#ISO 26262 Projects

Explore tagged Tumblr posts

Text

Making ISO 26262 Compliance Smoother and More Efficient for the Automotive Industry

Complying with ISO 26262, the international standard for functional safety in the automotive industry, is a critical requirement for ensuring the safety and reliability of automotive systems. While achieving ISO 26262 compliance may seem daunting, there are strategies and best practices that can make the process easier and more efficient for automotive companies. In this blog post, we will explore key steps to simplify ISO 26262 compliance and foster a safety-oriented culture within the automotive industry.

Establishing a Comprehensive Safety Framework for ISO 26262 Compliance

To make ISO 26262 compliance more manageable, it is essential to establish a robust safety framework that aligns with the standard's requirements. This framework should encompass safety management, hazard analysis, risk assessment, safety goals, safety plans, and safety verification and validation activities. By clearly defining ISO 26262 mandated processes and responsibilities, companies can ensure a structured and systematic approach to compliance.

ISO 26262 Compliance Needs a Risk-Based Approach

ISO 26262 encourages a risk-based approach to functional safety. Instead of applying the same level of rigor to every aspect of a system, companies should prioritize their efforts based on the level of risk associated with each component or function. Identifying and mitigating the most critical risks first can help optimize resource allocation and streamline compliance efforts.

Promoting Cross-Functional Collaboration for ISO 26262 Projects

ISO 26262 compliance requires collaboration among various disciplines, including engineering, safety, testing, and project management. Foster a culture of cross-functional collaboration to facilitate knowledge sharing and decision-making. Encourage open communication channels and create opportunities for regular meetings and workshops to ensure all stakeholders are aligned on compliance objectives.

Leveraging ISO 26262 Compliance Experts

Engaging automotive safety experts can significantly simplify ISO 26262 compliance. These experts possess in-depth knowledge of the standard's requirements and can provide guidance on best practices, gap analysis, and compliance strategies. They can help tailor the compliance process to the organization's specific needs and provide valuable insights throughout the development lifecycle.

Implementing ISO 26262 Qualified Tools and Processes

Invest in tools and processes that support safety-oriented development and verification activities. This includes utilizing functional safety tools, safety analysis tools, requirements management tools, and traceability tools. Automating safety-related processes can enhance efficiency, accuracy, and traceability, while reducing manual effort and errors.

Conclusion

By following a structured and systematic approach, collaborating across functions, leveraging expertise, and embracing a risk-based mindset, automotive companies can simplify the ISO 26262 compliance process. Implementing safety-oriented tools, fostering a safety culture, and providing continuous training further streamline the path to compliance. Ultimately, making ISO 26262 compliance easy is about embedding safety into the DNA of automotive organizations and prioritizing the well-being of both drivers and passengers.

#ISO 26262#ISO 26262 Compliance#Automotive Industry#ISO 26262 Projects#automotive safety experts#automotive safety#ISO 26262 consulting#ISO 26262 consultant#ISO 26262 services#ISO 26262 software#ISO 26262 development

0 notes

Link

#adaptiveinterfaces#automotiveAI#collaborativeR&D#displayecosystems#HMIevolution#innovationconvergence#RegionalTechStrategies#smartmobility

0 notes

Text

Document Management Software for the Automobile Lighting Industry

In the fast-evolving automobile lighting industry, managing vast amounts of technical documents, design revisions, compliance certifications, and production data is critical for success. Smart Factory Solutions Document Management Software (DMS) is tailored to streamline document control, improve collaboration, and ensure regulatory compliance, helping lighting manufacturers deliver innovation with precision and speed.

Key Benefits:

Centralized Information Access: All design files, test reports, and certifications are stored in a secure, easily accessible repository.

Enhanced Compliance: Maintain organized records to comply with global automotive standards like IATF 16949 and ISO 26262.

Faster Approvals: Accelerate project timelines with real-time document sharing, version control, and digital approvals.

Improved Traceability: Track every document revision and action for complete audit trails.

Cost Reduction: Minimize errors, rework, and physical storage costs by transitioning to a fully digital environment.

Key Features:

Secure document storage with role-based access

Automated version control and change management

Workflow automation for approvals and document reviews

Audit-ready records with full traceability

Integration with CAD, PLM, and ERP systems

Applications in the Automotive Lighting Industry:

Managing CAD drawings and design revisions

Storing material and compliance certifications

Tracking product testing and validation reports

Controlling supplier documentation for lighting components

Maintaining manufacturing process documents

Conclusion:

With Smart Factory Solutions Document Management Software, automobile lighting companies can achieve faster innovation cycles, stronger compliance, and smarter document control — setting the stage for delivering reliable, cutting-edge lighting solutions to the automotive world.

0 notes

Text

Functional Safety Market: Global Forecast Over 2032

Allied Market Research, titled, “Functional Safety Market by Device Type, Safety System, Industry Vertical: Global Opportunity Analysis and Industry Forecast, 2023-2032", The functional safety market was valued at $5.5 billion in 2022, and is estimated to reach $14.7 billion by 2032, growing at a CAGR of 10.52% from 2023 to 2032.

Functional safety includes automatic protection mechanisms within a system, designed to respond to input errors, hardware and software failures, and operational stresses such as extreme environmental conditions. Its objective is to minimize risks to individuals, assets, and the environment by ensuring system safety under adverse circumstances. This involves implementing multilayered safeguards, incorporating inherent safety mechanisms, fail-safe design, and thorough testing across critical industries such as automotive, aviation, medical devices, and industrial automation. Through the implementation of functional safety principles, engineers can create reliable systems capable of operating safely even in challenging situations.

The growing awareness among consumers, industries, and regulatory bodies about the importance of safety serves as a significant driver in the functional safety market. As incidents related to safety violations draw more attention and undergo intense investigation, there is a growing awareness of the necessity for strong safety measures. This awareness prompts industries to invest in functional safety solutions to mitigate risks, prevent accidents, and ensure compliance with stringent safety standards. With safety becoming a top priority for both businesses and regulatory bodies, the demand for functional safety solutions continues to rise, driving market growth and innovation in safety technologies and practices.

However, the difficulties or obstacles associated with combining different components, systems, or technologies in the functional safety market pose a significant restraint in the functional safety market. The process of integrating functional safety solutions with existing systems can be complex and time-consuming, presenting hurdles for businesses seeking to enhance safety measures. Integration challenges and the need for thorough testing often extend integration timelines and increase implementation costs. In addition, the diverse nature of existing systems across different industries further increases integration challenges, requiring customized solutions and advanced expertise. As businesses tackle these complexities, they may encounter delays in achieving full functional safety compliance and realizing the desired safety benefits, hindering functional safety market growth projections and adoption of functional safety solutions.

Despite these challenges, the rapid increase of IoT devices and connectivity presents a significant opportunity in the functional safety market. As IoT technology becomes more widespread, it offers innovative ways to enhance functional safety through real-time monitoring, predictive maintenance, and remote diagnostics. By utilizing IoT-enabled sensors and connected devices, industries can gather real-time data on equipment performance, environmental conditions, and potential safety hazards. This real-time insight allows for the proactive identification of safety risks, enabling timely interventions and preventive measures to mitigate accidents and disruptions. In addition, IoT-based predictive maintenance solutions enable organizations to anticipate equipment failures before they occur, minimizing downtime and optimizing safety and productivity. The ability to remotely diagnose and troubleshoot safety issues further enhances operational efficiency and ensures continuous compliance with safety standards. As industries adopt IoT and connectivity solutions, they unlock new opportunities to enhance functional safety and drive sustainable growth in the market.

The ISO 26262 standard plays a vital role in ensuring the safety of automotive systems. It provides a structured framework for implementing functional safety ISO 26262 measures throughout the development process. Adhering to this standard enables manufacturers to identify and mitigate potential hazards in electronic and electrical systems, increasing overall vehicle safety. By integrating ISO 26262 standard principles into their practices, companies can instill confidence in the reliability and safety of their products, thus boosting trust among consumers and stakeholders. In essence, functional safety ISO 26262 serves as a cornerstone for creating vehicles that prioritize safety without compromise.

The functional safety market is segmented into device type, safety system, industry vertical, and region. By device type, the functional safety market is divided into safety controllers/modules/relays, programmable safety systems (PSS), safety sensors, emergency stop devices, final control elements (valves, actuators), and others. By safety system, the market is classified into emergency shutdown systems (ESD), burner management systems (BMS), high-integrity pressure protection systems (HIPPS), turbomachinery control (TMC) systems, fire and gas monitoring control systems, and supervisory control and data acquisition (SCADA) systems. By industry vertical, the market is fragmented into oil and gas, power generation, food and beverage, pharmaceutical, automotive, and others.

By region, the global functional safety market segmentation is analyzed across North America (the U.S., Canada, and Mexico), Europe (the UK, Germany, France, and rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), Latin America (Brazil, Chile, Argentina, rest of Latin America ), and Middle East & Africa (UAE, Saudi Arabia, South Africa, rest of MEA).

The functional safety industry key players profiled in the report include Rockwell Automation Inc., Emerson Electric Company, Honeywell International Inc., Yokogawa Electric Corporation, ABB Ltd., Siemens AG, Schneider Electric SE, General Electric Company, Mitsubishi Electric Corporation, and Omron Corporation. The market players have adopted product launches, acquisitions, and agreements strategies to expand their foothold in the functional safety industry. This strategic activity is a critical component of functional safety market statistics and provides valuable functional safety market insights, highlighting the competitive dynamics and growth strategies shaping the market.

Key findings of the study

In terms of device type, safety sensor is the leading segment in functional safety market share in 2022 and are projected to experience the highest CAGR in the coming years.

By safety systems, Emergency Shutdown Systems (ESD) led in revenue generation in 2022, while Turbomachinery Control (TMC) Systems are expected to see the most rapid CAGR in the forecast period.

By industry verticals, the oil and gas segment accounted for the dominant functional safety market size in 2022, but the automotive sector is forecasted to grow at the quickest CAGR in the future.

Region wise, North America holds the largest portion of the market share in 2022. However, the Asia-Pacific region is predicted to have the highest CAGR during the forecast period.

0 notes

Text

Sensors For Ev Thermal Management Market: Boosting Safety And Performance In Electric Vehicles

The Sensors for EV Thermal Management Market have redefined the automotive industry, marking a significant shift towards sustainability and emission-free transportation. As EV adoption grows globally, thermal management has become a critical aspect of ensuring the optimal performance of these vehicles. The thermal management system in an EV maintains the temperature of key components, such as the battery, motor, and power electronics, to prevent overheating and ensure efficiency. Sensors play a crucial role in EV thermal management systems, providing real-time data to optimize the cooling and heating processes. This blog delves into the market growth, size, legal constraints, market segmentation, and future forecast of sensors for EV thermal management.

Market Growth and Size of Sensors for EV Thermal Management Market

The sensors for EV thermal management market is rapidly expanding, driven by the rising adoption of electric vehicles worldwide. As EV technology advances, maintaining optimal temperature control is essential for ensuring safety, extending battery life, and maximizing efficiency. The increasing focus on battery efficiency, government regulations promoting EV adoption, and advancements in sensor technology are major factors propelling market growth.

In 2024, the global market for sensors used in EV thermal management was valued at approximately USD 1.8 billion and is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.2% during the forecast period of 2024-2032. By 2032, the market size is expected to reach around USD 4.2 billion. The substantial growth of this market is driven by advancements in thermal management systems and an increasing number of electric vehicle launches by major automotive manufacturers. The demand for sensors that provide precise thermal control is on the rise, as manufacturers strive to improve the safety and reliability of their electric vehicles.

The growing EV sales in regions such as North America, Europe, and Asia-Pacific have further boosted the demand for sensors. The emphasis on range optimization and energy efficiency has resulted in an increased focus on advanced thermal management systems, which in turn has increased the demand for temperature, pressure, and humidity sensors.

Legal Constraints and Limitations of Sensors for EV Thermal Management Market

The growth of the sensors for EV thermal management market is not without its challenges. Various legal and regulatory constraints can affect the adoption and development of sensor technologies in EVs. Regulatory bodies in different countries have established standards for the safety and performance of electric vehicles, which include requirements for the thermal management systems and the sensors used within them.

In the European Union, there are strict standards regarding emissions and safety that impact the design and deployment of thermal management systems in EVs. Sensors must comply with industry standards such as ISO 26262 for functional safety, which applies to all electronic systems in vehicles, including thermal management. These regulations increase the cost and complexity of developing sensors, especially for small manufacturers looking to enter the market.

Moreover, privacy and data protection laws also impact the use of sensors. Many sensors collect data related to vehicle performance and driver behavior, and this data must be handled in compliance with regional data protection regulations such as GDPR in Europe. This creates additional responsibilities for manufacturers in terms of data security and compliance, which can hinder the widespread adoption of advanced sensor technologies.

Market Segmentation by Product and Application of Sensors for EV Thermal Management Market

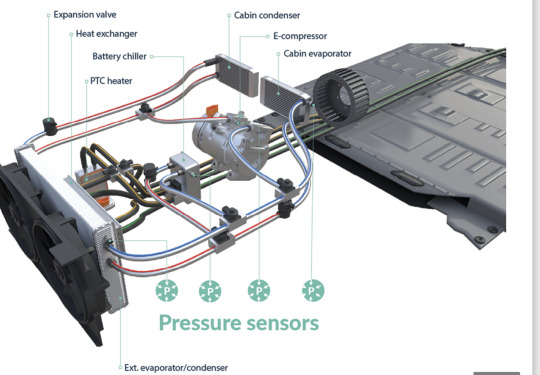

The market for sensors used in EV thermal management can be segmented based on product type and application. Understanding these segments is essential for identifying key growth areas and opportunities in the market. By Product Type

Temperature Sensors: Temperature sensors are the most commonly used type in EV thermal management. These sensors monitor the temperature of key components, such as the battery pack, electric motor, and power electronics, to prevent overheating and ensure efficient performance. As battery technology advances, temperature sensors have become more sophisticated to provide precise temperature readings.

Pressure Sensors: Pressure sensors are used to monitor the coolant pressure in the thermal management system. Maintaining optimal pressure levels is essential for efficient heat dissipation and preventing leaks. Pressure sensors are critical in maintaining the performance and reliability of the cooling systems used in EVs.

Humidity Sensors: Humidity sensors are used to monitor the moisture levels within the vehicle's thermal management system. Excess humidity can lead to corrosion and affect the performance of electronic components, making these sensors vital for maintaining system health.

Flow Sensors: Flow sensors are used to measure the flow rate of coolant in the thermal management system. Ensuring adequate coolant flow is crucial for preventing overheating of the battery and power electronics. These sensors help maintain an efficient cooling process, enhancing the overall reliability of the EV.

By Application

Battery Thermal Management: The battery is one of the most critical components of an electric vehicle, and its performance is highly dependent on maintaining an optimal temperature range. Sensors used in battery thermal management help monitor and control the temperature to ensure battery safety, extend life, and improve efficiency. The demand for sensors in this application segment is expected to grow significantly, as battery technology continues to evolve.

Motor Thermal Management: Electric motors generate significant amounts of heat during operation, which can affect their efficiency and lifespan. Sensors are used to monitor motor temperature and ensure effective cooling to maintain performance. As motor technology advances and power densities increase, the demand for reliable thermal management solutions, including sensors, is rising.

Power Electronics Thermal Management: Power electronics, including inverters and converters, are essential for controlling the power flow in an electric vehicle. These components generate heat during operation, and sensors play a crucial role in maintaining their temperature within a safe range. This helps prevent damage to sensitive electronic components and ensures the efficient operation of the vehicle.

Cabin Thermal Management: Sensors are also used in cabin thermal management systems to ensure passenger comfort. These sensors help control the heating, ventilation, and air conditioning (HVAC) systems to maintain a comfortable cabin environment while minimizing energy consumption.

Future Forecast of Sensors for EV Thermal Management Market

The future of the sensors for EV thermal management market looks highly promising, with multiple factors contributing to its growth. The increasing adoption of electric vehicles, advancements in sensor technology, and the growing importance of energy-efficient thermal management solutions are expected to drive market growth in the coming years.

Technological Advancements: The integration of advanced technologies, such as artificial intelligence (AI) and the Internet of Things (IoT), into thermal management systems is expected to boost the demand for sensors. AI can be used to predict thermal behavior, while IoT enables real-time monitoring and data analysis, leading to more efficient and adaptive thermal management solutions.

Focus on Battery Efficiency: As electric vehicles evolve, there is an increasing emphasis on extending battery life and optimizing performance. Sensors that can provide precise and reliable data on temperature, pressure, and other parameters will be critical in achieving these goals. The development of new battery chemistries, such as solid-state batteries, will further drive the need for advanced thermal management solutions.

Increasing Government Initiatives: Governments around the world are promoting the adoption of electric vehicles through subsidies, tax benefits, and infrastructure development. This is expected to drive the demand for sensors used in thermal management systems, as manufacturers strive to meet regulatory requirements and improve the safety and efficiency of their vehicles.

Expansion in Emerging Markets: The adoption of electric vehicles is not limited to developed regions; emerging markets in Asia, Latin America, and Africa are also showing increasing interest in EVs. As these markets grow, the demand for sensors for EV thermal management is expected to rise, providing new opportunities for market players.

Cost Reduction and Scalability: Advances in sensor manufacturing techniques and economies of scale are expected to reduce the cost of sensors, making them more accessible to a broader range of manufacturers. This will facilitate the widespread adoption of sensors for thermal management in electric vehicles of all price ranges.

Conclusion

The sensors for EV thermal management market is poised for significant growth, driven by the increasing adoption of electric vehicles, advancements in thermal management systems, and supportive government policies. Sensors play a vital role in ensuring the safety, efficiency, and performance of electric vehicles by providing real-time data for temperature, pressure, and humidity control. Despite facing challenges related to regulatory compliance and data privacy, the market's future looks promising, with opportunities for innovation and expansion across different regions. As the automotive industry moves towards electrification, the importance of effective thermal management cannot be overstated. Sensors will continue to play a crucial role in optimizing thermal management systems, ensuring the safety and efficiency of electric vehicles. The future of EVs is closely tied to advancements in sensor technology, making this a critical area of focus for manufacturers, investors, and policymakers alike.

Contact Us for more information on the sensors for EV thermal management Market Research 2023–2030 Forecast :

Or Phone Call us : USA — +1 507 500 7209 | India — +91 750 648 0373 Browse More Similar Articles. Sensors for EV Battery Pack and Cell Connection System Market Size Capacitor in Electric Vehicles EV Market Structure EV Charge Connector Assemblies Market Growth EV Range Extender Market Development

#sensors for EV thermal management#ev market#ev thermal management#sensors for EV thermal management market#market research#market report#report prime

0 notes

Text

IBM Engineering Systems Design Rhapsody 10.0.1 Declaration

Rational Rhapsody 10.0.1

Design of IBM Engineering Systems Strong model-based systems engineering (MBSE) tools like Rhapsody make it easier to design, analyze, and validate complex systems and create software based on those models. The complete product development lifecycle, including specification, development, testing, and delivery, is easily integrated into Rhapsody thanks to its strong support for the unified modeling language (UML) and systems modeling language (SysML).

IBM Engineering Systems Design Rhapsody

Deliver software and systems of higher quality more quickly with digital threading across domains, production code generation, smooth simulation, and reliable modeling.

- Advertisement -

What services does Rhapsody offer?

With its suite of tools, IBM Engineering Systems Design Rhapsody (formerly known as Rational Rhapsody) provides a tried-and-true method for modeling and systems design tasks, enabling you to handle the complexity that many organizations encounter while developing new products and systems. Rhapsody is a component of the IBM Engineering portfolio, offering systems engineers a collaborative design, development, and testing environment that supports AUTOSAR import and export capabilities along with UML, SysML, and UAF. Furthermore, the solution speeds up industry standards like ISO 26262, DO-178, DO-178B/C, and UPDM and permits control of defense frameworks like DoDAF, MODAF, and UPDM.

Advantages

Provides ongoing validation

Utilize quick simulation, prototyping, and execution to get ongoing validation and address mistakes early on, when they can be fixed more affordably.

Offers automated consistency verification

Employ collaborative reuse and automatic consistency checking to boost agility and lower recurring and non-recurring expenses.

Work together with your engineering group

With the use of design tools like Mathworks Simulink or Engineering Systems Design Rhapsody, you can share, work with, and evaluate your engineering lifecycle artifacts with the larger engineering team.

- Advertisement -

Usability

Simplify the design process with a cutting-edge UX that lets you customize the tool interface to your own requirements and tastes, making model visualization simpler.

Crucial characteristics of IBM Rhapsody goods

Examine and clarify the project’s needs

System specifications, interface design papers, and system test cases are automatically generated by the software using SysML, UML, UAF, and AUTOSAR import and export capabilities.

Go from design to implementation quickly

With the use of UML, it provides an affordable comprehensive software engineering environment for graphically designing C++, C, or Java applications.

Create documentation and automate design reviews

Using a central repository accessible via the web, Rhapsody – Model Manager facilitates cross-disciplinary team collaboration, sharing, review, and management of designs and models. Customers and suppliers can use a web client to access information. The program streamlines stakeholder communication, expedites decision-making, and enhances quality by automating design evaluations. Comprehensive documentation can be produced for reporting, compliance, communication, and specifications.

Develop, model, and implement designs for early verification

In addition to having all the features of Rhapsody Architect for Systems Engineers, Rhapsody – Designer for Systems Engineers enables you to simulate, prototype, and carry out designs for early requirements, architecture, and behavior validation. This is a model-based system engineering (MBSE) environment that makes use of the widely used SysML and UML frameworks. With enhanced validation and simulation, it shortens time-to-market, increases productivity, and helps you adjust to changing client requirements.

Engage in an agile engineering environment that is embedded and real-time

Agile software engineering environment for C++, C, Java, and Ada that is embedded and real-time (includes MISRA-C and MISRA-C++) is provided by Rhapsody – Developer. Along with the features of IBM Engineering Systems Design Rhapsody (Rational Rhapsody) – Architect for Software, it offers fast prototyping and simulation for design-level debugging, automated build generation for continuous integration, and support for safety-critical software lifecycle issues.

Allow for the smooth integration of the AUTOSAR standard. The AUTOSAR Extension is a part of IBM Rhapsody Model-Driven Development (MDD). This potent combination streamlines and expedites the process of developing automotive software, freeing up developers to concentrate on building reliable and effective solutions that satisfy the stringent demands of the modern industry.

Rhapsody 10.0.1

IBM is pleased to announce the introduction of IBM Engineering Systems Design Rhapsody version 10.0.1, which includes several new features and changes aimed at optimizing usability, automation, and integration.

Improved DOORS 9 integration promotes consistency and productivity

Rhapsody 10.0.1 enhances accuracy, traceability, and smoother operations by providing closer connection with the IBM Requirements Management DOORS system.

The new ReqXChanger interaction with DOORS 9 is crucial to this release. With better requirement visualization and traceability straight within Rhapsody, ReqXChanger replaces the Rhapsody Gateway and enables a more efficient workflow between Rhapsody and DOORS.

With seamless movement across the digital thread connecting DOORS and Rhapsody, users can now access and inspect model diagrams and elements in DOORS 9. The transition to the improved functionality is easy and seamless.

Change-aware synchronization maintains requirements and model in sync between Rhapsody 10.0.1 and DOORS 9, reducing effort and complexity in tracking changes in artifacts. To fit the unique requirements and surroundings of the users, this synchronization can be automated and tailored.

Extending IBM collaboration with Siemens to improve systems design through automation and integration

IBM has one major enhancement in this release as part of our continued collaboration between the Siemens and IBM product teams. By combining several components, this improvement aims to strengthen the digital thread and promote visibility, traceability, and interoperability.

Now, you may establish connections between Siemens Teamcenter specifications and parameters and model elements: To correlate Teamcenter requirements and parameters with model elements, choose them in the Rhapsody UI. Request the enabling plug-ins by contacting Siemens.

Significant improvements to workflows, usability, and testing

Better testing and usability are more important as system design complexity and interconnection increase. To address this difficulty, Rhapsody 10.0.1 has added new features and improved Test Conductor, such as increased test case coverage that offers a thorough rundown of all test cases. By transferring message-related test scenarios across multiple architectures, a technical preview of Message Mapper further streamlines scenario mapping.

Additional parallel development prompts improve design process efficiency by warning users when they are working with out-of-date model versions, streamlining merge operations, and fostering better teamwork. The product interface has been improved, allowing for more menu controls, such as toolbar and pop-up menu items, to enable complex customisation.

Rhapsody 10.0.1’s enhancements to the Rhapsody AUTOSAR Extension aid teams in managing challenging projects and increasing output. The installation package includes updated example models that are useful for understanding and implementing AUTOSAR standards.

Try out Rhapsody 10.0.1, IBM Engineering Systems Design, right now

Rhapsody 10.0.1 keeps up its good work as a top MBSE tool by providing enhanced automation, usability, and integration to facilitate the design and implementation of complex systems. Additionally, it advances the cooperation between IBM and Siemens Digital Industries Software in their quest to develop strong system engineering tools that empower businesses to design, develop, and produce high-performing, environmentally friendly products.

Read more on govindhtech.com

#IBMEngineeringSystems#SysM#design#IBMproduct#DesignRhapsody1001Declaration#featuresofIBM#systemdesign#automation#workflows#productivity#IBMcollaboration#ImprovedDOORS9#ibm#technology#technews#news#govindhtech

0 notes

Text

Mastering Automotive Embedded Systems: A Comprehensive Course at Technoscripts

Technoscripts is proud to present an immersive and comprehensive course on Automotive Embedded Systems, designed to equip aspiring engineers and professionals with the knowledge, skills, and expertise required to excel in the dynamic automotive industry. In today's fast-evolving automotive landscape, embedded systems play a crucial role in shaping the future of transportation, with innovations ranging from advanced driver assistance systems (ADAS) to autonomous vehicles revolutionizing the way we commute and interact with vehicles.

Our Automotive Embedded Systems course at Technoscripts is meticulously crafted by industry experts and seasoned professionals, ensuring that students receive cutting-edge training aligned with the latest industry trends and technological advancements. Through a combination of theoretical learning, hands-on practical sessions, and real-world projects, participants will delve into the intricacies of automotive embedded systems architecture, software development, communication protocols, sensor integration, and testing methodologies.

With a focus on industry-relevant skills and practical application, our course covers a wide range of topics, including microcontroller programming, automotive networks (CAN, LIN, FlexRay), embedded software development (C/C++, MATLAB/Simulink), real-time operating systems (RTOS), vehicle diagnostics, cybersecurity, and compliance standards (ISO 26262). Students will have the opportunity to work on industry-standard tools and platforms, gaining valuable experience and insights that will set them apart in the competitive automotive job market.

At Technoscripts, we are committed to providing a dynamic and engaging learning environment, where students can interact with industry experts, collaborate on projects, and build a strong foundation for a successful career in automotive embedded systems engineering. Whether you are a recent graduate looking to kickstart your career or a seasoned professional seeking to upskill and stay ahead of the curve, our Automotive Embedded Systems course offers the perfect blend of theoretical knowledge and practical expertise to help you thrive in the exciting world of automotive technology. Join us at Technoscripts and embark on a journey towards becoming a sought-after automotive embedded systems engineer, driving innovation and shaping the future of mobility.

#automotiveembeddedsystemscourse#automotiveembeddedinstitute#embeddedtraining#embeddedclasses#embeddedcourse#embeddedinstitute#automotiveembeddedcourse#automotiveembeddedclasses#embeddedsystemscoursepune#automotiveembeddedtestingcourse

0 notes

Text

Automotive Embedded Systems Course: Embedded Box

Course Overview:

The Automotive Embedded Systems Course at Embedded Box is designed to provide participants with a comprehensive understanding of embedded systems in the automotive industry. This course focuses on the design, development, and implementation of software and hardware components in vehicles, covering key

concepts and practical applications.

Course Duration:

Total Duration - 3 Months

Prerequisites:

Basic knowledge of embedded systems

Proficiency in programming languages (C, C++)

Familiarity with microcontrollers and electronics

Course Outline:

Introduction to Automotive Embedded Systems

Overview of embedded systems in automobiles

Importance and applications in the automotive industry

Emerging trends and challenges in automotive embedded systems

Embedded Hardware in Vehicles

Microcontrollers and microprocessors used in automotive systems

Sensors, actuators, and interfaces in vehicles

Communication protocols (CAN, LIN, FlexRay)

Embedded Software Development for Automotive Applications

Real-time operating systems (RTOS) for automotive systems

Software architecture design for automotive systems

Programming techniques for embedded systems in vehicles

Automotive Networking Technologies

Controller Area Network (CAN) bus architecture and applications

Diagnostic protocols like OBD-II and UDS

Integration of Ethernet and other communication protocols in vehicles

Embedded System Security in Automotive Industry

Cybersecurity threats and vulnerabilities in automotive systems

Best practices for secure coding in embedded software

Implementation of intrusion detection and prevention mechanisms in vehicles

Functional Safety Standards in Automotive Systems

Overview of ISO 26262 standard for functional safety in automobiles

Safety mechanisms and requirements specific to embedded systems

Application of Failure Modes and Effects Analysis (FMEA) in automotive settings

Automotive Embedded Software Testing

Testing methodologies for automotive software development

Validation and verification techniques for embedded systems in vehicles

Tools and frameworks used for testing automotive embedded software

Case Studies and Projects

Real-world examples showcasing automotive embedded systems

Hands-on projects to apply learned concepts practically

Industry standards and best practices within the automotive embedded systems domain

Assessment:

Regular quizzes and assessments to gauge understanding

Practical assignments to implement theoretical knowledge

Final project demonstrating skills acquired during the course

Certification:

Upon successful completion of the Automotive Embedded Systems Course at Embedded Box, participants will receive a certificate of completion, validating their expertise in designing and developing embedded systems for automotive applications.

#embeddedtraining#embeddedcourses#embeddedsystems#embedded training system#embeddedd#embeddedcourse#embeddedsystem#embeddedsysytem#embeddedsystemcourse#embedded

0 notes

Text

Functional Safety (FuSa) Services in India, USA, Europe

Leading automakers are quickly evolving to Software Defined Vehicles, with modern vehicles having multiple electronic systems with millions of lines of code running on them. In an industry like Automotive, humans are increasingly dependent on electronic systems to monitor and control many aspects of the vehicle. Therefore passenger safety becomes paramount.

Functional Safety (FuSa) Services is an integral part of the product development process in any Automotive Electrical and Electronic system, to ensure the safe and reliable operation of the system. Therefore, FuSa is about adopting a systematic approach to identify, assess, and devise ways to mitigate the risk/potential hazards that may arise. In other words, should something fail, we want it to fail predictably.

For automotive applications, the “ISO 26262 - Road vehicles -Functional safety Services” standard serves as the directive based on which the Functional safety development process is to be based.

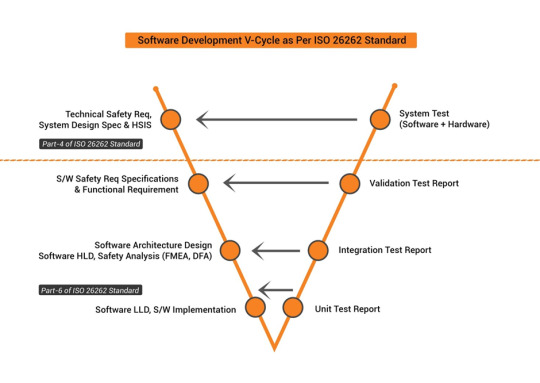

Functional Safety Process

We begin by conducting a thorough Hazard and Risk Analysis (HARA) where potential risks are identified and categorized. This is used to determine the ASIL Level ranging from A to D. Further analysis is conducted by DFMEA (Design Failure Mode Effect Analysis) and FMEDA (Failure modes, Effects and Diagnostic Analysis), and based on the assessment, the Functional Safety concept is developed, where safety requirements are defined and this is used to arrive at the System Level, Hardware and Software level requirements are defined in the implementation phase, along with rigorous testing and validation procedures used to ensure that the system meets the designed requirements. We base these processes as guided by ISO 26262 standards that is crucial in ensuring that the electronic systems operate predictably and can handle failures and events in a predetermined manner.

Our Functional Safety Services

We support major parts of ISO 26262 development such as the Concept Phase, Product Development at the System, Hardware, and Software Levels, along with Supporting processes.

Our team has a wide range of experience from more than a decade of working on individual system projects and full vehicle development projects. We can support individual aspects of the process as well as end-to-end services, traveling along with the development process.

0 notes

Text

IAR fully supports Infineon's latest TRAVEO T2G CYT6BJ body control MCU family products

According to the information received by Lansheng Technology, it has fully supported the latest CYT6BJ series in Infineon's TRAVEO™ T2G body control MCU family. IAR Embedded Workbench for Arm is a complete embedded development solution, equipped with highly optimized compiler and build tools, code analysis tools C-STAT and C-RUN, and powerful debugging functions. This enables developers working on complex automotive body electronics applications to take full advantage of the features of the TRAVEO™ T2G MCU to create innovative designs with high code quality. IAR Embedded Workbench for Arm supports AUTOSAR and provides a functional safety version to help customers accelerate product certification.

Clara Volkmar, Director Product Marketing Body and Driver Information, Infineon's Automotive Division, said: "Infineon's TRAVEO™ T2G microcontrollers provide a compact solution to meet the needs of modern automotive body electronics systems and can take advantage of IAR Professional and suitable third-party development tools such as Embedded Workbench for Arm to achieve efficient development. Thanks to such a powerful tool partner as IAR, developers can quickly realize their demanding automotive applications even with our latest CYT6BJ series chips project."

By supporting all available TRAVEO™ T2G series chips, including the latest CYT6BJ series, IAR Embedded Workbench for Arm ensures compatibility and provides developers with highly optimized build tools and advanced debugging features: such as complex code and data interrupts Points, runtime stack analysis, call stack visualization, code coverage analysis, and integrated monitoring of power consumption contribute to a seamless development experience. With the code analysis tools C-STAT and C-RUN, developers can fully control the code quality.

For companies with functional safety requirements, IAR Embedded Workbench for Arm offers a functional safety version certified by TÜV SÜD (certified according to ISO 26262 requirements). This functional safety version is also certified according to IEC 61508, IEC 62304, EN 50128, EN 50657, IEC 60730, ISO 13849, IEC 62061, IEC 61511 and ISO 25119. For companies using continuous integration (CI) workflows and automated build and test processes, IAR Build Tools is also available for Linux-based frameworks. In addition, IAR's professional technical support, training and flexible licenses enable all customers to find a solution that suits their specific needs.

Lansheng Technology Limited, which is a spot stock distributor of many well-known brands, we have price advantage of the first-hand spot channel, and have technical supports.

Our main brands: STMicroelectronics, Toshiba, Microchip, Vishay, Marvell, ON Semiconductor, AOS, DIODES, Murata, Samsung, Hyundai/Hynix, Xilinx, Micron, Infinone, Texas Instruments, ADI, Maxim Integrated, NXP, etc

To learn more about our products, services, and capabilities, please visit our website at http://www.lanshengic.com

0 notes

Text

TVS Motor Company Recruitment 2023 , Hosur plant

TVS Motor Company Recruitment 2023 | Hosur plant | White Collar Jobs in TVS Group of Company | Qualification : B.E.Mechanical & Electrical Engineer can apply Company Name : TVS Motor Company TVS Motor Company Recruitment 2023 | Hosur plant | White Collar Jobs in TVS Group of Company | Qualification : B.E.Mechanical & Electrical Engineer can apply. Development Engineer (Development Engineer_CP - Super Premium & Co-operation Projects), Sourcing & Development Engineer (Sourcing & Dev Eng_CP - Super Premium & Co-operation Projects) Office Location: Hosur Plant (Plant) Our Latest YOUTUBE Videos Link : https://www.youtube.com/channel/UCZYt-jtPk975fMuI6tLpUEg Our Telegram Channel Link: https://t.me/employmentjobs

TVS Motor Company Recruitment 2023 Related Jobs : - Sharda Motors Company Jobs - Hyundai Supplier Company Jobs - Nissan Company Jobs In Chennai Job Interview in Pegatron Company – Diploma & B. E. Engineers | Mahindra World City | Chengalpattu Designation: Engineer & Sr.Engineer Educational Qualifications: B.E. Engineer & Diploma Role: Permanent Year of Experience: Min Experience Job Location: Mahindra World City – Chengalpattu Apply link - Click Here BEL Recruitment 2023 | BEL நிறுவனத்தில் Apprenticeship Training அறிவிப்பு Designation: Apprenticeship Training Educational Qualifications: B.E, B.Tech Engineers Role: Trainee Year of Experience: Fresher Job Location: Bangalore Salary Details: 17,500 /- Per month Apply link - Click Here Latest Jobs By : Chennai JobsClick HereCoimbatore JobsClick HereBangalore JobsClick HereHyderabad JobsClick HereAndra Pradesh JobsClick HereSalem JobsClick HereMadurai JobsClick HereTrichy JobsClick HerePondicherry JobsClick HereAcross India JobsClick HereOther Cities JobsClick HereTVS Motor Company Recruitment 2023 Designation: Development Engineer Educational Qualifications: B.E.Mechanical & Electrical Role: Permanent Year of Experience: Min Experience Job Location: Hosur , Tamilnadu Salary Details: As per the Company Standard Mechanical JobsClick HereELE / ECE JobsClick HereCivil JobsClick HereIT / Software JobsClick HereBPO / Call Centre JobsClick HereH/W & Networking JobsClick HereHuman Resource Jobs Click HereAcc/Fins JobsClick HereArts & Science JobsClick HereTVS Motor Company Recruitment 2023 TVS Motor Company Recruitment 2023 Job Description : Understanding and implementation of GS / QV / LH (BMW standards - material, surface, process, marking, aesthetics etc.) requirements in EV part development Understand and review with suppliers periodically EV related standards such as i)Functional safety relevant according to ISO 26262 ii)EMI / EMC iii)Software development procedure for instance for Ensure stage wise maturity requirements are met in part development for each milestone. Status update in the project meetings and workshop to BMW Conduct & review DVP (before & after SOP) as per agreed test plan list among supplier, TVS & BMW Appearance sign off workshops between supplier, TVS & BMW for alignment on aesthetic requirements to contractual QZS requirement Evaluation of new product cost for subsystem by zero base costing / benchmarking / comparative quotations How to Apply for this Job? Details & Apply link : Click Here Titan Company Jobs | Hosur Location Designation: Mechanical Engineer Educational Qualifications: B.E.Mechanical Engineer Role: Permanent Year of Experience: Min 2 Years Job Location: Hosur , Tamilnadu Apply link - https://myemploymentjobs.com/titan-company-jobs-hosur-location-b-e-mechanical-engineer/ Foxconn Company Off Campus Drive 2023 Designation: Trainee Educational Qualifications: Mechanical , EEE , ECE & Arts and Science Role: Permanent Year of Experience: Fresher Job Location: Sriperumbudur , Chennai Apply link : https://myemploymentjobs.com/foxconn-company-off-campus-drive-2023/ TATA Auto Jobs | டாடா நிறுவன நிரந்தர வேலை வாய்ப்புகள் Designation: Engineers Educational Qualifications: B.E , B.Tech , M.E, M. Tech Role: Permanent Year of Experience: 1 – 8 Years Experience Job Location: Chennai , Bangalore & Pune Apply link : https://myemploymentjobs.com/tata-auto-jobs-permanent-job-openings-2023/ For more Job info, subscribe to our website & and check our website daily. Join Our youtube ChannelClick HereJoin Our Telegram ChannelClick HereOur linkedin PageClick HereOur Quora PageClick Here Read the full article

#TVSMotorCompanyRecruitment#TVSMotorCompanyRecruitment2023#TVSMotorCompanyRecruitment2023fresherjobs#TVSMotorCompanyRecruitment2023hosur#TVSMotorCompanyRecruitment2023hosurplant#TVSMotorCompanyRecruitmentmechanical

0 notes

Text

ISO 26262 FUNCTIONAL SAFETY TRAINING AND CERTIFICATION FOR AUTOMOTIVE

Gaining an ISO 26262 Functional basic security training and certificate offers operational security experts and their businesses that an upperhand in the business. ��It will help individuals develop a spot for themselves at the business enterprise. These aims are fulfilled while you gets an ISO 26262 Functional Security instruction:-

TÜV SÜD conducts instructor-led training programs to offer a practical comprehension of the idea of ISO 26262 operational safety of street vehicles at the automotive trade. The training program is tailored in accordance with the dependence on their audience. But, there are particular requirements for attending our Instructor-led ISO 26262 Functional Security Training Software conducted by TÜV SÜD at India. The requirements for your instruction module are as follows:

Make sure that you satisfy the requirements of the business enterprise through a whole comprehension of the model-based procedures to come up with safety related systems in accordance with ISO 26262 benchmark Prove your know how of operational safety with an internationally recognised ISO 26262 certificate and eventually become an essential component of the state TÜV SÜD operational security professional communityGain expertise for a operational basic security engineer, specialist or professional from the automotive industryConstruct internal competencies to successfully undertake operational security projects efficiently and economically and gain a competitive advantage WHAT ARE THE BENEFITS OF searching for THE iso 26262 training AND CERTIFICATION plan?

Any professional who's interested in realizing the operational safety related electric and electrical systems composed of hardware and software components in electrical vehicles, either working or prepared to generate a livelihood within the automotive industry sector has to attend the application. The path can be obtained upto really possess a crystal very clear understanding and working experience of the way that safety- related systems needs to be managed and commanded to mitigate threats and avoid errors. They can sometimes incorporate product programmers, R&D professionals, control engineers, engineers, safety engineers, system integrators, EPCs, managers of technology departments, sales agents to safety services and products systems and services, sales engineers, professionals and managers, promotion pros or anyone who would like to acquire their operational basic security knowledge certified in the relevant area of ISO 26262 Functional Security at the automotive trade.

Breakdown of ISO 26262 Training Program MODULES:

Course modules inch to 4 present one to the procedures essential for the function in the security lifecycle (recommended for beginners). You're going to be made knowledgeable about the respective topics together with the assistance of practical examples. All class modules 1 - 4 embrace a situation-based method of the use of safety investigations and encouraging procedures and the subsequent deliverables. Explanations of those essential job services and products and proper treatment of their security plan are naturally an integrated portion of modules.

This content with the brand new variant was revised related to the very first variant in some specific locations. Furthermore to two new parts into the variant, the Edition two introduces many developments, concretizations and brand fresh instances, that were originated from the adventures from the technical application of their norm from early decades. The 1day class offers a synopsis of the important shifts in Edition two and also exemplifies its own proper implementation with the assistance of examples.

ISO 26262 Functional Security Certification and Training Application, trains professionals to own absolute comprehension and upgraded technical understanding about their safety related systems which the normal makes up about. It is aimed in building a simple understanding about safety related works connected to electronic and electrical systems to minimise failure and risks from the automotive industry. Thus, fundamentally it covers the total life cycle of this automotive item. Implementing ISO 26262 at the original phase, really helps ensure no such risks routine at a subsequent period of manufacturing, even as it will become costly to repair the issue.

Together with gaining functional knowledge in security associated purposes, the iso 26262 certification and Training Program Offers additional advantages that are as follows-

Improve your efficacy with courses, joining theory with practical expertise in the field of operational basic security Minimise risks by maintaining your employees current concerning regulations and standards in mathematics and technology, thereby permitting them to spot issues before your surgeries are influenced Prevent product recalls and lack in standing by employing an optimized tailored procedure Prevent product failures, and save some time and monetary deficits Profit competitive advantage by employing your understanding of this diverse functions all through the security life cycle, as a way to come up with the best services for you and your clients WHO SHOULD ATTEND THE ISO 26262 TRAINING & CERTIFICATION PROGRAM?

Based on years of technical expertise within the industry of Profession basic safety training, we offer you the essential expertise in learning and understanding about ISO 26262 second Edition. Safety is just one of the vital issues in evolution now legal for several road vehicles such as buses, trucks, motor cycles and the rest of the automobiles. The sector-specific wants of electric or electronics (E/E) systems concerning road vehicles is clarified within this standard. Our training modules are all derived from the technical use with the standard in your ordinary business to prevent increasing hazard from systematic and arbitrary hardware failures. Our purpose is to offer professionals practical wisdom and experience with your assessments courses, to take informed decisions and mitigate risks.

The electric and electrical systems composed of both hardware and software components in vehicles have been regulated by this standard. Compliance to ISO 26262 operational security standards in automotive is now vital for its OEMs, automotive designers and providers for both automotive and protection improvement. ISO 26262 operational security hires automotive OEMs and providers to check out and record the operational security process to make sure their apparatus and procedures run safely and precisely with no malfunction. It places a summary for quantifying risks and ascertaining hazard categories called ASILs (Automotive Safety Integrity Levels) and targets at reducing potential threats in automotive systems. It defines the security life cycle from the concept phase before decommissioning of this automotive merchandise or system. It monitors and measures risks to make sure an acceptable degree of safety is achieved from the automotive item. With evolving automation and application of automotive systems, ISO 26262 makes up about establishing the principle for risk management by establishing the standards for hardware and applications development in addition to analyzing, looking to get the greatest levels of safety. Thus, in the modern period it's essential to coach professionals from the automotive industry to possess complete understanding of ISO 26262 operational safety automotive standards to effectively handle their systems together without minimum quantities of danger.

General Breakdown of the newest attributes of ISO 26262 Edition Two Display of this newest Part 1 2 for bicycles Display of this new Part 1-1 for semiconductor growth Changed demands Partly 2 9 New alternative options Cases of execution

TÜV SÜD has got the skill to give ISO 26262 Functional Security Certification and Training Software for all street vehicles such as buses, trucks, motor cycles and the rest of the automobiles depending on latest variant in India.

1 note

·

View note

Photo

!!! 😈

45/47th N.A President Clearance :

SEALPACKS -> N.A AIN'T BROKES ->

Domain : Israel/Antel/Palestine / Templi { .il/.tm/™ }: ICCID/IMSI

VISA TYPES / CLEARANCE :

: PROJECT NORTHWIND OPERATIONS{ ISRAEL } :

DAILY PRO FILINGS_PEAR.SON'S : SEXUAL ASSAULT INSTITUTIONS : VIGIL SEALPACK'S ISRALITES /

IL EXCHANGE ORIGIN : TESTMENTS BOOK }

3.5 -> CENTRAL SECTOR X , INDI.A

ieeexplore.ieee.org/document/8489377

KHRONOS/KNIGHTS ISS.US : In the Blood Wars : HELL NEEDS

{ RELIGIOUS_2015- : NON ISRALITES } : WITH SPARTANS } 😁 😮💨

_ Awareness Hardware Ones Campus -)

Political Tantrum -> Correndum : Concentos : Addendum : Reffrendum Over Political Observations

{ I. F.B.I/M.I-5 : Files Base Internet,

II. C.B.I/M.I-6 : Code Base Internet,

III. C.I.A : Code Internet Files Access,

IV. N.I.A : Network Internet Files Access }

https://www.embitel.com/product-engineering-2/iso-26262-functional-safety

#2015 : Passport/VISA { U.S Interviews : Status -> NUGET{ Cake/Choco } : Declining } -> Emrald Color#2015 : Les Républicains : Conservative - Party : Registrars : MI-*#WTO { EUROPA : : IMMIGRATION : ARTICLES -> IL { Ultra SPARC }EXCHANGE : : CATLOG }: Authorization Papers : Signitures ?#Tempos : . Helena Humphrey { EXORCIST / NUN : ? }WAT'S PRO SEALPACK'S Voice{ Voix }/Calls ?#https://dev.azure.com/applysolutions/c60b7e5c-4e3f-4700-bc8b-f553b789ae5b/_apis/build/builds/8230/logs/23#ISIP : SECTOR 16A /SECTOR 126 : CENTRAL: STAKEHOLDER : CONSENT : Kona / Cobo /Coco

184K notes

·

View notes

Link

TESSY - Automated testing of embedded software

The powerful and certified Unit and Integration Testing Tool for C / C ++ Embedded Software with support for a wide range of microcontrollers, compiler environments and target platforms. TESSY is qualified for safety-related software development according to IEC 61508 and ISO 26262.

TESSY automates the whole unit test cycle including regression testing for your embedded software in C/C++ on different target systems. As an easy-to-install and easy to operate testing tool TESSY guides you through the unit test workflow from the project setup through the test design and execution to the result analysis and reporting. TESSY takes additionally care of the complete test organization as well as the test management, including requirements, coverage measurement, and traceability.

1 note

·

View note