#LockoutTagoutProcedure

Explore tagged Tumblr posts

Text

OSHA Lockout Tagout Standard 1910.147(f) - Additional Requirements

In general, equipment and machines are customarily shut down following the normal LOTO procedures, and any residual / stored energy is safely released. However, under certain circumstances, for example, testing with the power on, is often necessary to ensure the proper assembly and functioning of the components. It may not be possible to apply Lockout Tagout during the test being performed.

In such cases, OSHA permits the removal of Lockout Tagout devices and the re-energization of equipment only during the time necessary for the testing or positioning of the machine, equipment, or component, and only when re-energization is essential to accomplish the servicing task.

However, appropriate measures should be taken to protect people and minimize the risk in such special cases.

Temporary removal of locks or tags and re-energization of the machinery or equipment is permitted to allow testing or repositioning, provided that specific procedures control the sequence of actions to be taken. The procedures must provide maximum safety coverage for employees when the equipment or machinery must be energized during the course of servicing. Employee exposure to hazards is high during these transition periods.

When this occurs, re-energization also requires that the authorized employee:

1. Clear the machines or equipment of tools and materials.

2. Remove employees from the immediate area.

3. Remove the LOTO devices as specified in your company plan.

4. Energize and proceed with testing or positioning.

5. De-energize all systems, isolate the machine or equipment from the energy source, and reapply lockout or tagout devices as specified.

Therefore, the energy control procedure for the equipment being serviced must reflect the required sequence of actions to be taken, and employees should be thoroughly trained in the use of procedures.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#LockoutTagout#OSHA#LOTORemoval#LockoutTagoutRemoval#LockoutTagoutProcedure#Safety#SafetyTips#SafetyFirst#WorkplaceSafety#OSHAGuidelines#LOTO#OSHARegulations#OSHALockoutTagout#LockoutTagoutDevice#LOTODevices#ESquare

0 notes

Text

Lockout Tagout - 8 Steps of LOTO Procedure for Workplace Safety

Our comprehensive lockout tagout guide focuses on 8 essential steps to implement LOTO procedure for critical safety. Learn how to identify hazardous energy sources, prepare for shutdown, isolate energy sources, ground and bond equipment, verify energy isolation, apply lockout devices, test for residual energy, and authorize work and release.

Follow these Lockout Tagout steps to minimize accidents and create a safer working environment for everyone.

#LockoutTagout#LOTOSteps#LockoutTagoutProcedure#8StepstoApplyLockoutTagout#LOTOProcedure#LockoutTagoutGuide#WorkplaceSafety#ESquareAlliance

0 notes

Text

INDUSTRIAL WATERPROOF PLUG LOCKOUT WHOLESALE AND RETAIL SUPPLIER IN ABUDHABI-UAE #14870 #14871 #14872

COLOUR Blue /Red / Yellow

WEIGHT 60gm

MATERIAL Made of engineering plastic PC

PADLOCK NUMBERS 1

PRINTED STICKER DANGER LOCKED OUT

APPLICATION Just need to insert the lockout device in the socket and fasten the socket in the right position and then use the padlock or hasp to lockout the socket in place

#ryxo#ryxosafety#ryxouae#ryxoabudhabi#ryxobrand#clearway#clearwayuae#clearwaysafety#clearwayabudhabi#clearwaysafetystore#ppesafetystore#safetyshopabudhabi#safetyshopuae#lockouttagout#lockouttagoutprocedure#pluglockout#pluglockoutuae#waterprrofpluglockout#industrialpluglockout#lockouttagoutabudhabi#lockouttagoutwholesale#lockouttagoutinuae#14870#14871#14872

0 notes

Text

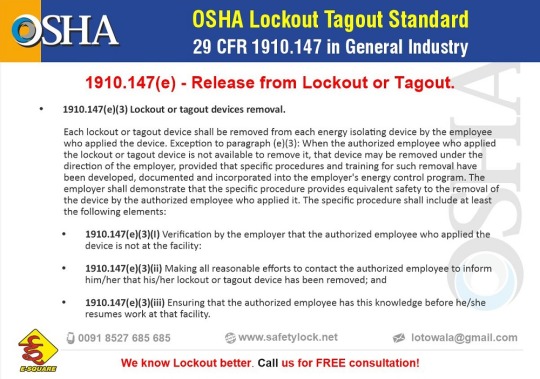

OSHA Lockout Tagout Standard 1910.147(e) - Lockout or Tagout Devices Removal

Each lockout or tagout device shall be removed from each energy isolating device by the employee who applied the device. But as per the Exception to paragraph (e)(3): If the employee who applied the LOTO device is not available to remove it, that device may be removed under the direction of the employer, provided that specific procedures and training for such removal have been developed, documented and incorporated into the employer's energy control program. The specific procedure shall include at least the following elements: (e)(3)(i) Verification by the employer that the authorized employee who applied the device is not at the facility: (e)(3)(ii) Making all reasonable efforts to contact the authorized employee to inform him/her that his/her lockout or tagout device has been removed; and (e)(3)(iii) Ensuring that the authorized employee has this knowledge before he/she resumes work at that facility. However, the removal of personal Lockout Tagout device by another employee is not possible for the sake of convenience or simply because the authorized person is not available. Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#LockoutTagout#OSHA#ReleaseLockoutTagout#LockoutTagoutRemoval#LOTORemoval#LockoutTagoutProcedure#Safety#SafetyFirst#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutDevice#LockoutTagoutManufacturer#ESquare

0 notes

Text

𝐋𝐨𝐜𝐤𝐨𝐮𝐭 𝐓𝐚𝐠𝐨𝐮𝐭 - 𝐓𝐫𝐚𝐢𝐧𝐢𝐧𝐠 𝐚𝐧𝐝 𝐂𝐨𝐦𝐦𝐮𝐧𝐢𝐜𝐚𝐭𝐢𝐨𝐧 (Part D, E and F)

𝐏𝐚𝐫𝐭 𝐃 specifies,

Tags must be made of materials capable enough of withstanding the environment to which they are exposed for the maximum period of time.

This also means that, exposure to weather conditions or wet and damp locations should not cause the tag to deteriorate.

𝐏𝐚𝐫𝐭 𝐄 further elaborates -

These Lockout Tags although play a very important part in providing safety to the worker applying the safety device, but they might induce false sense of security to the plant worker, if used alone.

Incidences occur where, due to bad environmental condition or physical dismantling, LOTO Tag got removed during servicing, lead to mishaps.

Therefore, Lockout tags must always be used along with LOTO Locks if the machine or equipment in use is capable of being Locked out.

𝐏𝐚𝐫𝐭 𝐅 says,

It is necessary that these Tags must be securely attached to the energy isolating devices so that they cannot be inadvertently detached.

They are non-reusable, self-locking, and non-releasable with a minimum unlocking strength of no less than 50 pounds.

Workers on the site must be specified and trained about these limitations of Tags.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#LockoutTagout#TrainingandCommunication#LOTOTraining#LockoutTags#LOTOLocks#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#OSHA#LockoutTagoutProgram#Safety#WorkplaceSafety#ESquare

0 notes

Text

Lockout Tagout - Training and Communication

Although Tags have a significant importance in the LOTO procedure, but when used alone, they have certain limitations, and employees should be trained in the limitations of tags when applied alone. Part A specifies, Tags are warning devices that are affixed to energy isolating devices; which means they do not act as physical restraint on those devices, unlike a lock. When a Lock is applied to an energy isolation device, it acts as a physical barrier that blocks the operation of the machine until the authorized employee removes it. Whereas, Tags applied along with the Lock acts only as a cautionary instruction. They might get dismantled, eroded, ignored, bypassed or defeated, if used alone. Part B says, for the placement of Lockout Tags, an authorized employee is always assigned by the supervisor as per the procedure. This person is a trained employee who knows what devices to be used, how and where to be used effectively to block the flow of hazardous energies. Since, these industrial tags are made of high performance, durable materials that can withstand harsh environments - both indoors and outdoors; they cannot be bypassed or defeated unless intentional. Part C says, Tags must be legible and understandable by all authorized, affected, and other employees who are involved. OSHA requires that the major message printed on the tag “warn against hazardous condition of the equipment is re-energized.” Five examples of acceptable warnings are provided, including Do Not Start. Do Not Open. Do Not Close. Do Not Energize. Do Not Operate. In all cases, employees must know and understand the meaning of the Tag. For more details about Tag limitations, visit - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#OSHA#LockoutTagout#TrainingandCommunication#Safety#WorkplaceSafety#LockoutTagoutTraining#LOTOTraining#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#LockoutDevices#LockoutTags#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#LockoutTagoutProgram#LockoutTagoutManufacturer#ESquare#ESquareAlliance

0 notes

Text

OSHA Lockout Tagout Standard - 1910.147(c)(6) Periodic inspection

To ensure that the energy control procedures in place are adequate and being properly and consistently applied, a Lockout Tagout program must be reviewed/inspected periodically and revised if needed. Section (c)(6) of the OSHA Standard sets forth specific requirements for conducting the periodic inspection.

The periodic inspection provisions of the standard 1910.147(c)(6)(i) require that energy control program be reviewed at least annually to ensure compliance. The intent of this requirement is to ensure that energy control program is updated, accessible, and being implemented properly, and that the employees remain familiar with their responsibilities under those procedures. The periodic inspection also serves as an essential check to verify the continued proficiency of the employees in the safe application, use, and removal of the energy controls.

Under section (c)(6)(i)(B) The periodic inspection must be designed to correct any deviations and inadequacies observed, and the employer must certify that the periodic inspections have been performed.

Further, under Section (c)(6)(i)(C) of the standard requires that the inspector reviews the responsibilities of each authorized employee under the procedure with that employee.

Under Section(c)(6)(i)(D) the standard requires that when tagout alone is used, both authorized and affected employees must review the use of the tagout system as part of the annual inspection. This additional review is necessary because of the shortcomings of the tagout system. Tags can be removed or bypassed, and provide limited protection when compared to locks. To ensure proper implementation of Tagout, it is also important to periodically review responsibilities with affected employees and remind them of the restrictions imposed on them under the program. When Tagout alone is used, the annual inspection must also include a review on the limitation of tags with each affected and authorized employee.

Certifying the Inspection - 1910.147(c)(6)(ii)

Under the Standard 1910.147, the employer shall certify that the periodic inspections have been performed. In addition to the equipment, date of the inspection, name of the inspector, the employees included in the inspection and the person performing the inspection must also be documented. This document is intended to ensure that the involved employees have had the opportunity to review their responsibilities and demonstrate their performance under the procedure.

The inspection must be able to determine:

· Whether the steps in the energy control procedure are being followed

· Whether the employees involved know their responsibilities under the procedure

· Whether the procedure is adequate to provide the necessary protection, and what changes, if any, are needed.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#OSHA#PeriodicInspection#Safety#WorkplaceSafety#LockoutTagout#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#LockoutDevices#LockoutTags#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#LockoutTagoutProgram#ESquare#ESquareAlliance

0 notes

Text

OSHA Lockout Tagout Standard - Lockout Tagout devices must be Standardized & Identifiable

Under section (B) of (c)(5)(ii) of the OSHA Standard 1910.147, requires that Lockout Tagout Devices must be standardized in either colour, shape, size, print or format. The requirement of the standardized devices is meant to ensure that they are readily identifiable, unique, and distinguished from other similar devices found in the workplace. The intent of these provisions is to elevate the importance of Lockout Tagout devices and ensure that all the employees understand their distinct and exclusive purpose - to protect services & maintenance employees from accidental start-up or the release of stored energy. Section (c)(5)(ii)(D) of the standard requires that Lockout Tagout devices identify the employees who apply them. This requirement adds a degree of accountability to the LOTO program. Once the involved employee is identified, he/she can be located when needed. This identification is also essential as it enables the employer to quickly determine the identity of the employee who forgot to remove his lockout Tagout device. Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#OSHA#ProtectiveMaterialandHardware#LockoutTagout#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#LockoutDevices#LockoutTags#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#LockoutTagoutProgram#ESquare#ESquareAlliancePvtLtd

0 notes

Text

OSHA Lockout Tagout Standard - 1910.147(c)(5)(ii)(A) - Protective Material and Hardware - Durability

According to OSHA Standard 1910.147(c)(5)(ii)(A) - The Lockout Tagout devices must be DURABLE. The durability requirements are intended to ensure that the Lockout Tagout devices will not fail to perform their intended job. The LOTO Devices must be durable enough to resist the harsh environmental conditions - chemicals, abrasion and temperatures, to which they are exposed to for the expected period of time.

Tags and their means of attachment must be constructed and printed, so that the exposure to weather or other environmental conditions does not cause them to become unserviceable or the message on the Tag to become illegible. Using laminated Tags with reinforcing eyelets is generally adequate for the vast majority of work environment.

Tags so constructed, must also be durable enough to withstand the corrosive environment, especially the areas where acid and alkali chemicals are handled and stored.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#ProtectiveMaterial#LockoutTagout#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#LockoutDevices#LockoutTags#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

OSHA 1910.147(c)(4) Energy Control Procedure

Most of the OSHA Violations are due to the unavailability of Energy Control Procedures (ECP) or Machine Specific Procedures (MSP) in organisations. Companies buy Local products, just to become LOTO compliant, but they do not know the correct procedure for safe isolation and control of Hazardous energies. Successful implementation of Energy Control Program requires an understanding and awareness of Hazardous energy types and magnitude, the methods, techniques, and devices used to control that energy.

To provide guidance to employees for putting the program into practice, written Energy Control Procedures should be developed. These procedures must define the purpose, scope, and application of the program, deploy the responsibilities of the managers, supervisors, and employees for implementing a systematic Lockout Tagout program.

A written Energy Control procedures (ECP) / Machine Specific procedures (MSP) needs to be developed, documented as it clearly and specifically outlines the steps to be followed, techniques to be used, and measures to be applied for the control of potentially Hazardous Energy.

This includes specific steps to shut down, isolate, block, secure, place, and remove lockout or tagout devices, and to determine the effectiveness of those devices by following verification steps.

The written ECP/MSP must have pictorial representation for isolation, installed images of LOTO devices that specifies procedural steps for the placement, removal and transfer of Lockout Devices or tagout devices.

Lack of compliance can lead to serious disciplinary actions. Industries need to mention the consequences in case of non-compliance of Lockout Tagout due to any reason, whatsoever.

Periodic inspections are mandatory to help ensure that the energy control procedures and the requirements of the standard are being followed.

Services of LOTO can be taken for developing ECPs/MSPs as they have vast industrial knowledge to prescribe the proper steps for the safe isolation by the correct use of Lockout Tagout.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#OSHA#EnergyControlProcedure#LockoutTagoutProcedure#LOTOProcedure#LockoutTagout#OSHAViolations#OSHAGuidelines#LOTO#LockoutTagoutProgram#OSHAStandard#OSHALockoutTagout#ESquare#ESquareAlliance

0 notes

Text

OSHA 1910.147 (c)(2) General - Lockout Tagout

The OSHA Standard, 1910.147 (c) set forth nine general principles which provide the framework for ensuring the safety of personnel who maintain the machines.

OSHA Standard 1910.147(c)(2) emphasizes on the importance of Full Employee protection by Lockout Tagout.

Generally, the isolation devices should be capable of being locked out in majority of circumstances. But, there can be incidences where a Tagout device is used instead. A Tagout device, without a Lockout, may be used only when energy isolating device, is not capable of being locked out, or when the employer demonstrates that use of the tagout system alone, is substantial enough to be used in place, where the Lockout device is not applicable. It must provide a level of safety equivalent to that obtained by using a Lockout device, and the Tagout device must be attached at the same location, where the Lockout device would have been attached.

In such a situation, it solely becomes the responsibility of the employer to provide ‘full employee protection.’

After January 2, 1990 according to the standard 1910.147 (c)(2)(iii), it has become mandatory for the manufacturers, that in case of modification of machines and equipments, whenever replacement, major repair or installation of new machines are done, the energy isolating devices for such machines or equipment shall be designed to accept a lockout device.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#EnergyControlProcedure#LockoutTagout#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

OSHA Lockout Tagout Standard 1910.147(c)(1) - Energy Control Program

LOTO is intended to provide effective safety in the modern industrial workplace. It saves lives by protecting workers from hazardous energy, and it reduces downtime by streamlining and standardizing work processes. For successful implementation of Lockout Tagout in an industry, it is important to have awareness about LOTO and a well-developed LOTO System. Lack of knowledge and absence of LOTO system, leads to uncalled eventualities. Even with the re-occurrence of repeated incidences, the workers and the management are not sure that it is due to the absence of proper LOTO System in place.

The employer is to establish an Energy Control Program - comprising of the energy control procedures, employee training and periodic inspections, all of which help to ensure that the machine and equipment are properly isolated from their energy sources, and rendered inoperative prior to any servicing and maintenance.

A well-defined energy control policy and procedure helps in planned and systematic working of the machines and equipment; Employee training is needed to provide employees with knowledge, skills and motivation to effectively implement a successful Lockout Tagout Program; Audits & periodic inspections help companies insure that, they have the up-to-date & accurate devices and procedures that allow employees of the companies to safely de-energize the equipment.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#EnergyControlProcedure#EnergyControlProgram#LockoutTagout#MaintenanceTask#OSHALockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

OSHA 29 CFR 1910.147(b) - Definition of Servicing and Maintenance & Setting Up

Most of the injuries and fatalities in industries occur while workers perform service and maintenance tasks. The Lockout Tagout Standard set forth in 29 CFR 1910.147 covers the servicing and maintenance of machines and equipment in general industry. Activities such as construction, installation, setting up, inspection, etc. are defined by OSHA as services and maintenance.

These activities include lubrication, cleaning, unjamming, making adjustments or tool changes, are integral to the use of equipment. These are considered service and maintenance if employees are exposed to unexpected energization or startup of the machines or equipment, or release of stored energy could cause injury to employees.

Setting up: Many servicing or maintenance activities require the machine, equipment, or its components to be disassembled or dismantled. These tasks are typically performed with the equipment stopped.

The reassembling of machines and equipment after the servicing and maintenance task has been performed is called setting up.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagout#MaintenanceTask#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

OSHA Standard 29 CFR 1910.147 - Definition of Hot Tap and & Normal Production Operations

Hot Tap:

As discussed in our previous post, OSHA standard 29 CFR 1910.147(a)(2) does not apply to Hot Tap and Normal Production Operations.

Hot tapping, or pressure tapping, is the method of making a connection to the existing piping or pressure vessels without interrupting the servicing for air, gas, water, steam, and petrochemical distribution systems. This means that a pipe can continue to be in operation while maintenance or modifications are being done to it. Only if the employer demonstrates that

· continuity of service is essential

· shutdown of the system is impractical

· documented procedures are followed, and special equipment is used which will provide proven effective protection for employees.

Normal Production Operation:

Certain tasks such as minor and repetitive adjustments are considered normal production operations when they are integral to the use of the equipment, and when they do not increase the risk of injury to employees.

So, OSHA Standard, 29 CFR 1910.147 (a)(2) does not apply to Hot tap and Normal Production Operations only when the employees working on it are considered to be SAFE.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#HotTap#LockoutDevices#LockoutTagoutDevices#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHALockoutTagout#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

OSHA Standard 29 CFR 1910.147 - Capable of being locked out

For isolation it is must that the equipment or machines should be capable of being locked out. The newer versions of equipment are manufactured with the in-built features for isolation. The challenge comes with the older equipment. Many a times it is noticed that workers who are working on the machines are actually unaware that these equipment can be locked out as well.

An energy-isolating device is considered capable of being locked out if: - It is designed with a hasp or other means of attachment to which a lock can be affixed.

- It has a locking mechanism built into it.

- If a lockout can be achieved without the need to dismantle, rebuild, or replace the energy isolating device or permanently alter its energy control capability.

Energized:

Before Manufacturing or servicing, the equipment or machines need to be in zero energy state. Energized equipment can pose a threat to the workers in the vicinity.

Just shutting off does not mean that the machine is de-energized. A machine or equipment is said to be energized if it is connected to an energy source like- electrical, mechanical, hydraulic, and pneumatic, etc. Or if it contains any residual/stored energy- from solid chemicals, gases, liquids and vapors; Energy from the movement of springs, wheels or elevated parts; Batteries and capacitors; Pressurized and moving gases.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#OSHA29CFR1910147#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

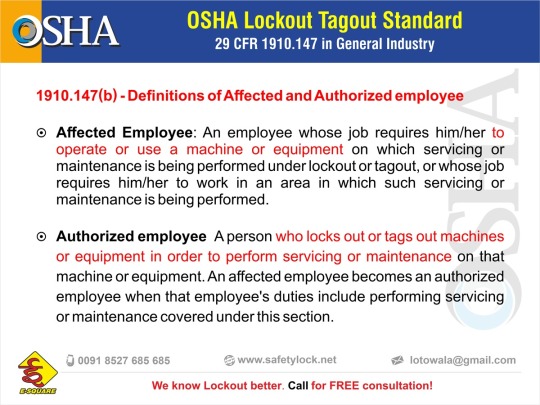

OSHA Lockout Tagout Standard 1910.147(b) - Definition of Affected and Authorized Employee

OSHA Lockout Tagout standard 1910.147(b) defines authorized and affected employees as:

An Authorized employee, by definition, is a person who locks out or tags out machines or equipment in order to perform servicing and maintenance on that machine or equipment. Authorized employees are those who are charged with the responsibility for implementing the energy control procedure prior to performing servicing and maintenance, and thus require the highest level of training.

Whereas, an Affected employee, by definition, is an employee whose job requires him/her to operate or use a machine or equipment on which servicing or maintenance is to be performed. Affected employees are generally the machine operators or users. An affected employee becomes an authorized employee when that employee’s duties include performing servicing and maintenance.

Check OSHA guidelines in detail - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#AuthorizedEmployee#AffectedEmployee#OSHALockoutTagout#OSHAGuidelines#OSHAStandard#LOTO#LockoutTagoutDevice#LOTODevices#LOTOProcedure#LockoutTagoutProcedure#WorkplaceSafety#Safety#LockoutTagoutAccidents#ESquare#ESquareAlliance#EsquareTrainingAcademy

0 notes