#Kaizen module

Explore tagged Tumblr posts

Text

Conducting Effective Business Process Improvement

Business Process Improvement (BPI) is the systematic approach to helping an organization optimize its core processes for greater efficiency, effectiveness, and adaptability.

1. Understand the Current State ("As-Is")

Map Out Existing Processes

Use process mapping tools like:

SIPOC (Suppliers, Inputs, Process, Outputs, Customers)

Flowcharts

Value Stream Mapping (VSM)

Collect Data

Key metrics: Cycle time, error rates, cost per transaction, throughput

Interview stakeholders, observe workflows, review logs and KPIs

Tip: Get cross-functional input to avoid blind spots.

2. Define Clear Goals and Metrics

Use the SMART framework:

Specific – What process needs to improve?

Measurable – What metrics define success?

Achievable – Is it realistic with current resources?

Relevant – Does it align with strategic goals?

Time-bound – When should results be achieved?

Examples:

Reduce invoice processing time by 40% in 90 days

Eliminate 80% of manual handoffs in customer onboarding

3. Analyze the Root Causes

Use proven diagnostic tools:

5 Whys Analysis

Fishbone (Ishikawa) Diagram

Pareto Analysis (80/20 rule)

Process mining tools for digital workflows

Look for:

Bottlenecks

Redundancies

Manual tasks that could be automated

Communication failures

4. Design the Improved Process ("To-Be")

Use Lean, Six Sigma, and Agile Principles:

Eliminate waste (Lean: TIMWOOD – Transport, Inventory, Motion, Waiting, Overproduction, Overprocessing, Defects)

Reduce variation (Six Sigma)

Shorten feedback loops (Agile)

Redesign for:

Simplicity

Speed

Scalability

Automation where possible (e.g., RPA, workflow platforms)

Create To-Be maps, RACI charts, and updated SOPs.

5. Implement the New Process

Focus Areas:

Change Management – Train teams, communicate clearly, and manage resistance

Pilot Testing – Try improvements on a small scale before a full rollout

Project Management – Use agile sprints or phased rollouts to maintain momentum

Key Tools:

Communication plan

Training modules

Feedback loops (daily standups, weekly reviews)

6. Monitor, Optimize, and Sustain

Track KPIs:

Real-time dashboards

Weekly metrics reviews

Before vs. after comparisons

Continuous Improvement:

Encourage feedback from frontline users

Use Kaizen or PDCA cycles to keep iterating

Build a culture of accountability and excellence

7. Document and Standardize

Finalize new SOPs and documentation

Create playbooks or handbooks

Assign process owners for ongoing accountability

Tip: Use a centralized knowledge base or BPM tool to manage version control.

Bonus Tools & Frameworks

Tool/MethodUse CaseLean Six Sigma (DMAIC)Structured process improvementBusiness Process Model and Notation (BPMN)Process design and documentationKPI Tree / Metrics TreeLinking process improvements to business goalsVoice of the Customer (VoC)Ensure customer impact is central to changes

Summary Cheat Sheet

StepFocus1. Assess Current ProcessMap + Measure2. Define GoalsAlign with business impact3. Root Cause AnalysisFind what's broken4. Design Future StateLean + tech + feedback5. Implement ChangesTraining + testing + rollout6. Measure & ImproveMonitor, adapt, optimize7. Document & SustainSOPs, ownership, culture shift

0 notes

Text

ERP for Manufacturing: Enabling Just-in-Time Production

In today’s hyper-competitive and globalized manufacturing landscape, efficiency is everything. Businesses must respond to fluctuating demand, supply chain uncertainties, and rising costs, all while meeting customer expectations for quality and speed. That’s where Just-in-Time (JIT) production and Enterprise Resource Planning (ERP) come together.

ERP systems are no longer just back-office tools. They are now mission-critical platforms that drive operational excellence, real-time data visibility, and agility, which are all foundational to successful JIT manufacturing.

In this guide, we explore how ERP empowers manufacturing companies to achieve lean production, minimize waste, reduce lead times, and improve profitability.

Understanding Just-in-Time Production — More Than a Buzzword

Just-in-Time (JIT) manufacturing isn’t a trend — it’s a disciplined approach to producing what’s needed, when it’s needed, and in the exact quantity required.

Born in post-war Japan and perfected by Toyota, JIT production aims to eliminate waste, reduce inventory holding costs, and improve product quality by syncing production with real-time demand.

Core principles of JIT include:

Inventory minimisation

Demand-driven scheduling

Waste reduction (Lean Manufacturing)

Continuous improvement (Kaizen)

But to execute JIT effectively, manufacturers need total visibility, data-driven foresight, and operational agility, which is where ERP comes in.

The Role of ERP in Modern Manufacturing

Enterprise Resource Planning (ERP) software is the digital backbone of modern manufacturing enterprises. It consolidates core business processes — finance, procurement, production, inventory, human resources, and supply chain into one unified platform.

Here’s how ERP platforms empower manufacturers:

Real-time production tracking

Demand forecasting & materials planning

Supplier coordination & logistics

Inventory and warehouse management

Workforce scheduling and capacity planning

With integrated modules and advanced analytics, ERP makes it possible to align production with actual demand fueling JIT execution with precision.

Aligning ERP with JIT — A Perfect Partnership

JIT demands agility. ERP delivers it. Together, they form a dynamic digital alliance.

1.Demand Forecasting & Sales Order Integration

JIT starts with accurate demand forecasting. ERP systems integrate sales data with historical trends, market indicators, and customer behaviour patterns to:

Predict order volumes

Avoid overproduction

Trigger just-in-time procurement

With real-time sales and demand data driving production schedules, ERP eliminates guesswork and overstock.

2.Inventory Optimisation

Traditional systems often rely on buffer stock. ERP systems enable real-time inventory visibility, automatic reorder points, and safety stock thresholds. This ensures you:

Minimise excess inventory

Avoid stockouts

Cut holding costs

3.Procurement Synchronisation

ERP automates supplier communication and ensures that raw materials are ordered only when needed. Procurement modules help with:

Vendor-managed inventory (VMI)

Lead time optimization

Supplier performance tracking

This tight control supports a leaner, more resilient supply chain.

4.Shop Floor Control & Production Scheduling

ERP’s manufacturing execution module (MES) offers real-time shop floor visibility:

Monitor work-in-progress (WIP)

Allocate machine capacity dynamically

Adjust shift patterns instantly

With digital twins and IoT integration, ERP lets manufacturers simulate production changes before executing them.

Key ERP Features that Empower Just-in-Time Production

To truly support JIT operations, a manufacturing ERP solution must offer the following capabilities:

1.Advanced Planning & Scheduling (APS)

Dynamically align resources and timelines based on actual orders.

2.Material Requirements Planning (MRP)

Trigger material orders only when needed based on the bill of materials (BOM).

3.Real-Time Data Capture

From barcode scanning to IoT sensors, get instant updates on inventory, machinery, and operator performance.

4.Supplier Portals & EDI Integration

Collaborate in real time with vendors for smooth material delivery.

5.Predictive Analytics & AI Forecasting

Move from reactive production to anticipatory, AI-driven operations.

6.Compliance & Quality Management

Ensure every product meets industry and customer standards without delays or waste.

Real-World Benefits of ERP-Enabled JIT Production

Increased Operational Efficiency

By eliminating bottlenecks and redundancies, manufacturers experience faster cycle times and improved throughput.

Lower Operating Costs

Reduce excess inventory, avoid overstaffing, and eliminate material wastage.

Improved Supply Chain Coordination

ERP aligns internal processes with external vendors and logistics partners, ensuring seamless operations.

Enhanced Risk Management

By enabling real-time visibility and agility, ERP helps mitigate supply disruptions and demand fluctuations.

Sustainability & ESG Alignment

JIT and ERP together reduce overproduction, energy consumption, and carbon footprints.

Challenges and How to Overcome Them

Change Management Resistance

Solution: Invest in employee training and choose an ERP with an intuitive UI.

Data Accuracy

Solution: Ensure clean data migration and implement regular audits.

Vendor Lock-in

Solution: Opt for modular ERP platforms with open APIs and third-party integration.

The Future of ERP and JIT in Smart Manufacturing

As Industry 4.0 matures, the future of manufacturing ERP is:

AI-powered and machine learning-driven

Edge-enabled and IoT-integrated

Voice-command and chatbot supported

Blockchain-backed for supply chain trust

JIT will no longer be a strategy; it will be the default. ERP platforms will serve as autonomous, intelligent control towers driving hyper-lean, hyper-smart factories.

Final Thoughts: Lean, Agile, Future-Ready

In a world where seconds matter and customer expectations evolve overnight, Just-in-Time production isn’t optional — it’s essential. And the only way to execute it with finesse is through a robust, modern ERP solution.

With the right technology foundation, your manufacturing business can move faster, waste less, and deliver more exactly when it’s needed.

Because in 2025 and beyond, the future belongs to those who can manufacture smarter, leaner, and with surgical precision.

0 notes

Text

ifLink: Toshiba’s Open IoT Platform Expands Internationally

Toshiba Group subsidiary brought ifLink, a cutting-edge and affordable IoT development solution, to Thailand. It utilises Toshiba Digital Solutions' ifLink. For this first ifLink firm outside Japan, TATC sells software licenses and provides customer care.

IfLink, an open IoT platform service, makes it easy to connect to a cloud-based application platform, combine IoT devices and web services into modules, and describe device operation using if-then (condition-action) rules. Over 100 Japanese firms and educational institutions have approved it, and Toshiba Digital Solutions has licensed it to several sectors.

Inexperience and high beginning costs have stopped certain Thai manufacturing facilities from embracing IoT. TATC is cooperating with the non-profit Technology Promotion Association (Thailand-Japan) (TPA) to develop human resources and transfer and distribute Japan's latest IoT technologies and know-how in Thailand. TATC has validated that it may be utilised for kaizen at manufacturing plants participating in the Thai Smart Monodzukuri Support Team Project as part of TPA's DX human resource development.

Toshiba held training on using it to build up IoT in November 2024 and January 2025 for project instructors who teach local workers and TPA member firms digital technologies. Toshiba Digital Solutions and TATC introduced ifLink in Thailand for Thai manufacturing businesses, including TPA members, after seminar attendees found the platform easy to use, even for IoT novices. Toshiba Digital Solutions provides ifLink software, while TATC handles software license sales, device configuration, and Thai-English customer care.

Thailand's TATC will offer a trial service leading to a full licence. The 10,500 baht (310 USD) TATC ifLink Starter Kit contains sensors, a data communications device, and an Android smartphone with the ifLink software. It lasts one month. Users don't need to install gadgets to use it. After using the trial service to test ifLink, users can acquire the full licence. The subscription service's 5,740 baht monthly licensing charge includes an Android smartphone, gadgets, sensors, and a one-time setup fee.

The monthly membership fee depends on the sensors utilised. TPA members who attended its IT conference would get a discount.

Toshiba Digital Solutions and TATC intend to sell 100 ifLink Starter Kit licenses to Thai businesses by 2027. They will seek business partners to create IoT solutions based on it.

Toshiba Digital Solutions is considering extending its used business in Asia-Pacific beyond Thailand and establishing an open IoT business environment in Japan and beyond.

IfLink platform

Open IoT speeds up company formation on ifLink

The open Internet of Things platform ifLink modularises IoT devices and web services to provide user-friendly, easy procedures.

This platform has applications in manufacturing, retail, physical shops, nursing care, education, entertainment, farming, and more. It may be put on smartphones, mounted gateways, professional business-use tablets, interactive robots, and more to speed up commercial service launch and increase user comfort.

ifLink makes IoT services easy to access. It works:

The ifLink App's “If-Then Execution Engine” lets you modularise IoT devices and web apps for If-Then recipes. Connecting devices and services to its platform and using their values and statuses as “if-then” rules. Create several IoT services with If and Then modules.

Many IoT devices and internet services

Use an ifLink-connected development kit to modularise microservices.

To create If-Then recipes, join modules using “If-Then” rules.

Apply the If-Then logic to quickly test IoT services.

IfLink platform expands open IoT business ecosystem

Its platform lets you create new IoT products and services fast. As modules increase, services will expand.

Toshiba's ifLink platform promotes service co-creation. Toshiba hopes to expand its worldwide business environment with its many partners.

Companies that sell information terminals with IfLink platform services are platform partners.

It module partners are company operators who construct microservices and sell compatible IoT devices and online services.

These platforms are used by businesses to deliver IoT services to customers.

System Architecture & Features

Its platform system includes the ifLink App, which connects modules and performs If-Then recipes, the ifLink Open Cloud, which maintains modules and terminals, and the Open Cloud, which produces and distributes recipes. The ifLink microservices development kit creates shared IMSs for devices, internet services, and smartphone apps.

The If-Then Recipe Editor lets you choose shared IMSs. Accessing ifLink Open Cloud terminal data via data APIs lets you construct apps for analysis, visualisation, and other functions.

Description of Point Function

Exchange and modularise IoT devices

A microservices SDK may generate IoT-compatible modules. Your shared it module may be used by many people.

Application execution outside the internet

Install on a terminal running the ifLink App to control and connect IoT devices across LAN, Bluetooth, and Wi-Fi. This can be enabled even without internet access.

App-controlled terminals

If-Then recipes built on ifLink Open Cloud may be distributed to several execution terminals and monitored for utilisation.

Server API IoT data use

A data API lets you display, monitor, analyse, and do other actions using ifLink Open Cloud-stored sensor and location data.

Examples of If-combined modules

You may connect to many IoT devices and internet services globally using the ifLink platform. “If” modules might be IoT devices and web services that detect something, “Then” modules that reply based on the detection, or modules linked to both.

Partners in the ifLink business ecosystem can access common modules.

#technology#technews#govindhtech#news#technologynews#ifLink#IoT devices#ifLink platform#Internet of Things#Open IoT Platform#Open IoT

0 notes

Text

Top Job Roles for Certified Warehouse Management Professionals

A warehouse management course equips aspiring professionals with the knowledge and skills needed to excel in the fast-paced logistics sector. Certification not only validates your expertise but also opens doors to a variety of high‑impact roles. Whether you’re just beginning your career or looking to advance, here are the top job roles for certified warehouse management professionals, and how enrolling in SLBS Marklance — the best warehouse management course in Kerala can set you on the path to success.

1. Warehouse Manager

Role Overview: Warehouse Managers oversee all aspects of warehouse operations, from inventory control and space utilization to staff management and safety compliance. They develop and implement strategies to optimize workflows, reduce costs, and meet delivery deadlines.

Key Responsibilities:

Planning and organizing daily warehousing activities

Supervising warehouse staff and performance evaluations

Maintaining accurate inventory records using WMS software

Ensuring compliance with safety and quality standards

Skills Gained from a Warehouse Management Course: Enrolling in a comprehensive warehouse management course covers modules on inventory management, lean warehousing principles, and WMS (Warehouse Management Systems), all essential for excelling as a Warehouse Manager.

2. Inventory Control Specialist

Role Overview: Inventory Control Specialists focus on maintaining optimal stock levels. They analyze inventory data, forecast demand, and coordinate with purchasing teams to prevent overstocking or stockouts.

Key Responsibilities:

Monitoring stock movements and conducting regular cycle counts

Utilizing demand forecasting techniques to predict inventory needs

Coordinating returns, damage assessments, and write‑offs

Implementing inventory control best practices

Why Certification Matters: A targeted warehouse management course provides hands‑on training in ERP/WMS integration and advanced forecasting tools—skills that make you indispensable in inventory-centric roles.

3. Logistics Coordinator

Role Overview: Logistics Coordinators manage the flow of goods between warehouses, suppliers, and customers. They liaise with carriers, schedule shipments, and ensure that orders are dispatched accurately and on time.

Key Responsibilities:

Planning and scheduling inbound and outbound shipments

Negotiating freight rates and managing carrier relationships

Tracking orders and resolving transportation issues

Preparing shipping documentation and customs paperwork

Course Benefits: A specialized warehouse management course delves into transportation management systems (TMS), route optimization, and cost‑analysis frameworks, empowering you to streamline logistics operations effectively.

4. Quality Assurance (QA) Supervisor

Role Overview: QA Supervisors ensure that warehousing processes adhere to quality standards and regulatory requirements. They design inspection protocols, audit processes, and lead corrective actions when deviations occur.

Key Responsibilities:

Developing and enforcing QA policies and procedures

Conducting regular audits of warehouse operations

Training staff on compliance and quality control measures

Investigating and resolving quality incidents

Skill Enhancement: Through modules on safety regulations, auditing methodologies, and continuous improvement (Kaizen), a warehouse management course prepares you to uphold the highest quality benchmarks in any facility.

5. Procurement Specialist

Role Overview: Procurement Specialists manage the acquisition of goods and services required for warehouse operations. They evaluate suppliers, negotiate contracts, and monitor supplier performance.

Key Responsibilities:

Identifying and qualifying suppliers based on cost, quality, and reliability

Negotiating purchase orders and long‑term contracts

Monitoring supplier KPIs and managing relationships

Integrating procurement plans with inventory forecasts

Course Takeaways: A robust warehouse management course often includes procurement strategy, vendor management, and cost‑optimization techniques—crucial for a role that bridges warehousing and supply chain functions.

6. Health, Safety & Environment (HSE) Officer

Role Overview: HSE Officers are responsible for creating a safe working environment within the warehouse. They design safety programs, conduct risk assessments, and ensure compliance with occupational health regulations.

Key Responsibilities:

Performing hazard identification and risk assessments

Implementing safety training and emergency response plans

Investigating incidents and near misses

Maintaining records of safety audits and corrective actions

Certification Edge: Courses in warehouse management cover essential HSE practices and legal frameworks, providing the expertise needed to protect your team and minimize operational disruptions.

Why Choose SLBS Marklance?

When it comes to selecting the best warehouse management course in Kerala, SLBS Marklance stands out for:

Industry-Aligned Curriculum: Modules on WMS, lean warehousing, and safety standards designed in collaboration with leading logistics firms.

Hands‑On Training: Real‑world simulations and case studies that build practical expertise.

Placement Support: Strong industry links that help you secure interviews for top warehouse roles.

Flexible Learning: Blended learning options to suit working professionals and fresh graduates.

By enrolling in SLBS Marklance — the best warehouse management course in Kerala, you’ll gain a competitive edge to land roles such as Warehouse Manager, Inventory Control Specialist, and more, while building a rewarding career in logistics.

Ready to Advance Your Career?

Invest in your future with a certification-focused warehouse management course at SLBS Marklance today. From mastering WMS software to leading safety initiatives, our program equips you with the skills employers demand and the confidence to excel in any warehousing role.

Unlock your potential as a certified warehouse management professional and explore the diverse career paths awaiting you!

0 notes

Text

Best Corporate Video Production Company in Pune | Kaizen 360 Branding Pvt. Ltd.

Enhance Your Brand with the Best Corporate Video Production Company in Pune

In today’s fast-paced digital world, businesses must communicate their brand story effectively. One of the most impactful ways to do this is through high-quality corporate video production in Pune. Whether you’re looking to create engaging corporate films, time-lapse videos, or immersive 3D visualizations, professional video content helps elevate your brand and establish credibility in the industry.

Why Corporate Videos Are Essential for Your Business

Corporate videos play a vital role in brand storytelling, audience engagement, and overall business growth. They not only capture the essence of your brand but also help in:

Building trust and credibility – Video testimonials enhance your brand image and foster customer confidence.

Boosting website engagement – Integrating videos on your website improves user experience and increases time spent on your site.

Enhancing brand visibility – Professionally produced videos are more shareable and can help you reach a larger audience on social media and digital platforms.

Strengthening corporate communication – Whether it’s internal training videos, promotional films, or investor presentations, well-crafted videos ensure clear and compelling messaging.

Kaizen 360 Branding Pvt. Ltd. – The Leading Corporate Video Production Agency in Pune

At Kaizen 360 Branding Pvt. Ltd., we specialize in end-to-end corporate video production in Pune, helping businesses communicate their brand story effectively. Our team of expert corporate video makers in Pune ensures that every project is crafted with precision, creativity, and strategic intent.

Our Comprehensive Corporate Video Services:

✅ Scriptwriting & Storyboarding – Crafting a compelling narrative that aligns with your brand’s objectives. ✅ Professional Filming & Direction – Capturing high-quality visuals with cutting-edge equipment. ✅ Time-lapse & Drone Videos – Offering stunning aerial and dynamic shots for a unique perspective. ✅ Video Editing & Post-Production – Enhancing video quality with professional editing, sound design, and graphics. ✅ 3D Visualizations & Interactive Presentations – Bringing your ideas to life with innovative technology.

As a leading corporate video company in Pune, we cater to businesses of all sizes and industries, ensuring that each project is customized to meet specific brand requirements. Our expertise spans across promotional videos, training modules, product demos, event coverage, and much more.

The Power of Audio-Visual Content in Digital Marketing

A well-executed corporate video is a game-changer for any business. Studies show that video content generates more engagement and conversions compared to text or static images. As one of the top corporate film makers in Pune, we understand the nuances of audience engagement and brand storytelling.

With increasing competition in the digital space, investing in high-quality corporate videos can set your business apart. By leveraging professional corporate video production in Pune, you can enhance brand recall, improve marketing ROI, and establish your business as a leader in the industry.

Why Choose Kaizen 360 Branding Pvt. Ltd.?

Experienced team – Skilled videographers, writers, editors, and voice-over artists working together to create compelling visuals.

Latest technology – High-end cameras, drones, and post-production tools for top-notch video quality.

Customized solutions – Tailored video production strategies to suit your business goals.

Affordable pricing – Cost-effective corporate video services without compromising on quality.

Elevate Your Brand with Professional Corporate Videos

If you’re looking for expert corporate video makers in Pune, Kaizen 360 Branding Pvt. Ltd. is your go-to partner. From concept to final cut, we ensure that your corporate videos align perfectly with your brand message and marketing goals.

1 note

·

View note

Text

Flow control valve Manufacturer

KAIZEN ENGINEERING offers high quality microfluidic modules and devices to design the flow control valve of any pipeline system. Our tailored solutions are ready to integrate your system by offering cost effective solutions. Flow control valve Manufacturer in India, Saddles Manufacturing Company in India, UPVC Ball Valve Manufacturer in India, Electrofusion Saddle Manufacturer in India, Electro Fusion Fittings Manufacturer in India, Exporter in India, PP Clamp Saddle in India

#kaizenengineering#saddles manufacturing#flow control valve#water meter protection box#ball valve manufacturers in india#saddle#compression fittings#electrofusion saddle

0 notes

Text

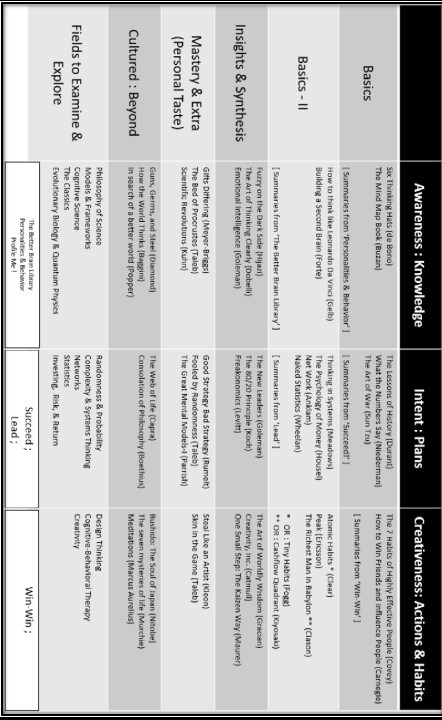

The Atlas of Worldly Wisdom

ReadingList

The different stages below include chronological suggested readings that will help in understanding and appreciating important ideas and perspectives. Some of these super ideas have been mentioned in The Atlas of Worldly Wisdom, and others serve to build on certain themes.

The assumption is that between half an hour to one hour per day can be dedicated to this project

thisis where the expected timeline for each stage comes

The different readings and suggestions are included in tabular form in the last page of this document. They have been categorized into the different spirals and the different stages. To get the complete information about any of the books, check the ‘References’ document.

Stage1: Basics-I– 10Books–~ 4months

SixThinking Hats (De Bono)

TheLessons of History (Durant)

The7 Habits of Highly Effective People (Covey)

TheMind Map Book (Buzan)

What theNumbers Say (Niederman)

TheArt of War (Sun Tzu)

Think-GrowModules : Personalities & Behavior 1

Think-GrowModules : Succeed

Think-GrowModules : Win-Win

ChooseOne :

Howto Win Friends and Influence People (Carnegie)

Oneof [ Brain Power or Verbal Intelligence ] (Both by Buzan)

1 For the Think-Grow Modules, check out the ‘Apps List’ Document, or go to: ahijazi.website

Stage2: Basics-II– 10Books–~ 4months

Howto think like Leonardo Da Vinci (Gelb)

Thinkingin Systems (Meadows)

ChooseOne :

AtomicHabits (Clear) or Tiny Habits (Fogg)

ThePsychology of Money (Housel)

Peak(Ericsson)

Think-GrowModules : The Better Brain Library

NakedStatistics (Wheelan)

ChooseOne:

TheRichest Man in Babylon (Clason)

CashflowQuadrant (Kiyosaki)

Think-GrowModules : Lead

ChooseOne:

Buildinga Second Brain (Forte)

NetWork (Anklam)

Stage3: Insights&Synthesis–10 Books– 4to5 months

Fuzzyon the Dark Side (Hijazi)

TheNew Leaders (Goleman)

TheArt of Worldly Wisdom (Gracian)

TheArt of Thinking Clearly (Dobelli)

The80/20 Principle (Koch)

Creativity, (Catmull)

Emotional Intelligence(Goleman)

ChooseOne :

Freakonomics(Levitt)

TheGreat Mental Models-I (Parrish)

OneSmall Step : The Kaizen Way (Maurer)

Theone left/not chosen from 10 [Stage 2]

Stage 4 (Mastery & Further) and Stage 5 (Cultured : Beyond) include a total of 16 books, but these will (probably) take significantly longer to finish than those in Stages 1 to 3.

I believe that going forward, personal tastes and preferences can play a bigger role. These are landmark books that will expand your knowledge and awareness into key fields and to include important super ideas. Choose the ones you prefer, but try to keep moving between the categories of the Triple-Spiral (Awareness, Intent, Creativeness).

As you read the books in this category, many ideas for further readings will come up. The path should get progressively more interesting as you advance and customize it further with more personally-relevant choices.

Stage4: Mastery& Further –10Books –4to5months

GiftsDiffering (Meyer-Briggs)

ChooseOne:

GoodStrategy Bad Strategy (Rumelt)

Steal Likean Artist (Kleon)

TheBed of Procrustes (Taleb)

Fooledby Randomness (Taleb)

Skinin the Game (Taleb)

ChooseOne:

ScientificRevolutions (Kuhn)

Theone left/not chosen from 8 [Stage 3]

Bookof your choice on Design Thinking & Creativity

Bookof your choice on the Philosophy of Science

Bookof your choice from cognitive science

Bookof your choice from Popular Science (Evolutionary Biology or Quantum Physics)

Next you can go through the list of books I’ve included in the ‘Cultured: Beyond’ category, and keep growing your knowledge and understanding of the world and yourself.

This reading list is a work-in-progress. It will keep changing and will be updated regularly (I hope).

On the following page you can see the suggested readings as a table, categorized by level and dimension.

Good Luck!

0 notes

Text

Hub 0851-0826-6666,Pelatihan Manajemen Lean: Membangun Keterampilan untuk Masa Depan Industri

Dalam dunia yang terus berkembang, industri harus terus beradaptasi untuk tetap relevan dan berdaya saing. Salah satu cara yang efektif adalah melalui Pelatihan Manajemen Lean di Kediri. Pelatihan ini tidak hanya memberikan pengetahuan, tetapi juga membentuk keterampilan yang diperlukan untuk menghadapi tantangan masa depan.

Baca juga:Pelatihan Manajemen Bisnis Lean Manufacturing di Kediri

Apa itu Manajemen Lean?

Manajemen Lean adalah pendekatan strategis yang bertujuan untuk mengoptimalkan proses bisnis dengan mengurangi pemborosan dan meningkatkan nilai bagi pelanggan. Ini melibatkan penggunaan alat dan teknik untuk meningkatkan efisiensi, kualitas, dan responsivitas dalam operasi perusahaan.

Mengapa Manajemen Lean Penting?

Manajemen Lean penting karena membantu perusahaan untuk:

Meningkatkan Efisiensi: Dengan menghilangkan pemborosan, perusahaan dapat menggunakan sumber daya secara lebih efektif.

Meningkatkan Kualitas: Fokus pada kualitas menghasilkan produk atau layanan yang lebih baik untuk pelanggan.

Menjadi Lebih Responsif: Dengan aliran kerja yang lebih lancar, perusahaan dapat merespons perubahan pasar dengan lebih cepat.

Kenapa Memilih Pelatihan Manajemen Lean di Kediri?

Keunggulan Pelatihan di Kediri

Fokus pada Industri Lokal: Pelatihan ini dirancang dengan mempertimbangkan kebutuhan dan konteks industri di Kediri, sehingga relevan dan mudah diimplementasikan.

Instruktur Berpengalaman: Mendapatkan panduan dari instruktur yang berpengalaman dalam menerapkan prinsip-prinsip Lean dalam berbagai industri.

Metode Pembelajaran Interaktif: Melalui diskusi, studi kasus, dan simulasi, peserta dapat memahami konsep secara mendalam dan menerapkannya dalam situasi nyata.

Manfaat Pelatihan Manajemen Lean di Kediri

Peningkatan Produktivitas: Dengan mengurangi pemborosan, perusahaan dapat meningkatkan produktivitas secara signifikan.

Peningkatan Kualitas Produk: Dengan fokus pada kualitas, perusahaan dapat menghasilkan produk yang lebih baik dan memuaskan pelanggan.

Peningkatan Keterlibatan Karyawan: Melalui pelatihan, karyawan akan merasa lebih terlibat dalam proses perbaikan dan inovasi.

Modul Pelatihan

1. Pengenalan Manajemen Lean

Modul ini memberikan pemahaman dasar tentang konsep dan prinsip-prinsip Lean serta bagaimana menerapkannya dalam berbagai industri.

2. Identifikasi Pemborosan

Peserta akan belajar mengidentifikasi dan menghilangkan pemborosan dalam proses bisnis mereka menggunakan alat-alat seperti Value Stream Mapping.

3. Penggunaan Alat Lean

Pelatihan akan mencakup pengenalan dan penggunaan alat-alat Lean seperti Kaizen, 5S, dan Poka-Yoke untuk meningkatkan efisiensi dan kualitas.

4. Implementasi dan Evaluasi

Peserta akan diajak melalui proses implementasi Lean dalam organisasi mereka dan bagaimana mengevaluasi keberhasilannya.

Tantangan dalam Implementasi Lean

Meskipun manfaatnya jelas, implementasi Lean bisa menghadapi beberapa tantangan, termasuk:

Resistensi Perubahan: Karyawan mungkin resisten terhadap perubahan yang diusulkan.

Kurangnya Pemahaman: Beberapa orang mungkin tidak sepenuhnya memahami konsep Lean dan manfaatnya.

Studi Kasus: Sukses Implementasi Lean di Kediri

Sebuah perusahaan manufaktur di Kediri berhasil meningkatkan produktivitasnya secara signifikan setelah menerapkan prinsip-prinsip Lean dalam operasinya. Mereka berhasil mengurangi lead time produksi dan meningkatkan kualitas produk.

Kesimpulan

Pelatihan Manajemen Lean di Kediri adalah langkah yang penting untuk meningkatkan efisiensi, kualitas, dan daya saing perusahaan dalam lingkungan bisnis yang kompetitif. Dengan memahami dan menerapkan prinsip-prinsip Lean, perusahaan dapat memperoleh keunggulan kompetitif yang signifikan dan mempersiapkan diri untuk masa depan yang lebih baik.

Pertanyaan Umum tentang Pelatihan Manajemen Lean di Kediri

Apa itu Pelatihan Manajemen Lean di Kediri?

Pelatihan Manajemen Lean di Kediri adalah program pelatihan yang dirancang untuk memberikan pemahaman mendalam tentang konsep dan praktik Lean Management serta bagaimana menerapkannya dalam konteks industri di Kediri.

Apa yang akan saya pelajari dalam pelatihan ini?

Anda akan mempelajari prinsip-prinsip dasar Lean Management, identifikasi pemborosan, penggunaan alat-alat Lean, dan bagaimana mengimplementasikan praktik-praktik Lean dalam operasi bisnis Anda.

Siapa yang seharusnya mengikuti pelatihan ini?

Pelatihan ini cocok untuk pemilik usaha, manajer operasional, supervisor, dan siapa pun yang tertarik meningkatkan efisiensi dan kualitas dalam operasi bisnis mereka.

Berapa lama durasi pelatihan ini?

Durasi pelatihan dapat bervariasi tergantung pada penyelenggara dan kedalaman materi yang disampaikan. Biasanya, pelatihan ini memiliki durasi antara beberapa hari hingga beberapa minggu.

Bagaimana cara mendaftar untuk pelatihan ini?

Anda dapat mendaftar melalui situs web penyelenggara pelatihan atau menghubungi langsung penyelenggara. Pastikan untuk memeriksa jadwal, biaya, dan persyaratan pendaftaran yang diberikan.

0 notes

Text

Hub 0851-0826-6666,Mengoptimalkan Proyek dengan Pelatihan Manajemen Proyek Lean di Kediri

Dalam dunia bisnis yang terus berkembang, manajemen proyek menjadi salah satu aspek yang krusial dalam memastikan kesuksesan suatu perusahaan. Pelatihan Manajemen Proyek Lean di Kediri merupakan investasi penting bagi perusahaan yang ingin meningkatkan efisiensi, mengurangi pemborosan, dan mencapai tujuan proyek dengan lebih efektif.

Apa itu Manajemen Proyek Lean?

Manajemen Proyek Lean menggabungkan prinsip-prinsip Lean dengan metodologi manajemen proyek untuk menciptakan pendekatan yang fokus pada penghapusan pemborosan, peningkatan efisiensi, dan pencapaian hasil yang optimal dalam proyek.

Mengapa Pelatihan Manajemen Proyek Lean Penting?

Pelatihan Manajemen Proyek Lean penting karena:

Mengurangi Pemborosan: Dengan menerapkan prinsip Lean, perusahaan dapat mengidentifikasi dan menghilangkan pemborosan dalam setiap tahap proyek, sehingga meningkatkan efisiensi dan mengurangi biaya.

Peningkatan Kualitas: Metodologi Lean membantu memastikan bahwa setiap langkah dalam proyek memberikan nilai tambah kepada pelanggan, sehingga meningkatkan kualitas produk atau layanan yang dihasilkan.

Pencapaian Tujuan dengan Lebih Efektif: Dengan fokus pada penghapusan pemborosan dan peningkatan aliran nilai, perusahaan dapat mencapai tujuan proyek dengan lebih cepat dan lebih efektif.

Keunggulan Pelatihan Manajemen Proyek Lean di Kediri

Penyesuaian dengan Konteks Lokal

Pelatihan Manajemen Proyek Lean di Kediri akan disesuaikan dengan kebutuhan dan tantangan unik yang dihadapi oleh perusahaan-perusahaan di wilayah tersebut. Ini memastikan bahwa pelatihan tersebut relevan dan mudah diimplementasikan dalam lingkungan kerja di Kediri.

Instruktur Berpengalaman

Para peserta akan dibimbing oleh instruktur yang berpengalaman dalam menerapkan Manajemen Proyek Lean dalam berbagai industri. Mereka tidak hanya memberikan pengetahuan teoritis, tetapi juga pengalaman praktis yang berharga.

Pendekatan Praktis dan Interaktif

Pelatihan ini menggunakan pendekatan praktis dan interaktif, termasuk studi kasus, simulasi, dan latihan langsung. Hal ini memungkinkan peserta untuk memahami konsep dengan lebih baik dan menerapkannya dalam situasi nyata.

Manfaat Pelatihan Manajemen Proyek Lean di Kediri

Peningkatan Efisiensi: Dengan menghilangkan pemborosan dan mengoptimalkan aliran nilai, perusahaan dapat meningkatkan efisiensi operasional mereka, sehingga menghemat waktu dan biaya.

Peningkatan Kepuasan Pelanggan: Dengan fokus pada pengiriman nilai tambah kepada pelanggan, perusahaan dapat meningkatkan kepuasan pelanggan dan memperkuat hubungan bisnis.

Peningkatan Daya Saing: Dengan mencapai tujuan proyek dengan lebih cepat dan lebih efektif, perusahaan dapat meningkatkan daya saing mereka di pasar.

Modul Pelatihan Manajemen Proyek Lean

1. Pengenalan Manajemen Proyek Lean

Peserta akan diperkenalkan dengan konsep dasar Manajemen Proyek Lean, sejarahnya, dan manfaatnya untuk perusahaan.

2. Alat dan Teknik Manajemen Proyek Lean

Peserta akan mempelajari berbagai alat dan teknik yang digunakan dalam Manajemen Proyek Lean, seperti Value Stream Mapping, Kanban, dan Kaizen.

3. Studi Kasus dan Simulasi

Melalui studi kasus dan simulasi, peserta akan memiliki kesempatan untuk mengaplikasikan konsep-konsep Manajemen Proyek Lean dalam situasi nyata dan mempraktikkan penggunaan alat-alatnya.

4. Implementasi dalam Organisasi

Peserta akan belajar tentang tantangan dan strategi untuk mengimplementasikan Manajemen Proyek Lean dalam organisasi, termasuk bagaimana melibatkan dan memotivasi tim proyek.

Tantangan dalam Implementasi Manajemen Proyek Lean di Kediri

Meskipun manfaatnya besar, implementasi Manajemen Proyek Lean bisa menghadapi beberapa tantangan, termasuk resistensi terhadap perubahan, kurangnya pemahaman tentang metodologi ini, dan kebutuhan untuk investasi waktu dan sumber daya.

Kesimpulan

Pelatihan Manajemen Proyek Lean di Kediri adalah langkah penting bagi perusahaan yang ingin meningkatkan efisiensi, kualitas, dan kesuksesan proyek mereka. Dengan memahami dan menerapkan prinsip-prinsip Manajemen Proyek Lean, perusahaan dapat mencapai tujuan mereka dengan lebih cepat, lebih efektif, dan dengan biaya yang lebih rendah.

Pertanyaan Umum tentang Pelatihan Manajemen Proyek Lean di Kediri

Apa itu Pelatihan Manajemen Proyek Lean di Kediri?

Pelatihan Manajemen Proyek Lean di Kediri adalah program pelatihan yang dirancang untuk memberikan karyawan dengan pengetahuan dan keterampilan dalam menerapkan metodologi Manajemen Proyek Lean untuk meningkatkan efisiensi dan kualitas pelaksanaan proyek.

Mengapa Pelatihan Manajemen Proyek Lean penting?

Pelatihan Manajemen Proyek Lean penting karena membantu organisasi meningkatkan efisiensi, mengurangi pemborosan, dan mencapai tujuan proyek dengan lebih efektif, yang pada gilirannya dapat meningkatkan kepuasan pelanggan dan keunggulan kompetitif.

Siapa yang seharusnya mengikuti pelatihan ini?

Pelatihan ini cocok untuk manajer proyek, anggota tim proyek, dan siapa pun yang terlibat dalam pelaksanaan proyek di berbagai industri dan bidang.

Apakah pelatihan ini hanya teori atau juga praktek?

Pelatihan ini mencakup kombinasi teori dan praktik. Peserta akan mempelajari konsep-konsep teoritis Manajemen Proyek Lean dan juga akan memiliki kesempatan untuk menerapkannya dalam studi kasus dan simulasi praktis.

Bagaimana cara mendaftar untuk pelatihan ini?

Anda dapat mendaftar melalui situs web penyelenggara pelatihan atau menghubungi mereka langsung. Pastikan untuk memeriksa jadwal, biaya, dan persyaratan pendaftaran yang diberikan.

0 notes

Text

Hub 0851-0826-6666,Mengoptimalkan Proyek dengan Pelatihan Manajemen Proyek Lean di Kediri

Dalam dunia bisnis yang terus berkembang, manajemen proyek menjadi salah satu aspek yang krusial dalam memastikan kesuksesan suatu perusahaan. Pelatihan Manajemen Proyek Lean di Kediri merupakan investasi penting bagi perusahaan yang ingin meningkatkan efisiensi, mengurangi pemborosan, dan mencapai tujuan proyek dengan lebih efektif.

Apa itu Manajemen Proyek Lean?

Manajemen Proyek Lean menggabungkan prinsip-prinsip Lean dengan metodologi manajemen proyek untuk menciptakan pendekatan yang fokus pada penghapusan pemborosan, peningkatan efisiensi, dan pencapaian hasil yang optimal dalam proyek.

Mengapa Pelatihan Manajemen Proyek Lean Penting?

Pelatihan Manajemen Proyek Lean penting karena:

Mengurangi Pemborosan: Dengan menerapkan prinsip Lean, perusahaan dapat mengidentifikasi dan menghilangkan pemborosan dalam setiap tahap proyek, sehingga meningkatkan efisiensi dan mengurangi biaya.

Peningkatan Kualitas: Metodologi Lean membantu memastikan bahwa setiap langkah dalam proyek memberikan nilai tambah kepada pelanggan, sehingga meningkatkan kualitas produk atau layanan yang dihasilkan.

Pencapaian Tujuan dengan Lebih Efektif: Dengan fokus pada penghapusan pemborosan dan peningkatan aliran nilai, perusahaan dapat mencapai tujuan proyek dengan lebih cepat dan lebih efektif.

Keunggulan Pelatihan Manajemen Proyek Lean di Kediri

Penyesuaian dengan Konteks Lokal

Pelatihan Manajemen Proyek Lean di Kediri akan disesuaikan dengan kebutuhan dan tantangan unik yang dihadapi oleh perusahaan-perusahaan di wilayah tersebut. Ini memastikan bahwa pelatihan tersebut relevan dan mudah diimplementasikan dalam lingkungan kerja di Kediri.

Instruktur Berpengalaman

Para peserta akan dibimbing oleh instruktur yang berpengalaman dalam menerapkan Manajemen Proyek Lean dalam berbagai industri. Mereka tidak hanya memberikan pengetahuan teoritis, tetapi juga pengalaman praktis yang berharga.

Pendekatan Praktis dan Interaktif

Pelatihan ini menggunakan pendekatan praktis dan interaktif, termasuk studi kasus, simulasi, dan latihan langsung. Hal ini memungkinkan peserta untuk memahami konsep dengan lebih baik dan menerapkannya dalam situasi nyata.

Manfaat Pelatihan Manajemen Proyek Lean di Kediri

Peningkatan Efisiensi: Dengan menghilangkan pemborosan dan mengoptimalkan aliran nilai, perusahaan dapat meningkatkan efisiensi operasional mereka, sehingga menghemat waktu dan biaya.

Peningkatan Kepuasan Pelanggan: Dengan fokus pada pengiriman nilai tambah kepada pelanggan, perusahaan dapat meningkatkan kepuasan pelanggan dan memperkuat hubungan bisnis.

Peningkatan Daya Saing: Dengan mencapai tujuan proyek dengan lebih cepat dan lebih efektif, perusahaan dapat meningkatkan daya saing mereka di pasar.

Modul Pelatihan Manajemen Proyek Lean

1. Pengenalan Manajemen Proyek Lean

Peserta akan diperkenalkan dengan konsep dasar Manajemen Proyek Lean, sejarahnya, dan manfaatnya untuk perusahaan.

2. Alat dan Teknik Manajemen Proyek Lean

Peserta akan mempelajari berbagai alat dan teknik yang digunakan dalam Manajemen Proyek Lean, seperti Value Stream Mapping, Kanban, dan Kaizen.

3. Studi Kasus dan Simulasi

Melalui studi kasus dan simulasi, peserta akan memiliki kesempatan untuk mengaplikasikan konsep-konsep Manajemen Proyek Lean dalam situasi nyata dan mempraktikkan penggunaan alat-alatnya.

4. Implementasi dalam Organisasi

Peserta akan belajar tentang tantangan dan strategi untuk mengimplementasikan Manajemen Proyek Lean dalam organisasi, termasuk bagaimana melibatkan dan memotivasi tim proyek.

Tantangan dalam Implementasi Manajemen Proyek Lean di Kediri

Meskipun manfaatnya besar, implementasi Manajemen Proyek Lean bisa menghadapi beberapa tantangan, termasuk resistensi terhadap perubahan, kurangnya pemahaman tentang metodologi ini, dan kebutuhan untuk investasi waktu dan sumber daya.

Kesimpulan

Pelatihan Manajemen Proyek Lean di Kediri adalah langkah penting bagi perusahaan yang ingin meningkatkan efisiensi, kualitas, dan kesuksesan proyek mereka. Dengan memahami dan menerapkan prinsip-prinsip Manajemen Proyek Lean, perusahaan dapat mencapai tujuan mereka dengan lebih cepat, lebih efektif, dan dengan biaya yang lebih rendah.

Pertanyaan Umum tentang Pelatihan Manajemen Proyek Lean di Kediri

Apa itu Pelatihan Manajemen Proyek Lean di Kediri?Pelatihan Manajemen Proyek Lean di Kediri adalah program pelatihan yang dirancang untuk memberikan karyawan dengan pengetahuan dan keterampilan dalam menerapkan metodologi Manajemen Proyek Lean untuk meningkatkan efisiensi dan kualitas pelaksanaan proyek.

Mengapa Pelatihan Manajemen Proyek Lean penting?Pelatihan Manajemen Proyek Lean penting karena membantu organisasi meningkatkan efisiensi, mengurangi pemborosan, dan mencapai tujuan proyek dengan lebih efektif, yang pada gilirannya dapat meningkatkan kepuasan pelanggan dan keunggulan kompetitif.

Siapa yang seharusnya mengikuti pelatihan ini?Pelatihan ini cocok untuk manajer proyek, anggota tim proyek, dan siapa pun yang terlibat dalam pelaksanaan proyek di berbagai industri dan bidang.

Apakah pelatihan ini hanya teori atau juga praktek?Pelatihan ini mencakup kombinasi teori dan praktik. Peserta akan mempelajari konsep-konsep teoritis Manajemen Proyek Lean dan juga akan memiliki kesempatan untuk menerapkannya dalam studi kasus dan simulasi praktis.

Bagaimana cara mendaftar untuk pelatihan ini?Anda dapat mendaftar melalui situs web penyelenggara pelatihan atau menghubungi mereka langsung. Pastikan untuk memeriksa jadwal, biaya, dan persyaratan pendaftaran yang diberikan.

1 note

·

View note

Text

Portfolio Based Underwriting

Take out Company Underwriting for Portfolio Underwriting

Benefits

More Companies get IPOs simultaneously

Safer Investment for Investors

Hedging Benefits for Investment Banks

Safe Exchange Entry for Smaller IPOs Companies

Automotive Industry

Supply-chain Network

Supply-chain networks are now more global than ever and are typically structured with five key areas: external suppliers, production centers, distribution centers (DCs), demand zones, and transportation assets.

Work Cell

A work cell is a logical and strategic arrangement of resources in a business environment. These arrangements are put into place to organize and improve process flow, increase efficiency, reduce costs, and eliminate wastage.

The concept of work cells is based on the platform of lean manufacturing, which focuses on value creation for the end customer and reduction of wastage. Work cells, which are also referred to as workcells, are typically found in manufacturing and office environments.

Lean Enterprise Principles

Lean enterprise is sometimes simply referred to as "lean." Although both terms came into popular usage in the 1990s, the concept itself was devised by Toyota Motor Corporation when it introduced the Toyota Production System (TPS).

Japanese industrial engineers, developed the system between 1948 and 1975.

According to Lean Thinking: Banish Waste and Create Wealth in Your Corporation, co-written by economists James Womack and Daniel T. Jones, lean enterprise is characterized by the following five chief tenets:

Value: This pertains to the manner in which end customers value a certain product or service as it relates to their wants or needs.

Value stream: This breaks down the life cycle of a product or service, including the acquisition of raw materials, the manufacturing of goods, the sale and delivery of inventory, and the ultimate consumption of items by end-users.

Flow: If any iteration of the value stream is stagnant or inefficient, it is considered wasteful and antithetical to creating customer value.

Pull: This is a directive stating that nothing should be produced until there is clear demand or official purchase orders from customers.

Perfection: This tenet states that in order for Lean Enterprise to be successful it needs to become part of the company culture, where every employee plays a role in implementing and perfecting the Lean Process.

Lean Enterprise and Lean Six Sigma; Lean Six Sigma's predecessor, Six Sigma, originated from the Motorola company in the United States in 1986. Six Sigma was developed within Motorola to compete with the kaizen (or lean manufacturing) business model in Japan.

By heavily borrowing ideals from Lean Six Sigma principles, lean enterprise seeks to eliminate "muda," a Japanese term that roughly translates to "waste" and refers to the inefficiencies that can be radically reduced or jettisoned.

Specifically, the following eight discrete categories comprise muda, easily memorized by the acronym "DOWNTIME," for Defects, Overproduction, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, Extra-Processing.

Porter's Value Chain Analysis

The firm’s primary activities include:

Investment team (portfolio managers, analysts): tasked with making the investment decisions.

Operations and traders: tasked with ensuring the investments are in line with the guidelines set forth by the client, and the trades are at the best execution price.

Marketing and sales: responsible for procuring clients.

Service (client relationship management): responsible for providing all the touch points to the client.

Support activities include:

Technology: designs a trading and client module that is efficient and effectively allows the team to provide the highest level of service and make the best investment decisions.

Human Resources: finds and retains the highest level of talent at the firm.

Infrastructure: includes the lawyers and risk managers whose oversight is crucial to ensuring the client’s guidelines are followed, the investment risk is controlled, and the firm is operating within the regulations established by the SEC.

VEDETTE

0 notes

Text

Büro-Kaizen Akademie von Jürgen Kurz: Alle Infos, Kosten & Erfahrungen

Die Büro-Kaizen Akademie von Jürgen Kurz, Patrick Kurz und Marcel Miller ist eine eLearning Plattform für Büroarbeit im digitalen Zeitalter. Lerne, wie du professionell und effektiv digital arbeiten kannst. Als Teil der Büro-Kaizen® Akademie wirst du nicht nur lernen, wie du dein Arbeitsleben effizienter gestalten kannst, sondern auch Teil einer lebendigen Community von Gleichgesinnten. Hier sind die Details, warum die Büro-Kaizen® Akademie die perfekte Lösung für dich ist: Die Vorteile ✅ - Praxisnah und umsetzbar: Lerne von den Besten ihres Fachs praxisnahe Tipps und Tricks, die du sofort in deinem Arbeitsalltag anwenden kannst. - Community + Forum: Trete einer lebendigen Community bei, stelle Fragen, tausche dich aus und profitiere von den Erfahrungen anderer. - Permanent Updates: Bleibe immer auf dem neuesten Stand mit exklusiven News und Updates aus der Welt des digitalen Arbeitens. Die Inhalte der Büro-Kaizen Akademie 📚 Entdecke 15 Online-Kurse zu allen wichtigen Themen für erfolgreiches Selbst- und Teammanagement. Jeder Kurs ist vollgepackt mit 10-20 Video-Lerneinheiten, begleitenden Handouts und praktischen Übungen, die dir helfen, das Gelernte direkt umzusetzen. Die Büro-Kaizen Akademie bietet 12 Online-Coachings mit der Expertise von Jürgen Kurz, Patrick Kurz und Marcel Miller. Hier sind die Module, die du in der Akademie finden kannst: 1. So geht Erfolg: 7 Lerneinheiten, 29:18 Minuten Video 2. E-Mail-Flut meistern: 6 Lerneinheiten, 1 Stunde 12:59 Minuten Video 3. Ihre Termine im Griff: 6 Lerneinheiten, 51:28 Minuten Video 4. Aufgaben planen und umsetzen: 5 Lerneinheiten, 40:27 Minuten Video 5. Papierlos arbeiten: 7 Lerneinheiten, 1 Stunde 40:14 Minuten Video 6. Dateiablage mit System: 4 Lerneinheiten, 31:58 Minuten Video 7. Team-Projekte managen: 6 Lerneinheiten, 1 Stunde 16:01 Minuten Video 8. Smartphone effizient einsetzen: 5 Lerneinheiten, 43:31 Minuten Video 9. Die richtige Hardware einsetzen: 7 Lerneinheiten, 48 Minuten Video 10. Effizienter Arbeitsplatz: 7 Lerneinheiten, 18:01 Minuten Video 11. Modernes Zeitmanagement: 7 Lerneinheiten, 30:10 Minuten Video 12. So geht Büro heute: 7 Lerneinheiten, 48 Minuten Video Die Coaching-Optionen 🎓 Je nach deinen Bedürfnissen kannst du zwischen drei verschiedenen Coaching-Paketen wählen: - Online-Coaching: Arbeite die Kurse selbstständig durch und stelle deine Fragen im Forum. - Premium-Coaching: Erhalte zusätzliche Unterstützung und schnellere Rückmeldung auf deine Fragen. - VIP-Coaching: Genieße individuelle Begleitung und Coaching-Einheiten für maximale Unterstützung. Erfahrungen mit der Büro-Kaizen Akademie Konrad R. berichtet von seinen Erfahrungen mit der Büro-Kaizen Akademie: "Mein Outlook Posteingang hatte über 24.000 Mails, davon 324 ungelesen als „Reminder“. Heute ist er leer und die ersten Tage klappten gigantisch einfach! Ich habe bereits seit 2 Jahren Office365, aber mit der täglichen Arbeit und Routine änderte sich einfach nichts. Ganz super an dem Kurs ist das „an die Hand nehmen“, „klare einfache Regeln“ und vor allem Beispiele aus der Praxis. Also erst mal sein GANZ GROSSES LOB UND DANKESCHÖN!!! Ich bin immer noch geplättet über den Leistungsschub, Klarheit und Arbeitserleichterung mit meinem Postfach!" Die Experten 👨🏫 Experten wie Jürgen Kurz, Marcel Miller und Patrick Kurz stehen bereit, um deine Fragen zu beantworten und dich auf deinem Weg zum Erfolg zu begleiten. Die 14-tägige Geld-zurück-Garantie 💰 Du gehst kein Risiko ein! Teste die Büro-Kaizen® Akademie risikofrei und erhalte dein Geld zurück, wenn du nicht zufrieden bist. Bist du bereit, dein Arbeitsleben zu optimieren und stressfrei zu gestalten? Trete noch heute der Büro-Kaizen® Akademie bei und starte deine Reise zu einem erfolgreichen und erfüllten Berufsleben im digitalen Zeitalter! 🌟 Verfasse deine eigenen Erfahrungen mit der Büro-Kaizen Akademie in den Kommentaren und teile deine Bewertung zu Umfang, Qualität, Preis und Nutzen! Lesen Sie den ganzen Artikel

0 notes

Text

5 Essential TPM Training Modules for Operational Excellence

Operational excellence is essential for any organization to achieve success. Achieving operational excellence requires a comprehensive training program that covers all aspects of the business, from customer service to production processes. One key component of this type of training is Total Productive Maintenance (TPM) Training Modules. TPM Training Modules provide employees with an understanding and knowledge of how to maintain equipment, manage resources efficiently, and increase productivity in their work environment.

Here are five essential TPM Training Modules for Operational Excellence:

1) Autonomous Maintenance: This module focuses on teaching employees about preventive maintenance techniques such as inspecting machines regularly, cleaning parts properly, and performing basic repairs without involving outside help or specialized tools or expertise. It also teaches them how to identify potential problems before they become major issues that can impact operations negatively over time if left unattended to proactively prevent downtime due to machine failure or malfunctioning components/parts being used in production process lines etc..

2) Planned Maintenance: This module provides instruction about scheduling regular maintenance activities based on specific criteria like usage frequency/duration; age & condition of machinery; current performance level etc., so that maximum output can be achieved while minimizing unexpected breakdowns & associated costs thereof by ensuring timely servicing/replacement whenever required accordingly as per set intervals determined beforehand itself thereby helping keep operations running smoothly at all times without disruption whatsoever!.

3) Quality Management System (QMS): The QMS module helps personnel understand the importance of quality control measures when it comes to achieving operational excellence by providing them with detailed information related to implementing quality standards throughout the entire manufacturing process right from raw material procurement stage till finished goods delivery phase – ultimately leading up towards successful deliveries made within stipulated timelines consistently every single time!

4) Continuous Improvement Processes (CIP): CIP enables employees to learn various improvement strategies that can be implemented both internally across departments within the organization as well as externally between suppliers & customers too - thus allowing everyone involved to gain better insights into what works best under different scenarios along with making necessary adjustments wherever applicable resulting overall improved efficiency levels attained eventually!

Also Read: Total Productive Maintenance Training

5) Kaizen Events: Finally kaizen events teach personnel ways to organize brainstorming sessions where ideas generated get discussed further amongst group members followed up implementation plans designed in order bring desired changes long run quickly effectively through collective efforts put forth collaboratively together!

0 notes

Text

Kaizen Management

Inroduction :

Kaizen module is an idea posting system, where any Employee within the organization can able to submit the idea which can be about anything, and once the idea posted to it will follow some Approval process which user has ability to configure the same.

Improvement of the organization is not the responsibility of the some of the employees of the organization. It involves every member of the organization irrespective of their hierarchy level. Whenever any abnormality or any issue occurred in the organization, the individual has to suggest or grab the attention of the superior or responsible person to fix the issue. Due to this model, the processes of the improvement get simplified and speed up. Read More

Visit our Website

#SaaS solutions#Leo TechnoSoft#Retail software solutions#Retail management solutions#saas development company#.net development company#Courier management#courier management system#kaizen management#Kaizen module#Chicago#Los Angeles#India

0 notes