#Manual Fabric Folding Machine

Explore tagged Tumblr posts

Text

I made a t-shirt! It was quite a simple project, but it's the first time I've worked with jersey so it was an adventure.

I drafted the pattern mostly based on an existing t-shirt that I like. The fabric is 100% cotton interlock jersey. After one brief frustrating attempt to use solid chalk to mark the fabric, I got some chalk wheel pens which are amazing. And I used a rotary cutter which was great too, I think scissors on stretchy fabric would have been horrible.

I did all the sewing using my mini vintage chain stitch machine that I restored last year.

My brother made a t-shirt a while back and told me that he struggled most with applying the binding to the collar, so I decided to just.. not do that. Some of my commercially-made t-shirts just have a double-folded hem at the collar and I like the look of that anyway so that's what I went for. I hemmed the front and back pieces separately first, before joining them at the shoulders.

Because of the shape of the collar, I had to notch the hem allowance at the corners which means there's some exposed raw edge inside, which I regret. Next time I'll adust the curve of the collar so it's shallow enough that the fabric can roll over without needing to be cut.

I like the way the finished collar looks from the outside though.

I decided to do all the construction with french seams to protect the raw edges (since I'm not overlocking or zigzagging anything). But it was actually kind of a nightmare, because the tiny machine can't cope with all the layers of fabric where two seams or seam+hem intersect. I had to keep re-doing the parts where the seams cross, and even had to resort to manually moving the thread into the right part of the mechanism from underneath the machine on every stitch just to get through the hard parts without it snapping yet again. Next time I'll give up on the french seam and maybe just do an extra line of stitching to reinforce the edges.

I'm also not totally happy with the shape and fit of the sleeves, the armpit area is a bit tight and weird. I think the sleeve openings just need to be bigger, so I need to reshape the armscye on the pattern for next time.

I'm pleased overall though. I learned a lot and I got a definitely wearable t-shirt out of it. :)

#sewing#vintage sewing machine#crafting#making#tailoring#dressmaking#what's the word for nonbinary sewing

8 notes

·

View notes

Text

I spent the day yesterday teaching myself how to sew a flat felled seam because that's what all my summer sewing projects call for. (All of the patterns for my summer projects are created by me. I am the one calling for flat felled seams.)

I accidentally made a table runner. Not bad for a first try.

I made a bunch of 5" squares so that I could measure them afterward to see what my seam allowances will need to be.

I swear they were square when I started!

They absolutely did not end up square (or even rectangular).

I have no idea why they distorted so much during sewing. Potential theories:

My iron was too hot (the floral fabric is 100% polyester, and it definitely didn't like it when I left the iron down too long).

The presser foot was too tight? I haven't used a sewing machine in almost 30 years*, and one thing I find continually frustrating is how the top fabric shifts as it passes under the presser foot. How do I keep this from happening? Like, they'll be perfectly lined up, and then as soon as they get under the presser foot the top fabric is suddenly like "Don't wanna!!"

My tension was too tight?** The seams puckered a bit.

Fraying. Omg this fabric started falling apart instantly! I starched the shit out of it in hopes that that would help, but it just disintegrated under my fingers. Since I was using the edges of the fabric as my seam line, this made for some wonky seams.***

I used a method inspired by pojagi, and while I don't really enjoy pulling out the basting thread afterwards (use a matching thread colour in case it breaks! Or better yet, baste by hand!), it's way easier for me than the traditional technique of folding over the seam allowance.

Overall I am very happy with my wonky first flat fells, and feel like I've pretty much got the hang of the basic idea.

I also decided to use the opportunity to work on my mitered corners, which went much less well.

For some reason this technique:

works way better than this technique:

for me even though my brain tells me that they should produce exactly the same result! ???

*Brief backstory: I have been sewing since I was a small child, but for the past 30 years I have been sewing exclusively by hand. A couple months ago I got a sewing machine for my daughter and I have been relearning how to use one. I find it significantly less straightforward than sewing by hand. (Coincidentally, I am also re-learning how to ride a bicycle after 30 years of not riding.)

**This is a problem that just doesn't happen when I sew by hand!

***I mean, that and my terrible driving skills. It doesn't help that the needle on the machine is not aligned with the stitch line on the presser foot. I don't have the manual for the machine, so I don't know if this is adjustable. That said, my daughter's stitch lines were perfectly straight from her very first try. (I can't ride a bicycle in a straight line either.)

7 notes

·

View notes

Text

Remember to clean your sewing machine between projects. The reason you may be dealing with things like pinched seams and skipped stitches is your sewing machine needs some attention. Do not blow into the machine!!! You will only push lint deeper into the gears.

Remember to change your sewing needles. The seams may be messy because of this, as well as torn threads. Seeing needles are very inexpensive unless you buy them at a fabric store.i purchase mine from Organ Neddles Co, in packs of 100, for less than $20 USD online.

Remember to sharpen your scissors and change your rotary cutter blades. There are scissor sharpeners sold at fabric and craft stores, and they are very inexpensive. If you're unable to acquire one, take some aluminum foil, about 18 inches, fold it in half, and cut down the middle. Put the layers on top of each other and cut again. Do this one more time and cut it into thin strips. Voila, your blade is sharpened. There are rotary blade sharpeners as well, but they're more expensive. Save your used blades for sharpening you can do at a later date.

Your machine will thank you by not breaking and requiring parts be replaced.

Oh, and you do need to get your machine into a shop for full maintenance at least once a year. Folks who specialize in this may even be willing to do this in your home, especially for antique machines. Shops that are approved by retailers will cost significantly more than independent specialists. The only place approved by retailers here charges $150 USD per machine, regardless of whether it's manual or computerized. I went on the NextDoor app and asked for references for finding an independent specialist. It was $89 USD per machine, and he had them back to me in less than two weeks whereas the retailer approved shop gave me an ETA of four months. Give your machine the spa treatment it deserves. When it's returned to you, you will discover it's suddenly quieter, running smoothly, and working significantly better because these were things that built up so gradually, you didn't even notice.

You're welcome.

198 notes

·

View notes

Text

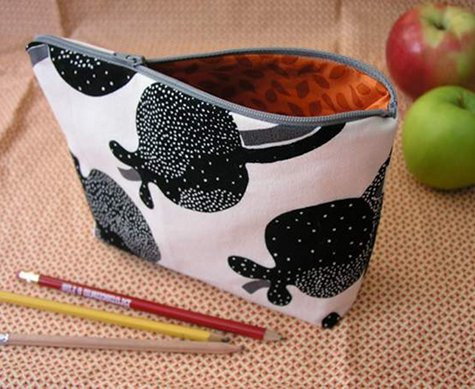

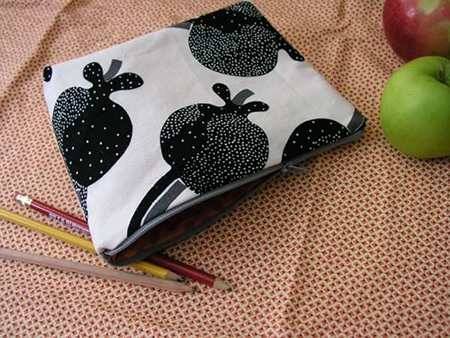

DIY Zippered Case

Project by Brett Bara:

It’s back-to-school time, and it’s hard not to have school supplies on the brain even if school days are nowhere in sight for some of us! Inspired by the good old-fashioned pencil case, I thought it would be fun to sew a lined, zippered pouch that you can use for pencils, makeup, electronics or anything else you need to organize and tuck away. The great thing about this bag is that once you understand the basic construction, you can easily make it any size you like. Try a short, long version with a wide base for knitting needles, or a flat bag for electronic cords. You can use oilcloth for the lining to create a waterproof makeup bag, or try stitching a label to the outside to indicate what’s hiding inside. Let’s get started! — Brett Bara

CLICK HERE for the full how-to after the jump!

Materials

approximately 1/2 yard of medium or heavy-weight fabric for the bag exterior

approximately 1/2 yard of medium-weight fabric for the lining

standard zipper, at least as wide as your bag will be

scissors

needles

sewing machine

iron

Instructions

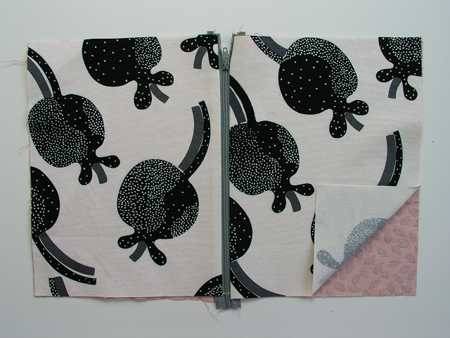

1. Cut the fabric.

Decide how large you want your bag to be and cut two pieces of your exterior fabric and two pieces of lining fabric to this size, plus 1″ in length and width for seam allowance. If possible, purchase a zipper that is the same width as your fabric piece or purchase a longer zipper and cut it to size. (Note: if your zipper is only 1 to 2″ longer than your fabric piece, you don’t have to cut it. A small amount of excess zipper length is okay.)

To cut your zipper to size, zip the zipper closed and place the zipper next to your fabric piece, aligning the top end of the zipper with one corner of the fabric. Place a pin in the zipper at the other corner of the fabric piece.

Set your machine to a narrow, short zigzag stitch and sew back and forth across the zipper teeth several times at the point you marked. (Yes, you can sew right across the zipper teeth — your machine can handle it!)

Then cut the zipper about 1/2″ past the spot you sewed. The stitches will act as a stopper on the end of the zipper. And that’s it!

2. Attach the zipper to the fabric.

Place your zipper face down on the right side of one of the exterior pieces and pin it in place.

Load your machine with a zipper foot (check your machine’s manual for help with this if necessary) and sew the zipper to the fabric.

3. Attach the lining.

Place the lining right-side down over the zipper and pin it in place. Sew it just as you did the previous piece. (You will be sewing directly over the line of stitching you made when attaching the zipper to the exterior piece. The zipper will now be sandwiched in between the right sides of one lining piece and one exterior piece.)

4. Press the seam.

Press the seams you just sewed, folding each piece of fabric back so that the wrong sides are facing each other. (Be careful when ironing near the zipper — after coming in contact with the iron, the metal zipper can get hot enough to burn you.)

5. Attach the next exterior piece.

Place the second exterior piece wrong-side down over the right side of the zipper. Pin it in place, then sew it as you did the other pieces.

6. Attach the second lining piece.

Flip the piece over and pin the lining piece right-side down over the wrong side of the zipper. Sew it in place. The zipper will now be sandwiched between the right sides of the second exterior piece and second lining piece.

7. Iron it flat.

Iron the seams you just made, folding the fabric pieces back so that the wrong sides are facing each other. The resulting piece will have the zipper in the middle, with one exterior piece and one lining piece on each side, and right sides facing out on all the fabric pieces.

8. Fold and sew around the perimeter.

Next, lift each exterior piece and bring them up to meet each other with their right sides together. Also, bring up each lining piece to meet with their right sides together. The zipper will be in the middle. Fold the seam allowance of the zipper toward the lining and pin everything together on all four sides.

9. Sew the perimeter.

Sew around all four sides of the piece, using a 1/2″ seam allowance and a regular presser foot. Leave an opening of about 4″ on the bottom of the lining side, which will be used to turn the bag right side out.

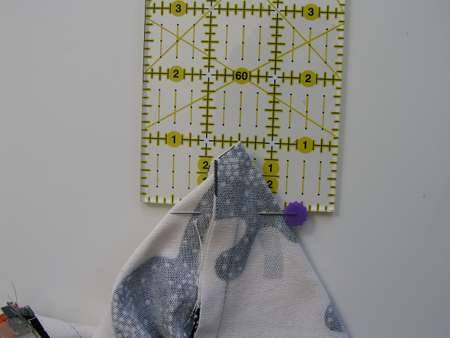

10. Make the corners.

If you prefer a flat bag, you can skip this step. But if you’d like to make corners to add depth to the bag, here’s how: fold the fabric at the corners so that the side and bottom seams meet. Measure from the point of the corner; here I used a depth of 1″, but if you prefer a deeper bag, just measure further from the corner. Mark the line with a pin.

11. Sew the corners.

Sew along the line you marked with the pin, backstitching to reinforce at the beginning and end of the seam. Trim away the excess fabric, cutting about 1/4″ from the seam.

Here’s how the piece will look after you’ve sewn and trimmed all four corners.

12. Turn it right-side out.

Turn the bag right side out, carefully working the bag through the opening you left in the lining. Press all the seams, then sew the lining closed by hand.

Turn the lining to the inside of the bag, and you’re done!

10 notes

·

View notes

Text

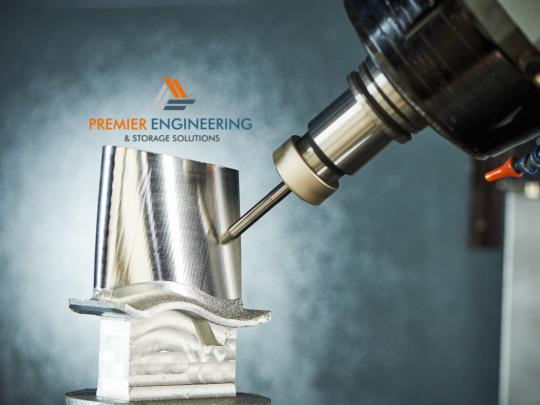

Enhancing Metal Fabrication: A Deep Dive into V Grooving Automation

In the world of sheet metal fabrication, precision and efficiency are paramount. Among the arsenal of cutting-edge tools transforming the industry, the Automatic V Grooving Machine has emerged as a game-changer—delivering sharp accuracy, reducing material deformation, and enhancing aesthetic appeal across architectural and industrial applications.Get more news about Automatic V Grooving Machine,you can vist our website!

What Is an Automatic V Grooving Machine?

An Automatic V Grooving Machine is a highly specialized piece of equipment designed to create narrow, precise V-shaped grooves on sheet metal or composite panels. These grooves allow for clean, sharp bends without distorting the surface—an essential requirement in high-end fabrication, particularly for elevator panels, cabinet doors, decorative finishes, and signage.

Unlike manual grooving, which can be inconsistent and labor-intensive, automatic systems ensure uniform depth, angle, and spacing. The technology typically features CNC (Computer Numerical Control) integration, enabling operators to input exact specifications and produce flawless results in a fraction of the time.

Key Features and Benefits

High Precision: Automatic V groovers offer micrometer-level accuracy, which translates to cleaner angles and better alignment when parts are bent or folded.

Reduced Material Stress: By pre-grooving the metal, the machine minimizes internal stress during bending, preserving the material’s surface and integrity.

Increased Efficiency: Automation dramatically reduces setup times and manual labor, improving overall throughput.

Customization and Flexibility: Advanced models allow programming of multiple groove patterns, depths, and panel dimensions, catering to diverse design requirements.

Cleaner Aesthetics: The resulting folds are crisp and professional, elevating the visual quality of the final product.

Applications Across Industries

The versatility of V grooving makes it indispensable across various sectors. In architecture, it’s used to fabricate decorative claddings, column covers, and wall panels with elegant seams. In the elevator industry, grooved panels provide seamless transitions and modern aesthetics. Furniture manufacturers utilize it for sleek cabinetry and fixture components, while signage companies rely on it for precise lettering and sleek edges.

Additionally, with the increasing demand for metal furniture and minimalistic interiors, V grooving supports thin, lightweight designs without compromising structural integrity.

Technological Advancements and Trends

Modern V grooving machines continue to evolve alongside digital manufacturing trends. Integration with CAD/CAM software enables seamless workflow from design to production. Real-time diagnostics, touch-screen controls, and remote monitoring are becoming standard features, increasing accessibility and reducing operator errors.

Environmental impact is also being considered: some machines are built with noise-reduction chambers and energy-efficient drives, aligning with green manufacturing principles.

Conclusion

The Automatic V Grooving Machine is more than just a fabrication tool—it’s a symbol of precision engineering and aesthetic craftsmanship. In an era where customization and speed are everything, its ability to elevate both function and form makes it an invaluable asset across industries. As manufacturing leans further into digital automation, machines like these will define the future of design and fabrication—where art meets industry in every flawless fold.

0 notes

Text

Best Laundry Franchise in India — Fabrico

Are you tired of the 9-to-5 grind and dreaming of owning a profitable business? In 2025, one of the most promising, low-risk, and high-demand business opportunities is the laundry franchise business in India — and Fabrico is leading this revolution.

With increasing demand for hygiene, professional garment care, and convenience, India is seeing an unprecedented rise in organized laundry and dry-cleaning chains. This is where Fabrico shines — not just as a service but as a franchise opportunity of the future.

Why Laundry Franchises Are Booming in India

Laundry was once a “maid’s job.” Not anymore. Urban families, working professionals, bachelors, and even students now prefer outsourcing laundry to professionals. Why?

Lack of time

Need for quality garment care

Disposable income growth

Urban lifestyle shift

These changing preferences are fueling the rise of laundry franchise businesses in India.

Laundry Franchise Business in India — A Growing Market

India’s laundry market is worth over ₹200,000 crores, but 95% is unorganized. This opens a massive opportunity for organized players like Fabrico to dominate with tech, consistency, and brand trust.

Why it’s booming:

Growing urban population

Shift to nuclear families

More clothes = more laundry!

Desire for hygiene post-COVID

What Makes Fabrico the Best Laundry Franchise in India?

Fabrico isn’t just another name in the market. It’s India’s fastest-growing laundry franchise business.

India’s Biggest Laundry and Dry Clean Chain

With a rapidly expanding network, Fabrico is establishing its presence in Tier 1, Tier 2, and Tier 3 cities alike.

Proven Franchise Success

From first-time entrepreneurs to seasoned investors, Fabrico’s franchise partners are enjoying steady returns, minimal risk, and unmatched support.

Tech-Driven Operations

From online bookings to AI-based garment tracking, Fabrico operates on smart, digital-first systems to reduce manual errors and boost efficiency.

Services Offered by Fabrico

It’s not just laundry. Fabrico offers a complete bouquet of services, including:

Professional Laundry — Wash & fold or wash & iron

Dry Cleaning — Suits, lehengas, delicate silks

Shoe & Bag Spa

Steam Ironing

Stain Treatment & Fabric Care

Customers get convenience. Franchise owners get diversified revenue streams.

Cost of Starting a Laundry Franchise Business in India

Wondering how much it costs to start?

Laundry Franchise Business Cost Breakdown

Franchise Fee: ₹28–35 Lakhs (depending on model)

Setup Cost: ₹10–12 Lakhs (store, machines, interiors)

Working Capital: ₹2–3 Lakhs (3-month buffer)

Low Investment, High Return

For around ₹10–15 Lakhs, you’re ready to start a premium laundry franchise business in India.

ROI Timelines

Break-even in 18–24 months

Monthly revenue potential: ₹1.5 — ₹3 Lakhs

Net margins: 30%+

Fabrico’s Franchise Models

Choose the model that suits your budget and area.

Store Model

Prime area

Walk-in customers

Ideal for high-footfall locations

Pickup & Delivery Model

Lower setup cost

Home-based or small outlet

Focused on app & online orders

Hybrid Model

Best of both worlds

Storefront + logistics

High scalability

Training & Support from Fabrico

No prior experience? No problem. Fabrico gives complete handholding.

Staff recruitment & training

Technical onboarding

POS system training

Marketing materials

Inventory & CRM guidance

It’s like starting a business with a safety net.

Why Choose Fabrico Over Other Laundry Franchise Brands

Here’s where Fabrico beats the competition:

Established SOPs & professional equipment

Strong digital presence with online booking & tracking

In-house marketing team for local lead generation

Bulk orders from corporates & hotels

Higher customer retention with loyalty programs

Steps to Start a Laundry Franchise with Fabrico

Apply Online at Fabrico Franchise

Get a free consultation call

Choose your location & model

Complete paperwork & training

Get your outlet launched & marketed by Fabrico

It’s a turnkey process, stress-free from Day 1.

Real Success Stories from Fabrico Franchisees

Meet Aarti from Lucknow. She started with Fabrico’s hybrid model and broke even in just 15 months.

Or Rohit from Pune — now running 3 outlets across the city with a team of 12.

Real people. Real profits. Real impact.

The Future of Laundry & Dry Cleaning Franchises in India

By 2030, over 60% of India’s urban households will rely on outsourced laundry.

Add in:

Smart lockers

Mobile-app-only models

AI-powered garment handling

…and you’ve got a business that’s future-proof and investor-friendly.

Conclusion

If you’re hunting for the best laundry franchise in India, Fabrico is your golden ticket.

It’s affordable, scalable, and future-ready. Whether you’re a full-time entrepreneur or a part-time investor, Fabrico’s laundry franchise business model in India gives you everything you need — minus the headaches.

From low entry barriers to strong ROI and all the way to handholding and growth support, Fabrico is more than a franchise — it’s a movement.

Ready to start your journey? Visit Fabrico.in and apply today.

FAQs: Best Laundry Franchise in India — Fabrico

Q1. What is the minimum investment required to start a Fabrico franchise? A: Around ₹10–12 Lakhs* including setup, franchise fee, and working capital.

Q2. Do I need prior experience in laundry or business? A: Not at all. Fabrico provides full training and operational support.

Q3. Can I operate a Fabrico franchise in a Tier 2 or Tier 3 city? A: Absolutely! In fact, Fabrico is expanding rapidly in smaller cities.

Q4. What are the main revenue streams? A: Laundry, dry cleaning, shoe cleaning, corporate orders, and steam ironing.

Q5. How long does it take to break even? A: Most franchisees reach breakeven in 18 to 24 months, depending on location.

#dry cleaning#fabrico#laundry#dry cleaners#drycleaners#drycleaners service#laundry near me#laundry services#laundry franchise

0 notes

Text

COMPLETION: Hand Folded Furniture

An exploration of sheet metal forming and robotic fabrication. Fourth-year comprehensive studio thesis.

“Throughout the course of the Digitally Fabricated Furniture Design studio, I sought out to make a piece of furniture that tried to combine the processes of sheet metal forming and robotic fabrication. Inspired by the art of folding paper, I wanted to use sheet metal as a material to create a stool that had a paper like resemblance. I was interested in taking something that is hard and rigid like metal, and making it appear as though it is delicate and flexible like paper.

During my twelve-week research-through-making process and experimenting with robotic fabrication, through many challenges I came to the realization that the method I was practicing was not the most effective nor efficient in achieving what I wanted. These challenges occurred while building the custom tooling, robotic fabrication set up, tool to material calibration, and more. This led me to the realization that digital fabrication is not always the most appropriate process, and that is okay. I quickly discovered that technology is only beneficial for certain means of fabrication and sometimes using manual and electric tools is actually the most efficient and effective.

My final piece is made entirely by using tools and machines that require manual work. This research-through-making experience guided me to many discoveries such as the importance of experimentation, but most importantly to be critical of every fabrication method and consider all ways of making when undergoing the design-to-production process.”

0 notes

Text

What Is a Sheet Metal Bending Press and How Does It Work?

A sheet metal bending press is a machine used to bend flat metal sheets into specific shapes and angles. It’s an essential tool in metal fabrication, especially when creating components that need to fit precisely—like brackets, enclosures, or frames.

This machine forms metal by pressing it between a punch and a die, giving it a clean, accurate bend. It's commonly used to shape steel, aluminium, and other metals into parts used in construction, manufacturing, automotive, signage, and architectural projects.

Where you’ll see it in action

Whether it’s a large-scale industrial job or a custom fabrication for a retail display, you’ll often find sheet metal bending press machines in workshops that also offer laser cutting, turret punching services, or full metal forming solutions. It's a key part of turning raw sheet material into functional, real-world products.

How Does a Sheet Metal Bending Press Actually Work?

The press brake process made simple

At its core, a sheet metal bending press uses two main parts: a punch (the top tool) and a die (the bottom tool). The metal sheet is placed between them, and the punch pushes down to form a bend. This setup is known as a sheet metal press brake, and it's one of the most common machines for bending applications.

This controlled force can shape the metal at different angles depending on the depth and shape of the die. The result is a clean, sharp bend with high repeatability.

How it differs from other methods

Unlike laser cutting, which slices through metal with heat, or turret punching services, which punch holes or patterns, the sheet metal press brake is strictly for shaping and forming. It's the step that brings flat parts to life—turning them into brackets, boxes, and frames.

What Are the Main Components of a Bending Press?

Key parts of the machine

A standard sheet metal bending press includes several key components:

Punch – The top tool that presses into the metal

Die – The bottom tool that supports the bend

Ram – The moving part that forces the punch downward

Back gauge – Helps position the sheet for accurate bends

Each part plays a role in shaping the metal precisely and consistently. Together, they allow fabricators to bend metal sheets into a wide range of angles and shapes.

CNC control brings precision to the process

Many modern sheet metal press brake machines now use CNC (Computer Numerical Control) systems. These systems automate setup, positioning, and movement, allowing for greater accuracy and less manual error. CNC controls also store programs, making it easy to repeat exact bends for large production runs.

If your fabrication shop also offers laser cutting service or turret punching services, there’s a good chance they rely on CNC bending to complete the job with precision and efficiency.

What Materials Can Be Bent with a Sheet Metal Bending Press?

Popular metals for bending

A sheet metal bending press can work with a wide range of metals, depending on the type and thickness. Common materials include:

Steel – great for structural components and general use

Aluminium – lightweight and corrosion-resistant, perfect for enclosures or trims

Brass and copper – often used for decorative or electrical applications

The machine's tonnage (pressing force) will determine how thick a metal sheet it can handle. For very thick or hard materials, a high-tonnage sheet metal press brake is needed.

How it compares to cutting methods

While laser cutting is excellent for creating precise patterns or edges in flat sheet metal, it doesn’t bend or shape. Likewise, turret punching services are better for making repeated holes or slots. If you need a 3D form or fold, bending is the only way to go—making the sheet metal bending press an essential part of any fabrication workflow.

How Is a Bending Press Different from Other Sheet Metal Tools?

When to bend, cut, or punch

Each tool in a metal workshop plays a specific role. A sheet metal bending press is used to fold or angle metal sheets. It doesn’t remove material—it reshapes it. On the other hand, a laser cutting service slices clean lines through metal, and turret punching services create shapes, holes, or louvres by punching through the sheet.

Why they work best together

In most professional settings, all three are used in combination. For example, a part might first go through laser cutting for its outline, then turret punching for internal cutouts, and finally a sheet metal press brake for final shaping. Together, they turn flat stock into fully formed, ready-to-install components.

What Types of Sheet Metal Bending Presses Are Available?

From manual to fully automated

There are several types of sheet metal bending press machines to choose from, each suited to different needs:

Manual press brakes – simple and budget-friendly, ideal for small shops or one-off jobs

Hydraulic press brakes – strong and reliable, suitable for a wide range of metal types

Electric press brakes – energy-efficient and precise, good for high-speed work

CNC press brakes – the most advanced, perfect for repeatable and complex bending tasks

Choosing the right fit for the job

For workshops that handle regular production runs or need high accuracy, a CNC sheet metal press brake is often the best choice. It combines speed, safety, and programmable precision—especially when integrated into full-service operations that include laser cutting or turret punching services.

Why Precision and Setup Matter in Sheet Metal Bending

Accuracy is everything

When it comes to bending, even a few millimetres off can ruin a part. That’s why setup and alignment are so important. The type of die, the position of the back gauge, and the thickness of the material all affect the outcome. Springback—when metal tries to return to its original shape after bending—also needs to be compensated for during setup.

Trained operators and CNC make the difference

Skilled technicians or CNC machines can account for these variables with ease. A modern sheet metal press brake with CNC capabilities can store bend sequences, calculate bend allowances, and even adjust for material behaviour in real time. That level of precision ensures every part is consistent—no matter how many you’re producing.

1 note

·

View note

Text

T-Shirt Manufacturing in Chennai: From Fabric to Finished Product

Chennai is one of India’s top hubs for textile manufacturing, known for its high-quality fabrics, skilled workforce, and advanced production facilities. Whether you’re a startup launching a clothing brand, a business needing bulk T-shirts, or an event organizer looking for custom apparel, understanding the T-shirt manufacturing process is essential.

If you're searching for trusted T-shirt manufacturers in Chennai, this blog will guide you through the entire T-shirt production process, from fabric selection to final packaging. Let’s explore how a T-shirt is made step by step!

Why Choose Chennai for T-Shirt Manufacturing?

Chennai has become a major center for T-shirt manufacturing in India due to:

✔️ Availability of high-quality cotton fabrics ✔️ Affordable labor and skilled workforce ✔️ Advanced textile and printing technology ✔️ Efficient logistics for national and international shipping ✔️ Customization options for bulk and retail orders

With these advantages, many businesses and brands prefer to work with T-shirt manufacturers in Chennai for cost-effective and high-quality production.

The T-Shirt Manufacturing Process: Step by Step

Step 1: Fabric Selection – The Foundation of Quality

The first step in T-shirt manufacturing is choosing the right fabric. The most common options include:

Cotton: Soft, breathable, and comfortable (best for casual wear)

Polyester: Lightweight and moisture-wicking (ideal for sportswear)

Cotton-Polyester Blend: Durable and shrink-resistant (used for corporate wear)

Lycra/Spandex: Stretchable fabric (used for fitted T-shirts)

✅ Pro Tip: If you want a premium feel, go for combed cotton or organic cotton, which are softer and more eco-friendly.

Step 2: Fabric Cutting – Precision Matters

Once the fabric is selected, it is measured, marked, and cut according to the T-shirt pattern. High-end T-shirt manufacturers in Chennai use:

Manual Cutting – For small batch orders

Automatic Laser Cutting Machines – For bulk orders with high precision

Cutting accuracy is essential to maintain size consistency across all pieces.

Step 3: Stitching – Bringing the T-Shirt to Life

After cutting, the fabric pieces are stitched together using high-speed sewing machines. The key stitching types used are:

✔ Overlock Stitching – Prevents fraying at the edges ✔ Flatlock Stitching – Used for sportswear and seamless designs ✔ Double Needle Stitching – Adds durability to seams

Quality T-shirt manufacturers in Chennai ensure strong stitching to enhance durability and comfort.

Step 4: Printing & Embroidery – Customizing the T-Shirt

Customization is a major factor in T-shirt production, and there are several printing techniques available:

✅ Screen Printing – Best for bulk orders, durable and vibrant colors ✅ Direct-to-Garment (DTG) Printing – Great for complex, multi-color designs ✅ Heat Transfer Vinyl (HTV) – Ideal for sports jerseys and name customization ✅ Sublimation Printing – Best for polyester T-shirts with full-color prints ✅ Embroidery – Adds a premium look with stitched logos and text

Choosing the right method depends on your design complexity and order quantity.

Step 5: Quality Control – Ensuring Perfection

Before the T-shirts are packed, they undergo strict quality checks to ensure:

✔ No stitching defects ✔ Accurate printing alignment ✔ Fabric softness and durability ✔ Proper sizing and measurements

High-quality T-shirt manufacturers in Chennai follow international quality standards to ensure zero defects in the final product.

Step 6: Ironing & Packaging – The Final Touch

Once the T-shirts pass the quality check, they are ironed, folded, and packed for delivery.

✔ Individual Poly Bags – Keeps T-shirts clean and wrinkle-free ✔ Bulk Packaging – Used for large orders (carton boxes) ✔ Custom Branding – Some manufacturers offer branded packaging with tags and labels

✅ Pro Tip: If you’re a brand, opt for custom labels and packaging to enhance your product’s appeal.

Why Work with Professional T-Shirt Manufacturers in Chennai?

If you’re planning to launch a clothing line, order bulk T-shirts, or create customized apparel, choosing the right manufacturer is crucial. Here’s why partnering with trusted T-shirt manufacturers in Chennai benefits you:

✔ Cost-Effective Production – Bulk orders reduce costs ✔ Custom Printing & Branding – Personalize T-shirts with logos, tags, and prints ✔ Fast Turnaround Time – Efficient production and delivery ✔ High-Quality Fabric & Stitching – Ensures durability and comfort ✔ Eco-Friendly Options Available – Organic cotton and sustainable dyes

How to Choose the Best T-Shirt Manufacturer in Chennai

Before finalizing a T-shirt manufacturer, check for:

🔹 Fabric quality and availability 🔹 Printing and customization options 🔹 Minimum Order Quantity (MOQ) 🔹 Production capacity and turnaround time 🔹 Customer reviews and past projects

The best T-shirt manufacturers in Chennai will provide samples, allowing you to test fabric quality and printing before placing a large order.

Get the Best T-Shirt Manufacturing Services in Chennai!

Looking for high-quality, affordable T-shirt manufactures in Chennai?

🌟 We offer premium T-shirt production with customization, bulk discounts, and fast delivery! 🌟

📞 Contact us today for a free consultation and quote! 🚀

0 notes

Text

How CNC Technology is Revolutionizing Sheet Metal Folding

Sheet metal folding, a seemingly simple process, has undergone a dramatic transformation thanks to the advent of Computer Numerical Control (CNC) technology. This leap forward has not only increased efficiency and precision but also opened doors to intricate designs and complex geometries previously deemed impossible.

Traditional vs. CNC Folding:

Before CNC, sheet metal folding was largely a manual or semi-automated process. Skilled sheet metal fabricators in Melbourne, using hand tools or basic bending machines, would carefully shape the metal. This approach, while time-honoured, had limitations:

Limited Complexity: Producing intricate shapes or achieving consistent results across multiple parts was challenging.

Reliance on Skill: The quality of the fold depended heavily on the operator's skill and experience.

Lower Production Rates: Manual processes were inherently slower, limiting production output.

CNC technology revolutionized this landscape by:

Automation: CNC machines are programmed with precise instructions, automating the folding process.

Increased Accuracy: CNC machines operate with high precision, ensuring consistent and accurate folds every time.

Enhanced Flexibility: Complex shapes and intricate designs can be easily programmed and produced with high accuracy.

Improved Efficiency: Automation significantly boosts production speed, leading to increased output.

Reduced Labor Costs: Automation reduces the reliance on manual labour, leading to potential cost savings.

Key Advantages of CNC Folding:

Superior Precision: CNC machines eliminate human error, leading to incredibly precise folds with minimal variation.

Versatility: From simple bends to complex 3D shapes, CNC machines can handle a wide range of folding tasks.

Repeatability: CNC programs can be easily saved and reused, ensuring consistent results across multiple production runs.

Reduced Material Waste: Precise control minimizes material waste, leading to cost savings.

Improved Quality: Consistent and accurate folds translate to higher-quality finished products.

Applications of CNC Folding:

CNC folding finds applications in a wide range of industries, including:

Automotive: Manufacturing of car bodies, frames, and components.

Aerospace: Production of aircraft parts, including wings, fuselage sections, and landing gear.

Electronics: Manufacturing of enclosures, brackets, and heat sinks.

Construction: Fabrication of metal roofing, siding, and structural components.

Medical Devices: Production of surgical instruments, implants, and other medical equipment.

CNC technology has undoubtedly revolutionized sheet metal folding, enabling manufacturers to achieve unprecedented levels of precision, efficiency, and flexibility.

Source

0 notes

Text

Comprehensive Guide to Sheet Bending Machines

Introduction

Sheet bending plays a crucial role in metal fabrication, enabling the shaping and processing of metal sheets for various industrial applications. From construction and automotive to aerospace and shipbuilding, the demand for high-precision sheet bending machines is growing rapidly.

Yash Machine Tools is a leading provider of technologically advanced sheet bending machines and components designed to enhance efficiency and productivity in metalworking operations. This guide explores different types of bending machines, including bending rollers, hydraulic presses, iron workers, shearing machines, press brakes, and more.

What is Sheet Bending?

Sheet bending is a metalworking process used to deform and shape metal sheets into desired angles and curves. It is a critical step in manufacturing, allowing industries to create structural components with high precision and durability.

Key Sheet Bending Methods:

Press Braking – Uses a punch and die to create precise bends.

Rolling – Forms curved or cylindrical metal parts.

Folding – Bends sheet metal without excessive force.

Stamping and Punching – Used for cutting and shaping metal sheets.

Types of Sheet Bending Machines

Various bending machines are available based on the type of bending process:

Manual Bending Machines – Suitable for small-scale operations.

Mechanical Bending Machines – Offer automation for increased efficiency.

Hydraulic Bending Machines – Provide high force for bending thick metals.

Bending Roller Machines

A bending roller machine is used to bend metal sheets and plates into cylindrical or curved shapes.

Industries Using Bending Rollers:

Construction

Automotive

Shipbuilding

Aerospace

Advantages: ✔ Smooth bending without damage ✔ Handles various sheet thicknesses ✔ Reduces material waste

3 Roll Pyramid Type Mechanical Plate Bending Machine

The 3 roll pyramid type plate bending machine is a widely used mechanical bending tool.

Features:

High precision for metal sheet rolling

Works with different materials like steel, aluminum, and copper

Requires less maintenance and is cost-effective

Profile & Pipe Bending Machines

Profile & Pipe Bending Machines are used to bend pipes, tubes, and structural metal profiles into complex shapes.

Common Applications:

✔ Metal furniture production ✔ Construction framework bending ✔ Automotive exhaust pipe shaping

Bus Bar Bending, Cutting, and Punching Machines

Bus bar bending, cutting, and punching machines are used in electrical and construction industries to shape copper and aluminum bus bars for power distribution.

✔ Performs multiple operations – bending, cutting, and punching ✔ Reduces manual labor and enhances precision

Metal Sheet Bending Machines

These machines are designed for shaping thin and thick metal sheets efficiently.

Hydraulic vs. Mechanical Bending:

✔ Hydraulic bending machines provide higher force and flexibility ✔ Mechanical bending machines are more economical for mass production

Folding Machines

Folding machines are used to bend thin sheets without damage. They are widely used in roofing, HVAC, and cabinet making.

✔ High accuracy in folding angles ✔ Quick operation with minimal labor

Hydraulic Press Machines

Hydraulic press machines use hydraulic force to bend, cut, or shape metal sheets.

✔ High tonnage capacity ✔ Precise pressure control for accurate bending

Hydraulic Iron Worker Machines

A hydraulic iron worker is a multi-functional machine that can: ✔ Cut metal sheets ✔ Punch holes ✔ Bend structural steel

These machines are widely used in fabrication workshops and steel processing plants.

Power Press Machines

Power press machines use mechanical or hydraulic force to punch, bend, or shape metals.

✔ Ideal for mass production ✔ High-speed operation for increased efficiency

Press Brake Machines

Press brakes are used for precise metal bending and shaping.

✔ Available in hydraulic and mechanical versions ✔ Used in automotive, aerospace, and industrial fabrication

Riveting Machines

Riveting machines are essential in sheet metal assembly for joining multiple metal sheets securely.

✔ Strong and durable connections ✔ Used in automotive and aircraft manufacturing

Shearing Machines

Shearing machines are used for cutting metal sheets without producing chips.

✔ High-speed cutting for efficiency ✔ Used in steel fabrication, shipbuilding, and industrial manufacturing

Sheet Metal Machines – Complete Overview

With automation and precision engineering, modern metal sheet Bending Machines have transformed the metalworking industry.

✔ CNC-controlled machines for precise bending ✔ Smart automation for higher productivity

Conclusion

Sheet bending machines play a crucial role in metal fabrication across multiple industries. Whether it’s a hydraulic press, iron worker, bending roller, or press brake, choosing the right equipment ensures precision, efficiency, and productivity.

youtube

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] kitchen Aid mixer cover. FEATURES: made of durable Polyester Taffeta Fabric Durable,Dust-proof and easy to clean Can folding into a small, space-saving Package include 1 x kitchen aide stand mixer cover mom valentines day gift Mother's day gifts for mom 【Stand Mixer Cover Size】 our kitchen mixer cover is 16"H x 12"W x 12"L,Suit for most 4.5-7 quart stand mixer(4-quart, 4.5-quart, 5-quart, 6-quart, 7-quart), compatible with Kitchenaid, Sunbeam, Cuisinart, Hamilton, kitchenaid mixer, bowl-lift, Tilt-Head stand mixer,covers up the whole mixer even the bowl, and also fit same size coffee maker and toaster machine. 【High Quality Kitchen Mixer Cover】This Unique Kitchen stand aid mixer Cover with high quality polyester with quilted fabric, anti-tear, durable, dust-proof will effectively extend the service life, with the neat stitches make it look so pretty.this quilted appliance cover will stand the test of time while keeping your appliances looking clean and spotless. 【Long-Lasting Quality Kitchen Small Appliance Cover】No heavy or more extra cleaning process required. If the kitchen aid covers for stand mixer becomes soiled or stained, throw the kitchen aide covers stand mixers attachments in the washing machine to refresh with your other kitchen or home linens and tumble dry on low. 【Waterproof 4.5-7 Quart Large Pocket Kitchen Stand Mixer Cover For Kitchenaid Mixer】Kitchen Mixer Covers For Stand Mixer Great for storing recipes, the manual, spatulas, flat attachments,kitchenaid pasta attachment, kitchen aid attachments or other kitchen gadgets. 【Dustproof & Durable Cake Mixer Cover with Large Exterior Pockets】Keep beaters, bowl covers, spatulas, cookbooks and other essentials right where you need them when you're ready to use the mixer, it is pioneer woman kitchen accessories,the cover for Kitchen aid mixer mixer is mothers day gifts for mom,mother's day gifts for her,mothers day gifts for wife [ad_2]

0 notes

Text

A Folding Machine is an industrial tool that automates the folding of materials such as fabrics, paper, and flexible packaging. Instead of relying on time-consuming manual folding, our machines ensure that each fold is precise, uniform, and completed in seconds.

#kewengineering#kewengg#machine#manufacture#export#supplier#services#industry#industrial#machinemanufacture#foldingmachine

1 note

·

View note

Text

How Technology Drives Efficiency in Wet Wipes Production

The wet wipes industry has undergone a massive transformation in recent decades, evolving from a small, niche market into a global staple. Whether for personal care, cleaning, or healthcare, wet wipes have become an essential item for millions of people worldwide. But have you ever wondered how they’re made so efficiently and at such a massive scale?

The answer lies in technology. Advances in automation, materials science, and sustainability practices have redefined how wet wipes are produced. These innovations allow manufacturers to meet growing demand while ensuring high quality and minimizing environmental impact. Here’s a closer look at the technologies shaping the wet wipes industry today.

The Early Days of Wet Wipes Production

It’s hard to imagine now, but early wet wipes were more of a luxury than a necessity. They were primarily used for baby care or occasional personal hygiene and weren’t as accessible as they are today.

Back then, production was labor-intensive, with significant challenges:

Inconsistent quality due to uneven saturation and cutting.

High production costs driven by manual processes.

Limited scalability, which made it hard to keep up with growing demand.

These problems also extended to the materials used. Many of the early wipes weren’t biodegradable, which led to environmental concerns as the products became more popular.

Enter Technology: How the Industry Evolved

The introduction of advanced technologies revolutionized wet wipes production, allowing manufacturers to overcome these challenges.

Automation: The Backbone of Modern Manufacturing

One of the most significant advancements has been automation. Automated production lines make it possible to produce wet wipes faster and with greater consistency than ever before.

Key examples of automation include:

Cutting and Folding: Machines precisely cut and fold nonwoven fabrics to ensure uniformity.

Solution Application: Automated systems ensure the cleaning or disinfectant solution is evenly distributed across all wipes.

Packaging: Advanced equipment seals and labels wipes quickly and efficiently, reducing waste and human error.

With automation, manufacturers benefit from:

Higher Productivity: Thousands of wipes can be produced every minute.

Consistent Quality: AI-powered sensors detect and correct any production defects.

Lower Costs: Fewer labor requirements mean reduced operational expenses.

Advances in Materials Science

The materials used in wet wipes have also come a long way, thanks to breakthroughs in materials science.

Modern nonwoven fabrics are now:

Durable: Designed to resist tearing during use.

Absorbent: Capable of holding just the right amount of solution without dripping.

Eco-Friendly: Increasingly made from biodegradable fibers to reduce environmental impact.

The chemical formulations in wet wipes have also improved, offering:

Gentle Ingredients: Alcohol-free and hypoallergenic options for sensitive skin.

Multi-Functionality: Wipes that clean, disinfect, and moisturize all at once.

Sustainability: The Industry’s New Focus

With growing awareness about environmental issues, sustainability has become a priority for wet wipes manufacturers.

Innovative practices include:

Water Efficiency: Closed-loop systems recycle water used during production, reducing overall consumption.

Renewable Energy: Factories are increasingly powered by solar and wind energy to cut emissions.

Biodegradable Packaging: Many manufacturers are switching to recyclable or compostable packaging options.

Digital Tools in Manufacturing

Digital technology is enhancing efficiency and reducing costs. For example:

IoT Sensors: Monitor equipment performance in real time, preventing downtime.

Predictive Analytics: Help manufacturers forecast demand and optimize supply chains.

AI-Driven Insights: Provide data to improve processes and reduce waste.

The Role of Collaboration

The wet wipes production process doesn’t happen in isolation. Suppliers, manufacturers, and contract producers all work together to ensure high-quality products.

Wet Wipes Suppliers

A reliable wet wipes supplier is key to sourcing high-quality raw materials like nonwoven fabrics and cleaning solutions. Suppliers equipped with advanced logistics systems ensure materials arrive on time and meet manufacturers’ exact specifications.

Specialized Manufacturers

Cleaning wipes manufacturers focus on creating products for household and industrial use. These manufacturers rely on cutting-edge technology to ensure their wipes are durable, effective, and eco-friendly.

Contract Manufacturing

Wet wipes contract manufacturing allows brands to outsource production to facilities with advanced capabilities. This model is scalable and cost-effective, giving brands access to the latest technology without needing their own infrastructure.

Antibacterial Wipes Manufacturers

Antibacterial wipes manufacturers are meeting the rising demand for hygiene products with effective, safe solutions. These manufacturers prioritize regulatory compliance and sustainability, making antibacterial wipes an everyday essential for households and businesses.

What’s Next for the Industry?

The wet wipes industry is constantly evolving, with several exciting trends on the horizon.

Artificial Intelligence

AI is revolutionizing quality control and supply chain management. Predictive algorithms ensure that manufacturers can meet demand without overproducing, while machine learning detects subtle defects in products to maintain high standards.

Smart Packaging

Innovative packaging features, such as resealable closures and antimicrobial materials, are becoming more common. Smart packaging may also incorporate QR codes to provide consumers with additional product information.

Fully Biodegradable Wipes

The push for sustainability is leading to the development of 100% biodegradable wipes. Research into plant-based and water-soluble materials is making this goal a reality.

Expansion into Niche Markets

Manufacturers are exploring new niches, such as:

Pet Wipes: Specifically designed for grooming and cleaning pets.

Travel Wipes: Compact and portable for on-the-go use.

Medical Wipes: Tailored for healthcare settings and specific medical needs.

Final Thoughts

Technology has completely transformed the wet wipes industry, enabling manufacturers to produce high-quality, sustainable products at scale. From automation and materials science to digitalization and sustainability, every aspect of production has been optimized to meet consumer demand.

The collaboration between suppliers, manufacturers, and contract producers ensures that innovation continues to drive the industry forward. As trends like AI, smart packaging, and biodegradable wipes gain momentum, the future of wet wipes looks more efficient, eco-friendly, and exciting than ever.

It’s fascinating to see how something as simple as a wet wipe can rely on such advanced technologies to make our lives easier—and greener.

0 notes

Text

How Quilting Sewing Machines Make Patchwork Projects Easier and Faster

Patchwork quilting involves stitching together various fabric pieces to create beautiful, often intricate designs. While the process itself is rewarding, it can also be time-consuming and challenging without the right equipment. This is where quilting sewing machines come in. These machines are specifically designed to make patchwork quilting easier and faster, providing quilters with the tools they need to achieve precision and speed. Here's how quilting sewing machines simplify patchwork projects:

1. Wider Throat Space for Large Quilts

One of the most significant advantages of quilting machines is their wider throat space. The throat is the area between the needle and the body of the machine where the fabric passes through. When working on large patchwork projects, such as quilts, having more room to maneuver your fabric is essential. A quilting machine's extended throat space allows for easy handling of large quilt layers, reducing the need to fold or bunch fabric as it feeds through the machine. This results in smoother, more accurate stitching.

2. Even Feed with Walking Feet

Patchwork projects often involve stitching multiple layers of fabric together. A walking foot, commonly found on quilting machines, helps feed all layers evenly through the machine, preventing the fabric from shifting or bunching. This feature is particularly useful when working with intricate patchwork designs, as it ensures all pieces stay in place and results in neat, consistent stitches across your project.

3. Built-In Quilting Stitches

Quilting sewing machines are equipped with a variety of built-in quilting stitches, which can be used for both functional and decorative purposes. Whether you're creating intricate patterns, adding borders, or performing straight-line quilting, these specialized stitches save you time and effort. Built-in stitches eliminate the need for manual adjustments, helping you achieve professional results with minimal effort.

4. Faster Stitching for Increased Efficiency

Quilting machines are designed to operate at higher speeds than regular sewing machines, allowing you to stitch through layers of fabric more quickly. Many quilting machines also come with automatic stitch length and tension adjustments, which ensure that the settings are optimized for your fabric and project. This speed and automation make patchwork quilting more efficient, enabling quilters to complete projects faster while maintaining high-quality results.

5. Precise Stitch Control for Accuracy

Accuracy is crucial in patchwork quilting, especially when working with smaller fabric pieces. Quilting machines come with features such as adjustable stitch length, tension control, and precise needle positioning to ensure that every stitch is placed accurately. These features help you create even seams, sharp corners, and clean edges in your patchwork designs, resulting in a polished final product.

Why Murthy Sewing Machines?

As the Best Sewing Machine Dealers in Chennai, Murthy Sewing Machines is the top choice for quilters seeking high-performance equipment to enhance their projects. If you're ready to Buy Quilting Sewing Machines, our collection includes the Usha Janome Quilt Magic Sewing Machine, designed to handle intricate patchwork and quilt layers with ease. Quilting sewing machines like this offer specialized features for smooth, even stitching across various fabrics, making them essential for efficient and beautiful quilting. Whether you're a beginner or a seasoned quilter, Murthy Sewing Machines provides expert guidance and top-quality machines to bring your creative quilting visions to life.

Conclusion

Quilting sewing machines are a game-changer when it comes to patchwork projects. With their enhanced functionality, speed, and precision, they help quilters produce beautiful, high-quality quilts in less time. If you're serious about quilting, investing in a quilting sewing machine can take your craft to the next level, making each project easier and more enjoyable.

0 notes

Text

The Process Behind T-Shirt Manufacturing in Chennai: From Fabric to Fashion

T-shirts have become a wardrobe staple worldwide, blending comfort and style effortlessly. But have you ever wondered about the journey a t-shirt takes from raw fabric to a finished product? Chennai, a major textile and garment manufacturing hub, is home to some of the best t shirt manufacturers in Chennai who follow a meticulous process to ensure high-quality apparel.

In this blog, we’ll take you through the step-by-step process of t-shirt manufacturing and why t shirt manufacturers in Chennai are leading the industry with their expertise, advanced technology, and sustainable practices.

Step 1: Sourcing the Right Fabric

The foundation of a great t-shirt starts with selecting the right fabric. T shirt manufacturers in Chennai source high-quality materials such as:

Cotton – Known for its softness, breathability, and comfort.

Polyester – Durable and moisture-wicking, ideal for sportswear.

Blends (Cotton-Polyester, Bamboo Fabric, etc.) – Offering a balance between comfort and durability.

Chennai’s textile market is known for its variety of premium fabrics, allowing manufacturers to choose the perfect material for different styles and customer needs.

Step 2: Designing & Pattern Making

Once the fabric is selected, the design phase begins. This step includes:

Creating digital sketches using design software.

Developing patterns for different t-shirt styles (round-neck, V-neck, polo, oversized, etc.).

Customizing logos, prints, and embroidery for branding.

Many t shirt manufacturers in Chennai offer custom printing and embroidery options, catering to businesses, fashion brands, and event organizers.

Step 3: Cutting & Stitching the Fabric

The selected fabric is then cut into different sections based on the pattern. Manufacturers use:

Manual cutting for small batches (ideal for custom t-shirts).

Automated laser cutting for mass production (ensures precision and consistency).

Once the fabric is cut, skilled workers stitch the pieces together using high-quality sewing machines. T shirt manufacturers in Chennai focus on:

Strong seams to improve durability.

Proper stitching techniques for flexibility and comfort.

Reinforced collars and hems for a premium finish.

Step 4: Printing & Embroidery

This is where the t-shirt gets its final look! There are several methods used for printing designs onto t-shirts:

Screen Printing – Best for bulk orders with vibrant colors.

DTG (Direct-to-Garment) Printing – Ideal for detailed, small-batch designs.

Heat Transfer Printing – Used for customized, one-off prints.

Embroidery – Adds a high-end touch, often used for corporate wear.

Leading t shirt manufacturers in Chennai invest in advanced printing technologies to ensure high-definition, long-lasting designs.

Step 5: Quality Control & Finishing

Before the t-shirts are packed and shipped, they undergo rigorous quality checks:

Checking for loose threads, stitching errors, or fabric defects.

Ensuring color consistency and print accuracy.

Testing the fabric for shrinkage and wash durability.

Once approved, the t-shirts are ironed, folded, and packed in eco-friendly packaging.

Step 6: Distribution & Delivery

After production, t-shirts are shipped to local retailers, e-commerce brands, and international clients. Many t shirt manufacturers in Chennai offer bulk orders with doorstep delivery services, ensuring timely supply to businesses.

Why Chennai is a Hub for T-Shirt Manufacturing

Chennai’s garment industry is booming due to:

Access to high-quality fabrics from leading textile mills.

Skilled workforce with expertise in garment production.

Advanced manufacturing technologies for efficient production.

Sustainable practices like organic cotton usage and eco-friendly dyes.

Final Thoughts: Choosing the Right T-Shirt Manufacturer in Chennai

If you’re looking for high-quality, customized, and affordable t-shirts, partnering with experienced t shirt manufacturers in Chennai is the way to go. Whether you need bulk orders for your brand or personalized t-shirts for events, Chennai’s manufacturers offer tailored solutions to meet your needs.

Ready to Bring Your T-Shirt Designs to Life?

Get in touch with leading t shirt manufacturers in Chennai today and start creating high-quality, stylish, and comfortable t-shirts for your business or brand!

0 notes