#LinearSlideBearingBlock

Explore tagged Tumblr posts

Text

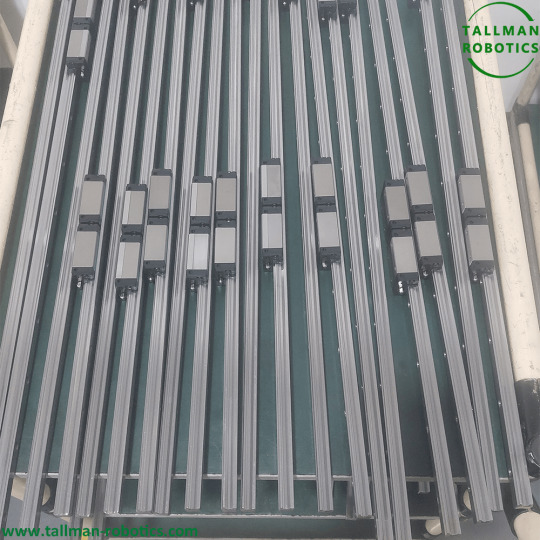

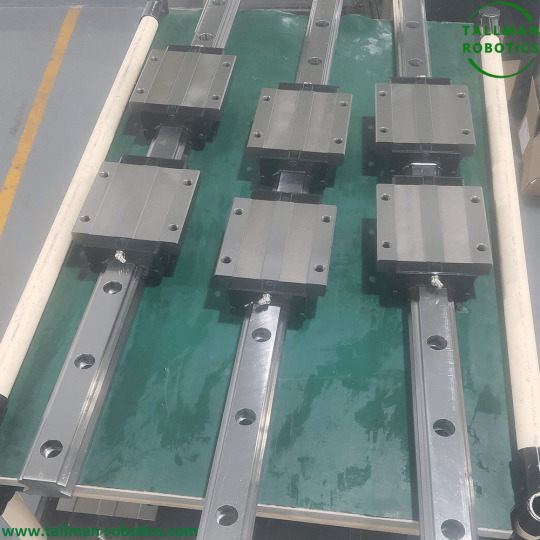

Linear Rail and Blocks are Ready for delivery to Russia

Linear Rail and Blocks will be delivered to Russia.

Linear rails and blocks are components commonly used in various applications, especially in mechanical and industrial systems. The purpose of linear rails and blocks is to guide and support linear motion, providing smooth and precise movement. Linear rails, also known as linear guides or guide rails, are long, rigid tracks made of durable materials such as steel, aluminum, or stainless steel. They have a profiled shape that serves as a guidance surface for the linear motion of the blocks. Linear rails are commonly available in different types, such as ball bearing slides, roller guides, and dovetail slides. They are designed to minimize friction and provide high rigidity to ensure accurate movement. Blocks are sliding elements that run along the linear rail. They are typically mounted on carriages or sliders that allow them to move back and forth along the rail. Blocks can be fitted with bearings, such as ball bearings or roller bearings, to reduce friction and enable smooth motion. Some blocks also have adjustable features to fine-tune the preload and ensure optimal performance. Together, linear rails and blocks form a linear motion system that offers precise and repeatable linear movement. These systems are widely used in various applications, including CNC machines, robotics, industrial automation, 3D printers, and many more. When selecting linear rails and blocks for a specific application, factors such as load capacity, precision requirements, speed, environmental conditions, and installation requirements need to be considered. It is essential to ensure compatibility between the rail and the block to achieve optimal performance and longevity of the system. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#GuideCarriages#LinearBearingPillowBlock#LinearBearingSliderBlocks#LinearGuideBlock#LinearGuideBlocks#LinearRailBlock#LinearSlideBearingBlock#Linearslides#Pillow-BlockBearings

0 notes

Text

Linear Rail Blocks will be sent to Russia

Linear Rail Blocks will be sent to Russia.

linear rail and Linear Slides are components used in linear motion systems to support and guide the linear motion of an object. They are typically made of a rigid material, such as steel or aluminum, and feature precision-machined surfaces for smooth and accurate movement. linear rail and Linear Slides consist of two main parts: the block or carriage and the linear rail. The block or carriage is usually mounted on top of the linear rail and contains ball bearings or rollers that run along the rail's groove. This design allows for low-friction movement and high precision. Linear Slides are commonly used in various industries and applications, including CNC machines, robotics, automation systems, and industrial machinery. They provide a stable and reliable means of linear motion, allowing for precise positioning and smooth operation. When selecting linear rail and Linear Slides, factors such as load capacity, accuracy, reliability, and system compatibility should be considered. It is also essential to choose the appropriate size and type of linear rail block based on the specific requirements of the application. Overall, linear rail and Linear Slides play a crucial role in ensuring smooth and precise linear motion in various industrial and automation processes, contributing to improved efficiency and performance. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#GuideCarriages#LinearBearingPillowBlock#LinearBearingSliderBlocks#LinearGuideBlock#LinearGuideBlocks#LinearRailBlock#LinearSlideBearingBlock#Linearslides#Pillow-BlockBearings

0 notes

Text

Linear Slide Bearing Blocks are ready for Italian Clients

Linear Slide Bearing Blocks are ready for Italian Clients. Linear slide bearing blocks are mechanical devices used in various applications to provide smooth and precise linear motion. They are a crucial component in systems that require controlled movement, such as CNC machines, 3D printers, robotic arms, and industrial automation equipment.

The main purpose of linear blocks is to support and guide a sliding element, such as a linear rail or shaft, allowing it to move linearly with minimal friction and play. These blocks typically consist of a housing and one or more bearing elements mounted inside. The bearing elements can be made from various materials, such as metal alloys or polymers, depending on the application's requirements. Some common types of linear slide bearing blocks include ball bearing slides, roller bearing slides, and plain bearing slides. Ball bearing slides use ball bearings to facilitate smooth and low-friction motion. They consist of a series of cylindrical bearing elements (balls) enclosed within a raceway. These slides are known for their high load capacity and excellent precision. Roller bearing slides use cylindrical rollers instead of balls for motion. The rollers distribute the load over a larger contact area, resulting in higher load capacities compared to ball bearing slides. They are often used in heavy-duty applications where high load capacity is required. Plain bearing slides are the simplest type of linear slide bearing blocks, utilizing a sliding contact between two surfaces. While they may not offer the same level of precision or load capacity as ball or roller bearing slides, they are often more cost-effective and suitable for less demanding applications. Linear blocks are typically designed to be compatible with specific linear guide rails or shafts, allowing for easy installation and interchangeability. They provide smooth and accurate linear motion, ensuring precise positioning and reducing wear and tear on the moving components. When selecting linear blocks for a particular application, factors to consider include load capacity, speed, precision, environmental conditions, and the required level of smoothness and reliability. It is important to choose the right type and size of bearing block to ensure optimal performance and longevity of the system. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#GuideCarriages#LinearBearingPillowBlock#LinearBearingSliderBlocks#LinearGuideBlock#LinearGuideBlocks#LinearRailBlock#LinearSlideBearingBlock#Linearslides#Pillow-BlockBearings

0 notes

Text

Linear Guide Rail Systems are Ready for delivery to France

Linear Guide Rail Systems will be delivered to France.

Linear guide rail systems are mechanical devices used to provide smooth and precise linear motion in various applications. They consist of a rail and a carriage that moves along the rail, allowing objects to be guided and supported in a linear direction. These systems are commonly used in industrial machinery, automation equipment, CNC machines, robotics, and other applications requiring accurate and repeatable motion. The rail is a long, straight metal or steel component with a specialized profile, usually with a groove or track along its length. The carriage, also known as a slider or runner, is mounted on the rail and contains rolling elements, such as ball bearings or rollers, that facilitate smooth and low-friction movement along the rail. Linear Motion Guide Rails offer several advantages over other types of motion systems, such as sliding friction-based systems. Here are some key benefits: 1. Precision and Accuracy: Linear guide rail systems provide high levels of precision and accuracy in linear motion. The rolling elements reduce friction, minimizing play and backlash, resulting in smooth and precise movement. 2. Load Capacity: These systems are designed to handle heavy loads and provide high load-carrying capacity. The load is distributed evenly along the rail, ensuring stability and preventing sagging or deflection. 3. Rigidity and Stability: Linear guide rail systems offer excellent rigidity, which helps maintain the position of the moving components during operation. This rigidity contributes to the overall stability and repeatability of the system. 4. Low Friction and Smooth Operation: The rolling elements in the carriage reduce friction, resulting in smooth and quiet operation. This feature is crucial for applications that require precise and controlled movement. 5. Long Service Life: Linear guide rail systems are designed to withstand repeated use and provide long service life. They are often constructed with durable materials and undergo rigorous testing to ensure reliability and durability. 6. Modular and Versatile: These systems are available in various sizes, lengths, and configurations, making them highly adaptable to different applications. They can be customized and combined to create complex motion systems or integrated into existing machinery. It's important to note that there are different types of linear guide rail systems available, such as ball-type, roller-type, and magnetic-based systems. The choice of system depends on factors such as load requirements, speed, precision, environment, and specific application needs. Overall, Linear Motion Guide Rails are widely used in industrial and automation settings to achieve precise, smooth, and reliable linear motion. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#GuideCarriages#LinearBearingPillowBloc#LinearBearingSliderBlocks#LinearGuideBlock#LinearGuideBlocks#LinearSlideBearingBlock#Linearslides

0 notes