#ESquareAlliance

Text

Lockout Tagout and Inform Your Co-Workers | LOTO Video

Lockout Tagout is an important aspect when you are working on any machine or planning to perform maintenance task. When multiple workers are doing maintenance on same machine then they must lockout tagout the equipment with their own device and also inform the other workers to avoid any accident or injury while doing maintenance.

In this video, you can check it very clearly why one should always lockout tagout and inform co-workers and what could be the consequences of not following this thing.

Always perform Lockout Tagout systematically.

We will help you in implementing Lockout Tagout system as per OSHA guidelines and make your premises safe for all. For more information on Lockout Tagout Solutions, visit - https://www.safetylock.net

0 notes

Text

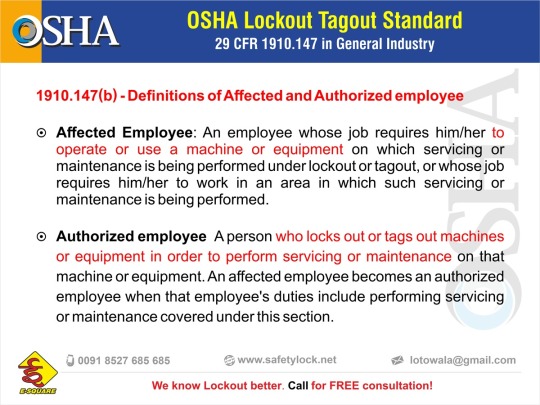

OSHA Lockout Tagout Standard 1910.147(b) - Definition of Affected and Authorized Employee

OSHA Lockout Tagout standard 1910.147(b) defines authorized and affected employees as:

An Authorized employee, by definition, is a person who locks out or tags out machines or equipment in order to perform servicing and maintenance on that machine or equipment. Authorized employees are those who are charged with the responsibility for implementing the energy control procedure prior to performing servicing and maintenance, and thus require the highest level of training.

Whereas, an Affected employee, by definition, is an employee whose job requires him/her to operate or use a machine or equipment on which servicing or maintenance is to be performed. Affected employees are generally the machine operators or users. An affected employee becomes an authorized employee when that employee’s duties include performing servicing and maintenance.

Check OSHA guidelines in detail - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#AuthorizedEmployee#AffectedEmployee#OSHALockoutTagout#OSHAGuidelines#OSHAStandard#LOTO#LockoutTagoutDevice#LOTODevices#LOTOProcedure#LockoutTagoutProcedure#WorkplaceSafety#Safety#LockoutTagoutAccidents#ESquare#ESquareAlliance#EsquareTrainingAcademy

0 notes

Text

Online Lockout Tagout Training and LOTO Courses | E-Square Training Academy

To support your workplace LOTO safety training needs, E-Square Training Academy offers variety of online lockout tagout training courses and programs. Our 20 years of experience in Lockout Tagout makes us experts at enabling you to gain insight into your LOTO program and into your business.

Training is an essential part of every employer’s health and safety program and several studies highlight that effective training and re-training for Lockout Tagout plays a pivotal role in preventing lockout tagout related injuries and fatalities.

We help health and safety practitioners, business owners and workers to stay safe, compliant and productive through our extraordinary, high impact, and experiential breakthrough training programs. E-Square Training Academy offers a variety of innovative and friendly training programs. Our training programs are based on internationally accepted most stringent standards on hazardous energy management to ensure optimum safety levels.

All of our training programs are based on OSHA’s Resource for development and delivery of training recommended ADDIE model for training development.

We offer:

On-site Lockout Tagout Training

Virtual-Live Training

Online LOTO Courses

Industry Specific LOTO Training

For more information about Lockout Tagout Training and Online Courses, visit - https://www.lototrainingcourses.com

#lototrainingcourses#lockouttagoutcourse#lockoutagouttraining#onlinelockoutagouttraining#lockoutagoutcourses#lototraining#lotocoursesonline#onlinelotocourses#lockouttagoutprogram#esquarealliance#esquaretrainingacademy#esquareacademy#esquare#lockouttagout#onlinelototraining#onlinelockouttagoutcourses

1 note

·

View note

Text

Lockout Tagout Video: How to Install Lockout Devices?

Lockout Tagout products are designed differently for different applications. This ‘Do It Yourself’ video guides you to handle them easily.

We have more than 1500 Lockout Tagout devices on our website. Wondering which LOTO product is perfect for your premises for LOTO procedure? Our engineers can visit your facility and can suggest you the right Lockout devices, which can be customized as per your requirement.

We will help you in implementing Lockout Tagout system as per OSHA guidelines and make your premises safe for all. For more information on Lockout Tagout Solutions, visit https://www.safetylock.net

#LockoutTagoutVideo#HowToLOTO#LockoutTagoutDevices#LockoutTagout#LOTO#LotoImplementation#HowtoLockoutTagout#LOTOInstallation#LockoutTagoutImplementation#ESquare#ESquareAlliance

0 notes

Text

Avail Lockout Tagout Solutions for Different Industries | E-Square

E-Square provides the comprehensive Lockout Tagout (LOTO) solutions to various industries for their workplace safety and enhancing productivity. We offer different types of LOTO services and Lockout Tagout products which can be beneficial to them.

E-Square understands the importance of industry-specific LOTO products and strives to suggest appropriate solutions that address the unique safety concerns of different industries.

#LockoutTagoutSolutions#LOTOSolutions#LockoutTagout#LockoutTagoutProducts#LockoutTagoutDevices#LOTODevices#LOTOforIndustries#LOTOSafety#LOTOSystem#LockoutTagoutProgram#ESquare#ESquareAlliance

0 notes

Text

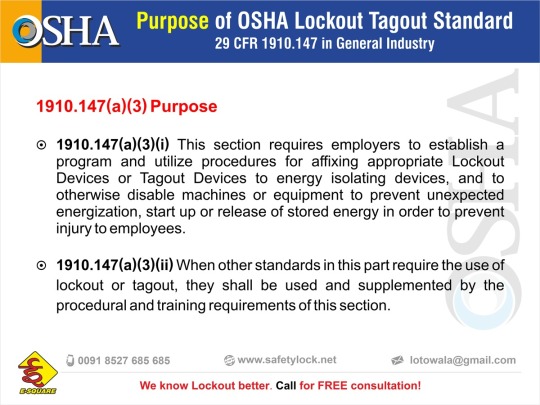

Purpose of OSHA Lockout Tagout Standard - 29 CFR 1910.147 in General Industry

More than half of the fatalities occur due to mishappenings caused while workers carry out service or maintenance related tasks. So, to avert these accidents and mishappenings OSHA Lockout Tagout Standard requires that employers must establish a well-defined LOTO Program which should have a complete Lockout Tagout planning, responsibilities and procedures for systematic application & removal of Lockout Tagout isolating devices to prevent unexpected energization, start up or release of Stored Energy that can cause serious injuries to employees working on it.

It should be supported by trainings, procedural reviews, retraining etc. to make it sustainable and effective in the long run.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#OSHAStandard#LOTO#LockoutTagoutDevice#LOTODevices#LOTOProcedure#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

LOTO Services - Energy Source Identification and Hazard Isolation

The most essential task associated with launching a Lockout Tagout Program includes, performance of a workplace survey and hazard assessment to identify the equipment and machines with Hazardous Energy, along with their isolation points.

LOTO can be accomplished easily and effectively if the surveyors study all the types of energies present, the hazards to be controlled, and the method of energy control, including the stored energies as well.

· Survey of the workplace should be performed to identify the machines and equipment that could accidentally energize, start up or release hazardous energies. Also, check that the machines are capable of being locked out.

· Access the Hazards and the Hazardous points of the equipment to be serviced or maintained.

· Understand the input of the employees, as they are the most affected ones, and they are often the ones most familiar with the equipment.

· Hazards should be labelled properly. Labelling of the isolating points & isolating devices is also of great benefit to the employees in assuring that energy control devices can be quickly and properly applied.

· Communication with and feedback from employees should be sought continuously to identify deficiencies and to detect opportunities for improvement.

· Right kind of Lockout Devices for different isolation points like electrical switches, isolators, ball valves, gate valves, butterfly valves, etc. need to be assessed carefully by someone who is experienced & is well aware of all kinds of Lockout devices available.

· A comprehensive report needs to be made and presented before the management, defining all the hazards with their locations & methods of their energy isolation, along with the prescription of Lockout Tagout Devices required.

A thorough study of all Hazard Isolations and the complete documentation is the base of a Successful LOTO System. So, it is essential that we seek the help of a LOTO Expert or get professional guidance for the same.

For professional Lockout Tagout hazard isolation at your premises, please send your request - https://www.safetylock.net/lockout-tagout-services/

#LockoutTagout#HazardIsolations#HazardousEnergy#LOTO#LOTOSurvey#LOTOProcedure#LockoutDevices#LockoutTagoutProgram#WorkplaceSafety#Safety#ESquare#ESquareAlliance

0 notes

Text

Lockout Tagout Installation/Implementation Service by E-Square

Not all Lockout Tagout devices are simple to install during LOTO procedure. Our Installation Engineers, backed by their extensive experience, have the skills and knowledge to handle such installations seamlessly. By opting for E-Square’s installation and implementation service, companies can complete their objectives at 1/8th the cost and in less time compared to replacing machines.

#LockoutTagout#lockouttagoutinstallation#lockouttagoutimplementation#LockoutTagoutSupplier#LockoutTagoutDevices#LOTODevices#LockoutTagoutProducts#LockoutDevices#LockoutTagoutExporter#ESquareAlliance

0 notes

Text

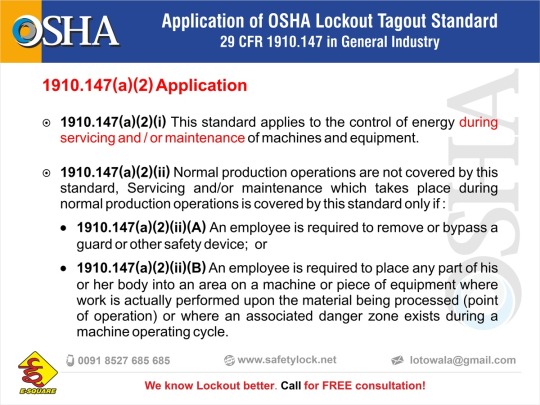

OSHA Lockout Tagout Standard 1910.147(a)(2) Application

The Lockout Tagout OSHA standard set forth in 29 CFR 1910.147 covers the servicing and maintenance of machines and equipment in general industry only. To define which activities are covered by this standard, one must clearly understand the difference between ‘service and maintenance’ and ‘normal production operations.’

Activities such as construction, installation, setting up, inspection, etc. are defined by OSHA as services and maintenance. These activities are leading to serious injuries and death of workers. Whereas, normal production operation defined as the utilization of machines or equipment to perform its intended production function, are generally not covered by the standard.

Differentiating between maintenance and normal production operation is not always easy. Certain tasks such as minor and repetitive adjustments are considered normal production operations when they are integral to the use of the equipment, and when they do not increase the risk of injury to employees. Other activities such as lubrication, cleaning, unjamming, etc. although integral to the use of equipment, would be considered service and maintenance if employees are exposed to greater or different hazards, which they did not come across during normal production operation.

Generally, if activities could expose employees to the unexpected energization or startup of equipment or release of Hazardous Energy, resulting to injuries, they should be considered service or maintenance and Lockout Tagout should be applied.

Servicing and/or maintenance which takes place during normal production operations is covered by this standard only if:

An employee is required to remove or bypass a guard or other safety device or is required to place any part of his body into danger zone during maintenance which could result in an injury.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHAGuidelines#OSHA#OSHASafetyRegulations#HazardousEnergy#OSHALockoutTagout#OSHAStandard#LockoutTagout#LOTO#LOTOSafety#ESquare#ESquareAlliance

0 notes

Text

Lockout Tagout Gap Analysis and Audit

Success of the Lockout system requires a commitment to a sustained effort highlighted by continuous improvement. Audits, reviews & LOTO Gap Analysis are most important for having a successful LOTO system in place. A lapse in implementing energy control processes, can lead to serious injuries if not checked, audited and verified.

To ensure that energy control measures are adequate and being properly and consistently applied, a Lockout Tagout Program must be reviewed periodically and revised if needed. Besides meeting the OSHA requirements, annual audits help companies ensure that they have the up-to-date and accurate devices and procedures that allow employees of the companies to safely de-energize equipment using the appropriate steps of disconnects.

E-Square helps its customers in gap analysis and internal audits to ensure the accuracy of LOTO Procedures; Meet the OSHA Compliance; ensure Employee Safety and save time and resources. This also ensures that new or overhauled equipment is capable of being locked out. These audit dates are specifically marked on all the MSPs installed in the industry at all the locations as well as in the internal binding copies available with the plant head.

For professional Lockout Tagout Audit at your premises, visit - https://www.safetylock.net/services/lockout-tagout-gap-analysis-audit/

#LockoutTagoutAudit#GapAnalysis#LOTOAudit#LOTOSurvey#LOTOProcedure#WorkplaceSafety#LockoutTagout#LOTO#Audit#OSHA#OSHALockoutTagout#WorkplaceAudit#ESquare#ESquareAlliance

0 notes

Text

Features and Benefits of Push Button Lockout Tagout Device

Push button lockout device (ES-Cocoon) is the most appreciated lockout solution of E-Square for the variety of oversize electrical push buttons placed on the electrical panels or control stations.

Benefits:

It is a universal design to completely enclose Electrical Push Buttons of varied sizes ranging from diameter 25 to 60 mm and height 30 to 80 mm. This lockout device can be easily installed in seconds by just placing it on the Emergency Push Buttons, thus concealing them in a cocoon to prevent machines from being energized accidently.

Features:

E-Square offers universal ES - Cocoon with inner size of 70 mm x 85 mm height and 30 mm hole dia in the center. This hole can be customized upto 50 mm according to the size of the push button.

This device is also applicable on the given panel of Emergency Push Buttons:

Machine Control Panels

Motor Control Center

Power Control Center

High Tension Panels

Mobile Equipment (Forklifts, Stacker etc.)

Get more information about ES-Cocoon, visit our website - https://www.safetylock.net/product/oversized-push-button-lockout-es-cocoon/

#PushButtonLockout#LockoutTagout#EmergencyPushButtonLockout#ElectricalPushButtonLockout EmergencyPushButtons#OversizedPushButtonLockout#ElectricalPanelLockout#Cocoon#LockoutDevices#LockoutTagoutManufacturer#LockoutTagoutSupplier#ESquare#ESquareAlliance

0 notes

Text

Carelessness can be Dangerous - LOTO Video by E-Square

Always isolate the energy source yourself, even if it has already been locked by the other workers. Each worker working on the same Machine, needs to lock it out and keep their respective keys with them safely.

During LOTO procedure, workers should follow the OSHA Lockout Tagout standards to keep the workplace and employee safe around them. E-Square can help you in implementing Lockout Tagout system as per OSHA guidelines and make your premises safe for all.

For more information on Lockout Tagout Solutions, visit - https://www.safetylock.net

#LockoutTagoutVideo#LockoutTagout#LOTOVideo#LOTO#LOTOAccidents#LotoSafetyVideo#LotoAccidentsVideo#LockoutTagoutAccidentsVideo#ESquareAlliance

0 notes

Text

Carelessness can be Dangerous - LOTO Video by E-Square

Always isolate the energy source yourself, even if it has already been locked by the other workers. Each worker working on the same Machine, needs to lock it out and keep their respective keys with them safely.

During LOTO procedure, workers should follow the OSHA Lockout Tagout standards to keep the workplace and employee safe around them. E-Square can help you in implementing Lockout Tagout system as per OSHA guidelines and make your premises safe for all.

For more information on Lockout Tagout Solutions, visit - https://www.safetylock.net

#LockoutTagoutVideo#LockoutTagout#LOTOVideo#LOTO#LOTOAccidents#LotoSafetyVideo#LotoAccidentsVideo#LockoutTagoutAccidentsVideo#ESquareAlliance

0 notes

Text

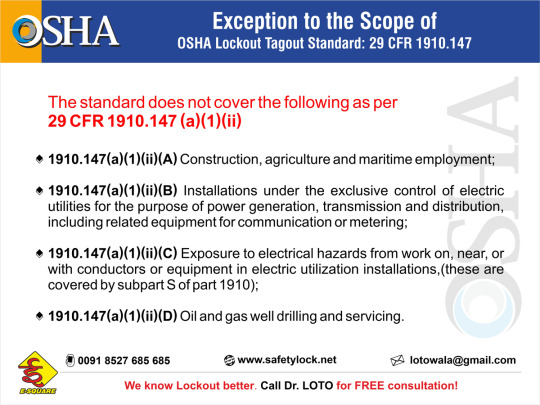

Exception to the Scope of OSHA Lockout Tagout Standard as per 29 CFR 1910.147 (a)(1)(ii)

The goal of every safety program, regardless of industry, should be to protect the employees from machines, equipment and hazards. In addition, it is important to be familiar with the particular standards applicable to stay in compliance. The OSHA Lockout Tagout Standard establishes requirements for Hazardous Energy control. It is used to ensure that machines and equipment are isolated from all potentially hazardous energy sources whenever maintenance activities are conducted on any equipment.

The Lockout Tagout Standard set forth in 1910.147 covers the servicing and maintenance of machines and equipment in GENERAL INDUSTRY, which does not include:

Construction, agriculture and maritime employment; installation of electric utilities for the purpose of power generation or distribution; electric hazards from work on conductors in electric utilization installations in any form; and drilling or servicing of oil and gas well as per 29 CFR 1910.147 (a)(1)(ii).

#OSHA exempted the above industries and limited the scope of the standard to general industry because of their unique situations and work practices that may complicate the standard.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#OSHAGuidelines#OSHAStandard#OSHALockoutTagout#LockoutTagout#LOTO#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

Lockout Tagout Train the Trainer Program by E-Square

At E-Square, we have trained thousands of companies in handling the hazards of isolating all kinds of energies. Our highly sought-after training programs are exclusively designed for our clients.

One needs to complete our three-level training program - Generic, Intensive, and Ultimate Lockout Mastery.

In our Train the Trainer program LOTO Champions are introduced from amongst the employees, they are the ones who now have complete knowledge about Lockout Tagout, and have the ability to give LOTO training to other employees of the company.

#LOTOTraintheTrainer#LockoutTagoutTraining#LockoutTagout#LotoTraining#LOTO#GapAnalysis#TraintheTrainer#LOTOTrainingProgram#LockoutTagoutCourses#LockoutTraining#ESquare#ESquareAlliance

0 notes

Text

Electrical Plug Lockout Device Large Isolation and Lockout Solution

Plug Lockouts are a simple solution for locking out Industrial Electrical Plugs. These Electrical Plug Lockouts prevent electrical plugs from being inserted into sockets. It is used when the plug is not under the exclusive control of the person performing service or maintenance.

Manufactured from sturdy polystyrene/ABS, these units have been developed to completely enclose electrical plugs to prevent a machine from being energized. The plug completely sits inside the unit with the cable being fed through an access hole.

E-Square introduced Electrical Plug Lockout devices (ES-LPLO) to accommodate a large variety of plug shapes and sizes. The large unit of our plug lockout is suitable for standard and larger electrical plugs, including 3 phase connectors.

Feature:

- This Large plug lockout is applicable for 220V-500V plugs

- Inner dimension: 155 H x 86 D x 84 W mm with 8.5 to 19 mm diameter holes for cable. These holes can be customized/ Extended upto a certain limit, if required.

To get more information about product, visit - https://www.safetylock.net/product/plug-lockout-device-large-es-lplo/

#PlugLockout#ElectricalPlugLockout#PlugLockoutDevice#LockoutTagout#LockoutTagoutManufacturer#LOTO#LockoutDevice#LOTODevices#LockoutTagoutSupplier#LockoutTagoutExporter#ESquare#ESquareAlliance

0 notes