#J1939 programming

Explore tagged Tumblr posts

Text

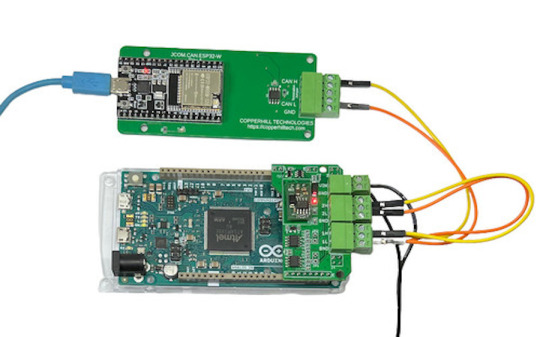

Unlocking SAE J1939 Development with the Arduino-Due-Based Programming Kit

Discover the Arduino-Due-Based SAE J1939 Programming Kit by Copperhill Technologies — a complete development platform for building, simulating, and monitoring heavy-duty vehicle networks using the J1939 protocol. Includes hardware, software, and detailed guides for ECU prototyping, diagnostics, and telematics.

#arduino due#can bus shield#sae j1939#can bus#embedded system#J1939 simulator#J1939 programming#arduino ide#J1939 protocol stack

0 notes

Text

PLC Programming Using CODESYS: An In-Depth Exploration

Programmable Logic Controllers (PLCs) are foundational to industrial automation, providing the control necessary for machinery and processes across various industries. Among the myriad of PLC programming environments available, CODESYS stands out as a versatile and powerful platform. This article delves into the intricacies of PLC programming using CODESYS, its adherence to the IEC 61131-3 standard, fieldbus support, IoT connectivity, and the services offered by Servotech Inc. in this domain.

Understanding CODESYS

CODESYS is a commercial PLC programming tool and real-time software platform designed for PLCs and embedded controllers. It offers a comprehensive suite of features that facilitate the development, testing, and deployment of control applications. One of its notable strengths is its manufacturer-independent nature, allowing engineers to program controllers from various vendors using a unified interface.

Adherence to IEC 61131-3 Standard

The IEC 61131-3 standard defines the programming languages and structures for PLCs, promoting consistency and interoperability across different systems. CODESYS supports all five languages outlined in this standard:

Instruction List (IL): An assembler-like language for low-level programming.

Structured Text (ST): A high-level, Pascal-like language suitable for complex algorithms.

Ladder Diagram (LD): A graphical language resembling electrical relay logic diagrams, widely used for its intuitive representation.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions and their interconnections.

Sequential Function Chart (SFC): A graphical language for depicting sequential control processes.

By adhering to this standard, CODESYS ensures that engineers can transition between different PLC hardware platforms without the need to learn new programming environments, thereby enhancing efficiency and reducing training costs.

Fieldbus Support in CODESYS

Fieldbus systems are critical for enabling communication between various components in an industrial setup. CODESYS provides extensive support for multiple fieldbus protocols, including:

EtherCAT: A high-performance Ethernet-based fieldbus system suitable for real-time control applications.

CAN Bus (CANopen, J1939): Widely used in automotive and industrial applications for robust communication.

Modbus: A serial communication protocol prevalent in connecting industrial electronic devices.

PROFIBUS: A standard for fieldbus communication in automation technology.

This extensive fieldbus support allows for seamless integration of various devices and systems, facilitating the development of complex automation solutions.

IoT Connectivity with CODESYS

In the era of Industry 4.0, the integration of IoT (Internet of Things) capabilities into industrial automation systems is paramount. CODESYS offers robust IoT connectivity features, enabling:

Remote Monitoring and Control: Access and control PLCs from remote locations, enhancing flexibility and responsiveness.

Data Logging and Analysis: Collect and analyze data from various sensors and devices to optimize processes and predict maintenance needs.

Cloud Integration: Seamlessly connect with cloud platforms for data storage, processing, and advanced analytics.

These IoT capabilities empower industries to implement smart manufacturing practices, leading to increased efficiency and reduced operational costs.

Servotech Inc.: Expertise in CODESYS PLC Programming

Servotech Inc. is a leading provider of PLC programming services utilizing the CODESYS platform. Their team of experienced engineers offers comprehensive solutions, including:

Custom PLC Application Development: Tailored solutions to meet specific automation requirements across various industries.

System Integration: Seamless integration of PLCs with existing hardware and software systems, ensuring optimal performance.

Training and Support: Providing clients with the knowledge and tools necessary to maintain and expand their automation systems effectively.

By leveraging CODESYS's versatile platform, Servotech Inc. delivers robust and scalable automation solutions that adhere to international standards.

Conclusion

PLC programming by Servotechinc using CODESYS offers a flexible and standardized approach to industrial automation. Its compliance with the IEC 61131-3 standard, extensive fieldbus support, and IoT connectivity make it a preferred choice for engineers and organizations aiming to develop sophisticated control systems. Servotech Inc.'s expertise in utilizing CODESYS further enhances the potential for creating customized, efficient, and future-ready automation solutions

#PLCProgramming#IndustrialAutomation#CODESYS#AutomationEngineering#SmartManufacturing#EmbeddedSystems#IndustrialControl#FactoryAutomation#IoTIntegration#ControlSystems

0 notes

Text

EngineBox - Single Engine

The EngineBox expands the possibilities of the NavBox for multi-engine applications or can be used as stand-alone when navigation information is not required. The EngineBox has a NMEA 2000® and a J1939 CAN port. The EngineBox can also be used on older, completely analog engines, thanks to the analog input ports provided and designed for RPM data, resistive sensors and capacitive sensors.

The EngineBox has to be set up using an intuitive PC configuration tool making it easy for programming the inputs (delivered free of charge). Thanks to the ISO 8846:1990 compliance, the EngineBox is also designed to be installed in engine compartments.

The Veratron Diagnostic Tool USB to NMEA 2000 (A2C3931270001) and Veratron Configuration Software tool are needed to configure this Engine Box.

Features:

Analog to NMEA 2000® gateway

J1939 to NMEA 2000® gateway

2 Models for single engine and dual engine configurations

Compact design

Status LED

Operating temperature range -40°C/+85°C

Technical Specifications:

1x J1939 (2x J1939 Dual Engine)

1x M12 5 pins NMEA 2000®

1x Input 0–4 kHz for RPM (2 inputs with Dual Engine Model)

4x Inputs 0–400 Ohm (up to 8 inputs with Dual Engine Model)

2x Inputs 4–20 mA

1x Input 0–5 V (2 inputs with Dual Engine Model)

In the Box:

Engine Cable

Cable Harness

Safety Instructions

*Sold as an Individual This product may not be returned to the original point of purchase. Please contact the manufacturer directly with any issues or concerns.

Specifications:

Voltage - Input Range (Volts): 8 to 16 VDC

Gauge Type: Multifunction

Gauge Size: N/A

Box Set: No

Box Dimensions: 4"H x 6"W x 6"L WT: 1.35 lbs

UPC: 7640178724426

0 notes

Text

Autelmfg introduces MaxiTPMS® TS508, the next generation of TPMS diagnostic and service tools

The Autel MaxiTPMS TS508 is Autel's next generation automotive pressure sensor. It replaces the popular TS401/408/501 models and offers many new features including quick and advanced modes, programming MX sensors and more. With its simple operation and powerful diagnostic features, the TS508 pressure sensor tire is perfect for any professional or DIYer looking to activate, diagnose or reset TPMS sensors.

The Autel MaxiTPMS TS508 Tire Pressure Monitor sensor offers Quick and Advanced modes for faster and smarter repairs.The Autel TS508's Quick mode can be used to check TPMS sensors, program MX sensors, and activate all TPMS sensors. In addition, it supports sensor information reading such as sensor ID, frequency, voltage, hardware version, OE manufacturer, etc. With such powerful features and simple operation, Autel TS508 will save you a lot of time and effort in your work.

Professionals can use Quick Mode to quickly check TPMS sensors and program MX-Sensors. The advanced mode then provides all the functions needed to diagnose, program and relearn sensor positions. This mode provides all TPMS services, including TPMS diagnostics, sensor programming, position relearning and information (OE and MX-Sensor data and vehicle OBDII port position map) The TS508 can read and erase DTCs, turn off warning lights, etc. With the advanced mode, you can clone sensor configurations and reprogram sensors to test specific thresholds. This gives technicians easy access to all the data necessary to perform diagnostics and repairs.

Autel TS508 is a professional diagnostic tool for tire pressure monitoring system sensor. It covers all OBDII protocols, including J1850 VPW, ISO9141-2, KWP2000, CAN BUS and SAE J1939. diagnostic functions include reading DTCs, real-time data streams, ECU information, freeze frame data and more, enabling users to pinpoint problems in the tire pressure monitoring system.

Compatible with domestic, Asian and European vehicles, the TS508 activates/reads all TPMS sensors and displays vehicle-specific relearning procedures. In addition, MX-Sensors can be programmed to replace the OE sensors in 98% of the vehicles on the road. When replacing a TPMS sensor, a relearning procedure must be completed so that the new sensor can be recognized by the vehicle's on-board TPMS module. There are three methods to relearn TPMS sensors including OBD relearn, automatic relearn, and fixed relearn.

By routinely checking the TPMS, you can ensure safe driving conditions for yourself and your passengers.The Autel TS508 tyre pressure monitor allows drivers to diagnose tire pressure and safety issues, and drivers can detect any potential problems with their tires so they can avoid unsafe driving. The scanner allows you to activate the sensors on each tire and monitor parameters such as position, sensor ID, tire pressure, tire temperature and battery charge.

If you are experiencing problems with your Tire Pressure Monitoring System (TPMS), the Autel TS508 can help you. This scan tool is designed to make diagnosing and fixing TPMS-related problems quick and easy. With a single click, the TS508 will clear any fault codes stored in your vehicle's ECU and turn off the warning lights. So if you are dealing with a TPMS malfunction, don't panic!

The Autel TS508 TPMS Universal Tool can assist you if your key fob has ceased functioning or has developed issues. By avoiding the need to visit the dealership and taking advantage of the convenience and peace of mind that come with owning this necessary item, you may test the signal strength of your key fob. The TS508 is a high-quality, user-friendly TPMS tool that is a great addition to your toolkit.

Additionally, the tool enables you to view saved TPMS DTCs, information on tire type and pressure, and print it off through PC for additional study. Very fast and simple. The car repair work will be more effective than the conventional repair approach. You may quickly and easily use this tool to identify any issues with the TPMS system in your automobile. The optimum protection for your driving is provided by TS508.

With a wealth of diagnostic features and years of experience in the automotive electronics industry, the Autel TS508 is a must-have tool for mechanics to effectively deal with any problems in the tire pressure sensor system.

0 notes

Photo

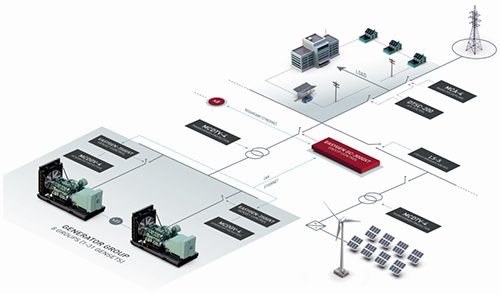

SmartGen | 10 Gensets Parallel + Cloud Monitoring System Application

At a user’s site, 10 mobile power supply vehicles installed in parallel (there are 10 gensets in the follow-up, 20 in total),. 10 ECU units of the same brand, which automatically make oil pre-supply before startup, have the function of automatically/ manually lifting the smoke exhaust compartment door, and the indoor fan, intercooler fan and radiator fan of the water tank are logically programmed through the PLC function of the parallel controller HGM9510 to realize automatic control.

After the genset is started, the noise measured by the sound attenuated box is 60db~75db. After loading, the frequency is not reduced, no black smoke is emitted, the voltage is not reduced, the load distribution is balanced, and genset is stable after sudden loading and unloading.

The connection of the cloud monitoring module is simple, and the DC power supply, RS485 communication line, GPS antenna and GPRS antenna are connected at the same time, and the SIM card is inserted; After registering and adding units on the SmartGen cloud plus, the remote control of 10 units can be realized, and the status of gensets can be understood in real time.

The user can realize accurate positioning and navigation through GPS and Beidou satellite. There is a reminder of the maintenance time due and a remote locking function, so that the user can know the status of the unit and remote control at any time thousands of miles away. Truly realize that science and technology serve our life!

SmartGen parallel controller HGM9510 can be adapted to ECU gensets of various brands and models, with high flexibility and wide adaptability. Select the corresponding engine type according to the existing engine; It supports two types of non-ECU Engines and ECU Engines. There are more than 30 types of ECU Engines to choose from. It supports the engine exhaust emission standards of national II, national III and National IV.

HGM9510 has the function of controlling GOV and AVR, and can automatically synchronize and load evenly. The controller is equipped with SAE J1939 interface and can communicate with various ECUs (engine control unit) with J1939 interface. SmartGen cloud plus supports GPRS, network cable, WiFi, 4G and other methods to connect to SmartGen cloud server, and can view and monitor the unit in real time. It supports Android, IOS and Harmony OS systems.

www.smartgen.cn

0 notes

Text

Minimizing Downtime With Predictive Maintenance

Predictive maintenance uses real-time data to inform fleet managers which parts on a vehicle are likely to fail, possibly even weeks before the failure is likely to happen. In the long term, predictive maintenance can extend the vehicle life span and help managers ensure that they have an adequate fleet capacity. Fleet managers are turning towards predictive analytics to stay on top of maintenance and mitigate part failures before they can occur. However, managing the large amount of new data generated by vehicle sensors is challenging.

Tangerine’s Solution for Predictive Maintenance

Tangerine’s AI integrated platform for fleet maintenance can build predictions based on direct measurements of equipment. This platform also provides contextual data like weather conditions, traffic, road quality, and driver behavior. The most important and an illustrative difference between a fleet preventive maintenance program and predictive maintenance is a paradigm shift from assumptions and strict scheduling to data-driven decisions and real-time fleet monitoring.Tangerine uses AI to improve many aspects of fleet maintenance, be it reducing unplanned downtime or increasing efficiency in the maintenance and repair process.

Get preventive and predictive maintenance information for each asset to track maintenance services and understand RUL. Keep tabs on everything from required repairs to scheduled services and daily inspections to keep assets at their highest performance levels. Monitor vehicle issues by capturing DTCs for both OBD II and J1939 protocols. Avoiding Vehicle Downtime

Any organization that relies on vehicles in daily operations understands how critical it is to keep them up and running. By outfitting vehicles with sensors, maintenance crews can collect useful information that helps them predict part failures on a large fleet. However, analyzing and managing this volume of new data can be overwhelming. Many organizations are moving towards ways to run analytics at the edge, on the device at the gateway level, as part of end-to-end fleet management.

Advanced Technologies Behind Fleet Maintenance

Artificial intelligence plays a critical role in building predictions based on collected telematics data. To process the data analytics and deliver fast alerts, predictive fleet vehicle maintenance platform relies on cloud computing and provides contextual data. Finally, the service and fleet managers must receive easy-to-use reports and be ready with all the tools at hand to plan relevant equipment maintenance.

Telematics Data Collection

By turning to telematics data, most fleet companies can shift from reactive to preventive measures. By doing so, it helps fleet managers address small problems before they become critical to address. Connected IoT sensors can provide real-time data on vehicle parts and send Diagnostic Trouble Codes (DTCs) to track mechanical failures in real time while fleet management platforms use this data for analytics and predictive maintenance planning.

User-friendly and Comprehensive Dashboards

When running AI data analytics for failure prediction,the platform for fleet maintenance must provide a visual representation of data in a consumable form. Dashboards with customizable functionality allows fleet managers to choose what data is the most critical to display,cross-platform accessibility ensures that fleet managers are always connected ,can react to potential issues and monitor fleets from their mobile devices.

Increased Efficiency of Fleets and Drivers

Advanced technologies applied to fleet maintenance improves the entire repair network. Continuously monitoring each fleet vehicle results in individual vehicle profiles, which makes it easier for technicians to perform repairs and take preventive measures to avoid related issues. As a result, the fleets avoid losing their equipment for extended periods to detect all malfunctions while drivers avoid accident incidents on the road.

Final Words

Predictive maintenance helps fleets by reducing vehicle downtime due to avoidable repairs. In addition, vehicles can be utilized more efficiently because maintenance is planned only when it’s required. With a pre-trip inspection and a preventative maintenance program, fleet managers can schedule maintenance based on accurate diagnostics and vehicle usage information and reduce unnecessary cost, fleet downtime, and jeopardy to the public safety. As vehicles with less use do not require as many maintenance stops, the availability of assets increases while losses due to unnecessary maintenance are minimized. Establishing thresholds of use for each asset and monitoring how close a vehicle gets to those thresholds makes outcomes more predictable and enables timely actions. To know more: https://tangerine.ai/blog/minimizing-downtime-with-predictive-maintenance/

0 notes

Text

SAE J1939 & NMEA 2000 Protocol Stack – A Complete Embedded Solution by EmSA

Explore EmSA's Micro J1939 protocol stack — a compact, ANSI C-based SAE J1939 implementation for embedded systems. Includes BAM, CMDT, and NMEA 2000 Fast Packet plug-ins for multi-frame CAN message support.

0 notes

Photo

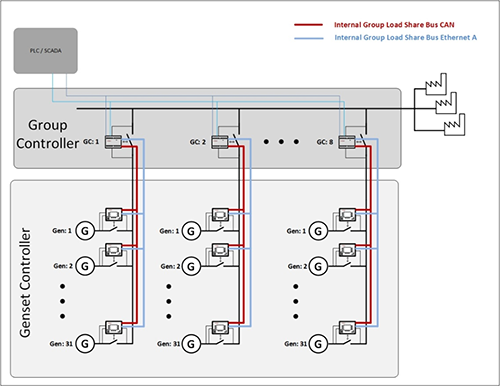

SmartGen | Complex System Management---GC-3000XT/easYgen-3500XT

GC-3000XT and easYgen-3500XT basically solve any problems of large genset power station control system, manage working status of up to 248 gensets. The standard CANBUS and ETHERNET communication redundancy function make the whole system more reliable. The control system has complete genset management, synchronization and power management function, also has mains peak shaving, emergency reserve, multi-unit parallel, mains grid-connection and other functions.

GC-3400XT Group Management Controller

1.The whole power station system can have 8 GC-3400XT group management controllers; 2.Each group can manage 31 gensets with easYgen-3500XT; 3.GC-3400XT and easYgen-3500XT have communication redundancy function; 4.Manage all gensets automatically start/stop according to load.

easYgen-3500XT Genset Parallel Controller

1.Genset controller for complex parallel application of up to 32 gensets and 16 MCB/GGB; 2.Complete engine, genset and practical program protection; 3.Up to 9 communication ports: 3 ETHERNETs, 3 CAN (CANopen and J1939), RS-485, USB, interface expansion card; 4.Customized logic, HMI screen and alarm.

System Simulation Tool

To facilitate the commissioning of large genset power station, we have analog simulation software of whole system. It is convenient for us to add equipment configuration via PC without starting genset, simulate genset start/stop and working logic under various conditions on PC and display it with graph. This allows us to avoid the safety problem and fuel consumption caused by repeated start during commissioning.

To sum up, WOODWARD complex system management of GC-3000XT and wasYgen-3500XT is worth your choice!

www.smartgen.cn

0 notes

Text

OS-Independent, License-Free On-Chip SAE J1939 Protocol Stack for Embedded, Linux, and Windows Systems — Copperhill Technologies Corp.

OS-Independent, License-Free On-Chip SAE J1939 Protocol Stack for Embedded, Linux, and Windows Systems — Copperhill Technologies Corp.

Copperhill Technologies offers a variety of hardware modules equipped with an On-Chip SAE J1939 Protocol Stack, relieving the end user from implementing third-party source code and avoiding license fees. The programming of J1939 network communication is accomplished through accessing a standard serial port, making the development virtually independent of the operating system. By: Copperhill…

View On WordPress

0 notes

Text

Minimizing Downtime With Predictive Maintenance

Predictive maintenance uses real-time data to inform fleet managers which parts on a vehicle are likely to fail, possibly even weeks before the failure is likely to happen. In the long term, predictive maintenance can extend the vehicle life span and help managers ensure that they have an adequate fleet capacity. Fleet managers are turning towards predictive analytics to stay on top of maintenance and mitigate part failures before they can occur. However, managing the large amount of new data generated by vehicle sensors is challenging.

Tangerine’s Solution for Predictive Maintenance

Tangerine’s AI integrated platform for fleet maintenance can build predictions based on direct measurements of equipment. This platform also provides contextual data like weather conditions, traffic, road quality, and driver behavior. The most important and an illustrative difference between a fleet preventive maintenance program and predictive maintenance is a paradigm shift from assumptions and strict scheduling to data-driven decisions and real-time fleet monitoring.Tangerine uses AI to improve many aspects of fleet maintenance, be it reducing unplanned downtime or increasing efficiency in the maintenance and repair process.

Get preventive and predictive maintenance information for each asset to track maintenance services and understand RUL.

Keep tabs on everything from required repairs to scheduled services and daily inspections to keep assets at their highest performance levels.

Monitor vehicle issues by capturing DTCs for both OBD II and J1939 protocols.

Avoiding Vehicle Downtime

Any organization that relies on vehicles in daily operations understands how critical it is to keep them up and running. By outfitting vehicles with sensors, maintenance crews can collect useful information that helps them predict part failures on a large fleet. However, analyzing and managing this volume of new data can be overwhelming. Many organizations are moving towards ways to run analytics at the edge, on the device at the gateway level, as part of end-to-end fleet management.

Advanced Technologies Behind Fleet Maintenance

Artificial intelligence plays a critical role in building predictions based on collected telematics data. To process the data analytics and deliver fast alerts, predictive fleet vehicle maintenance platform relies on cloud computing and provides contextual data. Finally, the service and fleet managers must receive easy-to-use reports and be ready with all the tools at hand to plan relevant equipment maintenance.

Telematics Data Collection

By turning to telematics data, most fleet companies can shift from reactive to preventive measures. By doing so, it helps fleet managers address small problems before they become critical to address. Connected IoT sensors can provide real-time data on vehicle parts and send Diagnostic Trouble Codes (DTCs) to track mechanical failures in real time while fleet management platforms use this data for analytics and predictive maintenance planning.

User-friendly and Comprehensive Dashboards

When running AI data analytics for failure prediction,the platform for fleet maintenance must provide a visual representation of data in a consumable form. Dashboards with customizable functionality allows fleet managers to choose what data is the most critical to display,cross-platform accessibility ensures that fleet managers are always connected ,can react to potential issues and monitor fleets from their mobile devices.

Increased Efficiency of Fleets and Drivers

Advanced technologies applied to fleet maintenance improves the entire repair network. Continuously monitoring each fleet vehicle results in individual vehicle profiles, which makes it easier for technicians to perform repairs and take preventive measures to avoid related issues. As a result, the fleets avoid losing their equipment for extended periods to detect all malfunctions while drivers avoid accident incidents on the road.

Final Words

Predictive maintenance helps fleets by reducing vehicle downtime due to avoidable repairs. In addition, vehicles can be utilized more efficiently because maintenance is planned only when it’s required. With a pre-trip inspection and a preventative maintenance program, fleet managers can schedule maintenance based on accurate diagnostics and vehicle usage information and reduce unnecessary cost, fleet downtime, and jeopardy to the public safety. As vehicles with less use do not require as many maintenance stops, the availability of assets increases while losses due to unnecessary maintenance are minimized. Establishing thresholds of use for each asset and monitoring how close a vehicle gets to those thresholds makes outcomes more predictable and enables timely actions.

VIEW MORE:

gps tracker | gps vehicle tracking | telematics | tracking devices | vehicle telematics | vehicle tracker | fleet management | driver safety | eld mandate | fleet maintenance | fleet tracking

0 notes

Text

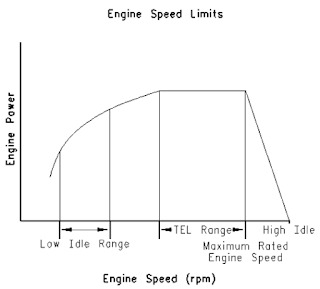

Speed Control on Caterpillar Engines

Desired Speed Control

Top Engine Limit (TEL) “TEL” is a customer programmable parameter that defines the maximum allowable engine speed for maximum power (Software Dependent). “TEL” can be programmed up to the maximum rated engine speed. “TEL” is defined along the engine’s lug curve.

Low Idle Speed “Low Idle Speed” is the minimum allowable operating speed for the engine. This parameter can be programmed between 600 and 1400 rpm

High Idle Speed “High Idle Speed” is the maximum no-load engine speed when the throttle or the PTO switch is in the maximum position (Software Dependent). “High Idle Speed” cannot be programmed lower than “TEL”. Read More: Setting LOW IDLE Speed and HIGH IDLE Speed on Caterpillar ET Software

Engine Acceleration Rate

“Engine Acceleration Rate” determines the rate of change of the engine speed (50 to 1000 rpm/s). This parameter may also help reduce smoke when you start the engine.

Intermediate Engine Speed “Intermediate Engine Speed” defines the speed for the engine when the intermediate engine speed switch is activated. This parameter can be programmed to any engine speed between “Low Idle Speed” and “TEL”. Engine speed will increase or engine speed will decrease at the rate that is defined by the programmed value for “Engine Acceleration Rate”.

Desired Speed Input Configuration

Program the “Desired Speed Input Configuration” to match the type of input signal for desired engine speed. The desired speed input defines the type of signal that is used for the throttle control. A numeric value is used by Cat ET to set the input for the ECM. The following inputs are available:

0-5 VDC Input 4-20 mA Input CAN Input – if the throttle signal is transmitted over the CAN J1939 data link. PWM – if a throttle position sensor or direct fuel control is used (as Figure 1.1 above).

Throttle Input Low Idle Duty Cycle Setpoint This parameter can be used to set the duty cycle for low idle. If the throttle position sensor that is used will not reach 10 % duty cycle, the duty cycle can be increased up to a maximum of 40 %.

Throttle Input High Idle Duty Cycle Setpoint This parameter can be used to set the duty cycle for high idle. If the throttle position sensor that is used will not reach 90 % duty cycle, the duty cycle can be decreased to a minimum of 50 %.

Throttle Position Sensor Program the “Throttle Position Sensor” to “Installed” if a throttle position sensor is used for desired speed control. Otherwise program this parameter to “Not Installed”.

PTO Mode

“PTO Mode” allows the ECM to be programmed to either one of the two PTO configurations that are available.

Ramp Up/Ramp Down – when “PTO Mode” is programmed to “Ramp Up/Ramp Down”, the ECM allows PTO operation with traditional features. Set/Resume – when “PTO Mode” is programmed to “Set/Resume”, the ECM allows PTO operation with enhanced features.

#Additional Information: -PTO Enable Switch – J1/P1:56 -PTO Rump Up/Set Switch – J1/P1:58 -PTO Rump Down/Resume Switch – J1/P1:60 -Intermediate Engine Speed Switch – J1/P1:45 -Throttle Position 1 (PWM) – J1/P1:66 -Throttle Position 2 (PWM) – J1/P1:68

0 notes

Text

When You Start That SAE J1939 App - Don't Forget the Engineering

A candid look from a seasoned engineer in the CAN and SAE J1939 field, highlighting common misconceptions, troubleshooting tips, and the importance of reading documentation to succeed in engineering projects.

0 notes

Text

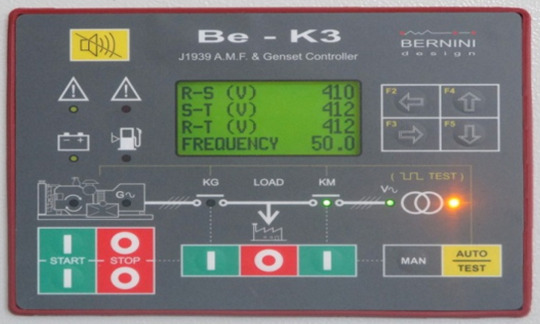

BeK3 3phase AMF Controller

BeK3 3phase AMF Controller

BeK3 CANbus AMF controller The AMF controller BeK3 is a 3-phase Automatic Mains Failure that includes a generator & engine controller. It connects, via CANBUS, to engines with ECU (SAE-J1939) but it works also with standard engines if analog sensors or digital sensors are available. All parameters, alarms and operating functions are indicated by means of a 128X64 graphic display capable of operating in a temperature range between -25°C and +70°C. Measurements including Vac, Aac, Vdc, kVA, kVar, kW, Energy, Pf, Hz, hour count, R.p.m., Oil Pressure, Engine Temperature, Battery Vdc (Engine) and Fuel Level. A monitoring and control software program is provided free of charge. The BeK3 provides MODBUS via RS485 and complies with NFPA-110 / NFPA-99 specifications. The optional module TCP-IP Server will allow you TCP-IP connection to INTERNET via a ROUTER. By using the Be16 module you can control the AMF Controller BEK3 from a remote location by using short messages (SMS) via GSM modem. You can download application for your mobile phone for a quick use of the messages. You can use also our RS485-USB converter to connect a computer as far as 1000 meters away.

#BeK3 3Phase AMF Controller#Genset Controller BeK3 3 Phase#Generator Set Control Panel#Automatic#BeK3#Bernini Design#Automatic Mains Failure Controller

0 notes

Text

Real CAT ET3 Adapter III 317-7485 2015A CAT truck diagnostic tool CAT III Communication Adapter III CAT3 without WIFI

2017 Real CAT ET3 Adapter Ⅲ P/N 317-7485 without WIFI USB Cable (Connect device to your computer) J1939/J1708 Cable (Connect device to your truck) CAT ET 2015A software disc with active tool (Unlimited, install in more laptop) Communications Adapter 3 Description: Communications Adapter 3 is the latest generation of the Communication Adapter group, and replaces the Comm Adapter II. This is the only recommended communication device for ET 3,and the only data link device that will allow you to properly communicate with a CA engine on dual datalinks. This function is needed for some ET (Electronic Technician) functions. Communications Adapter III Feature: 1. Caterpillar Communication Adapter 3 2.Allows communication between service tools and engine controls using various data links such as J1939/11, DeviceNet (future release), CT DataLink, and J1708 (ATA) vehicle networks; 3.Flash program allows adapter firmware upgrades as additional features become available; 4.Uses J1939/11, high-speed data link (part of ADEM III controls), substantially reducing flash times; 5.Automatically selects J1939/11 when flashing the engine (reduces the flash time approximately 80%, from 14 minutes to 3 minutes). Communications Adapter III Function: 1.ECM Summary screen lists every control module on equipment 2.Being tested and gives information on these modules. 3.Fast hookup and real time display of systems status. Displays ,readings such as rpm, boost, pressures, temperatures, etc. for Easy troubleshooting. 4.Identifies faulty sensors, harness connectors, and system parameters which are out of specification. Allows customers 5.To help dealer identify problems without visiting machine. 6.Identifies intermittent sensors and wiring problems during Machine operation and keeps a record of each one. Show When problem occurred and how often it happened. 7.Added information to allow customer to assist dealer in diagnosing and repairing problems. (Troubleshooting Help is not built in with in the program, you will still need go back to books in order to follow a repair description and steps in each Fault Code display within the program).English and metric units of measure integrated help file to easy learn the "How To" around the software. Note: 1.Functionalities Shows all operating conditions that cause high repair costs such as: Over speeds, high temperatures, fuel consumption, transmission shift counts. This can provide awareness to change operator. 2. "ET Trainer" is now included in ET Program. It allows Users to train and practice using ET without a Communications adapter or Electronic Control Module (ECM).This is a free feature of ET. Communications Adapter III Package CAT Comm Adapter III CD for installing the drivers USB Cable J1939/J1708 Cable

Read the full article

0 notes

Photo

WOODWARD easYgen-2000 Series Parallel / Grid Connected Controller

WOODWARD easYgen-2000 series controller is a kind of parallel controller with simple operation, rich functions and high reliability. It can be used for 16 same or different gensets islanding parallel operation or one genset in grid connected operation with mains. The automatic start and stop control logic of the controller can realize more control requirements according to different needs, and optimize the fuel efficiency of multiple units at the same time.

easYgen-2000 series controllers have rich interfaces: CANopen for load sharing, J1939 for engine ECU, RS485 for PLC, HMI and SCADA. Users can choose the appropriate controller according to different requirements.

The analog input interface easYgen-2000 series controller can directly use 0-20mA or 0-2000Ω type sensors without additional equipment.

The analog output of easYgen-2000 series controller can be used for speed regulation and voltage regulation of genset. It has current type, voltage type and PWM signal, which can be selected by controller software without additional conversion equipment.

easYgen-2000 series controller can expand I/O module through CAN interface to add more I/O interfaces, and support the third-party I/O expansion module.

easYgen-2000 series controller is available in 11 languages including English, German, French, Spanish, Chinese, Japanese, Italian, Portuguese, Turkish, Russian and Polish.

easYgen-2000 series controllers have different start and stop logics for diesel and gas engines, which are suitable for various types of engines.

easYgen-2000 series controller event log can record 300 alarms and operation events according to the first in and first out principle for customers to check.

easYgen-2000 series controller interface application:

easYgen-2000 series single-unit grid connected application:

easYgen-2000 series single-unit and grid connected application:

easYgen-2000 series controller alarm level, and most of the alarm input can be programmed to meet the needs of different alarm actions of customers.

www.smartgen.cn

0 notes