#Linear Static Stress Analysis

Explore tagged Tumblr posts

Text

How SOLIDWORKS Simulation Saves Time and Money in Product Development

In today’s competitive market, speed and efficiency in product development are more critical than ever. Traditional design processes involving physical prototypes and repeated testing can drain both time and resources. This is where SOLIDWORKS Simulation comes into play — offering a smarter, faster, and more cost-effective approach to engineering design validation.

At Tech Savvy, we help businesses harness the power of SOLIDWORKS Simulation Packages to streamline development, improve product reliability, and significantly reduce costs.

What is SOLIDWORKS Simulation?

SOLIDWORKS Simulation is an integrated analysis toolset within the SOLIDWORKS suite that enables engineers to virtually test and validate product designs under real-world conditions. It allows for structural, thermal, motion, and fluid dynamics simulations—all before building a physical prototype.

Whether you’re designing a consumer product or a complex mechanical component, SOLIDWORKS Simulation Packages offer solutions to verify performance, strength, durability, and more.

How It Saves Time

1. Early Design Validation

With SOLIDWORKS Simulation, you can test your design virtually from the earliest stages of development. This reduces the number of design iterations and helps identify potential issues before they become costly problems.

2. Faster Design Decisions

Real-time simulation feedback allows engineers to make quick, informed design changes. Instead of waiting for physical prototypes, teams can evaluate performance, stress points, and failure risks immediately.

3. Eliminates Delays in Prototyping

Building physical prototypes takes time—sometimes weeks or months. Virtual testing with SOLIDWORKS Simulation Packages significantly reduces or even eliminates the need for multiple prototypes.

How It Saves Money

1. Reduced Prototyping Costs

Each prototype built and tested adds to your project’s cost. By reducing the number of physical models required, SOLIDWORKS Simulation dramatically cuts expenses associated with materials, labor, and testing equipment.

2. Minimized Rework and Wastage

Simulation helps ensure that the first manufactured product is right. This reduces rework, scrap, and downtime, which directly impacts your bottom line.

3. Optimized Material Usage

SOLIDWORKS Simulation allows engineers to analyze and optimize material distribution, ensuring strength without overdesign. This leads to material cost savings and more sustainable designs.

Real-World Application: A Quick Example

A manufacturing company using SOLIDWORKS Simulation Packages for structural analysis was able to reduce their prototype count by 60% and cut their product development cycle in half. They also reported material cost savings of 15% by optimizing part geometry based on simulation results.

Choosing the Right SOLIDWORKS Simulation Package

Tech Savvy offers a range of SOLIDWORKS Simulation Packages tailored to different needs:

Simulation Standard – Ideal for static linear analysis and motion studies.

Simulation Professional – Includes frequency, buckling, thermal, and fatigue analysis.

Simulation Premium – Adds nonlinear, dynamic, and advanced composite material capabilities.

We help you choose the right package based on your product complexity, budget, and performance requirements.

Why Choose Tech Savvy?

As an authorized SOLIDWORKS reseller and simulation expert, Tech Savvy provides:

Genuine SOLIDWORKS licenses

Expert implementation and consultation

Customized training and ongoing technical support

We partner with you to ensure your team gets the most out of every simulation tool, saving both time and money in the long run.

Final Thoughts

Incorporating SOLIDWORKS Simulation Packages into your product development process is no longer optional—it's a competitive necessity. By reducing design cycles, limiting physical testing, and optimizing performance early, simulation helps you bring better products to market faster and at lower cost.

Ready to accelerate your product development journey? Contact Tech Savvy today to explore the right SOLIDWORKS Simulation Package for your business.

0 notes

Text

Servotech FEA Services for Smarter Engineering

In today’s competitive engineering landscape, staying ahead means designing smarter, safer, and more efficient products—faster than ever before. Servotech, a leader in simulation and digital engineering, delivers top-tier Finite Element Analysis (FEA) services to empower engineers, manufacturers, and innovators to make better design decisions early in the product development cycle. With cutting-edge tools and a deep understanding of structural mechanics, Servotech is revolutionizing how companies approach complex engineering challenges.

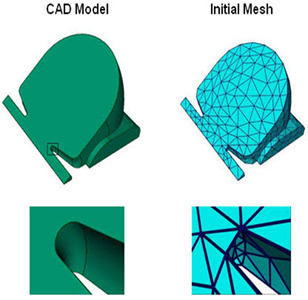

What is FEA and Why It Matters

Finite Element Analysis (FEA) is a computer-based simulation technique used to predict how products will react to real-world forces like heat, vibration, stress, and motion. By creating a virtual model and breaking it down into small finite elements, engineers can evaluate structural performance and identify weak points without the cost or time of building physical prototypes.

FEA plays a critical role in industries such as:

Automotive and aerospace

Electronics and consumer products

Energy and utilities

Heavy machinery and industrial equipment

Biomedical and healthcare devices

For companies seeking reliability, safety, and regulatory compliance, FEA is not just a tool—it’s an essential part of modern engineering.

Why Choose Servotech for FEA?

Servotech brings more than just simulation software to the table. Their FEA services combine technical precision, industry experience, and engineering intelligence to deliver results that matter.

1. Expertise Across Multiple Domains

Servotech’s team of certified FEA engineers have experience across mechanical, thermal, structural, and dynamic analysis. Whether it's crash simulation for an automobile or thermal stress in electronics, Servotech delivers multi-physics solutions that integrate seamlessly into your workflow.

2. Customized Simulation Solutions

No two projects are the same. Servotech tailors its FEA services to meet the unique demands of your product, industry, and design constraints. From linear static analysis to non-linear and dynamic simulations, the team adapts the modeling techniques and software tools to provide actionable insights specific to your needs.

3. Advanced Software Capabilities

Servotech utilizes industry-standard FEA software tools such as:

ANSYS

Abaqus

HyperMesh

SolidWorks Simulation

COMSOL Multiphysics

These tools allow them to offer high-fidelity simulation, mesh optimization, and fast computation, resulting in more accurate and reliable predictions.

4. Focus on Design Optimization

FEA isn’t just about identifying problems—it’s about solving them. Servotech’s engineers work collaboratively with your design team to recommend geometry improvements, material selection, and load optimization strategies that enhance performance while minimizing cost and weight.

5. Accelerated Time to Market

By integrating FEA early in the product development lifecycle, Servotech helps clients reduce prototyping cycles, prevent late-stage design changes, and accelerate time to market. This early detection of issues leads to significant cost savings and improved product reliability.

Key FEA Services Offered by Servotech

Structural Analysis

This includes static, dynamic, and non-linear stress analysis for components and assemblies. Servotech helps clients determine deformation, fatigue, failure risk, and load distribution across materials and structures.

Thermal Analysis

Heat management is crucial, especially in electronics, automotive, and aerospace applications. Servotech performs steady-state and transient thermal analysis to understand how temperature affects structural integrity and material behavior.

Modal and Vibration Analysis

Servotech simulates natural frequencies, mode shapes, and harmonic response to evaluate how components behave under dynamic loading. This is vital for rotating machinery, engines, and structural components prone to vibration.

Buckling and Stability

For slender structures under compressive loads, Servotech conducts buckling analysis to determine critical loads and ensure structural stability in columns, panels, and frameworks.

Fatigue and Lifecycle Prediction

Using industry-standard fatigue models, Servotech estimates product lifespan under cyclic loading and recommends design modifications to enhance durability and longevity.

Multi-Physics Simulations

Combining FEA with other domains like CFD (Computational Fluid Dynamics) and electromagnetics, Servotech performs multi-physics analysis for advanced applications such as battery systems, thermal-fluid systems, and smart electronics.

Industries Benefiting from Servotech’s FEA Expertise

Automotive

From chassis design to crashworthiness analysis, Servotech assists automotive OEMs and suppliers in designing vehicles that are lighter, safer, and more efficient.

Aerospace

In a field where weight optimization and safety are paramount, Servotech offers structural, thermal, and vibration analysis for aircraft components and space systems.

Consumer Electronics

With the miniaturization of electronics, thermal and structural integrity becomes critical. Servotech helps design heat-resistant and robust enclosures, PCBs, and connectors.

Medical Devices

For surgical tools, implants, and diagnostic equipment, Servotech ensures mechanical safety and regulatory compliance through simulation-backed development.

Energy and Utilities

Whether it's stress testing of wind turbine blades or thermal analysis of power distribution systems, Servotech supports the renewable and conventional energy sectors in designing more reliable systems.

The Servotech Advantage: Smarter Engineering, Delivered

Choosing Servotech means you’re not just outsourcing a simulation—you’re gaining a partner who understands the end goal: better performance, lower costs, and faster innovation. Their collaborative approach ensures that simulation insights directly inform design improvements and product strategy.

Key differentiators include:

In-house expertise and fast turnaround

Cross-disciplinary engineering support

Proven track record across diverse industries

Confidential, secure handling of proprietary data

Transparent reporting and clear interpretation of simulation results

Client Success Stories

Case Study 1: Automotive Suspension Design Servotech helped a leading auto parts supplier reduce component weight by 15% without compromising safety by using dynamic and fatigue FEA to optimize geometry and material.

Case Study 2: Medical Device Durability A medical device startup collaborated with Servotech to validate a new surgical tool design. Using non-linear FEA, Servotech identified potential fracture points, allowing the client to redesign for longer lifespan and pass FDA testing faster.

Conclusion

In a world driven by innovation and efficiency, Servotech’s FEA services are redefining what’s possible in engineering. By integrating high-fidelity simulation with engineering know-how, they help businesses transform bold ideas into high-performance products.

0 notes

Text

ISRO Scientist Syllabus

The Indian Space Research Organisation (ISRO) is one of the leading space agencies globally and offers a wide range of opportunities for candidates aspiring to work as scientists and engineers. The ISRO Scientist syllabus is designed to assess candidates on their technical knowledge, problem-solving abilities, and aptitude in relevant engineering disciplines. Typically, the ISRO recruitment exam is conducted for various technical positions like Scientist/Engineer in different engineering fields, including Electronics, Mechanical, and Computer Science. Below is a breakdown of the typical syllabus for ISRO Scientist recruitment.

1. General Aptitude:

The General Aptitude section is designed to assess the candidate's logical reasoning, quantitative aptitude, and analytical skills. This section often includes topics like:

Quantitative Aptitude: Number systems, ratios and proportions, profit and loss, time and work, time and distance, simple and compound interest, percentages, average, and permutation-combination.

Logical Reasoning: Blood relations, series, direction sense, coding-decoding, seating arrangements, puzzles, and analogies.

Verbal Ability: Vocabulary, reading comprehension, sentence correction, and grammar.

This section tests the candidate's ability to think logically and solve problems efficiently within a short span of time.

2. Core Subject Knowledge:

The core subject knowledge tests are designed according to the specific engineering discipline of the candidate. For example:

Electronics Engineering (EC):

Circuit Theory: Network theorems, AC and DC circuits, transient analysis, resonance, and filters.

Digital Electronics: Logic gates, combinational and sequential circuits, flip-flops, counters, and registers.

Microprocessors and Microcontrollers: 8085/8086 microprocessors, interfacing, and assembly language programming.

Control Systems: Stability analysis, Bode plot, Nyquist plot, transfer functions, and feedback control systems.

Signals and Systems: Fourier series, Laplace transform, and Z-transform.

Communication Systems: Analog and digital communication, modulation techniques, and transmission systems.

Mechanical Engineering (ME):

Engineering Mechanics: Laws of motion, friction, dynamics, kinematics, and work-energy principles.

Thermodynamics: Laws of thermodynamics, entropy, heat engines, and refrigeration cycles.

Strength of Materials: Stress, strain, shear force, bending moment, and material properties.

Fluid Mechanics: Fluid statics, fluid dynamics, Bernoulli’s equation, and flow measurement.

Manufacturing Processes: Casting, welding, forming processes, and machining operations.

Computer Science Engineering (CS):

Data Structures and Algorithms: Arrays, linked lists, stacks, queues, trees, graphs, sorting, and searching algorithms.

Operating Systems: Process management, memory management, file systems, and system calls.

Databases: Relational databases, SQL, normalization, and transaction management.

Computer Networks: OSI model, TCP/IP, routing, and protocols.

Software Engineering: Software development lifecycle, methodologies, and design principles.

These core subjects assess the candidate's depth of understanding of the concepts and their application in real-world scenarios.

3. Technical Aptitude:

Technical aptitude involves the ability to apply theoretical concepts to solve practical engineering problems. This section may include topics such as:

Electromagnetics: Electric fields, magnetic fields, Maxwell's equations, and wave propagation.

Linear Algebra: Matrices, eigenvalues, eigenvectors, and systems of linear equations.

Material Science: Properties of materials, alloys, composites, and failure analysis.

Instrumentation: Sensors, actuators, and measurement techniques.

4. Exam Pattern:

The ISRO Scientist exam typically consists of multiple-choice questions (MCQs) with four options, and candidates must select the correct answer. The exam duration is usually two to three hours, and the total marks vary depending on the specific exam.

5. Preparation Strategy:

Know the Syllabus: Candidates must understand the syllabus thoroughly and focus on topics with high weightage.

Study Materials: Referring to standard textbooks, previous years' question papers, and mock tests will enhance the preparation process.

Time Management: Efficient time management is crucial while preparing and attempting the exam to ensure each section is covered adequately.

In conclusion, preparing for the ISRO Scientist exam requires a comprehensive understanding of core engineering subjects, aptitude, and problem-solving skills. Candidates need to stay focused, practice regularly, and follow a structured study plan to succeed in this competitive exam.

0 notes

Text

youtube

Welcome to Episode 2 of our "CAE Simulation using SolidWorks" series! 🎉 Today, we're diving into Static and Dynamic Analysis—exploring the differences, applications, and how to set up each in SolidWorks. Whether you're a beginner or looking to deepen your understanding of Finite Element Analysis (FEA), this tutorial will guide you through setting up simulations, understanding stress-strain relationships, and when to choose linear or nonlinear analysis. Let’s get hands-on with SolidWorks and learn how to capture realistic behavior in mechanical parts and structures! 🌟 📌Key Highlights: Basics of Static vs Dynamic Analysis ⚖️ Linear and Nonlinear Analysis explained 📈 Real-world example: Tension Test on a Plate with a Hole 🧩 Step-by-step setup for Static and Nonlinear Analysis 🔧 When to use Static vs Dynamic simulations 💡

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#Youtube

0 notes

Text

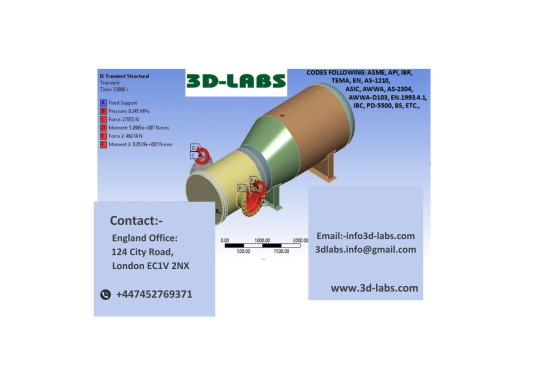

fea linear/nonlinear analysis In UK

thermal stress fea analysis services In UK Basics of Finite Element Analysis In UK https://3d-labs.com/fea-services/

3d-labs is an engineering consulting firm that provides full analysis using state-of-the-art FEA , CFD, and CAD/CAE tools. We help our clients reduce product development costs, decrease time-to-market , and improve product quality. We, offer not only reliable analysis results but also insight solutions to clients' projects….. We are from all sectors of the industry and have excellent analytical skills and knowledge. We have co-operation with universities, national laboratories, and other engineering firms, which enable us to address and solve clients' questions and problems simply and quickly. We solve a broad range of engineering analysis problems based on FEA techniques including stress analysis, fluid dynamics, kinematics, heat transfer, dynamics and vibration (seismic, harmonic), structural dynamics and electromagnetics. etc. +447452769371 Introduction Why Should we do Analysis Elastic Stress Analysis Method static Structural Analysis Engineering Data Geometry Model Setup Solution Results Fatigue Analysis Fatigue Tool Solution Results

0 notes

Text

Exploring Tefugen's FEA Capabilities: Harnessing Advanced Analysis Techniques

FEA is a computer application that uses numerical techniques to assess systems and structures. When subjected to thermal and structural loads, it accurately predicts how components will react. Instead of needing to construct the actual component, using a virtual computer-based model makes it easier to check the design and integrity of a component and pinpoint important areas for development. TEFUGEN offers exceptional FEA analysis and consultancy services to help with simulation-based structural and thermal evaluation of mechanical systems.

In the field of engineering design, Finite Element Analysis (FEA) has developed into a highly promising computer-aided engineering technique for modeling and analyzing structures with complex geometries and changeable material properties. It is commonly used during the design phase of a range of engineering fields, such as automotive, aerospace, power plants, and production engineering, to optimize products that increase performance.

Advantages of FEA:

Minimize the product development cost

Reduce the product lead time into the market

Accurately predict components response to load

Unlimited level of detail in the system

Analyze difficult & dangerous experiments

Easy repeatability of simulation

Linear Analysis:

The branch of FEA known as linear static analysis is most typically used to evaluate the structural and thermal performance of mechanical structures. The applied forces and displacements have a linear connection in linear static analysis. Actually, where stresses remain within the material's linear elastic range, this is relevant to all structural components. In a linear static analysis, the model's stiffness matrix is constant, and the solving time is quicker than in a nonlinear analysis of the identical model. In order to obtain an initial estimate, linear static analysis is usually used before performing a full nonlinear analysis.

Static stress analysis is likely the most common type of structural analysis using the FE technique. Stress, strain, and deformation of a component or assembly can be assessed under various load scenarios to avoid expensive failures during the design stage.

Typically, structural loads consist of one or more of the following:

Outside forces, like the clamping force in subsea connectors.

Surface loads, such as the pressure inside pressure vessels

Body pressures (gravity, acceleration such as centrifugal force in rotating machines)

Dynamic Analysis :

The phrase "dynamic FEA" describes a number of dynamic simulation methods that can be used to analyze even complicated engineering systems. Dynamic analysis is used to design and analyze potential noise and vibration issues as well as to assess the effects of transient loads. As seasoned development engineers, we rarely end our involvement in a dynamic assessment with the analytical output. We frequently collaborate with customers to identify creative solutions that are practical and beneficial from a business standpoint.

Thermal Analysis :

Thermal analysis and FEA can be used to solve heat transmission in or between solids. Convection, conduction, and radiation are a few examples of heat transport mechanisms that can be calculated. However, the analyst directly estimates convection and radiation, not the FEA software. Heat transfer analysis with FEA is normally carried out when the heat convection coefficient can be assumed to be constant along the surface of the part or when the value is precisely known. FEA-based heat transfer analysis can also be used to determine structural stresses brought on by temperature gradients in the component, including thermal expansion.

Buckling Analysis:

By the use of buckling analysis, a structure's stability under compressive loading conditions is evaluated. To verify the stability of the construction, a weight-lifting device will need to be used under compressive loads. The kind of buckling analysis employed in FE analysis is called linear buckling analysis. A static structural study must be followed by a linear buckling analysis. The results of a linear buckling analysis are buckling load factors, which are scales of the loads employed in the static structural analysis. The structure will buckle when the aforementioned level of static loading is attained, according to the simulation's results. There are countless buckling load elements that might affect a building. Every load factor has a distinct instability pattern associated with it, similar to modal analysis. The bulk of us, however, are focused on the load factor that is the lowest.

Fatigue Analysis :

A fatigue analysis is used to determine if a structure would fail after a specific number of repeated loading and unloading, or "load cycles," as opposed to replicating one load cycle as in a static analysis.

0 notes

Photo

CAD Amen Engineering Consultant gives FEA Static Stress Analysis Services in all around the world. Our team of engineers is skilled and eloquent to provide solutions a good way to be extraordinarily useful in enhancing designs to avoid failures, system defects and to beautify the product performance.

For More Details : - Website :- https://www.cadamen.com/ Email : - [email protected]

Aus No : - +61 0414061642 Ind No : - +91-9512404255

#FEA Static Stress Analysis Services#Finite Element Analysis Services#Mechanical Engineering Services#Structural Static Stress Analysis#Linear Static Stress Analysis#Nonlinear Static Stress Analysis

0 notes

Text

Finite Element Analyses in the Tunnel: An Overview-Iris Publishers

Authored by Buse Şeyda Hocaoğlu*

Abstract

With the development of the world and human beings’ rush to get somewhere, the need for tunneling has increased. Solutions have been made with the methods of end-to-end elements searched for a more straightforward resolution and visual thinking of tunnel projects that are complex and difficult to foresee. Thanks to these methods, geotechnical problems have been more easily detecting, and solutions have been producing in a short time. Several finite element methods have been developed in line with technology development and research. In this study, Plaxis, Flac, ABAQUS, Diana, Midas GTS NX programs, which are some of these programs, were briefly introduced, and tunnel projects solved with the mentioned programs were given

Keywords:Finite element method; Tunnel project; Plaxis 2D/3D; Flac 2D/3D; Geotechnical

Introduction

The finite element method is a numerical method that thoroughly solves mixed engineering problems. It was first developed and used in 1956 for stress analysis of aircraft bodies. It has been understood that it can also solve engineering and applied sciences problems in the following years. Over the years, the finite element method and solution techniques have developed rapidly and have become one of the best methods used to solve many problems today. The method is so popular for many engineering areas because a generic computer program can only solve any problem by changing the input data. By separating it into finite elements suitable for the structure of a problem, it implements a solution method in the form of a low energy level of internal and external forces on the obtained elements and then combining these elements. As a result, the system’s features, border conditions, sudden or continuous changes of external loads can be easily examined. It is also possible to reduce the element sizes in the constant system’s desired parts for the detailed examination of a region [1,2]. It can list the advantages of finite element methods: geometry allows complex problems to be solved, easily applicable in systems with different and complex material properties, easy to include border conditions in the fundamental equations of the system, and the use of the same model to solve many problems [2]. The disadvantages of the finite element method can be listed; found that the accuracy of the result obtained depends on the accuracy of the data, that the separation of regions requires experience to get an acceptable correct result, and that the accuracy of the result obtained is observed, and that the physical problem must be investigated well [2]. The finite element method has been used for 30 years in many engineering areas and was introduced in geotechnical engineering in 1996. The most important reason for this is that geotechnical engineering has complex issues and takes time to solve them. When used correctly, this method can provide accurate results for practical geotechnical engineering problems. A good analysis allows the engineer to understand the problem better [3]. The Finite element method can be applied to any linear-elastic medium. However, it requires many limitations for the implementation of the method in geotechnical engineering problems. In the method, material behavior is formulated by associating with changes between shape changes and total stress. In contrast, in geotechnical problems, the total tensor is decompressed into cavity water pressures and effective stresses, and material behavior is often expressed in terms of effective stresses. Most of the Geotechnical problems are interacting with the structure and the ground. Therefore, in analyzing these types of problems, it is necessary to use an intermediate surface between the structure and the soil. As a result, it is required to make changes to correctly apply the finite component method in geotechnical engineering [2]. To get a realistic result in analyzing finite elements for geotechnical engineering problems, the procedures are carried out step by step (phased loading, phased excavation). There are two benefits to ensuring that analysis can be performed in stages. First, the geometry changes at each step if the analyzes add or remove the padding. The change in geometry can be modeled by adding or removing elements from the network of end elements. Secondly, in the analysis, the ground properties change at each loading stage due to the change of stresses in the soil mass [2]. As a result of the study of finite elements in geotechnical engineering problems, parameters such as stresses, cavity water pressures, lateral and vertical movements, and groundwater flow are determined [1]. Today, programs used in finite element methods are used in many areas, such as ground mechanics, fluid mechanics, aircraft engineering, nuclear engineering, rock mechanics, etc. It can be studied by selecting the program that will give the most realistic results for problems. Examples of these programs include Plaxis 2D/3D, FLAC 2D/3D, ABAQUS, Diana, Midas GTS.

Methods

Plaxis 2D/3D

Plaxis 2D/3D, one of the finite element’s programs, is a program developed to analyze geotechnical engineering problems. The program consists of an input program, calculation program where analysis is performed, output program that graphically presents the study results, and curve program that enables the creation of the desired chart with the results obtained (Figure 1). This program is used to design projects where deformation and stabilization analyzes are needed, strain-shifting, ground structure interaction, loading conditions, carrying power, consolidation, current network, ground dynamics, and material are varied and bring real-life results [4]. According to the method of finite, a continuous environment is divided into many elements. The node points on each element have a degree of freedom. During the creation of a network of finite elements in the Plaxis program, the cells are divided into triangular elements with 6 or 15 nodes (Figure 2). Even if it takes a little more time to calculate the stresses and migration surfaces more realistically, it is better to select the 15-node element. The displacement is calculated at node points during the finite element calculation [4] (Figures 1,2).

Under the main heading Plaxisde Material Sets, the floor and structural members (Soil & Interface, anchor, Beam, and Geotextile) can be defined. The Plaxis program has several floor models, such as Mohr-Coulomb (MC), Hardening Soil (Model-HS), soft Soil Creep (Model-SSC), which are widely used for analyzing floor mechanics problems (Figure 3) [4].

Flac

FLAC is a program that uses the use of a finite element type to numerically or numerically examine the mechanical behavior of continuous media in equilibrium or progressive plastic yield. In the program, creating a network of finite differences defined by the user via elements can detect the behavior of materials such as ground and rock at the level of plastic flux. Every element behaves by the previously specified linear or non-linear stress-shape defining feature against forces applied under boundary conditions [6]. Thanks to the intermediate surface formulation in the software, the interaction between two sonly differences networks that are interconnected but are likely to divest or slide along a surface, such as a fault structure, can also be modeled. Hydrostatic pressure used in liquefies research or design of dams is carried out by applying fluid mechanics formulation. Structural elements are used to model entities such as anchors and flooring nails. In addition to all these, it is possible to perform realistic modeling with this software by applying static and dynamic boundary conditions. Although FLAC has been developed for Geotechnical engineering applications, it is also widely used in many research areas such as mining engineering, underground structures, and rock mechanics (Figure 4) [6].

The use of the FLAC finite element program in some engineering applications is as follows:

1. Calculation of transport capacities and deformations according to ground and loading conditions in the design of slope and foundations.

2. In the ground structures, calculate the safety coefficient in the stability analysis of fillers and slope.

3. Assessing the fault structure and impact of the interest structure in mining research projects.

4. Design of floor anchorages, rock bullion, ground nail, and support systems in geotechnical problems.

5. Examination of the dynamic effects that will occur resulting from vibration and explosion in tunnel and mine excavations.

6. performing seismic analysis of structures in the design of earth filling dams.

The solution of the Flac finite elements method consists of the three-step approach given below. The solution method for FLAC finite components consists of the following three-stage process. First, the finite differences phase, a limited time, and the change over field linear default variables are estimated by the time and finite differences of the first degree. Second, the model’s deposition phase: An equivalent environment replaces the continuous environment by a deposition. In the new environment, all forces are assumed to be gathered at the nodes of a three-dimensional network. Third, the dynamic solution phase is used to access the system’s balanced state, whose inertia terms in motion equations are analyzed as numeric agents [6].

Abaqus

Abaqus is a finite element method that works through a detailed analysis of engineering problems by creating realistic computeraided models (Figure 5).

It offers the ability to analyze linear and nonlinear projects that are difficult to solve due to the different material models and finite element types involved [8]. The program consists of five essential software: Standard, Explicit, CFD, Electromagnetic, and CAE. ABAQUS/Standard uses solution technology, ideal for static and low-speed dynamic events where highly sensitive stress solutions are critical. Within a single simulation, it is possible to analyze a model in both the frequency and time zone. Standard is closed finite elements software that can perform static and dynamic analyzes. Their solution uses advanced material and element features. It can also perform acoustic and associated doubleacting analyzes, and the plastic injection can be used in conjunction with various programs for mold analysis results [8]. Abaqus/Explicit, a particular purpose finite element analyzer that uses an open integration scheme to solve many complex contacts, nonlinear systems under transient loads. At the same time, automotive is particularly suitable for simulating short transient dynamic events such as collision capability and ballistic impact. It is a handy software for simulating semi-static events, such as handling nonlinear behavior and the rounding of hot metal effectively.

Collision tests can be used for dropping tests and resolution of strain problems [8]. Abaqus/CFD, it is the software that Abaqus offers to solve computational fluid dynamics problems. It can solve nonlinear fluid-structural and fluid-thermal problems. Real results are achieved when used in nonlinear structural-flow and heat- flow applications [8]. Abaqus/Electromagnetic offers an advanced computational solution of electromagnetic problems [8]. Abaqus/ CAE is a software used for both the modeling of mechanical components and its analysis and visualizes the analysis results. Thanks to its intuitive interface, it is user-friendly in modeling, research, and result visualization [8].

Diana

Chan in 1988, designed for dynamic, static, and consolidation analysis of geomechanical problems. It is a 2-dimensional element program that contains plane deformation and asymmetric analysis. The program has five ground models. It can be rank these models as a linear elastic model, Coulomb changing with average effective environmental pressure, a general elastic model with friction envelope, elastic-full plastic Mohr-Coulomb, original glass clay Pastor-Zienkiewicz Mark-III models. The DIANA program requires four input files for each finite element analysis to be performed. These input files consist of mesh, data, introduction, and earthquake files. Running an analysis requires these input files to be created in a specific order [10]. The network file defines the geometry of the finite element network to be used in the analysis. The geometry of the defined floor model is divided into smaller regions, creating a finite element net. The input file ‘DYNMGEN’ is used to prepare the network file [10]. The data file contains control data to be used to perform finite element analysis. All technical information about finite element analysis is stored in this file [10]. The Initial file creates the initial conditions for finite element analysis. This file’s data contains the initial speed, start time, start displacement, maximum displacement norm, earthquake status, initial acceleration, and internal parameters of the ground model. The ‘DYNINT’ input file is used to prepare the initial data file [10]. The earthquake file is the last input file required for finite element analysis. The important aspect to be considered in preparing this input file required for dynamic analysis is the type of earthquake and the scale factor. For dynamic analysis, the desired load transaction type and transaction scale must be created in the ‘DYNEQK’ input file and encoded in the scale factor data file [10].

Midas GTS NX

MIDAS GTS NX is an important method of finite elements for geotechnical and tunnel analysis systems. It can model geological problems that are difficult to model with advanced technology [11]. In Midas GTS NX, geometry is modeled in 2 shapes. The first is that geometry is drawn in 2D or transferred from drawing programs. A network of 2D finite elements is then created and offset to the 3rd dimension, resulting in a model of 3D finite elements. This method may not be available for complex geometries. The other method is to create 3D geometric objects by giving dimensions 3rd dimension in 2 sizes or transferred using the command “extrude” [12].

Examples Using the Finite Element Method

Tunnel example with Plaxis Program

In this tunnel project application, the Plaxis 2D program, one of the finite programs, has calculated deformations that can be caused by the passage of tunnels. In line with these deformations, ground improvement methods have been implemented. The Plaxis program is selected for this application because complex boundary conditions and nonlinear material behavior allow systematic programming in solving challenging and complex problems such as non-homogeneous materials. 6 different cases have been explored in this application. In the first application, the whole floor is assumed to be clay, and the tunnel is added. (Figure 6). In the second application, tunneling is performed in the clay and sandy variable ground profile with different ground parameters (Figure 7). The deformation of the floor surface and the deformation of the tunnel covering have the same value and have increased by 50,92 mm. In the third application, he implemented a building load without improving the previous project (Figure 8). The deformation of the floor surface has increased to 87,41 mm. Due to the tunnel covering’s building load; the deformation value has risen to 52, 57 mm. Improved soil with geotextiles and sealants before applying building load in the fourth application (Figures 6-9).

Due to the optimization, the deformation of the floor surface has been retightened to 67,49 mm. The deformation value in the tunnel covering is close to the previous example and has dropped to 51,71 mm. A 2 m thick floor injection method is implemented as an enhancement (Figure 10). As a result of this optimization, the soil surface’s deformation has been retightened from 67,49 mm to 58,62 mm. The deformation value in the tunnel lining is 52.54 mm. The sixth application assumes that a 5-story building with two basements is built on the ground, and the deformation value in the tunnel coating is 50.51 mm (Figures 10,11).

As a result of these examples, finite element programs must be analyzed to ensure that new structures built after tunnel construction are constructed without damaging the tunnel and existing structures. A non-damaged construction must be carried out by determining suitable solutions to the problems that will arise. Before applying a building load, improvements can be made to the characteristics of the floor, thus setting the seating values on the floor surface to lower values. It is important to maintain the ground during tunnel construction and select two to maintain the tunnel’s stability. The groundwater check must be carried out from the start of the project. The tunnel is to be built must be checked that it will not damage structures around it [13].

Tunnel example with FLAC 3D Program

Pressed floors can cause many problems, such as the collapse of supports due to heavy load, groundwater, excessive closure of pile profiles, or destruction of tunnel support. Therefore, before tunneling on such floors, the type and severity of the jamming that may occur should be investigated in advance. A specific formula produced by Hoek-Brown is used to predict the possibility of jamming and to analyze the jam. Flac 3D, Finite elements program, was used to determine the Hoek-Brown criteria parameters to be taken into account in the analysis of trapped floors in this application. For these studies, four Hoek-Brown input parameters are considered and modeled mainly: Rock mass parameters GSI (geological strength index), UCS (single-axis press strength), MI (Hoek material constant), and H (covering thickness). Code (FISH code) has been written by the Hoek-Brown criteria, as Flac3D is based on Mohr-Coulomb criteria. Numerical modeling results using GSI, H, UCS, and mi variables according to Hoek and Brown defeat criteria are presented separately as deformation contours and plastic zone contours. Deformation contours have been found to have a significant reduction in deformation contours around the tunnel as the GSI value increases from three-dimensional numeric models with different GSI values (Figure 12). In line with the results obtained by giving different tunnel cover thickness values, it was determined that the deformations around the tunnel increased rapidly as H increased (Figure 13). As a result of the deformation contours for the different mİ values from the three-dimensional numeric models, the mİ value has increased. In contrast, the deformation values have been found to have very little reduction than the other parameters (Figure 14). Thus, it is understood that the effect of mİ value on the potential for compression is not an important parameter. A significant reduction in deformation around the tunnel has been identified as the UCS value increases about deformation contours from three-dimensional numerical models using different single axis thrust strength values (Figures 12-15).

As a result of different GSI values, plastic zone contours decreased significantly in the thickness of the plastic area around the tunnel as the values increased (Figure 16). Using different cover thicknesses, it was determined that the value of plastic zone thickness increased as it increased (Figure 17). Using another mi value, it was determined that the plastic zone thickness values decreased due to the increase (Figure 18). While a change in the plastic zone size was observed with the increase in MI value, it was determined that this determined change MI parameter was not a useful parameter on the plastic zone. Using different single axis thrust strength values has determined that the plastic zone thickness around the tunnel decreases as the UCS value increases (Figures 16-19).

In parallel with the result of the plastic region radius, analyzes, and deformation analysis, the study’s parameters revealed that GSI, UCS, and H were the most influential parameters. It should be considered that the effect of the MI parameter will also change when the fixed parameters are changed, even though the impact of the MI parameter is low [14].

Result

As a result of developing technologies and research, existing programs have been designed and provided ease of solution to many engineering problems. The programs in which the method of finite elements was applied increased over time. In this way, almost every engineering branch has used appropriate programs for its problems. Many complex and time-long issues have been solved in fewer time thanks to these programs. Questions are broken down into pieces and solved in more detail, resulting in more realistic results. The development of programs and the introduction of 3D solutions have made it easier to understand problems and solutions. This makes tunnel projects easier to solve, and errors can be detected. Problems encountered during the opening phase of tunnels have been quickly resolved, and necessary improvements have been made. As technology evolves and people seek more realistic results, the finite element methods will continue to grow and develop.

Read More...FullText

For more about Iris Publishers slide share please click on https://www.slideshare.net/IrisPublishers/iris-publishers

For more articles in Current Trends in Civil & Structural Engineering (CTCSE) Please click on https://irispublishers.com/ctcse/

#iris publishers llc#Iris Publishers#Current Trends in Civil & Structural Engineering#Finite Element Analyses

1 note

·

View note

Text

~Sasusaku analysis ~

~~ Sasuke and Sakura - - pair analysis ~~ ~THE BRIDGE SCENE~ (Team 7 Reunion - - after the Five Kage Summit)

--- PART 4---

How would anyone act when given an impossible choice: be a shinobi or a lover.

This scene suggests that one can't be both (Zabuza states that they can't be both and the human wins every time, albeit Naruto begs to differ and state that it is realistic and achievable to balance the two antithetical perspectives).

"Kill her and I'll accept your offer." Sasuke gives her a pill of her own medicine. Because he doesn't speak randomly for the sake of conversation, cruelly with seemingly no remorse lingering in his heart, Sasuke gives Sakura one example of how her life would be if she were to join him; the life of an outlaw where murder and disposing of people like nothing would be ordinary.

Plus, the scene is also symbolic; Sasuke asks a famous medic - - his following sentence is more than revealing for he knows very well that Sakura is a medic - - to kill a suffering person, when the very essence of her jobs nature AND her symbolism in the manga as the representative of rebirth and regeneration is to heal, to cure, to lessen one's pain.

By joining him, Sakura would give up on her own self (Naruto answers to her shrouded confession that no sentient bring should event lose himself and betray his own morals, principles and feelings "I hate people who lie to themselves"). Hypothetically, Sasuke shows Sakura a glimpse into how her future beside him would look like.

Albeit is kosher and nuanced, barely noticeable, Sasuke still has a good nature and he proves he cares; he doesn't snap at her, he doesn't launch an attack, he takes his time to lecture her in his own blunt and sarcastic manner.

In the light of the most recent events - - Itachi’s death, the Kage summit, Danzo, Obito and his confession about Uchiha - - Sasuke might arguably have his ration altered, with interlaced moments of lucidity and madness, triggered by the emotional trauma, extreme stress and because he is being provoked. And that makes his moves seem mad, unusually erratic and exaggerated (his famous mad laughing moment when he shouts to Kakashi that no one could ever bring his family back and restore that status quo - - a doctrine that the manga embraces).

But that's not the case; not with Sasuke and not in this scene.

The overly popular consent postulates that "Sasuke went mad/ he is crazy". Which isn't the truth at all, but it's so facile to superficially judge a character with no proper introspection.

He is not mad at all. Nothing in his demeanor reveal that Sasuke lost the clarity or the ration and his furious state must not be mistaken for insanity.

Sasuke is perfectly lucid. He's, calm, composed, enigmatic, his words have double meaning, he is coherent, analytical, tactical and he knows perfectly well what he is saying; he has complete control of his thoughts.

The fact that his following conversation with Team 7 steals exacerbated reactions from him is due to the fact that he's more emotionally attached to them and thus his emotions would be pushed to extreme; he'd be more expressive and his rage would be more evident.

Sasuke is less reserved with Team 7 because he's emotionally involved; it’s very personal. But that doesn't make him a mentally deranged man.

He even kept his lucidity and perfectly placated Danzo with a sparkling strategy; he had enough lucidity to analyze Danzo's attacks and outsmart him, despite the emotional trump card of psychological upper hand that Danzo supposingly had on him. Even Obito himself thought at some point that Sasuke has lost it and he's only launching at Danzo erratically, aimlessly in his crazed mind, like Juugo. But it wasn't the suicidal rampage of a crazed man. Sasuke fooled everyone into thinking that he does not know what he is doing / that he lost it.

Nowhere in his attitude or his manner of speaking does Sasuke seem crazy and that's luckily to Sakura because she exposed herself to a ridiculously deadly situation. She came before him like it's a cakewalk with a confusing and conflicting strategy - - if it even existed.

That's the beauty of this pair. It's refreshing and novel, the dynamics are exciting, it lefts the reader constantly guessing and the finale isn't predictable. They aren't a cliché couple. Their movements, the inner feelings, the evident indecision and introspective turmoil is fabulous.

Sakura's ambiguous intentions and Sasuke's personal manner of speaking, his body language, her evident conflict and bedraggled approach are confusing and enigmatic. We keep in guessing what did she hope to accomplish?

Her presence alone holding a lethal weapon that she plans to use on Sasuke and the mention of the word "kill" on her lips when talking about Sasuke the man she loves might be symbolic for how much she treasures the bond with Naruto and how much she regrets for her innocent, naïve plea to bring Sasuke back.

A bond of blood, pain, rancor and emotional torment that she created, a harpoon of tm emotional trauma and torture for Naruto who didn't deserve it. Her present alone with murder intent is an attempt to free Naruto her best friend from this curse (a repentine decision taken after her "confession" failed - - her attempt to free Naruto from that promise failed because Naruto suggests that the supposed burden of her promise was also a conjoined personal motivation).

And maybe Sakura wants to confirm her own feelings and proceed from there: does she love him now when he's gone to this lengths or did her feelings changed for this new Sasuke and she'll be able to fulfill her shinobi duty?

That's how her disarrayed moves and the lack of any proper prior plan could be explained. She wanted to confront her own emotions and the best way to do so was to meet Sasuke herself and assess the situation with her own eyes and her suspicions coupled with the rumors about him lead to the verdict: he is not the same Sasuke that she fell in love with.

Solidifying Sasuke's role as a character with great development in the Manga (a Bildungsroman which follows the evolution of a character from childhood to adulthood, which emphasizes and supports the moral of the story). In antithesis with Naruto who is a linear character who didn't change in the bit, Uchiha is a dynamic character who evolves and never stays the same.

Both Sakura and Karin make it perfectly clear that Sasuke is not static like an unperturbed lake with no ripple to break the mirror-like stillness of its surface. He's a vivacious ocean - - unpredictable and fulminant with constant vicissitudes between tranquility and serenity and turbulent storms.

Sakura confronts her own feelings by approaching Sasuke and realization almost costs her life - - her heart gives us the painful confirmation that she loves him, still helplessly loves him ardently, in a moment when there's no safe turning back.

A moment of hesitation is lethal for a shinobi. A moment of indecision or unfortunate choice comes with devastating consequences.

She reveals her poisoned kunai from under her clothes while indecision takes control over her reeling emotions and fogged lucidity. Simultaneously, Sasuke prepares his Chidori and prepares to strike his attack.

The manga is very descriptive and suggestive. The transitions denote melodious cursively and the flow and cohesion of their interplay is assured by the constant introspection into the characters minds and hearts as the silent face expressions and body language emphasize their dialogue.

Sasuke sees Sakura's internal turmoil. He notices how she reviews her own feelings for he did the same when he heard the truth about Itachi. She's analyzing her feelings for him as he silently allow her to make a decision, up to the very last moment - - he wait for her to get close to him while he won't let any other enemy with murder intent to get so close to him.

Waiting for her to decide, to make up her mind, to choose the road to take and dictate the course of action. Up to the last moment when she reveals her kunai and her mind decides that "she doesn't matter", meaning that she won't comply with his request to kill Karin and "prove" her loyalty and feelings to him.

The implicit dubiety in Sasuke's voice has a moral purpose behind: in a couple, trust is fundamental for a healthy relationship. Love isn't enough when it’s not coupled with trust and respect.

When trust misses, there can't be any romance between two parties and that's what Sasuke's ironic and daring words mean when he dares Sakura to prove her loyalties and back up her confession.

Yes, she might love him but she won't do everything he asks and she does not NEED to comply to his requests. Sasuke tells Sakura that she does not BELONG to his world now. To this version of reality, according to the script of this play he can't be her lover, the one she dreams of.

His eyes, the mirrors of the soul as the symbols of the Third Eye in Buddhism - - the omnipotence of the one who beholds all the wisdom and knowledge / the spiritual part represented by Sasuke's Yin avatar - - are always scrutinizing and introspective. Sasuke is following Sakura's mimics, gesture and reactions with hawkish diligence, attentive and meticulous.

He sees right through her deception; he might not have accumulated enough life-experience, wisdom and information to unravel Itachi's truth ("how far can you see with that Sharingan of yours, Sasuke?"), but he sees right through Sakura's soul, reading her like an open book, every page and every line. She's transparent in front of the man she loves.

It can't be any different because romantic bonds are unique; nothing can begin to compare or come close to. There's nothing else tangible to compare romantic love with, nothing that can offer such a complete body and soul experience.

It's very difficult to draw a kokeshi doll mask on the face of a lover because primal instinct makes one react differently, in a peculiar manner in the presence of the loved one.

Is primal, animal instinct to entice and attract the attention of a potential match and thus it makes it difficult to fight against such strong innate reflexes.

For both Sasuke and Sakura, the primeval instinct to be a couple is very difficult to placate and hide. Sasuke makes it obvious from his tempered gestures, for how he allows her closer to him than anyone, and from he way he talks to her - - the syntax of the phrase and the choice of words are all very intimate, very personal.

And Sakura's pendulating actions shine with confusion and indecision, the inner turmoil revealing as theatrical and dramatic: she alternates between blubbing and shouting, rasping and barking at him and getting emotional and mellower with him.

The look in their eyes is one of this pair’s most symbolic feature. Since Japanese people aren't overtly extroverts with displaying emotions in public, subtlety is the key of this representative pair. There is an entire repertoire that composed the aria of love songs between this pair. There are heated glances, angst stares, incredulity and confusion. This time Sakura does not eschew her eyes from Sasuke; she doesn't glance shyly and flirtatiously aside from him like she does at the end of the manga. She holds Sasuke's gaze, leveling his piercing gaze as she knows she risks a lot because this man's eyes can see through everything.

He... Was always capable to see right through her deception. She can never hide from him.

Sasuke instead can perfectly mask his emotions, but chooses not to.

Considering how this couple's love story is embroidered into the tapestry of scorching passion, it’s no wonder that Sasuke is the one who initiates most the innuendos between them. No pronouns are more idoneous than the repetitive "Me" and "you" and the syntax of their dialogue; the flow of the conversation, the order of the words and the feelings elicited are extremely intimate.

There is history behind this couple and their now earmark stares and glances exchange support it.

Sasuke and Sakura are subtle but their body language is unique and a expressive. No fustian description can give their story justice, for it's far too complex.

That's why passion and intimacy scorch like a pyre with this pair. Every feeling, every emotion and every sentiment is augmented and exacerbated.

While he's clearly deranged by the women's litany of flirts and attempts to seduce him, he listens to Sakura's every word. He doesn't brush off her confession, he doesn't ask her to keep her distance from him, and he doesn't repay her confession with brusque scowls or growls (like he does to Karin, Ino and Mei).

Sasuke and Sakura's love story is very reminiscent to the compelling elements of Shakespeare drama in terms of its characteristic elements: the tragic hero who's suffering is the product of a peculiar trait of fate or an extraneous force (the Uchiha curse/ manipulation and lies that surround HIM); his inner struggle (the struggle between good or bad), darkness and hatred and evil that destroys any iota of goodness in the hero's heart, the stupendous internal and external conflict and the effect of catharsis that their feelings produce.

The strong, Naruto-esque happy ending is the only thing that differs, as Sasuke and Sakura don't end in a veritable tragedy, emphasizing the triumph of good in the manga.

I'd end by citing Obito and Hagoromo's hermeneutics: "When a man learns how to love he must shoulder the burden of hatred."

The negativism and pessimism that attributes a negative connotation to life and suggests that pain and suffering are inherent to life and win over positive emotions - - the reign of pain and suffering.

... In conjunction with:

"I hope that this time is hatred which turns into love."

The positive overview of the humanist manga conclusion.

The positive, idealist triumph of peace, love and happiness, with love winning over pain.

It's Sakura who returned the lost peace and gave Sasuke happiness. It's her love that turned his hatred (Sasuke set on redemption journey because of lingering Uchiha demons he's scared to hurt people).

#Sasusaku romance#Sasusaku pair#Sasusaku explained#Sasusaku analysis#sasusaku#sasuke and sakura love#Sasuke and Sakura pair

8 notes

·

View notes

Text

ROLE OF COMPUTER AIDED ENGINEERING IN ADDITIVE MANUFACTURING

In all over the world, manufacturing sector has emerged as one of the high growth sectors on which millions of people are dependent because of their jobs. Throughout history, people have always been dependent on technology. Of course, the technology of each era might not have the same shape and size as today, but for their time it was certainly something for people to look at.

People would always use the technology they had available to help make their lives easier and at the same time try to perfect it and bring it to the next level. This is how the concept of the industrial revolution began. Right now, we are going through the fourth industrial revolution, also known as Industry 4.0.

Basically Industry 4.0 can be defined as “digitization of the manufacturing sector, with embedded sensors in virtually all product components and manufacturing equipment, ubiquitous cyber physical systems and analysis of all relevant data”. There are total 4 main factors on which Industrial revolution 4.0 is based.

1. Data, computational power and connectivity – i.e. low-power, wide-area networks, for example

2. Analytics and intelligence

3. Human-machine interaction – i.e., touch interfaces and augmented reality

4. Digital-to-physical conversion – i.e., advanced robotics and 3-D printing

3 D printing or Additive manufacturing is yet another technological advancement made possible by the transition from analog to digital processes. In recent decades, communications, imaging, architecture and engineering have all under gone their own digital revolutions. Now, AM can bring digital flexibility and efficiency to manufacturing operations.

Additive manufacturing uses data computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes. As its name implies, additive manufacturing adds material to create an object. By contrast, when you create an object by traditional means, it is often necessary to remove material through milling, machining, carving, shaping or other means.

Although the terms "3D printing" and "rapid prototyping" are casually used to discuss additive manufacturing, each process is actually a subset of additive manufacturing. While additive manufacturing seems new to many, it has actually been around for several decades. In the right applications, additive manufacturing delivers a perfect trifecta of improved performance, complex geometries and simplified fabrication. As a result, opportunities abound for those who actively embrace additive manufacturing.

Computer aided engineering, or CAE plays key role in the process of additive manufacturing. CAE is mainly used to create the design which is later provided as an input to the machine. Rapid prototype is been made by the machine only after proper design of the object is achieved. Let us know more about such softwares which are commonly used for additive manufacturing technique:

ANSYS 3DSIM & FLEX:

One of the commonly used CAE software for additive manufacturing is ANSYS. This software along with other 2 software exaSIM and FLEX help users reduce the risks, trial and error of implementing a 3D printing workflow. It also hopes to speed up the installation and optimization of said 3D printing equipment. 3DSIM Company has launched the software exaSIM which is being used for 3D printing operation.

EXASIM ANALYSIS CAPABILITIES:

Ø Residual stress

Ø Distortion

Ø Build failure

Ø Tolerancing

FLEX capabilities:

Ø Ability to determine best process parameters based on material and 3D printer

Ø Optimization of part integrity, micro structure and properties

ANSYS ADDITIVE SUIT:

• MODULES:

TOPOLOGY OPTIMIZATION

Topology optimization in ANSYS Mechanical allows to:

Ø Take into account multiple static loads combined with optimizing for natural frequencies (modal analysis)

Ø Satisfy requirements for minimum material thickness

Ø Observe rules around feature direction (for machining operations)

Ø Easily validate results

Ø Easy extraction of optimized data in .stl format

STL FILE AND GEOMETRY MANIPULATION

This particular tool is used for

Ø Geometry repair

Ø Lattice creation

Ø Clean up of parts using the software’s faceted data tools.

STRUCTURAL AND THERMAL ANALYSIS AND DESIGN VALIDATION

Ø Full nonlinear, including transient, and linear analysis

Ø Capability to validate designs under a vast range scenario.

Ø Both thermal and structural loading conditions can be applied to models to understand performance and durability.

ADDITIVE PROCESS SIMULATION

Ø Predict Distortion

Ø Predict Stress

Ø Run Parametric Studies

ADDITIVE PRINT

Additive Print delivers unparalleled accuracy in predicting:

Ø Final shape of the printed part.

Ø Layer-by-layer distortion and stress.

Ø Optimal support structures.

Ø Distortion-compensated STL files.

Ø Potential blade crash.

ANSYS ADDITIVE SCIENCE

To determine optimum process parameters for metal additive manufacturing

**Capabilities of this module: **

Ø Analyze Porosity and Melt pools

Ø Predict Sensor Measurements

Ø Predict Thermal History

Ø Predict Microstructure

Ø Run Parametric Studies

Ø Track Phase Transformation

Materialise Magics

Materialise Magics is a versatile, industry-leading data preparation and STL editor software for Additive Manufacturing that allows you to convert files to STL, repair errors, edit your design and prepare your build platform.

MODULES

SINTER MODULE

With the Materialise Magics Sinter Module, you can:

Ø Nest parts quickly and automatically on multiple platforms

Ø Control the build time, height and density

Ø Avoid interlocking and colliding parts

Ø Create protective crates

Ø Re-nest from an existing configuration

SIMULATION MODULE

With the Simulation Module, you can:

Ø Predict areas prone to deformation, overheating and residual stresses

Ø Reduce the risk of build failures and make test prints redundant

Ø Speed up the search for the best parameter sets to build your parts

Ø Modification of support and orientation based on simulation results

Ø Counter-deform your parts to avoid deformations arising from the printing process

STRUCTURES MODULE

With Materialise Magics Structures Module, you can:

Ø Lower your powder consumption and production costs

Ø Add strength to the parts

Ø Reduce distortion (due to the heat generated during the build process)

Ø Create porous designs

Ø Available lattice structures include diamond, cross, diagonal etc

Ø Design your own unit cell structures to create a lattice structure

SUPPORT GENERATION MODULE FOR METAL (SG+)

With Materialise Magics SG+ Module, you can:

Ø Conduct heat and avoid deformation

Ø Optimize part orientation

Ø Recuperate powder

Ø Reduce build failures with build validation tools

TREE SUPPORT MODULE

With Materialise Magics Tree Support Module, you can:

Ø Improve the surface quality of metal prints

Ø Prevent part deformation with enhanced heat conduction systems

Ø Save time on finishing

Ø Use trees to create inlets in your lost-wax mold

IMPORT MODULE

With Materialise Import Module, you can:

Ø Manage the resolution of your data while importing it (for better STL quality)

Ø Import native color information

Ø Receive a repaired file after the import

AUTODESK Netfabb

Netfabb is software specially designed by AUTODESK for Additive Manufacturing applications. Netfabb software includes efficient build preparation capabilities alongside tools for optimizing designs for additive manufacturing, simulating metal additive processes, and planning for CNC post-processing.

Netfabb consists of following features:

Build Preparation:

Ø Import, analyze, and repair models:

Import models from a variety of CAD formats and use repair tools to quickly correct errors.

Ø Modify models for production:

Make your models production ready by adjusting wall thicknesses, smoothing rough areas, and more.

Ø Configurable build supports:

Identify areas that require support and use semi-automated tools to generate support structures.

Ø Mesh to CAD conversion

Convert organic, free-form mesh files to boundary representation models and make them available in CAD in STEP, SAT or IGES format.

Ø Automatic packing

Use 2D and 3D packing algorithms to optimally place parts within the build volume.

Ø Report generation

Create custom reports that include critical information for manufacturing and quoting.

Ø Advanced tool paths

Develop build strategies and define tool path parameters for maximum surface quality, part density, and speed.

Design optimization for additive manufacturing:

Ø Internal lattice structures

Create lightweight parts with performance characteristics specific to your application.

Ø Topology optimization

Generate forms that are optimized for stiffness and weight, based on the loads and constraints of the part.

Ø Integrated performance analysis

Test how your optimized designs will perform using built-in Autodesk Nastran simulation.

Ø Optimization engine

Automatically verify and optimize lattice and skin elements to meet load requirements and reduce weight.

Thus, we can say that there has been a lot of progress in the field of additive manufacturing day by day. As the technology progresses, it will be easy for us to analyze & manufacture the objects easily.

1 note

·

View note

Text

3D bioprinting of collagen to rebuild components of the human heart

For biofabrication, the goal is to engineer tissue scaffolds to treat diseases for which there are limited options, such as end-stage organ failure. Three-dimensional (3D) bioprinting has achieved important milestones including microphysiological devices (1), patterned tissues (2), perfusable vascular-like networks (3–5), and implantable scaffolds (6). However, direct printing of living cells and soft biomaterials such as extracellular matrix (ECM) proteins has proved difficult (7). A key obstacle is the problem of supporting these soft and dynamic biological materials during the printing process to achieve the resolution and fidelity required to recreate complex 3D structure and function. Recently, Dvir and colleagues 3D-printed a decellularized ECM hydrogel into a heart-like model and showed that human cardiomyocytes and endothelial cells could be integrated into the print and were present as spherical nonaligned cells after 1 day in culture (8). However, no further structural or functional analysis was performed.

We report the ability to directly 3D-bioprint collagen with precise control of composition and microstructure to engineer tissue components of the human heart at multiple length scales. Collagen is an ideal material for biofabrication because of its critical role in the ECM, where it provides mechanical strength, enables structural organization of cell and tissue compartments, and serves as a depot for cell adhesion and signaling molecules (9). However, it is difficult to 3D-bioprint complex scaffolds using collagen in its native unmodified form because gelation is typically achieved using thermally driven self-assembly, which is difficult to control. Researchers have used approaches including chemically modifying collagen into an ultraviolet (UV)–cross-linkable form (10), adjusting pH, temperature, and collagen concentration to control gelation and print fidelity (11, 12), and/or denaturing it into gelatin (13) to make it thermoreversible. However, these hydrogels are typically soft and tend to sag, and they are difficult to print with high fidelity beyond a few layers in height. Instead, we developed an approach that uses rapid pH change to drive collagen self-assembly within a buffered support material, enabling us to (i) use chemically unmodified collagen as a bio-ink, (ii) enhance mechanical properties by using high collagen concentrations of 12 to 24 mg/ml, and (iii) create complex structural and functional tissue architectures. To accomplish this, we developed a substantially improved second generation of the freeform reversible embedding of suspended hydrogels (FRESH v2.0) 3D-bioprinting technique used in combination with our custom-designed open-source hardware platforms (fig. S1) (14, 15). FRESH works by extruding bio-inks within a thermoreversible support bath composed of a gelatin microparticle slurry that provides support during printing and is subsequently melted away at 37°C (Fig. 1, A and B, and movie S1) (16).

The original version of the FRESH support bath, termed FRESH v1.0, consisted of irregularly shaped microparticles with a mean diameter of ~65 μm created by mechanical blending of a large gelatin block (Fig. 1C) (16). In FRESH v2.0, we developed a coacervation approach to generate gelatin microparticles with (i) uniform spherical morphology (Fig. 1D), (ii) reduced polydispersity (Fig. 1E), (iii) decreased particle diameter of ~25 μm (Fig. 1F), and (iv) tunable storage modulus and yield stress (Fig. 1G and fig. S2). FRESH v2.0 improves resolution with the ability to precisely generate collagen filaments and accurately reproduce complex G-code, as shown with a window-frame calibration print (Fig. 1H). Using FRESH v1.0, the smallest collagen filament reliably printed was ~250 μm in mean diameter, with highly variable morphology due to the relatively large and polydisperse gelatin microparticles (Fig. 1I). In contrast, FRESH v2.0 improves the resolution by an order of magnitude, with collagen filaments reliably printed from 200 μm down to 20 μm in diameter (Fig. 1, I and J). Filament morphology from solid-like to highly porous was controlled by tuning the collagen gelation rate using salt concentration and buffering capacity of the gelatin support bath (fig. S3). A pH 7.4 support bath with 50 mM HEPES was the optimal balance between individual strand resolution and strand-to-strand adhesion and was versatile, enabling FRESH printing of multiple bio-inks with orthogonal gelation mechanisms including collagen-based inks, alginate, fibrinogen, and methacrylated hyaluronic acid in the same print by adding CaCl2, thrombin, and UV light exposure (fig. S4) (15).

We first focused on FRESH-printing a simplified model of a small coronary artery–scale linear tube from collagen type I for perfusion with a custom-designed pulsatile perfusion system (Fig. 2A and fig. S5). The linear tube had an inner diameter of 1.4 mm (fig. S6A) and a wall thickness of ~300 μm (fig. S6B), and was patent and manifold as determined by dextran perfusion (fig. S6, C to E, and movie S2) (15). C2C12 cells within a collagen gel were cast around the printed collagen tube to evaluate the ability to support a volumetric tissue. The static nonperfused controls showed minimal compaction over 5 days (Fig. 2B), and a cross section revealed dead cells throughout the interior volume with a layer of viable cells only at the surface (Fig. 2C). In contrast, after active perfusion for 5 days, C2C12 cells compacted the collagen gel around the collagen tube (Fig. 2D), demonstrating viability and active remodeling of the gel through cell-driven compaction. The cross section showed cells alive throughout the entire volume (Fig. 2E), and quantitative analysis using LIVE/DEAD staining confirmed high viability within the perfused vascular construct (Fig. 2F). Others have 3D-bioprinted vasculature by casting cell-laden hydrogels around fugitive filaments, which become the vessel lumens (4, 5). In comparison, we directly print collagen to form the walls of a functional vascular channel, serving as the foundation for engineering more complex architectures.

Engineering smaller-scale vasculature, especially on the order of capillaries (5 to 10 μm in diameter), has been a challenge for extrusion-based 3D bioprinting because this is far below common needle diameters. However, at this length scale, endothelial and perivascular cells can self-assemble vascular networks through angiogenesis (17). We reasoned that the gelatin microparticles in the FRESH v2.0 support bath could be incorporated into the 3D-bioprinted collagen to create a porous microstructure, specifically because pores on the order of 30 μm in diameter have been shown to promote cell infiltration and microvascularization (18). FRESH v2.0–printed constructs contained micropores ~25 μm in diameter resulting from the melting and removal of the gelatin microparticles purposely entrapped during the printing process (Fig. 2G and movie S3). Collagen disks 5 mm thick and 10 mm in diameter were cast in a mold or printed and implanted in an in vivo murine subcutaneous vascularization model (Fig. 2, H and I, and fig. S7, A and B) to observe cellular infiltration. After implantation for 3 and 7 days, collagen disks were extracted and assessed for gross morphology, cellularization, and collagen structure (fig. S7, C to E). The solid-cast collagen showed minimal cell infiltration (Fig. 2J), whereas the printed collagen had extensive cell infiltration and collagen remodeling (Fig. 2K). Quantitative analysis revealed that cells infiltrated throughout the printed collagen disk within 3 days (Fig. 2L and fig. S8) and that the number of cells in the constructs was significantly greater for the printed collagen at 3 and 7 days compared to cast control [N = 6, P < 0.0001, two-way analysis of variance (ANOVA)] (15).