#Lap Joint Flanges

Text

Lap Joint Flanges Supplier & Manufacturers | Metalforgeindia

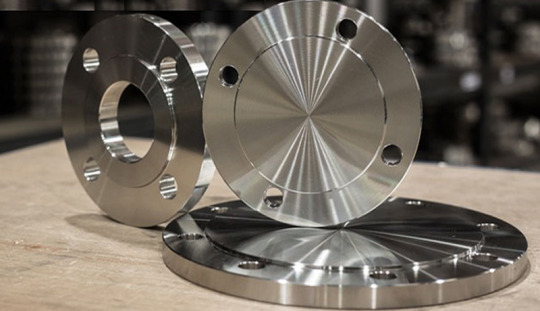

Metalforgeindia is top exporters and manufacturers of Lap Joint Flanges. Our company is a leading supplier and manufacturer of lap joint flanges, which are widely used in various industries for connecting pipes, valves, and other equipment. We offer a wide range of sizes, materials, and specifications to cater to the diverse needs of our customers. Our flanges are designed and manufactured to meet high-quality standards, ensuring reliable and durable performance in demanding applications. With our expertise and commitment to excellence, we are proud to be a trusted provider of lap joint flanges for businesses worldwide.

0 notes

Text

The Role of Lap Joint Flanges in Reducing Piping System Stress

In critical piping applications, managing system stress and strain is vitally important. Lap joint flanges are an ideal coupling solution that contributes significantly to this. Their unique design, durability, and flexibility make lap joint flanges perfect for reducing stress loads at pipe joints. To know more details visit https://mustafaashkar.com/the-role-of-lap-joint-flanges-in-reducing-piping-system-stress/

0 notes

Text

Lap Joint Flanges, Lap Joint Flanges Manufacturers, Lap Joint Flanges Suppliers, Lap Joint Flanges Exporters, Lap Joint Flanges Stockists.

Lap Joint Flanges in Mumbai, Lap Joint Flanges Manufacturers in Mumbai, Lap Joint Flanges Suppliers in Mumbai, Lap Joint Flanges Exporters in Mumbai, Lap Joint Flanges Stockists in Mumbai.

Lap Joint Flanges in India, Lap Joint Flanges Manufacturers in India, Lap Joint Flanges Suppliers in India, Lap Joint Flanges Exporters in India, Lap Joint Flanges Stockists in India.

These lap joint flanges are constantly utilized with either a stub end or taft which is butt welded to the pipe with the flanges loose behind it. This implies the stub end or taft dependably makes the face. The lap joint is favored in low weight applications since it is effectively assembled and adjusted. To lessen cost these stub end lap joint flanges can be supplied without a hub and/or in treated, coated carbon steel.SPECIFICATION

Standards:

ANSI B 16.5 Class 150 lb

ANSI B 16.5 Class 300 lb

ANSI B 16.5 Class 400 lb

ANSI B 16.5 Class 600 lb

ANSI B 16.5 Class 900 lb

ANSI B 16.5 Class 1500 lb

Carbon Steel:

ASTM A 105, ASTM A 181

Alloy Steel:

ASTM A 182, GR F1, F11, F22, F5, F9, F91

Nickel Alloys:

Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

Copper Alloys:

Copper, Brass & Gunmetal

Size:

1/8" NB TO 48"NB.

Class:

150#, 300#,400 #,600#,900#, 1500# & 2500 #.

ANSI:

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN:

DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S:

BS4504 , BS4504, BS1560, BS10

0 notes

Text

Steel Manufacturers In India: Elevate Your Projects With Platinex Piping Solutions LLP

Welcome to our blog dedicated to all things pipe elbows, flanges, and more! Whether you’re a manufacturer, stockist, vendor, or simply passionate about the world of piping, you’ve come to the right place. In this space, we aim to delve into the intricacies of pipe fittings, explore industry trends, and provide valuable insights into the art and science of mastering pipe systems.

Why Pipe Fittings Matter

Pipe fittings form the backbone of modern plumbing and industrial systems. They allow for the seamless connection of pipes, enabling the smooth flow of liquids, gases, and even solids in various applications. From residential plumbing to large-scale industrial projects, the right fittings ensure efficiency, safety, and durability.

Understanding pipe elbow

Buttweld fittings represent a crucial subset of pipe fittings known for their strength, reliability, and leak-proof design. By understanding the principles of buttwelding and the different types of buttweld fittings available, manufacturers and users can optimize their piping systems for maximum performance and longevity.

The Role of Manufacturers

steel manufacturers in india play a pivotal role in the pipe fitting ecosystem. They are tasked with designing, fabricating, and testing fittings to meet stringent quality standards and regulatory requirements. Through innovation and advanced manufacturing techniques, leading manufacturers continuously push the boundaries of what is possible in the world of pipe fittings.

Stockists and Vendors: Connecting Supply with Demand

Stockists and vendors serve as the bridge between manufacturers and end-users, ensuring a steady supply of pipe fittings to meet diverse needs. Their expertise in inventory management, logistics, and customer service is instrumental in keeping projects on track and customers satisfied.

Navigating Industry Challenges

Like any industry, the world of pipe fittings faces its fair share of challenges, from supply chain disruptions to regulatory changes and technological advancements. By staying informed, adaptable, and collaborative, stakeholders can overcome these challenges and drive positive change within the industry.

Exploring New Frontiers

As technology evolves and industries continue to innovate, the future of pipe fittings holds immense promise. From advanced materials and manufacturing techniques to smart sensors and IoT integration, the possibilities are endless. By embracing innovation and collaboration, the pipe fitting industry can continue to thrive in the digital age.

Join the Conversation

We invite manufacturers, stockists, vendors, engineers, and enthusiasts from around the world to join us on this journey of exploration and discovery. Together, let’s dive deep into the world of pipe fittings, share knowledge, and inspire innovation for generations to come.

Stay tuned for our upcoming articles, interviews, case studies, and more as we explore the fascinating world of pipe fittings from every angle.

Let’s connect the pipes and build a brighter future together! know more- https://platinexpiping.com/title-unveiling-excellence-elevate-your-projects-with-platinex-piping-solutions-llp/

#mild steel pipes#flanges#blind flanges#lap joint flange#weld neck flanges#steel manufacturing#buttweld fittings

0 notes

Text

Flanges Suppliers in AFRICA – Alkun Steel

Flanges are the unsung heroes of industrial piping systems, providing essential connections that keep our infrastructure running smoothly. The right flange ensures safe and efficient operation in oil refineries, chemical plants, or maritime vessels. In Africa, where industries are booming and demand for quality engineering solutions is at its peak, companies like Alkun Steel stand tall as providers of top-notch flange solutions. Alkun Steel is a trusted partner in Africa's industrial landscape with an array of flange types tailored to meet diverse needs. Let's delve into the world of flanges and explore the offerings of Alkun Steel, the go-to carbon steel and stainless steel flange supplier in Africa.

Carbon Steel Flange Supplier in AFRICA

Carbon steel flanges are essential for piping systems to connect pipes, valves, pumps, and other equipment. They are made from carbon steel, a steel alloy primarily composed of iron and carbon, with different elements added to enhance properties like strength, hardness, and durability. Carbon steel flanges are known for their strength, resistance to corrosion, and affordability, making them widely used in various industrial applications.

Several carbon steel flanges are designed for specific purposes and applications. Some of the most common types include:

1. Slip-on Flanges in AFRICA (SO): These flanges have a slightly larger bore diameter than the outside diameter of the pipe. They are slipped over the pipe and then welded at the inner and outer edges, providing a strong and secure connection.

2. Weld Neck Flanges in AFRICA (WN): Weld neck flanges feature a long, tapered hub that provides an ideal pipe connection. They are welded to the pipe and the adjoining pipe, offering excellent strength and stability, particularly in high-pressure and high-temperature applications.

3. Blind Flanges in AFRICA (BL): Blind flanges seal the end of a pipe or vessel. They are typically used in applications where future expansion might be needed or temporarily block off a pipeline.

4. Socket Weld Flanges in AFRICA (SW): Socket weld flanges are designed with smaller-diameter pipes. They are welded directly onto the pipe, creating a smooth bore and a tight seal.

5. Threaded Flanges in AFRICA: These flanges have internal threads that allow them to be screwed onto the pipe. They are commonly used in low-pressure applications and where welding is not feasible.

6. Lap Joint Flanges in AFRICA (LJ): Lap joint flanges are used with stub ends. They allow for easy alignment of bolt holes and are ideal for non-standard connections or systems requiring frequent dismantling.

7. Orifice Flanges in AFRICA: Orifice flanges are specifically designed for flow measurement or restriction applications. They feature a small orifice opening that can be used with an orifice plate to measure flow rates.

8. Ring-Type Joint (RTJ) Flanges in AFRICA: RTJ flanges use a ring joint gasket to create a tight seal in high-pressure and high-temperature applications. They are commonly used in the oil and gas industries.

These are just a few examples of the many carbon steel flanges available, each with unique features and advantages suited to different piping requirements.

Stainless Steel Flange Supplier in AFRICA

Stainless steel flanges are made from stainless steel, a corrosion-resistant alloy known for its durability, strength, and resistance to rust and corrosion. They are widely used in various industries, including chemical processing, oil and gas, food processing, pharmaceuticals, and water treatment, where corrosion resistance and hygiene are essential.

Here are the different types of stainless steel flanges:

1. Slip-on Stainless Steel Flange in AFRICA: These flanges have a bore slightly larger than the outer diameter of the pipe. They are slipped over the pipe and then welded on both sides for a secure connection.

2. Weld Neck Stainless Steel Flange in AFRICA: These flanges have a long tapered hub designed to provide an ideal pipe connection. They are welded inside and outside to ensure strength and stability, especially in high-pressure and high-temperature applications.

3. Blind Stainless Steel Flange in AFRICA: These flanges seal the end of a pipe or vessel. They are commonly used in applications where future expansion may be needed or to temporarily block off a pipeline.

4. Socket Weld Stainless Steel Flange in AFRICA: Designed for smaller diameter pipes, these flanges are welded for a tight seal. They feature a recessed area to insert the pipe, providing a smooth flow path.

5. Threaded Stainless Steel Flange in AFRICA: These flanges have threads machined onto their inner bore, allowing them to be screwed onto the pipe for easy installation and removal.

6. Lap Joint Stainless Steel Flange in AFRICA: These flanges allow for easy alignment of bolt holes. They are often used in non-standard connections or where the alignment of the bolt holes is critical.

7. JIS/Marine Stainless Steel Flange in AFRICA: Designed to Japanese Industrial Standards, these flanges are suitable for marine applications. They come in various pressure ratings, such as 5k, 10k, pn6, and 16k, catering to different requirements in aquatic environments.

Conclusion

Having reliable partners is paramount in the dynamic world of industry and infrastructure. Alkun Steel, with its commitment to quality, innovation, and customer satisfaction, emerges as a beacon in Africa's flange supply landscape. From Slip-on to Weld Neck, Blind to Socket Weld, Alkun Steel offers a comprehensive range of carbon steel and stainless steel flanges to cater to diverse applications across various industries. As Africa continues its industrialization and economic growth journey, companies like Alkun Steel play a vital role in providing the foundational components that keep the wheels of progress turning. With Alkun Steel, customers receive top-quality products and benefit from the expertise and support of a trusted ally in their journey towards success.

1 note

·

View note

Text

Nutech Overseas obvious Manufacturers of Copper Nickel Lap Joint Flanges maintained by Saudi Aramco. We are most important stockist of MSS SP-44 Lap Joint Flange.Nutech Overseas is a distFlangesuter of complete level of ANSI 150# Lap Joint Flanges, ANSI B16.5 Class 150 Lap Joint Flanges in various sizes.

#Lap Joint Flanges Manufacturers#Lap Joint Flanges Suppliers#Lap Joint Flanges Stockists#Lap Joint Flanges Exporters

0 notes

Photo

Looking for lap joint flange ? Induskart is one of the leading manufacturer and supplier of Mild Steel Flanges, Carbon Steel Flanges, Stainless Steel Flanges. We also provide one stop solution and vendor consolidation and act as project procurement partner. We deal in valves, pipes, fittings, flanges, gaskets and fasteners.

https://www.induskart.co.in/flange-manufacturer/lap-joint-flange/

0 notes

Text

Pipe Blind, Threaded, Socket Weld, Slip On, Weld Neck, Lap Joint Flange in Dubai

Mustafa Ashqar Trading LLC offers a comprehensive range of high-quality flanges including threaded, blind, socket weld, slip-on, weld neck, and lap joint flanges. For more details visit https://mustafaashkar.com/product-category/flanges/

1 note

·

View note

Text

Enhance Your Industrial Projects with Anand Steels Lap Joint Flanges.

At Anand Steels, we prioritize customer satisfaction by providing prompt assistance and expert advice. Our user-friendly arrangement makes it simple to find the right item for your needs, regardless of experience level in the field.Read about long-lasting stainless steel lap joint flanges that are designed to last. To ensure outstanding performance and compliance to industry standards, our goods undergo stringent quality checks.

0 notes

Text

Different Types of Flanges and Their Uses - Arcellor Controls

Different Types of Flanges and Their Uses

Flanges are an essential component in industrial piping systems. They connect pipes, valves, pumps, and other equipment to form a complete system. Flanges come in different sizes, shapes, and materials, and choosing the right flange for your system is critical. In this article, we will discuss the different types of flanges and their applications.

Weld Neck Flange

A weld neck flange is the most commonly used flange type. It has a long, tapered hub that gradually merges with the pipe's diameter. The flange's neck is welded to the pipe, providing a strong and permanent connection. Weld neck flanges are ideal for high-pressure and high-temperature applications.

Slip-On Flange

A slip-on flange is a ring that fits over the pipe and sits on the pipe's shoulder. The flange is then welded to the pipe, providing a strong and permanent connection. Slip-on flanges are ideal for low-pressure and low-temperature applications.

Socket Weld Flange

A socket weld flange has a socket that fits over the pipe's end, and the flange's backside is then welded to the pipe. This type of flange is ideal for small diameter pipes and high-pressure applications.

Lap Joint Flange

A lap joint flange is used in conjunction with a lap joint stub end. The flange slips over the stub end, and both are then bolted together. This type of flange is ideal for systems requiring frequent disassembly.

Threaded Flange

A threaded flange has threads on the inside bore that match the pipe's outside diameter. This type of flange is screwed onto the pipe, providing a strong and permanent connection. Threaded flanges are ideal for low-pressure and low-temperature applications.

Blind Flange

A blind flange is used to close the end of a piping system. It has no center bore and is bolted to the flange's mating surface. Blind flanges are ideal for high-pressure and high-temperature applications.

At Arcellor Controls, we provide a wide range of flange types to suit your piping system's needs. Our flanges are made from high-quality materials and are designed to provide a strong and permanent connection. Contact us today to learn more about our flange products and how we can help you build a robust piping system.

0 notes

Text

Things You Should Know About Hastelloy Flanges By Manilaxmi Industrial

Manilaxmi Industrial: When it comes to choosing materials for industrial applications, Hastelloy flanges stand out as a top option due to their remarkable properties and performance। Understanding Hastelloy flanges' characteristics and benefits can help you make informed choices about your projects, whether you're working in chemical processing, oil and gas production, or power generation। What you need to know about Hastelloy flanges is here।

What are Hastelloy Flanges?

Hastelloy flanges are components made from Hastelloy, a high-performance alloy primarily composed of nickel, chromium, and molybdenum. This superalloy is renowned for its excellent corrosion resistance, high-temperature strength, and durability in harsh environments. Flanges are used to connect pipes, valves, pumps, and other equipment, ensuring a secure and leak-proof system.

Key Properties of Hastelloy Flanges?

1. Corrosion Resistance: Hastelloy flanges are highly resistant to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for use in aggressive environments where other materials might fail.

2. Temperature Resistance: These flanges can withstand extreme temperatures, both high and low, without losing their structural integrity. This property is crucial for industries that operate under severe thermal conditions.

3. Mechanical Strength: Hastelloy flanges offer exceptional mechanical strength, ensuring durability and reliability even under high stress and pressure.

4. Versatility: Due to their unique properties, Hastelloy flanges are versatile and suitable for a wide range of applications across various industries

Types of Hastelloy Flanges?

Hastelloy flanges come in different types, each designed for specific applications and connection methods. Common types include:

• Weld Neck Flanges: These flanges are designed to be welded to the pipe, providing a strong and leak-proof connection ideal for high-pressure applications.

• Slip-On Flanges: Easier to install than weld neck flanges, these are slipped over the pipe and then welded. They are suitable for low-pressure environments.

• Blind Flanges: Used to close the end of a pipe or valve, blind flanges are essential for testing and maintenance purposes.

• Socket Weld Flanges: These flanges are similar to slip-on flanges but have a socket for welding, providing a smoother flow inside the pipe.

• Lap Joint Flanges: These are used with a stub end and are ideal for systems that require frequent disassembly.

Applications of Hastelloy Flanges?

Given their superior properties, Hastelloy flanges are used in a variety of demanding applications, such as:

• Chemical Processing: The exceptional corrosion resistance of Hastelloy makes it perfect for handling corrosive chemicals and acids.

• Oil and Gas: In the oil and gas industry, Hastelloy flanges are used in pipelines and equipment exposed to harsh environments and high pressures.

• Power Generation: These flanges are used in power plants, particularly in high-temperature and high-pressure sections.

• Marine Engineering: Hastelloy’s resistance to seawater corrosion makes it ideal for offshore and marine applications.

Advantages of Using Hastelloy Flanges?

1. Longevity: The durability and resistance to wear and tear extend the lifespan of the equipment, reducing the need for frequent replacements.

2. Safety: Enhanced mechanical strength and corrosion resistance ensure safer operations in critical applications.

3. Cost-Effective: Despite the higher initial cost, the longevity and reliability of Hastelloy flanges can lead to cost savings over time by minimizing downtime and maintenance.

#Hastelloy Flanges#Hastelloy Flange Manufacturer#Hastelloy Flanges Supplier#Buy Hastelloy Flanges Online#Hastelloy Flange Types#Hastelloy C276 Flanges#Hastelloy C22 Flanges#Hastelloy Flanges Price#Industrial Hastelloy Flanges#Hastelloy Flanges Exporter#Custom Hastelloy Flanges#High-Quality Hastelloy Flanges#Corrosion-Resistant Hastelloy Flanges#Hastelloy Flanges for Chemical Industry#Hastelloy Flanges for Oil & Gas#Hastelloy Flanges Specifications#Hastelloy Flanges Distributor#Hastelloy Flanges Stockist#Hastelloy Flanges Applications#Best Hastelloy Flanges

2 notes

·

View notes

Text

Sinopec-approved flanges in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C offers a wide quality extent of Incoloy 800/800H/800HT Flanges, which has presumably the best components like high versatility, outrageous arrangement, strength and that is only the start. Incoloy 800 Slip on Flanges (UNS N08800) is used for process piping, heat exchangers, warming part sheathing, carburizing gear, and nuclear steam-generator tubing. Incoloy 800 Flanges (UNS N08810) has added carbon and reinforcing treatment that considers higher jerk and break properties at 1100 Degree F (800 Degree C).

Incoloy 800 Weld Neck Flanges (UNS N08811) is a nickel-iron-chromium blend, which has a significant part of the comparable characteristics of various people from the 800 composite social occasion. Meanwhile, these Incoloy 800 Outwardly weakened flanges are furthermore being introduced in different sizes and shapes to our clients. We moreover offer these Incoloy 800H Connection Weld Flanges at market driving expenses. Also, similarly as with standard austenitic treated prepares, Incoloy 800 Lap Joint Flanges may be welded using methodologies like MIG, TIG, and shield metal round portion welding. Incoloy 800 Ring Joint Sort Flanges is impenetrable to chloride molecule stress utilization breaking.

The nickel content makes Incoloy 800 Presentation Blind Flanges astoundingly impenetrable to both chloride stress-utilization breaking and to embrittlement from precipitation of sigma stage. Incoloy 800 Spacer Flanges is ordinarily used in electric arrive at warming-part sheathing; steam methane further developing radiators and removed tubing for ethylene; smelling salts refluent coolers, etc. Incoloy 800HT Long Weld Neck Flanges is in like manner used in Compound and Petrochemical dealing.

#Incoloy 800/800HT Flanges Manufacturers in UAE#Incoloy 800/800HT Flanges Suppliers in UAE#Incoloy 800/800HT Flanges Stockists in UAE

2 notes

·

View notes

Text

Stainless Steel 310 Flanges | ASTM A182 SS 310 Slip On Flange

An extensively utilised flange in pipefitting, SS 310 tongue & groove Flanges are made from a top-of-the-line stainless steel combination that provides remarkable robustness, long life, and rust protection. It has been crafted to withstand the significant temperature and pressure of tough working environments where other substances could not hold up.

The ASME SA182 SS 310 Blind Flange are particularly distinguished by their ability to sustain extreme temperatures and endure up to 2100°F (1150°C). This is why it is ubiquitous in applications such as power plants, chemical processing, and oil refineries. This resilient characteristic is a consequence of its stainless steel alloy, created with a combination of high levels of chromium, nickel and other elements, providing incomparable protection against oxidation and high-temperature corrosion.

SS 310 tongue & groove Flanges are also known for their excellent sealing capabilities, ensuring a tight and leak-free connection in pipe systems. This makes them highly reliable in critical industries where safety and efficiency are paramount. Additionally, their corrosion resistance properties make them a cost-effective choice, as they require minimal maintenance and have a long service life.

UNDERSTANDING ON STAINLESS STEEL 310 FLANGES

Stainless Steel 310 Flanges are made from a high alloy stainless steel, which is designed for high-temperature and corrosion-resistant applications. These flanges are used in various industries such as oil and gas, chemical processing, and power generation.

Here are some key points about Stainless Steel 310 Flanges:

Material Composition: Stainless Steel 310 is composed of high levels of chromium and nickel, which provide excellent corrosion resistance and high-temperature strength.

Applications: These flanges are commonly used in high-temperature environments, including furnace parts, heat treatment baskets, and combustion chambers.

Corrosion Resistance: Stainless Steel 310 offers superior resistance to oxidation and sulfidation at high temperatures.

Weldability: The material is readily weldable and machinable, making it suitable for fabrication processes.

If you have specific questions or need more detailed information about Stainless Steel 310 Flanges, feel free to ask!

Introduction to Stainless Steel 310 Flanges

Stainless Steel 310 Flanges are an essential component in high-temperature and corrosion-resistant applications across various industries. They are known for their exceptional material composition, applications, corrosion resistance, and weldability. Let's delve into the key benefits and features of Stainless Steel 310 Flanges.

If you have specific questions or need more detailed information about Stainless Steel 310 Flanges, feel free to ask!

Stainless Steel 310 Flanges are highly versatile and can be used in a wide range of industries, including power generation, chemical processing, and oil and gas. Their ability to withstand extreme temperatures and resist corrosion makes them a reliable choice for demanding environments. With their excellent sealing capabilities and long service life, Stainless Steel 310 Flanges offer both safety and cost-effectiveness in critical applications.

Benefits of Choosing Stainless Steel 310 Flanges

Stainless Steel 310 Flanges offer a range of benefits that make them a preferred choice in various industries. Here are some reasons why you should choose Stainless Steel 310 Flanges:

High-Temperature Resistance: Stainless Steel 310 Flanges are designed to withstand high temperatures, making them suitable for use in applications where heat resistance is crucial.

Corrosion Resistance: They exhibit excellent corrosion resistance, making them ideal for use in corrosive environments such as chemical processing and oil and gas industries.

Versatility: Stainless Steel 310 Flanges are highly versatile and can be used in a wide range of industries, including power generation, chemical processing, and oil and gas, due to their exceptional material composition and properties.

Weldability: Their weldability allows for ease of installation and maintenance, providing flexibility in various industrial processes.

Sealing Capabilities: With excellent sealing capabilities, they ensure leak-free performance, contributing to the safety and reliability of critical applications.

Long Service Life: Stainless Steel 310 Flanges are known for their durability and long service life, offering cost-effectiveness and reliability over extended periods of use.

If you have more specific questions or need detailed information about any of these benefits, feel free to ask!

Conclusion on Stainless Steel 310 Flanges

Stainless Steel 310 Flanges are a reliable choice for various industrial applications due to their exceptional properties and benefits. In conclusion:

High Performance: Stainless Steel 310 Flanges offer high-temperature resistance, corrosion resistance, and excellent sealing capabilities, ensuring reliable performance in demanding industrial environments.

Versatile Application: Their versatility enables their use in a wide range of industries, including power generation, chemical processing, and oil and gas, making them a versatile and adaptable solution for different needs.

Cost-Effectiveness: The long service life and durability of Stainless Steel 310 Flanges Stainless Steel 310 Flanges contribute to their cost-effectiveness, providing a reliable and economical solution over extended periods of use.

Safety and Reliability: The weldability and leak-free performance of these flanges contribute to the safety and reliability of critical applications, making them a trusted choice in various industrial settings.

Stainless Steel 310 Flanges are an excellent choice for applications that demand high performance, durability, and safety. If you require further details or have specific queries, feel free to ask for more information.

#Werkstoff Nr. 1.4841 Square Flange#UNS S31000 Forge Flange#ASME SA182 Blind Flange#SS 310 Lap Joint Flange#UNS S31000 Groove Flange#Werkstoff Nr. 1.4841 SORF Flange#ASME SA182 Reducing Flange#ASME SA182 Socketweld Flange

1 note

·

View note

Text

Platinex Piping is a premier supplier of flanges, including slip on raised face flanges, blind, weld neck, groove &tongue threaded & socket flanges in Mumbai.

0 notes

Text

Mặt Bích Xoay Inox Là Gì? Thông Số Kỹ Thuật, Ưu Điểm, Ứng Dụng Thực Tế

Mặt bích xoay inox (Lap Joint Flange) còn có rất nhiều tên gọi như mặt bích cổ lồng inox, bích hàn lồng inox, mặt bích l��ng…Chất liệu chính để chế tác thiết bị đó chính là inox, bao gồm inox 201/ 304/ 316/ 410 nên có độ bền cứng tuyệt đối, đảm bảo tính thẩm mỹ cao.

#matbichxoayinox #matbich #matbichinox #tongkhovan

Link tham khảo: https://tongkhovan.vn/mat-bich-xoay-inox-7490.html

3 notes

·

View notes

Text

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes