#HighStrengthBolts

Explore tagged Tumblr posts

Text

Grade 12.9 Bolts: The Ultimate Guide to Properties, Applications, and Benefits

Introduction

When it comes to high-strength fasteners, Grade 12.9 bolts are among the most robust and reliable options available. These bolts are widely used in industries that demand exceptional tensile strength, durability, and resistance to shear forces.

In this comprehensive guide, we’ll explore:

What Grade 12.9 bolts are

Their material composition and mechanical properties

Common applications

Advantages over other bolt grades

Installation and torque specifications

Frequently asked questions

What Are Grade 12.9 Bolts?

Grade 12.9 bolts are high-tensile steel fasteners known for their exceptional strength and hardness. The "12.9" designation indicates:

12 – The tensile strength in 100 MPa units (12 × 100 = 1,200 MPa minimum tensile strength)

9 – The yield strength ratio (9 × 100 = 900 MPa minimum yield strength)

These bolts are heat-treated (quenched and tempered) to achieve their superior mechanical properties, making them ideal for high-stress applications.

Material Composition and Mechanical Properties

Material:

Grade 12.9 bolts are made from alloy steel, typically containing:

Carbon (C): 0.20–0.55% (increases hardness)

Manganese (Mn): 0.30–1.50% (enhances strength)

Chromium (Cr): 0.90–1.20% (improves corrosion resistance and hardness)

Molybdenum (Mo): 0.15–0.30% (prevents brittleness)

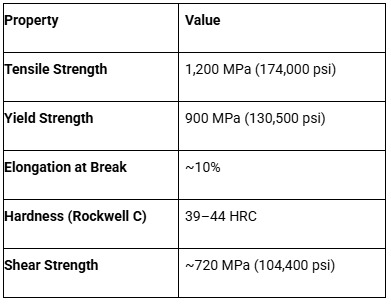

Mechanical Properties:

Compared to Grade 8.8 (800 MPa tensile strength) or Grade 10.9 (1,000 MPa), Grade 12.9 bolts offer 20% higher tensile strength than Grade 10.9 and 50% more than Grade 8.8.

Common Applications of Grade 12.9 Bolts

Due to their extreme strength, these bolts are used in critical, high-load applications, including:

1. Automotive & Aerospace

Engine components

Suspension systems

Aircraft structural fasteners

2. Heavy Machinery & Construction

Excavators, cranes, and bulldozers

High-stress structural connections

3. Industrial Equipment

Hydraulic presses

Machine tools

Robotic arms

4. Marine & Offshore

Shipbuilding (where corrosion-resistant coatings are applied)

Oil rig structures

5. Military & Defense

Armored vehicles

Weapon systems

Advantages of Grade 12.9 Bolts

✅ Higher Load Capacity – Withstands extreme tension and shear forces. ✅ Superior Fatigue Resistance – Performs well under cyclic loading. ✅ Durability – Heat-treated for long-term reliability. ✅ Precision Manufacturing – Tight tolerances ensure consistent performance.

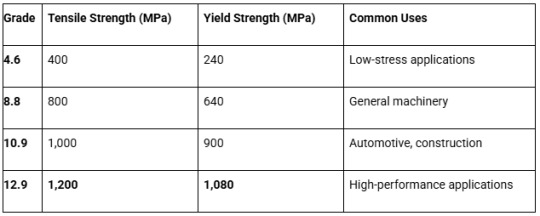

Comparison with Other Bolt Grades

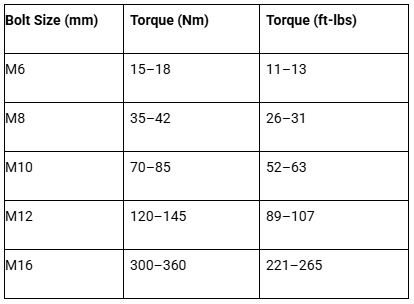

Installation & Torque Specifications

Recommended Torque for Grade 12.9 Bolts

(Lubricated threads, dry torque values may vary)

Installation Tips:

Use a calibrated torque wrench for precision.

Avoid over-tightening – Grade 12.9 bolts are brittle and can snap under excessive force.

Apply thread lubricant to reduce friction and ensure accurate torque.

Check for fatigue cracks periodically in high-vibration environments.

Frequently Asked Questions (FAQs)

Q1: Can Grade 12.9 bolts be used in outdoor environments?

Yes, but they require corrosion-resistant coatings (e.g., zinc plating, Dacromet, or galvanizing) since alloy steel is prone to rust.

Q2: Are Grade 12.9 bolts stronger than Grade 8?

Yes! Grade 12.9 has 1,200 MPa tensile strength, while Grade 8 (SAE) has 150,000 psi (~1,034 MPa).

Q3: Why are Grade 12.9 bolts brittle?

Due to their high hardness, they have lower ductility. They can snap under sudden impact if not installed correctly.

Q4: Can I replace a Grade 10.9 bolt with a 12.9?

Yes, but only if the design allows. Over-engineering may lead to thread stripping in softer materials.

Q5: What is the difference between ISO 12.9 and SAE Grade 8?

ISO 12.9 = Metric, 1,200 MPa tensile strength

SAE Grade 8 = Imperial, ~1,034 MPa tensile strength

Conclusion

Grade 12.9 bolts are the pinnacle of high-strength fasteners, offering unmatched tensile and yield strength for critical engineering applications. Whether in aerospace, automotive, or heavy machinery, these bolts provide reliability under extreme loads.

However, proper installation, torque control, and corrosion protection are essential to maximize their lifespan. If your project demands the strongest bolts available, Grade 12.9 is the ideal choice.

#Fasteners#HighStrengthBolts#Engineering#MechanicalDesign#Construction#Aerospace#Automotive#anankafasteners#manufacturer#ananka#supplier#bolt#mumbai#Ananka#Anankafasteners#articles#grade#gradematerial#bolts#tumblr#blog tumblr

0 notes

Text

Choosing the Right Material for Your Bolts: Expert Advice from Manufacturers

When you're selecting bolts for your project, the material they are made from plays a pivotal role in their performance and durability. But with so many options available, how do you know which one is right for you? Let’s break down the essential advice from manufacturers to help you make the best decision.

Why Material Choice Matters for Your Bolts

Choosing the right material for your bolts isn’t just about picking a metal—it's about ensuring the longevity and reliability of your entire project. The material determines:

Strength and Durability: The right material will ensure your bolts hold up under pressure and resist wear over time.

Corrosion Resistance: Different materials perform better in various environmental conditions, such as outdoor or marine environments.

Cost Efficiency: Some materials are more affordable than others, but cheaper options might sacrifice durability.

Let’s dive into the common materials manufacturers recommend for bolts, so you can make an informed decision.

Common Bolt Materials and Their Benefits

Here are some of the most popular materials used in bolts, along with their benefits:

Steel Steel is a common choice due to its strength and versatility. It’s ideal for general-purpose use, offering high tensile strength and resistance to wear. If you’re looking for something durable but affordable, steel is a great option. Many anchor bolt manufacturers use steel for their products due to its reliability and cost-effectiveness.

Stainless Steel If your project requires resistance to rust and corrosion, stainless steel is your best bet. It’s particularly useful for outdoor or marine applications. While stainless steel is more expensive than regular steel, the added corrosion resistance makes it worth the investment. Stainless steel U bolt manufacturers often recommend this material for applications in harsh environments.

Brass Brass bolts are known for their excellent corrosion resistance and aesthetic appeal. They’re often used in projects where visual appearance is important, like in decorative hardware, plumbing, and electrical applications. U bolts manufacturers sometimes offer brass options for these specialized uses.

Titanium Titanium bolts are extremely strong and lightweight, making them perfect for high-performance applications, like aerospace or automotive industries. Although they’re more expensive, the combination of strength, low weight, and corrosion resistance makes them highly valuable.

Aluminum Lightweight and resistant to corrosion, aluminum bolts are a great option for applications where weight is a concern. They are commonly used in the automotive and aerospace industries, as well as in outdoor structures where resistance to the elements is needed.

Copper Copper bolts are highly resistant to corrosion and are great for electrical applications due to their conductivity. They're also used in plumbing and other applications where electrical or thermal conductivity is a factor.

How to Choose the Right Bolt Material for Your Project

Choosing the ideal material depends on several factors. Here’s what you should consider when making your decision:

Application Environment: Where will the bolts be used? If your project involves exposure to moisture or chemicals, you’ll need materials like stainless steel or titanium for added resistance to rust and corrosion. For foundation bolts, choosing a material with high corrosion resistance is crucial if they will be exposed to the elements.

Strength Requirements: What’s the load your bolts will bear? Stud bolts are often used when high strength is needed, especially in heavy-duty applications. Steel is a solid choice for most applications, but if you need something lighter without sacrificing strength, consider titanium.

Budget Constraints: Different materials come at different price points. For general-purpose applications, steel or brass might be your best value. But for specialized projects, the investment in titanium or stainless steel could be worthwhile. If you're working with specific needs, like U clamp manufacturer requirements, consider the precise material specifications they offer.

Appearance: If aesthetics matter to you, consider brass or copper bolts, which can add a unique touch to decorative elements in your project. Foundation J bolts are often seen in industrial settings, and manufacturers of these products will guide you on the best materials for your needs.

Conclusion

When it comes to bolts, choosing the right material is critical for ensuring the success of your project. By taking into account factors like environment, strength, budget, and appearance, you can make an informed decision. If you're still unsure, consulting with manufacturers or experts in the field can help you navigate the many material options available.

Now that you have the knowledge, you’re ready to choose the perfect bolt material for your project. Remember: the right choice will save you time, money, and headaches down the line, whether you're purchasing foundation bolts, anchor bolts, or stainless steel U bolts.

#BoltMaterials#BoltManufacturing#IndustrialFasteners#MetalBolts#SteelBolts#BrassBolts#HighStrengthBolts#FastenerIndustry#DurableBolts

0 notes

Photo

Grade 8 Bolts are utilized in heavy manufacturing and are specifically for high-strength applications. Wrights Auto Supplies have assortments of sturdy and durable Grade 8 bolts. Visit our site to buy a selection of bolts and nuts as per your needs.

0 notes