#LLDPE foam

Explore tagged Tumblr posts

Text

LLDPE foam material for multi layer plastic water tank — LLDPE Foam

Shree Umiya Group LLDPE (Linear Low-Density Polyethylene) are leading manufacturer of LLDPE Raw Material including Plastic Raw Material and Water Tank Raw Material. Plastic is everywhere and it is an easy material to work with. It has many applications and is available in countless variations.

Plastic Raw Material Manufacturer

Plastics today are mostly made from natural materials such as cellulose, coal, natural gas, salt and crude oil. Plastic pollution can alter habitats and natural processes, reducing ecosystems’ ability to adapt to climate change, directly affecting millions of people’s livelihoods, food production capabilities and social well-being.

Plastics manufacturing also involves a variety of manufacturing processes, including injection molding, blow molding, extrusion, rotational molding, and thermoforming.

Our Products

LLDPE FOAM MATERIAL

STONE EFFECT MARBLE COLOUR

LLDPE AGGLOMERATES

LLDPE POWDER

ROTOMOLDING POWDER

LLDPE PLASTIC RAW MATERIAL

For More Details Click here : https://www.lldpefoam.com/

0 notes

Text

Scrap Metals Trader

Global Leader in Recyclable Materials

In today’s environmentally conscious world, recycling plays a crucial role in preserving resources and reducing waste. At Scrap Metals Trader, we provide a reliable and sustainable solution for industries and individuals looking to buy or sell high-quality scrap materials worldwide. With a commitment to competitive pricing, efficient logistics, and eco-friendly practices, we are your trusted partner in the scrap trade.

Wide Range of Scrap Metal Products

Whether you are looking for bulk quantities or specific types of metal scrap, we’ve got you covered. Our inventory includes:

Aluminum extrusion 6063 scraps: Ideal for manufacturing and recycling industries.

HMS 1 2 scrap heavy metal: A consistent source of ferrous scrap for steel production.

Aluminum UBC scrap price: Perfect for beverage can recycling.

Aluminum sheet for sale price: Available in various thicknesses and grades.

Aluminum radiator scrap: Sourced from vehicles and HVAC systems.

Aluminum wire scrap: Suitable for remelting and reuse.

Aluminum engine block scrap: A cost-effective raw material for casting industries.

Aluminum wheel scrap: Commonly used in automotive and recycling sectors.

Copper wire scrap for sale price: Known for high conductivity and value.

Brass honey scrap: A versatile and recyclable alloy.

Aluminum coils for sale price: Ideal for construction and manufacturing needs.

Cast iron scrap: Great for foundry applications.

Lead battery scrap: Essential for secondary lead production.

Electric motor scraps for sale price: Useful for copper and metal recovery.

Catalytic converter scrap: Rich in valuable precious metals.

AC compressor scrap: Extracted from HVAC and refrigeration systems.

Copper sheets for sale price: Available in multiple sizes and thicknesses.

Aluminum ingot for sale: High-purity aluminum for industrial use.

Copper ingot for sale: Premium grade for electrical and industrial applications.

Zinc ingots for sale: Offered with up to 99.995% purity.

Lead ingots for sale: Ideal for battery manufacturing and radiation shielding.

Trusted Supplier of Recycled Plastics and Paper

Besides metals, Scrap Metals Trader also deals in recyclable plastics and paper scraps, including:

PU foam scrap

PET flakes for sale price

HDPE blue drum regrind

PET bottle scrap

EPS foam blocks

ABS plastic scrap

Butyl rubber inner tube scrap

Virgin LLDPE granules

Over issued newspaper scraps for sale

OCC waste paper scrap

BOPP scrap film rolls supplier

Why Choose Scrap Metals Trader?

Global Export & Logistics: We deliver worldwide with efficient and secure logistics.

Competitive Pricing: We offer real-time prices and volume discounts.

Quality Control: Every shipment undergoes rigorous inspection to meet industry standards.

Customer Satisfaction: With years of experience, we’ve built a reputation for trust and reliability.

Partner with Scrap Metals Trader today for all your recyclable material needs. Whether you’re sourcing metals, plastics, or paper waste, we are here to support your sustainability goals and procurement demands.

0 notes

Text

Medical Device Packaging Is Crucial

Medical device packaging and labeling play a vital role in ensuring safety and efficacy in the healthcare sector. This packaging system involves sterile barrier systems and protective packaging that safeguard sterile devices from damage and prepare them for safe use. It is also used for non-sterile implants and instruments. The importance of proper packaging cannot be overstated, as it directly impacts the quality and reliability of medical devices.

Primary Packaging

Primary packaging refers to the material that comes into direct contact with the medical device or medication. Its primary function is to preserve the device, prepare it for future use, and ensure it reaches the user safely. When selecting primary packaging, considerations include product compatibility, weight, sharp edges, barrier requirements, and sterilization methods.

Secondary Packaging

Secondary packaging is the protective outer layer that shields the primary package during transportation and handling. It not only protects the primary package and product but also facilitates efficient transportation by consolidating product components. Packaging professionals develop various layers of packaging based on the required level of protection, ensuring compliance with regulatory standards and passing transportation tests.

Packaging Development Process

The development process for medical device packaging involves several steps. These include design and layout, material selection, sterilization compatibility, validation tests such as accelerated aging and vibration resistance, and regulatory compliance testing. All these elements are considered to ensure that the packaging is safe, secure, and effective.

Packaging Materials and Testing

Common packaging materials for medical devices include vinyl, LLDPE, PP, PC, APET, PETG, HIPS, and PETG foam. These plastics are often used for flexible structures and are combined with other materials to enhance durability. Packaging must have appropriate barrier systems or material coatings to prevent contamination and ensure compatibility with sterilization and medical device requirements.

Types of Packaging

Various types of packaging are used for medical devices, including trays, blister packaging, pouches, cartons, and individually-wrapped packages. Trays are commonly used for sterile equipment and implants, while blister packaging is used for medications. Pouches are suitable for products with unusual shapes.

Regulatory Compliance

Medical device packaging must comply with various regulatory standards. These standards ensure that packaging is safe and effective. The ISO 11607 standard is used for terminally sterilized medical device packaging. These standards test the functionality and durability of packaging, ensuring it withstands transportation and storage conditions.

In conclusion, medical device packaging is a critical aspect that ensures patient safety and product functionality. Proper design and testing of this packaging guarantee that products remain safe under all conditions and fulfill their intended purpose.

See more: https://www.linkedin.com/company/kangyi

0 notes

Text

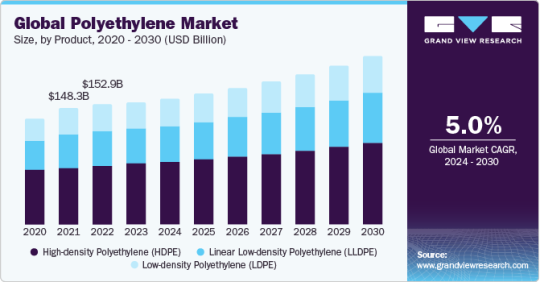

Polyethylene Market Size To Reach USD 213.77 Billion By 2030

Polyethylene Market Growth & Trends

The global polyethylene market size is anticipated to reach USD 213.77 billion by 2030, growing at a CAGR of 5.0% during the forecast period, according to a new report by Grand View Research, Inc. The market growth is driven by the increasing consumption of plastics in the automotive, medical, construction, and electrical & electronics industries. Moreover, the increasing demand for lightweight materials in the automotive industry contributes to industry growth. Polyethylene (PE) is commonly used for manufacturing lightweight plastics, films, and foams used in vehicles.

The emphasis of the automotive industry on enhancing the fuel efficiency of vehicles by reducing their weight leads to the adoption of PE in this industry. As recycling technologies advance, the PE market adapts to integrate more recycled content into its products, contributing to a more circular and resource-efficient approach. Government policies and regulations supporting sustainable practices further bolster the demand for recycled PE. The circular economy encourages the collection, separation, and reprocessing of used PE products, diverting them from landfills.

One of the major challenges faced by the market includes fluctuations in raw material prices. The global crude oil prices have witnessed severe fluctuations in the past few years. Social disruption in key crude oil-producing regions, such as Venezuela, Libya, Iran, Nigeria, and Iraq has hampered crude oil supply, generating inelasticity in the supply-demand balance. These factors are short-lived in the market causing immediate fall and rise in prices, thus impacting market growth.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/polyethylene-pe-market

Key Polyethylene Company Insights

Key companies are adopting several organic and inorganic growth strategies, such as new product development, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

In November 2023, Dow announced an investment in the Fort Saskatchewan Path2Zero project in Alberta, Canada, with an investment of USD 6.5 billion, as part of the company's goal to achieve carbon neutrality by 2050. The project involves the construction of a new ethylene plant and expanding polyethylene capacity by 2 million metric tons annually. The construction is scheduled to commence in 2024, and the increased capacity is set to be implemented in stages, with the initial phase anticipated to begin in 2027

In October 2023, Borealis AG and TotalEnergies SE announced plans to construct a USD 1.4 billion Borstar PE unit within their Baystar joint venture. This PE unit, boasting a capacity of 625,000 metric tons annually, marks a significant increase, doubling the current production capabilities at the Baystar site including two existing PE production units

In August 2023, Dow partnered with Mengniu, a dairy company, to launch a PE yogurt pouch, specifically designed for recyclability. This joint effort signifies a significant step for both companies in reinforcing their dedication to promoting a circular economy in China. The partnership with Mengniu enables both brands to take the lead in pioneering recyclable all-PE dairy packaging in the Chinese market.

Polyethylene Market Report Highlights

High-density Polyethylene (HDPE) dominated the product segment with more than 49.0% share in 2023. The demand for efficient and long-lasting solutions in water infrastructure and agriculture enhances the growth prospects of the HDPE segment

The Linear Low-density Polyethylene (LLDPE) type segment is expected to grow at the fastest CAGR of 5.5% over the forecast period

The bottles & containers application segment held a substantial market share in 2023. The sustainability trend in the packaging industry contributes to the growth of this segment

The use of recyclable materials is growing due to environmental concerns. The recyclability and compatibility of PE with recycling processes are essential for eco-conscious industries and consumers

Asia Pacific dominated the global market in 2023. The growing manufacturing industry in Asia Pacific is anticipated to drive the demand for PE

In October 2023, Borealis AG and TotalEnergies SE announced plans to construct a USD 1.4 billion Borstar PE unit within their Baystar joint venture. This PE unit, boasting a capacity of 625,000 metric tons annually, marks a significant increase, doubling the current production capabilities at the Baystar site including two existing PE production units

Regional Insights

The North America Polyethylene Market accounted for a significant revenue share of 19.2% in 2023. The shale gas boom in North America has transformed the regional PE market. The abundant and easy availability of cost-effective feedstocks derived from shale gas, particularly ethane, has given PE producers, based in North America, a significant competitive advantage.

U.S. Polyethylene Market Trends

The Polyethylene Market in the U.S.is expected to grow over the forecast period. The U.S. energy landscape, specifically the abundant availability of shale gas, is a critical driver for the PE market growth in the country. Shale gas serves as a primary feedstock for ethylene production, which is a key building block for PE. The accessibility and the cost competitiveness of shale gas contribute to the expansion of ethylene production capacities in the U.S., thereby supporting market growth.

Asia Pacific Polyethylene Market Trends

The Asia Pacific Polyethylene Market dominated the global industry in 2023 with a share of over 50.3%. Asia Pacific is a diverse market for PE owing to the growing automotive and construction industries in the region that are key consumers of this material. The growing manufacturing industry in Asia Pacific is anticipated to drive the requirement for PE.

The Polyethylene Market in China held a significant share in the Asia Pacific region. The market is anticipated to register a CAGR of 5.3% over the forecast period. Government initiatives for infrastructure development projects are driving market growth in China. The ambitious infrastructure development plans of the country, including the Belt and Road Initiative, stimulate the demand for PE in construction and related activities.

Polyethylene Market Segmentation

Grand View Research has segmented the global polyethylene market on the basis of product, application, end-use, and region:

PE Product Outlook (Volume, Kilotons, Revenue; USD Million, 2018 - 2030)

Low-density Polyethylene (LDPE)

High-density Polyethylene (HDPE)

Linear Low-density Polyethylene (LLDPE)

PE Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Bottles & Containers

Films & Sheets

Bags & Sacks

Pipes & Fittings

Other Applications

PE End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Packaging

Construction

Automotive

Agriculture

Consumer Electronics

Other End-uses

PE Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

Europe

Asia Pacific

Central & South America

Middle East & Africa

List of Key Players in the Polyethylene Market

BASF SE

Borealis AG

Braskem

Dow

Exxon Mobil Corporation

Formosa Plastics

INEOS Group

LG Chem

LyondellBasell Industries Holdings B.V.

Mitsubishi Chemical Corporation

MOL Group

SABIC

China Petrochemical Corporation (Sinopec)

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/polyethylene-pe-market

#Polyethylene Market#Polyethylene Market Size#Polyethylene Market Share#Polyethylene Market Trends#Polyethylene Market Growth

0 notes

Text

Antirodent Master batch and Films

Masterbatches Kinetic Polymers is one of the leading manufacturer of Conductive Master Batch Compound based on Polypropylene which are used for making conductive PP Corrugated sheets used for packaging boxes and partition for electro static safe products.

We are regularly supplying this product to various companies across India.

We can offer you the following at the competitive prices.

Anti Static Masterbatch for PP / HDPE / LDPE & HIPS – ABS Conductive Master Batch Compound based on PP / LDPE / LLDPE / PVC / & EVA VCI Masterbatch – Nitrite based and Nitrite free for LDPE/ LLDPE / & HDPE Fim Antirodent Master batch for PVC / LDPE / & PP Anti Microbial Masterbatch for PP / & HIPS Slip Masterbatch for LLDPE & EVA Anti Block Masterbatch for LLDPE & EVA Foaming Agent Masterbatch for PVC / & LDPE Nucleating Agent Masterbatch for HDPE & PP

0 notes

Text

LLDPE Foam Material Manufacturer in India | Shree Umiya Group

Our latest experimental results indicate that heating time and the processing temperature plays important roles in determining fine cell structure in rotational foam moulding. For More Details, Visit:-https://www.lldpefoam.com/lldpe-foam-material.html Contact Us:-+91 94294 70409

0 notes

Text

LLDPE Foam Material & Roto Foam Material Manufacturer in Ahmedabad

LDPE foam is a closed cell foam, also referred to as a PE foam or Polyethylene. The material starts off as a thermoplastic which is then blown into a foam format. This is a highly durable as well as versatile product. Our teamwork and co-operation is what makes us unique from others. Customer satisfaction and excellent service ensuring you that our production will contribut greatly to your business and bring you benefit.

For more info,

Visit: https://www.lldpefoam.com/

Contact no: +91–9429470409

2 notes

·

View notes

Text

LLDPE Powder, Rotomoulding Powder, Rotational Moulding Powder Manufacturer and Supplier

Since 2002, We are manufacturer and supplier of premium quality Plastic Raw Material, LLDPE Rotomoulding Powder in India. LLDPE Powder is finely pulverized & processed material which is used in rotomoulding process to make the hollow products. This is mostly used in thermoplastic polymers best known for excellent flexibility, very good impact strength and versatility.

LLDPE foam material for multi layer plastic water tank

LLDPE stone effect marble color for rotomoulding molding products

LLDPE agglomerates

Water Tank Raw Material, LLDPE Raw Material

LLDPE Powder, Foam Powder, Roto Powder, Unbreakable Powder, Rotomoulding Powder, Rotomolding LLDPE Powder, Rotational Moulding Powder

LLDPE rotomoulding granules and powders

LLDPE unbreakable powders

LLDPE is used for pond liners or blended into other films to give them more flexibility and extra strength.

PRODUCT

LLDPE FOAM MATERIAL

STONE EFFECT MARBLE COLOUR

LLDPE AGGLOMERATES

LLDPE POWDER

ROTOMOLDING POWDER

LLDPE PLASTIC RAW MATERIAL

For more Details Click here : https://www.lldpefoam.com/

0 notes

Text

Plastic Recycling Machine by Neoplast

Neoplast's is produce a high-efficiency, one-step plastic recycling machine designed to reprocess flexible packaging consisting of PE polyethylene (HDPE, LDPE, LLDPE) and PP polypropylene, both printed and unprinted. Our cutter-integrated pelletizing technology doesn't require pre-cutting the material and utilises less energy and space while producing high-quality plastic pellets quickly.

In addition to domestic film waste, which is pre-crushed hard plastic waste from injection and extrusion, the system can process cleaned flakes, scraps, and regrind. The usage of this machinery is advised for manufacturers of agricultural films, food packaging, commercial bags, waste bags, shrink and stretch films, PP woven bags, jumbo bags, tapes, and yarns. You can also use materials like PE and PS foam, PE net, EVA, and PP mixed with PU on this machine.

Neoplast is a manufacturer of completely and partially automatic waste plastic recycling machines in India. We manufacture plastic recycling machines in India, and our machines are renowned for their great productivity, low cost, and reliable after-sales service. Thermoplastic film, soft polyvinyl chloride, and plastic products are routinely recycled using the Plastic Recycling Machine Die Face Cutter. a high efficiency, one-step plastic recycling machine from Neoplast, is made for reprocessing flexible packaging made of PE polyethylene (HDPE, LDPE, LLDPE), and PP polypropylene, both printed and unprinted. Call us at +91-79-4019-4030 if you'd like further details.

Advantages of Plastic Recycling Machine

Combining cutting, extrusion, and pelletizing, plastic recycling machines build a compact and efficient recycling process. The material is compacted by the recycling machine's cutter compactor into a state that is ideal for the extrusion procedure, and it is then fed directly into the extruder using centrifugal force. When opposed to traditional recycling machines, this integrated solution eliminates the problem of irregular input because it doesn't require a separate crusher. Neoplast fulfil all client’s needs.

The nip roll feeder for whole film rolls and the belt conveyor for film scraps and hard plastic regrind both simultaneously feed waste materials into the machine. An additional silo tank can be used to store and feed pre-washed film flakes. The feeding is automatically changed according on how full the cutter compactor is. The material is then minced, dried, and compacted into a semi-molten state that is perfect for the next extrusion procedure. The cutter compactor then feeds the material steadily and directly onto the extruder screw.

The pre-compacted material is continuously fed into the extruder through its tangential connection thanks to the cutter compactor and extruder's integration, which makes feeding extremely rapid and steady. Compared to other recycling systems on the market, this results in a much higher manufacturing output.

0 notes

Text

Polyolefin Catalyst Market – Forecast (2021-2026)

Polyolefin catalyst market size is forecast to reach $3.6 billion by 2026, after growing at a CAGR of 4.9% during 2021-2026. The polyolefin polymerization using the Ziegler-Natta catalysts, polyolefin has become one of the most important polymers produced industrially. In particular, polyethylene, polypropylene and ethylene propylene diene monomer (EPDM) rubber have been widely used for catalysis. The rapid growth of the packaging industry has increased the demand for polyolefin catalysts; thereby, fueling the overall market growth. In addition, increased R&D investment on new manufacturing technologies, along with capacity expansion for polyolefin plants, would also boost product demand in the coming years. Furthermore, the flourishing automotive and packaging industry is also expected to drive the polyolefin catalyst industry substantially during the forecast period.

Polyolefin Catalyst Market COVID-19 Impact

Companies were moving steadily towards their sustainability targets before COVID-19. However, a multitude of industries around the world, especially the packaging industry, have been adversely affected by the coronavirus pandemic. Innovative developments have been developed by packaging companies that are environmentally friendly, reusable, and biodegradable. Concerns over the hygiene and safety of recycled packaging, however, have temporarily stalled the progress of the packaging industry towards a healthy, evolving and circular supply chain. The use of polyolefin catalysts such as single-site catalyst and ziegler-natta catalyst for injection molding also suddenly halted, contributing to a major loss in the polyolefin catalysts market. Thus, there was a disruption in the supply and demand of packaging materials owing to the pandemic, which largely impacted the polyolefin catalyst market.

Report Coverage

The report: “Polyolefin Catalyst Market – Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the polyolefin catalyst Industry.

By Resin: Polyethylene (High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE), and Others), Polypropylene (PP), and Ethylene Propylene Diene Monomer (EPDM) Rubber.

By Catalyst Type: Ziegler-Natta catalyst, Single Site catalyst (Metallocene, and post-Metallocene), Chromium catalyst, and Others.

By Application: Injection Molding, Extrusion Molding, Blow Molding, Films, Fibers, Foam, and Others.

By End-Use Industry: Automotive (Passenger Cars, Light Commercial Vehicles (LCV), Heavy Commercial Vehicles (HCV), and Others), Packaging (Food & Beverages, Cosmetics, and Others), Medical & Healthcare (Medical Packaging, Bone Substitute, Drug Delivery, Tissue Adhesive, and Others), and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (U.K, Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Request Sample

Key Takeaways

Asia-Pacific dominates the polyolefin catalyst market, owing to the increasing demand for the packaging materials in the region. The increasing per capita income coupled with the population growth is a key factor in the region's rising personal care and cosmetic products industry.

The demand for packaging has pushed steadily towards lightweight and translucent materials. This has resulted in a rising market for films with polyolefin.

The increasing commercial performance of polyolefin materials in various end-user segments, including automotive, food and beverage and packaging, among others, is expected to contribute significantly during the forecast period to the overall demand for catalysts.

Polyolefin Catalyst Market Segment Analysis - By Resin

The polypropylene and polyethylene segment held a significant share in the polyolefin catalyst market in 2020 and is growing at a CAGR of 5.6% during 2021-2026. Polypropylene is being utilized in everything from drinking straws and food containers and reusable water bottles, to thermal underwear, roofing materials, marine ropes and carpet. Polypropylene, the polymerized embodiment of propylene, is both solid and versatile (hence its use in drinking straws), highly resistant to heat (making it useful in laboratory research applications) and lightweight. By polymerizing ethylene, polyethylene (PE) is formed. It is the most common type of plastic that occurs everywhere, from plastic bags and bottles to electrical cable insulation and water pipes. Such wide application of polypropylene and polyethylene is the major factor driving the segment growth.

Polyolefin Catalyst Market Segment Analysis - By Catalyst Type

The Ziegler-Natta catalyst segment held the largest share in the polyolefin catalyst market in 2020. Because of their wide use in the production of polypropylene, high density polyethylene, and linear low-density polyethylene, Ziegler-Natta catalysts are the most common. Ziegler-Natta catalyst is used by over 90% of global polypropylene production, while ziegler-Natta catalyst is used by more than 50 percent in all cases in polyethylene production. Another big catalyst used mostly to manufacture high density polyethylene is the Phillips or chromium catalyst (HDPE). The catalyst used for the development of polypropylene is mainly a titanium-based ZN catalyst enabled by aluminium alkydes and external donors, whereas the catalyst used for HDPE comprises titanium, Phillips and metallocene systems. Linear low density polyethylene use over 80% of Ziegler Natta catalyst and metallocene catalyst at a lesser extent.

Polyolefin Catalyst Market Segment Analysis - By Application

The film segment held the largest share in the polyolefin catalyst market in 2020 and is growing at a CAGR of 5.4% during 2021-2026. Among the different polymers that are used in film extrusion, polyethylene (HDPE, LDPE and LLDPE) is the main polymer. PVC films are increasingly being replaced by polyolefin films because they are safer for food packaging and more stable in a wide range of temperatures. In 2018, approximately 2.53 million tonnes of plastic films and sheets were manufactured in Japan, according to the Ministry of Economy, Trade, and Industry, Japan, reflecting a small increase from about 2.46 million tonnes in 2016. This increase can be attributed to the increasing packaging industry in various regions. Thus, the continuous growth of these industries has made films the largest and fastest-growing segment under the application segmentation of the market during the forecast period.

Polyolefin Catalyst Market Segment Analysis - By End-Use Industry

The packaging segment held the largest share in the polyolefin catalyst market in 2020 and is growing at a CAGR of 5.9% during 2021-2026, owing to the increasing usage of polyolefins in the packaging industry. Polyolefins are chemically inert and do not react with the contents of the material. This makes them perfect food packaging materials. No hazardous chemicals, additives or goods are present that can be ingested by the contents of the packaging and thus consumed by the consumer. Polyolefins, when in contact with food, are extremely healthy. It can then be used to manufacture anything from lightweight food packaging wrap to much heavier film for agricultural use, depending on the thickness of the film. According to the Sea-Circular Organization, the packaging industry in China is projected to record a Compound Annual Growth Rate (CAGR) of 13.5 percent during the forecast period (2021-2026). It is anticipated that the flourishing packaging industry will accelerate the growth of polyolefin catalyst market for manufacturing packaging materials.

Polyolefin Catalyst Market Segment Analysis - By Geography

Asia-Pacific region held the largest share in the polyolefin catalyst market in 2020 up to 38%, owing to the flourishing food & beverage industry, which is boosting the demand for packaging materials in the region. According to the United States Department of Agriculture (USDA), in 2018, the total value of all retail food and beverage sales in Japan was $479.29 billion (¥53,339 billion), an overall increase of 2.3 percent. According to the United States Department of Agriculture (USDA), China’s food processing industry continued to grow in 2017. Revenue climbed to $1.47 trillion, an increase of 6.3 percent compared with the previous year. The rising disposable income has resulted in the increasing demand for the food and beverage industry in various regions, which is further driving the growth of the packaging material in the region. And with the increasing demand for packaging materials in the region, the demand for polyolefin to manufacture packaging materials will substantially increase, which will then drive the polyolefin market growth in Asia Pacific during the forecast period.

Inquiry Before Buying

Polyolefin Catalyst Market Drivers

Increasing Automotive Production

Polyolefins in automobiles have experienced a great deal of interest in the recent years, and their applications have been increasing with a tendency of further growth compared with other materials used in automobiles. The major advantages of polyolefin catalysts are their functionality, cost-effective manufacturing methods, and comparatively lower fuel consumption. In automobiles, the polyolefin catalysts are largely used in the internal and external areas, in the engine section, and in the bodywork. The automotive production is increasing. For instance, the Automotive Mission Plan 2016-26 (AMP 2026) initiatives is launched by the Indian government to boost the automotive industry in the country. According to Organisation Internationale des Constructeurs d'Automobiles (OICA), the production of passenger cars in Africa was 776,967 in 2018, which then rose to 787,287 in 2019, an increase of 1.3%. Thus, increasing automation production will require more polyolefin catalyst, which will act as a driver for the polyolefin catalyst market.

Increasing Demand for Polyolefins from the Healthcare Industry

In the medical and healthcare sectors, polyolefin catalysts has recently gained traction as they are easy to fabricate into useful products and have increasing design capability. They also have the potential for use in many applications because of their excellent cost/performance values such as low density, easy recyclability, and diverse processability. Biomedical applications of these POs are in medical implants, medical devices, and in the production of pharmaceutical consumables in the form of packaging materials; vials, bottles, and syringes. And the growing investment in healthcare services is strengthening the healthcare industry. For instance, in 2018, the Australian Government announced to drive a new era of better health care in Australia and will invest $1.3 billion in the Health and Medical Industry Growth Plan. According to the European Commission, public expenditure on healthcare and long-term care is expected to increase by one-third by 2060 in Europe. Thus, the polyolefin catalysts market growth will be spurred by the rapid expansion of the healthcare industry across the regions

Polyolefin Catalyst Market Challenges

Volatility in Crude Oil Prices

Polyolefin catalyst is a derivative of crude oil and its domestic price is highly susceptible to the prices of its crude oil-derived feedstock. Both polyethylene and polypropylene are produced from crude oils; thus, increases in feedstock prices in turn hamper the overall production, adversely affecting the market for catalysts. In the last few years, there has been volatility in the price of crude oil. For instance, the price of crude oil has decreased from $98.95/bbl in 2014 to $52.39/bbl in 2015 and increased from $43.73/bbl in 2016 to $71.31/bbl in 2018 and then decreased to $64.21/bbl in 2019, according to the BP Statistical Review of World Energy. And because of this uncertainty in crude oil prices, the price of polyolefin catalysts also increases, which is expected to be a significant challenge for the polyolefin catalyst market manufacturers during the forecast period.

Buy Now

Polyolefin Catalyst Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the polyolefin catalyst market. Major players in the polyolefin catalyst market are W.R. Grace, Univation Technologies, LLC, LyondellBasell Industries N.V., Johnson Matthey Inc., TOHO Titanium Company Limited, Idemitsu Kosan Co., Ltd., INEOS Group, Mitsui Chemicals, Inc, Clariant AG, Evonik Industries, DuPont, Inc., DORF-KETAL Chemicals India Private Limited, AGC Chemicals Inc., and NOVA Chemicals Corporation.

Acquisitions/Technology Launches

In March 2020, LyondellBasell signed definitive agreements to expand in China with the Liaoning Bora Enterprise Group through a 50-50 joint venture. Under the agreement, the partners formed a Sino-foreign joint venture, the Bora LyondellBasell Petrochemical Co. Ltd, which operated a 1.1 million metric tons per annum ethylene cracker and associated polyolefin derivatives complex in Panjin, China.

In November 2019, PQ Group Holdings Inc. signed an agreement with INEOS Polyolefin Catalysts to commercialize certain polyethylene catalysts to customers of selected processes. This collaboration expanded PQ’s current catalyst product offering to its customers. In addition, enabled PQ to access new customers through an enhanced product offering and associated technical support.

Relevant Reports

Polyolefin Foam Market – Forecast (2021 - 2026)

Report Code: CMR 1179

Polyethylene Catalyst Market – Forecast (2021 - 2026)

Report Code: CMR 1325

For more Chemicals and Materials Market reports, Please click here

0 notes

Text

Role and Applications of Additive Masterbatch in Plastic Industries

In this plastic industry-centric blog, we are going to highlight about an additive masterbatch, its role, and its applications in the plastic based industry. Before we move forward, it makes sense to learn about the product in simple words.

Learning about the additive masterbatches

According to industry experts, this type of masterbatch is also famous as a functional masterbatch in industry circles. Why? Since these types of masterbatches improve the performance of plastic products by imparting various features and properties to the plastic products. These special granules are added in small quantity, however, brings about terrific changes to the product. As a result, their market is rapidly increasing. UV masterbatch, PPA masterbatch, Slip Masterbatch, and Anti Block masterbatch are among the most sought-after masterbatches in the plastic manufacturing industries.

Unique features of a special type of additives

Here are a few unique features of the product, making it perfect for a wide range of applications:

Greater production flexibility

Improves thermal stability

Excellent dispersion

Customization option possible

Let’s now shift our focus to the core subject, role, and applications of additive masterbatches in plastic manufacturing industries.

Applications of additive masterbatches

UV masterbatches: Suitable for Agricultural greenhouse film, FIBC bags, molded crates, drums, garbage cans, garden furniture, outdoor articles, Woven sacks, HDPE/PP raffia tapes, LDPE/LLDPE/PP lamination, etc.

PPA masterbatch: Improving the performance of blown films & other extrusion products in terms of optical properties

Slip masterbatch: Film, sheet, injection molding.

Anti Block masterbatch: PE, PP, PO blown film products, steam beads bags products. Blow molding, extrusion, injection moulding, and casting processing.

Anti Oxidant masterbatch: Designed for protection and retaining the gloss and mechanical properties of the end product.

Anti Static masterbatch: Ideal for films, PE and PP molded items, extrusion process, EPE foams, and electrical appliances.

Nucleating agents: Processed for injection molded items, LDPE and PP polymers.

Bio-degradable masterbatch: Used in plastic processing during molding, extrusion, or blow-molded components Ideal for Shopping Bags, Grain Bags, Plastic Containers, Mulch Films, Packaging bags, Liners, etc.

Optical brightener masterbatch: Used in a wide range of applications in plastic manufacturing industries, including Films and Sheets, Fibers, Molded Thermoplastic, Extruded Products, Roto Moulding, etc.

Customization

Additive masterbatches empower manufacturers with greater flexibility to design and manufacture products according to their industry requirements. In this sense, you don't have to compromise with the specifications of the product. Get what you require! You can easily customize the product. This type of flexibility can’t be made possible with pigments. That’s why additives’ is growing at a rapid pace in Ahmedabad, India.

Industries

Given the properties and salient features, additive masterbatches are changing the fortune of numerous plastic-based industries. Here is a list of sectors/ industries that draw benefits from the masterbatches:

Building & construction

Agriculture

Automotive

Packaging

FMCG

Household items

Quality makes the difference in this era of tough competition. Never compromise the quality of the product!

Join Hands with Sumiran

Are you into the plastic industry? Are you looking for a leading masterbatch manufacturer? If your answer to these two questions is yes, then join Hands with Sumiran Masterbatches. The professionally managed company is a leading manufacturer and supplier of a wide range of masterbatches, including White Masterbatch, Black Masterbatch, Colour Masterbatch, and Additive Masterbatches among others.

0 notes

Text

Polymers Market - Forecast, 2024-2030

Global Polymers Market

Global Polymers Market size is forecast to reach around $ 997.77 billion by 2030, after growing at a CAGR of 5.4% during 2024-2030. Polymer is one of the widely used chemical products in almost all the sectors such a medical, aerospace, packaging, automotive, construction, electrical appliances, and medical sector, and consequently, the global polymers market is thriving. Polymers are used widely as a substitute of metal and mineral based products due to its high performance, cost-effectiveness, and low weight. Increase in the retail sector and prospering e-commerce industry is demanding for more packaging material that is influencing the significance of the polymers market. The major factors driving the growth of this market are the increasing demand for polymers in various end-use industries, the rising adoption of lightweight and sustainable materials, the technological innovations, and the supportive government policies and initiatives. However, some of the challenges faced by this market are the fluctuations in the raw material prices, the environmental concerns, the competition from alternative materials, and the trade barriers. Furthermore, growing demand for polymer in the electronic industry for the manufacturing of different electrical parts such as switches and sockets are driving the Polymers Market.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞

Report Coverage

The report: “Polymers Market – Forecast (2024-2030)”, by Industry ARC, covers an in-depth analysis of the following segments of the Global Polymers Market.

By Type: Polypropylene, Polyethylene (HDPE, LDPE, LLDPE, and Others), Polyvinyl Chloride, Polystyrene (Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS)), Polyurethane (Flexible Polyurethane Foam, Rigid Polyurethane Foam, Thermoplastic polyurethane (TPU), and Others), and Others.

By Process: Injection Moulding, Extrusion, and Others.

By End-Use Industry: Packaging (Rigid and Flexible), Building and Construction (Roofing, Windows, Flooring, and Others), Automotive (Engine, Tires, Body Panel, and Others), Electrical and Electronics, Agriculture, Medical/Healthcare, and Others.

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Spain, Netherlands, Russia, Belgium, and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia and New Zealand, Taiwan, Indonesia, Malaysia, and Rest of Asia Pacific), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle East and Africa)

Key Takeaways

In the Latin America region, Brazil is the major market for the Polymer owing to a rise in the purchasing power of consumers, growing consumer packaged goods market, and rise in corn, wheat, and sugarcane production and consumption across the country owing to the Bio-based plastic and polymers are gaining prominent growth.

The polymers are observed to be the better substitutes than glass, and metals that is leveraging the polymers market. The increasing demand for specialty polymers are fuelling the growth of the polymers market.

Progression in 3D printing is improving the growth aspects of polymers and plastic manufacturing. The changing preference of consumers from metal 3D printing to plastic material 3D printing is leading to substantial growth in the polymers market.

Fluctuation in international oil prices tend to force companies to search for an alternative stable source of the raw material for packaging, which further provides lucrative opportunities for the growth of Polymer industry.

Evolution of the natural and environment-friendly polymers in the packaging sector for food packaging, cosmetics packaging and pharmaceutical packaging is driving the growth.

Comparatively lower awareness about the biodegradable polymer in emerging nations like India, Thailand, South Africa and Qatar are hampering the market growth.

0 notes

Text

PP, EVA, EVOH, PS and PE Multi-Layer Sheet Co-Extrusion Line

PP, EVA, EVOH, PS and PE multi-layer sheet co-extrusion line To meet market's high request on products, Shanghai JWELL develops advanced technology of five layer symmetrical distribution and seven layer asymmetrical distribution, which makes the sheets having better barrier performance. PP/EVA/EVOH/EVA/PP five or seven multi-layer co-extrusion high barrier fresh keeping sheet has the excellent anti-oxygen and anti-humidity features. It is one of the best barrier packing materials.Mainly used for Jelly packing,meat packing,snack food packing,medicine and cosmetic packing and so on. Main technical specification Model JW100/45/45-1000 JW120/45/30/65-1200 JW150/45/45-1500 Suitable material PP, PE, PET, PS Products Width 800mm 1000mm 1200mm Products thickness 0.5-2mm 0.5-2mm 0.5-2mm Designed speed 15m/min 20m/min 30m/min Capacity 300kg/h 400kg/h 600kg/h Note: The specifications are subject to change without prior notice. T-die(mold) Our T-die (mold)are suitable for the following products: • PET, PP, PA, PVC, PS, PC, PE printing, packaging sheet • PC, PMMA, PS, HIPS, PP, PE, PVDF plate • ABS, PS, HIPS, PMMA sanitary ware board, refrigerator board • PVC hard board, soft board, foam board, aluminum composite board • PP + stone powder, PP + wood powder, PP + hemp fiber sheet • TPO, PE, PVC, EVA waterproofing membrane • CPP, CPE cast film • PP, PP, PVC, PVDF, EVA cast film • PP, PE, EVA paper composite, aluminum composite coating products • PP, LLDPE, PA, EVOH, TPX, EVA Laminating products • PC optical grade sheet, sheet • PET optical grade sheet, sheet • PMMA, GPPS light guide sheet, plate • PMMA, GPPS diffusion sheet • BOPET Biaxially Stretch Film Products • BOPP Biaxially oriented film products • BOPA Biaxially oriented film products • PETG Shrinking film products • PE wet lithium battery two-way stretch diaphragm products • PP dry lithium battery separator products Read the full article

#Barrierpackagingsheetproductionline#Foodpackagingsheetproductionline#Multi-layerco-extrusionpackagingsheetequipment#PAsheetextrusionline#PPSheetExtrusionMachine#Seven-layerbarriersheetequipment

0 notes

Text

Rotomolding LLDPE Powder, Plastic Raw Material

We have a reputation of being profoundly reliable LLDPE Powder, Foam Powder, Rotomolding LLDPE Powder, Plastic Raw Material, LLDPE Raw Materials that is equipped for understanding the requirements.

For More Details, Visit:-https://www.lldpefoam.com/ Contact us:-+91 9429470409

0 notes

Text

Best Kneeboards

When you need to train your children about Kneeboarding, a proper board will let you do it in style. A premium board like O’Brien black magic is the perfect choice for any beginner as well as medium riders. Its low profile design allows it to give learners stable riding. Also, the dual tip shape enhances stability hence great for deep-water training.Apart from a low profile, the board is extra high performing. Depending on the user experience, it has retractable fins. It is these fins that enable it to improve stability hence allowing high-speed training. Also, the flat knee pad is impressive since it enables comfortable riding.Regardless of weight, the board is highly durable and robust. It features rotomolded plastic base that enjoys great sturdiness. To ensure the rider has full control, knee pads offer a snug fit for comfortable and perfect board maneuvering. Together with padded 3-inch strap, they ensure your knees are perfectly locked.Kneeboarding is one of the fun tow sports. Therefore, a kneeboard is the main requirement that one needs to have. In fact, the sports are very popular that, statistics indicate that over 100,000 kneeboards are sold per year. If you love the game, it’s time to join millions who also enjoy the sport. However, don’t be a victim of poor quality boards only to complement your performance.

These days, with stores shifting their muscles online, it gives you a chance to get the best products. Same happens to kneeboards; you can compare hundreds of brands while in your home. Getting best board always depend on your ability to examine features and quality. However, for beginners, it can be tricky.

Well, as you plan to buy a kneeboard, keep in mind there are available in different types. There are recreational and competitive. Also, styles differ depending on your Kneeboarding experience. Materials are also vital when it comes to the quality of boards. While taking all the aspects, we have reviewed top 9 best kneeboards in 2019. This gives everyone to have a fair chance of getting the best.

1. Rave New Defy Kneeboard

The Rave new defy is one of the premium quality kneeboards that are perfect for everyone. Especially, for newbies and intermediate riders, it offers all the qualities to sharpen their skills. Unlike the heavy boards, this one is classic and lightweight to enable easy maneuvering.

The construction is durable to withstand heavy utilization without breaking. The shell features LLDPE and PU foam inside. This combination creates a premium and lightweight board. Apart from the premium construction, it’s sleek and inspiring. With a glossy surface and matte bottom, it keeps riders inspired.

For comfort, the kneepad features a flexible sponge that ensures no hard spots. Even when water is rough, there is no hard landing as it excellently cushions your knee. With fitted Velcro straps, the keep your knees in position and allows precise board control.

2. O’Brien Black Magic Kneeboard with Hook

When you need to train your children about Kneeboarding, a proper board will let you do it in style. A premium board like O’Brien black magic is the perfect choice for any beginner as well as medium riders. Its low profile design allows it to give learners stable riding. Also, the dual tip shape enhances stability hence great for deep-water training.

Apart from a low profile, the board is extra high performing. Depending on the user experience, it has retractable fins. It is these fins that enable it to improve stability hence allowing high-speed training. Also, the flat knee pad is impressive since it enables comfortable riding.

Regardless of weight, the board is highly durable and robust. It features rotomolded plastic base that enjoys great sturdiness. To ensure the rider has full control, knee pads offer a snug fit for comfortable and perfect board maneuvering. Together with padded 3-inch strap, they ensure your knees are perfectly locked.

3. Leader Accessories Kneeboard with Hook

Everyone deserves to have the best kneeboards. However, some are only ideal for use by experts. To cater for any level rider, Leader Accessories created this kneeboard that helps everyone achieve their Kneeboarding dreams. Unlike the cheap quality boards, this one is sturdy and extremely durable. Besides boasting remarkable crafting, the board offers outstanding comfort. Featuring thick ¾ -inch foam padding, it cushion knees from impacts. Additionally, the thick 3-inch straps provide comfort and knee stabilization. Thereby, even when water is rough, the board doesn’t move even a millimeter. The economically designed knee pads keeps the rider enjoying maximum control.

When you think about safety, the kneeboard provides excellent measures. The edges are beveled which allows it to cut smoothly with less resistance. Moreover, with great cut, it achieves low profile riding hence delivering great stability. Having an integrated hook, this kneeboard is excellent beginners’ choice as well as veterans.

5. Driftsun Crush Kneeboard – 2018

If you want to get a kneeboard that is usable by the whole family, Driftsun Crush is the answer. Whether it’s for adult or kids use, the board is highly versatile. Designed to allow you to teach your kids, safety and performance are exceptionally enhanced. To keep it stable, it comes enjoying twin tip design that let it cut through water perfectly.

Every user enjoys riding this board. It fits all people whether kids or adults while cushioning their knees. In fact, the knee pads are extra deep and have generous EVA flex foam. Besides, the foam allows soft landing even when Kneeboarding is rough due to big water waves.

Regardless of the tricks, you want to perform; the board is excellent. Due to its sturdy and hard shell, it is hard to break or get damaged easily. Amazingly, the Rotomolded shell and EPS core give the exceptional kneeboard strength. To keep your knees correctly positioned, the board features reinforced and padded straps.

1 note

·

View note

Text

Best Manufacturer of LLDPE Plastic Raw Material for Water Tank Manufacturing

Plastic raw materials are something that you use in your everyday life. Linear low-density LLFPE polyethylene is produced by copolymerizing ethylene with an alpha-olefin like butene, hexene, or octene co-monomers

LLDPE is used for pond liners or blended into other films to give them more flexibility and extra strength. If You are manufacturer of Watertanks we are supplier of raw materials to provide recommendations, but generally the best options are bases made of concrete or boxed compacted crusher dust. LDPE is widely used for manufacturing various containers, dispensing bottles, wash bottles, tubing, plastic parts for computer components, and various molded laboratory equipment.

Low-Density Polyethylene (LDPE) is a diverse plastic material that is commonly applied in various uses, such as plastic packaging film, disposable plastic products, pipes, and medical/healthcare. We provide Water Tank Raw material for making best Watertank.

PRODUCT

LLDPE FOAM MATERIAL

STONE EFFECT MARBLE COLOUR

LLDPE AGGLOMERATES

LLDPE POWDER

ROTOMOLDING POWDER

LLDPE PLASTIC RAW MATERIAL

For more Details Click here : https://www.lldpefoam.com/

0 notes