#LockoutTagoutDevices

Explore tagged Tumblr posts

Text

OSHA Lockout Tagout Standard: Application of Control 1910.147(d)(4)

The next element of the sequence is:

Lockout Tagout application: The isolating device must be locked and tagged out by the authorized employee using individual Locks and Tags. These Locks & Tags must be affixed to each energy isolating device to hold it in a safe or off position and physically prevent its operation. Tagout devices must be affixed in a manner that it indicates the movement of the isolating device from the safe or off position is prohibited. Moreover, when the Tagout device is used along with the Lockout device, capable of being locked out, the tag so attached must be fastened at the same point at which the lock would have been attached. Although the Tag is supposed to be attached to the equipment along with the isolating device, in cases where the tag cannot be directly attached to the energy isolating device, it shall be located as close as safely possible to the device. Making sure that it is easily visible to the employee working on the machine, or around the machine, to avoid any inadvertent energization. Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#LockoutTagout#OSHA#LockoutDevice#TagoutDevice#LockoutTagoutDevices#OSHAGuidelines#LockoutTagoutManufacturer#LOTODevices#Safety#OSHAStandard#LOTO#WorkplaceSafety#SafetyTips#ESquare#ESquareAlliance

2 notes

·

View notes

Text

OSHA Standard 29 CFR 1910.147 - Definition of Hot Tap and & Normal Production Operations

Hot Tap:

As discussed in our previous post, OSHA standard 29 CFR 1910.147(a)(2) does not apply to Hot Tap and Normal Production Operations.

Hot tapping, or pressure tapping, is the method of making a connection to the existing piping or pressure vessels without interrupting the servicing for air, gas, water, steam, and petrochemical distribution systems. This means that a pipe can continue to be in operation while maintenance or modifications are being done to it. Only if the employer demonstrates that

· continuity of service is essential

· shutdown of the system is impractical

· documented procedures are followed, and special equipment is used which will provide proven effective protection for employees.

Normal Production Operation:

Certain tasks such as minor and repetitive adjustments are considered normal production operations when they are integral to the use of the equipment, and when they do not increase the risk of injury to employees.

So, OSHA Standard, 29 CFR 1910.147 (a)(2) does not apply to Hot tap and Normal Production Operations only when the employees working on it are considered to be SAFE.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#HotTap#LockoutDevices#LockoutTagoutDevices#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

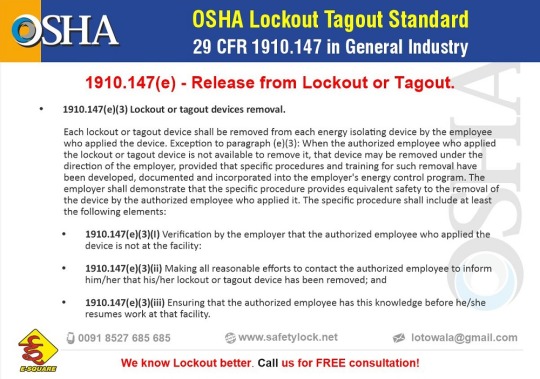

OSHA Lockout Tagout Standard 1910.147(e) - Release from Lockout or Tagout

After the maintenance task is complete, the machines are supposed to be reenergized and restored to normal production operation. But, before that reenergization takes place, OSHA’s Lockout Tagout standard requires that, standardized procedures should be followed, to ensure that employees are not subject to an increased potential for injury. Section (e)(1) requires that when the maintenance task is complete, the work area should be examined and thoroughly checked to ensure that all the nonessential items, including guards, left-behind tools, parts, and materials, have been removed, and that the equipment is operationally intact to avoid any mishap. Section (e)(2) requires a check of the work area to ensure that all employees are safely positioned, and the affected employees are notified that the Lockout Tagout devices have been removed, and the machine is safely reenergized. Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#LockoutTagout#OSHA#LockoutDevice#LockoutTagoutDevices#OSHAGuidelines#LOTODevices#Safety#OSHAStandard#LOTO#WorkplaceSafety#SafetyTips#ESquare#ESquareAlliance

0 notes

Text

OSHA Lockout Tagout Standard: Application of Control

Under section (a)(3)(i) of the Lockout Tagout standard 1910.147, the employers are required to establish a program and utilize procedures for affixing appropriate lockout devices or tagout devices to Energy Isolating Devices, and to otherwise disable machines or equipment to prevent unexpected energization, start up or release of stored energy in order to prevent injury to employees.

This section (d) of the Lockout Tagout standard, highlights the elements of the application of control of the established procedures.

The procedure shall cover the following elements and actions and it shall be done in the sequence mentioned below:

• 1910.147(d)(1): Preparation for shutdown.

• 1910.147(d)(2): Machine or equipment shutdown.

• 1910.147(d)(3): Machine or equipment isolation.

• 1910.147(d)(4): Lockout or tagout device application.

• 1910.147(d)(5): Stored energy.

• 1910.147(d)(6): Verification of isolation.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#LockoutTagout#OSHA#Safety#LOTODevices#LockoutTagoutDevices#LockoutTagoutProducts#WorkplaceSafety#OSHAGuidelines#LOTO#OSHAStandard#SafetyTips#LOTOProgram#OSHARegulations#OSHALockoutTagout#LockoutTagoutManufacturer#ESquare#ESquareAlliance

0 notes

Text

OSHA Lockout Tagout 1910.147(c)(5): Lockout Tagout devices must be Substantial

Lockout Devices typically Locks, hold energy Isolation Devices in a safe, off or neutral position. They provide protection by preventing machines or equipment from becoming energized because they are positive restraints, consequently. They should be substantial enough to prevent their removal by an authorized person without the use of excessive force or special techniques.

Tags and their means of attachment constructed must be substantial enough to minimize the potential for them to be disconnected, lost or accidentally removed. Tag attachment means are further required to be attachable by hand, and equivalent in strength to a one-piece non-releasable, self-locking cable tie. To meet these requirements, environment tolerant nylon cable tie that has an unlocking strength of about 50 pounds is used for attaching tags.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#OSHALockoutTagout#ProtectiveMaterial#LockoutTagoutDevices#LockoutTagout#LockoutDevice#OSHAGuidelines#LOTO#OSHAStandard#ESquare#ESquareAlliance

0 notes

Text

OSHA 29 CFR 1910.147(b) - Definition of Lockout and lockout Devices

Lockout consists of placing a disconnect switch, breaker, valve, spring, pneumatic assemble, or other energy-isolating mechanism in the off or safe position. A device is placed over, around, or through the energy-isolating mechanism to lock it in the off or safe position, and only the person attaching it applies a removable lock to the apparatus.

When the machine’s energy sources are locked out, there are specific guidelines that must be followed to make sure that the lockout device cannot be removed, and the system cannot be inadvertently operated. OSHA illustrates certain Lockout Tagout procedures that need to be followed while performing LOTO.

Every company has its drafted Energy Control Procedures/MSP that needs to be implemented systematically. It is the duty of the employer to make sure that the machine is not restarted until the Lockout device is removed.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#LockoutDevices#LOTODevices#LockoutTagoutDevices#ESquare#ESquareAlliance

0 notes

Text

OSHA Standard 1910.147(b) Definition - Energy Isolating Devices

Energy Isolating Devices are the primary tool for providing protection under the standard. They are mechanisms that prevent the transmission or release of energy and to which locks and tags are applied. Isolating a machine or piece of equipment from an energy source means using energy isolating device to interrupt the flow of energy from the means of transmission of the energy to the machine.

They include:

- A manually operated electrical circuit breaker

- A disconnect switch

- A manually operated switch by which the conductors of a circuit can be disconnected from all ungrounded supply conductors

- A line valve

- A block or any similar device

But Push buttons, selector switches and other control circuit type devices are not considered as Energy Isolating Devices.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#EnergyIsolatingDevices#EnergyIsolationDevices#LockoutTagoutDevices#LockoutTagoutProducts#LOTODevices#OSHA#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#ESquare#ESquareAlliance

0 notes

Text

Lockout Tagout Video: How to Install Lockout Devices?

Lockout Tagout products are designed differently for different applications. This ‘Do It Yourself’ video guides you to handle them easily.

We have more than 1500 Lockout Tagout devices on our website. Wondering which LOTO product is perfect for your premises for LOTO procedure? Our engineers can visit your facility and can suggest you the right Lockout devices, which can be customized as per your requirement.

We will help you in implementing Lockout Tagout system as per OSHA guidelines and make your premises safe for all. For more information on Lockout Tagout Solutions, visit https://www.safetylock.net

#LockoutTagoutVideo#HowToLOTO#LockoutTagoutDevices#LockoutTagout#LOTO#LotoImplementation#HowtoLockoutTagout#LOTOInstallation#LockoutTagoutImplementation#ESquare#ESquareAlliance

0 notes

Text

Avail Lockout Tagout Solutions for Different Industries | E-Square

E-Square provides the comprehensive Lockout Tagout (LOTO) solutions to various industries for their workplace safety and enhancing productivity. We offer different types of LOTO services and Lockout Tagout products which can be beneficial to them.

E-Square understands the importance of industry-specific LOTO products and strives to suggest appropriate solutions that address the unique safety concerns of different industries.

#LockoutTagoutSolutions#LOTOSolutions#LockoutTagout#LockoutTagoutProducts#LockoutTagoutDevices#LOTODevices#LOTOforIndustries#LOTOSafety#LOTOSystem#LockoutTagoutProgram#ESquare#ESquareAlliance

0 notes

Text

Lockout Tagout Installation/Implementation Service by E-Square

Not all Lockout Tagout devices are simple to install during LOTO procedure. Our Installation Engineers, backed by their extensive experience, have the skills and knowledge to handle such installations seamlessly. By opting for E-Square’s installation and implementation service, companies can complete their objectives at 1/8th the cost and in less time compared to replacing machines.

#LockoutTagout#lockouttagoutinstallation#lockouttagoutimplementation#LockoutTagoutSupplier#LockoutTagoutDevices#LOTODevices#LockoutTagoutProducts#LockoutDevices#LockoutTagoutExporter#ESquareAlliance

0 notes

Text

OSHA Lockout Tagout Standard 1910.147(f) - Additional Requirements

In general, equipment and machines are customarily shut down following the normal LOTO procedures, and any residual / stored energy is safely released. However, under certain circumstances, for example, testing with the power on, is often necessary to ensure the proper assembly and functioning of the components. It may not be possible to apply Lockout Tagout during the test being performed.

In such cases, OSHA permits the removal of Lockout Tagout devices and the re-energization of equipment only during the time necessary for the testing or positioning of the machine, equipment, or component, and only when re-energization is essential to accomplish the servicing task.

However, appropriate measures should be taken to protect people and minimize the risk in such special cases.

Temporary removal of locks or tags and re-energization of the machinery or equipment is permitted to allow testing or repositioning, provided that specific procedures control the sequence of actions to be taken. The procedures must provide maximum safety coverage for employees when the equipment or machinery must be energized during the course of servicing. Employee exposure to hazards is high during these transition periods.

When this occurs, re-energization also requires that the authorized employee:

1. Clear the machines or equipment of tools and materials.

2. Remove employees from the immediate area.

3. Remove the LOTO devices as specified in your company plan.

4. Energize and proceed with testing or positioning.

5. De-energize all systems, isolate the machine or equipment from the energy source, and reapply lockout or tagout devices as specified.

Therefore, the energy control procedure for the equipment being serviced must reflect the required sequence of actions to be taken, and employees should be thoroughly trained in the use of procedures.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#LockoutTagout#OSHA#LOTORemoval#LockoutTagoutRemoval#LockoutTagoutProcedure#Safety#SafetyTips#SafetyFirst#WorkplaceSafety#OSHAGuidelines#LOTO#OSHARegulations#OSHALockoutTagout#LockoutTagoutDevice#LOTODevices#ESquare

0 notes

Text

OSHA Lockout Tagout Standard 1910.147(e) - Lockout or Tagout Devices Removal

Each lockout or tagout device shall be removed from each energy isolating device by the employee who applied the device. But as per the Exception to paragraph (e)(3): If the employee who applied the LOTO device is not available to remove it, that device may be removed under the direction of the employer, provided that specific procedures and training for such removal have been developed, documented and incorporated into the employer's energy control program. The specific procedure shall include at least the following elements: (e)(3)(i) Verification by the employer that the authorized employee who applied the device is not at the facility: (e)(3)(ii) Making all reasonable efforts to contact the authorized employee to inform him/her that his/her lockout or tagout device has been removed; and (e)(3)(iii) Ensuring that the authorized employee has this knowledge before he/she resumes work at that facility. However, the removal of personal Lockout Tagout device by another employee is not possible for the sake of convenience or simply because the authorized person is not available. Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#LockoutTagout#OSHA#ReleaseLockoutTagout#LockoutTagoutRemoval#LOTORemoval#LockoutTagoutProcedure#Safety#SafetyFirst#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutDevice#LockoutTagoutManufacturer#ESquare

0 notes

Text

OSHA Lockout Tagout Standard: Application of Control 1910.147(d)

The established procedures for the application of energy control (the lockout or tagout procedures) covers the following elements and actions as mentioned above. Preparation of Shutdown: Before an authorized employee turns off the machine, he must have knowledge regarding the types, magnitude, hazards, and the means to control the energy. The first step is intended to notify all the affected employees regarding the Lockout and allow the employees to get ready for the shutdown, and plan ahead to perform safely.

In complex or group Lockout Tagout situations, all involved personnel should be made aware of their respective roles and assignments. Machine or Equipment shutdown: To place the machine in a state that it will let employees work on it safely, it must be turned off or shutdown using established procedures. An orderly shutdown must be used to avoid any increased or additional hazards to employees as result of shut down. Machine isolation: All the isolating devices such as isolators, valves, etc. that are needed to control the energy of the machines, must be physically located and operated so that the machine is isolated from its energy sources. Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#LockoutTagout#OSHA#LockoutDevice#TagoutDevice#LockoutTags#Safety#OSHAGuidelines#LOTO#OSHAStandard#SafetyTips#LOTOProgram#OSHARegulations#OSHALockoutTagout#LockoutTagoutDevice#LOTODevices#ESquare#ESquareAlliance

0 notes

Text

Lockout Tagout - Energy Isolation and Notification of Employee

Section (c) states that the process of Lockout Tagout shall be performed only by the authorized employees who are servicing. This is so because, an authorised employee is especially trained for the particular isolation, which any other employee might not be able to perform efficiently.

Lockout Tagout requires technical understanding, which cannot be done by any unskilled professional. Therefore, an authorised employee is assigned by the supervisor.

Notification of Affected Employees.

Lack of information regarding the status of equipment could endanger the employees who re-energize, operate or work around the machines. Whenever LOTO control might directly affect another employee’s work activities, paragraph (c) (9) requires the employer or authorized employee to notify the affected employees prior to applying, and after removing the Lockout Tagout device.

Such notification informs affected employees of the impending interruption of the normal production operation and reinforces the importance of the restrictions imposed.

After removing a LOTO device, notifying employees, alerts them that the equipment is capable of being started-up. Else, employees might mistakenly believe that a system is safe to continue working around the machine, leading to heinous accidents.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#LockotuTagout#OSHA#EnergyIsolation#EnergyIsolationDevices#Safety#OSHAGuidelines#LOTO#OSHAStandard#SafetyTips#LOTOProgram#OSHARegulations#OSHALockoutTagout#AffectedEmployee#LockoutTagoutDevice#LOTODevices#ESquare

0 notes

Text

OSHA Lockout Tagout: Full Employee Protection

OSHAs Lockout Tagout Standard does not prescribe the specifics of the energy control measures to be employed. Although, the standard lays down general procedures to be achieved, giving the employers flexibility in choosing the control procedures to be implemented, it focuses on achieving full employee protection.

Full Employee Protection:

As per OSHA Standard 1910.147(c)(3) - A lockout device should always be used when the machine’s energy isolating devices are capable of being locked out. But, there might be situations when, an isolating device is not capable of being locked out, a Tagout device is used alone in place of a Lockout device {1910.147(c)(3)(i)}.

In such a situation, it must provide a level of safety equivalent to that obtained by using a Lockout device, and the Tagout device must be attached at the same location, where the Lockout device would have been attached.

The employer must demonstrate full compliance with all Tagout related provisions of this standard. Additional protective measures, such as the removal of an isolating circuit element, blocking of a controlling switch, opening of an extra disconnecting device, or the removal of a valve handle to reduce the probability of inadvertent energization are needed to demonstrate that full employee protection has been achieved. Along with this, if an energy isolation device is not capable of being locked out, it must be redesigned or modified to accept the lock whenever major replacement, repair, renovation or modification of the machine is performed. The main motive is to achieve Full Employee Protection always. Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagoutDevice#EnergyIsolatingDevice#LOTODevices#EmployeeProtection#WorkerSafety#LockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#ESquare#ESquareAlliancePvtLtd

0 notes

Text

OSHA Lockout Tagout Standard 1910.147(b): Tagout and Tagout Device

A Tagout Device is a prominent Warning Device, such as a Tag and a tie i.e. any means of attachment, that clearly states that the machinery being controlled must not be operated until the tag is removed in accordance with an established procedure.

Tagout Device indicates employee photo, maintenance details, reason of isolation, numbering, specific instructions or warnings useful to avoid accidental energization of equipment under repair. These devices should be sturdy & substantial enough to withstand harsh conditions at the workplace.

The Tagout devices also indicate that the Energy Isolating Device and the equipment being controlled may not be operated until the tagout device is removed.

The procedure of placing a Tagout device on an energy isolating device in accordance to the established procedure is called Tagout.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#Lockout#Tagout#TagoutDevice#LockoutTagoutDevice#EnergyIsolatingDevice#OSHAGuidelines#LockoutTags#LOTO#OSHAStandard#OSHALockoutTagout#OSHARegulations#ESquare#ESquareAlliance

0 notes