#Lab equipment Baths And Circulators

Explore tagged Tumblr posts

Text

Constant Temperature Water Bath

Labtron Constant Temperature Water Bath features precise temperature control ranging from ambient +5°C to 100°C, with a stability of ±0.1°C. It includes a digital display, over-temperature protection, stainless steel inner chamber, and capacities from 2 to 28 liters. Suitable for laboratory use.

1 note

·

View note

Text

0 notes

Text

Low-Temperature Water Circulating Bath

A Low-Temperature Water Circulating Bath is a specialized piece of laboratory equipment designed to maintain a constant and precise temperature of water for various scientific and industrial applications. It consists of a well-insulated chamber that holds water and a built-in heating and cooling system to regulate the water temperature within a specific range.

0 notes

Text

How to Choose the Best Low Temperature Constant Temperature Reaction Bath for Your Laboratory Needs

When conducting experiments that require precise temperature control, especially at low temperatures, a Low Temperature Constant Temperature Reaction Bath is an essential piece of equipment. Whether you’re working with chemical reactions, material testing, or pharmaceutical research, maintaining stable and consistent temperatures is critical. In this post, we will discuss the features you should look for when selecting the right bath for your laboratory.

What is a Low Temperature Constant Temperature Reaction Bath?

A Low Temperature Constant Temperature Reaction Bath is a device designed to maintain a stable temperature environment during chemical processes, experiments, and industrial applications. These baths are often used in fields like chemical synthesis, pharmaceutical research, and material testing, where temperature stability is essential for ensuring accurate results.

Key Features to Look for When Choosing a Low Temperature Constant Temperature Reaction Bath

1. Temperature Range and Stability

The first thing to consider is the temperature range of the bath. Depending on the nature of your experiment, you may need a bath that can operate at extremely low temperatures. The AKFY-100L Low Temperature Constant Temperature Reaction Bath offers reliable and stable temperature control for various laboratory needs.

2. Circulation System

A good circulation system is crucial to maintaining uniform temperature throughout the bath. Devices with both internal and external circulation systems allow for better temperature distribution and flexibility when connecting other equipment like rotary evaporators.

3. Cooling Efficiency

For experiments that require quick changes in temperature, fast cooling is important. High cooling efficiency ensures that the bath can reach the desired temperature quickly and maintain stability during the process.

4. Durability and Material Quality

Durability is essential when selecting laboratory equipment. A Low Temperature Constant Temperature Reaction Bath should be made from corrosion-resistant materials, such as stainless steel, to ensure long-lasting performance. Models like the AKFY-100L are known for their robust construction and resistance to mechanical and chemical damage.

5. Safety Features

Since low temperature baths are often used in sensitive experiments, safety features are essential. Look for models that have built-in protections like automatic shut-off in case of overheating, or safeguards against overpressure to ensure safety during operations.

Common Applications for Low Temperature Constant Temperature Reaction Baths

1. Pharmaceutical Research

Low Temperature Constant Temperature Reaction Baths are vital in pharmaceutical labs for stability testing of drugs and the synthesis of new pharmaceutical compounds. Maintaining a precise temperature is essential for ensuring the consistency and quality of the substances being developed.

2. Chemical Synthesis

When performing chemical reactions like crystallization or polymerization, it’s important to maintain a constant temperature. These baths help to achieve efficient reactions without fluctuations that could impact the outcome.

3. Material Testing

In material science, testing materials under extreme conditions is often necessary. These baths ensure that the test environment remains stable, allowing researchers to gather accurate data on material performance under controlled temperature conditions.

4. Compatibility with Rotary Evaporators

Many laboratory setups require the use of both low temperature baths and rotary evaporators. Ensuring compatibility between the two allows for efficient solvent removal and distillation at low temperatures, which is particularly useful in chemical and pharmaceutical labs.

Why Choose EquilRxnLab for Your Low Temperature Constant Temperature Reaction Bath?

If you’re in the market for a high-quality Low Temperature Constant Temperature Reaction Bath, EquilRxnLab offers top-of-the-line equipment such as the AKFY-100L model. Visit our product page for more information and to explore our catalog of laboratory solutions.

Don’t forget to check out our YouTube, Instagram, and Facebook for the latest updates and videos. For inquiries, feel free to contact us.

#LowTemperatureBath#ConstantTemperatureReactionBath#LaboratoryEquipment#TemperatureControl#ChemicalSynthesis#PharmaceuticalResearch#MaterialTesting#RotaryEvaporator

0 notes

Text

Dive into the Depths of Circulating Water Baths

If you've ever found yourself second-guessing the accuracy of your lab's temperature control, you're not alone. It's a common hurdle that can throw a wrench in the works, affecting everything from sample integrity to experiment outcomes.

Here's the good news: there's a straightforward way to navigate these waters, and it's through the dependable use of circulating water baths. In this post, we'll dive deep into how these devices stand as pillars of precision in temperature regulation—covering their wide-ranging applications, answering your burning questions, and offering insights into making the right choice for your lab's needs.

Unpacking the Applications

Circulating water baths aren't limited to one specific task in the lab—they're the jack-of-all-trades in temperature regulation. Here’s how they shine across different fields:

Chemical reactions: Whether it's getting compounds to react via synthesis or helping polymers form through polymerization, bath circulators ensure even heating—crucial for success.

Metallurgical processes: In the world of metals, these baths assist in annealing, and heating metals to relieve internal stresses, making them easier to work with.

Culture incubation: For those tiny cultures and microorganisms that need just the right temperature to thrive, these baths are a godsend.

Enzyme and DNA work: Whether it's facilitating enzyme reactions or making sure DNA amplification goes off without a hitch, consistent temperatures are non-negotiable.

Product quality assurance: Testing how products withstand temperature changes? Circulating baths help ensure that every test is as accurate as the last.

Viscosity testing: For liquids whose flow properties are temperature-dependent, these baths provide the stability needed for precise measurements.

Thermal property analysis: Understanding how materials react to heat is easier when you can precisely control the temperature, making these baths invaluable for thermal conductivity studies and supporting DSC (Differential Scanning Calorimetry) analyses.

Diagnostic assays: Maintaining the right temperature can mean the difference between a clear diagnosis and ambiguity.

Protein and enzyme studies: For research that delves into the nitty-gritty of proteins and enzymes, a stable temperature environment is key.

Petroleum and cosmetics: Testing how these substances flow can tell you a lot about their quality—these baths make such tests possible.

Chocolate tempering: There's an art to getting chocolate just right, and a circulating water bath ensures it's always at the perfect temperature for that smooth, glossy finish.

FAQs: Everything You Wanted to Know

Let's tackle some common queries you might have about bath circulators:

1. What’s Special About Them?

They offer precision that’s hard to beat, essential for the myriad of applications they’re used in—from research labs to production floors.

2. How Do They Push Scientific Research Forward?

Consistent and repeatable results are the bedrock of scientific progress. Circulating water baths provide just that, enabling breakthroughs and advancements.

3. User-Friendly for Lab Newbies?

Yes, they’re designed with all users in mind. Simple controls and built-in safety features mean even newcomers can use them with confidence.

4. Sustainability Considerations?

Look for energy-efficient models and keep up with maintenance. This not only supports sustainability goals but also ensures your equipment lasts longer.

5. Keeping Them Running Smooth?

A bit of TLC goes a long way—regular cleaning and calibration keep them in tip-top shape, ensuring they’re ready for whatever your lab throws at them.

Circulating water baths may not always be in the limelight, but their role across scientific and industrial processes cannot be overstated. They're about maintaining the balance—ensuring that temperature conditions are just right, whether it’s for a delicate biological sample or a robust material testing procedure.

If you're aiming to make these improvements without stretching your budget, HiTechTrader.com is where you might find reliable laboratory equipment at great prices . Whether upgrading your lab or setting the foundation for new experiments, the right equipment is key to unlocking potential—bath circulators included.

For more information about Gas Chromatography Machine and Analytical Chemistry Equipment please visit:- Hi Tech Trader

1 note

·

View note

Text

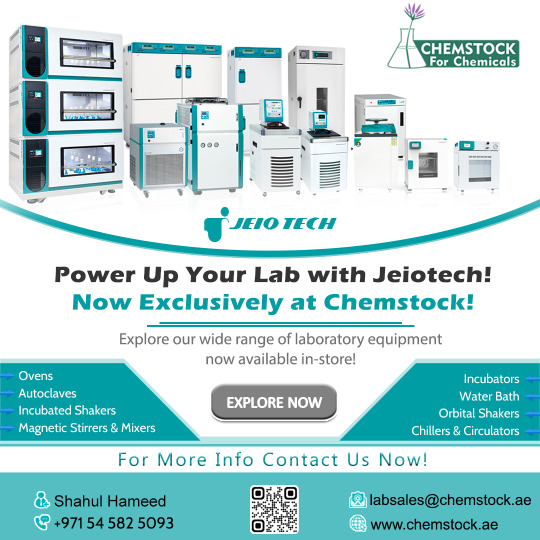

Jeiotech Lab Equipments - Chemstock UAE

🔬 Level Up Your Lab with Jeiotech Equipment: Now Available at Chemstock!

Attention researchers and lab professionals in the UAE! 🚀 Chemstock is thrilled to announce our exclusive distributorship of Jeiotech laboratory equipment.

💡 Jeiotech offers a comprehensive range of high-quality instruments, including:

Ovens

Incubated Shakers

Magnetic Stirrers & Mixers

Chillers & Circulators

Incubators

Water Baths

Orbital Shakers

Autoclaves

By partnering with Chemstock, you gain access to:

The latest Jeiotech lab equipment: Stay at the forefront of scientific advancements with cutting-edge technology.

Unparalleled selection: Find the perfect instrument for your specific research needs.

Unwavering reliability: Trust Jeiotech's reputation for quality and performance.

Exceptional customer support: Our team is here to assist you throughout the entire process.

🔍 Elevate your laboratory capabilities today! Contact Chemstock to explore the extensive range of Jeiotech equipment and find the ideal instruments to propel your research forward.

👨💼 Contact Person: Shahul hameed

📧 Email: [email protected]

🌐 Website: https://chemstock.ae/

📞 Mobile: +971 54 582 5093

📲Whatsapp: https://wa.link/mtv38c

#Jeiotech #LabEquipment #ScientificInstruments #Chemstock #ExclusiveDistributor #UAELabs #LabRevolution #ScientificBreakthroughs #LabEssentials #QualityScience #FutureProofLab #UAEResearchers #LabScientists #BiotechUAE #LifeScienceUAE #ChemistsUAE #DubaiScience #JeiotechLabs #LaboratoryAutomation #ScienceCommunity #ScientificNetwork #dubai #uae #abudhabi

Discover more at Chemstock today!

#chemical#chemicaldistribution#chemicals#chemstock#laboratory#organic chemicals#research chemicals#uae#equipment#lab#sciencenature

0 notes

Text

Formulation Solutions With IKA Advanced Lab Equipment

IKA laboratory technology offers a wide range of innovative equipment for numerous applications in research and development. Market leaders trust in our proven technology for their mixing, heating, distilling and crushing applications. IKA has gained a leading position in the world market with its innovative magnetic stirrers, mixers, overhead stirrers, shakers, homogenizers, mills, rotary evaporators, calorimeters, laboratory reactors and specially developed software for laboratory and analysis applications, as well as temperature control products such as circulators, baths and chillers.

In Order To Find Out More Details On IKA Advanced Laboratory Equipment Please Be Touch With Us Today Onwards..!

#T 25 easy clean digital ULTRA-TURRAX®#C-MAG HS 7 Package#ROTAVISC lo-vi HELI Complete Package#LR 1000 Basic Package#EasySyn 1000 Advanced Reactor System

0 notes

Text

30L high and low temperature thermostatic water bath HW-30

30L high and low temperature thermostatic water bath HW-30 1.Applications Suitable for factory, company, construction unit, research institute, colleges and university,etc. Use famous air conditioner host, good cooling property, low noise. Large volume, high temperature control accuracy, very suitable for highway engineering construction lab. Equip with external circulating water pump, can…

View On WordPress

0 notes

Link

Tex Technology is Water Bath Circulator Manufacturer and suppliers in India. Our product range Furnace, Laminar Air Flow, Peristaltic Pump, Vacuum Oven, Water Bath and many more Analytical Equipments. We are Manufacturer and suppliers of Engineering Lab Equipment. For more details about Water Analysis Kit Manufacturer and suppliers in India visit our website now.

#Water Bath Circulator Manufacturer in India#Water Bath Circulator Manufacturer#Engineering Lab Equipment Manufacturers#Analytical Equipments Manufacturers in India

0 notes

Text

8 Hole Thermostatic Bath

8 Hole Thermostatic Bath Volume=19-8-l; Rows=2; Holes=8; Internal dimension (W x L x H)=600-times-300-times-110-mm; Heating mode=bottom-heating; Shop online at Labtron.cc.

0 notes

Link

Heating circulating bath LEMC-A10 is a precise circulating water bath with an advanced temperature controller at a range of RT (+5 ? ~ 70 ?) and a chamber volume of 22 L. Equipped with a digital display for visual monitoring of the parameters and timing function for optimization of operating schedules. Integrated with electromagnetic pump for efficient fluid mixing. Features audible and visual alarm for over and under temperature, protecting samples at set temperature.

0 notes

Link

Unique Techno Lab LLP is having its H.O. as well as their Works at Ahmedabad, which is known as the Central Hub for Plastic Machineries & Ancillaries for all India.

Product we Manufacture 1 Universal Tensile Testing Machine 2 Melt Flow/Auto Melt Flow Indexer 3 Digital Computerized Hydro Pressure Testing Machine 4 Carbon Black Content Test Apparatus 5 Carbon Black Dispersion Tester 6 Hot Deformation Tester 7 Motorized Notch Cutter 8 Pipe Notch Cutter 9 Impact Tester For Pipes 10 Opacity Tester 11 Density Test Apparatus 12 Muffle Furnace 13 Humidity Chamber 14 Freezer(Zero Degree Chamber) 15 Emitting Flow Rate Checking Machine 16 Dumbbell Press 17 Hot Water Bath 18 Cool Water Bath 19 Hot / Cold Water Bath 20 Reversion Oil Bath 21 Air Circulating Oven / Hot Air oven 22 Full Width Projects 23 End Fittings 24 Tear Strength Tester 25 Laboratry Hot Plate 26 Izode / Charpy Impact Test Apparatus 27 Sheet Mouldig Press 28 Travelling Microscope 29 OIT Tester

*INDUSTRIES SERVED BY US*

- PIPE INDUSTRY – HDPE, MDPE, LLDPE, U-PVC, C-PVC, R-PVC, O-PVC, CASING, SWR, LATERAL, IN-LINE, CONDUITS AS PER INDIAN AS WELL AS INTERNATIONAL STANDARDS. - ROTO MOULDING – WATER TANKS - FILMS - RUBBER - PLYWOOD - FIRE RETARDANT PLYWOOD - CEMENT - CABLE - WOVEN SACKS - BLOW MOULDING - SANITARY PADS

For more information visit our web site www.uniquetechnolab.com or call 9316274635 also mail us on [email protected]

1 note

·

View note

Text

Cidaltek ID50

Aldehyde Free Triamine base Instrument Disinfectant

Description:

Effective and efficient dental Instrument disinfection is essential for the safety of patients and to ensure that productivity does not suffer. Infection control programs all include the cleaning and disinfection of reusable dental instruments and devices. CidalTek-ID50 is an efficient disinfection & cleaner solution which is made for disinfection of dental instruments & tools used in dental medical colleges and laboratories and dental hospitals. It is high-performance concentrated solution for the cleaning and disinfection of heat-resistant and heat-sensitive semi-critical instruments. The formulation inhibits instrument corrosion and protects them from discoloration even with prolonged immersion.

For RO Membrane Disinfection

Prepare 2% solution of CidalTek -ID50 as per the requirement.

Circulate this solution in the RO membranes for 30-45 minutes.

After 30-45 minutes drain the solution.

Flush RO membranes thoroughly with water until water becomes free from residual disinfectant. (2-4 times flushing will remove the residual disinfectant)

CidalTek-ID50 does not cause any harm or oxidation to polyamide layer of RO membranes.

Note:

Before using disinfectant read the product label & instruction carefully

Use appropriate PPE before handling disinfectant

Use freshly Prepared disinfectant

Salient Features:

Aldehyde- free, disinfects tools rapidly

Does not contain phenols, aldehydes, chlorine or EDTA

Triamine based technology

Eco-friendly

Highly effective

Provides excellent anti-microbial efficacy

It is recommended for all types of surgical and dental instruments

Excellent compatibility with RO membrane

Short soaking time for pre-cleaning only 15 mins

Lubricant for instruments

2 in 1 product: cleans & disinfects

Use in immersion bath or ultrasonic bath

Effectively removes organic residues

Good surface-active properties & cleaner

High efficacy even in the presence of heavy organic soiling, such as protein or blood

Best choice for dental critical and semi critical device disinfection.

Broad-spectrum microbial efficacy

Active against tubercle bacilli and specific viruses (e.g., Hepatitis-B)

Excellent virucidal activity

Sporicidal in action

Excellent Material compatible, even with the most sensitive materials

Best option for dental Hospitals, College, labs & Clinics.

Direction Of Use:

For Dental device, Instruments & Tools Precleaning & Disinfection

For Pre-clean all heat sensitive semi-critical medical device such as surgical instruments, extraction forceps, bone chisels, periodontal scalers, scalpel blades, surgical dental burs, dental mouth mirror, amalgam condenser, air/water syringes reusable dental impression trays, dental handpieces, endodontic files by scrubbing or brushing with disinfectant in dental settings and submerging into CidalTek -ID50 2% solution for 15 min

Wear the PPE & gloves

Remove heavy soil/organic deposits from surface

Rinse thoroughly with tap water (hardness less than 400 ppm)

For effective disinfection, submerse clean instrument/equipment in CidalTek -ID50 2% solution for 60 min according to the requirement.

Rinse with sterile distilled water with 2-3 times and allow to dry before use.

Prepare a fresh solution daily or more often if the solution become visibly dirty or diluted then discard it.

0 notes

Text

INTBUYING Refrigerated Circulating Water Liquid Bath Cooling Circulator Pump Chiller for Lab Refrigeration Equipment 6L -5℃-100℃ with 110V Converter

INTBUYING Refrigerated Circulating Water Liquid Bath Cooling Circulator Pump Chiller for Lab Refrigeration Equipment 6L -5℃-100℃ with 110V Converter

Price: (as of – Details) The machine has intelligent instrument control, which easy to operate and of high temperature stability. It is also has alarm function when the temperature reach the upper and lower limitationLarge-screen LCD display, software automatically control the cooling system to open, convenient and quickEfficient air-cooled fully enclosed compressor refrigeration, with delay,…

View On WordPress

0 notes

Text

What Is Quartz Made Of — And What Are The Pros and Cons of a Quartz Countertop?

If you’re in the market for a new kitchen countertop, you likely have one burning question: What is quartz made of? And then also these: Is quartz expensive? Is it durable? What are the pros and cons. Etc! So many questions! See, quartz has gotten incredibly popular over the last 10 years or so. Yet, people don’t really know much about it. Let’s take a look!

What is Quartz Made Of?

Artificial quartz stone countertops are man-made engineered stone countertops formed by combining around 90 percent ground quartz (a natural hard mineral) with eight to 10 percent resins, polymers, and pigments. This forms a very hard granite-like surface. The appearance depends on how the quartz is ground: coarsely ground quartz produces a flecked appearance, while finely ground quartz produces a smooth look.

What are the Major Brands of Quartz Countertops?

The Italian company Breton owns the patent to manufacture solid surfaces from quartz and resins. All other companies use that patent for their own brand of quartz countertops, including Silestone, Corian, Cambria, CaesarStone, Avanza, and Technistone.

What’s the Environmental Impact of Quartz?

Light to moderate! Quartz is the second most abundant material in the earth’s crust (which is good), but the acrylic resins used in quartz countertops are petroleum by-products, and they often contain alumina trihydrate fillers made from bauxite ore, which is mined primarily under toxic conditions in developing countries. However, the countertops are still extremely durable and non-porous. Additionally, a few major brands including Formica, Wilsonart and Silestone have been certified by GreenGuard as low emitting. Other brands, like Cambria Quartz, are mined and made entirely in the USA.

Calacatta and Carrara quartz are among the most preferable options for countertops today. With their clean white shade and beautiful veining, they blend well with any kitchen design and amplify the look of the interior. Perfect addition for both commercial and residential spaces, these quartz can be installed as kitchen countertops, waterfall islands, or even as bath vanity tops and vanity sinks.

Both Calacatta quartz and Carrara quartz are inspired by the look of natural marble and hold a replicative resemblance. Some mutual characteristics of these quartz countertops are white, light grey, or beige background, with dark shade veining, fine or bold. They feature such a classic and always highly desirable look. However, there are some differences between the two quartz. Let’s see what those are.

Quartz calacatta: It consists of bolder, more dramatic, wider, and darker grey veining over a serene white base. It’s perfect for interior designers and homeowners who are looking for a powerful focal point in the kitchen. Due to its seamless design pattern, this quartz countertop is apt for installation as a waterfall island.

Carrara quartz: While Carrara Quartz features soft, subtle, very fine, and delicate veins and usually seems to be in blue-grey color. The veining is so fine that it almost disappears and merges in the background. When you place both these quartz sides by side, you will notice that Carrara quartz has a much granier pattern than that of Calacatta Quartz.

Imperial Vanities has a classic collection of prefabricated Carrara and Calacatta Quartz countertops that could embellish the space and fit well in any interior design project.

Among many cabinet countertop materials, quartz stone has become the preferred surface material. Quartz stone is an artificial stone surface material die-casted by a quartz stone manufacturer through equipment, and later made into a quartz stone countertop by a stone processor.

Nowadays, the quartz stone market is chaotic, the quality is uneven, and the price of quartz stone varies from high to low. How to choose a quality quartz stone countertop in this situation? We can start from the following points.

Before buying, we should do a good job of positioning, that is, we should clarify our real needs, and don't buy with the trend. Because the price of quartz stone is much higher than other surface materials, if it is more limited, it is better to give up buying quartz stone and choose other materials to prevent buying low-quality plates. Quartz stone is artificially pressed by 93% quartz sand and resin. Inferior plates may use other materials as fillers or use other binders. This type of plate has certain harm to the human body and should be purchased with care.

First of all, we should choose branded quartz stone, which has a certain guarantee for quality.

Furthermore, choose the color of the quartz stone according to the color of the cabinet panel. Most of the countertops are made of monochrome quartz. Simple patterns are better. If it is too fancy, it will easily dazzle the viewer and lose the distinction between primary and secondary.

The last is to check the quality of the board, such as hardness, odor, penetration and acid resistance and so on.

The Basic Process

Although the process varies based on the source, the basic formula involves irradiating the stones at 60 megarads (mrd) with cobalt 60, X-rays, or electrons. The material will return from the lab an opaque black or brown. Then, heat the stones in a household toaster oven to 650° F. Household ovens list their maximum temperature as 550° F. However, if you leave the oven temperature at the maximum setting for long periods, the temperature will rise above the rated settings. If the economics justify it, a glass door laboratory furnace makes a better tool. Since each individual piece will change color at a different time, seeing the heating action is absolutely necessary.

You can modify the basic process to achieve different effects, depending on the quartz source. In some instances, you might only achieve a quartz color by first destroying the existing color center. This requires heating the crystal until it’s clear or white at temperatures up to 550° F. If you exceed this temperature, you risk creating an opaque, opalized stone. In other words, the quartz turns to a milky consistency resembling a common opal.

If heating to 550° F doesn’t achieve the quartz color you want, try increasing the radiation dosage or subject the work piece to a different type of irradiation. For example, a quartz that goes to a straw yellow color on cobalt 60 might turn canary when exposed to electrons. Again, the color you might achieve depends on the material’s origin.

Below, you’ll find some results and individual treatment processes.

Smoky Quartz

All quartz can be irradiated to create the morion variety of smoky quartz. Additionally, all quartz will turn a blackish or brownish color on exposure to 0.5 to 1.5 mrd of cobalt 60, gamma, X-ray, or electron radiation. However, this won’t yield uniform color.

If that’s your goal, first irradiate then separate the lighter ones for re-irradiation at a higher dosage. Next, separate those with the optimum color. Heat the stones that come back opaque black in a household toaster oven until you reach the desired shade.

Except for this post irradiation heating step, the lab process involves little heat or static electricity. Thus, you can treat included material. The maximum temperature the quartz will be exposed to during the irradiation process is 400° F.

Arkansas Quartz (USA)

I tested stones from various areas of this deposit. None took color. I just treated them all to smoky quartz.

Milky (Silk) Quartz

After testing stones from numerous locations in Brazil, the United States, and other nations, I found that, apparently, all hazy quartz with silk-like inclusions, no matter what intensity, will treat. This includes natural rose quartz. Common results ranged from various yellows, an occasional orange cast, to an occasional greenish cast.

In some cases, you can cook out the silk through pre-irradiation heating. In other cases, you can dissolve it during the irradiation process. You can even observe the lessening of the silk in the final heating step. However, some silk won’t dissolve during this heating process. Use caution when performing this step. The crystal may shatter during heating. This material seemed to reach its maximum color saturation at a dosage of 60 mrd. Again, different types of radiation produce different shades of color.

Controlling Your Milky Quartz Color Results During Heating

During the final heating process, you can control the color somewhat. After you’ve irradiated the stones, spread them evenly on your toaster oven rack or a perforated baking sheet. (You must allow air to circulate freely around the stones, so don’t place them on a regular cookie sheet). Set your toaster oven to maximum temperature, then wait patiently.

By continuously observing through the glass door, you’ll see the stones change color from an opaque black. Remember, each stone may change at a different time. Larger crystals require more heating time. Therefore, size grade and heat stones of one size together to operate more efficiently.

Keep in mind that most ovens reach hotter temperatures front to back. You might try putting larger crystals on the last row to better observe them. So, while they’re still heating, you can remove the faster turning smaller crystals in the front row.

Starting from a cold oven, expect to wait about two to eight hours for the crystals to turn. The transition can go from opaque black to slightly transparent brownish black, to greenish yellow, to canary yellow. This material changes slowly, so you have plenty of time to remove them at the desired color. Again, a glass door comes in handy. You can observe the quartz color change without constantly opening and closing the oven, which will delay the process.

Once you’re happy with a stone’s color, remove it with metal tongs and set it on a metal cooling tray. If you leave the stones in at maximum temperature for very long periods, they can fade to light yellow and eventually revert to white.

Reducing Breakage

This is quite a hands-on heating process. Keep the opening and closing of the oven door to a minimum. Thermal shock will occur if too much cool air enters the oven chamber. However, you can’t avoid this completely. Expect some breakage but take steps to minimize it.

Wait until a good number of stones have turned to a desired shade. Then, shut off your oven and let it cool to room temperature by cracking the door slightly. If you don’t vent the oven, the temperature will continue to rise and overheat your stones. Luckily, if you do overheat, all is not lost. Simply re-irradiate and start the process all over.

Caramel Quartz

If you treat quartz from various locations, you’ll likely encounter this type. I found three mines in the Arasuai area of the state of Minas Gerais, Brazil that produce caramel quartz. None of the stones showed any identifying inclusions. I don’t believe they occur well-formed. They were presented to me in broken crystals or in cobbed form. One location produced only crystals up to 30 grams. The other two produced crystals of 1 to 2 kilos.

I irradiated and heated these stones using the milky quartz process I’ve described above. However, they have a different color transition. They go from opaque black to slightly transparent brownish to reddish or orangish brown. With continued heating, some eventually went pure orange. These stones required longer heating times. Some crystals, however, stayed brownish orange even after two days of heating. I expect they might go pure orange at a higher temperature than I could achieve with a toaster oven.

One mine produced stones with a transition to pure orange. They went from black to a brownish orange and then turned a golden orange.

Neon Green Quartz

Two adjacent mines just outside of the village of Itacambira, Minas Gerais, Brazil produce quartz of widely varying colors. These stones range from golden and neon green (limon) to bicolors and tricolors of golden and black or brownish. You’ll also find green, black, or brownish. Both mines yield very clean to flawless crystals up to about 100 grams maximum. These elongated crystals have unusual 10-sided terminations.

You irradiate these as you would other quartz, but the similarity ends there. Their heating process is quite involved and difficult. The crystals return from the lab opaque black. Start heating them at a lower temperature of 350° F. This way, you’ll have the time to take out the maximum number of green ones, which are most valuable. The crystals go from black opaque to a slight transparency in the center only. Just the center will lighten and turn green. The two ends will remain opaque black or slightly transparent brown or black.

Creating Pure Green Stones

Unlike milky quartz, quartz pure color lasts from a matter of seconds to a maximum of a minute or two. Therefore, you must remove these stones quickly from the heat as they change. If you delay, the centers will turn a golden yellow color. At that point, you’ll have a tricolor stone with a green center and blackish ends. If you take too long, you’ll have a tricolor with a golden yellow center.

To create a strictly green product line, at the first removal step, saw or cob away the two ends. Keep them separate. Next, put all the sawed sections of crystals, from the end away from the termination, back in the oven. Now, these pieces can also turn green. Again, heat them to 350° F so the change from blackish will be more gradual. If you heat them at a higher temperature, like 550° F, you’ll have more difficulties removing the green ones before they change to golden.

After you’ve finished processing the ends away from the termination, process the terminated ends. These will all have slight inclusions right on their tips. Saw or knock them off. When heated, these go mainly golden. While you might have a small portion of green stones, it’s impossible to catch the green and golden together, because the green comes out at a lower temperature. Right at the termination, you won’t get any green first. It goes straight to golden. If you overheat at any step, simply re-irradiate and repeat the process.

Red Quartz

When irradiated, all milky or rose quartz will treat to various shades of yellow, from golden to canary. There is very little difference between rose quartz and clear quartz. However, submicroscopic inclusions of dumortierite create the color of rose quartz. This borosilicate mineral, usually blue or pink, contains titanium.

A deposit just outside the small city of Governador Valadares, Minas Gerais, Brazil, in an area called Ganga Rosa, produces rose quartz crystals. To the best of my knowledge, only Ganga Rosa yields rose quartz in terminated crystals. These crystals can occur anywhere from colorless, to a hint of pink, to a fine rose color. For irradiation coloring purposes, it doesn’t seem to matter if you begin with well-saturated or clear pieces. Simply dose this material to 60 mrd. The subsequent heat treatment can vary depending on the location of the material.

Ganga Rosa Quartz and Irradiation

So far, my testing shows that quartz achieves its full saturation at a dose of around 60 megarads. Higher dosage serves no purpose, except for the Ganga Rosa material. While other irradiated quartz stones return from the lab opaque black and need heating, Ganga Rosa turns strawberry red at 60 mrd, with medium to light intensity. No subsequent heating is necessary. The higher the radiation dosage, the darker the color.

My experiments were limited to gamma radiation, using cobalt 60 and X-rays in the form of residual irradiation. During the X-ray testing, I noted that the material continued to darken. I placed crystals just outside of the direct beam cylinder at a linear accelerator laboratory. Then, the material inside the cylinder received a dosage at 24 MEV of 5,000-10,000 mrd electrons.

While I couldn’t gauge exactly what dosage the exterior area containing the quartz received, I estimate it at several thousand mrd at an accelerated dosage rate, at least. As the laboratory explained, this residual irradiation is X-ray (gamma) only. Undoubtedly, with higher dosage, we could reach a color intensity as dark as ruby. Note that, most likely, you can’t overdose this material. You can heat back all irradiated materials in stages on low temperature treatments.

I observed another interesting effect with Ganga Rosa quartz with attached calcite (or more likely a calcite pseudomorph). With irradiation, this attached mineral goes black, as you would assume a quartz would do but not a calcite. This can create an interesting bicolor effect in some of the pieces.

0 notes

Text

2 Hole Thermostatic Bath

2 Hole Thermostatic Bath Volume = 6-3-l; Rows = 1; Holes = 2; Internal dimension (W x L x H) =305-x-160-x-130-mm; Heating mode=bottom-heating; Shop online at Labtron.cc.

0 notes