#Gravure printing press

Explore tagged Tumblr posts

Text

Milestone Monday

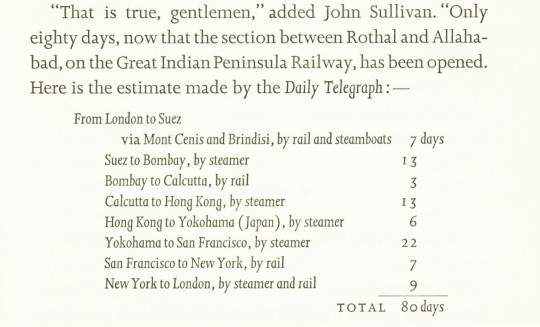

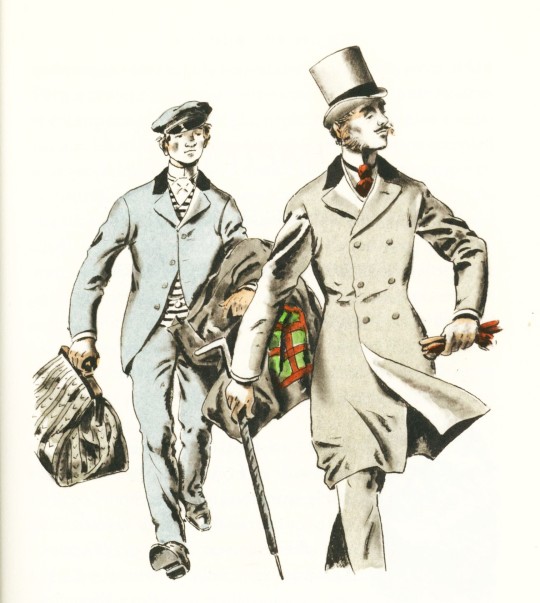

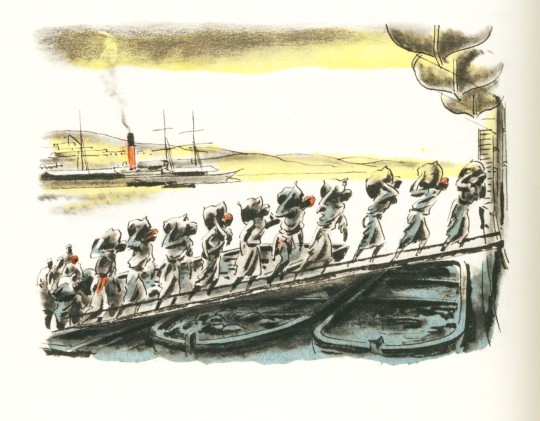

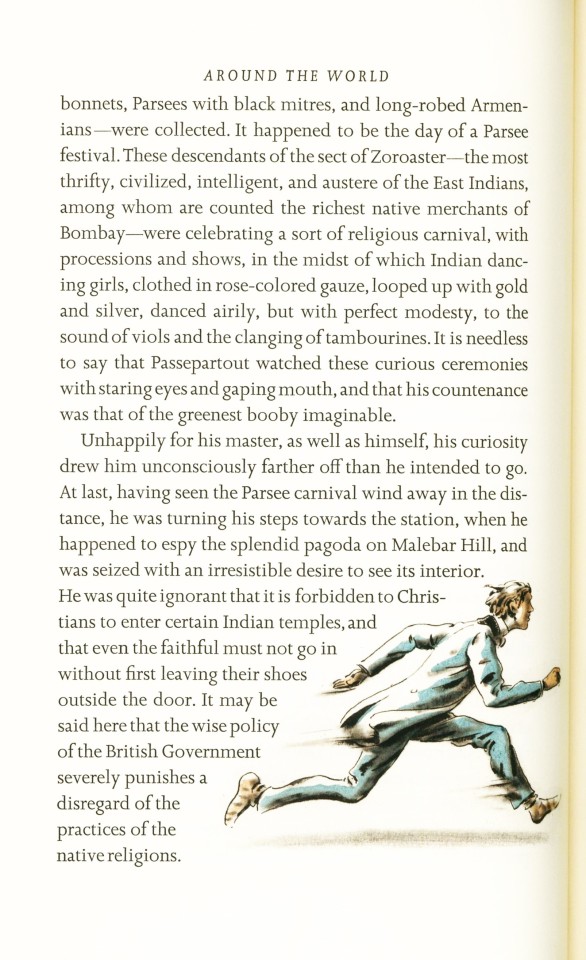

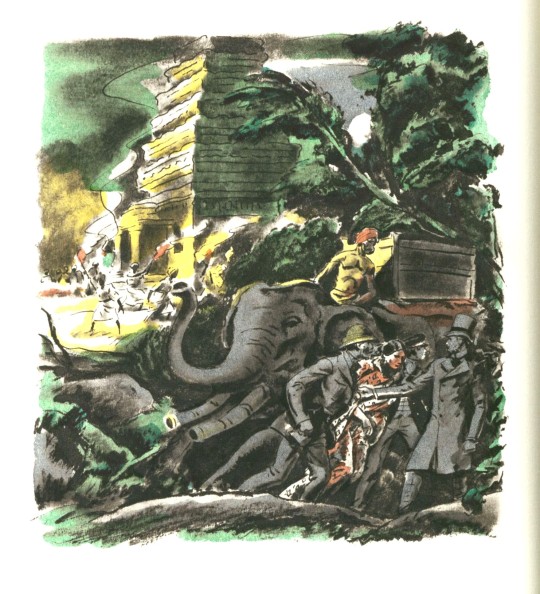

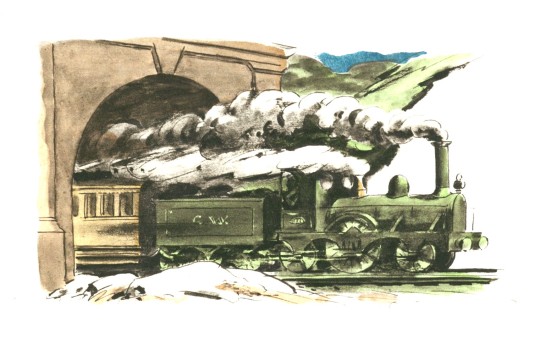

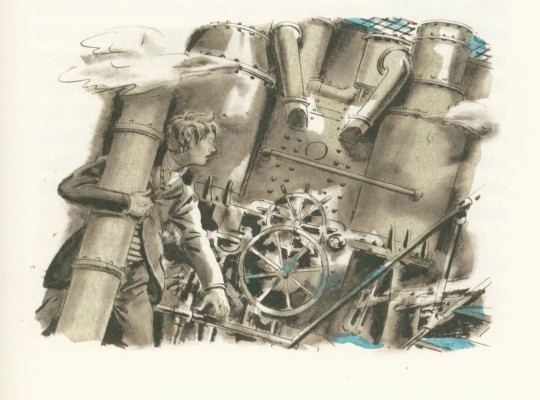

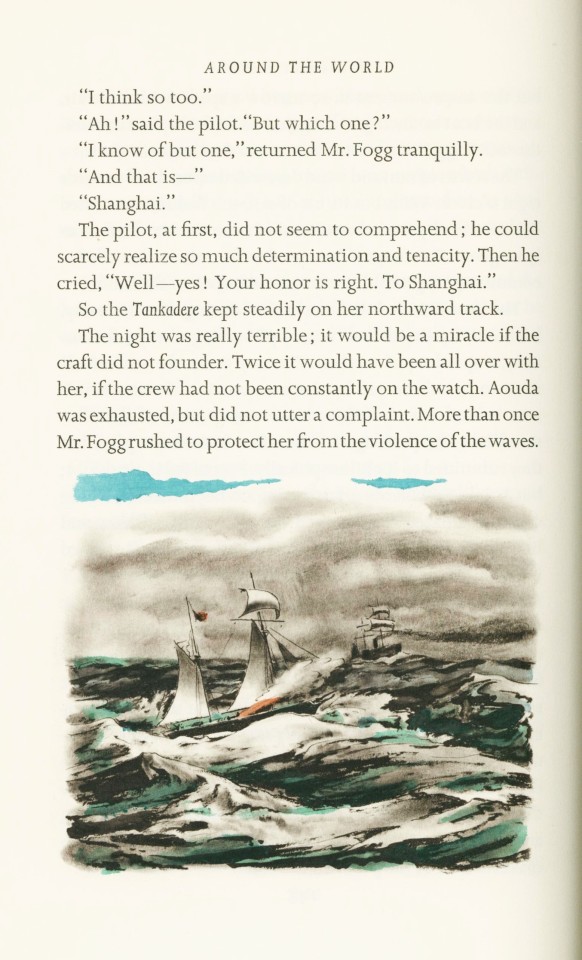

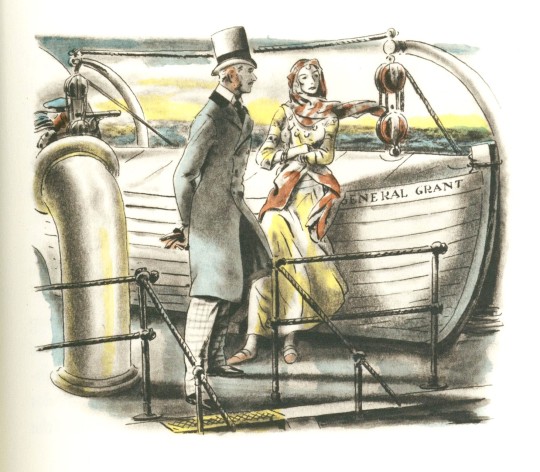

On this day, October 2, 1872, Jules Verne (1828-1905) sent his protagonist Phileas Fogg out on the adventure of a lifetime in his novel Around the World in Eighty Days. On the evening of October 2nd, while at the Club playing cards and debating how the world has grown smaller since a new railway section in India had made it possible to travel around the world, Fogg accepts a wager from his comrades for £20,000 to follow the Daily Telegraph’s itinerary of steamers and rails around the world and make it back to London in eighty days.

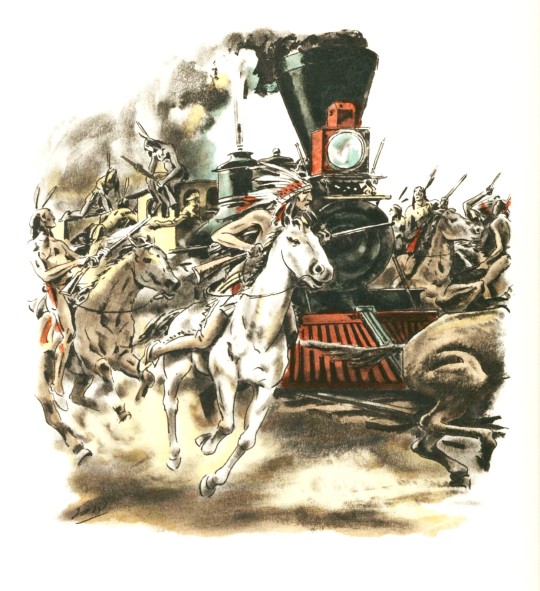

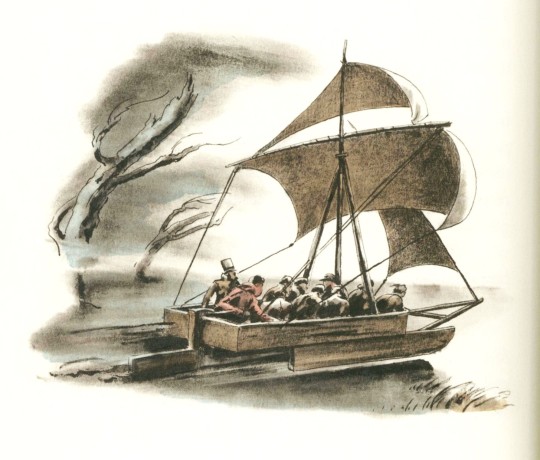

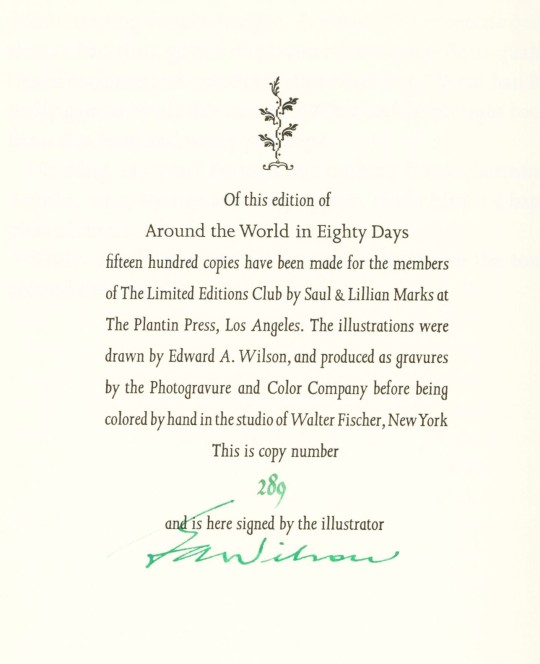

In observance of this fictional anniversary, we’re looking at The Limited Editions Club (LEC) publication of Around the World in Eighty Days written by Jules Verne and illustrated by Edward A. Wilson (1886-1970). It was published in 1962 and printed in an edition of 1500 copies by Saul and Lillian Marks at The Plantin Press in Los Angeles, California. The illustrations consist of sixteen pen-and-wash drawings by Wilson, reproduced in gravure by the Photogravure and Color Company of New York and then colored by hand in the studio of Walter Fischer.

Wilson, an attendee of the Art Institute of Chicago, illustrated over a dozen books, magazines, and World War II propaganda posters between 1924 and 1950. His vibrant work within LEC’s Around the World in Eighty Days reinforces a sense of wanderlust and adventure throughout the novel. In an eerie coincidence, October 2, 1970 is also the day Wilson passed away after a long struggle with an undisclosed illness.

The Special Collections holds number 289 of this limited-edition publication, from long-standing LEC member Austin Fredric Lutter of Waukesha, Wisconsin.

View more Limited Edition Club posts.

View other Milestone Monday posts.

-Jenna, Special Collections Graduate Intern

#milestone monday#milestones#around the world in eighty days#jules verne#Phileas Fogg#edward a. wilson#limited editions club#lec#plantin press#Saul and Lillian Marks#illustrations#Walter Fischer#Photogravure and Color Company

29 notes

·

View notes

Text

From Digital to Offset: Understanding Various Types of Printing Techniques

1. Digital Printing: Faster, more efficient and more convenient

Digital printing is one of the most popular and viable printing options available today. This involves transferring images directly to paper or other media using PDFs and other digital files. This approach has gained traction due to speed and low setup costs, making it ideal for short runs or scheduled projects.

Applications: Digital printing is widely used to print marketing materials such as brochures, flyers, business cards and banners. It is also commonly used in printing custom products such as photo books, invitations and garments.

Advantages:

· Speed: Digital printing is faster than printing methods, making it suitable for fast turnaround jobs.

· Cost-effective in smaller quantities: There are no setup fees, making it more affordable for smaller publishing businesses.

· Customization: Digital printing allows for easy personalization, perfect for targeted marketing.

However, digital printing doesn’t always produce the same depth of color or texture as other methods, especially on larger pieces.

2. Offset printing: Better quality, greater volume production

Offset printing or offset lithography is one of the most common and reliable methods of printing large volumes. This process involves transferring an image from a metal plate to a rubber cushion, then pressing the image onto paper. It is known for its image quality and is particularly suitable for more demanding stability applications.

Applications: Offset printing is ideal for many productions, such as magazines, magazines, catalogs, and larger merchandise.

Advantages:

· Higher Image: Offset printing produces sharper, cleaner images with more accurate colors, making it ideal for jobs that require higher quality print work.

· Cost effective for large volumes: Although the initial process is more expensive than digital printing, offset is more expensive when printing in large quantities.

· Consistency: Offset printing provides consistent results throughout printing, ensuring that each print is perfect.

3. Screen Printing: Robust and versatile

Screen printing, also known as silk screening, uses grid stencils to ink various surfaces. The process is particularly popular for printing products such as t-shirts, mugs and promotional materials, as it produces vibrant and long-lasting colors.

Application: This process is widely used for creating custom clothes, clothing, signs and even posters.

Advantages:

· Durability: Screen printing is extremely durable, making it ideal for products that require durability.

· Versatility: Works with a variety of materials including fabrics, plastics and metals.

· Bold colors: Screen printing is known for producing vivid and opaque colors, making it popular for more visual images.

However, like offset printing, screen printing can be cost-effective in small volumes due to its setup costs.

4. Flexographic printing: Perfect for packaging

Flexographic printing, commonly referred to as flexo, uses flexible rubber or photopolymer plates to transfer images onto a variety of materials such as plastic, foil, paper, etc. It is most often used in packaging, labels and packaging.

Application: Flexo printing is commonly used to print labels, flexible packaging, boxes, and other packaging.

Advantages:

· Faster and more efficient: Flexographic printing offers faster production speeds, making it ideal for larger orders.

· Extensive alignment: This technique can print on virtually any substrate, including porous materials such as plastic and metal objects.

· Production efficiency: Flexographic printing can produce high-quality, consistent results, especially with larger print sizes.

5. Gravure Printing: High-volume gravure printing

In gravure printing, or rotogravure, the image is engraved onto a cylinder, which is then applied to the print. High-resolution images and continuous tone images are often printed with this technique.

Application: Gravure printing is widely used for printing packaging, magazines, catalogs and wallpaper.

Advantages:

· High Quality: Graver produces beautiful images with beautiful details and rich colors.

· Ideal for long-term printing: Although setup costs are high, gravure is cost-effective for very large runs, making it perfect for mass-market printing.

Conclusion: Choosing the Right Printing Method

The type of printing method you choose depends largely on the needs of your project, including volume, budget, and desired output. If you’re looking for quick, smooth printing with a fast turnaround time, digital printing could be the right fit. Offset printing or gravure printing can provide consistent results for high quality, intense production. For special applications such as custom garments or packaging, screen printing and flexographic printing stand out as excellent options.

If you want to get high-quality printing services, it is important to choose someone who is skilled in the specific technique that best suits your project. Whether you print a few brochures or thousands of labels, the right printing techniques ensure that your content looks professional and effectively communicates your message.

#online printing services#online printing services australia#printing services australia#printing services#high quality printing services

3 notes

·

View notes

Text

"The Hoopoe" (Upupidae) is a limited edition fine art print with a maximum of 10 prints.

Each print was individually hand-printed on a etching press using two intaglio plateson Vellum Arches BFK Rives 180gsm paper ( 28x 38 cm / 11 x 15 inches). The printed area measures 20 x 25 cm / 8 x 10 inches .

6 notes

·

View notes

Text

From Beverages to Beauty: How Stretch Sleeve & Shrink Sleeve Labels Are Taking Over Every Industry

Rising Dominance of Stretch Sleeve And Shrink Sleeve Labels Market

The global stretch sleeve and shrink sleeve labels market is entering a transformative era marked by innovation, sustainability, and digitalization. With projections estimating the stretch sleeve and shrink sleeve labels marketto reach USD 25.6 billion by 2032, driven by a 7.1% CAGR, this evolution is fueled by technological breakthroughs and heightened regulatory scrutiny.

The labeling sector now demands 360-degree branding, tamper-evident features, smart packaging integration, and eco-conscious materials. As industries recalibrate to consumer expectations and environmental commitments, shrink and stretch sleeves emerge as the definitive solution for modern packaging.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40652-global-stretch-sleeve-shrink-sleeve-labels-market

Strategic Trends Fueling Market Acceleration

1. Advanced Sustainable Materials for Regulatory Compliance

The shift away from PVC toward PETG, PLA, and polyolefin-based shrink films is reshaping the labeling material landscape. These high-performance alternatives offer excellent clarity, superior shrinkability, and recyclability, making them ideal for high-shrink contour packaging applications.

PETG leads with 42.9% market share, offering a unique balance between functionality and sustainability.

Bio-based and biodegradable films are witnessing the fastest CAGR at 9.2%, as industries align with ESG mandates and plastic reduction frameworks.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40652-global-stretch-sleeve-shrink-sleeve-labels-market

2. Digital Printing Revolutionizing Personalization and Efficiency

As short-run, high-resolution packaging becomes essential, digital printing now stands at the frontier of custom labeling. With a projected CAGR of 8.5%, digital presses allow brands to launch limited editions, personalized campaigns, and regional SKU adaptations at unprecedented speed.

Digital watermarks, variable data printing, and QR-integrated storytelling now turn packaging into an interactive, data-rich engagement point.

3. Smart Labels and RFID-Enabled Authentication Systems

Innovations such as RFID integration, blockchain-verified authenticity, and augmented reality (AR) are being actively deployed in stretch and shrink sleeve formats. These smart features protect brands from counterfeiting, support supply chain transparency, and improve inventory management.

4. Eco-Design Integration and Solvent-Free Manufacturing

In pursuit of circularity, label manufacturers are adopting:

Solvent-free adhesives to reduce VOC emissions

Lightweight film substrates to minimize transport emissions

Mono-material sleeves to facilitate recycling compatibility

Stretch sleeves, which require no adhesives or heat, are increasingly preferred in closed-loop recycling systems, further propelling their relevance in low-carbon packaging strategies.

Segmental Stretch Sleeve And Shrink Sleeve Labels Market Insights

Stretch Sleeve And Shrink Sleeve Labels Market By Label Type

Shrink Sleeve Labels: Maintain 76.3% dominance, excelling in full-body coverage, product protection, and flexibility for complex geometries.

Stretch Sleeve Labels: Expand steadily at 5.8% CAGR, leveraging cost-efficiency and recyclability without requiring heat or adhesives.

Stretch Sleeve And Shrink Sleeve Labels Market By Material

Polyvinyl Chloride (PVC)

Polyethylene Terephthalate Glycol (PETG)

Polypropylene (PP) & Polyethylene (PE)

Polylactic Acid (PLA)

Biodegradable & Eco-friendly Materials

Others

Stretch Sleeve And Shrink Sleeve Labels Market By Printing Technology

Gravure Printing: Holds 39.8% share due to rich visuals, suited for large volumes.

Digital Printing: Fastest growth at 8.5% CAGR, enabling real-time brand responsiveness.

Stretch Sleeve And Shrink Sleeve Labels Market By Labeling Process

Shrink Tunnel: Dominates with 51.4% share, preferred for pharmaceuticals and beverages due to speed and reliability.

Roll-fed: Valued in mass production environments for its efficiency and cost control.

Stretch Sleeve And Shrink Sleeve Labels Market By Application

Food & Beverage: Commands 54.7% of the market, driven by visual appeal and regulatory compliance.

Pharmaceuticals: Rising at 8.2% CAGR, increasingly adopting tamper-evident smart sleeves for safety and authentication.

Personal Care: Benefits from shrink films’ premium finish and product fit for complex bottle shapes.

Stretch Sleeve And Shrink Sleeve Labels Market By Region

North America: Leads with 37.6%, shaped by robust FMCG presence and early tech adoption.

Asia-Pacific: Fastest growth at 8.4% CAGR, underpinned by rapid urbanization, digitization, and e-commerce.

Europe: Prioritizing eco-design and regulatory compliance, maintaining a 29.4% market share.

Competitive Landscape and Innovation Frontier

Key Stretch Sleeve And Shrink Sleeve Labels Market Players Shaping the Industry

Berry Global Inc.: Sustainability leadership through circular packaging programs

CCL Industries Inc.: Expansion via acquisitions in Europe; leading in premium segments

Amcor plc: Pioneer in recyclable high-shrink PET sleeves

Fuji Seal International Inc.: Innovator in AR-integrated smart packaging

Huhtamaki Oyj, Bonset America, and Taghleef Industries: Driving material science advancement and solvent-free printing innovations

Recent Stretch Sleeve And Shrink Sleeve Labels Market Strategic Moves

July 2023: Amcor launched PET shrink sleeves with improved recyclability.

Sept 2024: CCL acquired a European firm to bolster beverage/pharma shrink sleeve capacity.

Feb 2024: Fuji Seal introduced digital watermark-enabled sleeves to elevate traceability and engagement.

Emerging Technologies Defining the Next Decade

Hybrid Printing Systems: Merging gravure's quality with digital’s agility

Smart Augmented Reality Labels: Enabling immersive storytelling directly on packaging

Circular Label Design: Developing sleeves that detach cleanly during bottle recycling

Biopolymer Innovation: New PLA and cellulose derivatives with enhanced shrink properties

Outlook to 2032: The Future of Labeling

Stretch sleeve and shrink sleeve labels market are no longer mere packaging components—they are strategic tools for branding, compliance, and consumer engagement. The convergence of sustainability, digitization, and automation places sleeve labels at the core of next-generation packaging solutions.

Stakeholders investing in green chemistry, smart labeling, and high-speed customization will define leadership in this sector. With smart packaging mandates, plastic bans, and evolving consumer preferences, the market trajectory remains robust.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40652-global-stretch-sleeve-shrink-sleeve-labels-market

Conclusion

To win in the stretch sleeve and shrink sleeve labels market, manufacturers must go beyond print quality—they must innovate across materials, technology, sustainability, and consumer interaction. The years ahead will be defined by the agility to adapt, the foresight to invest in sustainable infrastructure, and the capability to tell compelling product stories directly through packaging.

As demand surges across global industries—from beverages to biotech—the stretch sleeve and shrink sleeve label segment will remain a vital, ever-evolving force in shaping the future of intelligent, compliant, and high-impact packaging.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Tired of inconsistent print results? With AxisValence’s Valflow Ink Temperature Controller, you’ll get perfect color and viscosity control—cutting down waste and improving profits. Ideal for gravure and flexographic presses. Let your prints speak for themselves!

For more details, visit- https://www.axisvalence.com/product/ink-handling/valflow-ink-temperature-controller/

#axisvalence#valflowinktemperaturestabiliser#valflowinktemperaturecontroller#inktemperaturestabiliser#valflowitssystem

0 notes

Text

Precision Printing Solutions with Singla Engravures LLP

In the dynamic world of printing and packaging, precision and consistency are non-negotiable. Singla Engravures LLP stands as a pioneer among printing cylinder manufacturers in India, known for delivering high-performance cylinders that meet international standards. Whether it’s for gravure or flexo printing, their advanced technology and skilled craftsmanship ensure a perfect print—every time.

Meeting Industry Demands with Reliable Cylinder Technology

Modern printing demands speed, detail, and repeat accuracy. Many businesses face production challenges due to poor-quality cylinders that wear quickly or deliver inconsistent results. Singla Engravures addresses these challenges with cylinders engineered to last, customized to fit any press, and built to support long production runs without compromising quality.

How Singla Engravures Manufactures Precision Printing Cylinders

Every order begins with a careful understanding of your printing needs. The cylinders are crafted using modern electroplating and laser engraving technology to produce sharp images and clean transitions. Singla’s deep experience in the industry has earned them a trusted name among printing cylinder manufacturers in India, with a commitment to innovation and quality at every stage of production.

Why Businesses Trust Singla Engravures

When you partner with Singla, you’re not just buying cylinders—you’re investing in reliability. Their products support faster production cycles, reduce machine downtime, and deliver unmatched image consistency. With a legacy of excellence and a focus on quality, Singla provides:

Precision-fit cylinders for rotogravure and flexo machines

Advanced surface treatments for durability

High-definition engraving for fine detail printing

On-time delivery across India

Tailored solutions for unique production environments

Start Scaling Your Print Performance with Singla

Whether you're in the packaging, labeling, or textile industry, Singla Engravures has the tools to take your production to the next level. As one of the most reliable printing cylinder manufacturers in India, their custom solutions help businesses improve efficiency, maintain consistency, and deliver superior print quality to clients around the world.

Frequently Asked Questions

What printing services does Singla specialize in? Singla Engravures specializes in manufacturing rotogravure and flexo printing cylinders with high precision.

Are your printing cylinders compatible with modern machines? Yes, our cylinders are designed to fit seamlessly with modern flexographic and gravure printing presses.

Do you offer customization? Absolutely. Each cylinder is customized based on your machinery specs and the type of material being printed.

What makes your cylinders stand out? Our cylinders are long-lasting, precision-engineered, and made using state-of-the-art engraving technology.

Can I place a bulk order? Yes. We cater to both small and large-scale orders with consistent quality across each unit.

Highlights of Singla Engravures LLP

Two decades of experience in cylinder engineering

In-house laser engraving and electroplating

Fast turnaround times and pan-India delivery

Dedicated support for commercial and industrial printing

Precision-focused production with global quality standards

Contact Singla Engravures LLP

Website: www.singlaengravuresllp.com Email: [email protected] Phone: +91 93131 83167

0 notes

Text

Water Base Inks

Z-Inks offers a premium range of Water Base Inks designed for eco-friendly and high-performance printing applications across a variety of substrates. Our water-based inks are ideal for flexographic and gravure printing processes, delivering vibrant colors, excellent print clarity, and superior adhesion while significantly reducing environmental impact.

Formulated with advanced technology, Z-Inks' water-based inks are free from harmful solvents, making them a safer and more sustainable choice for industries focused on responsible packaging. These inks are especially suitable for paper, board, and biodegradable film surfaces, offering fast drying, high rub resistance, and outstanding consistency during high-speed press operations.

At Z-Inks, we combine technical expertise with a commitment to innovation to deliver customized water-based ink solutions that meet diverse printing needs. Whether you’re in the food packaging, paper bag, or label printing sector, our inks provide reliable performance, regulatory compliance, and excellent print durability.

Choose Z-Inks for environmentally responsible, cost-effective, and high-quality water base inks that align with modern printing and sustainability goals.

0 notes

Text

TAZJ601400 (DLLW-800) 4feets gravure printing coating (embossing) machine

This machine is designed specifically for pre impregnated paper printing, coating, and embossing in one go.

Equipped with printing and coating, vertical and horizontal, multi-layer oven, and embossing unit.

The design has three major uses: printing, printing and coating, and printing and coating embossing.

There are three groups for storage: 1 group for storage, 2 groups for storage, 1 group for printing, and 1 group for coating and pressing.

High precision full servo motor synchronous printing, computer printing, automatic cutting and material changing.

Contact Us

Phone: +86-13757197838 (Manager Chen)

Tel: +86-0571-61071715

Fax: +86-0571-61071706

Mail: [email protected]

Add: No.32 Wujiatou, Qingke Village, Jincheng Street, Lin'an District, Hangzhou City, Zhejiang Province

0 notes

Text

Flexo automation and the shift to digital and hybrid labels

The pressure-sensitive label industry in India continues to grow as packed and labeled products in numerous types of containers, formats, and sizes multiply. Every food and snack product is available in various exotic and localized flavors. You can now buy packs of Hershey’s chocolates filled with California almonds with guava and Mexican chilli flavor, or Hershey’s Exotic Dark blueberry and acai flavored centers. Also, you can find Mazan chocolate cubes filled with paan flavour and many other products in the market with a variety of localized flavors including Kurkure packs with ‘UP Taste.’ In short, the number of SKU’s of pouches and labeled containers have substantially multiplied.

It is no longer about flexo versus digital versus flexo. At the Labelexpo India in 2022, the European plate and roller manufacturers said that ‘digital is the death of flexo.’ To bolster their views they pointed to challenges such as print density, banding, and handling newer substances – a virtual laundry list of difficulties with digital label production.

Digital printing has found its place in various label applications, especially when personalization, variable data, and shorter print runs are required. Flexo holds significant advantages in terms of cost-effectiveness in large-volume production runs and printing on certain materials and increasingly for short-run flexible packaging, especially with the widespread availability of locally manufactured presses.

Managing shorter print runs is challenging for flexo converters, considering the cost of creating printing plates, time-consuming press set-up, and set-up waste. Adding flexo units to a digital module in a hybrid configuration, or investing in a digital roll-to-roll press alongside established flexo lines has helped converters adopt a more sustainable ‘print-on-demand’ business model for shorter-run labels and packaging.

Hybrid printing can be a more sustainable and economical approach. “The flexo technologies being retrofitted with add-on features to a digital press are referred to as hybrid,” explained Ajit Bharadwaj of Vinsak. “Features such as variable data printing, foiling, stamping, die-cutting, and more automated features are increasingly in demand among converters. Reducing avoidable print waste saves both converters and brands money and reduces the need to handle excess printed stock,” he said.

Parwez Izhar, senior vice president of the printing cylinders business at UFlex shares that the Indian packaging industry is witnessing a surge in smart packaging that features technologies such as track-and-trace systems integrated into labels and packaging including RFID, NFC, QR codes, holograms, and more.

Izhar explains that approximately 20% of the gravure market share has shifted to flexo, primarily due to its cost-effectiveness and faster turnaround time. He says, “In the label industry, both flexo and digital are gaining ground, and with the increasing demand for short-run jobs, converters are also turning to digital.”

“However, converters are not focusing on just one approach, they are thinking about growth. Many opt for both technologies—if they have flexo, they add digital. Converters recognize the demand for a premium look and feel, so the future lies in hybrid technologies that can meet all the quality, volume, and variable data requirements,” Izhar adds.

The automated flexo presses that include hybrid LED UV systems, die-cut units, pre-register, auto-register, movable turn bar, lam and relam units, peal and seal kits, and foiling stations for labels, shrink sleeves, and flexible packaging are increasing in global demand. Faridabad-based Multitec’s mid-web flexo presses can print on various substrates including thin and extensible materials with capability ranging from 10 microns up to 450 microns at 200 meters a minute with impressive registration and low setup wastage.

Multitec generally leads the industry in new technology adoption and implementation with 40% of its manufacturing being exported. Amit Ahuja, managing director of Multitec explained, “The growing short-run demand is creating a market space for digital. This does not pose any threat to veteran flexo users – but the future is in the hybrid production of labels together with the increasing demand for more automation features and quicker and more precise make-ready solutions.”

0 notes

Text

Characteristics of Solvent-Based Gravure Inks and Their Relationship with Printing

Solvent-based gravure printing inks consist of pigments, resins, additives, and a significant amount of solvents, making the ink relatively thin. The drying process of solvent-based gravure inks is volatile, which makes them suitable for printing on paper, films, aluminum foil, and other materials. Given that gravure printing presses operate at high speeds and deposit a thick ink layer, it is essential to understand the impact of ink properties like thixotropy, flowability, viscosity, and drying speed on print quality. This knowledge is crucial for enhancing the quality of printed materials.

Thixotropy

Thixotropy refers to the change in the flow properties of ink under the influence of external forces. Specifically, it is the phenomenon in which a suspension or dispersion thins when stirred and thickens again when left undisturbed. Generally, high-quality inks have low thixotropy, allowing them to be used directly on the press without special treatment. However, inks without thixotropy tend to experience sedimentation, which is not ideal. In general, white, yellow, and cyan inks have low thixotropy, while magenta and black inks exhibit higher thixotropy. The thixotropy of inks is influenced by the following factors: 1. Properties of the Pigment: For example, carbon black pigments treated with ozone have significantly lower thixotropy compared to untreated ones. 2. Pigment Particle Size: Smaller pigment particles result in lower thixotropy, while larger particles cause higher thixotropy. 3. Pigment Quantity: Larger amounts of pigment can cause coagulation between pigment molecules, which increases thixotropy. 4. Molecular Weight of the Resin: Inks with high molecular weight resins but low n-heptane values tend to have higher thixotropy, and vice versa. 5. Pigment Wettability: Inks with better wettability of pigments generally have lower thixotropy. Some ink manufacturers pre-disperse pigments in the production of black inks to improve wettability and reduce thixotropy. For solvent-based gravure printing inks, an appropriate level of thixotropy is required. If thixotropy is too high, the ink may exhibit poor leveling, viscosity control issues, and can result in printing defects like mottle or orange peel. If thixotropy is too low, dot gain may increase, causing text and lines to appear thicker.

Flowability

The flowability of solvent-based gravure printing inks is a comprehensive reflection of factors such as relative density, viscosity, thixotropy, and cohesion. To achieve optimal flowability, the ink must have suitable viscosity, good pigment wettability, and a balanced pigment concentration, while minimizing thixotropy. When testing the flowability of ink, aside from measuring its flow time using a #4 or Zahn #3 cup, the amount of ink remaining on the cup wall compared to the amount that flowed out is also important. With a fixed viscosity, the smaller the ratio of retained ink to flowing ink, the better the flowability. If the ink’s flowability is poor, printing faults such as uneven ink transfer or print defects are likely to occur.

Viscosity

Viscosity in solvent-based gravure inks is closely related to flowability, and maintaining the correct viscosity is key to ensuring effective ink transfer. Although many factors, such as resin type, ink adhesion, printing speed, pressure, substrate material, and environmental conditions, influence ink transfer, viscosity remains a critical factor. The relationship between viscosity and transfer rate is depicted in the diagram below. Factors affecting viscosity in solvent-based gravure inks include: 1. Viscosity of the Resin Solution: Higher resin viscosity increases ink viscosity, and vice versa. 2. Pigment-Resin Compatibility: If pigments react with the resin and cause coagulation, the ink’s viscosity increases. 3. Solvent and Dispersant Compatibility: If solvents dilute the dispersants at any ratio, the ink’s viscosity will decrease. 4. Temperature: Lower temperatures increase ink viscosity, while higher temperatures reduce it. Low viscosity in solvent-based gravure inks can result in issues such as pinholes, uneven color coverage, rough patches, or poor adhesion, leading to print defects. On smooth surfaces, ink adhesion may be weak, and on paper substrates, powdering or flaking may occur. Conversely, high viscosity can cause issues like scratching, color bleeding, plate flooding, and “orange peel” defects.

Conclusion

In the design and production of solvent-based gravure printing inks, it is crucial to select compatible pigments, resins, and solvents to achieve the desired initial viscosity. Printers should use appropriate solvent blends, preferably provided by the original ink manufacturer, to adjust the ink to its optimal “working viscosity” for printing. This ensures high-quality printed results. Furthermore, ink viscosity is also influenced by printing speed. Typically, faster printing speeds require lower ink viscosity to achieve optimal ink transfer. Solvent-based gravure printing inks are volatile inks, meaning that when solvents evaporate from the wet ink film, it transitions from liquid to solid. The rate at which solvents evaporate directly affects the drying speed of the ink. In designing and manufacturing solvent-based gravure printing inks, a mix of medium, low, and high boiling-point solvents is typically chosen to meet drying requirements. Incorrect resin selection, low softening points, poor solvent release from resins, or excessive high-boiling solvents can slow down solvent evaporation and result in residual solvent in the cured ink film. When formulating solvent-based gravure printing inks, resins are typically selected first, followed by solvents. Solvents with similar solubility parameters to the materials being dissolved tend to dissolve more easily and evaporate faster. However, the presence of pigments reduces solvent evaporation rates, especially if the pigments are large. Additionally, environmental factors such as higher ambient temperature, lower relative humidity, and faster air circulation increase the evaporation rate of solvents.

Explore our book printing services on the printing in China page. Common printing issues caused by improper drying include: 1. Ink drying too quickly at certain printing speeds can cause plate flooding, scratching, ink whitening, poor gloss, and leveling issues. 2. In multi-color printing, slow drying can result in roller adhesion or ink smearing during the next printing station, leading to print defects. The evaporation rate of solvents in ink depends not only on their boiling point, vapor pressure, and latent heat of evaporation but also on factors such as printing environment temperature, relative humidity, air flow, and ink layer thickness. Therefore, ink solvent evaporation rates should be adjusted based on varying conditions. Under normal production conditions, if ink dries too quickly, slow-drying diluents should be added. If ink dries too slowly, fast-drying diluents should be used. Where possible, printing environments should be controlled between 18-25°C, with relative humidity kept below 65% to stabilize ink performance.

0 notes

Text

Printed Electronics: Revolutionizing Modern Technology

Printed electronics is an innovative field that has transformed the way electronic devices are designed, manufactured, and integrated into everyday applications. By leveraging advanced printing techniques, this technology enables the production of lightweight, flexible, and cost-effective electronic circuits and components. As industries increasingly embrace smarter and more efficient solutions, printed electronics have emerged as a cornerstone of modern technological advancements.

Understanding Printed Electronics

At its core, printed electronics involve the use of functional inks containing conductive, semiconductive, or dielectric materials. These inks are deposited onto flexible substrates such as plastic, paper, or textile using printing techniques like screen printing, inkjet printing, or gravure printing. Unlike traditional manufacturing methods that rely on rigid circuit boards, printed electronics offer unmatched versatility in form factor and application.

This shift from conventional fabrication processes has opened doors to countless possibilities, including wearable technology, flexible displays, smart packaging, and energy-harvesting devices. By reducing material usage and simplifying manufacturing steps, printed electronics also promote sustainability, which is a pressing need in today's tech-driven world.

Key Advantages of Printed Electronics

1.Cost Efficiency: Traditional electronics manufacturing involves complex processes, multiple materials, and expensive equipment. Printed electronics, on the other hand, reduce costs significantly by using additive processes, minimizing waste, and eliminating the need for high-temperature treatments.

2. Design Flexibility: With the ability to print circuits on various flexible substrates, manufacturers can create lightweight and adaptable devices. This flexibility is crucial for applications in wearable technology, medical devices, and Internet of Things (IoT) devices.

3. Scalability: Printing techniques are inherently scalable, allowing for the mass production of electronic components with consistent quality. This scalability makes printed electronics an ideal choice for industries requiring high-volume manufacturing.

4.Eco-Friendliness: The additive nature of printed electronics means fewer materials are wasted during production. Additionally, the use of recyclable substrates and energy-efficient processes further enhances their eco-friendly profile.

Applications Transforming Industries

The versatility of printed electronics has made them a game-changer across multiple industries:

Healthcare: Flexible biosensors, wearable devices, and smart patches that monitor vital signs or deliver medication are made possible with printed electronics. Their lightweight and adaptable nature ensures comfort and functionality.

Consumer Electronics: Foldable smartphones, ultra-thin televisions, and transparent displays are just a few examples of how printed electronics have redefined consumer experiences.

Energy Sector: Printed solar panels and energy storage solutions have significantly lowered the cost of renewable energy adoption. These innovations are paving the way for sustainable energy systems.

Automotive Industry: Printed sensors and lighting solutions integrated into car interiors and exteriors enhance safety and aesthetics while reducing weight.

Smart Packaging: The retail and logistics sectors benefit from printed electronic labels and tags that provide real-time tracking, condition monitoring, and interactive consumer engagement.

Challenges in Printed Electronics

Despite its potential, printed electronics face challenges such as:

Material Limitations: While significant progress has been made, finding materials that balance conductivity, flexibility, and cost remains a challenge.

Durability: Flexible electronics must endure bending and stretching without compromising functionality, which requires advanced material development.

Standardization: As a relatively new technology, the lack of standardization across the industry can slow its adoption.

The Future of Printed Electronics

The rapid evolution of printed electronics is reshaping how devices are designed and manufactured. Innovations in materials science, combined with advancements in printing technologies, are expected to address current challenges and unlock new applications. As industries continue to demand smaller, smarter, and more sustainable solutions, printed electronics will play a pivotal role in meeting these needs. Cutek Circuits, a leader in innovative electronic solutions, is at the forefront of this revolution. With a commitment to quality and cutting-edge technology, Cutek Circuits delivers printed electronic solutions that empower industries and drive technological progress. Whether it's smart interfaces, flexible keyboards, or advanced components, Cutek Circuits is dedicated to shaping a sustainable and connected future.

0 notes

Text

Gravure Printing Machines: Precision for High-Quality, Large-Scale Printing

Gravure printing, or rotogravure printing, is the practice of high-speed print technique. It brings out high-quality printed products with an excellent precision level. It is mainly used for mass production of items like packaging, labels, and magazines. Gravure printing machines ensure that the images are clear and sharp with well-saturated colors and good quality. The technique of this printing is very suitable for any long run because it guarantees high quality in any plastic, paper, or even foil.

How Gravure Printing Works

In gravure printing, actually the design or image is engraved into the cylinder. These engraved cells are filled up with ink, and when pressed on the substrate, ink transfers accurately to create a good quality print. The color density and details of the image depend on the depth and size of the cells on the cylinder, thus enabling gravure printing machines to create rich and consistent tones. The gradations that gravure printing machines produce are very smooth and feature good details, hence very photo-realistic, mainly for highly color-intensive projects.

Advantages of Gravure Printing Machines

Gravure printing machines have several unique advantages. Its engraved cylinders provide a long-lasting image quality, hence graver is very well suitable for massive production. They are used at very high speeds with thousands of impressions per hour and do not lose the consistency. Gravure printing is well applicable for large works with intricate designs because of extraordinary image reproduction and fine details.

Applications of Gravure Printing Machines

Gravure printing is widely used for various products. These include flexible packaging, labels, gift wrap, wallpapers, and magazines. With the accuracies and quality of gravure printing machines, brands and manufacturers can actually guarantee visually pleasing yet sturdy objects. With gravure printing, in businesses, effectiveness and quality go along with meeting actual production demands on an impressive standard for print.

The company specializes in providing advanced gravure printing machines that suit different industrial applications for companies seeking reliable solutions for high quality printing and large scales.

#Gravure Printing Machines Manufacturer#UV Coating Machines Manufacturer#Flexo Printing Machines Manufacturer

0 notes

Text

Exploration of the application of optical anti-counterfeiting pigments in gravure printing

In today's era of rapid technological development, optical anti-counterfeiting technology has become one of the important means to protect intellectual property rights and brand reputation. Among them, optical anti-counterfeiting pigments occupy a pivotal position in the field of anti-counterfeiting due to their unique properties. This special pigment can be applied to a variety of printing technologies, the most common of which is gravure printing. Today, let's explore the application of optical anti-counterfeiting pigments in gravure printing.

Optical anti-counterfeiting pigments are materials that can produce specific visual effects through the refraction, reflection or diffraction of light. These effects can include color change, metallic luster, fluorescence, and holographic images. They are usually composed of tiny crystals or special structures that can present different colors or patterns under different lighting conditions. This property makes optical anti-counterfeiting pigments ideal for making security features that are difficult to imitate.

Gravure printing is an ancient printing method that forms patterns by pressing ink into grooves engraved on metal plates and then transferring the ink to paper or other substrates. Due to its high precision and clarity, gravure printing is widely used to produce high-quality printed products such as banknotes, stamps, and advanced packaging materials. When optical anti-counterfeiting pigments are combined with gravure printing, extremely complex patterns can be created, which increases the difficulty of counterfeiting and thus improves the safety of the product.

As a leading company in the optical anti-counterfeiting pigment industry, Sunflower Chemical Group not only provides high-quality products, but also continuously innovates and develops new technologies to meet the growing market demand. Their products are widely used in the fields of currency, certificates, and high-end commodity packaging, providing reliable security for global customers. For example, a new type of optical anti-counterfeiting pigment they developed can show a specific pattern under ultraviolet light and another color under natural light. This double verification mechanism greatly increases the threshold for counterfeiting.

In addition, with the increase in environmental awareness, the entire printing industry tends to favor environmentally friendly anti-counterfeiting pigments. These pigments reduce the impact on the environment while ensuring safety, which is in line with the concept of sustainable development.

In short, the combination of optical anti-counterfeiting pigments and gravure printing technology has brought unprecedented opportunities to the anti-counterfeiting industry. With the advancement of technology and changes in market demand, companies like Sunflower Chemical Group play a vital role in promoting the development of the industry. In the future, we can expect more innovative applications to appear in our daily lives, further ensuring people's quality of life and social security.

0 notes

Text

"Northern Cardinal"

Original etching from a limited edition of 12 fine art print max.

Single photopolymer plate (Carbon Black AkuaInks) print on Vellum Arches BFK Rives 180gsm white paper (13 x 18 cm / 5.1 x 7 inches).

The print measures 10 x 15 cm (3.9 x 5.9 inches). Each print is signed, stamped, and numbered at the bottom of the print area. Each print is hand-pulled on an intaglio press.

Color additions are created using the chine-collé technique and Awagami Mingeishi 48grm yellow paper.

3 notes

·

View notes

Text

Industry trend|This nearly 20-year-old RFID company was acquired by a listed company

Multi-Color Corporation (MCC) was founded in 1985 and listed on the NASDAQ on August 28, 1987. It has 8,300 employees worldwide. MCC mainly produces and sells self-adhesive labels, serving the home and personal care, food and beverage, wine and spirits, and medical and health food packaging industries. MCC has new trademark pressure-sensitive, bonding, molding, shrink sleeve and cold migration technologies. In addition, MCC is also good at digital printing and provides a complete printing method including flexographic printing, lithography, gravure printing and digital printing, as well as internal pre-press services. MCC entered the Chinese market in 2011 and continues to serve existing multinational consumer brands.

MCC has factories and technical support in North America, Central and South America, Europe, Australia, New Zealand, South Africa and China, and can provide customers with global services. MCC also pays attention to environmental protection and sustainable development. The company uses environmentally friendly printing materials and production processes to reduce the impact on the environment.

Recently, MCC announced the acquisition of Starport Technologies, a smart label technology provider based in Kansas City, Missouri. The financial terms of the transaction were not disclosed.

Starport Technologies was founded in 2006 and has been focusing on the research and development and application of RFID technology since its inception. The company not only has strong R&D capabilities, but also has unique manufacturing processes that can meet the production needs of various surface materials, adhesives, RFID transponders, printing and other special coating rolls. This professional capability makes Starport Technologies highly competitive in the production and manufacturing of RFID tags.

Starport Technologies has a clear market positioning in the RFID industry, mainly serving consumer and supply chain applications. As major consumer products and retailers integrate smart label solutions, including RFID technology, into consumer and supply chain applications, Starport Technologies is in a stage of accelerated profitable growth. The company has won wide market recognition and customer trust with its professional RFID label products and services.

Starport Technologies has also achieved remarkable results in RFID technology innovation. For example, the company has developed a single-chip RFID reader IC for UHF mobile device applications. This reader has the advantages of wide range and low cost, providing a new solution for the application of RFID technology on mobile devices. In addition, Starport Technologies is constantly exploring and developing new RFID technologies and applications to meet the ever-changing market and customer needs.

This acquisition not only brings more resources and support to Starport Technologies, but also enables it to leverage MCC's global leadership to expand its marketing capabilities to meet the needs of customers in the United States and around the world. At the same time, the addition of Starport Technologies also provides MCC with more innovative technologies and features in RFID tags, which will help MCC continue to maintain close cooperation with customers.

Hassan Rmaile, CEO of MCC, said, “RFID is one of the fastest growing areas of MCC’s business and we are very pleased to welcome Starport and its expertise as an industry-leading RFID master label converter to the MCC family. Bringing our two high-performing teams together will allow us to continue to provide the industry with innovative, technical and functional RFID label solutions with exceptional service, quality and customer intimacy.”

Starport Technologies founder and CEO Jeff Nedblake and his staff will move to MCC to manage the newly formed Smart Packaging business unit of the combined company. “MCC’s core products, channel access, operational excellence and balance sheet make them the perfect partner from which we can expand our collective capabilities to meet the needs of our customers both in the U.S. and globally,” Nedblake concluded.

This paper is from Ulink Media, Shenzhen, China, the organizer of IOTE EXPO (IoT Expo in China)

0 notes

Text

Swiss Pac India elevates Digital Printing capabilities with HP Indigo 25K

HP Indigo 25K Digital Press meets the growing demand for a sustainable packaging market

New Delhi, May 30, 2024 – As part of its dedication to pioneering packaging solutions, Swiss Pac India has recently integrated the cutting-edge HP Indigo 25K Digital Press into its operations in Gujarat. This strategic installation equips Swiss Pac with the capability to swiftly meet the evolving demands of the market, particularly catering to the needs of small and medium-sized businesses (SMBs). With the HP Indigo 25K, Swiss Pac is poised to deliver vibrant packaging solutions across various sectors, ranging from colorful coffee and tea pouches to sophisticated beauty product packaging, stylish pet food packs, and eco-conscious health food bags.

Prashant Vachhani, Managing Director, Swiss Pac said, “Swiss Pac has always been at the forefront of innovation, from being the first to market with India’s largest stock range of ready-made pouches to now the addition of the HP Indigo to our repertoire. It is a testament to our unwavering commitment to providing our customers in India and beyond with the best-in-class solutions. This investment allows us to offer small to medium-sized artisanal businesses the opportunity to elevate their brand presence through highly customized packaging that truly reflects their unique identity.

He further added “We understand the challenges faced by small to medium-sized businesses in today's competitive market, and our goal is to empower them with the tools they need to succeed. With the HP Indigo, we are opening a world of possibilities for businesses in India to unleash their creativity and make a meaningful impact with their packaging”.

Speaking on the new installation, A Appadurai, Country Manager, HP Indigo & PageWide Web Press, HP India market said, " We are proud to partner with Swiss Pac on the cutting-edge technology that will revolutionize the flexible packaging industry. Like HP, Innovation and Quality has been the DNA of Swiss pac. The HP Indigo 25K at Swiss Pac will be boon to the brand owners in India by eliminating the MoQ’s, significantly reducing the turnaround times and producing the packaging with least carbon footprint compared to any printing technology that exist. This is going be a game changer for the flexible packaging industry”.

Tailored to meet the growing demand for shorter print runs and faster time-to-market, this cutting-edge digital press ensures Swiss Pac's customers enjoy personalized experiences. With increased efficiency and capability to handle larger label runs, the HP 25K empowers small and medium-sized businesses to compete directly with industry giants.

HP Indigo 25K digital press uses HP Indigo LEP and One-Shot Color Technologies to deliver gravure-matching color quality. With patented Indigo Spot Master technology, the brands can reach the perfect color registration in minutes and maintain consistent color output with the highest quality. With the widest color gamut and a comprehensive white portfolio, Swiss Pac can also ensure precise spot colors matching up to 97% of PANTONE® colors and deliver tailored solutions that stand out on the shelf.

With sustainability at its core, the HP Indigo 25K Digital Press offers reduced production waste and enables the creation of compostable and recyclable pouches. By integrating printing, lamination, and pouch-making technologies, HP provides the most sustainable and efficient method for producing on-demand flexible packaging.

0 notes