#Integrated Marine Automation System

Explore tagged Tumblr posts

Text

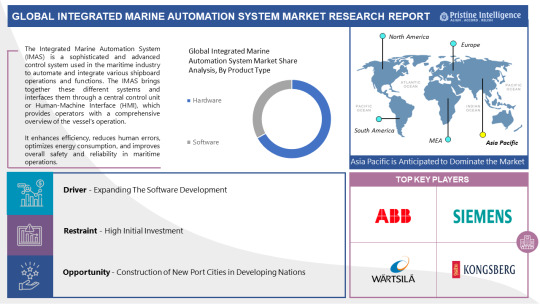

Global Integrated Marine Automation System Market Size Expected To Reach USD 14800 Million With CAGR 9.90% By 2030

The Global Integrated Marine Automation System Market size was valued at USD 6900 Million in 2023 and is projected to reach USD 14800 Million by 2030, growing at a CAGR of 9.90% from 2023 to 2030.

In order to automate and integrate a variety of shipboard operations and tasks, the marine sector uses the Integrated Marine Automation System (IMAS), a complex and cutting-edge control system.

Through the use of a central control unit, also known as a Human-Machine Interface (HMI), the IMAS unifies these disparate systems and gives operators a thorough perspective of how the vessel is operating. It optimizes energy use, boosts productivity, lowers human mistake rates, and raises general safety and dependability in maritime operations.

Integration of IMAS with more comprehensive Fleet Management Systems (FMS) or Vessel Management Systems (VMS) is possible. Through data exchange and coordination amongst several vessels in a fleet, this integration optimizes fuel usage, maintenance scheduling, and fleet-wide operations.

Leading players involved in the Integrated Marine Automation System Market include:

"ABB (Switzerland), Siemens (Germany), Kongsberg Maritime (Norway) Wärtsilä (Finland), Rockwell Automation (US), General Electric (US), Schneider Electric (France), Emerson Electric (US), Honeywell International (US), Yokogawa Electric Corporation (Japan), Rolls-Royce Holdings (UK), Marlink (Norway), Praxis Automation Technology (Netherlands), Hyundai Heavy Industries (South Korea), Larsen & Toubro (India), Navis Engineering (Finland), Rh Marine (Netherlands), Acoem (France), Consilium (Sweden), Samsung Heavy Industries (South Korea) and Other Major Players."

Get Sample Report: -

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Market Driver:

One key driver fueling the growth of the Integrated Marine Automation System Market is the increasing emphasis on operational efficiency and safety in the maritime sector. Shipowners and operators are increasingly adopting automation solutions to reduce human errors, minimize operational costs, and comply with stringent regulations. Integrated automation systems enable real-time monitoring of critical parameters, predictive maintenance, and rapid response to emergencies, thereby improving overall vessel performance and safety.

Market Opportunity:

A significant market opportunity lies in the integration of advanced technologies such as artificial intelligence (AI) and Internet of Things (IoT) in marine automation systems. Leveraging AI algorithms and IoT sensors can further enhance the predictive capabilities of these systems, enabling proactive maintenance, fuel optimization, and route planning. Additionally, there is growing demand for cybersecurity solutions to protect integrated marine automation systems from cyber threats, presenting opportunities for providers to develop robust security solutions tailored to the maritime industry.

If You Have Any Query Integrated Marine Automation System Market Report, Visit:

Segmentation of Integrated Marine Automation System Market:

By Product Type

Hardware

Software

By Solution

Vessel Management System

Power Management System

Safety System

Others

By End-User

Commercial

Défense

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Effective Points Covered in Integrated Marine Automation System Market Report: -

Details Competitor analysis with accurate, up-to-date demand-side dynamics information.

Standard performance against major competitors.

Identify the growth segment of your investment.

Understanding most recent innovative development and supply chain pattern.

Establish regional / national strategy based on statistics.

Develop strategies based on future development possibilities.

Purchase This Reports: -

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#Integrated Marine Automation System#Integrated Marine Automation System Market#Integrated Marine Automation System Market Size#Integrated Marine Automation System Market Share#Integrated Marine Automation System Market Growth#Integrated Marine Automation System Market Trend#Integrated Marine Automation System Market segment#Integrated Marine Automation System Market Opportunity#Integrated Marine Automation System Market Analysis 2022#US Integrated Marine Automation System Market#Integrated Marine Automation System Market Forecast#Integrated Marine Automation System Industry#Integrated Marine Automation System Industry Size#china Integrated Marine Automation System Market#UK Integrated Marine Automation System Market

0 notes

Text

South Korea Integrated Marine Automation System Market Insights 2024-2032

The South Korean integrated marine automation system market is set to experience significant growth from 2024 to 2032. South Korea’s maritime industry is rapidly adopting advanced automation technologies to enhance operational efficiency and safety. Here’s an in-depth look at the market insights and key trends shaping South Korea’s integrated marine automation system sector.

Market Insights

Technological Integration: South Korean maritime companies are investing heavily in advanced technologies such as AI, IoT, and data analytics to enhance vessel management and operational efficiency. These technologies enable real-time monitoring, predictive maintenance, and optimized resource management, driving market growth.

Government Support: The South Korean government’s focus on modernizing the maritime industry and supporting technological innovation is a significant driver of market growth. Government initiatives and funding for research and development are helping accelerate the adoption of integrated marine automation systems.

Operational Efficiency: Automation systems play a crucial role in improving operational efficiency by automating routine tasks, enhancing navigation, and optimizing fuel consumption. South Korean maritime companies are leveraging these systems to reduce costs and improve overall performance.

Competitive Landscape: The South Korean market is competitive, with several key players focusing on technological innovation and operational excellence. Companies that offer advanced automation solutions and demonstrate a strong understanding of market needs are well-positioned to capture market share.

Market Forecast

The South Korean integrated marine automation system market is expected to grow at a compound annual growth rate (CAGR) of approximately 7-9% from 2024 to 2032. This growth is driven by technological advancements, government support, and a focus on enhancing operational efficiency and safety.

Opportunities for Stakeholders:

Leverage Government Support: Companies can benefit from government initiatives and funding to advance their automation technologies and expand their market presence.

Focus on Innovation: Developing cutting-edge technologies that address industry needs will create valuable business opportunities.

Enhance Operational Efficiency: Solutions that improve efficiency and reduce operational costs will be highly sought after.

Request Free Sample Report - Receive a free sample report to preview the valuable insights and data we offer.

Challenges:

Market Competition: The competitive landscape necessitates continuous innovation and differentiation.

Regulatory Compliance: Ensuring compliance with maritime regulations requires ongoing investment and attention.

About US

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions. To stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact us:

Market Research Future (part of Wants tats Research and Media Private Limited),

99 Hudson Street,5Th Floor, New York, New York 10013, United States of America

Sales: +1 628 258 0071 (US) +44 2035 002 764 (UK)

Email: [email protected]

0 notes

Text

Integrated Marine Automation System Market 2024 Size Predicted to Increase at a Positive CAGR

The Global Integrated Marine Automation System Market research report published by Exactitude Constancy reveals the current outlook of the global and key regions from the following perspectives: Key players, countries, product types, and end industries. The report studies the top companies in the global market and divides the market into several parameters.

This Integrated Marine Automation System Market research report pinpoints the industry's competitive landscape to understand the international competition. This report study explains the expected growth of the global market for the upcoming years from 2024 to 2030. This research report is accumulated based on static and dynamic perspectives on business.

The global integrated marine automation system market is expected to grow at 10% CAGR from 2024 to 2030. It is expected to reach above USD 10.38 billion by 2030 from USD 4.40 billion in 2023.

Browse Complete Summary and Table of Content @

https://exactitudeconsultancy.com/ja/reports/2212/integrated-marine-automation-system-market/

#Integrated Marine Automation System Industry#Integrated Marine Automation System Market 2024#Integrated Marine Automation System Market Analysis#Integrated Marine Automation System Market Research Report#Integrated Marine Automation System Market Demand#Integrated Marine Automation System Market Growth#Integrated Marine Automation System Market Insights

0 notes

Text

https://pristineintelligence.com/reports/integrated-marine-automation-system-market

#Integrated Marine Automation System Market#Integrated Marine Automation System Market Size#Integrated Marine Automation System Market Growth#Integrated Marine Automation System Market Trends#Integrated Marine Automation System Market Analysis

0 notes

Quote

The Global Integrated Marine Automation System Market size was valued at USD 6900 Million in 2023 and is projected to reach USD 14800 Million by 2030, growing at a CAGR of 9.90% from 2023 to 2030.

Integrated Marine Automation System Market Research Report 2023

0 notes

Text

Control valve supplier in Dubai

UAE Valves is one of the top Control Valve Supplier in Dubai. A control valve is a mechanical device used in various industrial processes to regulate the flow of fluids, such as gas, steam, or liquid, through a pipeline or duct. It achieves this regulation by adjusting the size of the flow passage according to signals received from a controller.

Control valves are crucial components in systems requiring precise control of flow rate, pressure, temperature, or liquid level. They are widely used in industries such as oil and gas, chemical processing, power generation, and water treatment.

Working Principle:

The working principle of a control valve is straightforward. In an industrial setting, a control valve adjusts the size of an opening to control the flow of fluid through a pipeline. When the valve is fully open, it allows maximum flow, and when fully closed, it stops the flow completely. Between these extremes, the valve can be precisely adjusted to allow a specific amount of fluid to pass through.

This adjustment is typically performed automatically based on signals from a controller, which monitors conditions such as pressure, temperature, or flow rate. Essentially, a control valve acts like a gatekeeper, regulating the flow of fluid to meet the system's requirements.

Parts of a Control Valve:

Valve Body: The main structure that contains the fluid and through which the fluid flows.

Actuator: A device that moves or controls the valve's mechanism, often powered by air, electricity, or hydraulic fluid.

Closure Element: The component that makes contact with the seat to restrict or allow flow.

Trim: Internal components such as the plug, seat, and stem that modulate the flow.

Seat: A surface against which the closure element seals to stop flow.

Positioner: A device that adjusts the valve actuator's position based on control signals.

Bonnet: The top part of the valve body that houses the stem and provides a seal.

Yoke: A support structure that holds the actuator in place and connects it to the valve body.

Stem: A rod that connects the actuator to the closure element and transmits motion.

Packing: Material that provides a seal around the stem to prevent fluid leakage.

Advantages:

Precisely controls the amount of fluid passing through a system.

Maintains the desired pressure levels within the system.

Helps maintain a stable temperature by regulating fluid flow.

Reduces energy consumption by optimizing fluid flow.

Enhances system performance by maintaining consistent operating conditions.

Prevents system overpressure and potential hazards.

Easily adjustable for various operating conditions.

Allows for control from a distance and integration into automated systems.

Designed for durability and ease of maintenance.

Ensures consistent production quality by maintaining optimal conditions.

Meets industry standards and regulatory requirements.

Industries Using Control Valves:

Control valves are used across numerous industries, including nuclear power, oil and gas, power generation, manufacturing and process industries, automotive, aerospace, mining and minerals processing, water treatment and distribution, pulp and paper, refining, marine, renewable energy, chemical and petrochemical, and steel and metal processing. These valves play a critical role in ensuring operational efficiency, safety, and compliance within these diverse sectors.

Types of Control Valves:

Three-way control valve

Cage type control valve

Double seat control valve

O type shutoff control valve

Single seat control valve

Water control valve

Globe control valve

Angle type control valve

We are a Control Valve Supplier in Dubai, supplying valves in the following descriptions:

Available Materials: Stainless Steel (SS316, SS304), Ductile Iron, Super Duplex (F51, F53, F55), Cast Iron (WCB, WCC, WC6), LCC, LCB

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: Air, Water, Chemical, Steam, Oil

Operations: Electro Pneumatic Operated and Pneumatic Operated

Size: 1/2” – 24”

Ends: Butt Weld, Flanged, Threaded, Socket Weld

Electric Actuator Details:

Torque: 3 – 9 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Configuration of a Pneumatic Actuator:

Torque: 3 – 9000 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Temperature Ranges:

Standard: -4°F to 200°F (-20°C to 93°C)

Low: -40°F to 176°F (-40°C to 80°C)

High: 0°F to 300°F (-18°C to 149°C)

Visit us: https://www.uaevalves.com/product-category/control-valve/

3 notes

·

View notes

Text

Why GPS & RADAR Services Are Vital in the Marine Industry?

GPS and radar services are crucial in the marine industry for navigation, safety, and efficiency. GPS provides precise positioning for safer voyages, port management, and operations like underwater surveying and commercial fishing. Radar systems enhance safety by detecting other vessels and weather conditions, aiding in collision avoidance. Integration of GPS and radar ensures compliance with regulations, supports vessel traffic control, and improves overall maritime operations. Contact Blessed Marine Automation for best marine services.

2 notes

·

View notes

Text

Advanced Composites Market Size, Share, and Industry Outlook

Advanced Composites Market to Exceed USD 91.1 Billion by 2032, Driven by Demand in Aerospace, Automotive, and Renewable Energy Sectors.

The Advanced Composites Marketsize was valued at USD 38.5 billion in 2023 and is expected to reach USD 91.1 Billion by 2032, growing at a CAGR of 10.07% Over the Forecast Peroid of 2024-2032.

The Advanced Composites Market is driven by increasing demand from sectors such as aerospace, automotive, defense, renewable energy, and sports equipment. These composites, primarily made from carbon fiber, aramid fiber, or glass fiber reinforced with a polymer matrix, offer exceptional strength-to-weight ratio, corrosion resistance, and durability. With industries seeking lighter and more fuel-efficient solutions, especially in aerospace and electric vehicles (EVs), advanced composites are becoming essential in modern engineering and design.

Key Players

Hexcel Corporation

Toray Industries, Inc.

Solvay S.A.

Teijin Limited

SGL Carbon SE

Mitsubishi Chemical Corporation

3M Company

BASF SE

Huntsman Corporation

DSM Company

Covestro AG

Axiom Materials, Inc.

Royal Ten Cate N.V.

Zoltek Companies, Inc.

General Electric Company

Northrop Grumman Corporation

Gurit Holding AG

Lanxess AG

Boeing Company

Airbus S.A.S.

Future Scope & Emerging Trends

The future of the advanced composites market is marked by innovations in recyclable composite materials, automation in composite manufacturing, and increasing integration into next-generation EVs, hydrogen storage systems, and wind turbine blades. Aerospace remains a major consumer, but automotive lightweighting strategies and construction of energy-efficient buildings are accelerating adoption. Governments and private entities are also investing in composite recycling technologies and nanocomposite development to meet environmental and performance demands. Moreover, 3D printing with composite materials is emerging as a game-changing trend, enabling complex and customizable parts with lower production waste.

Key Points

Market projected to exceed USD 91.1 billion by 2032.

Strong growth in aerospace, automotive, wind energy, and marine sectors.

Demand fueled by lightweighting, durability, and fuel efficiency.

Rising innovation in recyclable and bio-based composites.

Asia-Pacific and North America lead in production and consumption.

Conclusion

The advanced composites market is on a strong upward trajectory, powered by material innovations and growing environmental consciousness. As industries prioritize performance, sustainability, and cost-efficiency, advanced composites will remain a critical enabler of next-gen applications. Strategic collaborations, investment in R&D, and scalable manufacturing will define the competitive edge in this evolving global market.

Related Reports:

Micro Flute Paper Market Size, Share & Segmentation, By Flute Size (A-Flute, B-Flute, C-Flute, E-Flute, F-Flute, and Other), By Application (Food and Beverages, Agriculture, Industrial, Personal Care & Cosmetics, Transportation & Logistics, Pharmaceuticals, and Other), by Regions and Global Forecast 2024-2032.

Oxalic Acid Market Size, Share & Segmentation, By Grade (Standard Grade (Purity 96%-99%), Technical/Pharma Grade (Purity 99%-99.9%)), Electronic/Food Grade (Purity 99.9%-99.999%), By Application, By End-use, By Region and Global Forecast for 2024-2032.

Glutaraldehyde Market Size, Share & Segmentation By Product (Glutaraldehyde 25% and Glutaraldehyde 50%), By Application, By End-user, By Region and Global Forecast for 2024-2032.

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Advanced Composites Market#Advanced Composites Market Size#Advanced Composites Market Share#Advanced Composites Market Report#Advanced Composites Market Forecast

0 notes

Text

Leisure Boat Market : Witnesses Growth Through Cutting-Edge Innovations and Recent Global Developments

The leisure boat market is undergoing a transformative phase, driven by a wave of recent developments that are redefining how consumers experience marine recreation. With technological advancements, sustainability initiatives, and post-pandemic consumer behavior shifts, the industry is charting new waters of opportunity and innovation.

Technological Advancements Drive Market Innovation

One of the most influential recent developments in the leisure boat market is the integration of smart technology. Manufacturers are increasingly embedding Internet of Things (IoT) devices, GPS navigation, automated docking systems, and real-time monitoring solutions into boats. These technologies enhance user safety and convenience, especially for novice boaters.

A noteworthy innovation is the rise of electric propulsion systems. As electric vehicles become mainstream on land, similar demand is influencing the marine sector. Companies like Candela and X Shore are gaining traction by launching fully electric leisure boats with longer ranges and faster charging capabilities. These boats not only reduce carbon emissions but also operate quietly, enhancing the serene boating experience.

Design Customization and Modular Build Trends

Another major recent trend is the shift toward customizable and modular boat designs. Consumers now demand vessels tailored to their preferences—be it for fishing, cruising, or watersports. Leading manufacturers are offering modular deck layouts, interchangeable seating configurations, and adaptable onboard amenities.

Boat builders such as Groupe Beneteau and Brunswick Corporation are investing in digital configurators, allowing customers to personalize their boats before production. This digital approach has elevated customer engagement while improving order accuracy and satisfaction.

Growth of Shared Ownership and Subscription Models

The recent growth in shared ownership and boat club memberships has significantly changed how consumers access leisure boats. Rather than purchasing a boat outright, users can now enjoy the benefits of boat usage without the burdens of maintenance, storage, or high initial investment.

Companies like Freedom Boat Club and Boatsetter have rapidly expanded their footprints in North America and Europe, catering to millennials and urban dwellers seeking flexible, on-demand marine experiences. This trend is lowering entry barriers and attracting new demographics to the leisure boating lifestyle.

Sustainability as a Core Design Element

Sustainability has become a central concern for consumers and regulators alike. Recent developments in sustainable boatbuilding materials—such as bio-based composites, recycled aluminum, and solar panels—are helping manufacturers reduce environmental footprints. Electric outboards and hybrid engines are becoming standard options in newer models.

Governments are also incentivizing eco-friendly marine solutions, especially in the European Union and parts of Asia-Pacific. This regulatory support is encouraging manufacturers to accelerate green innovations and meet emission standards while preserving aquatic ecosystems.

Post-Pandemic Market Acceleration

The COVID-19 pandemic prompted a surge in outdoor and socially distant leisure activities, with boating becoming a safe and appealing option. This trend has persisted post-pandemic, further fueling demand for leisure boats across all segments—from personal pontoons and speedboats to high-end yachts.

Boat shows, such as the Fort Lauderdale International Boat Show and Boot Düsseldorf, have seen a resurgence in attendance, showcasing new models and technologies. These events play a crucial role in driving consumer interest and dealer engagement.

Digital Marketing and E-Commerce Expansion

In response to changing consumer behavior, many boat manufacturers and dealers have embraced digital transformation. Recent developments include virtual boat tours, 360-degree model previews, and online purchasing platforms. These tools empower potential buyers to explore options remotely and make informed decisions without visiting a dealership.

Brands are also leveraging social media and influencer marketing to target niche boating communities. This digital shift is particularly appealing to younger audiences and tech-savvy first-time buyers.

Rising Demand in Emerging Markets

Recent economic growth and increased disposable incomes in Asia-Pacific, Latin America, and the Middle East have boosted demand for leisure boats. Countries like China, India, and the UAE are witnessing growing marina infrastructure and coastal tourism development, which support the market’s expansion.

Local manufacturers are entering the scene, offering competitively priced options while partnering with international brands to enhance technology and design. These developments are creating new revenue streams and strengthening global supply chains.

Challenges and Future Outlook

Despite the positive momentum, the market faces challenges such as fluctuating raw material prices, supply chain disruptions, and skilled labor shortages. However, recent developments in automation and robotics are helping to optimize production and reduce manufacturing costs.

Looking ahead, the leisure boat market is expected to continue evolving with innovations in autonomous navigation, AI-based maintenance alerts, and enhanced connectivity. As consumer preferences shift toward sustainable, tech-enabled, and personalized experiences, manufacturers must stay agile to remain competitive.

In conclusion, the recent developments in the leisure boat market reflect a dynamic industry poised for sustainable and technology-driven growth. By embracing innovation, digital tools, and eco-conscious practices, stakeholders are charting a promising course for the future of marine leisure.

0 notes

Text

Fuel Transfer Equipments: Ensuring Safety, Efficiency, and Accuracy

In the complex world of fuel management, Fuel Transfer Equipments are the unsung heroes that ensure a smooth, safe, and precise distribution of fuels across industries. From transportation and agriculture to manufacturing and mining, these systems are integral in keeping operations running without disruption.

What Are Fuel Transfer Equipments?

Fuel Transfer Equipments refer to a broad range of mechanical systems and tools designed to safely and efficiently move fuel from one location to another. These typically include fuel pumps, hoses, meters, nozzles, storage tanks, and filtration units. The key objective is to transfer fuel from bulk containers or storage units into vehicles, machinery, or smaller tanks with minimal loss and maximum safety.

Components of a Fuel Transfer System

A typical Fuel Dispensing System comprises several key components:

Pump Unit: Powers the transfer of fuel.

Flow Meter: Measures the quantity of fuel dispensed.

Hoses and Nozzles: Direct fuel flow and facilitate controlled delivery.

Filtration System: Removes impurities to maintain fuel quality.

Control Panel: Enables automation and safety monitoring.

These components work in sync to ensure operational efficiency and prevent spills, overflows, and environmental contamination.

Applications Across Industries

Fuel Transfer Equipments are widely used in sectors such as:

Agriculture: Refueling tractors, harvesters, and irrigation engines.

Construction: Supplying fuel to heavy machinery on-site.

Logistics and Transportation: Managing fleet fueling needs.

Aviation: Ensuring precise delivery of aviation fuel.

Marine: Facilitating bunkering operations for ships and boats.

Their adaptability across different environments makes them indispensable for fuel-intensive industries.

Why Safety Matters

Fuel is highly flammable, and improper handling can lead to serious hazards including fires, explosions, and environmental harm. Fuel Dispensing Systems must comply with stringent safety standards and include features like:

Flameproof motors

Emergency shut-off valves

Anti-static hoses

Leak detection sensors

These safeguards are essential for both worker protection and regulatory compliance.

Industry Insight: What Users Are Saying

"Our operations became more efficient after upgrading to a modern Fuel Transfer Equipment setup. The precision of the system has helped us reduce wastage by nearly 15%." - Rajeev Menon, Plant Manager, Southern Mining Corp.

"As a fleet manager, the integration of a smart Fuel Dispensing System has been a game-changer. Real-time tracking and digital metering have simplified our fuel reporting and audits." - Priya Sharma, Logistics Lead, SkyTransport Pvt Ltd.

FAQs About Fuel Transfer Equipments

Q1: Are fuel transfer systems customizable? Yes. Depending on the application, systems can be tailored with different pump capacities, hose lengths, and monitoring features.

Q2: How often should Fuel Transfer Equipments be maintained? Routine checks every 3-6 months are recommended, with full servicing annually to ensure longevity and safety.

Q3: Can these systems handle biofuels or alternative fuels? Absolutely. Many modern systems are compatible with biodiesel, ethanol blends, and other fuel types.

Q4: Do they require power to operate? While most systems are electrically operated, manual and battery-powered options are available for remote locations.

Staying Ahead with Compliance and Innovation

The evolution of Fuel Transfer Equipments continues with innovations like:

IoT-enabled fuel monitoring

Mobile app integration

Enhanced filtration systems

Modular and portable units

As businesses scale, investing in reliable and efficient Fuel Dispensing Systems not only enhances performance but also contributes to long-term cost savings and environmental sustainability.

Conclusion

With increasing demand for safer and smarter fuel handling, the role of Urea Nozzle has never been more critical. By understanding their components, applications, and best practices, industries can harness their full potential while adhering to modern safety and environmental standards.

0 notes

Text

The Integrated Marine Automation System Market is poised for significant growth in the coming years, driven by a combination of factors and trends that shape the marine industry. According to a report by MarketsandMarkets, this market is expected to expand from USD 4.9 billion in 2020 to USD 7.8 billion by 2025, demonstrating a Compound Annual Growth Rate (CAGR) of 10.0% during the forecast period.

0 notes

Text

"The Role of Advanced Shipbuilding in Enhancing Marine Services in UAE"

The United Arab Emirates (UAE) is known as the worlds global nautical superpower in the past few decades. This growth is not simply based on its geography or port infrastructure—it is far more closely linked with its investment in developing the next level in shipbuilding. Better, greener, more specialized ships have resulted in better speed, safety, and sustainability in marine services all over the country.

This post looks at how revolutionary shipbuilding practices today are supporting the UAE to ramp up its marine potential–and how that plays out in terms of trade, security, jobs, and the environment.

Boosting Port Efficiency and Logistics Jebel Ali Port, one of the world’s top 10 busiest container ports, is part of the UAE. In 2023, it handled over 13.7 million TEUs (twenty-foot equivalent units) and thus an integral point of passage in the international trade.

The speed, size, and fuel efficiency of newly constructed cargo vessels lie behind this efficiency. These are the ships, which are equipped with smart cargo handling systems, automated navigation, hydrodynamic designs – to shorten the loading and unloading time and the time spent loading and unloading times. This directly improves marine logistics and cuts off operating expenditure of shipping lines.

Thanks to these improvements, the country has become one of the most trusted marine service providers in UAE, handling everything from global shipping to last-mile delivery with precision and speed.

Seizing Undersea Oil & Gas Exploitation Offshore a significant part of the oil production is being conducted in the UAE, which will require a spectrum of support vessels. These consist of Platform Supply Vessels (PSVs), Anchor Handling Tug Supply Vessels (AHTSVs), and offshore building vessels constructed to withstand hard operating marine environments.

Sleek ships such as these are important working tools for transporting crew to the rigs, or taking tools and supplies, especially to the rigs in offshore areas. Companies such as ADNOC Logistics & Services rely heavily on these specialized vessels. When it comes to jobs that involve a lot of sweating, these are the jobs they are built for with such features as reinforced hull and dynamic positioning as well as real time systems which are actually increasing safety and productivity.

A growing number of ship building companies in UAE are now focusing on constructing such purpose-built vessels to meet the increasing demand from offshore energy players.

Enhancing National Maritime Security Due to its proximity to one of the world’s most strategic shipping lanes, The Strait of Hormuz, maritime security is given high priority in the UAE. That means a competent, contemporary navy—and built in our neighbourhood.

ADSB is at the core of the manufacture of patrol boats and corvettes and amphibious ships for the UAE Navy. These vessels have next generation radars, stealth designs e are integrated combat system for the purpose of regional defense.

ADSB won a Dh3.5 billion deal to build a fleet of escort ships to supply to the ranks of the emirate’s armed forces in 2021, which underlines the need for the country to embark on domestic shipbuilding to prop up national security. Many of the region’s top ship building companies now contribute to naval projects, combining defense capabilities with cutting-edge marine engineering.

Smart and Autonomous Vessel Technology Ships are operating in a different way due to technology. In the UAE, the idea of smart/autonomous vessels is no longer just a vision – it’s being built and tested today.

"Blue Pass” initiatives are pushing innovation in unmanned vessels, remote diagnostics, and AI powered navigation by the Ministry of Energy and Infrastructure. Such features enhance safety, minimize human-error, as well as minimize the cost for the shipping operators.

Building such ships requires specialized shipyards, modern tooling, and software integration—something that ship manufacturing companies in UAE are now ramping up. These are the companies which are developing vessels that can carry out port inspection operations, cargo carrying operations, even search and rescue mission without full human crews.

Environmental Sustainability in Shipbuilding In the wake of international pressure to reduce carbon emissions, the UAE is embracing green shipbuilding. Some of the new vessels being built up currently includes:

Low-sulphur fuel engines

Ballast water treatment systems

Hybrid and electric propulsion

Solar-powered auxiliary units

These technologies assist the shipping lines to achieve international standards such as the IMO 2020 sulphur cap, while at the same time, mitigating long-term fuel cost. The UAE is at the head of the Middle East in new ships ordered with green technologies according to DNV.

Sustainable design is not just a case of fulfilling environmental requirements, it also attracts global partners to the UAE-built ships and it reduces the ecological footprint of its maritime industry.

Creating Jobs and Local Talent Advanced shipbuilding is linked with thousands of jobs in design, engineering, welding, logistics and control of quality. Other shipyards in Dubai Maritime City and Abu Dhabi Ship Building also train marine engineers and naval architects in local universities.

This develops a pipeline of local talent familiar with global standards but also have knowledge of regional standards. At 7% to the UAE’s GDP, the maritime world is a social and an economic imperative for human capital development through shipbuilding.

Expanding Global Partnerships The UAE is not building its ships alone; it is partnering with the world-leading maritime nations of France, South Korea, Italy and so forth. These partnerships bring new technologies and enable UAE shipyards to increase their production rate.

For example the EDGE Group, ADSB’s parent company is now exporting vessels to other Middle Eastern and African nations. Such arrangements are not only mutually reinforcing acts of diplomacy, but also positions the UAE as a regional marine vessel export hub.

With local production resource behind it, this outward-looking strategy gives the country a competitive advantage in a global business.

Final Thoughts Advanced ship building is a cornerstone of the UAE’s rise as a maritime leader. It supports everything that ranges from fast container handling and offshore energy up to environmental goals and defense. Already the UAE is constructing the vessels and the infrastructure to meet growing demands for smarter, greener and safer marine services.

With a mix of technology, investment, and talent development, ship building companies in UAE are helping redefine what’s possible in maritime services. They’re mapping the waters from military ships to autonomous cargo vessels, one hull at a time, into the future of the ocean economy.

0 notes

Text

#Integrated Marine Automation System Market#Integrated Marine Automation System Market Size#Integrated Marine Automation System Market Growth#Integrated Marine Automation System Market Trends#Integrated Marine Automation System Market Analysis 2023

0 notes

Text

How Manufacturers Meet Zero-Leakage Demands in Heat Exchangers

Heat exchangers are essential components in industries ranging from power generation to oil & gas, chemical processing, and marine applications. As operational demands grow more stringent, the margin for error narrows—especially when it comes to leakage. For leading heat exchanger manufacturers in India, achieving zero leakage is no longer just a goal—it's a fundamental requirement. Here's how industry leaders are rising to meet this challenge.

The Zero-Leakage Imperative in Modern Industries

Leakage in a heat exchanger can lead to cross-contamination, corrosion, safety risks, environmental hazards, and costly downtime. In sensitive industries like pharmaceuticals, petrochemicals, or nuclear energy, even minimal leakage can compromise product purity or plant safety. That's why the demand for zero-leakage heat exchangers has surged, and manufacturers are redesigning their approach from the ground up.

Engineering Precision from the Ground Up

Zero leakage starts with meticulous engineering. From CAD design to final fabrication, every component is built with tight tolerances and high precision. Manufacturers are investing in advanced design software, simulation tools, and CNC machining to ensure that each part aligns perfectly during assembly.

The Crucial Role of High-Quality Heat Exchanger Tubes

At the heart of any shell and tube heat exchanger lie the tubes. Their strength, finish, and integrity play a pivotal role in determining the overall durability and leak resistance of the system. Manufacturers like Anand Seamless Tubes prioritize cold-drawn seamless tubes known for their superior wall uniformity, tight tolerances, and high pressure-withstanding capacity.

Joint Integrity: The Make-or-Break Factor

Even the strongest tubes are only as reliable as the joints that connect them. Whether it's tube-to-tubesheet joints, welds, or gasketed flanges, manufacturers pay close attention to joint design, welding processes, and post-weld heat treatments. Specialized welding techniques and automated orbital welders are now standard in achieving uniform, defect-free joints.

Testing Beyond Industry Standards

Zero-leakage isn’t just a design claim—it must be proven. That’s why manufacturers conduct rigorous testing well beyond standard regulatory requirements. Common procedures include hydrostatic testing, helium leak testing, pneumatic testing, dye penetrant inspections, and radiographic analysis. The aim is to simulate real-world operating conditions and identify any potential weak points before deployment.

The Material Science Edge

Selecting the right material is critical in preventing leakage caused by corrosion, temperature extremes, or fluid incompatibility. Today’s manufacturers utilize high-grade stainless steel, duplex alloys, Inconel, and other specialized metals, each selected based on the operating environment. Material traceability and certification are integral to ensuring long-term reliability.

Customisation for Industry-Specific Demands

Different industries have distinct requirements—be it ultra-high purity in pharmaceuticals or extreme pressure tolerance in offshore rigs. Customisation is key. Heat exchanger manufacturers work closely with clients to tailor designs for specific temperature, flow, and pressure conditions, ensuring optimal performance and zero leakage across diverse applications.

Collaboration Across the Supply Chain

Meeting zero-leakage demands is a collective effort. From tube manufacturers and metallurgists to assembly teams and quality inspectors, every stakeholder in the supply chain must align with the zero-defect mindset. Leading companies foster strong partnerships, transparent communication, and joint quality assurance protocols to maintain consistency and accountability.

Looking Ahead: Smart Monitoring and Predictive Maintenance

The future of zero-leakage lies in proactive monitoring. Smart sensors, IoT-enabled diagnostics, and predictive maintenance tools are being integrated into modern heat exchangers. These technologies can detect early signs of wear, fatigue, or minor leaks—allowing maintenance teams to act before failures occur.

Conclusion: Zero Leakage Is a Standard, Not a Luxury

Today, zero leakage isn’t an added feature—it’s an operational standard. Top heat exchanger manufacturers in India are continuously evolving their design, material, and testing practices to meet this expectation. The result: safer, more efficient, and longer-lasting equipment that industries can rely on.

Partner with the Leading Heat Exchanger Manufacturer in India

Looking for a trusted partner that delivers zero-leakage solutions tailored to your industry needs? Anand Seamless Limited offers premium-quality seamless tubes and heat exchangers engineered for maximum reliability and leak-free performance.

Visit us at: How Top Manufacturers Eliminate Leakage in Heat Exchangers

0 notes