#Manual Fabric Rolling Machine

Explore tagged Tumblr posts

Text

"April to lab 3... April to lab 3 for a systems check." The pa blurted out into her office. April rolled her eyes as she grabbed her clipboard and started meandering through the halls. Her heels clacking against the hard cold floors. Her footsteps echoing as she passed the labs. As she peered In through the windows checking on the various projects her company was working on.

Lab 1 was busy burning one of their plants that had been exposed to plant fertilizer. grapes the size of a fist popping and exploding as they outgrew their environment. The vines crept out into the hallways as the team tried to contain its growth to one room.

Lab 2 was much less destructive. Their love potion seemed to be working wonders as two of her co-workers were currently sprawled against the floor. Hungarily tearing their clothing off. She smirked as she called it into the radio that lab 2 had had a chemical leak... Again.

Finally she pulled up to lab 3. Punching in the code as she readjusted her button up. She priced open the door as she slinked into abrupt chaos. Technicians and scientists running to and thro. In the center of the room a sparking growth ray haphazardly swinging in a circle. A tech furiously typing into the computer as the machine started to shirt to life. A bright bean forming at the tip of the nozzle "it's gonna fire FIND COVER." April shoved the tech down as she tried to take control of the situation. Clearing the error codes as she punched in the manual override.

The growth ray swung around and violently spasmed as the room started to shake. A large hum filling the room deafening any sound. Stephen the senior tech screamed at her but she heard none of it as she punched in the final commands. She turned to look at the machine as her eyes opened up wide. Too late. She realized as a bright green beam shot out at hef. She barely had time to think before it splashed into her. She gasped and shrieked as it shoved her to the floor. Her skin glowed and throbbed as she felt the heat course through her. Her body hit the wall behind her with a smack as she thudded to the floor. The machine powering down as everyone gathered around April.

Meanwhile in a haze April was cautiously trying to stand back up. Not having fully realized what had happened. She opened her eyes as everyone surrounded her. "What.. happened." Before any could respond April felt her body shudder and rapidly heat up.

April snapped back as she felt her body get hot with wave after wave of energy. In tandem her body responded by growing larger with each rush of heat. The first to respond was her chest which made its entrance as it billowed forward. Her blouse stood no chance as her measly cups expanded into a letter April didn't even know was possible for her frame. Her buttons snap off in quick succession. Her bra lifted off of her as her boobs bulged over and under the fabric. The straps loosened and dug into her shoulders before they snapped off entirely. April quickly raised her hands to cover as she sat up. April tried to turn as a couple scientists caught an eyeful. "Stop looking you perverts".

She felt herself cool down as April raised herself up. She peered down into her cleavage as she slinked her blouse off. Her shirt no longer capable of covering her. She stood awkwardly as she saw a couple people bust out measuring tapes and cameras. "For research purposes" she muttered as she let them approach.

She stared coldly as they wrapped around her. Noting measurements and radiation levels. she felt her skin grow warmer but she attributed it to nerves. Everything seemed normal except of course her new bust size. Meanwhile April felt a nagging pressure inside of her. She tried holding it back but it seemed to grow and grow and "FUCK"

April screamed as her skin glowed and expanded. Her body filled the room as she doubled her height. Her butt ruptured her skirt in half as her leggings and shoes exploded off of her. Her panties popped off into a technician as he fell to the floor. Aprili raced to cover herself with a hand now at 10 ft tall but felt the feeling grow again. "I'm not stopping" she screamed before she doubled again.

Her head smashed into the roof as she recoiled off of it. Groaning and yelping In pain as her head met the 20 ft ceiling. A tech slammed the panic button as the sirens and red lights flooded the room. April turned to and thro as she tried to figure out how to leave. The techs rushed out the emergency exit as she felt her body pressurize.

"wait don't leave me somebody..." She doubled again. She tried to brace for impact but her head easily smashed the floor as she raced in. Her cleavage similarly busting the floor open as it punched through. Her head hit the second ceiling as she peered over her cleavage to the screaming attendants in lab 8 who were currently watching a woman fill half the room. Her waist at eye level.

"HELP MEEE" she screamed before she filled the entire room. Her body smashed them as she doubled again. Her feet below her filled the entire room as she bursted through the facilities roof. Her waist stuck in the framework as she tried to get away from the carnage and panic she was causing. Her body pressurized and glowed again. "nooooo"

She grimaced before filling out again. Over a hundred feet tall. Her head rushed with vertigo as her cleavage dragged her down. The survivors watch as a hundred foot...AAAAHHHHH...THREE hundred foot April crushed the lab in one fall. What they weren't expecting was her to suddenly swell closer. April raised to her hands and knees as she spurted again. Her feet dug into the soil as they raced across the road and hills each one falling to either side of the surviving scientists as her butt encroached in front of them. Her boobs dragged into the building as her head raced forward a couple hundred feet. Before anyone could react it was too late. A butt the size of a col de sac crushed the group in seconds. She spurted again and again her body filling the country side as April gave up. Groaning and crying as her body finally sizzled out after filling half the state.

266 notes

·

View notes

Text

Best Things I Have Bought

I'm not sure how successful I will be in remembering all of it, but I'll try. These have all been game-changers for me, in a variety of ways. If teen me had had access to all of these, I would have been a vastly happier person.

This one is long, so I'll put in a cut.

-outlet timers. Not having to go around and manually turn off lamps at bedtime? Amazing. I bought these but you can and should get some that have a grounded outlet with three prongs so you can attach good extension cords to them.

-famotidine. aka Pepcid, it's the safest option I currently know of for managing acid reflux. I get nauseated when I get acid reflux, so this is a necessity for me.

-T-Gel shampoo. The only one that keeps my husband's insane dandruff under control. Coal tar shampoos smell peculiar, but are totally worth it if they work. For my hair, I like anti-dandruff conditioner--I apply it to my scalp and my other conditioners to the length of my hair. After bleaching my hair, I use Olaplex 3 to prevent more severe damage; the difference is very noticeable.

-white vinegar for a laundry rinse. I get horrendous contact dermatitis and adding this in the "fabric softener" cup in my washer keeps things from making my skin burn.

-on a similar note, all Oxy laundry booster. Doesn't make my skin burn but does make stains and smells noticeably better than detergent alone.

-Aquaphor. If you have eczema, nothing helps like Aquaphor, unless it's hydrocortisone ointment (the same white petrolatum base as Aquaphor but with hydrocortisone) or a prescribed steroid.

-Bissell Stomp 'N' Go pads. I have stomped. The stain goes.

-Prune puree. A packet a day keeps the chronic constipation at bay. Less volume to consume than prune juice and, in my opinion, slightly more palatable.

-Chinotto is a bitters-based beverage that I discovered by accident really helps my chronic nausea. I've tried other brands, and San Pellegrino is definitely my favorite. Tastes weird at first, but when heavy-duty ginger ale doesn't ease it, Chinotto can. And when that doesn't work, I have Zofran (ondansetron) my doctor prescribed me for the nausea I get with migraines, and that's an effective anti-nausea agent for more than just migraines.

-"You Just Need to Lose Weight (And 19 Others Myths About Fat People)" by Aubrey Gordon.

-rolling laundry cart. Doesn't have to be this one but if you CAN roll your laundry to and fro from the machines, do it.

-"Why Does He Do That? Inside the Minds of Angry and Controlling Men" by Lundy Bancroft. If you Google, you can usually find a free pdf floating around.

-"The Vagina Bible," by Dr. Jen Gunter.

-satin scrunchies. Wet Brush. Terry cloth lined shower cap. AOA terry cloth hair turban (way, way better than similar ones from drugstore).

-stretchy work pants.

-bra liners. For large-chested people who tend to get sweaty underboob, this is a life-saver.

-Goo Gone.

-Dr. Scholls medicated foot powder and the Earth Therapeutics tea tree oil foot spray. The foot powder works for super long days and the spray for lighter days.

-Reflective heat pad. I use this on my car seat in the winter and I am so happy for that every single chilly morning. I've repurchased it... once or twice? now.

-Retin-A. I used to use Differin, which is adapalene, the most potent retinoid available over the counter, but the switch to prescription-only Retin-A has been very noticeable. Decreased wrinkles, clearer skin. More inclined to flake and burn but it's worth it for me.

-Red LED therapy. Near-infrared stimulates collagen production in the skin. The only other thing that really does that is retinoids. I bought the Omnilux mask, which is certainly high-end, but HotandFlashy (a YouTube content creator) did a great comparison of different masks available by specs and this was the best at the time. The difference is noticeable within days. I've tried other, lower-powered masks, but what made me make the jump to high-end was that I got the Dennis Gross red LED eye mask for crows' feet off eBay and I was like "holy shit, this is better." And Omnilux is better still. It makes sense, since they were the OG of the models that have been in dermatology clinics for a couple of decades now.

-AOA foundation has been at least as good at my TooFaced foundation, and it's like 1-2 bucks instead of 40. There are light, medium, and deep shades, each on different pages; I'm linking to light because that's what I use. The lightest shade works for me, and I'm basically translucent.

-AOA VitaGlow tinted moisturizer is absolutely my go-to for lighter coverage days.

-AOA PawPaw blending sponges. Best out there and also the cheapest.

-(do not buy any of the AOA eyeshadows. Total waste of time, zero pigment. I've tried repeatedly and they're just garbage. The highlights are generally fine though.)

-Direct acid foot peels. The calluses come off. Just don't do it when you have ANY open wound on the feet, because it's acid and will sting like hell.

-blendercleanser solid cleanser for blending sponges and brushes. Actually a) gets them clean and b) rinses out.

-PureWine wine wands. I let these puppies sit for three minutes in a glass and suddenly I can drink red wine without migraines or hangovers. Fucking miraculous.

-Dustbuster. Holy shit it's amazing for ADHD peeps. Small thing bugging you? Can't get yourself to bust out the "real" vacuum? USE THIS.

-Crocs. Don't @ me. I wear a black pair around the house and for garden chores and they make my feet happy. Salonpas patches and/or BenGay for a topical when you're sore--topicals are great pain relief.

-Vibrating neck pillow. Don't need it right now? Wait until your next head cold. Vibration clears sinuses.

-PooPourri. I love not having to smell poop. This, and similar products, work pretty well by trapping scent particles in the oil layer instead of letting them evaporate into the air.

-Electric snow thrower. I can't manage a large, heavy snow blower and I don't want to deal with a gas engine. This little guy helped me clear my large driveway in 3-4 hours instead of 12.

-The Demon-Haunted World: Science as a Candle in the Dark, by Carl Sagan.

-Handheld home IPL for hair removal. I ordered this exact one and I like it. You can get these on eBay or Amazon for cheaper sometimes; just make sure you PROTECT YOUR EYES during flashes. Targets pigment in the hair bulb so lighter skin and darker hair work better, and deeper skin tones may burn.

-Lanolin chapstick. Makes all other chapsticks I've used look like garbage.

-Steam eye masks. ShopMissA sells these and you can find them on a lot sites; shouldn't cost more than about a dollar per mask. I ended up buying an electric eye mask because I wanted to treat my dry eye and that just felt more environmentally responsible, but I love falling asleep with these on and I can't do that with my plug-in mask.

I think this is where I'll leave it--I've gone back quite a ways in my shopping history across multiple sites and thought about my daily routines--but if any of these problems torture you, these are my suggestions.

228 notes

·

View notes

Text

Why Stretch Wrap is Essential for Safe and Secure Shipping in the UK

Shipping products in the UK has always come with its fair share of challenges—from safeguarding goods during transport, to reducing the risk of damage, to maintaining cost efficiency. However, one standout solution that has revolutionized packaging across industries is stretch wrap. Widely recognized for its versatility and effectiveness, stretch wrap plays a vital role in ensuring safe and secure shipping.

Whether you're in logistics, manufacturing, or retail, stretch wrap provides an indispensable way to protect your items and optimize your shipping process. In this blog, we’ll explore what makes stretch wrap essential, its benefits, and why more businesses in the UK are choosing premium solutions like Tilak Polypack stretch films.

What is Stretch Wrap?

Stretch wrap, also referred to as stretch film or stretch wrap roll, is a highly stretchable plastic film made from polyethylene. Its elastic properties allow the material to tightly and securely wrap items or pallet loads without the need for adhesives or heat. It ensures tight containment, reduces risk of shifting during transport, and protects goods from external elements.

Stretch films are available as hand rolls for manual application and machine rolls for automated operations, making them highly versatile for various packaging needs. Advanced versions now also come with additional features like UV resistance or pre-stretching for added convenience and cost savings.

Popular Use Cases for Stretch Wrap:

Logistics and Warehousing: Streamlining palletized shipping and reducing the risk of goods tipping over.

E-commerce and Retail: Efficiently bundling packages together and securing items for delivery.

Food and Beverage Industries: Safeguarding products against dust, moisture, and contamination.

Manufacturing: Containing irregularly shaped items or bundling loose components.

Why Stretch Wrap is Essential for Shipping in the UK

1. Protection from Damage and Moisture

Shipping involves handling, vibrations, and exposure to external factors like rain or humidity. Stretch wraps act as a durable shield, preventing scratches, dents, dust, and moisture from damaging your goods. For sensitive or fragile products, such as electronics or fabrics, this level of protection is critical.

2. Secure Load Stability

Stretch wrap increases the stability of pallet loads, reducing the risk of shifting or toppling during transport. This makes it a reliable choice for the UK’s busy distribution networks, where goods are constantly loaded and unloaded at warehouses, ports, and delivery hubs.

3. Cost-Effective Packaging Solution

Stretch film is not only affordable but also reduces the need for additional packing materials such as strapping or adhesives. Its high conformability ensures that every inch of material is effectively used, minimizing waste while delivering superior results.

4. Ease of Usage for Businesses of All Sizes

From small retailers to large-scale logistics operations, stretch wrap offers scalability. Hand rolls cater to small packaging needs, while machine stretch wraps are perfect for bulk operations. Combined with its lightweight and recyclable nature, stretch wrap becomes a practical addition to any packaging workflow.

5. Sustainability and Eco Friendliness

Many businesses are now adopting more sustainable practices, and using recyclable stretch wraps is a great way to reduce environmental impact. Choosing eco-friendly options from a provider like Tilak Polypack not only ensures high quality but also supports your business’s green initiatives.

Benefits of Stretch Wrap Rolls

Here are some solid reasons why stretch wrap rolls are the go-to packaging choice for UK businesses:

Secure Packaging: Keeps items tightly bound, preventing them from slipping or shifting.

Damage Prevention: Minimizes the risk of scratches, breaks, or exposure to external elements.

Load Stability: Provides excellent grip for stacked pallets, preventing toppling during transport.

Versatility: Ideal for pallets, irregularly shaped loads, or bundling small items.

Transparency: Easy product identification during inventory checks.

Efficiency: Streamlines packaging and unpacking processes, saving time.

Eco-Friendly: Recyclable materials are available, contributing to sustainability goals.

Customizable Options: Different thicknesses, lengths, and features are available to meet unique needs.

Why Choose Tilak Polypack for Your Stretch Film Needs?

When it comes to premium stretch wraps, Tilak Polypack stands out as a trusted manufacturer and supplier. What makes them the ideal choice for UK businesses? Here’s why:

Top-Quality Products

Tilak Polypack offers durable, high-performance stretch film that meet stringent manufacturing and quality standards. You can trust their products to keep your shipments protected at all times.

Eco-Friendly Solutions

Committed to sustainability, Tilak Polypack provides recyclable and eco-conscious wraps that minimize environmental impact—a win for your business and the planet.

Customizable Packaging Options

With a variety of film thicknesses, lengths, and widths available, Tilak Polypack ensures you receive the perfect solution tailored to your needs.

Global Reach and Trusted Expertise

With over 20+ years of experience and a strong presence in global markets like the US, UK, Australia, and Singapore, Tilak Polypack is a reliable partner for businesses worldwide.

Excellent Customer Support

From choosing the right type of stretch film to resolving queries, their attentive team ensures a seamless experience for all their customers.

2 notes

·

View notes

Text

How to Store Long & Heavy Items with Industrial Storage Racks?

Space is not the only challenge faced by warehouse workers — often they have difficulty storing items due to their shape and size. It is extremely difficult to store long, oversized, or heavy materials like pipes, lumber, steel bars, rods, or beams efficiently if your facility deals with them. Floor stacking wastes space, standard shelving cannot support the weight or length, The result? A cluttered, unsafe, and inefficient workspace.

That’s where the right Industrial Storage Racks make all the difference — and not just for storage, but for better workflow and safety too.

Why Do Standard Racks Just Don’t Work?

When trying to fit long products on pallet racks or regular shelving, you may run into problems. Overhanging materials may pose a safety risk, and deep shelves may prevent access to the product. And if stock is poorly arranged, your team will spend more time managing materials than moving them.

Using standard racking for the wrong product type often creates more problems than it solves. That’s why dedicated storage solutions for long and heavy items are essential in industries like construction, manufacturing, plumbing, fabrication, and more.

Cantilever Racking: The Go-To Solution for Long Loads

When it comes to long, heavy items, Cantilever Racks are the industry’s most practical answer. These racks don’t have vertical posts on the front, so materials can be loaded and retrieved easily, no matter their length. Items rest on horizontal arms that extend from a central column — and these arms can be adjusted based on what you’re storing.

Whether it’s pipes, plastic tubing, wooden planks, or rolled materials, cantilever systems let you keep everything visible, secure, and off the ground.

Plus, they work just as well in indoor warehouses as they do in outdoor yards.

Go Vertical — Don’t Waste Floor Space

When you’re storing long items on the floor or stacking them sideways, you’re using more space than you need to. A big benefit of Industrial Racking Systems is their ability to scale vertically. That means more material in less floor area — without compromising safety or accessibility.

Instead of expanding your facility or renting more space, investing in the right rack setup helps you work smarter within your existing footprint.

Custom-Built for Real Warehousing Challenges

At Sigma Racks, we know every warehouse runs differently. That’s why we don’t just offer racks — we offer custom-designed Industrial Storage Solutions based on the products you actually handle.

We consider:

The size, shape, and weight of your materials

Whether your warehouse uses forklifts or manual picking

The kind of movement flow your team follows

Indoor or outdoor storage environments

All our racks — from Cantilever Racking Systems to Mezzanine Structures and Pallet Racks — are built using modern automated machines that guarantee precision, strength, and long-lasting durability. And since we manufacture in-house, we offer all our storage systems at factory-direct prices, making them cost-effective even for small and mid-size businesses.

Why Teams Across India Choose Sigma Racks?

We’ve helped companies across industries — from retail to manufacturing to logistics — upgrade their warehouses with better, stronger, and smarter storage. What sets us apart?

✅ Custom-built racks to suit your needs

✅ Budget-friendly pricing without compromising quality

✅ Automated manufacturing for accuracy and consistency

✅ Quick turnaround time with Pan India delivery

✅ Hands-on support before and after purchase

So, if you’ve been struggling to organize your long or heavy inventory, don’t settle for floor stacking or mismatched racks. Let’s build a system that actually works for your space — and your workflow.

📞 Need help choosing the right rack? Call us at: +91-9670777737

🌐 Visit: www.sigmastorage.com

#heavy duty racks#industrial racking#industrial storage rack manufacturer#cantilever racking#racks for warehouse#Storage Rack Solutions#Warehouse Racking Systems#Warehouse Storage Systems#Long Item Storage Solutions

1 note

·

View note

Text

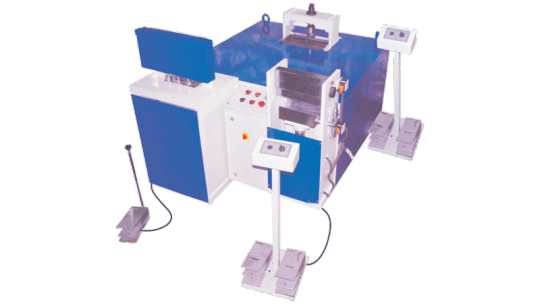

Bending machine Manufacturer in Ahmedabad

A bending machine is a versatile tool designed to form bends in various materials, primarily metals, by applying force through different mechanisms. These machines are integral to manufacturing processes across industries such as automotive, construction, aerospace, and furniture. Depending on the application, bending machines come in several types, including press brakes, pipe benders, plate rolling machines, and CNC-controlled systems. Each type caters to specific bending requirements, from simple right-angle bends to complex, multi-radius shapes. The choice of machine depends on factors like material type, thickness, desired bend radius, and production volume. Modern bending machines offer numerous advantages that enhance manufacturing efficiency and product quality. They provide high precision and repeatability, ensuring consistent results across large production runs. Automation features reduce manual labor, minimize errors, and increase throughput. Additionally, these machines are equipped with safety mechanisms to protect operators and reduce workplace hazards. Their versatility allows them to handle a wide range of materials and thicknesses, making them suitable for diverse fabrication needs. Furthermore, the integration of advanced control systems enables quick setup changes and efficient handling of complex bending tasks. The applications of bending machines are extensive and varied. In the automotive industry, they are used to manufacture components like exhaust systems, brackets, and structural frames.

For More Details Click Here:

0 notes

Text

How a Digital Core Compression Tester Improves Testing

How a Digital Core Compression Tester Improves Testing – LabZenix

In the packaging and paper industries, ensuring the strength and durability of materials is crucial. One of the most essential tools in this process is the Digital Core Compression Tester. But the question arises – how a digital core compression tester improves testing in modern industrial applications? Let’s dive deep into the subject, understand its working, and discover how companies like LabZenix are innovating this segment.

Understanding the Need for Core Compression Testing

Before we explore how a digital core compression tester improves testing, it’s important to understand why core compression testing is important in the first place.

Core compression testing is used to evaluate the strength of cylindrical cores, like those used in paper rolls, films, foils, and fabric rolls. These cores must be strong enough to withstand the pressure during storage, transportation, and usage. A weak core can collapse under weight, leading to product damage and losses. Hence, compression testing ensures that the cores meet industry quality standards.

What is a Digital Core Compression Tester?

A Digital Core Compression Tester is a precision instrument used to test the compressive strength of core materials. Unlike manual testing methods, the digital version offers highly accurate readings with digital display systems, programmable test parameters, and automated load applications.

LabZenix, a leading manufacturer in the testing equipment industry, offers state-of-the-art digital core compression testers that deliver fast, accurate, and repeatable results. They play a key role in helping manufacturers improve quality control and reduce waste.

How a Digital Core Compression Tester Improves Testing in Practical Terms

So, how a digital core compression tester improves testing? Let’s break it down into specific advantages:

1. Accuracy and Repeatability

Digital systems ensure each test is performed with the same parameters and force application. Manual errors are eliminated, leading to more trustworthy results.

For example, the LabZenix digital core compression tester is equipped with high-precision load cells and digital displays, allowing technicians to read measurements down to the smallest variation. This consistency is vital for high-volume industries.

2. Time Efficiency

Digital testers drastically reduce testing time. Automated loading and data capturing mean technicians spend less time on each sample and more time analyzing results.

With LabZenix’s digital model, users can test multiple samples within a shorter time, improving overall productivity without compromising on test quality.

3. Data Logging and Analysis

One of the biggest advantages of digital equipment is the ability to store and analyze data. Modern testers can connect to computers or printers, allowing for efficient record-keeping.

How a digital core compression tester improves testing becomes even more apparent when you realize how easy it is to generate test reports, share results, and monitor trends over time using tools from manufacturers like LabZenix.

4. Standardized Testing Procedures

Digital core compression testers operate using pre-set testing standards such as ASTM, ISO, and TAPPI. By using these globally accepted procedures, companies ensure their products meet international quality expectations.

LabZenix has engineered its digital testers to comply with major industry standards, making them ideal for global brands.

5. Minimal Human Intervention

Reducing human involvement minimizes errors. Once the test is set, the machine performs the compression automatically, calculates the result, and displays it. No guesswork, no assumptions – just precise numbers.

This reliability is exactly how a digital core compression tester improves testing compared to manual setups.

6. Long-Term Durability

LabZenix designs its instruments for rugged industrial environments. Their digital core compression testers are built to last, ensuring reliable performance for years. A sturdy build means fewer breakdowns and higher ROI.

Features That Make LabZenix Core Compression Testers Stand Out

LabZenix has become a trusted name because of its focus on innovation, usability, and customer satisfaction. Their digital core compression testers come loaded with features that improve testing procedures across industries.

Digital Display: Clear, easy-to-read output during and after tests.

Adjustable Testing Speed: Allows customization for different core materials.

Sturdy Build: Powder-coated body ensures resistance to corrosion and wear.

High Capacity Load Cell: Handles a wide range of compression values.

Safety Features: Emergency stop and overload protection.

Software Connectivity: Integration with LabZenix software for analysis.

When professionals ask how a digital core compression tester improves testing, the answer often lies in these value-added features offered by advanced brands like LabZenix.

Applications Across Industries

Digital core compression testers aren’t just limited to one industry. Here's how they improve testing in various sectors:

Paper & Packaging: Verifies the strength of paper cores in roll formats.

Textile & Fabric: Ensures fabric rolls don't collapse during transport.

Plastic Film Manufacturing: Maintains quality of plastic roll cores.

Aluminum Foil Industry: Confirms strength to handle rolled metal sheets.

Construction Material Supply: Tests cardboard or fiber cores used for protective purposes.

In all these areas, knowing how a digital core compression tester improves testing helps companies prevent product failures, maintain brand reputation, and comply with quality norms.

Maintenance and Calibration – Key to Long-Term Efficiency

To fully leverage the advantages of a digital tester, regular maintenance and calibration are necessary. LabZenix offers after-sales services that include:

Annual Maintenance Contracts

Calibration Certification

Spare Parts Support

Operator Training

These services ensure the machine continues to provide accurate and reliable readings over the years.

Frequently Asked Questions (FAQ)

Q1. What is the primary function of a digital core compression tester?

A1. The primary function is to measure the compressive strength of cylindrical cores used in products like paper rolls, films, and textiles. It helps determine if the core can withstand external pressure during handling and transport.

Q2. How a digital core compression tester improves testing compared to manual methods?

A2. It improves testing by offering accurate, repeatable results, eliminating human error, enabling automated load application, reducing test time, and allowing digital data storage and analysis. These features ensure better quality control and operational efficiency.

Q3. Is LabZenix a reliable brand for digital core compression testers?

A3. Yes, LabZenix is known for manufacturing high-quality testing instruments, including digital core compression testers. They focus on precision, durability, and customer service, making them a preferred choice in many industries.

Q4. What materials can be tested using a digital core compression tester?

A4. You can test cardboard, fiberboard, plastic, and even lightweight metal cores. These are common in the packaging, paper, textile, and construction industries.

Q5. Can LabZenix digital core compression testers be customized?

A5. Yes, LabZenix offers customization based on industry needs. You can choose load range, testing speed, data output options, and size configurations to suit your application.

Q6. How often should the tester be calibrated?

A6. Calibration is typically recommended once every 6 to 12 months, depending on usage. LabZenix provides calibration services to ensure continued accuracy.

Q7. What safety features are included in LabZenix digital testers?

A7. Safety features include overload protection, emergency stop buttons, and secure enclosure of moving parts. These features reduce the risk of accidents during operation.

0 notes

Text

For sell New Mimaki UJV100-160Plus UV-LED roll-based printer

For sell New Mimaki UJV100-160Plus UV-LED roll-based printer

Price: $5,248.00 Find more Mimaki UV LED Printers at www.indraminer.shop

Productivity And Versatility At An Entry-Level Price The UJV100-160Plus is a competitively priced UV-LED roll-based printer with many productivity features found in higher-end models. It features Mimaki instant-dry UV-LED inks that adhere to a variety of media including paper, PET film, fabric, vinyl, and more -making post-printing handling and finishing effortless. With UV-LED lamps, the inks cure instantly, dramatically increasing printing speed and efficiency. This multi-purpose machine is suited for a variety of applications while keeping costs low. Backlit applications utilizing Multiple-layer prints New features allow for the reduction of ink consumption by up to 50% while maintaining the color balance of the original design. Instantly cured prints for shorter turnaround time and no waiting to laminate. With a maximum power consumption of 0.5kW, the UJV100-160Plus consumes less than 20% the power of eco-solvent and latex printers in the market (approximately) Eco-friendly UV-LED six color ink set in 1-liter bottles: C, M, Y, K, White, Clear Dot Adjustment System (DAS) automates dot position and feeding corrections, reducing manual intervention and workflow interruptions.

Specifications Printhead Two on-demand piezo heads, staggered layout Print Resolutions 360 dpi, 720 dpi, 900 dpi, 1200 dpi Maximum Print Area 63.4″ (1610.0 mm) Maximum media width 63.8″ (1620 mm)

0 notes

Text

"April to lab 3... April to lab 3 for a systems check." The pa blurted out into her office. April rolled her eyes as she grabbed her clipboard and started meandering through the halls. Her heels clacking against the hard cold floors. Her footsteps echoing as she passed the labs. As she peered In through the windows checking on the various projects her company was working on.

Lab 1 was busy burning one of their plants that had been exposed to plant fertilizer. grapes the size of a fist popping and exploding as they outgrew their environment. The vines crept out into the hallways as the team tried to contain its growth to one room.

Lab 2 was much less destructive. Their love potion seemed to be working wonders as two of her co-workers were currently sprawled against the floor. Hungarily tearing their clothing off. She smirked as she called it into the radio that lab 2 had had a chemical leak... Again.

Finally she pulled up to lab 3. Punching in the code as she readjusted her button up. She priced open the door as she slinked into abrupt chaos. Technicians and scientists running to and thro. In the center of the room a sparking growth ray haphazardly swinging in a circle. A tech furiously typing into the computer as the machine started to shirt to life. A bright bean forming at the tip of the nozzle "it's gonna fire FIND COVER." April shoved the tech down as she tried to take control of the situation. Clearing the error codes as she punched in the manual override.

The growth ray swung around and violently spasmed as the room started to shake. A large hum filling the room deafening any sound. Stephen the senior tech screamed at her but she heard none of it as she punched in the final commands. She turned to look at the machine as her eyes opened up wide. Too late. She realized as a bright green beam shot out at hef. She barely had time to think before it splashed into her. She gasped and shrieked as it shoved her to the floor. Her skin glowed and throbbed as she felt the heat course through her. Her body hit the wall behind her with a smack as she thudded to the floor. The machine powering down as everyone gathered around April.

Meanwhile in a haze April was cautiously trying to stand back up. Not having fully realized what had happened. She opened her eyes as everyone surrounded her. "What.. happened." Before any could respond April felt her body shudder and rapidly heat up.

April snapped back as she felt her body get hot with wave after wave of energy. In tandem her body responded by growing larger with each rush of heat. The first to respond was her chest which made its entrance as it billowed forward. Her blouse stood no chance as her measly cups expanded into a letter April didn't even know was possible for her frame. Her buttons snap off in quick succession. Her bra lifted off of her as her boobs bulged over and under the fabric. The straps loosened and dug into her shoulders before they snapped off entirely. April quickly raised her hands to cover as she sat up. April tried to turn as a couple scientists caught an eyeful. "Stop looking you perverts".

She felt herself cool down as April raised herself up. She peered down into her cleavage as she slinked her blouse off. Her shirt no longer capable of covering her. She stood awkwardly as she saw a couple people bust out measuring tapes and cameras. "For research purposes" she muttered as she let them approach.

She stared coldly as they wrapped around her. Noting measurements and radiation levels. she felt her skin grow warmer but she attributed it to nerves. Everything seemed normal except of course her new bust size. Meanwhile April felt a nagging pressure inside of her. She tried holding it back but it seemed to grow and grow and "FUCK"

April screamed as her skin glowed and expanded. Her body filled the room as she doubled her height. Her butt ruptured her skirt in half as her leggings and shoes exploded off of her. Her panties popped off into a technician as he fell to the floor. Aprili raced to cover herself with a hand now at 10 ft tall but felt the feeling grow again. "I'm not stopping" she screamed before she doubled again.

Her head smashed into the roof as she recoiled off of it. Groaning and yelping In pain as her head met the 20 ft ceiling. A tech slammed the panic button as the sirens and red lights flooded the room. April turned to and thro as she tried to figure out how to leave. The techs rushed out the emergency exit as she felt her body pressurize.

"wait don't leave me somebody..." She doubled again. She tried to brace for impact but her head easily smashed the floor as she raced in. Her cleavage similarly busting the floor open as it punched through. Her head hit the second ceiling as she peered over her cleavage to the screaming attendants in lab 8 who were currently watching a woman fill half the room. Her waist at eye level.

"HELP MEEE" she screamed before she filled the entire room. Her body smashed them as she doubled again. Her feet below her filled the entire room as she bursted through the facilities roof. Her waist stuck in the framework as she tried to get away from the carnage and panic she was causing. Her body pressurized and glowed again. "nooooo"

She grimaced before filling out again. Over a hundred feet tall. Her head rushed with vertigo as her cleavage dragged her down. The survivors watch as a hundred foot...AAAAHHHHH...THREE hundred foot April crushed the lab in one fall. What they weren't expecting was her to suddenly swell closer. April raised to her hands and knees as she spurted again. Her feet dug into the soil as they raced across the road and hills each one falling to either side of the surviving scientists as her butt encroached in front of them. Her boobs dragged into the building as her head raced forward a couple hundred feet. Before anyone could react it was too late. A butt the size of a col de sac crushed the group in seconds. She spurted again and again her body filling the country side as April gave up. Groaning and crying as her body finally sizzled out after filling half the state.

133 notes

·

View notes

Text

Silica gel packing roll

Silica Gel Packing Roll is specially made for high-speed production of silica gel sachets. Crafted from breathable laminated non-woven fabric, it allows moisture to pass through effectively, making silica gel work at its best. This roll is suitable for both automatic and manual packing machines.

Key Features:

✔ Breathable & moisture-permeable ✔ Strong, tear-resistant, and machine-friendly ✔ Available in various GSM, widths & roll lengths ✔ Perfect for electronics, pharma, textiles & leather packaging

Use Silica Gel Packing Roll to produce reliable and efficient moisture absorber sachets for industrial and commercial use.

0 notes

Text

Rebar Processing Machine in Delhi

Rebar Processing Machine in Delhi

Introduction

A Rebar Processing Machine in Delhi is a crucial tool in the construction industry, designed to automate cutting, bending, and shaping of reinforcement bars. These machines improve efficiency, reduce manual labor, and ensure precision in construction projects. Topall Impex is a trusted supplier of high-quality rebar processing machines, providing durable and efficient equipment to meet the needs of modern construction.

Why Choose a Rebar Processing Machine in Delhi?

Construction projects in Delhi require accuracy and speed to meet deadlines and maintain quality standards. A Rebar Processing Machine in Delhi simplifies the task of cutting and bending steel bars, ensuring structural strength and efficiency.

Benefits of Using a Rebar Processing Machine:

Increases Productivity: Automates the process, saving time and effort.

Ensures Precision: Delivers accurate cuts and bends, reducing material wastage.

Reduces Labor Costs: Requires minimal manual intervention, enhancing efficiency.

Enhances Safety: Minimizes the risks associated with manual cutting and bending.

Durable and Long-Lasting: Built with high-quality components for extended use.

Types of Rebar Processing Machines We Offer

1. Rebar Cutting Machine

Designed for fast and precise cutting of steel bars.

Suitable for different bar diameters and thicknesses.

High-speed operation to increase productivity.

2. Rebar Bending Machine

Bends reinforcement bars into required shapes and angles.

Ensures accuracy, reducing manual errors.

Ideal for large-scale construction projects.

3. Rebar Stirrup Bender

Used for shaping rebar stirrups for reinforced concrete structures.

Ensures uniformity and structural integrity.

Suitable for bridges, tunnels, and high-rise buildings.

4. Rebar Straightening and Cutting Machine

Straightens coiled rebar and cuts it to required lengths.

Reduces material wastage and improves efficiency.

Perfect for steel fabrication units and construction sites.

5. Rebar Thread Rolling Machine

Creates threaded rebar ends for easy and strong connections.

Enhances construction stability and safety.

Supports multiple threading sizes.

Why Choose Topall Impex for Rebar Processing Machines in Delhi?

Topall Impex is a leading supplier of Rebar Processing Machines in Delhi, offering top-quality products with advanced technology to meet industry demands.

Key Features of Our Machines:

High-Quality Blades & Components: Ensures precise cutting and bending.

Durable Build: Made from robust materials for long-term reliability.

User-Friendly Operation: Easy to use with simple controls.

Low Maintenance: Designed for minimal upkeep, reducing operational costs.

Affordable Pricing: Competitive rates with superior quality.

Applications of Rebar Processing Machines

Residential Construction: Apartments, villas, and housing complexes.

Commercial Projects: Shopping malls, office buildings, and IT parks.

Infrastructure Development: Bridges, highways, metro rail, and flyovers.

Industrial Structures: Factories, warehouses, and manufacturing plants.

Buy the Best Rebar Processing Machine in Delhi

If you are looking for a high-quality Rebar Processing Machine in Delhi, Topall Impex offers the best solutions. Our machines ensure efficiency, precision, and safety, making them the perfect choice for construction professionals.

Contact Us:

For more details, visit our website: https://barbendingmachine.in/delhi/rebar-processing-machine.html or call us at +91 9716467843.

Conclusion

A Rebar Processing Machine in Delhi is essential for modern construction projects. Topall Impex provides high-performance, durable, and cost-effective machines to enhance productivity and safety. Contact us today for the best rebar processing solutions!

0 notes

Text

High-Performance Printing & Converting Machines | Advanced Solutions

In the modern world, the printing and packaging industry has started to completely rely on precision, effectiveness, and novelty. Advanced technology such as slitting rewinding machines, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems is among the most significant tools rendering final mba product quality.

Machine manufacturers and converters rely heavily on high-level technological tools to speed up the process of production, increase accuracy, and aid versatility of their machines. The description of the machines' importance in various industrial applications has been outlined in a set of present practice method, showing machines' necessity in printing and packaging industries today.

Slitting Rewinding Machine

A slitting rewinding machine is a vital component in industries dealing with flexible packaging, paper, films, and foil materials. It enables the precise slitting and rewinding of large master rolls into smaller rolls with accurate tension control.

Key Features of a Slitting Rewinding Machine:

High-Speed Performance: Ensures rapid slitting and rewinding without compromising quality.

Precision Cutting: Adjustable slitting blades provide clean and accurate cuts.

Tension Control Mechanism: Maintains optimal tension for smooth rewinding.

User-Friendly Interface: Automated controls for easy operation and reduced downtime.

Versatile Applications: Suitable for plastic films, aluminum foils, paper rolls, and adhesive tapes.

Applications of Slitting Rewinding Machines:

Flexible Packaging Industry: For slitting plastic films and foils.

Label Production: Converts large rolls into label-sized formats.

Printing Industry: For handling coated and laminated materials.

Label Die Cutting Machine

A label die cutting machine is essential for the precise cutting of labels, stickers, and adhesive sheets. It ensures clean edges, intricate shapes, and high-speed production for industries requiring mass labeling.

Key Features of a Label Die Cutting Machine:

Rotary & Flatbed Cutting: Supports various die-cutting methods for different label types.

Automatic Waste Removal: Ensures a cleaner output with no excess material.

High Cutting Accuracy: Ideal for custom shapes and intricate label designs.

Multi-Layer Processing: Allows multiple layers for enhanced durability.

User-Friendly Control Panel: Simplifies operation and reduces labor requirements.

Applications of Label Die Cutting Machines:

Food & Beverage Labeling: Used for bottle and container labeling.

Pharmaceutical Industry: For precision-cut medical labels.

Cosmetic & Personal Care Products: Ensures premium quality label cutting.

Paper Core Cutting Machine

A paper core cutting machine is used to cut paper tubes and cores to the desired length, ensuring smooth edges and accurate dimensions for various industrial applications.

Key Features of a Paper Core Cutting Machine:

High Cutting Precision: Produces accurate and smooth cuts for uniform core sizes.

Adjustable Cutting Lengths: Allows customization for different applications.

Heavy-Duty Construction: Ensures durability and longevity.

Automatic & Manual Operation: Supports both automatic and manual cutting modes.

Dust-Free Operation: Minimizes waste and enhances cleanliness.

Applications of Paper Core Cutting Machines:

Packaging Industry: For manufacturing paper cores for packaging rolls.

Printing Sector: Used for paper roll cores and film winding.

Textile Industry: For fabric and yarn core cutting.

Hot Foil Stamping Machine

A hot foil stamping machine enhances the visual appeal of printed products by adding metallic and holographic foil designs. It is widely used in luxury packaging, book covers, greeting cards, and promotional materials.

Key Features of a Hot Foil Stamping Machine:

Advanced Foil Transfer Technology: Ensures sharp and clean imprints.

Temperature & Pressure Control: Allows precise adjustments for different materials.

Multi-Purpose Applications: Works on paper, plastic, leather, and fabric.

Automatic Foil Feeding System: Ensures smooth and continuous foil application.

Energy-Efficient Design: Reduces operational costs and improves efficiency.

Applications of Hot Foil Stamping Machines:

Luxury Packaging: Enhances premium product packaging.

Branding & Promotions: Used for high-end business cards and brochures.

Security Printing: Adds holographic elements for anti-counterfeiting.

UV Curing Systems

A UV curing system is an advanced technology used for instant drying and curing of inks, coatings, and adhesives using ultraviolet light. This method ensures high-quality finishes, durability, and eco-friendly operations.

Key Features of a UV Curing System:

Instant Drying & Curing: Reduces production time significantly.

Energy Efficiency: Consumes less power compared to traditional drying methods.

Eco-Friendly Operation: Eliminates the need for solvents and harmful chemicals.

High Durability: Ensures scratch-resistant and long-lasting prints.

Wide Compatibility: Suitable for offset, flexographic, and screen printing.

Applications of UV Curing Systems:

Printing Industry: For UV-cured inks and coatings.

Electronics & PCB Manufacturing: Ensures durable protective coatings.

Medical Devices: Used for adhesive bonding in healthcare applications.

Why Invest in High-Performance Printing & Converting Machines?

Enhanced Production Efficiency – Reduces downtime and increases output.

Precision & Quality – Ensures accurate cutting, stamping, and curing.

Cost-Effective Solutions – Optimizes material usage and reduces waste.

Versatile Applications – Suitable for various industries, from packaging to textiles.

Advanced Automation – Minimizes manual labor and improves operational accuracy.

By integrating the latest slitting rewinding machine, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems, manufacturers can achieve superior productivity and quality.

Project Name: UV Graphic Technologies Pvt. Ltd

Address: Plot 15, Sector 140A, Noida UP 201305

Contact No: 919810114365

Email ID: [email protected]

Our Website: https://gtigti.com/

Linkedin ID: https://www.linkedin.com/company/uv-graphic-technologies-pvt-ltd/

You tube: https://www.youtube.com/watch?v=EleXfuBanIk&ab_channel=AbhayDatta

0 notes

Text

JUGMUG Roll Forming: Revolutionizing the Solar Industry with Precision Roll Forming Machines

The global shift towards renewable energy has placed immense importance on solar power as a sustainable and eco-friendly solution. With solar panel installations growing exponentially, the demand for high-quality mounting structures has surged. One of the most critical aspects of solar panel installation is the durability and precision of its mounting frames.

This is where JUGMUG Roll Forming stands out as an industry leader, providing state-of-the-art roll forming machine that cater specifically to the solar industry.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of metal is passed through successive sets of rolls to achieve the desired shape. This process ensures high precision, uniformity, and efficiency, making it ideal for manufacturing solar panel mounting frames. Unlike traditional fabrication methods, roll forming minimizes material waste, reduces production time, and enhances product strength.

The Role of Roll Forming Machines in the Solar Industry

The solar industry relies heavily on roll forming machines to manufacture mounting structures that support solar panels. These structures need to be robust, lightweight, and corrosion-resistant to withstand various environmental conditions. JUGMUG Roll Forming specializes in designing and manufacturing roll forming machines specifically for the solar sector, ensuring superior performance and cost-effectiveness.

Benefits of Using Roll Forming Machines for Solar Panel Mounting Frames:

High Precision and Consistency – Roll forming machines ensure uniform profiles with tight tolerances, crucial for seamless solar panel installation.

Material Efficiency – The roll forming process reduces material wastage, making it a cost-effective solution.

Increased Production Speed – Continuous operation leads to faster production rates, helping meet the growing demand for solar installations.

Enhanced Durability – Formed structures exhibit superior strength and resistance against harsh weather conditions.

Customization Flexibility – Roll forming machines can be tailored to produce different profiles according to specific solar panel requirements.

JUGMUG Roll Forming: Pioneers in Solar Mounting Frame Production

JUGMUG Roll Forming has established itself as a trusted name in the industry by providing cutting-edge roll forming solutions. Their machines are engineered to produce high-quality solar panel mounting frames with unparalleled accuracy and efficiency. Whether for ground-mounted or rooftop solar installations, JUGMUG’s machines deliver outstanding results that align with global standards.

Key Features of JUGMUG Roll Forming Machines:

Automated Operations – Advanced automation ensures precision, reduces manual errors, and enhances productivity.

High-Speed Production – Capable of handling bulk production without compromising quality.

Durable Build – Manufactured with high-grade materials to ensure longevity and consistent performance.

Custom Profile Options – Ability to produce a variety of profiles tailored to different solar mounting needs.

User-Friendly Interface – Intuitive controls make it easy for operators to manage the production process efficiently.

Applications of JUGMUG Roll Forming Machines in Solar Panel Mounting

JUGMUG Roll Forming machines cater to various applications in the solar industry, making them a preferred choice for manufacturers. Some of the key applications include:

1. Ground-Mounted Solar Structures

Ground-mounted solar panels require strong and stable support structures to ensure durability. Roll-formed steel or aluminum frames provide the necessary strength while keeping the weight manageable.

2. Rooftop Solar Panel Mounting Systems

Rooftop installations demand lightweight and precisely engineered mounting frames to ensure secure installation without adding excessive load to the structure. JUGMUG Roll Forming machines produce profiles that fit these requirements perfectly.

3. Solar Tracker Components

Solar tracking systems improve efficiency by allowing solar panels to follow the sun’s trajectory. The structural components of these systems are often manufactured using roll forming technology for enhanced precision and strength.

4. Structural Beams and Rails

Solar panels require robust support rails and beams to hold them securely. Roll forming machines produce these structural components with precise dimensions and exceptional durability.

Why Choose JUGMUG Roll Forming?

JUGMUG Roll Forming is committed to excellence in manufacturing roll forming machines for the solar industry. Their dedication to innovation, quality, and customer satisfaction sets them apart from competitors. Here are some compelling reasons to choose JUGMUG:

Industry Expertise – Years of experience in roll forming technology ensure high-quality machines tailored to specific industry needs.

Advanced Technology – Continuous research and development result in state-of-the-art machines that maximize efficiency and precision.

Customization Capabilities – Machines can be designed to accommodate unique production requirements and profiles.

Global Standards Compliance – JUGMUG Roll Forming machines adhere to international quality and safety standards.

Comprehensive Support – A dedicated customer support team ensures seamless installation, training, and after-sales service.

Future of Roll Forming in the Solar Industry

As the demand for solar energy continues to rise, the need for high-quality mounting structures will also increase. Roll forming technology will play a crucial role in meeting these demands efficiently. Companies like JUGMUG Roll Forming are poised to lead this transformation by continuously innovating and providing advanced roll forming machine tailored to the solar sector.

Conclusion

JUGMUG Roll Forming is at the forefront of revolutionizing the solar industry with its state-of-the-art roll forming machines. Their commitment to precision, efficiency, and customization makes them a trusted partner for solar mounting frame manufacturers. As the world moves towards a greener future, JUGMUG Roll Forming continues to play a pivotal role in driving sustainable energy solutions through high-quality roll forming technology.

Whether you are a solar panel manufacturer, an EPC contractor, or an industrial supplier, investing in JUGMUG Roll Forming machines is a step towards ensuring superior quality, efficiency, and reliability in solar mounting frame production.

0 notes

Text

The Excellence of JUGMUG RollForming: Revolutionizing Manufacturing with Roll Forming Machines

In the ever-evolving world of metal fabrication, the demand for precision, efficiency, and cost-effectiveness is paramount. One of the most significant advancements in the industry is the roll forming machine, a vital piece of equipment that has revolutionized manufacturing processes. JUGMUG RollForming, a leading name in the roll forming machine industry, has set benchmarks in quality and innovation, catering to various industries across India and beyond.

Understanding Roll Forming Machines

A roll forming machine is an advanced metalworking tool used to shape metal sheets into desired profiles through continuous bending. Unlike other metal forming processes, roll forming involves passing a metal strip through a series of roller dies that progressively shape the material. The technique is widely utilized in the automotive, construction, and manufacturing industries due to its ability to produce complex profiles with high precision.

Benefits of Using a Roll Forming Machine

1. Enhanced Precision and Consistency

One of the key advantages of roll forming machines is their ability to maintain consistent quality and precision. The automated process ensures that each product meets exact specifications, eliminating human errors and material wastage.

2. Cost-Effective Production

Roll forming machines significantly reduce production costs by minimizing material waste and optimizing energy consumption. The continuous process enables high-volume production, making it ideal for large-scale manufacturing.

3. High-Speed Operation

Efficiency is a crucial factor in modern manufacturing, and roll forming machines excel in delivering high-speed production. The automated system allows for seamless operations, reducing downtime and increasing output.

4. Versatility in Applications

Whether it is roofing sheets, automotive components, or structural framing, roll forming machines can create a wide range of profiles to meet diverse industry requirements. The versatility of these machines makes them an indispensable asset in metal fabrication.

5. Reduced Labor Costs

Automation in roll forming machines decreases dependency on manual labor, resulting in lower labor costs and increased operational efficiency. This not only improves productivity but also ensures worker safety.

6. Minimal Material Waste

Unlike traditional metalworking processes, roll forming machines optimize material usage by precisely cutting and forming metal sheets, reducing scrap and overall production costs.

JUGMUG RollForming: A Pioneer in Roll Forming Machine Manufacturing

JUGMUG RollForming has established itself as a trusted name in the roll forming industry, known for its cutting-edge technology and superior-quality machinery. As one of the top exporters of roll forming machines in India, the company is dedicated to providing innovative solutions tailored to the needs of various industries.

Key Features of JUGMUG RollForming Machines

Advanced Automation: JUGMUG RollForming integrates state-of-the-art automation technology in its machines, ensuring seamless operation and precise output.

Customization Options: Every industry has unique requirements, and JUGMUG RollForming offers customized roll forming machines designed to cater to specific production needs.

Robust Build Quality: Built with high-grade materials, these machines ensure durability, longevity, and excellent performance even under rigorous conditions.

User-Friendly Interface: The machines are designed with an intuitive interface, making them easy to operate and maintain.

Energy Efficiency: JUGMUG RollForming prioritizes sustainability, offering machines that consume less energy while maximizing production efficiency.

The Growing Demand for Roll Forming Machines in India

India's manufacturing sector is experiencing significant growth, leading to increased demand for roll forming machines. From infrastructure development to automotive production, roll forming machines play a crucial role in various industries. JUGMUG RollForming has capitalized on this demand by offering top-tier solutions that cater to both domestic and international markets.

youtube

Industries Benefiting from Roll Forming Machines

Construction Industry: Roofing sheets, wall panels, and structural components are commonly manufactured using roll forming machines.

Automotive Sector: Roll forming is widely used to produce car body parts, chassis, and structural reinforcements.

Aerospace Industry: Precision-formed metal parts are essential for the aerospace sector, and roll forming machines ensure high-quality manufacturing.

Electrical Industry: The production of enclosures, cable trays, and other electrical components relies on roll forming technology.

Furniture Manufacturing: Metal-based furniture parts, including frames and rails, are efficiently manufactured using roll forming machines.

Why Choose JUGMUG RollForming?

JUGMUG RollForming has carved a niche in the industry with its unwavering commitment to quality, customer satisfaction, and technological advancements. Here are some reasons why businesses trust JUGMUG RollForming for their roll forming machine requirements:

Extensive Industry Experience: With years of expertise, JUGMUG RollForming understands the evolving needs of the manufacturing sector.

Global Reach: As a leading exporter of roll forming machines, the company serves clients worldwide, ensuring high-quality standards.

Comprehensive Support: From installation to maintenance, JUGMUG RollForming provides end-to-end support to its customers.

Competitive Pricing: The company offers cost-effective solutions without compromising on quality and performance.

Future of Roll Forming Machines

With continuous advancements in automation and material science, roll forming machines are set to become even more efficient and versatile. The integration of AI and IoT in roll forming technology will further enhance production capabilities, ensuring smarter manufacturing processes. JUGMUG RollForming remains at the forefront of these innovations, constantly upgrading its technology to meet future industry demands.

Conclusion

JUGMUG RollForming stands as a beacon of excellence in the roll forming industry, offering top-tier roll forming machines that redefine manufacturing efficiency. As India continues to emerge as a global manufacturing hub, the demand for high-quality roll forming machines will only grow. Businesses looking to optimize production, reduce costs, and enhance precision can rely on JUGMUG RollForming for unparalleled solutions.

For those seeking the best in roll forming technology, JUGMUG RollForming remains the trusted partner in innovation and excellence.

#roll forming machine#roll forming machine suppliers#roll forming machinery#roll forming uk#roll forming usa#Youtube

0 notes

Text

Just text update on the shirt cause the damn machine said time to be a problem and jam and bird nest jam at that MULTIPLE TIMES even with each time rethreading and cleaning the machine that is trying my patience.

Anyways, I noticed that part of the French seams are managing to fray themselves out so to solve this I am going back over them and rolling the seams for them, and still manually shoving the fabric into the metal roll of the rolled hem foot.

Seriously why do tutorials say use the anchor threads when they won’t pull this in unless it has to be stouter fabric than voile in which case please, MENTION THAT.

Anyways the most surprising thing that hasn’t happened. Wait no I shouldn’t say the thing that shockingly hasn’t happened because if I do IT’LL PROBABLY FRICKING HAPPEN.

Such is my luck with sewing and shiny hunting in Pokémon.

#sewing#sewing machine being a nuisance#cosplay#costume#idv photographer#idv necromancer#idv#identity v#Pokémon mention

1 note

·

View note

Text

Comprehensive Guide to Sheet Bending Machines

Introduction

Sheet bending plays a crucial role in metal fabrication, enabling the shaping and processing of metal sheets for various industrial applications. From construction and automotive to aerospace and shipbuilding, the demand for high-precision sheet bending machines is growing rapidly.

Yash Machine Tools is a leading provider of technologically advanced sheet bending machines and components designed to enhance efficiency and productivity in metalworking operations. This guide explores different types of bending machines, including bending rollers, hydraulic presses, iron workers, shearing machines, press brakes, and more.

What is Sheet Bending?

Sheet bending is a metalworking process used to deform and shape metal sheets into desired angles and curves. It is a critical step in manufacturing, allowing industries to create structural components with high precision and durability.

Key Sheet Bending Methods:

Press Braking – Uses a punch and die to create precise bends.

Rolling – Forms curved or cylindrical metal parts.

Folding – Bends sheet metal without excessive force.

Stamping and Punching – Used for cutting and shaping metal sheets.

Types of Sheet Bending Machines

Various bending machines are available based on the type of bending process:

Manual Bending Machines – Suitable for small-scale operations.

Mechanical Bending Machines – Offer automation for increased efficiency.

Hydraulic Bending Machines – Provide high force for bending thick metals.

Bending Roller Machines

A bending roller machine is used to bend metal sheets and plates into cylindrical or curved shapes.

Industries Using Bending Rollers:

Construction

Automotive

Shipbuilding

Aerospace

Advantages: ✔ Smooth bending without damage ✔ Handles various sheet thicknesses ✔ Reduces material waste

3 Roll Pyramid Type Mechanical Plate Bending Machine

The 3 roll pyramid type plate bending machine is a widely used mechanical bending tool.

Features:

High precision for metal sheet rolling

Works with different materials like steel, aluminum, and copper

Requires less maintenance and is cost-effective

Profile & Pipe Bending Machines

Profile & Pipe Bending Machines are used to bend pipes, tubes, and structural metal profiles into complex shapes.

Common Applications:

✔ Metal furniture production ✔ Construction framework bending ✔ Automotive exhaust pipe shaping

Bus Bar Bending, Cutting, and Punching Machines

Bus bar bending, cutting, and punching machines are used in electrical and construction industries to shape copper and aluminum bus bars for power distribution.

✔ Performs multiple operations – bending, cutting, and punching ✔ Reduces manual labor and enhances precision

Metal Sheet Bending Machines

These machines are designed for shaping thin and thick metal sheets efficiently.

Hydraulic vs. Mechanical Bending:

✔ Hydraulic bending machines provide higher force and flexibility ✔ Mechanical bending machines are more economical for mass production

Folding Machines

Folding machines are used to bend thin sheets without damage. They are widely used in roofing, HVAC, and cabinet making.

✔ High accuracy in folding angles ✔ Quick operation with minimal labor

Hydraulic Press Machines

Hydraulic press machines use hydraulic force to bend, cut, or shape metal sheets.

✔ High tonnage capacity ✔ Precise pressure control for accurate bending

Hydraulic Iron Worker Machines

A hydraulic iron worker is a multi-functional machine that can: ✔ Cut metal sheets ✔ Punch holes ✔ Bend structural steel

These machines are widely used in fabrication workshops and steel processing plants.

Power Press Machines

Power press machines use mechanical or hydraulic force to punch, bend, or shape metals.

✔ Ideal for mass production ✔ High-speed operation for increased efficiency

Press Brake Machines

Press brakes are used for precise metal bending and shaping.

✔ Available in hydraulic and mechanical versions ✔ Used in automotive, aerospace, and industrial fabrication

Riveting Machines

Riveting machines are essential in sheet metal assembly for joining multiple metal sheets securely.

✔ Strong and durable connections ✔ Used in automotive and aircraft manufacturing

Shearing Machines

Shearing machines are used for cutting metal sheets without producing chips.

✔ High-speed cutting for efficiency ✔ Used in steel fabrication, shipbuilding, and industrial manufacturing

Sheet Metal Machines – Complete Overview

With automation and precision engineering, modern metal sheet Bending Machines have transformed the metalworking industry.

✔ CNC-controlled machines for precise bending ✔ Smart automation for higher productivity

Conclusion

Sheet bending machines play a crucial role in metal fabrication across multiple industries. Whether it’s a hydraulic press, iron worker, bending roller, or press brake, choosing the right equipment ensures precision, efficiency, and productivity.

youtube

0 notes

Note

[Silas didn't have anything else to go off of, so he decided to dutifully take Sonny's word for it.]

It sounds... rather dreadful. I'm sure once things are back on track you can make a good difference with what you have made.

[There's another bit of quiet, one of Silas' fins twitching at small sounds outside of the cave. The few birds left this time of year trilling away, he supposed.]

Here, you just... do what you need to survive. If you are gifted with claws and teeth and the will to live, you make it out here. If you aren't, you feed someone else who will.

[He had begun to run out of rations a week prior, himself. Hard to hunt right now, and GOD was he tired of dried fish. The idea of food made his stomach pang, yet with a slight hiss he pushed it back. He'll hunt later. He was needed currently, if even as a mere distraction from nagging voices and blithering fools]

Intellect is measured by how well you survive and nothing more out here... However, I imagine that within the ceph's walls, it is quite different.

What are you working on, currently?

- Silas

"Claws and teeth, money and brains... Really, there's no difference. At the end of the day, they're both gifts you've got to be lucky enough to be born into. It would seem our worlds are more similar than you might realize; they're just wearing different coats of paint."

He mused absently, rubbing at the dark bristles under his chin with a talon.

"As for this machine. It's to be a physical interface for tracking purposes; It'll ping whatever important items and files that set it to search for. Without a map, I'll only be able to see the general location in blank space, but it's better than nothing, at least for now... Most importantly, it'll mask my location, so if that orange bastard tries the same thing to try and find me he'll be shit out of luck."

A rounded, forest green screen began to appear on the topmost surface, looking like a radar display you'd see on a ship. He hesitated before presenting his next words, aware that it was much more sensitive information.

"...I didn't mention this before, but I've already got the first code... The one for the credentials. It's the easiest in the set to remember, as it's just my own name. I mean, obviously. I never stopped being admin out there, after all."

He rolled his eyes with a bemused smirk.

"As for the rest... They are based in a homebrew cryptographic scheme. Unfortunately, tackling it by brute force is not an option given the time crunch, so I'm going to need to retrieve them manually."

The fabrication of the unit paused, and Sonny leaned forward and squinted at the screen as he stopped to figure out some kinks in the code. Typical dev stuff.

"Sam will likely figure out or find the code for the credentials - including its format - given enough time, but for now I'm at an advantage as I can start looking for the other keys right away. He doesn't know the system nearly as intimately as I."

5 notes

·

View notes