#flange types

Explore tagged Tumblr posts

Text

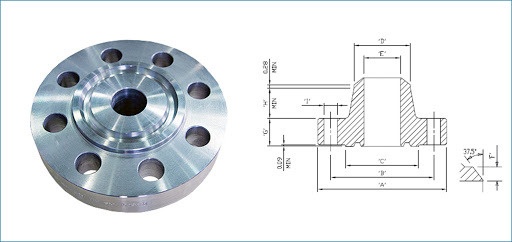

Stainless Steel Pipe Flanges Specifications

Stainless steel pipe flanges are essential components in piping systems, used to connect pipes, valves, pumps, and other equipment. They provide easy access for cleaning, inspection, and modification. The specifications of stainless steel pipe flanges cover various aspects including dimensions, pressure ratings, materials, and design standards.

0 notes

Text

Where can I buy Top Flanges from at a reasonable price in Germany?

Flanges serve as indispensable components in business piping systems, imparting a steady and leak-proof connection among pipes, flange valve, and different gadgets. As an important detail in fluid and gas coping with procedures, selecting wonderful flanges is paramount to ensuring operational performance, safety, and reliability. In Germany, corporations seeking top-grade flanges at reasonable prices turn to us as a company of premium flange solutions. Let's delve into the world of flanges, discover the various kinds presented via us and find out why they are the preferred desire for discerning clients in Germany.

Understanding Flanges:

Flanges are flat, round discs with frivolously spaced bolt holes across the circumference. They are welded or screwed onto pipes or devices to facilitate the connection and meeting of piping structures. Flanges come in diverse sorts, sizes, and materials, every designed to satisfy specific operational requirements and requirements.

Types of Flanges:

It gives a complete variety of flange sorts to cater to various industrial programs. Some of the important thing types consist of:

Weld Neck Flanges: These flanges are designed with a protracted, tapered neck that is welded to the pipe, supplying reinforcement and preventing leakage at the joint.

Slip-On Flanges: Slip-on flanges slide over the stop of the pipe and are then welded in vicinity. They are clean to install and suitable for low-pressure packages.

Blind Flanges: Also known as blanking flanges, blind flanges are used to seal the quit of a pipe or vessel, stopping the drift of fluid or gas. They are generally used for pressure checking out and preservation purposes.

Socket Weld Flanges: Socket weld flanges have a recessed region or socket into which the pipe is inserted after which it is welded. They provide a smooth bore and are best for small-bore piping systems.

Why Choose Arcellor Controls Flanges in Germany:

Premium Quality: We are devoted to handing over types of flange of the best first-rate, manufactured the use of advanced substances and advanced production strategies. Their flanges undergo rigorous checking out and inspection approaches to ensure compliance with international requirements and specs.

Competitive Pricing: Despite providing top-grade flanges, it maintains aggressive pricing to offer customers a super price for their investment. Their obvious pricing rules and value-powerful solutions cause them to favor companies in Germany.

Extensive Inventory: Arcellor Controls keeps an intensive inventory of flange types, sizes, and materials to satisfy the diverse needs of customers throughout industries. Whether you require general or custom flanges, they've the functionality to fulfill your necessities right away and effectively.

Technical Expertise: With years of enjoyment within the enterprise, boasts a team of skilled engineers and technical professionals who provide treasured assistance and guide for the duration of the procurement procedure. From product choice to setting up steering, they make certain a continuing revel in for customers.

In the end, for groups in Germany looking for top-pleasant flanges at reasonable prices, emerged as the favored supplier. With their complete variety of flange kinds, unwavering commitment to high-quality, aggressive pricing, and tremendous customer service is poised to meet the evolving wishes of industrial operations in Germany. Choose Arcellor Controls for your flange necessities and experience reliability, performance, and peace of thoughts for your operations.

0 notes

Text

Multilanguages of some of my favorite sims [Re-Do]

So i decided to remake these. Because i really didn't like how the older versions looked like. And while i was redesigning them i decided to do some others as well because... Yes

Nora Zeal-Ott:

Lily Gates:

(NOTE: there were 2 chinese fanmade translations. The one with the taiwanese flag seems to be the same name for lily as the other chinese build and it was somewhat unfinished. It started being completely in English after the bird minigame. But it was labeled as T.Chinese while the other was M.Chinese)

Kayleigh Wintercrest:

+ Kayleighs Japanese Description and name

Vaughn Braun:

(Note for all TSBO Console ones: Portuguese and Polish left the whole game in English despite having a released version (and polish even having a custom title „Poza Domem“ which Norwegian Danish and Swedish DON'T have))

Makino Nada:

(French and German use her old intended full name while Norwegian uses her old first name )

Fanny Adoré:

Crispin Black:

Neo Flange:

Bella Ciao:

Arthur Pop:

Roxanna Hardplace:

Idk if i should continue with more characters but i just wanted to share these ones I've tried to do

#The Urbz#The Sims Bustin Out#The Sims 2#Lily Gates#Nora Zeal-Ott#Kayleigh Wintercrest#Vaughn Braun#Makino Nada#Fanny Adore#Crispin Black#Neo Flange#Arthur Pop#Bella Ciao#Roxanna Hardplace#This was inspired by the meet your neighbors pamphlet#I only noticed afterwards that I used the BRITISH flag for all except Lily. So oopsie#Listening to Multilanguages of Disney channel stuff while typing them out yass#Multilanguage

7 notes

·

View notes

Text

Things You Should Know About Hastelloy Flanges By Manilaxmi Industrial

Manilaxmi Industrial: When it comes to choosing materials for industrial applications, Hastelloy flanges stand out as a top option due to their remarkable properties and performance। Understanding Hastelloy flanges' characteristics and benefits can help you make informed choices about your projects, whether you're working in chemical processing, oil and gas production, or power generation। What you need to know about Hastelloy flanges is here।

What are Hastelloy Flanges?

Hastelloy flanges are components made from Hastelloy, a high-performance alloy primarily composed of nickel, chromium, and molybdenum. This superalloy is renowned for its excellent corrosion resistance, high-temperature strength, and durability in harsh environments. Flanges are used to connect pipes, valves, pumps, and other equipment, ensuring a secure and leak-proof system.

Key Properties of Hastelloy Flanges?

1. Corrosion Resistance: Hastelloy flanges are highly resistant to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for use in aggressive environments where other materials might fail.

2. Temperature Resistance: These flanges can withstand extreme temperatures, both high and low, without losing their structural integrity. This property is crucial for industries that operate under severe thermal conditions.

3. Mechanical Strength: Hastelloy flanges offer exceptional mechanical strength, ensuring durability and reliability even under high stress and pressure.

4. Versatility: Due to their unique properties, Hastelloy flanges are versatile and suitable for a wide range of applications across various industries

Types of Hastelloy Flanges?

Hastelloy flanges come in different types, each designed for specific applications and connection methods. Common types include:

• Weld Neck Flanges: These flanges are designed to be welded to the pipe, providing a strong and leak-proof connection ideal for high-pressure applications.

• Slip-On Flanges: Easier to install than weld neck flanges, these are slipped over the pipe and then welded. They are suitable for low-pressure environments.

• Blind Flanges: Used to close the end of a pipe or valve, blind flanges are essential for testing and maintenance purposes.

• Socket Weld Flanges: These flanges are similar to slip-on flanges but have a socket for welding, providing a smoother flow inside the pipe.

• Lap Joint Flanges: These are used with a stub end and are ideal for systems that require frequent disassembly.

Applications of Hastelloy Flanges?

Given their superior properties, Hastelloy flanges are used in a variety of demanding applications, such as:

• Chemical Processing: The exceptional corrosion resistance of Hastelloy makes it perfect for handling corrosive chemicals and acids.

• Oil and Gas: In the oil and gas industry, Hastelloy flanges are used in pipelines and equipment exposed to harsh environments and high pressures.

• Power Generation: These flanges are used in power plants, particularly in high-temperature and high-pressure sections.

• Marine Engineering: Hastelloy’s resistance to seawater corrosion makes it ideal for offshore and marine applications.

Advantages of Using Hastelloy Flanges?

1. Longevity: The durability and resistance to wear and tear extend the lifespan of the equipment, reducing the need for frequent replacements.

2. Safety: Enhanced mechanical strength and corrosion resistance ensure safer operations in critical applications.

3. Cost-Effective: Despite the higher initial cost, the longevity and reliability of Hastelloy flanges can lead to cost savings over time by minimizing downtime and maintenance.

#Hastelloy Flanges#Hastelloy Flange Manufacturer#Hastelloy Flanges Supplier#Buy Hastelloy Flanges Online#Hastelloy Flange Types#Hastelloy C276 Flanges#Hastelloy C22 Flanges#Hastelloy Flanges Price#Industrial Hastelloy Flanges#Hastelloy Flanges Exporter#Custom Hastelloy Flanges#High-Quality Hastelloy Flanges#Corrosion-Resistant Hastelloy Flanges#Hastelloy Flanges for Chemical Industry#Hastelloy Flanges for Oil & Gas#Hastelloy Flanges Specifications#Hastelloy Flanges Distributor#Hastelloy Flanges Stockist#Hastelloy Flanges Applications#Best Hastelloy Flanges

2 notes

·

View notes

Text

Swing Check Valve Manufacturer from Ahmedabad, Gujarat

Swing Check Valve in Ahmedabad - Manufacturer of Swing Check Valve offered by Gold Techno Casting, Ahmedabad, Gujarat.

Google Map:--> https://maps.app.goo.gl/6Ax9sqWEXaXMWSgi6

Swing Check Valves Manufacturer from Ahmedabad, Swing Check Valve in Ahmedabad, Swing Check Valve in Gujarat, Swing Check Valve Manufacturer from Ahmedabad, Check Valve Manufacturer from Ahmedabad, Top Swing Check Valve Dealers in Ahmedabad Near Me, Swing Check Valve Manufacturer in Ahmedabad, India, Swing Check Valve Manufacturer from Kheda, Swing Check Valve Manufacturer from Narol, Swing Type Check Valve Exporters from Gujarat, India, Manufacturer, Exporter & Supplier of Swing Check Valves, Check Valves in Ahmedabad, Check Valves in Gujarat, SS Swing Check Valve Flanged Gujarat, India, Swing Check Valve in Ahmedabad Price, www.goldtechnocasting.com/swing-check-valves-manufacturer-in-ahmedabad-gujarat.php, Gold Techno Casting

#Swing Check Valves Manufacturer from Ahmedabad#Swing Check Valve in Ahmedabad#Swing Check Valve in Gujarat#Swing Check Valve Manufacturer from Ahmedabad#Check Valve Manufacturer from Ahmedabad#Top Swing Check Valve Dealers in Ahmedabad Near Me#Swing Check Valve Manufacturer in Ahmedabad#India#Swing Check Valve Manufacturer from Kheda#Swing Check Valve Manufacturer from Narol#Swing Type Check Valve Exporters from Gujarat#Manufacturer#Exporter & Supplier of Swing Check Valves#Check Valves in Ahmedabad#Check Valves in Gujarat#SS Swing Check Valve Flanged Gujarat#Swing Check Valve in Ahmedabad Price#www.goldtechnocasting.com/swing-check-valves-manufacturer-in-ahmedabad-gujarat.php#Gold Techno Casting

1 note

·

View note

Text

Industrial Flange Selection Guide: One Step to the Right Place

Selecting the proper business flange is crucial for making sure a dependable, efficient, and secure piping system. With numerous flange kinds and makes use of, industries ought to apprehend the important element elements that impact flange selection. From stress rankings to cloth compatibility, each detail performs an important role. This flange selection guide will assist you navigate the complexities of choosing the right flange in your specific wishes. At Manilaxmi Industrial, we offer awesome industrial flanges tailored to meet numerous commercial necessities.

Understanding Industrial Flanges

Industrial flange selection serves as vital connectors in piping structures, making an allowance for smooth meeting, protection, and disassembly of pipes. The preference of a flange relies upon several elements, alongside software, strain, temperature, and material compatibility.

Common Flange Types and Uses

Different industries require unique flange types and uses and make use of to ensure optimal overall performance. Below are the maximum not unusual flange types:

Flange Type

Uses and Applications

Weld Neck Flange

High-pressure and high-temperature applications such as refineries and chemical plants.

Slip-On Flange

Low-pressure systems where welding is required to strengthen the joint.

Blind Flange

Sealing off piping systems or isolating sections for maintenance.

Socket Weld Flange

Ideal for small-diameter, high-pressure pipes in industrial processes.

Threaded Flange

Used in low-pressure systems where welding is not feasible.

Lap Joint Flange

Works well with stub ends and allows easy alignment adjustments.

Orifice Flange

Installed in flow measurement applications using an orifice plate.

Flange Material Selection

Selecting the appropriate flange raw material is essential for making sure durability and overall performance. The raw materials need to be like minded with the medium flowing through the pipes to prevent corrosion and put on. Below are the most common materials utilized in commercial flanges:

Material Type

Characteristics and Applications

Carbon Steel

Cost-effective, strong, and widely used in general piping systems.

Stainless Steel

Corrosion-resistant, ideal for chemical and food processing industries.

Alloy Steel

Enhanced strength and resistance to high temperatures and pressures.

Duplex Stainless Steel

Combines strength and corrosion resistance, used in marine and oil industries.

Copper-Nickel

Resistant to seawater corrosion, used in marine applications.

Aluminum

Lightweight and corrosion-resistant, ideal for specific aerospace and marine industries.

Factors in Flange Selection Guide

When choosing the proper flange, consider the subsequent key elements:

1. Pressure and Temperature Ratings

Different flange training, which embody Class A one hundred fifty, 300, 600, 900, 1500, and 2500, decide the stress coping with capacity. Selecting a flange with the perfect rating guarantees protection and normal overall performance.

2. Flange Standards and Applications

Flanges should observe enterprise standards to ensure compatibility and safety. Some key flange standards and applications consist of:

ASME/ANSI B16.5 – Standard for pipe flanges and fittings.

ASME B16.47 – Large-diameter flanges.

API 6A – Flanges used in oil and gasoline industries.

DIN and EN Standards – European standards for business applications.

JIS Standard – Japanese flange widespread.

3. Flange Face Types

The flange types and makes use of vary based totally on face kinds, which have an impact on sealing performance:

Flange Face Type

Characteristics and Uses

Flat Face (FF)

Used in low-pressure applications.

Raised Face (RF)

Common in high-pressure applications where a better seal is required.

Ring Type Joint (RTJ)

Used in extreme pressure and temperature conditions.

Tongue and Groove (T&G)

Prevents gasket blowout, used in high-pressure settings.

Male and Female (M&F)

Ensures better alignment and gasket containment.

Industrial Flanges Comparison

Understanding commercial flanges evaluation facilitates in determining the best option in your software:

Criteria

Weld Neck Flange

Slip-On Flange

Blind Flange

Threaded Flange

Strength

High

Moderate

High

Low

Installation

Requires welding

Requires welding

No flow passage

No welding needed

Cost

Higher

Lower

Moderate

Lower

Applications

High-pressure

Low-pressure

Maintenance

Low-pressure systems

Best Flange for Piping

The best flange for piping relies upon the system’s precise desires. Here’s how to decide the proper one:

For excessive-strain, high-temperature programs – Weld neck flanges

For easy installation and decrease price – Slip-on flanges

For separating piping sections – Blind flanges

For threaded connections without welding – Threaded flanges

For flexible alignments – Lap joint flanges

Selecting the proper flange requires a radical knowledge of flange choice guide factors, consisting of material, strain ratings, face types, and applications. The right preference complements gadget durability, efficiency, and safety. At Manilaxmi Industrial, we concentrate on offering top-best industrial flanges comparison to meet the best industry standards. Whether you need flange sorts and make use of, flange raw materials selection, or flange requirements and programs, we are right here to assist you.

For professional guidance in deciding on the right flange, contact Manilaxmi Industrial today!

#industrial flange selection#flange selection guide#choosing the right flange#flange types and uses#best flange for piping#industrial flanges comparison#flange material selection#flange standards and applications

0 notes

Text

The VCS Type Flange Insulation Kit works against galvanic corrosion and conductivity control in a pipeline system. The pre-fabricated sealing gasket is supplied with insulating sleeves and washers, which provide an excellent and durable seal at the flange joints. The use of these kits extends from the oil and gas to petrochemical to power plant industries, ensuring truly reliable and safe operations in the long run. Compassionate towards high pressure and extreme temperature operations, it provides leak-proof pipelines free of corrosion to run efficiently.

0 notes

Text

GI Ducting, Galvanized Iron Duct, Manufacturer, Exporter, Pune, India

GI Ducting, Galvanized Iron Duct, Cable Trays, Manufacturer, Supplier, Exporter, Pune, India, Japan, South Africa, Russia, Japan, Philippines.

#GI Ducting#Galvanized Iron Duct#Wire Mesh Cable Trays#Wiremesh Cable Trays#Wiremesh Trays#Cable Trays#Cable Tray#SS Ducting#Industrial Cable Trays#Industrial Cable Tray#Perforated Cable Trays#Perforated Cable Tray#Ladder Type Cable Trays#Rectangular GI Duct#Stainless Steel Ducting#Aluminium Ducting#Spiral Ducting#Round Ducting#Pre Insulated Ducts#Waves Flange System#Ladder Type Cable Tray#Cable Tray Accessories#Cable Tray Accessory#Cable Tray Ducts#Cable Tray Duct#Cable Tray Trunking#Cable Tray Covers#Cable Tray Cover#Manufacturer#Supplier

0 notes

Text

Ring Type Joint Flanges in Maharashtra ensure leak-proof connections through several design features:

0 notes

Text

Double Flange Butterfly Valves: The Game-Changer Your Facility Needs!

In the dynamic world of industrial operations, every component plays a crucial role in ensuring smooth functionality. One such vital component is the Double Flange Butterfly Valve, a true game-changer for facilities in the oil and gas industries. Let's dive into the realm of HTC Valves' innovative creation and explore why it's a must-have for your operations.

Understanding Butterfly Valves

Butterfly valves are essential components in industrial pipelines, allowing control and regulation of flow. They operate similarly to a disc rotating on a central axis, regulating flow by turning perpendicular to the direction of the fluid.

Introducing Double Flange Butterfly Valves

HTC Valves introduces the Double Flange Butterfly Valve, an innovative solution designed to enhance performance and reliability in industrial settings. Unlike traditional butterfly valves, double flange variants offer added stability and durability, making them ideal for high-pressure applications.

How Double Flange Butterfly Valves Work

The operation of double flange butterfly valves is straightforward yet effective. When fully open, the disc aligns with the flow direction, minimizing resistance and pressure drop. Conversely, closing the valve involves rotating the disc perpendicular to the flow, effectively blocking it.

Advantages of Double Flange Butterfly Valves

Double flange butterfly valves offer several advantages over their counterparts. Their design ensures a tight seal, reducing leakage and minimizing maintenance requirements. Additionally, their lightweight construction and compact size make them easy to install and integrate into existing systems.

Applications in Oil and Gas Industries

In the oil and gas industries, where efficiency and reliability are paramount, double flange butterfly valves excel. Their ability to handle high pressures and temperatures makes them indispensable in pipeline systems, storage tanks, and processing plants.

Installation and Maintenance Considerations

Installing and maintaining double flange butterfly valves is relatively straightforward. Proper alignment during installation ensures optimal performance, while regular inspection and lubrication prolong valve life and prevent issues.

Comparing Double Flange vs. Standard Valves

Compared to standard butterfly valves, double flange variants offer enhanced stability and sealing capabilities. While both serve similar functions, double flange valves are preferred for applications requiring higher pressures and greater reliability.

Innovations in Valve Technology

The realm of valve technology is constantly evolving, with innovations aimed at improving efficiency, durability, and sustainability. HTC Valves continues to lead the way with cutting-edge designs and materials, ensuring their products meet the ever-changing needs of industries worldwide.

Sustainability and Environmental Impact

As industries focus more on sustainability, the environmental impact of valve systems comes into focus. Double flange butterfly valves, with their efficient design and reduced leakage rates, contribute to lower energy consumption and emissions, aligning with sustainability goals.

Choosing the Right Valve for Your Facility

Selecting the right valve for your facility is crucial to ensure optimal performance and longevity. Factors such as operating conditions, fluid characteristics, and system requirements should be carefully considered when choosing between double flange and other valve types.

Common Challenges and Solutions

While double flange butterfly valves offer numerous benefits, they are not without challenges. Issues such as corrosion, erosion, and fouling can impact valve performance over time. Regular maintenance, proper material selection, and preventive measures can mitigate these challenges effectively.

Future Trends in Valve Design

Looking ahead, the future of valve design is exciting, with advancements in materials, automation, and smart technologies shaping the industry. HTC Valves remains committed to innovation, ensuring their products continue to meet the evolving needs of tomorrow's industries.

Conclusion

In conclusion, Double Flange Butterfly Valves offered by HTC Valves stand as a testament to innovation and reliability in industrial valve technology. With their superior performance, durability, and efficiency, they are indeed the game-changer your facility needs.

FAQs

1. What distinguishes double flange butterfly valves from standard butterfly valves? Double flange butterfly valves offer enhanced stability, durability, and sealing capabilities compared to standard valves, making them suitable for high-pressure applications.

2. Are double flange butterfly valves suitable for use in the oil and gas industries? Yes, double flange butterfly valves excel in the oil and gas industries, where they are used in pipeline systems, storage tanks, and processing plants due to their ability to handle high pressures and temperatures.

3. How do I ensure proper installation of double flange butterfly valves? Proper alignment during installation is crucial for optimal performance. Ensure that the valve is correctly positioned and securely fastened to prevent leaks or malfunctions.

4. What maintenance procedures are required for double flange butterfly valves? Regular inspection, lubrication, and cleaning are essential maintenance procedures to ensure the longevity and optimal performance of double flange butterfly valves.

5. Can double flange butterfly valves contribute to environmental sustainability? Yes, double flange butterfly valves, with their efficient design and reduced leakage rates, can contribute to lower energy consumption and emissions, aligning with sustainability goals in industrial operations.

1 note

·

View note

Text

JIS B2220 10K flanges

Introduction:

In the realm of industrial piping systems, precision and reliability are non-negotiable factors. JIS B2220 10K flanges stand as pillars of strength, offering robust solutions for a multitude of applications. From dimensions to types and reliable suppliers, understanding the intricacies of these flanges is crucial for seamless operations. Join us as we delve into the world of JIS B2220 10K flanges, exploring their dimensions, types, and trusted suppliers in Mumbai, India.

Dimensions of JIS B2220 10K Flanges:

JIS B2220 10K flanges adhere to specific dimensions to ensure compatibility and ease of installation. The standard dimensions typically include flange outer diameter (OD), bolt circle diameter (BC), bolt hole diameter (BH), and thickness (T). These standardized dimensions streamline the integration of flanges into diverse piping systems, enhancing efficiency and reliability.

Types of JIS B2220 10K Flanges:

Forged Flanges: Engineered for durability and strength, JIS B2220 10K forged flanges offer robust solutions for high-pressure applications, ensuring leak-free connections and long-term performance.

Reducing Flanges: Designed to accommodate pipes of different diameters, JIS B2220 10K reducing flanges facilitate smooth transitions between piping systems, optimizing flow dynamics and minimizing pressure drop.

Flat Flanges: Featuring a flat surface, JIS B2220 10K flat flanges provide a reliable sealing mechanism, making them ideal for applications where leakage prevention is paramount.

Blind Flanges: Employed to seal the end of a piping system, JIS B2220 10K blind flanges offer versatility and convenience, allowing for easy isolation and maintenance of pipelines.

Weld Neck Flanges: Known for their superior strength and reliability, JIS B2220 10K weld neck flanges provide secure connections in high-stress environments, minimizing the risk of leakage or failure.

Trusted Suppliers of JIS B2220 10K Flanges in Mumbai, India:

[Supplier Name 1]: Renowned for their extensive inventory and commitment to quality, [Supplier Name 1] is a trusted source for JIS B2220 10K flanges in Mumbai, India.

[Supplier Name 2]: With a proven track record of excellence and customer satisfaction, [Supplier Name 2] offers competitive prices and prompt delivery of JIS B2220 10K flanges to meet diverse industrial requirements.

[Supplier Name 3]: Committed to exceeding customer expectations, [Supplier Name 3] provides comprehensive support and timely solutions for JIS B2220 10K flanges, ensuring seamless integration into industrial projects.

Conclusion:

In conclusion, JIS B2220 10K flanges represent the epitome of reliability and precision in industrial piping systems. With standardized dimensions, diverse types, and trusted suppliers in Mumbai, India, these flanges offer versatile solutions for a wide range of applications. By partnering with reputable suppliers and adhering to industry standards, businesses can harness the full potential of JIS B2220 10K flanges, ensuring efficient operations and optimal performance in their projects.

0 notes

Text

Who are the Top Flange Manufacturers in Usa ?

In the elaborate world of business pipelines, endless components work collectively to make certain safe and efficient fluid glides. Among these vital elements are flange, the unsung heroes that join pipes, valves, and different devices. Arcellor Controls, a dependent on companion in industrial automation solutions arcellor manipulate ON Arcellor Controls, recognizes the importance of superb flanges. But with several producers in the USA, how do you identify the top contenders?

Flanges: The Cornerstones of Secure Connections

A flange is a ring-shaped steel element with holes drilled around its circumference. It is connected to the ends of pipes, valves, or other equipment the usage of bolts and gaskets to create a stable and leak-evidence connection. Flanges are an essential part of flange couplings, which might be assemblies that are a part of pipes or tubes together completely. Flanges are available in diverse sorts, each suited for precise applications and pressure requirements:

Weld Neck Flange: Considered the strongest and most flexible flange kind, proposing an extended neck that is welded to the pipe for top-quality strain dealing with. This is a famous choice for high-strain packages.

Slip-On Flange: A price-effective option that slips over the pipe quit and is welded at the backside for a good stress score. This is suitable for lower strain packages where ease of meeting is vital.

Threaded Flange: Ideal for low-stress applications wherein frequent disassembly is needed, providing internal threads that screw onto the pipe. This is a superb option for clean renovation.

Socket Weld Flange: Similar to a slip-on flange however with a smaller internal socket for welding, supplying right strength in smaller diameter pipes. This is a space-saving option for programs with confined rooms.

Blind Flange: A stable disc-formed flange used to seal off the stop of a pipeline. This is useful for separating sections of a pipeline for upkeep or destiny growth.

The Advantages of Using Flanges

Flanges offer several benefits in business piping structures:

Leak-Proof Connections: The combination of bolts and gaskets ensures a tight seal, stopping leaks and safeguarding towards environmental contamination.

Easy Assembly and Disassembly: Flanges permit for easy connection and disconnection of pipes and systems, facilitating preservation and repair techniques.

High-Pressure Rating: Different flange sorts are designed to resist various pressure degrees, accommodating diverse business programs. Flange selection is vital for the safe operation of flange couplings in excessive-strain structures.

Versatility: The extensive form of flange kinds and substances guarantees compatibility with various pipe sizes, pressures, and fluids. This permits flexibility in designing and constructing exclusive sections of a pipeline.

Top Flange Manufacturers in the USA

While a definitive rating can be subjective and rely on unique desires, a number of the top flange producers within the USA are renowned for their best, reliability, and numerous product services:

Shaw Stainless and Alloy: A main manufacturer of incredible flanges in diverse grades of stainless-steel, alloy metal, and carbon metallic.

Texas Flange: Specializes in a comprehensive range of ASME and non-code flanges, catering to numerous industries like petrochemical, system, and waterworks.

SWEP International AB: A global dealer of flanges and different piping components, recognized for his or her commitment to international requirements and nice management.

Conclusion

Flanges are the silent workhorses of business pipelines, the crucial components forming the inspiration of secure and reliable flange couplings. Understanding special flange types, their benefits, and legitimate manufacturers inside the USA empowers you to make knowledgeable selections on your specific wishes. When it comes to industrial automation solutions, Arcellor Controls is your one-prevent shop for tremendous flanges and different essential components. We associate with leading manufacturers to offer you with the excellent possible products in your commercial initiatives.

0 notes

Text

Flange is used to connect valves, pumps, pipes, and many other different types of components and plumbing equipment to form a strong, reliable, and seal-proof piping system. There are many different types of flanges available in the market with varying flanges prices, and this guide will introduce you to some of the most widely used common and uncommon flanges.

0 notes

Text

Monolithic Insulating Joint Gasket in Canada By Goodrich Gasket.

Now the Monolithic Insulating Joint gasket is also available in Canada by Goodrich Gasket. The Monolithic Insulating Joint in Canada is a welded pre-fabricated 3-piece union applicable for pipeline electrical sectioning and commonly used when cathodic protection is present to prevent any interference in corrosion control. The gasket has the right facilities to do several non-destructive tests. Goodrich gasket is a wide range of industrial gasket manufacturers and exporters across the world, especially in Canada. Know more about Goodrich's Monolithic Insulting Joint:- www.goodrichgasket.com/Monolithic-Insulating-Joint

#goodrich gasket#gasket manufacturers#industrial gasket#gasket exporter#monolithicinsulatingjoint#ring type joint gasket#flange insulting gasket

1 note

·

View note

Text

Swing Check Valve Manufacturers in Ahmedabad Gujarat - Gold Techno Casting

Gold Techno Casting - Leading swing check valve manufacturers in Ahmedabad, Gujarat. We provide high-quality, durable industrial check valves for various applications. Get customized solutions, ISO-certified products, and reliable performance. Contact us today!

Google Map:--> https://maps.app.goo.gl/RnpnTrRdbLToF5YWA

Swing Check Valve Manufacturers in Ahmedabad Gujarat, Swing Check Valve Manufacturers in Ahmedabad, Swing Check Valve Manufacturers in Gujarat, Swing Check Valve in Ahmedabad, Swing Check Valve in Gujarat, Swing Check Valves Manufacturer from Ahmedabad, Swing Check Valves Manufacturer from Gujarat, Manufacturer Exporter & Supplier of Swing Check Valves in Ahmedabad, Swing Check Valves Exporter Gujarat, Swing Check Valve, Check Valves in Ahmedabad, Check Valves in Gujarat, Carbon Steel CS(WCB) Swing Type Check Valve Flanged ASA150, Valve Size: 3.0 inch, Stainless Steel Swing Check Valve, Valve Size: 8.0 inch, Stainless Steel Swing Check Valve in Ahmedabad, Stainless Steel Swing Check Valve In Gujarat, Carbon Steel Swing Check Valve in Ahmedabad, Carbon Steel Swing Check Valve in Gujarat, Swing Check Valve Manufacturer in Ahmedabad, Gujarat, India, Top Swing Check Valve Dealers in Ahmedabad, Top Swing Check Valve Dealers in Gujarat, www.goldtechnocasting.com/carbon-steel-swing-check-valve-in-ahmedabad.php, Gold Techno Casting

#Swing Check Valve Manufacturers in Ahmedabad Gujarat#Swing Check Valve Manufacturers in Ahmedabad#Swing Check Valve Manufacturers in Gujarat#Swing Check Valve in Ahmedabad#Swing Check Valve in Gujarat#Swing Check Valves Manufacturer from Ahmedabad#Swing Check Valves Manufacturer from Gujarat#Manufacturer Exporter & Supplier of Swing Check Valves in Ahmedabad#Swing Check Valves Exporter Gujarat#Swing Check Valve#Check Valves in Ahmedabad#Check Valves in Gujarat#Carbon Steel CS(WCB) Swing Type Check Valve Flanged ASA150#Valve Size: 3.0 inch#Stainless Steel Swing Check Valve#Valve Size: 8.0 inch#Stainless Steel Swing Check Valve in Ahmedabad#Stainless Steel Swing Check Valve In Gujarat#Carbon Steel Swing Check Valve in Ahmedabad#Carbon Steel Swing Check Valve in Gujarat#Swing Check Valve Manufacturer in Ahmedabad#Gujarat#India#Top Swing Check Valve Dealers in Ahmedabad#Top Swing Check Valve Dealers in Gujarat#www.goldtechnocasting.com/carbon-steel-swing-check-valve-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

Ring Type Joint Flanges Stockists in India

Nutech Overseas Flanges Aspects are reasonable for high-weight and high-temperature applications. ASME B16.5 RTJ Flanges are relentlessly applied to brilliant, going with Alloy Steel Ring Type Joint Plate flanges. Which accordingly guarantees thrilling, with the right assurance of profiles and material in the ASME B16.47 Series An and B RTJ Flanges.

ASME B16.5 RTJ Flanges manufacturers and exporter in India. We are exporing Ring Type Joint flanges, Level Confronted Ring Type Joint Flanges, Ring Type Joint Weld Flanges and Ring Type Joint Raised Face flanges at dumbfounding expense because of sensible expert hours in India and complete wellspring of astounding ANSI B16.5 Class 150 Ring Type Joint flanges, most very smart arrangement, cost open in Mumbai, India. You ought to check ASME B16.5 Ring Type Joint Flanges Aspects, RTJ Flanges weight structure and RTJ Flanges groove assessments. We have organized stock in various assessments like rtj Flanges examinations 1500 and rtj Flanges assessments 900.

Ring Type Joint Flanges Manufacturers, Ring Type Joint Flanges Suppliers, Ring Type Joint Flanges Stockists, Ring Type Joint Flanges Exporters

We are financial expert of Duplex Steel RTJ flanges, most very smart arrangement, cost as we are one of the most exceptional suppliers and vendor of Hastelloy C22 Ring Type Joint Flanges in India. We have our stocking traders in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our ANSI B16.5 RTJ flanges cost going before purchasing Class 300 Ring Type Joint Flanges from India or China. other than mail for our live deftly of Inconel Ring Type Joint Flanges to check types and sizes with our set up stock we can give you best cost of DIN86029 PN10 Ring Type Joint Flanges.

We can correspondingly give free event of Alloy 20 Ring Type Joint Flanges, Nutech Overseas is having our Seller and Wholesaler in Chhattisgarh, Karnataka, Faridabad, Gujarat, Karnataka, Gurgaon, Bhosari, Rajkot, Ghaziabad, Delhi, Chennai (Madras), Ahmedabad, West-Bengal, Haryana, Kolkata, Pune, Raipur, Uttar Pradesh, Nagpur, Madhya Pradesh, Khopoli, Ludhiana, Aurangabad, Jaipur, Bangalore, Punjab, Maharashtra, Tamil Nadu, Rajasthan, Kolhapur, Indore, Vadodara. So on the off chance that you are searching for best cost of MSS SP-44 RTJ Flanges or ASME B16.5 Ring Type Joint Flanges, RTJ Flanges Class 1500 close to you with most limited time transport or free illustration of Stainless Steel RTJ Flanges.

#Ring Type Joint Flanges Manufacturers in India#Ring Type Joint Flanges Suppliers in India#Ring Type Joint Flanges Stockists in India#Ring Type Joint Flanges Exporters in India

0 notes