#EngineeringSimulation

Explore tagged Tumblr posts

Link

#aerodynamicsimulation#artificialintelligence#CFD#computationalfluiddynamics#engineeringsimulation#foundationmodel#Honda#IEA#JobyAviation#LuminaryCloud#LuminaryCloudAeroSUV#LuminaryCloudShift-SUVmodel#nTop#Nvidia#physicsAI#PiperAircraft#RuneAero#SAE#SAEWCX#Sceye#SutterHillVentures#SUVaerodynamics#TechnischeUniversitätMünchen

0 notes

Text

Simulink System Modeling: A Comprehensive Guide to Model-Based Design

In the realm of modern engineering, the complexity of systems has grown exponentially, necessitating advanced tools and methodologies to design, analyze, and implement these systems efficiently. One such powerful approach is Model-Based Design (MBD), prominently facilitated by tools like MATLAB and Simulink. This article delves into the intricacies of Simulink system modeling, exploring its significance, applications, and the advantages it offers in the engineering landscape.

Understanding Model-Based Design

Model-Based Design is a systematic approach that utilizes mathematical models as the foundation for designing and verifying complex systems. By creating executable specifications, engineers can simulate and validate system behavior early in the development process, leading to more efficient workflows and reduced time-to-market. This methodology is particularly beneficial in handling the multifaceted nature of modern systems, where traditional design approaches may fall short.

The Role of Simulink in System Modeling

Simulink, developed by MathWorks, is a graphical environment for modeling, simulating, and analyzing multidomain dynamic systems. It extends MATLAB's capabilities by providing a platform where engineers can construct block diagrams to represent system components and their interactions. This visual representation simplifies the understanding of complex systems and facilitates seamless integration across various domains.

Key Features of Simulink

Graphical User Interface (GUI): Simulink's intuitive GUI allows users to drag and drop blocks, connecting them to form a comprehensive system model. This approach enhances accessibility, enabling engineers to focus on design logic rather than syntax.

Multidomain Modeling: Simulink supports the integration of mechanical, electrical, hydraulic, and other physical domains within a single model. This capability is crucial for accurately representing systems that encompass multiple engineering disciplines.

Simulation Capabilities: With Simulink, engineers can perform time-domain simulations to observe system behavior under various conditions. This feature aids in identifying potential issues and optimizing performance before physical prototypes are developed.

Code Generation: Simulink facilitates automatic code generation for embedded systems, streamlining the transition from model to implementation. This functionality reduces manual coding errors and accelerates the development process.

Extensive Libraries: Simulink offers a vast array of pre-built blocks and toolboxes, catering to different applications such as control systems, signal processing, and communications. These resources expedite model development and ensure consistency across projects.

Applications of Simulink System Modeling

Simulink's versatility makes it applicable across various industries and engineering domains:

Automotive Industry: Simulink is extensively used for designing and testing control systems in vehicles, including engine management, transmission control, and advanced driver-assistance systems (ADAS). By simulating these systems, manufacturers can enhance safety and performance while reducing development costs.

Aerospace Sector: In aerospace engineering, Simulink aids in modeling flight dynamics, control systems, and avionics. The ability to simulate different flight scenarios ensures that systems meet stringent safety and performance standards.

Industrial Automation: Simulink facilitates the development of control algorithms for industrial machinery and processes. By modeling these systems, engineers can optimize efficiency, reduce downtime, and improve overall productivity.

Telecommunications: Simulink's capabilities extend to modeling and simulating communication systems, including signal processing and network protocols. This application is vital for designing robust and efficient communication infrastructures.

Medical Devices: In the medical field, Simulink assists in developing control systems for medical devices, ensuring they operate safely and effectively. Simulation allows for rigorous testing under various conditions, which is crucial for patient safety.

Advantages of Using Simulink for System Modeling

Early Detection of Issues: By simulating system behavior early in the design process, engineers can identify and address potential problems before they escalate, reducing costly revisions later.

Cost Efficiency: Simulink reduces the need for multiple physical prototypes by enabling virtual testing and validation, leading to significant cost savings in development.

Improved Collaboration: The visual nature of Simulink models facilitates better communication among multidisciplinary teams, ensuring that all stakeholders have a clear understanding of the system design.

Scalability: Simulink models can be scaled from simple components to complex systems, providing flexibility to adapt to projects of varying sizes and complexities.

Continuous Integration: Simulink supports integration with other tools and platforms, allowing for continuous testing and development, which is essential in agile development environments.

Implementing Model-Based Design with MATLAB and Simulink

To effectively leverage Simulink for system modeling, a structured approach to Model-Based Design is essential:

Define System Requirements: Clearly outline the system's functional and performance requirements to guide the modeling process.

Develop Mathematical Models: Use MATLAB to create mathematical representations of system components, which will serve as the foundation for Simulink models.

Construct Simulink Models: Utilize Simulink's block diagram environment to build graphical models of the system, incorporating the mathematical representations developed earlier.

Simulate and Analyze: Perform simulations to observe system behavior, analyze results, and validate that the model meets the defined requirements.

Iterate and Refine: Based on simulation outcomes, refine the model to address any identified issues or to optimize performance.

Generate Code: Once the model is validated, use Simulink's code generation capabilities to produce code for implementation in embedded systems.

Test and Deploy: Conduct hardware-in-the-loop (HIL) testing to ensure the system operates correctly in real-world conditions before full-scale deployment.

Challenges and Considerations

While Simulink offers numerous benefits, certain challenges may arise:

Learning Curve: New users may require time to become proficient with Simulink's features and functionalities.

Model Complexity: As system complexity increases, models can become intricate, necessitating careful

Conclusion

Simulink system modeling by Servotechinc revolutionizes engineering design by enabling rapid prototyping, simulation, and validation of complex systems. Its graphical approach, extensive toolboxes, and seamless integration with MATLAB streamline development across industries. By adopting Model-Based Design with Simulink, engineers can enhance efficiency, reduce costs, and ensure robust system performance, making it a cornerstone of modern engineering solutions.

#Simulink#ModelBasedDesign#MATLAB#SystemModeling#EngineeringSimulation#ControlSystems#EmbeddedSystems#Automation#AerospaceEngineering#AutomotiveEngineering#DigitalTwin#IndustrialAutomation#SoftwareDevelopment#SimulationTools#CodeGeneration

0 notes

Text

Did you know that cold and hot spark plugs are more different than you might think?

🤔 From their heat range and performance to their ideal engine applications, each plays a crucial role in ensuring optimal engine performance! Understanding the differences can help you choose the right spark plug for your engine. 🔧💡

Check out our website https://skill-lync.com/ for more details or contact us at [+91-9342691281]. 📲

👉 Follow Skill Lync for more engineering insights and industry trends. 🚀

🔄 Don’t forget to share this post with your peers and save it for future reference! 📌

#skilllync#mechanicalengineering#learnsolidworks#engineeringsimulation#solidworks#fea#youtube#automotive#unreal engine

0 notes

Text

Are you looking to advance your career in engineering simulations? The Ansys Training Course in Noida at APTRON Solutions is designed to provide you with a comprehensive understanding of Ansys software, a leading tool used in various industries for finite element analysis (FEA), computational fluid dynamics (CFD), and more. Whether you are an engineering student, a working professional, or someone aiming to switch careers, this course will equip you with the skills needed to excel in simulation and analysis.

#AnsysTraining#EngineeringSimulation#APTRONSolutions#NoidaTechEducation#CareerAdvancement#SimulationSkills#LearnAnsys#EngineeringExcellence

0 notes

Text

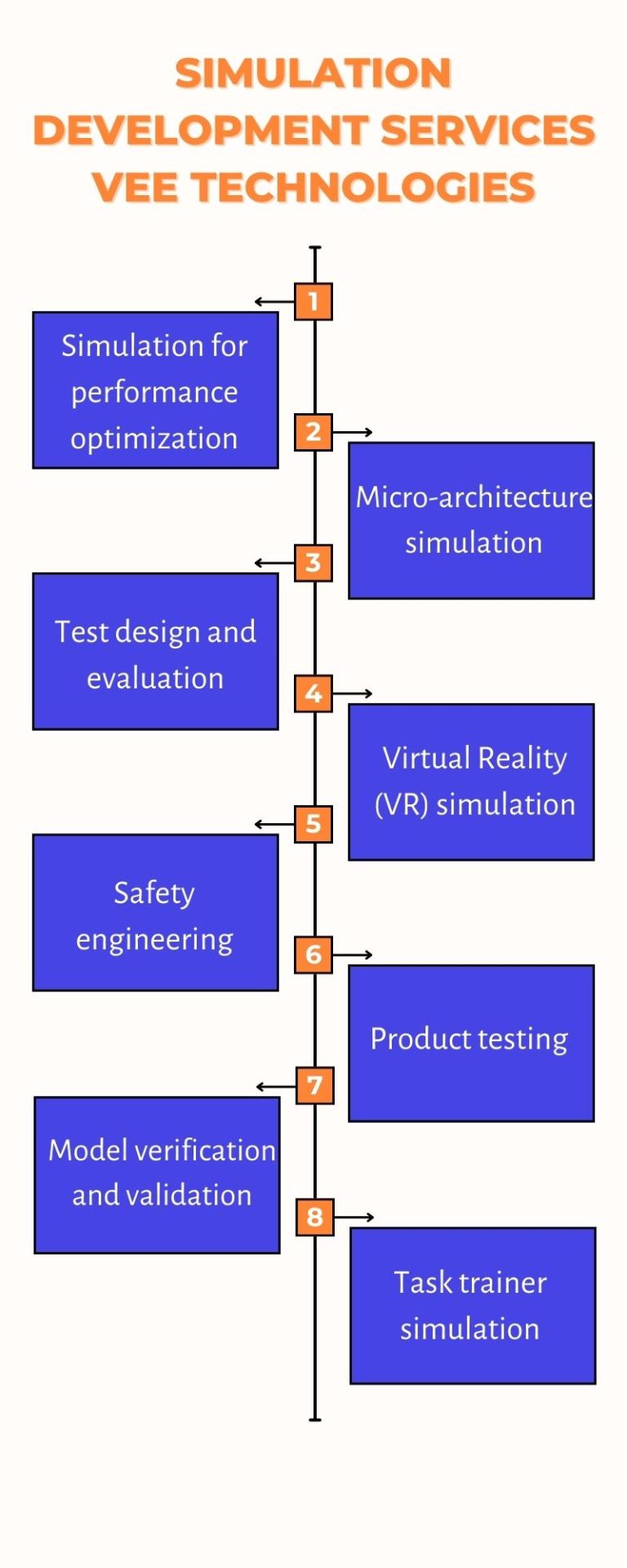

Vee Technologies' Simulation Development Services

At Vee Technologies, They provide simulation development services for both technical and non-technical learning requirements. Our high-quality, lightweight, and instant-loading videos make it easy for your target audience to learn on the go.

Explore More: https://www.veetechnologies.com/industries/animation-services/simulation-development.htm

#SimulationDevelopment#Simulations#3DModeling#VirtualSimulation#SimulationSoftware#TrainingSimulations#ModelingAndSimulation#DataVisualization#SimulationServices#InteractiveSimulations#SimulationDesign#EngineeringSimulations#SimulationTechnology

0 notes

Text

Vee Technologies' Simulation Development Services

At Vee Technologies, They provide simulation development services for both technical and non-technical learning requirements. Our high-quality, lightweight, and instant-loading videos make it easy for your target audience to learn on the go.

Explore More: https://www.veetechnologies.com/industries/animation-services/simulation-development.htm

#SimulationDevelopment#Simulations#3DModeling#VirtualSimulation#SimulationSoftware#TrainingSimulations#ModelingAndSimulation#DataVisualization#SimulationServices#InteractiveSimulations#SimulationDesign#EngineeringSimulations#SimulationTechnology#veetechnologies

0 notes

Text

youtube

Ultimate Guide to Reality Engineering Code Reviews: Best Practices & Tips for Optimal Performance

Click here to learn : https://tinyurl.com/RealityEngineering Discover the essential techniques for effective Reality Engineering code reviews in our comprehensive guide. Learn how to enhance code quality, optimize performance, and ensure robust simulations with top industry practices. This video covers best practices, common pitfalls, and actionable tips to elevate your code review process. Perfect for developers and engineers involved in creating advanced simulations and virtual environments. Watch now to master Reality Engineering code reviews and improve your project's success! Click here to learn : https://tinyurl.com/RealityEngineering Reality Engineering Code Reviews Code Review Best Practices Software Quality Assurance Performance Optimization Simulation Development Virtual Environments Code Review Tips Software Development Debugging Techniques Code Review Tools Engineering Simulations Code Consistency Security in Software Development Technical Debt Management Tags: Reality Engineering Code Reviews Code Quality Performance Optimization Simulation Engineering Virtual Reality Development Software Engineering Debugging Code Review Best Practices Development Tips Software Security Technical Debt Engineering Best Practices Code Documentation Software Performance Hashtags: #RealityEngineering#CodeReviews#SoftwareQuality#PerformanceOptimization#SimulationDevelopment#VirtualEnvironments#CodeReviewTips#SoftwareDevelopment#Debugging#CodeReviewTools#EngineeringSimulations#CodeConsistency#SoftwareSecurity#TechnicalDebt#CodingBestPractices

#Reality Engineering#Code Reviews#Code Review Best Practices#Software Quality Assurance#Performance Optimization#Simulation Development#Virtual Environments#Code Review Tips#Software Development#Debugging Techniques#Code Review Tools#Engineering Simulations#Code Consistency#Security in Software Development#Technical Debt Management#Youtube

1 note

·

View note

Text

WHAT´S NEW Simcenter STAR CCM+ 2302 https://www.prolim.com/whats-new-simcenter-star-ccm-2302/

Discover the potential of Simcenter STAR-CCM+ 2302 and unlock advanced capabilities for your CFD simulations. Benefit from improved multiphase modeling, efficient workflows, and accelerated solver performance. Elevate your engineering simulations to new heights with our cutting-edge software.

We value your feedback and encourage you to share your thoughts. For further details, please feel free to reach out to us at [email protected].

#ThinkPROLIM#DigitalTransformation#TodayMeetsTomorrow#PLMSolutions#SiemensPLM#SimcenterSTARCCM+#CFDsimulations#EngineeringSimulation#InnovationinEngineering

0 notes

Photo

Publish and showcase your simulations in 3D on FetchCFD for free. Check this project out in 3D here https://fetchcfd.com/view-project/258. Join now for free at https://fetchcfd.com/register

#fetchcfd#SimulationPlatform#cfd#EngineeringSimulation#fluid dynamics#computational fluid dynamics#simulation library#engineering#fluid mechanics

13 notes

·

View notes

Text

youtube

Welcome to Episode 7 of the "CAE Simulation using SolidWorks" series! 🎉 In this video, we’ll dive into Fatigue Analysis, exploring how repetitive loading affects the life and durability of materials. Using an S-hook model, we’ll demonstrate the setup, analysis, and interpretation of fatigue life and damage results. Whether you’re analyzing gold ornaments or industrial components, this tutorial will sharpen your simulation skills. 🌟 📌Key Highlights: Why Fatigue Analysis Matters: Real-world applications explained 🔍 Understanding S-N Curves: Predicting material failure under cyclic loads 📊 Types of Loading in SolidWorks: Fully reversed, zero-based, and more ⚙️ Step-by-Step Fatigue Analysis Setup 🛠️ Interpreting results: Damage and Life Predictions

💡 Pro tips for optimizing designs to extend fatigue life 🚀 Check out the episodes of this series here!

https://www.youtube.com/playlist?list=PL9-f9hWLZS61PrvBWiw94i5Kx3xjaFRnx

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4fPCi4a

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#skilllync#Youtube

0 notes

Text

youtube

Welcome to Episode 6 of the "CAE Simulation using SolidWorks" series! 🎉 In this episode, we tackle a buckling analysis challenge for a Cyclone Separator stand. Learn how to model and position a stiffener between the legs, perform buckling analysis, and use Design Studies to find the optimal stiffener position for maximum stability. This video is packed with practical tips to enhance your SolidWorks simulation skills! 💡 📌Key Highlights: How to model and position a stiffener in SolidWorks 🛠️ Setting up and running buckling analysis for structural stability 🔧 Understanding buckling factor of safety 📊 Using Design Studies to optimize stiffener placement and maximize stability ✨ Pro tips for managing parameters and constraints efficiently ⚡ Check out the episodes of this series here! https://www.youtube.com/playlist?list=PL9-f9hWLZS61PrvBWiw94i5Kx3xjaFRnx If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4eNKlNJ

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#Youtube

0 notes

Text

youtube

Performing Buckling Analysis in SolidWorks | Cyclone Separator Stand Simulation 🚀 Welcome to Episode 5 of the "CAE Simulation using SolidWorks" series! 🌟 In this episode, we’ll explore Buckling Analysis, an essential simulation technique for evaluating structural stability under axial loads. Using a Cyclone Separator stand, we’ll show you how to set up and analyze buckling behavior in SolidWorks. Learn how to interpret buckling factor of safety and optimize designs for improved stability. Whether you’re a beginner or an advanced user, this video will help you understand the nuances of buckling simulations. 💡 Key Highlights: Introduction to Buckling Analysis and its importance in FEA 🧩 Step-by-step setup for a buckling analysis in SolidWorks 🔧 How to interpret buckling factor of safety 📊 Exploring the impact of stiffeners on structural stability 💡 Pro tips for optimizing column designs for buckling resistance ✨

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#Youtube

0 notes

Text

youtube

Welcome to Episode 4 of the "CAE Simulation using SolidWorks" series! 🌟 This episode takes you on a detailed journey of analyzing a uniformly loaded cantilever beam using 1D, 2D, and 3D finite element methods in SolidWorks. Plus, discover how to perform a Parametric Study to optimize your designs efficiently. Whether you're a beginner or looking to refine your skills, this video is packed with practical insights and pro tips to elevate your SolidWorks expertise. 💡 ✨Key Highlights: Step-by-step guide to performing 1D, 2D, and 3D FEA on a cantilever beam 🧩 Comparing stress, displacement, and strain results across different models 📊 How to set up and run a Parametric Design Study 🔄 Understanding grid dependency and mesh refinement 🎛️ Pro tips on optimizing design using SolidWorks tools ✨

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3Z30adI

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#Youtube

0 notes

Text

youtube

Welcome to Episode 3 of our "CAE Simulation using SolidWorks" series! 🌟 This episode delves into the world of Nonlinear Analysis and 2D Simplification in SolidWorks. Learn how to set up nonlinear simulations, handle complex material behaviors, and optimize your models for computational efficiency. This tutorial is ideal for those looking to enhance their FEA skills with real-world simulation scenarios! 💡 🌟Key Highlights: Linear vs Nonlinear Analysis for Static and Dynamic Models 📐 Geometric, Material, and Contact Nonlinearities Explained 🧩 Practical Example: Using 2D Simplification to Reduce Computational Load 🖥️ Step-by-Step Guide to Nonlinear Material Models 🔧 Tips on Choosing the Right Material Model for Accurate Results 🧪

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#Youtube

0 notes

Text

youtube

Welcome to Episode 2 of our "CAE Simulation using SolidWorks" series! 🎉 Today, we're diving into Static and Dynamic Analysis—exploring the differences, applications, and how to set up each in SolidWorks. Whether you're a beginner or looking to deepen your understanding of Finite Element Analysis (FEA), this tutorial will guide you through setting up simulations, understanding stress-strain relationships, and when to choose linear or nonlinear analysis. Let’s get hands-on with SolidWorks and learn how to capture realistic behavior in mechanical parts and structures! 🌟 📌Key Highlights: Basics of Static vs Dynamic Analysis ⚖️ Linear and Nonlinear Analysis explained 📈 Real-world example: Tension Test on a Plate with a Hole 🧩 Step-by-step setup for Static and Nonlinear Analysis 🔧 When to use Static vs Dynamic simulations 💡

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#Youtube

0 notes

Text

youtube

Welcome to Episode 1 of our new instructional series, "CAE Simulation using SolidWorks!" 🎉 In this video, we’ll walk you through the fundamentals of Finite Element Analysis (FEA) in SolidWorks and introduce you to various simulation modules available in the software. If you're new to FEA or looking to solidify your understanding, this is the perfect starting point! Let's dive into the world of simulations and discover how to break down complex engineering problems into manageable elements. 💡 💥Key Highlights: Introduction to FEA and how it works ⚙️ Understanding stress-strain plots and material properties 📊 Differences between linear and nonlinear analysis 🔄 Essential steps of FEA: Pre-processing, Solving, Post-processing 🛠️ Types of analysis: Static, Fatigue, Frequency, Buckling, and more 🔍 Introduction to meshing, grid dependency, and element refinement 🎛️

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#Youtube

0 notes