#Hydraulic Motor Market Primary Research

Text

#Hydraulic Motor Market COVID-19 Analysis Report#Hydraulic Motor Market Demand Outlook#Hydraulic Motor Market Primary Research#Hydraulic Motor Market Size and Growth#Hydraulic Motor Market Trends#Hydraulic Motor Market#global Hydraulic Motor market by Application#global Hydraulic Motor Market by rising trends#Hydraulic Motor Market Development#Hydraulic Motor market Future#Hydraulic Motor Market Growth#Hydraulic Motor market in Key Countries#Hydraulic Motor Market Latest Report#Hydraulic Motor market SWOT analysis#Hydraulic Motor market Top Manufacturers#Hydraulic Motor Sales market#Hydraulic Motor Market COVID-19 Impact Analysis Report#Hydraulic Motor Market Primary and Secondary Research#Hydraulic Motor Market Size#Hydraulic Motor Market Share#Hydraulic Motor Market Research Analysis#Hydraulic Motor Market Trends and Outlook#Hydraulic Motor Industry Analysis

1 note

·

View note

Text

Comprehensive Analysis of the Automotive Steering Systems Market

The automotive steering systems market is undergoing significant transformation driven by technological advancements, regulatory changes, and evolving consumer preferences. Steering systems are critical components that impact vehicle safety, performance, and driving experience. This comprehensive analysis explores the current landscape, key trends, challenges, and future prospects of the automotive steering systems market.

Buy the Full Report for More Insights on the Automotive Steering Systems Market Report Forecast

Download a Free Report Sample

Introduction to Automotive Steering Systems

Automotive steering systems are responsible for controlling the direction of a vehicle. These systems have evolved from simple mechanical linkages to sophisticated electronic and hydraulic systems that enhance precision, safety, and driver comfort. The primary types of steering systems include:

Manual Steering Systems

Hydraulic Power Steering (HPS) Systems

Electric Power Steering (EPS) Systems

Electro-Hydraulic Power Steering (EHPS) Systems

Key Drivers of Market Growth

Technological Advancements

Technological innovations are at the forefront of the steering systems market. The shift from hydraulic to electric power steering systems has been a game-changer. Electric Power Steering (EPS) systems offer several advantages, including reduced fuel consumption, improved steering response, and enhanced integration with advanced driver-assistance systems (ADAS). The development of steer-by-wire technology, which replaces mechanical and hydraulic linkages with electronic controls, is further revolutionizing the market.

Regulatory Requirements

Stringent regulatory standards aimed at improving vehicle safety and reducing emissions are propelling the adoption of advanced steering systems. For instance, regulations mandating the inclusion of safety features like lane-keeping assist and automatic emergency steering are driving the integration of sophisticated steering technologies.

Consumer Preferences

Modern consumers demand vehicles that offer superior handling, comfort, and safety. The increasing popularity of electric and autonomous vehicles is also influencing the market. These vehicles require advanced steering systems that can seamlessly integrate with autonomous driving technologies and provide precise control.

Types of Steering Systems

Hydraulic Power Steering (HPS)

HPS systems use hydraulic pressure to assist the driver in steering the vehicle. While these systems have been widely used for decades, they are gradually being replaced by electric systems due to their higher energy consumption and maintenance requirements.

Electric Power Steering (EPS)

EPS systems use an electric motor to provide steering assistance. These systems are more energy-efficient and offer better performance compared to HPS systems. They also enable the integration of advanced safety features and are essential for electric and autonomous vehicles.

Electro-Hydraulic Power Steering (EHPS)

EHPS systems combine elements of both hydraulic and electric power steering systems. They use an electric motor to drive the hydraulic pump, offering a balance between performance and efficiency. These systems are often used in larger vehicles where pure electric systems may not provide sufficient assistance.

Steer-by-Wire Systems

Steer-by-wire systems eliminate the physical connection between the steering wheel and the wheels, using electronic controls instead. This technology offers significant advantages, including weight reduction, increased design flexibility, and enhanced integration with autonomous driving systems. However, it also presents challenges related to system reliability and safety.

Market Challenges

High Development Costs

The development and implementation of advanced steering systems require substantial investment in research and development. This includes the cost of developing new technologies, testing, and ensuring compliance with safety standards. These costs can be a barrier for smaller manufacturers and may slow down the adoption of new technologies.

Complexity and Integration

The integration of advanced steering systems with other vehicle systems, particularly in autonomous and electric vehicles, can be complex. Ensuring seamless operation and maintaining safety and reliability are significant challenges that manufacturers must address.

Regulatory and Safety Concerns

As steering systems become more advanced, ensuring their reliability and safety becomes increasingly critical. Regulatory bodies impose stringent requirements to ensure that new technologies do not compromise vehicle safety. Meeting these requirements can be challenging and time-consuming.

Future Trends and Opportunities

Integration with Autonomous Driving

The development of autonomous vehicles presents a significant opportunity for the steering systems market. Advanced steering systems that can integrate with autonomous driving technologies are essential for the safe and efficient operation of self-driving cars. Steer-by-wire technology, in particular, is expected to play a crucial role in this area.

Electric and Hybrid Vehicles

The shift towards electric and hybrid vehicles is driving demand for advanced steering systems. EPS systems are particularly well-suited for these vehicles due to their energy efficiency and compatibility with electric powertrains. As the adoption of electric vehicles grows, the demand for EPS and other advanced steering systems is expected to increase.

Advanced Driver-Assistance Systems (ADAS)

The integration of ADAS features, such as lane-keeping assist, adaptive cruise control, and automatic emergency steering, requires advanced steering systems. These features enhance vehicle safety and driving experience, and their increasing adoption is driving demand for sophisticated steering technologies.

Conclusion

The automotive steering systems market is poised for significant growth, driven by technological advancements, regulatory changes, and evolving consumer preferences. The shift towards electric and autonomous vehicles presents new opportunities and challenges for the industry. By embracing innovation and focusing on integrating advanced technologies, manufacturers can capitalize on these opportunities and drive the future of the automotive steering systems market.

0 notes

Text

Fluid Power Pump and Motor Market Analysis 2023 Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2033

The Fluid Power Pump and Motor Market encompasses the industry involved in the manufacturing, distribution, and usage of pumps and motors used in fluid power systems. Fluid power systems utilize hydraulic or pneumatic power to transmit force and motion through the use of pressurized fluids such as oil or air. Pumps are responsible for generating the fluid pressure required for the system, while motors convert fluid energy into mechanical motion.

Driven by factors such as industrial automation, construction activities, and the growing demand for energy-efficient systems, the Fluid Power Pump and Motor Market has witnessed significant growth. These components are essential in a wide range of applications across industries such as manufacturing, construction, agriculture, and automotive.

Fluid power pumps and motors come in various types, including gear pumps, vane pumps, piston pumps, hydraulic motors, and pneumatic motors. These components are selected based on factors such as flow rate, pressure requirements, efficiency, and application-specific needs. Hydraulic systems typically use pumps to generate high-pressure fluid, which is then directed to hydraulic motors to produce mechanical motion. Pneumatic systems, on the other hand, use air compressors as pumps and pneumatic motors to convert air pressure into rotational or linear motion.

The Fluid Power Pump and Motor Market is characterized by technological advancements aimed at improving efficiency, performance, and reliability. Innovations such as variable displacement pumps, high-efficiency motors, and integrated sensor technologies enhance system efficiency, reduce energy consumption, and optimize performance in various applications.

Furthermore, the market is influenced by trends such as electrification, digitization, and the adoption of smart technologies. Manufacturers are developing electrically driven pumps and motors with advanced control features, enabling precise control, predictive maintenance, and remote monitoring capabilities. Additionally, the integration of digital sensors, IoT connectivity, and data analytics enhances system intelligence, enabling real-time performance monitoring and optimization.

As industries continue to evolve and demand for fluid power systems grows, the Fluid Power Pump and Motor Market is expected to expand further. Manufacturers, suppliers, and end-users are investing in advanced pump and motor technologies to meet the demands of modern applications for efficiency, reliability, and sustainability

Trends: Identify and analyze trends relevant to the market you're researching. This could include shifts in consumer behavior, industry regulations, technological advancements, or changes in market demand. Look at both short-term and long-term trends to provide a comprehensive view.

Technological Developments: Highlight the latest technological innovations impacting the market. This might involve advancements in automation, artificial intelligence, IoT (Internet of Things), blockchain, or any other relevant technologies. Discuss how these developments are shaping the industry landscape and driving change.

Analysis: Conduct a thorough analysis of the market, including SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis, Porter's Five Forces analysis, and any other relevant analytical frameworks. Assess market dynamics, competitive landscape, and barriers to entry. Provide insights into market segmentation, customer demographics, and buying behavior.

Growth Drivers: Identify the primary drivers fueling market growth. This could include factors such as increasing demand for certain products or services, expansion into new geographic regions, rising disposable income levels, technological advancements driving innovation, or favorable regulatory policies. Quantify the impact of these drivers on market growth wherever possible.

Receive the FREE Sample Report of Fluid Power Pump and Motor Market Research Insights @ https://stringentdatalytics.com/sample-request/fluid-power-pump-and-motor-market/14964/

Market Segmentations:

Global Fluid Power Pump and Motor Market: By Company

Hydro-Gear

Bosch Rexroth Corporation

Parker-Hannifin Corporation

ITT Corporation

Sulzer Pumps

East West Manufacturing

M P Pumps

Rockford Concentric

Bucher Hydraulics

The Oligear Company

Mcnally Industries

Global Fluid Power Pump and Motor Market: By Type

Non-Aerospace Hydraulics

Aerospace Hydraulics

Non-Aerospace Pneumatics

Aerospace Pneumatics

Global Fluid Power Pump and Motor Market: By Application

Military

Aerospace

Mining

Earthmoving Equipment

Marine

Others

Regional Analysis of Global Fluid Power Pump and Motor Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Fluid Power Pump and Motor market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Fluid Power Pump and Motor Market Research Report @ https://stringentdatalytics.com/purchase/fluid-power-pump-and-motor-market/14964/?license=single

Challenges: Identify and discuss the challenges that the market is currently facing. These challenges could include regulatory hurdles, economic instability, supply chain disruptions, intense competition, changing consumer preferences, or technological limitations. Provide insights into how these challenges are impacting the industry and potentially hindering growth or innovation.

Future Outlook: Offer a forward-looking perspective on the market's trajectory. Based on the analysis conducted earlier, forecast the future direction of the market. Consider factors such as emerging technologies, shifting consumer behaviors, regulatory changes, and global economic trends. Discuss potential opportunities that may arise in the future and how stakeholders can capitalize on them. Additionally, highlight potential threats or disruptions that could impact the market landscape.

Mitigation Strategies: Suggest mitigation strategies to address the challenges identified and capitalize on future opportunities. This could involve recommendations for businesses to adapt their strategies, invest in R&D, forge strategic partnerships, or diversify their product/service offerings. Provide actionable insights that stakeholders can use to navigate uncertainties and position themselves for success in the evolving market environment.

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected] ), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

HIGH-PRESSURE COMPRESSED AIR FOR BRAKING POWER

Automobile Market in India

India is the 4th largest producer of automobiles in the world, with an average annual production of more than 4 million motor vehicles. As per the reports, the Indian passenger car market is expected to reach USD 160 billion by 2027 while registering a CAGR of over 8.1% between 2022-27. India could be a leader in shared mobility by 2030. As a result, many manufacturers are investing in new manufacturing plants and increasing capacities in existing plants to cater to the increasing demand.

Overview

Brakes are one of the most critical parts of the active safety systems in automobiles. Better the brakes, the safer the vehicle. Based on the power source, brakes are classified as follows.

Mechanical braking system

Hydraulic braking system

Air or pneumatic braking system

Vacuum braking system

Magnetic braking system

Electric braking system

Out of the above, hydraulic brakes, especially disc brakes, are used predominantly in modern-day automobiles because of higher reliability, increased braking force, etc. Most cars manufactured today use the disc brake system; some manufacturers still use drums; however, their effectiveness diminishes in comparison to the disc brake.

Disc Brake Systems are most widely used in almost all modern-day vehicles, so the need for a good quality disc brake at optimum cost is extremely high. This, in turn, creates a market for more research to be done to optimize the product by keeping the safety intact, thereby creating a huge potential in the field of testing.

Disc Brake Operation

The disc braking system involves many different components, but at its most basic function, the system consists of a disc/rotor, a brake caliper, and brake pads. When the brake pedal is applied, brake fluid creates pressure, squeezing the brake pad against the rotor and creating friction. This friction slows the rotation of the wheels and the vehicle itself.

Brake calipers are a clamp-like component that fits over the disc. Their primary function is to push the brake pads into the disc, and they do this via pistons and hydraulic brake fluid. Inside the calipers are pistons, which have brake pads attached to them. When we put our foot on the brake, pressurized fluid is sent to the pistons, and they push against the pads, which come into contact with the disc surface.

Testing of Brake Calipers

No product reaches the user before it gets tested. Different products undergo different testing processes. Even though various braking system components are tested separately, the calipers should be tested after assembly for leakage and fault-free operation.

Though the hydraulic brake uses brake fluid for the operation, pneumatic testing with high-pressure air will be used in the testing process of the brake assemblies. Using high-pressure air relatively decreases the testing time and increases the life of components compared to hydraulic testing. It also prevents hydraulic oil spillage, thus maintaining a clean and safe work Environment.

Once the brake caliper components are assembled, high-pressure air will be filled and held inside the component. The Pressure range would be approximately 250 barg. In case of any leakages, there would be a drop in air pressure, and thus the leakages in the component will be identified.

The products passing the test parameters will be approved, and the components get rejected if there are any leakages.

Testing of Brake Hoses

Since the actual operation of these brakes is with hydraulic oil, the oil needs to be also fed at pressure to the callipers during operation. This is achieved by a hose connecting the fluid sump to the callipers.

Since the brake operation is at high pressure, the hose carrying also has to be rated at high pressure; thereby, they are also subject to high-pressure pneumatic testing to maintain overall safety.

Solutions at ELGI SAUER

‘Reliable Systems Provide Reliable Solutions’.

ELGI SAUER Compressors have proven expertise in designing and supplying high-pressure air and gas compressors that deliver consistent performance with utmost reliability.

Direct driven – high efficiency and low losses

Capable of working from 0) C to 55 C

Excellent reliability, even during intermittent operation

100 % compressor check at final pressure

State-of-the-art compressor control

Long operating life 24/7

0 notes

Text

Superconducting Magnets Market's Boundless Growth Beyond 2023 through Exhaustive Research

Cylindrical grinders are precision machining tools used to shape the outer surface of a workpiece. They are commonly used in manufacturing and metalworking industries to achieve high levels of accuracy and surface finish on cylindrical or tapered surfaces. The primary function of a cylindrical grinder is to remove material from the workpiece to create the desired shape and dimensions.

Here are some key features and components of cylindrical grinders:

Workpiece: The workpiece is the object being machined on the cylindrical grinder. It can be made of various materials such as metal, plastic, or ceramics. The workpiece is mounted on the grinder and rotates while being processed.

Request For Sample Report: Elevate Your Industry Intelligence with Actionable Insights

https://www.futuremarketinsights.com/reports/sample/rep-gb-17217

Grinding Wheel: The grinding wheel is a rotating abrasive wheel that removes material from the workpiece. It is typically made of abrasive particles bonded together in a specific shape and hardness. The grinding wheel can be adjusted for different diameters and surface finishes.

Wheelhead: The wheelhead is the part of the cylindrical grinder that houses the grinding wheel. It can be moved horizontally and vertically to position the grinding wheel accurately on the workpiece. The wheelhead can also rotate to perform external or internal grinding operations.

Workhead: The workhead holds the workpiece and provides rotational movement. It can be driven by various mechanisms, such as electric motors or hydraulic systems, to rotate the workpiece at the desired speed and direction.

Tailstock: The tailstock is located opposite the wheelhead and supports the other end of the workpiece. It can be moved along the bed of the grinder to accommodate different workpiece lengths. The tailstock may have a center for supporting the workpiece or other devices for specific grinding operations.

Bed: The bed is the main base of the cylindrical grinder, providing stability and support for the various components. It is typically made of a heavy and rigid material, such as cast iron, to minimize vibrations and ensure accuracy during grinding operations.

0 notes

Text

RS Security Co., Ltd (www.szrssecurity.com) is a business with smart biometric barrier gates equipment and top quality services as its core A modern enterprise. The business's primary business is: construction website access control, face recognition security turnstile gates, full height gates barrier, acrylic servo motor swing turnstiles gates, detachable biometric barrier gates, full height turnstiles gates, basketball court payment revolve barrier doors, parking area boom barriers gates, fully automated hydraulic bollards, etc, with car park management equipment, pedestrian turnstile gates Relying on the research and development, production, sales and service of management devices, smart door openers and other products, we provide consumers with thorough management solutions.

RS Security Co., Ltd has concentrated on waist high turnstile gate, half height turnstile gates, dc brushless swing gates gates, train flap gates doors, optical barriers gate, revolve turnstiles doors, barrier-free system, access control, parking area system as the leading role, slowly enhanced The integrated application of magnetic cards, IC/ID cards, barcodes, and infrared series products has developed into the most powerful clever gates barrier items.

RS Security Co., Ltd. is people-oriented, theoretically ingenious, and continuously develops various brand-new products to fulfill the requirements of the marketplace and clients. The business's items and systems have been incorporated into different fields of contemporary life (such as enterprises and institutions, going shopping malls, military units, wise neighborhoods, stations, tourism, etc) with their remarkable functions, outstanding stability, fashionable look design, and very high expense performance. attractions, and so on).

RS Security Co., Ltd. has a number of independent copyright rights and has numerous departments consisting of professional product R&D workers, production workshops, marketing, technical support, and after-sales service. With domestic leading core innovation, it has actually developed a series of software application and hardware products, which have actually passed the nationwide scientific and technological accomplishment appraisal and acquired nationwide intellectual property defense. The company adopts advanced scientific and standardized management style and management approaches, stressing people-oriented and appreciating understanding. We respect talents and are committed to producing a cooperative, unified and favorable working environment, and after that supply our clients with quick, reliable, high-quality and effective services.

0 notes

Text

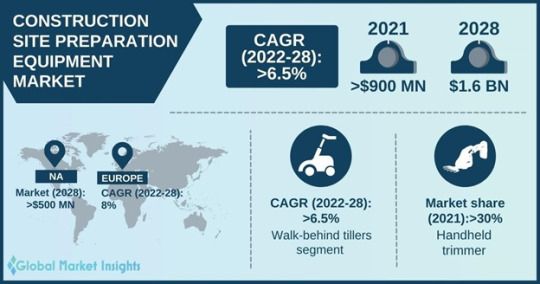

Construction Site Preparation Equipment Market Size, Incredible Possibilities, Growth Analysis and Forecast by 2028 End

The construction site preparation equipment market is expected to grow substantially by 2028 on account of rising number of public infrastructure development projects worldwide. In addition, increasing investments towards R&D activities from manufacturers across key regions is likely to accelerate market expansion over the forecast period.

Burgeoning infrastructure expansion plans from the private sectors across key regions have augmented industry adoption over the past few years. Furthermore, to accommodate the mounting demand for construction site preparation equipment, industry participants have actively been employing gainful strategies, which has positively impacted the overall business outlook.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/5223

For instance, in February 2021, VST Tillers Tractors Limited, an India-based manufacturer of agricultural multipurpose tractors and tillers, entered into a technical partnership with Monarch Tractors, a leading manufacturer of automated, electric, and smart tractors, to co-develop the hardware for tractors. According to the deal, both firms have agreed to collaborate on the technical development for Monarch Tractor's first Series in the compact tractor category.

To cite another instance, in February 2021, STIHL Inc., a U.S.-based manufacturer of outdoor power tools, such as trimmers, construction tools, blowers, and brushcutters, launched its first battery-powered professional trimmer, dubbed the STIHL 135 professional battery platform. The STIHL AP Battery Series provides professional-grade power that may be used for a variety of tasks. The FSA 135 and FSA 135 R provide professional users an energy-efficient and low-maintenance solution with excellent power run times and durability, owing to a commercial-grade brushless motor.

Similarly, in June 2021, Chicago Pneumatic, a prominent industrial manufacturer of power tools, generators, hydraulic equipment, and air compressors, launched its novel cordless connected torque wrench, dubbed the CP86 Series. The CP86 Series includes four models designed for bolting applications in the construction, wind turbines, energy, heavy-duty vehicles, mining, off-road equipment, oil & gas pipelines, and railway industries.

Request for customization @ https://www.gminsights.com/roc/5223

The construction site preparation equipment market has been segregated on the basis of product and region. From the product point of view, the market has further been classified into handheld augers, walk-behind tillers, and handheld trimmers. The construction site preparation equipment industry share from the handheld augers sub-segment is projected to grow at a significant CAGR over the review timeline to reach a notable valuation by the end of 2028. Increasing number of expansion plans from the private sector is likely to fuel segmental expansion through the assessment period.

On the regional front, the Middle East & Africa construction site preparation equipment market is speculated to showcase robust development over the study timeframe owing to supportive government initiatives for smart city and commercial constructions in the region.

Table of Contents (ToC) of the report:

Chapter 1 Methodology & Scope

1.1 Scope and definitions

1.2 Methodology and forecast parameters

1.3 Region-wise COVID-19 impact:

1.3.1 North America

1.3.2 Europe

1.3.3 Asia Pacific

1.3.4 Latin America

1.3.5 Middle East & Africa

1.4 Regional trends

1.4.1 North America

1.4.2 Europe

1.4.3 Asia Pacific

1.4.4 Latin America

1.4.5 MEA

1.5 Data sources

1.5.1 Secondary

1.5.2 Primary

1.6 Industry glossary

Chapter 2 Executive Summary

2.1 Construction site preparation equipment industry 3600 synopsis, 2018 - 2028

2.1.1 Business trends

2.1.2 Regional trends

2.1.3 Product trends

Browse complete Table of Contents (ToC) of this research report @ https://www.gminsights.com/toc/detail/construction-site-preparation-equipment-market

HVAC & Construction Research Reports

Rubber Conveyor Belt Market

Lawn & Garden Equipment Market

Metal Structural Insulation Panels Market

About Global Market Insights:

Global Market Insights, Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider; offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy and biotechnology.

Contact Us:

Aashit Tiwari

Corporate Sales, USA

Global Market Insights Inc.

Toll Free: 1-888-689-0688

USA: +1-302-846-7766

Europe: +44-742-759-8484

APAC: +65-3129-7718

Email: [email protected]

#Construction Site Preparation Equipment Market Analysis#Construction Site Preparation Equipment Market by Type#Construction Site Preparation Equipment Market Share#Construction Site Preparation Equipment Market Development#Construction Site Preparation Equipment Market Growth

1 note

·

View note

Text

Automotive Automatic Clutch, 2022 Growing Demand, Size and Business Outlook

Automotive Automatic Clutch Market Overview:

For the global industry’s Automotive Automatic Clutch market analysis, a research team did thorough primary and secondary research. Secondary research was carried out in order to supplement existing data, segment the market, estimate overall market size, and anticipate market size and growth rate.

Expected Growth is expected to be 9.4% during the forecast period and the Automotive Automatic Clutch market size is expected to reach nearly US$ xx by 2029.

Primary and secondary research is used to identify market leaders, while primary and secondary research is used to assess market revenue. In-depth interviews with important thought leaders and industry professionals, such as experienced front-line staff, CEOs, and marketing executives, were conducted as part of the core research. Primary research comprised in-depth interviews with key thought leaders and industry professionals, such as experienced front-line staff, CEOs, and marketing executives, while secondary research included a review of the main manufacturers’ annual and financial reports. Secondary data is used to calculate global market percentage splits, market shares, growth rates, and breakdowns, which are then compared to primary data.

Request a Free Sample Copy or View Report Summary:

Market Scope:

By defining and assessing market segments and predicting market size, the study aids comprehension of the Global Automotive Automatic Clutch Market dynamic structure. In addition, the report includes a competitive analysis of significant firms based on pricing, financial state, application expansion ambitions, and geographical presence. The research also includes a PESTLE analysis to help shareholders prioritize their efforts and investments in the Global Automotive Automatic Clutch Market.

External and internal factors that are predicted to have a positive or negative impact on enterprises have been researched, presenting decision-makers with a clear picture of the sector’s future. By studying market segments and projecting Automotive Automatic Clutch Market size, the study also assists in understanding the dynamic structure of the Global Automotive Automatic Clutch Market. The study acts as a resource for investors by depicting the competitive analysis of prominent businesses in the Global Automotive Automatic Clutch Market based on price, financial status, growth strategies, and geographical presence.

Market Segmentation:

Automotive Automatic Clutch Market by Type Mechanical Motor Automatic Clutch Hydraulic Automatic Clutch

Automotive Automatic Clutch Market by Applications Passenger Car, Commercial Vehicle

Automotive Automatic Clutch Market Key Players:

Major Key Players are Schaeffler, NSK, Exedy Corporation, Valeo, F.C.C., Aisin Seiki, Clutch Auto, Eaton Corporation, ZF Friedrichshafen, Borgwarner and Others.

Regional Analysis:

A study of the Automotive Automatic Clutch Market at the national level focuses on categories indicated as potentially high-growth, nations with the biggest market share, and countries with the highest development potential. North America (USA, Canada), South America, Asia Pacific (China, Japan, India, Korea), Europe (Germany, UK, France, Italy), and Other nations are the geographical breakdowns in the Automotive Automatic Clutch Market study.

To Gain More Insights into the Market Analysis, Browse Summary of the Research Report:

COVID-19 Impact Analysis on Automotive Automatic Clutch Market: The report covers COVID-19 impact on Automotive Automatic Clutch market.

Key Questions Answered in the Automotive Automatic Clutch Market Report are:

What will be the Automotive Automatic Clutch market’s CAGR throughout the projected period?

Which market category emerged as the market leader in the Automotive Automatic Clutch market?

Who are the key players in the Automotive Automatic Clutch market?

How big will the Automotive Automatic Clutch market be in 2029?

Which firm had the biggest market share in the Automotive Automatic Clutch market?

About Us

Market Report Service began its journey in 2021 with a simple goal to help entrepreneurs know market insights effortlessly. It is a platform that serves businesses with accurate analysis and market insights reports that help in making smart decisions.

Contact Us:

(+1) 479 715 4209

0 notes

Text

Elevators Market Positive Outlook for Industry Opportunities & Trends for Expansion by 2030

Elevators are useful for saving time and efforts taken to climb the stairs. Market Research Future (MRFR) has published a research report about the global elevators market that projects progress for this market during the forecast period between 2021 and 2030.

Analyzing the market structure, this report calculates the future growth potential of the market. It weighs the strategies of the key players in the market and supports the competitive developments like joint ventures, new product developments, mergers and acquisitions, research and developments (R&D) in the market.

The key factors driving the global elevators market growth include growing construction business, high demand for security, huge investment, rapid urbanization, and technological advancement. However, high maintenance cost and installation cost can restrain market growth.

The global elevators market has been segmented on the basis of application, type, and lastly, region. The application-based segmentation segments this market into residential areas and commercial areas. Residential areas are areas where housing societies are located. Commercial areas the areas where corporate offices, businesses, retail outlets, and sometimes, factories are located in.

By type, the market has been segmented into automobile elevators, capsule elevators, goods elevators, hydraulic elevators, passenger elevator, and stretcher elevators. Automobile elevators are meant for transferring vehicles like a car when their location in the showroom needs to be changed. Capsule elevators are mostly used in corporate buildings, usually adding a decorative look to those buildings. Their shape is similar to the shape of a capsule in a pipeline. Popularly, known as “luggage lifts,” goods elevators have been designed to move heavy items easily between main floors of a building. A passenger elevator is most common elevators that are used by people for going from one floor of the building to another floor. Stretcher elevators are used in hospitals to transport stretchers or stretcher-bound patients from one location to another.

The regional segmentation of the global elevators market can segment the market into the regional markets known as North America, Europe, South America, Asia Pacific, and rest of the world (RoW). During the forecast period, Asia Pacific is one of the leading regional markets in terms of value and volume due to the presence of a big market like China. In India and Indonesia, the construction sector is growing due to foreign direct investment. Hence, the demand for elevators is rising in this region. Another important country in this region where the construction sector is rapidly growing due to urbanization is Japan, that can be a potential market.

Key Players

The key players in the global elevators market include Armor (USA), Dover Elevators (USA), Fujitec (Japan), Hyundai (South Korea), Kone Corporation (Finland), Mitsubishi Motors Corporation (Japan), Omega Elevators (India), Schindler (Switzerland), Sigma (USA), and ThyssenKrupp AG (Germany).

Browse Full Report @ https://www.marketresearchfuture.com/reports/elevators-market-1546

Scope of Report

The report for Global Elevators Market of Market Research Future comprises of extensive primary research along with the detailed analysis of qualitative as well as quantitative aspects by various industry experts, key opinion leaders to gain the deeper insight of the market and industry performance. The report gives the clear picture of current market scenario which includes historical and projected market size in terms of value and volume, technological advancement, macro economical and governing factors in the market. The report provides details information and strategies of the top key players in the industry. The report also gives a broad study of the different market segments and regions.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Edibles.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

0 notes

Text

#Hydraulic Motor Market COVID-19 Analysis Report#Hydraulic Motor Market Demand Outlook#Hydraulic Motor Market Primary Research#Hydraulic Motor Market Size and Growth#Hydraulic Motor Market Trends#Hydraulic Motor Market#global Hydraulic Motor market by Application#global Hydraulic Motor Market by rising trends#Hydraulic Motor Market Development#Hydraulic Motor market Future#Hydraulic Motor Market Growth#Hydraulic Motor market in Key Countries#Hydraulic Motor Market Latest Report#Hydraulic Motor market SWOT analysis#Hydraulic Motor market Top Manufacturers#Hydraulic Motor Sales market#Hydraulic Motor Market COVID-19 Impact Analysis Report#Hydraulic Motor Market Primary and Secondary Research#Hydraulic Motor Market Size#Hydraulic Motor Market Share#Hydraulic Motor Market Research Analysis#Hydraulic Motor Market Trends and Outlook#Hydraulic Motor Industry Analysis

0 notes

Text

Bearings MarketSize to Worth USD 52.44 Billion at 3.6% CAGR Share, Growth and Forecast [2022-2026] | Fortune Business Insights™

The Global Bearings Market USD 39.46 billion in 2018 and is projected to reach USD 52.44 billion by 2026, exhibiting a CAGR of 3.6% during the forecast period (2022 - 2026). The booming automotive sector will contribute tremendously to the growth of the market. The rising application of bearings in the food processing industry will bolster healthy growth of the market during the forecast period, states Fortune Business Insights in a report, titled “Bearings Market Size, Share & Industry Analysis, By Type (Ball Bearing, Roller Bearing), By Application (Automotive, Industrial Machinery, Aerospace, Others), and Regional Forecast, 2022-2026” the market size stood at USD 39.46 billion in 2018.

Impact of Covid-19:

The emergence of COVID-19 has brought the world to a standstill. We understand that this health crisis has brought an unprecedented impact on businesses across industries. However, this too shall pass. Rising support from governments and several companies can help in the fight against this highly contagious disease. There are some industries that are struggling and some are thriving. Overall, almost every sector is anticipated to be impacted by the pandemic.

We are taking continuous efforts to help your business sustain and grow during COVID-19 pandemics. Based on our experience and expertise, we will offer you an impact analysis of coronavirus outbreak across industries to help you prepare for the future.

Market Driver:

Increasing Demand for Precision Bearing is Expected to Drive the Bearing Market

The rising industrial automation has led to the demand for precision bearings, which, in turn, will aid the expansion of the market. The increasing application of bearings in the aerospace industry will foster the growth of the market during the forecast period. Moreover, the growing development of advanced robots will fuel demand for miniature bearings in the forthcoming years. The growing focus of manufacturers towards the product offering of miniature bearings owing to the advantages over other bearings will enable speedy expansion of the market. For instance, SKF, a seal and bearing manufacturer offers an extensive range of miniature ball bearings available in stainless steel along with seals or shields for various applications. The technological advancement in medical equipment, and audio-visual equipment and other automation will spur opportunities for the market. Furthermore, the growing demand for coated bearings for as compressors, hydraulic pumps & motors, and marine & offshore applications will favor the growth of the market in the foreseeable future. In addition, the increasing collaborations and partnerships among major key players will subsequently aid the expansion of the market. For instance, Calico Coatings collaborated with ACL, Mahle/Clevite, and Durabond to deliver CT-1 Dry Film Lubricant coated bearings for a high-performance engine.

Who will benefit from the Report?

Market Industry Manufacturers

Consultants and Analysts

Researchers

Industry Specialists

Primary Objectives of Bearings Industry Report:

To analyze target consumers and their preferences.

To determine potential opportunities, challenges, obstacles, and threats in the Bearings Sales

To identify and make suitable business plans according to industry and economic shifts.

To analyze market rivalry and obtain maximum competitive advantages.

To mitigate risks and hurdles to drive informed business decisions.

In this study, the years is taken into consideration to approximate the market

Regional-level analysis of the top geographies:

[North America (United States, Canada, and Mexico), Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe), Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia), South America (Brazil, Argentina, Colombia, and Rest of South America), Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of the Middle East & Africa)

Browse Research Report:

What Will You Find in the Report?

An in-depth analysis of the Bearings Industry across regions – North America, Latin America, Western Europe, Central and Eastern Europe, Asia Pacific, Middle East, and Africa.

How the Market sales are anticipated to grow throughout the forecast period?

How geopolitical policies and technical changes will affect the Market in near future

Where the stakeholders should invest to generate higher profit margins

How consumers (end-users) will reflect to the Bearings industry during the forecast period

Who are the industry leaders and what are the key initiatives taken by them for long term growth?

0 notes

Text

Automotive Steering System Market Explored In the Latest Research

According to The Insight Partners’ research, the global automotive steering system market was valued at US$ 22,501.0 million in 2020 and is likely to hit US$ 30,875.8 million by 2028 to rise at a CAGR of 4.3% from 2021 to 2028. The stringent fuel efficiency norms and rising demand for electrification in vehicles are the potential factors attributed to the market expansion.

Several governments across the world have adopted some concrete automotive emission norms and fuel economy legislation. Various regulatory bodies such as National Highway Traffic and Safety Administration in the US and International Council of Clean Transportation in Europe have laid down fleet-level regulations. Such stringent laws and regulations compelled automakers to spend more on electronic power steering (EPS) instead of conventional hydraulic steering systems. In ideal conditions, an electronic power steering system improves fuel efficiency by 2–4%, reduces fuel consumption by 6%, and lowers CO2 emission by 8gm/km.

The logistics and transportation (public and private) are expanding worldwide. Public transportation is preferred more in Asia and Europe. While in North America, private cars serve as the primary mode of transportation. However, as the urban population is increasing, this current transportation medium is proving inadequate. Hence, the automobile manufacturers are focusing on electrification of vehicles, especially passenger cars. Major countries across the world are striving hard to create green transportation ecosystem. Governments around the world are providing tax deductions and incentives to promote the use of e-trucks and e-buses in public transport. Thus, the rising demand for electric vehicles and the rigid fuel norms drive the global automotive steering system market.

On the other hand, the high cost of electronic power steering systems and difficulties associated with their maintenance hinder the growth of global automotive steering system market.

Based on type, the market is segmented into electronic power steering, hydraulic power steering, and electro-hydraulic power steering. The electronic power steering segment held 73.4% market share in 2020. It amassed US$ 16,521.6 million in 2020 and is speculated to garner US$ 23,230.0 million by 2028 to expand at 4.6% CAGR during 2021–2028.

According to type of vehicle, the global automotive steering system market is split into passenger cars and commercial vehicles. The passenger cars comprises class A, class B, class C, class D, class E, class F, SUV, and MPV sub-segments. The commercial vehicles segment include light commercial vehicles (LCV), medium commercial vehicles (MCV), and heavy commercial vehicles (HCV). With 70.6% market share, the passenger cars segment led the business in 2020. It generated US$ 15,885.6 million in 2020 and is projected to be worth US$ 20,912.2 million by 2028 to grow at 3.8% CAGR throughout the forecast period.

Oure regional analysis states that the Asia Pacific market captured 50.9% share of the domain in 2020. It was evaluated at US$ 11,448.3 million in 2020 and is predicted to reach US$ 16,429.0 million by 2028 to elevate at the highest CAGR of 4.9% over the forecast period.

Key players dominating the global automotive steering system market are China Automotive Systems, Inc.; Nexteer Automotive; Hitachi Automotive Systems Americas, Inc.; Hyundai Mobis; JTEKT Corporation; The Mando Corporation; NSK Ltd; Robert Bosch GmbH; Showa Corporation; and ThyssenKrupp AG, among others.

In March 2021, China Automotive Systems launched a new EPS product to empower advanced driver-assistance system (ADAS). This new product is based on proprietary technology developed by CAAS research & development team. The company started mass production of the product for Great Wall Motors, a leading Chinese automaker.

In February 2019, Nexteer Automotive announced its production milestone of 60 million electronic power steering (EPS) systems globally. The system is used in vehicles ranging from small cars to heavy-duty trucks.

In October 2019, Hitachi Automotive Systems merged with three affiliates of Honda, namely, Keihin, Showa, and Nissin Kogyo, to become a global mega-supplier and expand the business. With this merger, the company would manufacture electrified vehicle drivetrains, electronic control units, chassis parts, engine components, shock absorbers, brakes, and steering systems.

In July 2018, Hyundai Mobis developed an electronic power steering system that takes advantage of two electronic circuits during autonomous driving to maintain normal steering capabilities under any circumstances.

0 notes

Text

Bio-Lubricants Market | Industry Insights, Trends, Outlook and Key Players

Stratview Research, a global market research firm announces the release of the report titled – Bio-Lubricants Market which provides an in-depth analysis of the market dynamics, current and emerging trends, industry forecast, and competitive landscape.

Request a Free Sample here:

According to this report, the global Bio-Lubricants Market is estimated to growth at a healthy CAGR of 5% by 2027.

Market Segments Analysis

The market researchers have studied the Bio-Lubricants Market minutely for better understanding. The report consists of segment-wise details to assist the users in making suitable decisions for better growth opportunities. Below is the short piece of information -

Key Players

ExxonMobil Corporation

Royal Dutch Shell Plc

Total SA

Chevron Corporation

BP Plc

Albemarle Corporation

Fuchs Petrolub AG

Panolin AG

Klüber Lubrication München Se & Co. Kg

Emery Oleochemicals

Binol Lubricants.

Growth drivers and Market Value:

This report, from Stratview Research, studies the Bio-Lubricants Market value and growth drivers over the trend period of 2022-27. According to the report -

Bio-Lubricants market is likely to witness an impressive CAGR of 6.2% during the forecast period. The prime factor that is contributing to the demand for industrial absorbents is mainly the rising sternness of environment-related regulations on chemical and oil spills.

Segment Analysis:

Based on Application Type:

Based on the application type, the market is segmented as hydraulic fluids, metalworking fluids, chainsaw oils, mold release agents, gear oils, two-cycle engine oils, greases, and others. The hydraulic fluid segment accounted for the largest share in 2021, owing to high demand from hydraulic elevators, sweepers, garage trucks, fork lifts, motor graders, and front-end loaders. This segment is estimated to maintain its dominance during the forecast period as well.

Based on Region:

In terms of regions, North America is estimated to be the fastest-growing bio-lubricants market during the forecast period owing to various emission standards and the growing adoption of bio-degradable products. The growth of the market is driven by the evolution of various government initiatives to reinforce environmental regulation. Europe is also anticipated to offer significant growth opportunities over the forecast period, with Germany, France, Finland, Norway, and Italy being the major countries.

Know more about the report, click here

What else are available in this report?

The answer lies in the TOC and other details. Take a sneak-peek into the TOCs of this report.

Report Scope

Report Objectives

Research Methodology

Market Segmentation

Secondary Research

Primary Research

Breakdown of Primary Interviews by Region, Designation, and Value Chain

Data Analysis and Triangulation

Custom Research:

Stratview research delivers custom research services across the sectors. In case of any custom research requirements, please send your inquiry to [email protected]. Or connect with our experts at +1-313-307-4176.

About Us Stratview Research is a global market research firm, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with insightful market data to aid strategic decision making. These exclusive reports are the result of exclusive research methodology and are available for key industries such as chemicals, composites, advanced materials, technology, renewable energy, and more.

0 notes

Text

HIGH-PRESSURE COMPRESSED AIR FOR BRAKING POWER

Automobile Market in India

India is the 4th largest producer of automobiles in the world, with an average annual production of more than 4 million motor vehicles. As per the reports, the Indian passenger car market is expected to reach USD 160 billion by 2027 while registering a CAGR of over 8.1% between 2022-27. India could be a leader in shared mobility by 2030. As a result, many manufacturers are investing in new manufacturing plants and increasing capacities in existing plants to cater to the increasing demand.

Overview

Brakes are one of the most critical parts of the active safety systems in automobiles. Better the brakes, the safer the vehicle. Based on the power source, brakes are classified as follows.

Mechanical braking system

Hydraulic braking system

Air or pneumatic braking system

Vacuum braking system

Magnetic braking system

Electric braking system

Out of the above, hydraulic brakes, especially disc brakes, are used predominantly in modern-day automobiles because of higher reliability, increased braking force, etc. Most cars manufactured today use the disc brake system; some manufacturers still use drums; however, their effectiveness diminishes in comparison to the disc brake.

Disc Brake Systems are most widely used in almost all modern-day vehicles, so the need for a good quality disc brake at optimum cost is extremely high. This, in turn, creates a market for more research to be done to optimize the product by keeping the safety intact, thereby creating a huge potential in the field of testing.

Disc Brake Operation

The disc braking system involves many different components, but at its most basic function, the system consists of a disc/rotor, a brake caliper, and brake pads. When the brake pedal is applied, brake fluid creates pressure, squeezing the brake pad against the rotor and creating friction. This friction slows the rotation of the wheels and the vehicle itself.

Brake calipers are a clamp-like component that fits over the disc. Their primary function is to push the brake pads into the disc, and they do this via pistons and hydraulic brake fluid. Inside the calipers are pistons, which have brake pads attached to them. When we put our foot on the brake, pressurized fluid is sent to the pistons, and they push against the pads, which come into contact with the disc surface.

Testing of Brake Calipers

No product reaches the user before it gets tested. Different products undergo different testing processes. Even though various braking system components are tested separately, the calipers should be tested after assembly for leakage and fault-free operation.

Though the hydraulic brake uses brake fluid for the operation, pneumatic testing with high-pressure air will be used in the testing process of the brake assemblies. Using high-pressure air relatively decreases the testing time and increases the life of components compared to hydraulic testing. It also prevents hydraulic oil spillage, thus maintaining a clean and safe work Environment.

Once the brake caliper components are assembled, high-pressure air will be filled and held inside the component. The Pressure range would be approximately 250 barg. In case of any leakages, there would be a drop in air pressure, and thus the leakages in the component will be identified.

The products passing the test parameters will be approved, and the components get rejected if there are any leakages.

Testing of Brake Hoses

Since the actual operation of these brakes is with hydraulic oil, the oil needs to be also fed at pressure to the callipers during operation. This is achieved by a hose connecting the fluid sump to the callipers.

Since the brake operation is at high pressure, the hose carrying also has to be rated at high pressure; thereby, they are also subject to high-pressure pneumatic testing to maintain overall safety.

Solutions at ELGI SAUER

‘Reliable Systems Provide Reliable Solutions’.

ELGI SAUER Compressors have proven expertise in designing and supplying high-pressure air and gas compressors that deliver consistent performance with utmost reliability.

Direct driven – high efficiency and low losses

Capable of working from 0) C to 55 C

Excellent reliability, even during intermittent operation

100 % compressor check at final pressure

State-of-the-art compressor control

Long operating life 24/7

For brake assembly and hose testing, ELGI SAUER offers different series of products that operate at a wide range. However, as the volume of air consumed in this process is typically low, compressors with low flow rates are generally used.

for visit : https://www.elgisauer.com/blogs/high-pressure-compressed-air-for-braking-power/

0 notes

Text

Get Grab bucket Crane at Reasonable Price

To get a grip on the current market scenario, you need to acquire a market research report. This report provides in-depth analysis of the market with its growth prospects and competitive landscape. It provides insights based on the key players in the market, their primary growth strategies, new product innovations, and geographical expansion. It also contains sales statistics of various manufacturers.

Benefits of open loop control method

The present embodiment enables the grab bucket crane to be automated. The process can be accomplished by a simple configuration and entirely through software processing. This method significantly enhances the open lowering operation of the bucket crane. It can also reduce the downtime associated with the crane. Furthermore, the method provides improved control stability and reduced setting errors.

The present embodiment provides five alignment speed control circuits PI on the grab bucket. Circuit 5 calculates the difference between the motors 12 and 22 and feeds the result to the command circuit of the opening and closing speed control circuit. The present invention also includes six feedforward speed compensation circuits to minimize performance degradation as the speed increases.

Types of crane grab buckets

There are various types of crane grab buckets available in the market. Some of them are specifically designed to handle sand and gravel. Some are open while others have closed claws. There are several different configurations for each type to meet the needs of different industries. The types of crane grab buckets also differ in bulk density.

The report also contains detailed information on the market competition, development policies, manufacturing processes, and cost structures. The study also includes the key players operating in the global crane grab bucket market, along with their product offerings and contact details. In addition, it contains detailed information about the supply chain, revenue, and price, and includes information about the market's growth potential.

Control method

The control method for a Grab bucket crane manufacturers provide control the speed of the machine. It uses the speed difference between the motors to determine the operating speed. It also uses a feedforward method to calculate the compensation amount using the design data. This control method has more advantages than the conventional method. It offers more stable operation, which decreases the risk of setting error. Moreover, it eliminates the need for re-opening the bucket after landing, improving the efficiency of the crane.

The control method for a Grab bucket crane has three important aspects. The first aspect of load balance control includes at least one trial operation. In the trial operation, mechanical rigidity of the load balance is detected and the proportional gain for the control is selected.

Applications

The shell-type grab bucket crane has a broad range of applications in construction sites. It is particularly suitable for loading bulk cargoes such as sand and minerals. Its other uses include trench excavation, road construction, railroad track laying, and foundation excavation. Its hydraulic system is also capable of operating in harsh environments.

Its hoisting mechanism can raise and lower the bucket in an open position, and the automatic closing mechanism is operated by one crank.

Cost

The cost of a Grab bucket crane will depend on several factors, including its size, capacity, and features. A typical model will cost between $30k and $180,000. However, these prices will vary widely depending on size and capacity. For this reason, it is important to know the exact specifications of your crane before purchasing it.

The lifting capacity of a Grab bucket crane will depend on the weight of the material to be lifted. These cranes can handle a weight of up to 20 tons and can be used for a variety of different tasks. They are suitable for a variety of industries, including mining and construction.

0 notes

Text

You may as well get services online

When pruchasing an item, you should verify the warranty to understand the coverage and timeline of the warranty. Many products can still be saved with the help of electric motor repairs. If you notice something wrong with your device, don;t force it to work. He also developed a motor-propelled vehicle. Devices could be equipped from its own electric motor, presenting easy management and improving transmission efficiency. A few inventors adopted the creation of DC motors but will also encountered expensive difficulty with electric batteries. Therefore, a number of electrical industries organized service facilities for electric motors.Electric motors in AustraliaElectric motors have an important role in the industry.- Malfunction.1886: Franklin Julian Sprague built the primary practical Direct current electric motor.

You may as well get services online.1837: Emily and Thomas Davenport discovered the direct current electric motor for commercial use. Motors can be found in household equipment, blowers, pumps, and industrial fans. You may additionally search the net to look for the reliability of the company. After all, you will be paying for it. The development of electric power distribution has ceased for the mean time. Check if they can be using high quality motor parts. Machines is often complicated and are sometimes hard to understand. Do not simply throw away everything.The principle purpose of these kinds of motors is to switch electrical energy into mechanical energy.Generators like alternators and dynamo turn out electrical energy from mechanical energy. There is no need to grasp everything, but at least try to get the description.Ideas about electric motor repairsMachines also have limits.Common parts of electric motor:- Brushes- Rotor or armature- Axle- Field magnet- Commutator- Power supply (AC/DC)Background and advancement1832: British scientist William Sturgeon invented the primary direct current electric motor.

The interaction of magnetic fields and current-carrying conductors creates pressure, helping to make the motors function. If you are not knowledgeable with tools, you should realize some fundamental information about how it works. On the other hand, quite a few motors Household Elevator could also be used as generators. This is typically called electric machines.1873: Modern Direct current was created by chances. In Australia, there are lots of companies offering engine parts, total motor overhauls, engine rewinds, and electric motor repairs.1887-1888: Sprague;s creations greatly improved such as first electrical trolley system in Richmond VA. All of manufacturing techniques do not have limitation in transferring power using regular lines like shaft belts along with other hydraulic pressure. You may even browse on the manual to learn more about it. Always look for the most reliable company for electric motor repairs. There is no commercial market yet for motors.

Motors run up to 600 revolutions per minute and are utilised in several machine devices and printing press. During this time period, Davenport got bankrupt because of the high cost of the zinc electrodes.1892: Electrical elevator and control system was created. In many cases, people tend to throw expensive things. Zenobe Gramme released the earliest successful electric motor in the market. If you do not know something concerning the product you happen to be obtaining, make a research. Power it down and ask for help.1855: Jedlik created a tool soon after comparable principles of electromagnetic self-rotors. You may encounter difficulties with your own product.

0 notes