto-ignition temperature, which is usually above 526 °C (979 °F). At engine start-up, supplemental heating of the cylinders may be necessary. These engines are sometimes called compression-ignition engines because combustion relies on air heated by compression rather than an electric spark.

Fuel is introduced into the diesel engine as the piston approaches the top dead center of its stroke, under high pressure, either into a precombustion chamber or directly into the combustion chamber. Most diesel engines use direct injection. Fuel-injection systems typically provide pressures between 7 and 70 megapascals. Precise control of fuel injection is crucial for diesel engine performance, as it regulates the entire combustion process.

Combustion in a diesel engine is heterogeneous, meaning the fuel and air are not premixed. Rapid vaporization and mixing of fuel in air are critical for thorough combustion, emphasizing injector nozzle design. Engine work is obtained during the power stroke, which includes both the constant-pressure process during combustion and the expansion of combustion products after fuel injection stops.

Diesel engines are often turbocharged and aftercooled to enhance power and efficiency. They achieve higher compression ratios than spark-ignition engines, leading to greater theoretical cycle efficiencies. Diesel engines do not rely on throttling the intake mixture to control power, making them more efficient at idling and reduced power than spark-ignition engines.

However, diesel engines emit higher levels of pollutants, including particulate matter, nitrogen compounds (NOx), and odor, which limits their acceptance in the small-engine category.

Starting a diesel engine involves using an external power source until it can run by itself. Methods include high-pressure air admission to the cylinders, electric starting motors, or small gasoline engines geared to the engine flywheel.

Diesel engines are categorized into three size groups: small (less than 188 kW), medium (188-750 kW), and large (over 750 kW). Small engines are used in automobiles, light trucks, and some agricultural and construction applications. Medium engines power heavy-duty trucks and are usually six-cylinder turbocharged systems. Large engines are used for marine, locomotive, and mechanical drive applications, often operating at low speeds for reliability.

Diesel engines use petroleum distillates with high carbon atoms per molecule as fuel, with specifications provided by the American Society of Testing and Materials (ASTM). Clean fuel is essential for efficient injection systems, and the cetane number determines fuel ignition quality.

Rudolf Diesel, a German engineer, invented the diesel engine to increase the efficiency of the Otto engine. The first commercial diesel engine was installed in St. Louis, Mo., by Adolphus Busch. Diesel engines became the primary power plant for submarines during World War I and were adapted for peacetime use after the war. Developments in fuel-injection technology, such as cam-operated pumps and improved nozzle designs, enhanced diesel engine efficiency and reduced smoke emissions.

.

0 notes

Text

Understanding Manifolds inside the Oil and Gas Industry

In the complicated international of oil and gasoline exploration and production, manifold systems play an important position in facilitating the glide of fluids inside wellheads and production centers. These complicated systems are critical additives of the oil and gas infrastructure, serving numerous functions to make certain efficient operations and maximize manufacturing output.

In this article, we will delve into the concept of manifolds, their uses, and their significance in the oil and fuel company.

What is a Manifold?

A manifold, in the context of the oil and gas industry, refers to a gadget of interconnected pipes or channels designed to accumulate, distribute, and control the flow of fluids alongside crude oil, natural gas, and water inside a production facility. Manifolds are generally crafted from long lasting substances along with metallic or alloy, capable of withstanding immoderate pressures and corrosive environments normally encountered in oil and gas operations.

Uses of Manifolds inside the Oil and Gas Industry:

1. Wellhead Manifolds:

One of the number one programs of manifolds is on the wellhead, in which multiple manufacturing wells are interconnected to a major manifold system. Wellhead manifolds gather crude oil, natural gasoline, and other fluids constituted of personal wells and channel them to downstream processing centers or storage tanks. By consolidating the go with the flow from more than one wells, wellhead manifolds streamline production operations and reduce the need for large ground infrastructure.

2. Production Manifolds:

In large oil and gas fields, manufacturing manifolds are mounted at strategic places to gather and distribute fluids from multiple wellheads inside a designated location. These manifolds serve as primary hubs for managing the go together with the go with the flow of manufacturing fluids, permitting operators to manipulate and optimize production quotes primarily based totally on reservoir overall performance and market call for. Production manifolds might also additionally consist of valves, chokes, and instrumentation to modify the flow prices and monitor process parameters.

3. Injection Manifolds:

In higher oil recovery (EOR) operations, injection manifolds are employed to supply fluids which incorporate water, steam, or chemical components into reservoirs to decorate oil healing costs. These manifolds obtain injection fluids from surface centers and distribute them to injection wells strategically located at some stage in the world. Injection manifolds play an essential function in retaining reservoir stress, displacing oil toward production wells, and maximizing hydrocarbon extraction performance.

4. Separator Manifolds:

Separator manifolds are applied in downstream processing centers to gather and segregate manufacturing fluids into their respective levels, together with oil, gasoline, and water. These manifolds get hold of multiphase fluids from production separators and direct them to similarly processing devices for remedy, separation, and storage. Separator manifolds help optimize the separation manner, lower fluid managing fees, and make sure compliance with environmental recommendations.

Significance of Manifolds in the Oil and Gas Industry:

Manifolds are vital additives of oil and fuel production systems, supplying essential infrastructure for fluid coping with, distribution, and manipulation. Their strategic placement and robust layout permit operators to correctly control production operations, optimize reservoir overall performance, and maximize hydrocarbon restoration charges. By consolidating drift streams from more than one wells and directing them to processing facilities, manifolds contribute to the overall productiveness, profitability, and sustainability of oil and gas duties.

Manifolds play a pivotal function within the oil and gas business enterprise, serving as essential conduits for the float of production fluids from wellheads to processing facilities. Their flexible layout, coupled with advanced automation and control structures, permits operators to streamline manufacturing operations, beautify reservoir performance, and optimize useful resource utilization. As the oil and gasoline industry keeps evolving, manifolds will live vital additives of upstream and midstream infrastructure, helping the continuing quest for strength protection and sustainability.

0 notes

Text

By 2027 Gasoline Direct Injection (GDI) Device Market Worth US$ 14 Bn

By 2027 Gasoline Direct Injection (GDI) Device Market Worth US$ 14 Bn

The Gasoline Direct Injection (GDI) Device Market has been forecast based on volume (kilo tons) and value (US$ Mn) from 2020 to 2027. The report analyzes and forecasts the Gasoline Direct Injection (GDI) Device market at a global and regional level. The study includes drivers and restraints of this market. The study provides an analysis of the global Gasoline Direct Injection (GDI) Device Market…

View On WordPress

0 notes

Photo

Chapter 28: The Missing Pan

A03

Chapter 1: Pan meets a Wendy

· Chapter 2: Scars (Felix’s Story)

· Chapter 3: Day One

· Chapter 4: Revenge and Fireflies

· Chapter 5: Brighter than Stars

· Chapter 6: filler: The Tigress

· Chapter 7: Operation Spotless!

· Chapter 8: Operation Spotless: Reporters Down

· Chapter 9: A Dance with the Devil

· Chapter 10: filler: Felix and the Pancake

· Chapter 11: The Girl with Blue Eyes pt. 1

· Chapter 12: The Girl with Blue Eyes pt. 2

· Chapter 13: The Girl With Blue Eyes: Underground

· Chapter 14. Recovery

· Chapter 14.2 Recovery some more

· Chapter 15: Trapped

Chapter 16: Filth

Chapter 17: Fairydust pt. 1

Chapter 18: Fairydust pt. 2

Chapter 19: The Mystery of the Dead Nun pt. 3

Chapter 20: The Mystery of the Dead Nun pt. 2

Chapter 21: The Mystery of the Dead Nun pt. 3

Chapter 22: Reflections pt. 1

Chapter 23: Reflections pt. 2

Chapter 24: Closing

Chapter 25: Felix is helping Pan

Chapter 26: Temporary Fix

Chapter 27: The Search Begins

It was like a bizarre book club meeting, except there was no book and the meeting was held at Tink’s forest of a living room.

He had found Pan’s broken cellphone nearly three days ago, and hadn’t seen hide or hair of him since.

He was worried, especially as he saw less and less of Wendy roaming the town looking for him.

No, he wasn’t stalking her that would be creepy. He was just watching her from afar, usually behind buildings, in case Pan reappeared by her side.

He was worried about the little shit, even if he’d rather not think about him and what they were—or rather what they had been.

Their relationship was on Pan’s terms, as it had been the night August returned to Storybrooke two years ago.

It had been just a glitch on their timeline, a moment in history that would go unrecorded.

He had returned to Storybrooke after the money he pawned from several of his father’s tools ran out.

He was tired and sore, not sure whether he was back to ask for forgiveness or to take more from his loving father. His motorcycle was nearly out of gas, his tires shreds of rubber attached to rims.

He hadn’t realized the clusterfuck he’d road in on. That Storybrooke was practically on lockdown after Jekyll killed those two girls—and nearly a third, he’d find out later.

And—for his own sanity—Pan was waiting at the town line for the psychopath to return, with the blunt end of his camera at that.

As his head was spinning from being clabbered over the head from the hit, Pan had kicked him onto his back.

“Shit,” he had said. “You’re not him.”

“Lucky for me,” August deadpanned, wobbling as he picked himself up. “Want to explain why the hell you did that?”

“Monster hunting,” Pan had stated, staring at him suspiciously, offering him no assistance.

It was close to 3 a.m., a completely unreasonable hour for anyone to be running around—travelers or off-their-knocker journalists.

“Yeah,” August muttered, grabbing his bike and preparing to head into the town.

“Everything’s closed,” Pan said. “You’re better off sleeping in the woods.”

It was none of the little shit’s business. In fact it was probably best if he kept his entire being to himself. For he knew his father had taken out a report to the police.

“I’ll be fine,” he said. “Thanks for not giving me a concussion.”

“You might as well come back with me.”

The weight of those words still clung to August’s brain this very day.

That brutal, flirtatious, broken boy…

“What’s this about?

August looked up. Tink, Felix and Lily Tigress were surrounding him, trying to figure as much as he was what the hell was going on.

August stood, feeling the mix of emotions from the people in the room.

“Pan’s missing.” He said, simply.

The reactions that followed fit everyone perfectly.

Tinkerbell scoffed and rolled her eyes while Felix seemed to melt with fear. Tigress snorted.

“Have you checked all the holes in the city?” she teased.

“And ditches,” he replied humorlessly. “He’s not anywhere.”

“Maybe check in the depths of hell.” Tink muttered, flopping down on her couch.

“What happened,” Felix inquired, obviously the only other person in the room that had general concern.

“I have no idea,” August sighed.

“It’s probably nothing!” Tink exclaimed, visibly aggravated. “He’s always pulling shit like this, we all know it!” she looked around at everyone, their eyes dropping .

“I don’t know this time—” August began before Tink cut him off.

“He’s fine! He’s off screwing someone or ruining a life. He’ll come back and continue as normal.”

August blinked hard and reached into his pocket. In a flash he threw Pan’s broken, dead cellphone onto Tink’s coffee table, an inch away from Tigress’s boots.

The occupants of the room stared at the device like it was something that had just fallen from the sky, as if they had no idea what to make of it.

“I found this the other night at the docks,” August explained, swallowing a lump. “I’ve been looking for him ever since. It died a few hours after I found it.”

Felix gripped his kneecaps until his fingers turned white. Tigress glanced at him and then at Tink’s still shoulders, wishing she could reach into her back and unknot every single one of her muscles.

“It could be an accident,” Tink said, her mind numb.

“There’s something wrong here, Tink,” August said. “Something I don’t think we’ve dealt with before.”

Tink nodded slightly. She could accept that this was a bit odd, but she wasn’t ready to relent to a search just yet.

“Did you go through the phone, see who he called last?” Felix inquired.

A cold sweat ran down August’s back.

“Yeah…it…it was me,” he looked straight ahead, trying to avoid Tink’s direct gaze. “The night he wrote that story about you.”

Tink barely moved, the only indication that she heard August was the darkening of her pupils.

“Last time I saw him was the morning after that when Wendy showed up and…all the other stuff happened.”

“Have you talked to her?” Tigress asked. “Why isn’t she here?”

August thought about the blonde enigma who spent the better part of two days searching for the wild boy…

And then she stopped…

Not from falling into a fate like Pan’s, but rather a strange dark haired man seemed to be gypsying her away from her task.

Maybe she had the same mindset as Tink, that Pan was somewhere safe and sound but avoiding the rest of the world.

Or perhaps she’d finally realized she deserved to use her time the way she wanted and not focus so much on Pan.

When he’d see her in town, her gaze would occasionally stray to the streets and into shops, looking for him without trying.

But she wasn’t alone. There was someone else with her, some dark entity that always seemed to be just out of both their line of site.

“She’s looking for him,” August concluded.

“Have you gone to Graham?”

“No, not yet,” he admitted.

Tink smiled bitterly. “There’s your answer,”

August leaned forward. “Do you really think Graham is going to take this seriously with Pan’s track record?”

“That’s the best thing to do!” Tink yelled. “He’s not our problem.”

“Yeah, he is,”

“No he’s fucking not! We have nothing to do with any of this!”

“Yeah we do!”

“He’s your little fuck buddy not mine!”

A wave of sand coursed through August’s throat, cutting him off.

“Okay, that’s enough!” Felix finally jumped in, evenly meeting Tink’s glare. “He’s right, we have to help.”

“Are you kidding me, Felix!” Tink exploded.

“What he did was terrible,” Felix injected, putting everything everyone in the room had held in for days now. “But if you turn your back on him and something really is wrong, you’ll regret it for the rest of your life. Because he is family, Tink. He’s one of us.”

He stepped forward, keeping his distance after taking her stiff posture into account.

“And you know he didn’t do any of this to hurt you, even if he did,”

Tink scoffed. “I know that. But I’m so sick of him thinking rules don’t apply to him and that he’s invincible,” she paced a bit, thinking about the wild-haired boy to always brought so much chaos into their lives. Who was more trouble than any of them knew what to do with.

“What if he’d been alone that night?” She wondered aloud, knowing firsthand the type of cruelty Mother Superior could enact when pushed too far.

Pan was in trouble, and this time it was more serious than ever of them had ever seen before.

He was usually good at getting himself out of messes and suffering the consequences on his own. But things were different this time. This time he was somewhere none of them could find.

Tink groaned, tucking her anger away for later.

“When was the last day you talked to Wendy?” she sighed in August’s direction.

His lip twitched in gratification. “The day she told me Pan was missing.”

“Then Lily and I will check with her first.” Tink said, voice strong with leadership. “You and Felix check the paper and Graham and all his usual haunts.”

Before Felix could ask for more, Tink was out the door.

Lily gave the men a shrug before following her friend, not looking to cause a fight with the fiery blonde.

Felix sighed in relief when they finally left, trying his best to stay calm. Last thing he needed was to fall into a seizure.

“That takes care of that,” August teased. “You ready?”

Felix looked over at him, frowning heavily. He had no feeling for August, good or bad. The two didn’t see or speak to each other than the few times he left Pan’s place.

He wasn’t a bad person from what Felix could gather, but he wasn’t the best influence on Pan. He was too casual, not interested in settling down.

Adding gasoline to the fire of Pan’s soul.

Still, obviously he cared about him enough that he cared if he was missing or not, so some points were warranted.

“We’ll need to start with Graham first,”

“Why’s that?”

Felix frowned. “I might know the reason he’s missing.”

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

Pan wasn’t sure where to target his latest wave of sickness from.

The swaying ship, the dehydration, or the infection building around his numb wrists from the metal cuffs?

He was more than certain he was developing some kind of bladder infection as well.

God he was tired.

Jones hadn’t been to see him in a day and a half, or at least that’s what he was estimating judging by the light that was coming in thorough the cracks of the ship.

He wondered what he was doing, especially to Wendy. Had he hurt her? Was he torturing her right now to get information out of her?

What did this asshole hope to accomplish keeping him locked up? Why didn’t he just off him already?

Or maybe this was it. Maybe he just wanted to kill him slowly.

As he nodded in and out of consciousness, he caught images of the people in his life. Wendy and Felix up front, Tink, August, and Tigress just behind them. Even Glass and Gold, and deeper in the shadows, Belle.

Each time he woke up, they would vanish, and Pan wouldn’t remember who he was dreaming about.

The smell of salt was enough to make him vomit now. He was dying, and he was doing so cruelly slow.

Would any of the people he kept seeing in that place between sleep and awake ever know what had happened to him.

Was anyone looking for him?

-.-.-.-.-.-.-.-.-.-.-.-.-.-.-.-

The last few days had become sort of a new routine for Wendy. She’d leave her apartment at the crack of dawn and visit Pan’s apartment…knocking just in case he’d come home.

But he hadn’t, and she’d let herself in and feed his fuzzy orange cat who had yet to be utterly concern about his master’s disappearance.

It was comforting feeding the large cat without Pan’s interference, she thought. No one to pick fun at her at every opportunity. No one to push her into a corner, away from her safest places.

No one to pick fun at her at every opportunity. No one to push her into a corner, away from her safest places.

It was unsettling, Pan’s absence. But there was an odd peace in the air. One that didn’t quite fit in Storybrooke’s atmosphere, but one that was welcome. If only for a short time.

Each day without the wild boy was like a blurry vacation: you knew each day was passing by but the details were unclear.

And somehow Pan was blurring from her memory as well.

She’d wake up in the dead of night with a glimpse of him in the air above her head.

Then he’d disappear, and she’d fall asleep without concern.

It felt wrong, to brush him off after all they’d been through, even in her sleep.

But there was an odd freedom to letting him go, especially if he didn’t want to be found.

She stared at the number on her cell phone glaring back at her, the one she’d called constantly in the last four days.

He doesn’t want to be found, she reminded herself. Calling him again would be fruitless.

She knew this, it was imbedded in her brain at this point.

Yet she pressed his number again and listened as his voice mail immediately came up.

It’s Pan. Call me back.

No, she decided solemnly, she wouldn’t.

“Hi, Pan…it’s…it’s me again.” Wendy chuckled. “I guess you know that by now…”

She paused, knowing if she were quiet for too long she’d have to start over.

She didn’t want to start over. She wanted to go forward.

“Look,” she sighed. “I can’t keep doing this with you. Everyday it’s a fight with you and I have no idea why. I don’t know what I did the other day to make you leave like that…but you need…”

She paused again.

“Well I don’t know what you need o honestly, but it’s something you have to figure out for yourself.”

She considered hanging up then, but she didn’t want to leave him on such a harsh note.

“I really hope you try, Pan, because I don’t want to fight with you anymore. After everything, I really want us to be—“

The voicemail beeped, inquiring if she wanted to start over or if she was satisfied with her message.

She didn’t want to start over.

So she hung up and headed to the docks.

Killian was there, as he always seemed to be.

Perhaps it was her need for new freedom that silenced the warning bells in her head, that made her drop the walls and inhibitions that had clung to her like a second skin during the last several months.

She approached him without fear, without any type of concern holding her back.

And she didn’t question him when he slid a manila folder into his leather coat.

“Is dinner still on the table?” she questioned.

He tilted his head, amused, though his pulse was racing. “I thought lunch was the next step.”

Wendy shrugged, stepping a bit closer. “I’m feeling…braver than I did yesterday.”

He chuckled, concealing the folder further into his jacket for dear life. “Well then, Miss Wendy Darling, tomorrow night?”

She smiled, relieved. “I’d like that.”

He watched her leave, noting the little pep in her step.

Such a lovely girl, he thought, and more malleable than he had originally foreseen. Jones thought he was going to have to push her more to fall into his grip, but it would seem she was finally crumbling.

He made his way back to this ship quickly, opening the folder full of information for his backup plan.

He stepped into his cabin, breaking out his best rum. This was a small victory after all.

Some of the glasses on his counter shook lightly, so little they could almost be missed. Jones rolled his eyes. He’d forgotten to feed his captive again…and water him for that matter.

Whoops.

He still hadn’t told him why he’d requested those files, what he was digging for.

Who he was searching for.

And how Miss Darling was involved was still being revealed, but time was running short.

He had been given orders to find out now.

He spread his new leverage across the table, frowning a bit.

The two boys, preteens by the look of it, caught his eye first. He hated targeting kids. It was so pointless.

His eyes traveled to the woman next. He could see bits of Wendy in her, especially in the shape of her eyes. She had the man’s jaw however…and his frown, he noticed with amusement.

A tidy little family in danger of meeting the blunt end of his gun.

Hopefully it wouldn’t come to that, he decided as he hid the folder. Hopefully, very soon, Wendy would tell him what he wanted to know.

The pipes sang from Pan’s struggle again.

He was already a dead man walking, and too tight-lipped to save now.

Feeding time.

18 notes

·

View notes

Text

What is a Diesel Auto Power Injector?

Diesel Auto Power Injector (DAPI) is a kind of fuel injection system for diesel vehicles. It consists of an injection pump, injectors, fuel supply pipes and other components. The injector is a device designed to deliver an accurately measured quantity of fuel into the combustion process.

Injectors are used in diesel engines to deliver the correct amount of fuel to the engine's combustion chamber at every moment. Diesel auto power injector uses high pressure injection to force liquid diesel into the combustion chamber.

Diesel auto power injector works on principles similar to those used in gasoline engines. It has an injector nozzle that sprays liquid fuel into the engine cylinder via a high-pressure fuel line connected to the intake manifold. This creates enough pressure in the cylinder so that it can accept more air than necessary for combustion without creating excess pressure that would cause damage or excessive wear inside the engine chamber walls (valves, pistons).

Why is a Diesel Auto Power Injector Important for my Vehicle?

Diesel auto power injector is the latest innovation in the auto industry. It is a type of fuel injected system. Diesel auto power injectors are used in diesel and gasoline engine vehicles.

The best quality Diesel auto power injectors for automobiles can be purchased from Source Automotive website.

These injectors are an essential part of any diesel engine. They are used to inject fuel into the combustion chamber, where it can be ignited by spark plugs to produce energy for your vehicle. Diesel auto power injectors are available in a variety of sizes and types, which can be customized to meet the needs of your specific engine.

What are the Different Types of Diesel Auto Power Injectors Available?

Diesel auto power injectors come in a variety of styles, but they all function in the same way: They spray fuel directly into the combustion chamber, causing it to ignite and produce energy for your car or truck.

Different types of Diesel auto power injectors include:

· Common rail injectors

· Piston injectors

· Unit Injectors

The Diesel auto power injector is a very small component in your engine, but it’s an important one. Its job is to mix fuel with air and direct it into the combustion chamber where it can be ignited by spark plugs. Without a working set of injectors, your car or truck simply won’t run. The exact location of your Diesel auto power injectors will depend on your vehicle’s make and model. But in general, they are located near the engine block, where they can be easily accessed by the fuel system.

0 notes

Text

TECHRON D CONCENTRATE – READ THIS IF YOU LOVE YOUR DIESEL ENGINE!

An ultra-high-performance fuel system cleaner, Techron® D Concentrate, Diesel Fuel System Cleaner is designed for one-tank cleanup and can be used in all diesel passenger cars- including SUVs, PPVs pickup trucks & mini-van engines.

One 591ml bottle of Techron D Concentrate, Diesel Fuel System Cleaner treats up to 80 liters of diesel fuel for every 10,000 km, however, it is not recommended for gasoline engines.

A few things to note about Techron D Concentrate, Diesel Fuel System Cleaner is that it will not harm after-treatment devices such as Diesel Particulate Filters (DPFs) and it always complies with the US federal low-sulphur content requirements for use in diesel motor vehicles. This ultra-high-performance fuel system cleaner is effective in petroleum diesel as well as biodiesel blended diesel fuels.

It helps restore lost engine power, improve engine responsiveness, drivability, and engine noise reduction as well as maximizes fuel economy by restoring dirty fuel injectors to like-new condition.

What makes Techron D Concentrate, Diesel Fuel System Cleaner stand out is that it is uniquely designed to be a one-tank cleanup solution that will clean diesel injectors and keep them performing like new. It can be used with petroleum diesel fuels, including ultra-low sulphur diesel, biodiesel, and bio-diesel blended diesel fuel. It also helps in the removal of the natural buildup of carbon deposits throughout the entire fuel system. Also, it helps clean internal diesel injector deposits (IDID), and indirect injection (IDI) and high-speed direct injection (HSDI) nozzle-cooking deposits. At the same time, it offers a cetane boost, improving combustion for reduced emissions and improved cold starting as well as preventing fuel injector sticking and failure.

This powerful patented formulation offers superior deposit cleanup, control, and engine protection. Its advanced chemistry promotes the efficient removal of harmful nozzle deposits as well as internal diesel injector deposits (IDID). It is effective in both older engines and the latest generation common-rail diesel engines and offers highly effective performance when used with petroleum diesel or biodiesel blended diesel fuels.

1 note

·

View note

Text

Intelligent Electrochemical Sensors Market to Perceive Substantial Growth during 2031

Intelligent Electrochemical Sensors Market:

Intelligent electrochemical sensors are devices that give information about the composition of a system in real time by linking a chemically selective layer to an electrochemical transducer.

Manufacturing of intelligent electrochemical sensors in terms of geometry, physical size, and selection of various components depends on its use.

Intelligent electrochemical sensors market are mainly divided into three types: potentiometric, conductometric, and amperometric/voltammetric. The sensor has capability to produce electronic output in digital signal. The reaction found in these sensors are due to the interaction between electrical and chemical signals, which are based on the potentiometric, conductometric, and amperometric measurements.

An intelligent electrochemical sensor is a compact system that collects the sensing signal through conducting wires to provide a reliable and stable measurement function over a long period of time. The sensors are used in various end-use industries such as healthcare, oil & gas, food & beverage, biotechnology, and chemicals.

Get PDF brochure for Industrial Insights and business Intelligence @ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=68669

Rise in Demand for Intelligent Electrochemical Sensors in Petroleum and Healthcare Industry

One of the major driving factors of the global intelligent electrochemical sensors market is increasing adoption of intelligent electrochemical sensors in the oil & gas industry. In the oil & gas sector, the sensors are used in various applications such as detection of toxic gas, measuring temperature, pressure measurement, and volume percent measurement. Intelligent electrochemical sensors are capable of measuring multiple processes.

Additionally, they offer low detection limits, fast response, comprehensive self-diagnosis options, and optimized selectivity. Intelligent electrochemical sensors are rapidly adopted in the oil & gas industry owing to these features and the adoption rate of the sensors is anticipated to further rise during the forecast period.

In the healthcare industry, intelligent electrochemical sensors are used in various applications such as in analysis of biological samples, forensic drugs analysis, and bacterial growth analysis.

Moreover, the sensors are also used in the chemical industry for analysis of various chemicals. Thus, intelligent electrochemical sensors are being increasingly used in healthcare as well as the chemical industry, which is anticipated to be one of the key factors driving the market in the near future.

North America to Lead the Global Intelligent Electrochemical Sensors Market

In terms of region, the global intelligent electrochemical sensors market can be divided into North America, Europe, Asia Pacific, Middle East & Africa, and South America.

North America has the largest market share owing to the growing adoption of direct gasoline injection and turbocharged engines in the automotive industry. Furthermore, the high concentration of market players in the region and the availability of proficient technical expertise is also boosting market growth.

The market in Asia Pacific is expected to register the fastest growth due to the growing healthcare and life sciences sector, and automotive industries in the region.

Moreover, increasing awareness about health issues coupled with an expanding population in China and India are driving the growth of the global intelligent electrochemical sensors market.

Get COVID-19 Analysis @ https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=68669

Key Players in the Global Intelligent Electrochemical Sensors Market

ABB

AlphaSense Inc.

City Technology Ltd.

Dynament

Figaro Engineering Inc.

Membrapor

Nemoto & Co. Ltd.

Robert Bosch LLC

Siemens

GfG Gas Detection UK Ltd.

FLIR Systems, Inc.

Global Intelligent Electrochemical Sensors Market, Research Scope

Global Intelligent Electrochemical Sensors Market, by Type

Potentiometric

Conductometric

Amperometric

Global Intelligent Electrochemical Sensors Market, by End-use Industry

Oil & Gas

Food & Beverages

Healthcare & Pharmaceuticals

Chemical

Biotechnology

Others

Enquiry Before Buying: https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=68669

About Us

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyse information. Now avail flexible Research Subscriptions, and access Research multi-format through downloadable databooks, infographics, charts, interactive playbook for data visualization and full reports through MarketNgage, the unified market intelligence engine. Sign Up for a 7 day free trial!

Contact

Transparency Market Research

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Blog: https://tmrblog.com/

Follow Us: Twitter | LinkedIn

0 notes

Text

Automotive Pump Market to Grow at a CAGR of 6.56% During the Forecast Period

Increasing demand for automatic transmission is driving the growth in global automotive pump market in the forecast period, 2022-2026

According to TechSci Research report, “Automotive Pump Market - Global Industry Size, Share, Trends, Competition, Opportunity, and Forecast, 2016-2026”, The global automotive pump market stood at USD79.35 billion in 2020 and is expected to grow at a steady CAGR of 6.56% during the forecast period on account of rising demand for automatic transmission and growing vehicle fleet.

An automotive pump is a device installed in automobiles for transmitting fluids (liquid or gas) by decreasing or increasing the pressure on fluids. Depending upon the fluid the pump is transmitting and the application of pump, various types of pumps are installed in an automobile like the fuel pump which draws fuel out of the tank through a pipe to the carburetor through a fine grain filter. The global automotive pump market is driven by the growing vehicle usage worldwide, lined with the increasing research and development to produce fuel-efficient automobiles that adhere to emission regulations. Major automotive manufacturers are investing heavily in making state-of-the-art automotive components by integrating smart technologies such as automatic transmission, gasoline direct injection, and gasoline turbocharger, which require automotive pumps for optimum functioning. Manual transmission runs of clutch, while the automatic transmission runs on torque convertor which works on the concept of fluid coupling. For fluid coupling to happen, the required amount of fluid needs to be delivered inside the torque convertor, which is done with the aid of an automotive pump called the transmission pump. The increasing penetration of automatic transmission in vehicles across the world is driving the sales of transmission pumps, which is airing the global automotive pump market growth. Automotive pumps are critical components of an automobile and need to be replaced when needed. The inappropriate working of an automotive pump can lead to 100% engine failure. Oil pump works as the heart of the lubrication system of automobiles. The oil pump draws oil from the oil pan and forces oil around the engine before the oil drops back into the sump and is recirculated back. Working of the oil pump is highly critical for the engine, the misfunctioning of an oil pump can lead to expensive engine failure. As a result, the global automotive pump market is getting a fair share from the aftermarket. But the development in innovative technologies is expected to reduce the replacement ratio of the automotive pumps, which is anticipated to hamper the aftermarket growth of the global automotive pump market.

Browse over 187 market data Figures and spread through 110 Pages and an in-depth TOC on "Global Automotive Pump Market"

https://www.techsciresearch.com/report/automotive-pumps-market/2333.html

Global automotive pump market can be segmented based on by pump type, by technology, by sales channel, by vehicle type, by displacement type and by region.

In terms of pump type, global automotive pump market is segmented into transmission pump, fuel pump, oil pump, steering pump, water pump, windshield washer pump, vacuum pump with majority of market share is taken by the oil pump followed by water pump in year 2020. The oil pump is used for engine lubrication to reduce the wear and tear of an engine and water pumps for cooling the engine. In addition to that, by region, globally the automotive pump market is segmented into Asia Pacific, North America, Europe, South America, Middle East and Africa. Majority of demand for the automotive pumps comes from Asia Pacific and North America, making them leaders of the mainstream market.

The sales of automotive pumps declined in 2020 compared to 2019 as most of the countries across the globe experienced strict lockdown in the second and third quarter of year 2020 as a measure to contain the spread of the COVID-19 virus. The imposition of lockdown across majority of countries resulted in the temporary closing down of all factories, including automotive pump manufacturing facilities, resulting in production loss for global automotive pump market. Furthermore, the governments of most of the COVID-19 affected countries infused norms such as social distancing to limit the number of workers working in at any given point in the same facility. Measures such as lockdown and social distancing hampered the workflow of automotive pump manufacturing facilities temporarily. Nevertheless, in the first quarters of 2021 the market is showing positive signs of recovery and is anticipated to recover by around 2023.

Key players in the automotive pump market include :

Aisin Group

Robert Bosch GmbH

DENSO Corporation

ZF Friedrichshafen AG

Continental AG

Rheinmetall AG

Hitachi Ltd.

BorgWarner Inc.

Johnson Electric Holdings Limited

SHW AG

Global automotive pump is fragmented with a lot of well-established players having presence in several countries and Aisin Group holds the highest market share and is among the top five market players globally, Robert Bosch GmbH ranks second in terms of market share in the overall automotive pump market on account of strong presence worldwide even in the emerging countries. Additionally, there are other prominent players such as Denso Corporation, ZF Friedrichshafen AG, Continental AG, Rheinmetall AG, Hitachi, Ltd., BorgWarner Inc., Johnson Electric Holdings Limited, SHW AG, which are holding a significant position in the global automotive pump market.

Download Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=2333

Customers can also request for 10% free customization on this report.

“Asia Pacific is anticipated to hold the largest revenue shares of the market in the upcoming years on the account of largest automobile fleet across the globe. However, North America is giving neck to neck competition. Moreover, increasing installations of automatic transmissions in automobiles is boosting demand for automotive pumps globally. Furthermore, the market's growth is being aided by the quick research and development in the field. Emerging market players are suggested to invest and focus on the research and development of the automotive pumps for the brand establishment. Collaborations and regulated deals with the established market players would help the prospects of the new market player,” said Mr. Karan Chechi, Research Director with TechSci Research, a research based Global management consulting firm.

“Automotive Pump Market - Global Industry Size, Share, Trends, Competition, Opportunity and Forecast, 2016-2026, Segmented By Pump Type (Transmission Pump, Fuel Pump, Oil Pump, Steering Pump, Water Pump, Windshield Washer Pump, Vacuum Pump), By Technology (Mechanical Pump, Electrical Pump), By Sales Channel (OEM, Aftermarket), By Vehicle Type (Passenger Car, Light Commercial Vehicle, Medium & Heavy Commercial Vehicle), By Displacement Type (Fixed Displacement, Variable Displacement), By Region”, has evaluated the future growth potential of global automotive pump market and provides statistics & information on market size, structure and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides, the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in global automotive pump market.

Press Release : https://www.techsciresearch.com/news/6879-automotive-pump-market.html

Contact

Mr. Ken Mathews

708 Third Avenue,

Manhattan, NY,

New York – 10017

Tel: +1-646-360-1656

Email: [email protected]

Web: https://www.techsciresearch.com

0 notes

Text

How I Got Trigger Finger and What I Did to Treat It

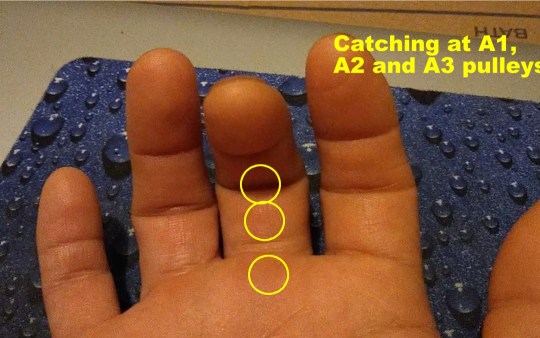

In my case, I have trigger finger in the middle and ring fingers of my right hand, mostly in the A1 and A2 pulley, and less in the A3, with the middle finger being more problematic. Pain is most pronounced in the middle of the night and upon waking, then gets better rather quickly in my case, in the first waking hour of the day. This is because as you sleep, there is less movement of the joints and less synovium produced, causing them to be stiffer.

I have the classic symptom where there is locking of those fingers when I move them from the natural, half-open relaxed hand to fully extending the fingers. As I force them past the locked angle, they snap at the A1 and A2 pulleys, then straighten out. It’s momentarily painful, but tolerable. But for some people, it’s a lot worse. All those weeks of sustained power gripping and twisting caused the flexor tendons and synovium to rub excessively against the ligaments holding them in place, causing microtears and initiating the inflammatory response.

TREATMENT FOR TRIGGER FINGER

The medical standard of care for trigger finger is corticosteroid injection below the affected ligament. This quickly knocks down the inflammation, and in some cases, symptomatic improvement happens within seconds. However, some patients report pain following the injection, and slower or no results.

Splinting is sometimes attempted. The idea is that if you immobilize the tendon, inflammation will stop and the tendon will shrink and heal, bringing things back to normal. However, this is not always the case. Sometimes inflammation takes a life of its own, and prolongs long after the injurious event ceases.

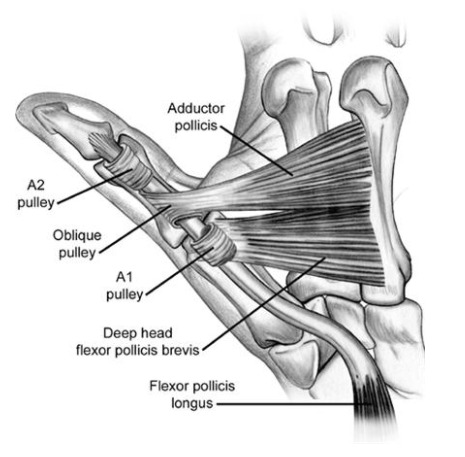

If neither corticosteroid injection nor finger splinting fail to correct the problem, surgery is an option. Direct, open surgery and percutaneous (minimal incision, special surgical tools) surgery are the two options, with direct surgery usually having better results. This is where the ligament is cut to provide more room for the tendon to move. This is possible because the adjacent ligament serves as a backup; for example, the A2 can back up A1 if A1 needs to be cut/ split apart. However, as you can imagine such destruction of a functional component means some strength and stability are sacrificed. I’m sure those having this kind of surgery lose some power in their grip.

MY TREATMENT STRATEGY

As I write this article, my trigger fingers have improved about 75%, from their worst presentation. It could be that my connective tissues are in pretty good shape; my healing capacity is strong; my injury was not very severe; or my treatment regimen is helping accelerate healing. Some sufferers don’t see such a quick pace of resolution.

Here is what I’m doing: as I mentioned, the symptoms are most pronounced in the middle of the night (when I get up to use the bathroom) and upon waking. In the middle of the night, I simply don’t move my fingers, and go back to sleep.

In the morning, I run cold water over my hand for 2 minutes, and gently move my fingers. I get the snapping, but it dissipates shortly after. I still feel some stiffness and soreness in my knuckles throughout the day, but no snapping.

I get localized cryotherapy done on my fingers. Cryotherapy is extremely cold air, as in sub-zero, for 3 minutes. The cold not only slows inflammation, it is said to cause a shock to the sensory nerves, which causes the central nervous system to respond by increasing blood flow, fibroblast activity, and nutrients to the area.

Note: the image above is a localized cryotherapy session on my hand, for a previous complaint. The red dot is not red light therapy; it is a laser thermometer the technician uses to measure my skin temperature so that it doesn’t too low (his hand is visible in the picture). Localized cryotherapy can reach temperatures of -30 degrees F.