#Custom Hastelloy Flanges

Explore tagged Tumblr posts

Text

Things You Should Know About Hastelloy Flanges By Manilaxmi Industrial

Manilaxmi Industrial: When it comes to choosing materials for industrial applications, Hastelloy flanges stand out as a top option due to their remarkable properties and performance। Understanding Hastelloy flanges' characteristics and benefits can help you make informed choices about your projects, whether you're working in chemical processing, oil and gas production, or power generation। What you need to know about Hastelloy flanges is here।

What are Hastelloy Flanges?

Hastelloy flanges are components made from Hastelloy, a high-performance alloy primarily composed of nickel, chromium, and molybdenum. This superalloy is renowned for its excellent corrosion resistance, high-temperature strength, and durability in harsh environments. Flanges are used to connect pipes, valves, pumps, and other equipment, ensuring a secure and leak-proof system.

Key Properties of Hastelloy Flanges?

1. Corrosion Resistance: Hastelloy flanges are highly resistant to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for use in aggressive environments where other materials might fail.

2. Temperature Resistance: These flanges can withstand extreme temperatures, both high and low, without losing their structural integrity. This property is crucial for industries that operate under severe thermal conditions.

3. Mechanical Strength: Hastelloy flanges offer exceptional mechanical strength, ensuring durability and reliability even under high stress and pressure.

4. Versatility: Due to their unique properties, Hastelloy flanges are versatile and suitable for a wide range of applications across various industries

Types of Hastelloy Flanges?

Hastelloy flanges come in different types, each designed for specific applications and connection methods. Common types include:

• Weld Neck Flanges: These flanges are designed to be welded to the pipe, providing a strong and leak-proof connection ideal for high-pressure applications.

• Slip-On Flanges: Easier to install than weld neck flanges, these are slipped over the pipe and then welded. They are suitable for low-pressure environments.

• Blind Flanges: Used to close the end of a pipe or valve, blind flanges are essential for testing and maintenance purposes.

• Socket Weld Flanges: These flanges are similar to slip-on flanges but have a socket for welding, providing a smoother flow inside the pipe.

• Lap Joint Flanges: These are used with a stub end and are ideal for systems that require frequent disassembly.

Applications of Hastelloy Flanges?

Given their superior properties, Hastelloy flanges are used in a variety of demanding applications, such as:

• Chemical Processing: The exceptional corrosion resistance of Hastelloy makes it perfect for handling corrosive chemicals and acids.

• Oil and Gas: In the oil and gas industry, Hastelloy flanges are used in pipelines and equipment exposed to harsh environments and high pressures.

• Power Generation: These flanges are used in power plants, particularly in high-temperature and high-pressure sections.

• Marine Engineering: Hastelloy’s resistance to seawater corrosion makes it ideal for offshore and marine applications.

Advantages of Using Hastelloy Flanges?

1. Longevity: The durability and resistance to wear and tear extend the lifespan of the equipment, reducing the need for frequent replacements.

2. Safety: Enhanced mechanical strength and corrosion resistance ensure safer operations in critical applications.

3. Cost-Effective: Despite the higher initial cost, the longevity and reliability of Hastelloy flanges can lead to cost savings over time by minimizing downtime and maintenance.

#Hastelloy Flanges#Hastelloy Flange Manufacturer#Hastelloy Flanges Supplier#Buy Hastelloy Flanges Online#Hastelloy Flange Types#Hastelloy C276 Flanges#Hastelloy C22 Flanges#Hastelloy Flanges Price#Industrial Hastelloy Flanges#Hastelloy Flanges Exporter#Custom Hastelloy Flanges#High-Quality Hastelloy Flanges#Corrosion-Resistant Hastelloy Flanges#Hastelloy Flanges for Chemical Industry#Hastelloy Flanges for Oil & Gas#Hastelloy Flanges Specifications#Hastelloy Flanges Distributor#Hastelloy Flanges Stockist#Hastelloy Flanges Applications#Best Hastelloy Flanges

2 notes

·

View notes

Text

How Custom Flanges Can Solve 80% of Your On-Site Compatibility Issues

Ever stood on-site with your team, staring at a pipe that just won’t fit? The specs looked right. The angle seemed okay. But the connection? Off. By a sliver.

Now multiply that by 20 pipe joints across a tight project deadline — and suddenly, that “silver” is a serious setback.

Welcome to the world of on-site compatibility issues, where mismatched pipe ends, uneven surfaces, and non-standard dimensions wreak havoc on industrial timelines. But what if we told you that 80% of these headaches could be avoided with one smart decision?

Custom flanges.

Why Standard Flanges Often Don’t Cut It

In theory, standard flanges are great. They’re readily available, budget-friendly, and follow universal specifications.

In reality?

a. That old pipe was installed years ago with custom specs. b. Your imported machinery uses a different pressure class. c. The orientation needs an angular offset. d. The required material grade isn’t available off-the-shelf.

Now you’re either spending hours modifying parts on-site (not ideal) or calling in urgent replacements (even worse).

Real-World Scenarios Where Custom Flanges Saved the Day

Scenario 1: Offshore Platform Retrofit An oil company was retrofitting pipelines on an offshore rig. Standard flanges weren’t aligning due to corroded pipe ends and mismatched bolt patterns. Solution? Custom flanges machined to match both the old and new equipment specs — saving two weeks of delay and thousands in downtime.

Scenario 2: Food Processing Plant Upgrade A food plant switching to stainless steel pipelines found that their imported equipment used DIN-standard connections while the rest of the plant used ANSI. Solution? Dual-standard custom flanges made the conversion seamless without replacing expensive machinery.

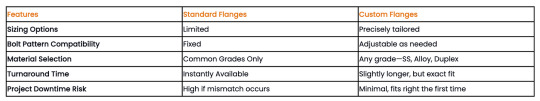

Custom v/s Standard Flanges: A Quick Comparison

How Custom Flanges Solve Compatibility Issues

1. Tailored Dimensions From OD and ID to bolt circle diameter, every spec is customized. No need to force-fit or modify pipe ends.

2. Mixed Standards? No Problem. Need to bridge JIS to ANSI or DIN to BS10? A custom flange can be your translator — engineering-wise.

3. Material Matching for Unique Environments Acidic fluids? High pressure? Extreme temperatures? Choose a custom flange in exotic materials like Inconel, Hastelloy, or Super Duplex.

4. Angular Adjustments and Tapered Ends When alignment is tricky, custom flanges with slight tapers or offset holes solve the issue with surgical precision.

But What About Cost and Time?

We get it — custom sounds expensive. But consider the full picture:

a. Cost of rework b. Labour hours wasted on poor fits c. Downtime penalties d. Delays in commissioning

A one-time custom part can eliminate cascading costs across your entire project.

Still Not Sure? Start Small

If you’re uncertain, begin with just the critical junctions. Let OnlineFittings.com help you spec out custom flanges only where needed. With CNC machining, fast delivery, and material certification — we make custom feel like standard.

Final Thought: Fit First, Fix Later or Never Fix at All?

Currently where industrial efficiency is currency, every misalignment is money lost. Custom flanges don’t just solve problems — they prevent them altogether.

So the next time your project demands precision, think beyond off-the-shelf. Think custom.

Think Online Fittings — where we don’t just deliver steel, we deliver peace of mind.

Tailored. Tested. Trusted.

0 notes

Text

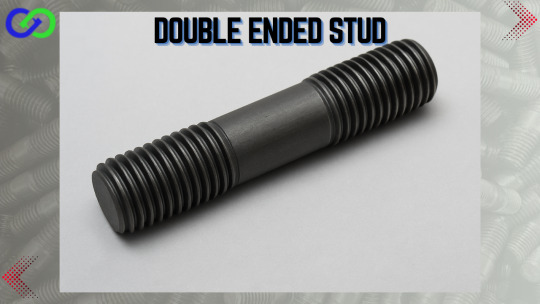

Double Ended Stud: Complete Guide

Ananka Fasteners offers premium-quality Double Ended Studs, engineered for maximum performance and durability. Designed to meet the highest industrial standards, our double ended studs deliver superior fastening solutions across industries that demand strength, precision, and corrosion resistance.

With advanced manufacturing facilities and a deep understanding of industrial fastening solutions, we deliver top-quality double ended studs tailored to meet diverse engineering applications.

What is a Double Ended Stud?

A Double Ended Stud is a type of fastener that features threads on both ends, separated by an unthreaded shank or a body in the middle. These studs are designed to be screwed into a tapped hole at one end while the other end accommodates a nut to fasten components together securely. Unlike standard bolts, double ended studs offer higher strength, precise alignment, and improved load distribution.

Key Features of Double Ended Studs

Threaded on both ends with consistent or varied thread types/sizes

Chamfered ends for easy assembly

Available in metric and imperial sizes

Custom lengths and threads as per client specifications

High tensile strength and excellent mechanical stability

Corrosion-resistant materials available for harsh environments

Applications of Double Ended Studs

Double ended studs are widely used in:

Automotive (engine assemblies, exhaust systems)

Oil & Gas (flanges, high-pressure fittings)

Petrochemical and Chemical Industries

Power Plants (turbines, boilers)

Construction and Heavy Machinery

Marine and Offshore Installations

Types of Double Ended Studs We Manufacture

We offer a wide variety of double ended studs to meet industrial requirements:

Fully Threaded Studs

Tap-End Studs (one short thread for screwing into a tapped hole, one long for a nut)

Reduced Shank Studs

Continuous Threaded Studs

Studs with Chamfered Ends

Material Grades

We manufacture double ended studs in various grades and alloys:

Stainless Steel:

SS 304, 304L, 316, 316L, 310, 321, 347

Alloy Steel:

ASTM A193 Grade B7, B7M, B8, B8M, B16

High-Temperature Alloys:

Inconel 600, 625, 718

Hastelloy C22, C276

Monel 400, K500

Nickel 200/201

Titanium Grade 2 / Grade 5

Duplex & Super Duplex:

UNS S31803, S32205, S32750, S32760

Others:

Brass, Copper, Silicon Bronze, Carbon Steel, Aluminium Bronze

Standard Specifications

Our double ended studs conform to the following standards:

ASTM / ASME: A193, A320, A307

DIN / ISO / BS / JIS Standards

Custom specifications as per client drawings

Surface Coating & Finishes

To improve performance and corrosion resistance, we offer various coatings:

Zinc Plated (Clear/Yellow/Black)

Hot Dip Galvanized (HDG)

PTFE Coated (Blue, Green, Red)

Xylan, Teflon, and Fluoropolymer Coating

Black Oxide, Dacromet, Geomet

Why Choose Ananka Fasteners?

Precision Engineering with CNC machining and threading Wide Range of Materials and grades available Custom Manufacturing to meet specific application needs Strict Quality Control in accordance with ISO standards Timely Delivery with export-ready packaging Global Supply Network across the USA, Europe, Middle East, Africa & Asia

Industries We Serve

Oil & Gas

Aerospace

Automotive

Marine

Petrochemical

Power Generation

Construction & Infrastructure

Double Ended Studs Exporter – Global Reach

Ananka Fasteners exports premium quality double ended studs to several countries including:

USA, UK, Germany, France, and Italy

UAE, Saudi Arabia, Oman, Qatar

South Africa, Nigeria, Kenya

Australia, Singapore, Malaysia

Brazil, Mexico, and Canada

Contact Us

Looking for a reliable Double Ended Stud supplier?Contact Ananka Fasteners today for competitive pricing, technical consultation, and bulk orders.

Frequently Asked Questions (FAQs)

Q1. What is the difference between a double ended stud and a threaded rod?A double ended stud has threads on both ends with an unthreaded middle portion, while a threaded rod is fully threaded along its entire length.

Q2. Can double ended studs be customized?Yes, we offer custom sizes, thread types, and coatings based on your requirements.

Q3. Which coating is best for marine applications?PTFE or Xylan-coated stainless steel studs are ideal for corrosion resistance in marine environments.

Q4. Do you provide test certificates?Yes, we provide MTC, NABL-approved lab reports, and third-party inspection reports on request.

#DoubleEndedStuds#StudBolts#IndustrialFasteners#FastenerSolutions#EngineeringFasteners#PrecisionFasteners#MechanicalFasteners#ThreadedStuds#BoltingSolutions#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#Tumblr#tumblr blog#bolt#stud bolt#articles

0 notes

Text

Innovations In Flange Manufacturing: What UAE Suppliers Offer

Flanges are critical piping system fittings, serving as connectors, seals, and reinforcements for pipes, pumps, and valves employed in a multitude of industries. For UAE industries that require efficient flange supplier options, the region has a robust market with suppliers to address diverse industrial requirements.

Why Choose a Flanges Supplier in UAE?

UAE acts as a central location for oil, gas, petrochemical, water treatment, and construction sectors which require premium flanges to maintain their operational efficiency and safety standards.

The UAE suppliers of flanges offer an extensive range of products which consists of blind flanges and slip-on flanges together with weld neck flanges and socket weld flanges and threaded flanges and lap joint flanges that are produced using stainless steel and carbon steel and alloy steel and Inconel and Monel and Hastelloy materials.

The best suppliers including Ali Yaqoob, distribute multiple product lines which meet international standards ASME, ANSI, DIN as well as other standards to maintain safety during corrosive environments and high-pressure applications.

Best Flanges Suppliers in UAE deliver essential characteristics which define their quality.

Product Diversification: The suppliers supply flanges which range across all sizes and pressure ratings for applications starting from low-pressure water networks to high-pressure oil and gas pipelines.

Quality Assurance: The products meet high industry standards through their manufacturing process to provide durability while maintaining leak-tight seals and vibration and pressure fluctuation resistance.

Industry Expertise: Experienced suppliers give technical assistance to their clients for choosing appropriate flange types between welding neck flanges for pressure applications and threaded flanges for safe installation in hazardous environments.

Strategic Locations: Suppliers maintain warehouses and offices inside Dubai and Abu Dhabi as well as Sharjah and other UAE emirates which allows them to deliver quick service for projects across the UAE.

Flange Distributor in the United Arab Emirates: Ali Yaqoob Trade

Ali Yaqoob a reliable flange distributor, with a series of fittings and accessories to choose from. Their catalog includes blind and socket weld types for standard and specialty industrial applications, with weld neck and slip-on flanges. Ali Yaqoob serves as a one-stop shop for many local businesses because they prioritize product quality, price, and excellent customer service.

Conclusion

Your industrial piping systems require the top UAE flange supplier to ensure safety and keep operations running. With proven market players like Ali Yaqoob among others, businesses are able to get big selection, quality flanges, technical consultancy, as well as quality service, ensuring their projects at the utmost levels of performance and safety. Regardless of whether you require standard or customized flanges, in the region market can meet your requirements and is thus a very suitable destination to source industrial piping components.

0 notes

Text

Hastelloy C276 Round Bar: Key Features, Benefits & Industrial Uses

Hastelloy C276 Round Bar: Key Features, Benefits & Industrial Uses

In this detailed guide, we explore the features, benefits, industrial uses, and chemical profile of Hastelloy C276, including comparisons with equivalent materials and other product forms like Hastelloy C276 flanges and pipe fittings. Book A Consultation Hastelloy C276, a corrosion-resistant superalloy from the nickel-molybdenum-chromium family, is widely trusted in industries that demand long-lasting performance under extreme conditions. Whether in aggressive chemical environments, high-temperature processing systems, or deep-sea exploration, Hastelloy C276 round bars stand as a critical material solution for engineers and project managers. What Is Hastelloy C276? Hastelloy C276 (UNS N10276) is a nickel-molybdenum-chromium alloy with added iron and tungsten. It was designed for severe environments, particularly those involving strong oxidizers, reducing agents, acids, and chlorides.

Key Highlights:Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking Performs well in wet chlorine gas, hypochlorite, and chlorine dioxide Often used in highly corrosive processing conditions Hastelloy C276 Chemical Composition The alloy’s unique strength lies in its precisely balanced chemical composition, providing excellent corrosion resistance.Key Features of Hastelloy C276 Round Bar - Corrosion Resistance: Immune to pitting, stress corrosion, and acid attack (hydrochloric, sulfuric, nitric, phosphoric) - Weldability: Easily welded using GTAW, SMAW, and MIG techniques without the need for post-weld heat treatment - High-Temperature Resistance: Performs well up to 1000°C in oxidizing and reducing environments - Formability: Suitable for machining, forging, and cold/hot forming into custom shapes Product Forms Related to Hastelloy C276 FormStandardsApplicationRound BarASTM B574Shafts, pins, flanges, high-pressure assembliesFlangesASTM B564Leak-proof pipe connections in corrosive systemsPipe FittingsASTM B366Elbows, tees, reducers for chemical pipingSheets/PlatesASTM B575Linings, vessel walls, and marine hardware Industrial Applications of Hastelloy C276 Round Bars Hastelloy C276 is the alloy of choice across many industries due to its outstanding resistance to corrosion and chemical process applications. Industry ApplicationsChemical ProcessingReactors, scrubbers, heat exchangers, mixersOil & GasSubsea valves, manifolds, risers, drill collarsPharmaceuticalsAcidic processing tanks, sterilization componentsPulp & PaperBleaching towers, digesters, chemical recovery systemsWaste TreatmentIncinerators, evaporators, waste processing systemsMarinePump shafts, propeller shafts, deep-sea components Hastelloy C276 vs Equivalent Materials MaterialComparison FactorRemarksAlloy 625Better strength, less acid resistanceUsed in aerospace, marineAlloy C22Higher resistance in oxidizing mediaBetter for nitric acid/chloride mixtures316 StainlessLower cost, inferior resistanceNot suitable for strong acids or high temperaturesMonel 400Good in saltwater, less acid-resistantUsed in marine and oil transport Hastelloy C276 Round Bar: Technical Overview Chart Feature DetailsProductHastelloy C276 Round BarStandardASTM B574Available Sizes6 mm – 200 mm (or customized)LengthUp to 6 meters (custom cut available)FinishBright, Black, Peeled, GroundCertificationMTC EN 10204 3.1, NACE MR0175ApplicationsHigh-pressure components, chemical systems Looking for trusted Hastelloy C276 round bar, flanges, or pipe fittings?- We offer ASTM-certified materials - Custom cut sizes and quick delivery - MTC, test reports, and global shippingContact a trusted Hastelloy supplier in India today to get a competitive quote on your next Hastelloy alloy procurement!Hastelloy C276 round bars are an engineering favorite for critical applications where most alloys fail. With their exceptional chemical resistance, mechanical integrity, and thermal stability, they provide a reliable solution in sectors where performance equals safety.Whether you're constructing chemical reactors, operating in seawater environments, or building high-pressure vessels, choosing Hastelloy C276 means choosing peace of mind and long-term operational reliability. FAQ What is Hastelloy C276 used for? It’s used in industries dealing with highly corrosive chemicals—like chemical processing, pharmaceuticals, waste treatment, and oil & gas—where materials like stainless steel exhibit excellent corrosion resistance against acids. What is the chemical composition of Hastelloy C276? The alloy, composed of nickel, molybdenum, and chromium, exhibits excellent corrosion resistance, particularly against corrosive environments and chemical process applications. Is Hastelloy C276 stronger than stainless steel? Yes, especially in terms of excellent corrosion resistance, thermal stability, and long-term strength in aggressive environments, though it’s costlier than standard stainless steels. What is the ASTM standard for Hastelloy C276 round bar? ASTM B574 is the standard for round bars, rods, and wires made of resistant alloys like nickel-molybdenum-chromium alloys, including Hastelloy C276, known for excellent corrosion resistance. Can Hastelloy C276 be welded easily? Yes, it’s weldable using standard techniques like GTAW (TIG) and SMAW, without requiring post-weld heat treatment. Read the full article

0 notes

Text

Trusted Pressure Safety Valve Manufacturer – Ped-Lock Valve

When it comes to protecting equipment, systems, and personnel from overpressure conditions, having a reliable pressure safety valve (PSV) is not just important—it's critical. Ped-Lock Valve, a leading manufacturer based in India, delivers high-performance pressure relief valves designed to meet the most stringent international safety standards.

What is a Pressure Safety Valve?

A pressure safety valve, also known as a pressure relief valve, is a safety device used in fluid systems to automatically release pressure when it exceeds a preset limit. This prevents equipment failure, potential explosions, and other safety hazards in pipelines, pressure vessels, and industrial processes.

Why Choose Ped-Lock Valve?

With a reputation built on precision engineering and robust design, Ped-Lock Valve has become a trusted name in the industry. Our pressure relief valves are:

Manufactured with corrosion-resistant materials like SS 304, SS 316, brass, and other industrial-grade alloys.

Calibrated for accurate pressure release, ensuring the safety of your systems and personnel.

Tested for leak-proof performance under extreme temperature and pressure conditions.

Available in a wide range of sizes and pressure ratings, with customization options available on request.

Key Features of Ped-Lock Pressure Relief Valves

Set Pressure Range: From 1 bar to 600 bar (customizable)

Connection Types: NPT, BSP, threaded, flanged

Materials: Stainless Steel, Brass, Monel, Hastelloy

Design Compliance: ASME, API, ISO, and other global standards

Applications

Ped-Lock’s pressure relief valves are widely used in:

Oil & Gas

Chemical & Petrochemical Plants

Power Generation

Water Treatment

Pharmaceutical & Food Processing

Instrumentation and Control Systems

A Global Manufacturer with Local Service

As a top pressure safety valve manufacturer in India, Ped-Lock Valve exports to over 30 countries including the Middle East, Africa, Southeast Asia, and Europe. Our technical team supports clients with sizing, selection, and after-sales service, ensuring long-term performance and compliance.

Need a Reliable Pressure Safety Valve Supplier?

Explore our full range and technical specifications online: https://pedlockvalves.com/products/instrument-accessories/pressure-relief-valve/

Contact Us Today: Email: [email protected] Website: www.pedlockvalves.com

0 notes

Text

Reactive Silencers

The silencers designed for use on original and other positive displacement blooms and compressors use reactive silencer technology to reduce the noise produced by the machine. The advantage of this approach is that reactive designs do not use any kind of noise absorption material, which gives the silencers a longer life and eliminates any possibility of compressor production or machinery reduction. This allows effective silencers to be established in the treatment of food application, pharmaceuticals, air handling systems, chemical plants and water where the downstream defusers are a problem with traditional silencers.

Reactive silencer by Anpam Engineering is a high performance sound control solution designed to effectively reduce low-frequency noise in industrial dysfunction and mechanical systems. Exactly engineered and built to survive, it uses reactive acoustic principles to cancel unwanted noise without compromising the airflow or system functionality. Ideal for compressors, blooms and HVAC systems, reactive silencers guarantee calm operations while maintaining peaceful performance and reliability.

Available in different sizes

May be inlet or discharge

Filters can be separate or integral on inlet

Made from a range of materials and specifications

Standard construction

All silencers are made of at least 5 mm of carbon steel internally and externally

Alternative construction

Silencers can also be produced from stainless steels, aluminum or nickel -based alloys such as Hastelloy for very debris applications

Flanges can be British Standard, ANSI, DIN or any customer choice

Exterior shells for high pressure applications can be designed to suit British standards or ASME pressure vessel codes.

Sizable Information:

The nature of the machine, that is, the original blower, the reciprocal compressor, the van pump, etc.

Flowing

At a working temperature

Operation pressure

Machine speed

Lobs, van, number of cylinders per stage, etc.

The nature of the gas (air, steam, other - molecular weight and CP/CV value)

0 notes

Text

Nuts: Types, Characteristics, and Applications

Ananka Group is the best leading high-quality Nuts Manufacturer in India. We have a wide range of Nuts, with ready stock for export and supply. We take orders and manufacture as per the customers’ requirements. We are India’s largest nut manufacturer of bigger diameter Nuts and Bolts in high tensile and stainless steel grades, as well as fasteners, for major contractors and consultants working on projects in the power, renewable energy, wind, and infrastructure sectors in India. We also specialize in stainless steel Nuts, Bolts, and other fasteners.

1. Hex Nuts

Hex Nuts are six-sided fasteners widely used in construction, automotive, and engineering industries. We offer high-quality Hex Nuts in Stainless Steel, High Tensile, Monel, Inconel, Hastelloy, and more. Ready stock available for export and supply.

Uses: Hex Nuts are widely utilized across industries like construction, automotive, and engineering. They are essential for fastening bolts and securing components in applications such as machinery, infrastructure, and heavy-duty projects.

Characteristics: Hex Nuts come in various sizes (M6 to M42), materials (including High Tensile, Stainless Steel, Inconel, Hastelloy, and others), and coatings (like PTFE, Zinc, and Nickel) to suit diverse industrial needs.

2. Hex Jam Nuts

Hex Jam Nuts are thin, low-profile nuts used for locking standard nuts in place. Common in construction projects like bridges, docks, and highways, they come in various sizes, materials, and grades.

Uses: Hex Jam Nuts are primarily used to prevent loosening in machinery, construction, and automotive applications. They are often paired with standard nuts for added locking strength.

Characteristics: Available in sizes from M12 to M100, Hex Jam Nuts come in materials like Stainless Steel, High Tensile, and Inconel, with coatings including PTFE and Zinc for enhanced durability.

3. Hex Coupling Nuts

Hex Coupling Nuts are long, hexagonal nuts used to connect two threaded rods or pipes, ensuring extended length and secure alignment in structural applications.

Uses: Hex Coupling Nuts are designed to extend the length of bolts or rods, providing secure connections in structural frameworks, piping systems, and electrical installations

Characteristics: These nuts are available in sizes from M4 to M100 and made from materials like Stainless Steel, Inconel, and Carbon Steel. They come in various finishes, such as PTFE coating and Zinc plating, for added protection

4. Hex Flange Nuts

Hex Flange Nuts have a wide, flanged base that provides a larger bearing surface, ensuring a secure fit and reducing the chance of damage to the material being fastened.

Uses: Hex Flange Nuts are commonly used in heavy-duty applications where secure fastening is required, such as in machinery, automotive systems, and structural assemblies.

Characteristics: Hex Flange Nuts have a built-in flange that evenly distributes pressure and enhances stability, making them perfect for high-vibration and heavy-duty applications.

5. Slotted Nuts

Slotted Nuts have slots cut into the top, allowing them to be secured with a cotter pin for added safety in heavy-duty applications.

Uses: Slotted Nuts are ideal for securing components in machinery and structural projects, ensuring stability in applications where locking or adjustments are necessary, such as in construction and industrial machinery.

Characteristics: Featuring a slotted top, these nuts allow for secure fastening with a cotter pin, enhancing safety in high-demand environments.

Also we are India's largest Fasteners Suppliers. We provide fastener grades that satisfy all international and national specifications. We also specialise in stainless steel Hex bolts, nuts, Stud bolts, and other fasteners.

#Nuts Manufacturer in India#Nuts Manufacturer#Nuts Supplier in India#Fasteners Manufacturer in India

0 notes

Text

How ASTM A105 Flange Compares with Other Flange Standards

You must know the materials and standards before you pick the suitable flange for your piping system. People rely extensively on ASTM A105 Flange as their preferred choice. Various industries depend on this material for their carbon steel piping systems because it provides excellent strength and performance. Other industry standards exist beyond their use. Examining different flange options against each other allows you to select the right one for your particular needs. This blog shows how ASTM A105 performs in comparison to other flange varieties used across different industries.

Strength and Application Range

Manufacturers produce the ASTM A105 Flange from carbon steel material through forging. This material serves in high-pressure systems under normal and heated environments. This flange type provides excellent service in oil and gas facilities chemical plants and water systems. The material enables the product to withstand intense pressure and high temperatures.

ASTM A105 performs better at both strength and temperature resistance than steel and aluminum options produced by Mild Steel Flanges manufacturers and Aluminium Fittings manufacturers. Companies preferring strong reliable performance for their industrial applications find A105 the right material choice.

Cost and Availability

The main benefit of ASTM A105 is its affordable pricing. Its high performance level makes it a popular selection across various industries because it provides a good deal. Many reliable flange producers in India keep sufficient A105 product stock available.

Flanges created using Inconel and Hastelloy need higher costs than those made with ASTM A105 material. The manufacturer companies of Inconel Flanges and Hastelloy Flanges specialize in creating these materials for extreme chemical and high-temperature applications. At standard applications the price of A105 gives better performance value compared to other materials.

Corrosion Resistance and Suitability

ASTM A105 serves well in various applications but needs additional measures to prevent corrosion formations. The material needs added protection through layers or external systems to work in wet or chemical-intensive surroundings.

SS Flanges manufacturers and their counterparts provide flanges that naturally withstand corrosion better than standard products. These types of flanges handle environments involving sea water, chemicals and heavy moisture. The selection of suitable material depends on the exact place where the flange will operate.

Compatibility with Other Components

ASTM A105 Flange proves suitable for many different applications. The product matches properly with carbon steel pipeline and fitting components. Leading Carbon Steel Fittings and Flanges producers make product matches for A105 flange applications. The flange connects easily to fittings from ASTM A234 WPB and ASTM A420 WPL6 because it works well with both specifications.

Buttweld fittings producers in India regularly hold stock of suitable materials provided by Carbon Steel Forged Fittings manufacturers. Having uniform components eases purchasing steps which produces reliable performance across the entire pipeline.

Conclusion

ASTM A105 Flange provides users with reliable durability at reasonable costs and easy purchase options. Even though it cannot match corrosion-resistant materials it works well in normal usage across industries. Ramesh Group provides customers access to different types of flange products and pipe parts. Our company supplies dependable materials in every product category including Duplex Fittings stainless steel and Alloy Steel Flanges as well as various IBR fittings systems to customers.

0 notes

Text

What Makes ICCL DBB Valves Ideal for Oil & Gas Operations?

In the world of oil and gas, ensuring system integrity, safety, and effective shutdown control is absolutely critical. The conditions can be tough, the pressures can be intense, and the stakes are incredibly high. That’s why Double Block and Bleed (DBB) valves have become a vital component in today’s pipeline and process designs.

When engineers are on the hunt for a reliable DBB valve, they often turn to ICCL (Industrial Component Corporation Limited). Known for their engineering prowess and dependability, ICCL produces high-performance DBB valves that are specifically crafted to meet the rigorous standards of the oil and gas industry.

Let’s dive into what makes ICCL DBB valves the go-to option for oil and gas projects across upstream, midstream, and downstream operations.

What Are Double Blocks and Bleed Valves?

A Double Block and Bleed (DBB) valve is a streamlined valve system that combines two isolation valves and a bleed valve into one compact assembly. This innovative design offers:

- Primary and secondary isolation from process media

- The ability to bleed or drain the cavity between the two valves to confirm isolation

- Enhanced safety during maintenance and testing

- A reduction in weight, space, and potential leak paths

DBB valves are typically utilized in:

- Pipeline instrumentation

- Pressure relief systems

- Metering skids

- Wellhead control panels

- Separator units

Why ICCL DBB Valves Excel in Oil & Gas Applications

ICCL’s DBB valves are specifically engineered for critical operations in the oil and gas sector. Here’s what sets them apart:

1. Sturdy, Compact Design

ICCL’s DBB valves merge two independent ball or needle valves with a bleed valve into a single forged or barstock body. This design minimizes the need for multiple fittings, cuts down on leak paths, and ensures a smaller installation footprint — which is essential for offshore rigs and tight metering stations.

Design options include:

- Ball-Ball-Bleed

- Needle-Needle-Bleed

- Ball-Needle-Bleed (hybrid configuration)

Each valve design undergoes rigorous testing to meet ANSI, API, and ASME standards, ensuring reliability even in high-pressure situations.

Built for High-Pressure and Sour Service

ICCL designs its DBB valves to handle extreme pressures, reaching up to 10,000 psi, and the corrosive substances found in crude oil, natural gas, and chemical injection systems.

These valves are crafted to meet the following standards:

NACE MR0175 for sour gas environments

API 6A / API 6D for petroleum production and pipeline systems

ASME B16.34 for valve integrity and pressure containment

3. Top-Quality Materials for Tough Conditions

In the oil and gas sector, choosing the right materials can be the key to safety or disaster. ICCL only uses certified and traceable materials that are customized to meet client needs.

Material choices include:

316 / 316L Stainless Steel

Duplex / Super Duplex

Inconel, Monel, Hastelloy (for areas with high corrosion)

Carbon Steel with zinc phosphate or Xylan coating

Every valve is accompanied by complete Mill Test Certificates (MTCs) and traceability documentation to ensure QA compliance.

4. Zero Leakage, Guaranteed

Preventing leaks is absolutely crucial in the oil and gas industry, especially in hazardous locations. ICCL DBB valves are subjected to 100% pressure testing, which includes:

Hydrostatic shell & seat testing

Pneumatic seat leak testing

Helium leak detection (available upon request)

ICCL’s metal-to-metal and soft seat options guarantee a bubble-tight shutoff. Plus, valves can be fire-safe tested according to API 607 if needed.

Versatile End Connections and Configurations

ICCL provides DBB valves in a variety of configurations to fit your project’s piping and instrumentation layouts:

End Connections: Flanged (ANSI/ASME/RTJ), NPT, BSP, Butt Weld, Socket Weld

Mounting: Panel-mounted, bracketed, or block-mounted

Optional Add-ons: Drain ports, test points, vent valves, lockable handles, anti-tamper caps

This versatility makes ICCL your go-to solution provider for oil & gas EPCs and OEMs.

Custom-Made for Complex Projects

A deepwater subsea skid

A refinery fuel line

Or an LNG export terminal

ICCL is equipped to design, build, and deliver DBB valves that fit seamlessly into your system — guaranteeing performance, safety, and easy maintenance.

Global Delivery and Technical Support

With an expanding footprint in the Middle East, Africa, Southeast Asia, and North America, ICCL caters to oil and gas clients around the globe. The company prioritizes timely deliveries, precise documentation, and attentive after-sales support.

Documentation includes:

QAP, ITP, MTCs, FAT reports

NDT reports (DPT, UT, RT)

Hydro test and calibration certificates

ICCL DBB Valves — Built for Energy Sector Demands

The oil and gas sector requires precision, safety, and unwavering performance — and ICCL rises to the occasion. With a solid history of producing high-integrity DBB valves, ICCL has established itself as a trusted partner for critical isolation in some of the world’s most intricate energy projects.

From offshore platforms to onshore pipelines, ICCL DBB valves are designed to excel, built to endure, and relied upon globally.

0 notes

Text

Hastelloy G3 Flanges Supplier | Alloy G3 | Renine Metalloys

Hastelloy G3 Flanges Supplier | Alloy G3 | Renine Metalloys

Renine Metalloys is a trusted supplier and exporter of Hastelloy G3 Flanges, offering high-quality flange solutions engineered for exceptional corrosion resistance and long-lasting performance in aggressive chemical environments. Hastelloy G3, also known as Alloy G3 and designated as UNS N06985, is a nickel-based alloy that provides excellent resistance to oxidizing agents and acidic media, especially in environments containing phosphoric, nitric, and sulfuric acids.

Our Hastelloy G3 flanges are manufactured using premium-grade materials and are available in a wide range of types including weld neck, slip-on, blind, socket weld, lap joint, threaded, and custom-designed flanges. These flanges meet international standards such as ASTM B462 and ASME B16.5.

Product Features:

Material: Hastelloy G3 / Alloy G3 / UNS N06985 / W.Nr. 2.4619

Standards: ASTM B462, ASME B16.5, ANSI, DIN, BS

Types: Weld Neck, Slip-On, Blind, Socket Weld, Lap Joint, Threaded, Custom Flanges

Excellent resistance to oxidizing acids and chloride-induced stress corrosion

Good fabricability and weldability

Stable performance in both oxidizing and reducing environments

Applications:

Chemical and petrochemical processing

Flue gas scrubbers and pollution control systems

Pulp and paper industry

Waste treatment plants

Marine and offshore applications

Renine Metalloys delivers Hastelloy G3 flanges with precision dimensions, robust construction, and excellent surface finish. With strict quality control and global shipping capabilities, we serve clients across industries with reliable and corrosion-resistant flange solutions.

0 notes

Text

Complete Fasteners Product List — Types & Applications

Fasteners are the mechanical backbone of countless structures and systems, ranging from industrial machines to home appliances. They serve as crucial elements engineered to firmly join two or more components in an assembly. At Ananka Fasteners, we specialize in manufacturing, supplying, and exporting a wide array of high-performance fasteners to meet diverse industrial requirements across the globe.

Below is a detailed list of fastener products we offer:

1. Coated Fasteners

Coated fasteners are surface-treated fasteners designed to resist corrosion, enhance durability, and improve performance under extreme conditions.

Types of Coatings:

Zinc Coating (Electroplated, Hot Dip Galvanized)

PTFE Coating (Xylan, Teflon)

Cadmium & Nickel Coating

Black Oxide Coating

Applications:

Marine structures

Offshore platforms

Petrochemical industries

Construction projects are exposed to weathering

2. SMO 254 Fasteners

SMO 254 is a high-alloy austenitic stainless steel known for excellent corrosion resistance and strength, especially in chloride-bearing environments.

Available Fastener Types:

SMO 254 Bolts

SMO 254 Nuts

SMO 254 Washers

SMO 254 Screws

Applications:

Desalination plants

Pulp and paper industries

Seawater cooling systems

Chemical processing industries

3. Bolt Fasteners

Bolts are externally threaded fasteners designed to be used with nuts or threaded holes to securely join multiple components.

Common Bolt Types:

Hex Bolts

Heavy Hex Bolts

U Bolts

Eye Bolts

Carriage Bolts

Flange Bolts

Applications:

Structural steel fabrication

Equipment and machinery

Automotive and heavy-duty applications

Aerospace and defense

4. Screw Fasteners

Screws are threaded fasteners that create their mating thread during installation, often used without a nut.

Popular Screw Types:

Wood Screws

Machine Screws

Self-Tapping Screws

Socket Head Cap Screws

Sheet Metal Screws

Applications:

Electronics and electrical panels

Wood and furniture work

HVAC and appliance assembly

Construction and industrial machinery

5. Washers Fasteners

Washers are disk-shaped components used under nuts or bolt heads to distribute loads and prevent loosening.

Types of Washers:

Plain Washers

Spring Washers

Lock Washers

Conical and Dome Washers

Applications:

Vibration-prone assemblies

Automotive and aerospace

Electrical and electronics

Construction and pipelines

6. Stud Bolts Fasteners

Stud bolts are fully threaded rods paired with nuts on both ends, specifically designed for use in high-pressure and high-temperature applications.

Types of Stud Bolts:

Full Threaded Studs

Tap-End Studs

Double-End Studs

Continuous Thread Studs

Applications:

Flanged pipe connections

Oil & gas industry

Chemical and petrochemical equipment

Pressure vessels and reactors

7. Custom Fasteners

Custom fasteners are specially manufactured to meet unique project requirements based on dimensions, material, and finish.

Options Available:

Unique threading and shapes

Non-standard lengths or heads

Special alloys (Titanium, Inconel, Monel, etc.)

OEM & drawing-based production

8. Nuts Fasteners

Nuts are internally threaded fasteners paired with bolts or screws to secure components.

Common Nut Types:

Hex Nuts

Lock Nuts

Wing Nuts

Cap Nuts

Flange Nuts

Square Nuts

Applications:

General engineering

Automobile assembly

Power generation equipment

Home improvement and furniture

Why Choose Ananka Group?

Wide Material Range – From carbon steel to exotic alloys like Inconel, Monel, Hastelloy, and SMO 254

Worldwide Presence – Catering to industries throughout the USA, Europe, the Middle East, and Asia

Custom Solutions – Precision manufacturing based on client drawings or specifications

Compliance – All fasteners are manufactured to ASTM, DIN, ISO, and other global standards

Conclusion

Whether you're building infrastructure, assembling machinery, or fabricating precision equipment, choosing the right fastener is critical. The extensive range of fasteners we offer at Ananka Fasteners ensures reliable performance, safety, and longevity in every application. From coated fasteners for enhanced corrosion resistance to custom-engineered solutions for niche applications, our products meet the highest quality standards.

Frequently Asked Questions (FAQ)

Q1. What material types do you provide for these fasteners?We offer fasteners in stainless steel, carbon steel, alloy steel, brass, copper, Inconel, Monel, Hastelloy, SMO 254, titanium, and more.

Q2. Do you provide testing certificates?Yes, we provide Mill Test Certificates (MTC), third-party inspection reports, and compliance certificates as required.

Q3. Can fasteners be customized? Absolutely. We specialize in custom fastener production based on your drawing, specifications, and application.

Q4. What industries do you serve?We serve industries such as oil & gas, petrochemical, marine, construction, automotive, aerospace, and power generation.

Q5. Do you export globally?Yes, Ananka Group exports fasteners globally, with a strong presence in the USA, UK, Germany, UAE, Singapore, and more.

#Fasteners#IndustrialFasteners#BoltManufacturer#StudBolts#CustomFasteners#WasherManufacturer#QualityMatters#TrustedSupplier#ExportQuality#ManufacturingExcellence#EngineeringSolutions#IndustrialSupply#Ananka#AnankaFasteners#manufacturer#supplier#tumblr#blog tumblr#tumblr blog

0 notes

Text

Long Radius 3D Bend, ASME B16.9 Long Radius 3D Bend Manufacturer

Product Description: Long Radius 3D Pipe Bend – ASME B16.9

Product Name: Long Radius 3D Pipe Bend Standard: ASME B16.9 / MSS-SP-75 Bend Radius: 3D (Centerline Radius = 3 × Pipe Diameter) Bend Type: Long Radius (Smooth flow curve) Bend Angle Options: 15°, 30°, 45°, 60°, 90°, 180°, or custom angle Manufacturing Method: Hot Induction Bending / Cold Bending / Mandrel Bending

Material Grades Available:

Carbon Steel: ASTM A234 WPB / WPC

Stainless Steel: ASTM A403 WP304 / 316 / 304L / 316L

Alloy Steel: ASTM A234 WP11 / WP22 / WP5

Duplex / Super Duplex: UNS S31803, S32750

Nickel Alloys: Inconel 625 / 825, Hastelloy, Monel

Other Materials: Aluminum, Copper-Nickel (90/10, 70/30)

Size Range:

Diameter: ½” to 48” (DN15 to DN1200)

Wall Thickness: SCH 10 to SCH XXS and custom

Radius Options: 1D, 1.5D, 3D, 5D, 6D, or per customer requirement

End Types:

Beveled Ends (for buttweld)

Plain Ends

Flanged Ends (on request)

Applications:

Oil & Gas Pipelines

Petrochemical Plants

Power Generation

Offshore & Marine Systems

Process Piping

Refineries and Chemical Processing Plants

Key Features:

Smooth inner flow path to reduce turbulence and pressure drop

Suitable for high-pressure, high-temperature environments

Durable and corrosion-resistant (depending on material)

Manufactured with precision bend radius and wall thickness control

Custom bends available for special projects

Testing & Certification:

100% Radiographic or Ultrasonic Testing (on request)

Hydrostatic Testing

Dimensional Inspection

PMI (Positive Material Identification)

MTC (Mill Test Certificate) – EN 10204 3.1 / 3.2

Third-party inspection available (TÜV, SGS, BV)

Packaging:

Plastic caps on ends

Wrapped with moisture-proof material

Wooden crates, pallets, or steel frames for export

0 notes

Text

Stainless Steel 321 Flanges Suppliers

Introduction:-

Stainless Steel 321 flanges are widely used in high-temperature and corrosion-resistant applications due to their excellent mechanical properties and oxidation resistance. Manufactured from ASTM A182 F321 stainless steel, these flanges contain titanium, which stabilizes the alloy and prevents carbide precipitation, making them ideal for applications requiring resistance to intergranular corrosion.

Stainless Steel 321 flanges are essential components in industrial piping systems, known for their excellent high-temperature strength, oxidation resistance, and corrosion resistance. These flanges are manufactured using ASTM A182 F321 stainless steel, a titanium-stabilized alloy that prevents carbide precipitation and enhances intergranular corrosion resistance, making them ideal for applications in extreme environments.

Product Overview:-

We are a leading manufacturer of stainless steel flanges in various qualities, scales, shapes and standards. We specialize in manufacturing 321 stainless steel flanges with a yield strength of 320 ksi and a tensile strength of over 75 ksi. The nominal inside diameter size of our flanges ranges from 1/2 inch to 48 inches. Additionally, our company manufactures his 321 stainless steel blind flanges. This is used to close the flow at the end of the pipe, making cleaning and maintenance easier.

We manufacture slip-on flanges from 321 stainless steel that are used in low pressure environments where the risk of leakage is minimized. We offer a selection of affordable ASTM A182 F321 flanges that can be customized to meet your specific requirements. We also offer affordable and high quality material, No. 1.4541 Orifice Flange, and other flanges, which can be delivered to your doorstep.

Specifications:-

Stainless Steel 321 FlangesTechnique Use In Forging

Forged, Heat treated,& machined Flanges Top 4 TypesScrewed / Forged/ Threaded / PlateMostly Use TypesLap Joint, Threaded, Weld Neck, Blind, Slip-On, Socket-WeldIndustries UseWaterworks & Municipal Pipe Systems Nuclear Power And The Power Plants Industry Food Processing & Manufacturing High TemperatureAbove 400°C (750°F) And Above 200°C (400°F) For 150LBLow TemperatureAbove -29 °C (−20°F)JIS Standards5K To 63KManufacturing Flange FaceLap-Joint Face, Large Tongue & Groove And Small Tongue Groove, RTJ, FF, Raised Face, Large Male-Female And Small Male-FemaleSize1/2 Inch To 48 InchWe Manufacturer This MaterialsCarbon Steel, Inconel, Hastelloy, Copper Nickel, Stainless Steel, Cast Iron, Duplex Steel & Super Duplex Steel, Wrought Iron, Alloy Steel, Mild Steel.Thickness SizeNormal Pipe Size ≤ 18Bore DiameterNPS ≤ 10RPF India Manufacturer Below StandardsUNI, EN-1092, ANSI/ASME B16.5, B16.47 Series A & B, BS1560-3.1, API7S-15, ASME B16.48, AWWA C207, IS 2062, EN1092, API7S-43, MSS S44, ISO70051, ASME B16.36, DIN, API, ISO, API605, BS4504Pressure Ratings150 To 2500

Benefits:-

Our 321 SS weld neck flange can withstand hazardous conditions such as high temperatures and large pressure fluctuations. We also manufacture large diameter stainless steel 321 flanges, which are metal rings used to connect valves, pipes, and other equipment to pipelines. Here, you can get different types of flanges all from one source. Our UNS S32100 socket weld flanges are made from Alloy 321, a titanium-stabilized true stainless steel with excellent resistance to intergranular corrosion.

Conclusions:-

Manufacturers employ advanced forging, machining, and heat treatment techniques to ensure precision, durability, and compliance with international standards such as ASME B16.5, ANSI, and DIN. SS 321 flanges are widely used in industries like petrochemicals, aerospace, power generation, and marine applications, where reliable performance under high temperatures and aggressive conditions is crucial. Leading manufacturers focus on quality assurance through rigorous testing methods, including ultrasonic testing, hydrostatic testing, and PMI (Positive Material Identification), to deliver high-performance flanges for critical industrial applications>

Email Id:[email protected]

Contact Number:-88797-09191

0 notes

Text

Hastelloy Flanges Manufacturer in India

Rishabh Steel Industries is one of the leading Hastelloy Flanges Manufacturer in Mumbai, India. We are an ISO 9001:2008 certified company with an existence in the metal market. Hastelloy C276 Flanges products are designed and developed per international and national quality standards.

We offer the best possible prices for Hastelloy B3 Flanges to all our customers, with a stock of standard sizes, materials, and types available for immediate delivery worldwide. Our available qualitative range of Hastelloy Flanges is exclusively designed for several piping applications.

Rishabh Steel Industries is the top manufacturer of C276 Hastelloy Flanges Our company offers Hastelloy Flanges manufactured under the strict supervision of professionals per national and international standards. We manufacture Hastelloy Flanges Manufacturer in India Cupro-Nickel Flanges, and SMO 254 Flanges at our units using optimum grade materials and with the help of our best state of technology. We design high-quality Hastelloy B3 Flanges in various thicknesses and diameters. We mostly use very high-quality raw materials for manufacturing these Flanges.

We are a well known manufacturer, supplier & exporter of high quality Hastelloy flanges in Mumbai, India. These Hastelloy flanges are manufactured by national & international standards. These flanges are widely used in various application industry such as petroleum, chemical, construction, engineering, gas and shipbuilding industries and many more. We offer a comprehensive range of all types of Hastelloy flanges grades including slip on flanges, socket weld, blind, lapped, screwed, weld neck, reducing, spectacle, slip on boss, plate, plate blank, screwed boss, Hastelloy c276, c22, b2 flanges etc.

Hastelloy Flanges Manufacturer in India ASTM b366 Hastelloy Flanges, Manufacturer of Hastelloy Flanges in India, Hastelloy C276 Flanges, Hastelloy C22 Flanges, Hastelloy B2 Flanges, Hastelloy X Flanges Manufacturer in India, Hastelloy UNS N06022 Flanges, Hastelloy C22 Flanges, ASTM B366, ASTM SB 366, ASTM B564, ASME SB564 Hastelloy Flanges, Hastelloy UNS N06022 Flanges, UNS N10276 Hastelloy C276 Flanges, Hastelloy C276 Flanges, Hastelloy C276, C22, B2 Fitting, ANSI/ASME B16.9, B16.28, MSS-SP-43 Hastelloy Flanges, Hastelloy Seamless/Seam Welded Flanges, Hastelloy Fabricated Flanges Manufacturers in India.

#hastelloyflangesmanufacturerinindia#hastelloyflanges#manufacturerinindia#rishabhsteelindustries#hastelloy#flanges#manufacturer#in#india

0 notes

Text

Supplier of Industrial Flanges in Uttar Pradesh

Keshar Bhawani Metal & Tubes Pvt. Ltd. is a leading Manufacturer, Stockiest, and Supplier of Industrial Flanges in Uttar Pradesh, India.

We are Based in Ahmedabad, Gujarat, India.

We offer a wide range of industrial flanges that cater to various industries with high precision and durability.

Our flanges are designed to meet the highest quality standards and are used in pipelines, machinery, and equipment, providing excellent sealing and connection solutions.

Specifications:

Specifications: ASTM A105 / ASME SA105, A105N Dimensions: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. Size: 1/2″ to 48″ Material Forms: Stainless Steel, Carbon Steel, Alloy Steel, Duplex & Super Duplex Steel, Titanium, Hastelloy, High Nickel Alloy, etc. Equipment: Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc. Coating: Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Flanges

Features of Our Flanges:

Durable Construction: Our flanges are made from high-strength materials, ensuring long-lasting performance under challenging conditions.

Corrosion Resistance: With superior corrosion-resistant finishes, our flanges offer protection against harsh environmental factors.

Precision Engineering: Each flange is manufactured with precision, ensuring a perfect fit and optimal performance.

Leak-Proof: Our flanges are designed to provide tight, leak-proof seals, enhancing the safety and efficiency of systems.

Cost-Effective: We offer competitive prices without compromising on quality, ensuring that you receive the best value for your investment.

FAQs:

What are industrial flanges used for? Industrial flanges are used to connect pipes, valves, pumps, and other equipment in a pipeline system. They provide a reliable, secure, and leak-proof connection.

Do you provide custom flanges? Yes, we provide customized flanges tailored to your specific requirements, including size, material, and pressure rating.

How can I order flanges from Keshar Bhawani Metal & Tubes Pvt. Ltd.? You can place an order by contacting us directly through our website or customer service team. We will guide you through the order process and ensure prompt delivery.

Keshar Bhawani Metal & Tubes Pvt. Ltd. is a leading Manufacturer, Stockiest and Supplier of Industrial Flanges in Uttar Pradesh, India including locations Kanpur, Lucknow, Ghaziabad, Agra, Meerut, Varanasi, Prayagraj, Bareilly, Aligarh, Moradabad, Saharanpur, Gorakhpur, Noida, Firozabad, Jhansi, Muzaffarnagar, Mathura-Vrindavan, Ayodhya, Rampur, Shahjahanpur, Farrukhabad-Fatehgarh, Budaun, Maunath Bhanjan, Hapur, Etawah, Mirzapur-Vindhyachal, Bulandshahr, Sambhal, Amroha, Hardoi, Fatehpur, Raebareli, Orai, Sitapur, Bahraich, Modinagar, Unnao, Jaunpur, Lakhimpur, Hathras, Banda, Pilibhit, Barabanki, Khurja, Gonda, Mainpuri, Lalitpur, Etah, Deoria, Ghazipur, Sultanpur, Azamgarh, Bijnor, Sahaswan, Basti, Chandausi, Akbarpur, Ballia, Tanda, Greater Noida, Shikohabad, Shamli, Awagarh, Kasganj.

Contact us today for more information or to request a quote.

#india#ahmedabad#manufacturer#gujarat#stockiest#Uttar Pradesh#Kanpur#Lucknow#Ghaziabad#Agra#Meerut#Varanasi#Prayagraj#Bareilly#Aligarh#Moradabad#Saharanpur#Gorakhpur#Noida#Firozabad#Jhansi#Muzaffarnagar#Mathura-Vrindavan#Ayodhya#Rampur#Shahjahanpur#Farrukhabad-Fatehgarh#Budaun#Maunath Bhanjan#Hapur

0 notes