#Manufacturing Execution System software

Text

PLC Automation in pune | India

PLC and automation are closely related to one another. PLCs, or programmable logic controllers, are now a crucial component of any business's industrial and technological progress strategy. The manufacturing industry makes substantial use of programmable logic controller (PLC) automation due to its long lifespan and adaptability to industrial backgrounds.

#Plc and Scada Services#Solutions for OEMs and Machine Builders#Conveyor Systems for OEM Machine Builder Partners#MES Manufacturing Execution System#Manufacturing Execution System Software#Material handling systems#Material handling

1 note

·

View note

Text

Power of Real-Time Monitoring and Predictive Analytics

Companies have employed new technologies to streamline their operations for as long as the manufacturing sector has existed. The four industrial revolutions delineate distinct phases in the development of the sector’s technological application.

#Predictive Analytics#Real-Time Monitoring#manufacturing operations management#manufacturing execution system software

0 notes

Text

Why MES Software Is Key To Improve Quality Control?

Do you know why MES software is the trend that has gained popularity among manufacturers? Manufacturing Execution System software helps to improve quality control by automating manual labor, streamlining processes, and making them more efficient.

Today we'll tell you about this technology, and its benefits, and give some examples of how it can be used in different industries.

Automated Quality Control Checks

Automated quality control checks are a key component of MES software. MES software can automate quality control checks for a variety of processes and industries, which can help to ensure that your company's products meet the highest standards.

Let's look at an example: Let's say that you work in the automotive industry and have just finished building a car door for a customer order. Automated quality control checks can be used to verify that all necessary components have been installed correctly on this particular vehicle before it leaves your factory floor.

This will prevent costly mistakes down the line when customers receive their vehicles with missing or damaged parts!

Real-time Monitoring

Real-time monitoring of quality control is an essential part of any MES software. With real-time monitoring, you can detect problems earlier and fix them before they become big problems.

The best companies have a system in place that allows them to monitor their products as they are being produced, ensuring that all levels of quality are met as well as helping them identify and fix problems before they get out of hand.

Data-Driven Quality Control

Data-driven quality control is a process of monitoring and analyzing data to improve quality. It is a method of quality control that uses statistical methods to measure the quality of manufactured products.

The basic principle behind this approach is that if you can measure something, you can control it. In other words, by measuring your product's performance against its specifications at regular intervals during production and then comparing these measurements with those taken at previous stages in production (and possibly also with historical data), any problems should become apparent early enough for you to take corrective action before they become serious issues affecting customer satisfaction or profitability

Standardised Workflows

Standardised workflows are the key to successful quality control. Workflows can be standardised using MES software, which is a valuable tool for quality control. A MES software collects data on the production process, including the time it takes to complete each step in the workflow.

This information can then be used to calculate standard times for each step, by comparing actual times with those calculated from historical data. Using this standardised workflow will ensure consistency between operators and batches of products.

Conclusion

Quality control is a crucial part of any business, but it's especially important for those who work with food. With MES software, you can automate your quality checks and ensure that every product meets your standards before it leaves the factory.

This ensures that no matter how large or small your operation is, you'll always have accurate data about what went wrong in case there ever is an issue.

Source Link: https://imonitorsoftwaresolutions.blogspot.com/2023/04/why-mes-software-is-key-to-improve.html

0 notes

Text

Manufacturing Software (MES) for Metal Fabrication, Millwork and Furniture

Empower your metal fabrication, millwork and furniture production with our advanced MES software. Increase efficiency, increase accuracy, and maintain control to increase quality, reduce costs, and streamline operations, creating a competitive edge in your industry.

#MES#manufacturing execution systems#benefits of mes software#inventory management system#purchase order management#predictive maintenance managements

0 notes

Text

#Electronic logbooks#equipment log book#machine log book#equipment life cycle management#manufacturing execution system#online logbook software#electronic equipment log book

0 notes

Text

5 Ways ERP and MES Integration Makes Manufacturers Agile

What Is MES Software?

A manufacturing execution system that is MES is a complete software system that observes, tracks, documents and controls the process of manufacturing merchandise from raw materials to complete products.

MES Provides a functional layer between enterprise resource planning and procedure control structures, an MES gives resolution-makers the data they want to create the plant floor more successfully and optimize production.

It doesn’t matter about the size of a manufacturing procedure. The Manufacturing Execution Software can contribute to complete productivity and productivity by making the manufacturing procedure information focused. Regulated businesses such as pharmaceuticals, food and drink, medical devices, defence, aeronautics and aerospace, and biotechnology mostly benefit – because regulated companies must stick to strict principles to confirm traceability compliance. They must ensure that the right procedures are in place for building compliant products, that these processes are documented, and that the resultant products can be simply recalled if necessary.

What Does MES Software Do?

The main job of a Manufacturing Execution System is to track and control the flow of the goods process through a factory. Since the moment a manufacturing mechanism order is out by an order management system, for instance, a financial accounting package or an MRP system, a manufacturing execution system is what takes over.

Why MES And ERP Systems Are Both Essential?

Today, MES and ERP systems assist businesses to effortlessly track and automate their procedures, providing them with important data they can use to increase visibility and productivity and implement tighter control over the business hence, Integrating MES and ERP systems is essential for maximum manufacturing businesses

An MES improves quality control and increases work time while also reducing inventory and expenses.

MES provides product traceability, connectivity of manufacturing processes to the back office, quality management at all levels, and optimization of shop floor tasks and resources.

ERP solution provides transparency about how difficulties affect the other remaining process, permitting managers to examine, gain better visions, and make real decisions. It provides actual financial data that offers a competitive gain, increases efficiency, and helps ensure cost savings.

ERPs are an important tool for any fast-developing business that is essential to optimize its systems, keep up with customer demands, and measure its operations. ERP system provides speed to the business and consumer response. It reduces repetitive tasks, unites the data, and also improves team dynamics.

A manufacturing ERP system is specifically designed for the manufacturing industry, providing advanced functionality for manufacturing-specific needs. Manufacturing ERP software aids in the automation and integration of processes in all areas of a manufacturing company.

5 Ways ERP and MES Integration Can Help Manufacturing Become More Agile

1. Attain Accuracy in Demand Forecasting

Lacking inventory will delay distributions and reduce consumer satisfaction hurting your company’s reputation. Also, extra inventory occupied the cash flow that could be used to improve your business through essential investments in such kinds of stuff as new equipment or technology.

Association between MES and ERP software synchronizes operations in the factory with customer service, logistics, and transport to more perfectly forecast demand so that you can keep inventory at the right points. Knowing the appropriate amounts of stock needed also ensures there is no employee or machine interruption due to the incapacity to create orders. With the ability to keep on top of inventory requirements you can effortlessly pivot to meet purchaser demand with a vision of customer trends

2. Improved Customer Service with Accurate Traceability

When product problems rise via customer objections, the ability to trace each share back to original parts and batches, or shared stacks can allow for an instant resolution of consumer issues. Tracing from inventory receipt, throughout production, through which parts and ingredients were used can help management quickly determine the scope of the problems and plan long-term or short-term resolutions.

3. Entire business process modeling

Whole business process modeling includes taking new business procedures and modeling them through the whole line of management, trades, Consumer services, manufacturing, and operations. In an integrated ERP/MES System, managers can outline each component of the business process firmly to confirm the finest implementation from the start. It reduces manual procedures and updates new processes. By constantly modeling new business practices, the association becomes more agile to respond to marketplace events.

4. Quick delivery

Within-time Delivery allows quick fulfillment and decreases the time inventories are kept at the store. By integrating ERP with MES, work-in-progress inventory can be achieved to react to changes. The ability to manage ERP schedules through production scheduling to include the latest manufacturing changes on the factory floor means that accurate expectations are set. Inbound inventory and outbound inventory visibility are radically increased to let the success of Just-in-time Delivery.

5. ERP Can Contribute to Customization

The purpose behind the small and mid-size industrialists’ regular scope for agility is to be capable of working for more customers with custom-built, short-run manufacturing services. This customization can be able with an ERP application that helps groups simplify the manufacturing process so that the exchangeable constituents of the process are examined closely, and the constituents that aren’t exchangeable can be substituted to create a custom product when needed.

Small and mid-size manufacturers in the earlier functioned seamlessly fine without an ERP system. Some used financial applications instead of ERP; others used to do it manually for planning and resource management.

Though, in today’s market, small and mid-size manufacturers need to require a solid ERP application that will benefit to create visibility and scheduled improvement as it enables the automation that are the main benefits of being an agile manufacturer.

Conclusion

We have seen the concept of MES. Also, we have learned about the functions and advantages of using the Manufacturing Execution System. This series is all about How ERP and MES are essential for the business. PMTrack ERP has listed the 5 ways ERP and MES integration can help manufacturing become more agile in the middle of this article.

We know as ERP and MES are important for business growth, PMTrackERP is an Application provider among the entire manufacturer, Metal, and Plastic industries.

PMTrack ERP helps to reduce the manual procedure in the manufacturing business and allows them to become more agile with the application benefits for small and mid-sized firms. PMTrack ERP fulfills accurate expectations such as improvement in schedule and within-time delivery.

#erp integration#erpsoftware#erpsolution#erpManufaurers#manufacturing erp software#manufactur#pmtrackManufacturing erp software#What Is MES Software? A manufacturing execution system that is MES is a complete software system that observes tracks documents and controls

0 notes

Text

Why an MES software is the ideal Place to Start Your Industry 4.0 Journey?

Are you ready to take your manufacturing business to the next level with Industry 4.0? Look no further than an MES (Manufacturing Execution System) to lead the way.

A factoryworx MES software is the perfect starting point for your Industry 4.0 journey, offering a range of benefits that can streamline your production processes and increase efficiency. From real-time data tracking to improved decision-making capabilities, an MES system is the key to unlocking the full potential of your manufacturing operations. Keep reading to learn more about why MES software is the ideal place to start your Industry 4.0 journey

Top reasons asset maintenance management software is helping in industry 4.0. Transformation?

Improved efficiency & agility

MES software can help streamline production processes, reduce waste, and improve overall equipment utilization, leading to increased efficiency and cost savings.

With MES software, manufacturers can quickly and easily adapt to changes in demand or production requirements, improving agility and responsiveness.

Enhanced visibility

MES software provides real-time visibility into all aspects of the production process, enabling manufacturers to identify bottlenecks and other inefficiencies in real-time and take corrective action.

Having an MES system can help your company take full advantage of the valuable data that is already present in your warehouse. Without an MES system, your ability to use this data to its full potential may be limited. By implementing an MES system, you can stay ahead of the competition and maximize the resources available to your company.

Enhanced quality control

MES software provides tools and functionality to improve quality control, such as real-time monitoring of equipment performance and material usage, as well as alerts and notifications to identify potential issues.

An MES system can help your company improve the accuracy of product tracing, which can be particularly beneficial for businesses in regulated industries such as medical equipment and food production.

Better decision-making

MES software provides relevant, actionable data to support informed decision-making at all levels of the organization, including analytics capabilities.

By using an MES system, you can provide more reliable reporting, which can help you achieve your sustainability goals and increase customer confidence in your products.

resources from unnecessary maintenance work.

Factors to consider before selecting the right MES software in Australia

Read this ultimate guide for manufacturing execution systems before choosing the right MES software for your business. There are several key factors to consider:

Scalability: Choose an MES software that can grow and adapt to your business. Consider whether the software can handle increases in production volume, changes in the production process, or the integration of new equipment.

Customizability: Consider whether the MES software can be customized to meet the specific requirements of your business. Look for software with flexible configurations and the ability to add custom modules or integrations as needed.

Ease of use: Select an MES software that is intuitive and easy to use so that it can be quickly adopted by your team. Consider software with user-friendly interfaces and comprehensive training and support resources.

Integration capabilities: Consider whether the MES software can integrate with other systems and technologies that you already use, such as your ERP or PLM systems. This can help streamline your production process and improve efficiency.

Cost: Determine your budget for MES software and choose a solution that fits within your price range. Consider the long-term cost of the software, including maintenance, updates, and support.

Why Get An MES Now, Before Full Industry 4.0 Implementation?

There are several compelling reasons to consider implementing an MES system before fully embracing Industry 4.0. First and foremost, an MES system can help... Read More

#factoryworx MES software#ultimate guide for manufacturing execution systems#Industry 4.0 transition#FactoryWorx Team Management

0 notes

Text

There’s little doubt that the American government has decided to slow China’s economic rise, most notably in the fields of technological development. To be sure, the Biden administration denies that these are its goals. Janet Yellen said on April 20, “China’s economic growth need not be incompatible with U.S. economic leadership. The United States remains the most dynamic and prosperous economy in the world. We have no reason to fear healthy economic competition with any country.” And Jake Sullivan said on April 27, “Our export controls will remain narrowly focused on technology that could tilt the military balance. We are simply ensuring that U.S. and allied technology is not used against us.”

Yet, in its deeds, the Biden administration has shown that its vision extends beyond those modest goals. It has not reversed the trade tariffs Donald Trump imposed in 2018 on China, even though presidential candidate Joe Biden criticized them in July 2019, saying: “President Trump may think he’s being tough on China. All that he’s delivered as a consequence of that is American farmers, manufacturers and consumers losing and paying more.” Instead, the Biden administration has tried to increase the pressure on China by banning the export of chips, semiconductor equipment, and selected software.

It has also persuaded its allies, like the Netherlands and Japan, to follow suit. More recently, on Aug. 9, the Biden administration issued an executive order prohibiting American investments in China involving “sensitive technologies and products in the semiconductors and microelectronics, quantum information technologies, and artificial intelligence sectors” which “pose a particularly acute national security threat because of their potential to significantly advance the military, intelligence, surveillance, or cyber-enabled capabilities” of China.

All these actions confirm that the American government is trying to stop China’s growth. Yet, the big question is whether America can succeed in this campaign—and the answer is probably not. Fortunately, it is not too late for the United States to reorient its China policy toward an approach that would better serve Americans—and the rest of the world.[...]

Since the creation of the People’s Republic of China in 1949, several efforts have been made to limit China’s access to or stop its development in various critical technologies, including nuclear weapons, space, satellite communication, GPS, semiconductors, supercomputers, and artificial intelligence. The United States has also tried to curb China’s market dominance in 5G, commercial drones, and electric vehicles (EVs). Throughout history, unilateral or extraterritorial enforcement efforts to curtail China’s technological rise have failed and, in the current context, are creating irreparable damage to long-standing U.S. geopolitical partnerships. In 1993 the Clinton administration tried to restrict China’s access to satellite technology. Today, China has some 540 satellites in space and is launching a competitor to Starlink.

When America restricted China’s access to its geospatial data system in 1999, China simply built its own parallel BeiDou Global Navigation Satellite System (GNSS) system in one of the first waves of major technological decoupling. In some measures, BeiDou is today better than GPS. It is the largest GNSS in the world, with 45 satellites to GPS’s 31, and is thus able to provide more signals in most global capitals. It is supported by 120 ground stations, resulting in greater accuracy, and has more advanced signal features, such as two-way messaging[...]

American measures to deprive China access to the most advanced chips could even damage America’s large chip-making companies more than it hurts China. China is the largest consumer of semiconductors in the world. Over the past ten years, China has been importing massive amounts of chips from American companies. According to the US Chamber of Commerce, China-based firms imported $70.5 billion worth of semiconductors from American firms in 2019, representing approximately 37 percent of these companies’ global sales. Some American companies, like Qorvo, Texas Instruments, and Broadcom, derive about half of their revenues from China. 60 percent of Qualcomm’s revenues, a quarter of Intel’s revenues, and a fifth of Nvidia’s sales are from the Chinese market. It’s no wonder that the CEOs of these three companies recently went to Washington to warn that U.S. industry leadership could be harmed by the export controls. American firms will also be hurt by retaliatory actions from China, such as China’s May ban on chips from US-based Micron Technology. China accounts for over 25 percent of Micron’s sales.[...]

The U.S. Semiconductor Industry Association released a statement on July 17, saying that Washington’s repeated steps “to impose overly broad, ambiguous, and at times unilateral restrictions risk diminishing the U.S. semiconductor industry’s competitiveness, disrupting supply chains, causing significant market uncertainty, and prompting continued escalatory retaliation by China,” and called on the Biden administration not to implement further restrictions without more extensive engagement with semiconductor industry representatives and experts.

The Chips Act cannot subsidize the American semiconductor industry indefinitely, and there is no other global demand base to replace China. Other chip producing nations will inevitably break ranks and sell to China (as they have historically) and the American actions will be for naught. And, in banning the export of chips and other core inputs to China, America handed China its war plan years ahead of the battle. China is being goaded into building self-sufficiency far earlier than they would have otherwise. Prior to the ZTE and Huawei components bans, China was content to continue purchasing American chips and focusing on the front-end hardware. Peter Wennink, the CEO of ASML, stated that China is already leading in key applications and demand for semiconductors. Wennink wrote, “The roll-out of the telecommunication infrastructure, battery technology, that’s the sweet spot of mid-critical and mature semiconductors, and that’s where China without any exception is leading.”[...]

Former State Department official Susan Thornton, who oversaw the study as director of the Forum on Asia-Pacific Security at NCAFP, said: “This audit of U.S.-China diplomacy shows that we can make progress through negotiations and that China follows through on its commitments. The notion that engagement with China did not benefit the U.S. is just not accurate.”[...]

One fundamental problem is that domestic politics in America are forcing American policymakers to take strident stands against China instead of pragmatic positions. For instance, sanctions preventing the Chinese Defense Minister, Li Shangfu, from traveling to the United States are standing in the way of U.S.-China defense dialogues to prevent military accidents.

19 Sep 23

128 notes

·

View notes

Note

Hello. So what's the deal with computer chips? Let's say, for example, that I wanted to build a brand new Sega Genesis. Ignoring firmware and software, what's stopping me from dissecting their proprietary chips and reverse-engineering them to make new ones? It's just electric connections and such inside, isn't it? If I match the pin ins and outs, shouldn't it be easy? So why don't people do it?

The answer is that people totally used to do this, there's several examples of chips being cloned and used to build compatible third-party hardware, the most famous two examples being famiclones/NESclones and Intel 808X clones.

AMD is now a major processor manufacturer, but they took off in the 70's by reverse-engineering Intel's 8080 processor. Eventually they were called in to officially produce additional 8086 chips under license to meet burgeoning demand for IBM PC's, but that was almost a decade later if I remember correctly.

There were a ton of other 808X clones, like the Soviet-made pin-compatible K1810VM86. Almost anyone with a chip fab was cloning Intel chips back in the 80's, a lot of it was in the grey area of reverse engineering the chips.

Companies kept cloning Intel processors well into the 386 days, but eventually the processors got too complicated to easily clone, and so only companies who licensed designs could make them, slowly reducing the field down to Intel, AMD, and Via, who still exist! Via's CPU division currently works on the Zhaoxin x86_64 processors as part of the ongoing attempts to homebrew a Chinese-only x86 processor.

I wrote about NES clones a while ago, in less detail, so here's that if you want to read it:

Early famiclones worked by essentially reverse-engineering or otherwise cloning the individual chips inside an NES/famicom, and just reconstructing a compatible device from there. Those usually lacked any of the DRM lockout chips built into the original NES, and were often very deeply strange, with integrated clones of official peripherals like the keyboard and mouse simply hardwired directly into the system.

These were sold all over the world, but mostly in developing economies or behind the Iron Curtain where official Nintendo stuff was harder to find. I had a Golden China brand Famiclone growing up, which was a common famiclone brand around South Africa.

Eventually the cost of chip fabbing came down and all those individual chips from the NES were crammed onto one cheap piece of silicon and mass produced for pennies each, the NES-on-a-chip. With this you could turn anything into an NES, and now you could buy a handheld console that ran pirated NES game for twenty dollars in a corner store. In 2002. Lots of edutainment mini-PC's for children were powered by these, although now those are losing out to Linux (and now Android) powered tablets a la Leapfrog.

Nintendo's patents on their hardware designs expired throughout the early 2000's and so now the hardware design was legally above board, even if the pirated games weren't. You can still find companies making systems that rely on these NES chips, and there are still software houses specializing in novel NES games.

Why doesn't this really happen anymore? Well, mostly CPU's and their accoutrements are too complicated. Companies still regularly clone their competitors simpler chips all the time, and I actually don't know if Genesis clones exist, it's only a Motorola 68000k, but absolutely no one is cloning a modern Intel or AMD processor.

The die of a Motorola 68000 (1979)

A classic Intel 8080 is basically the kind of chip you learn about in entry level electrical engineering, a box with logic gates that may be complicated, but pretty straightforwardly fetches things from memory, decodes, executes, and stores. A modern processor is a magic pinball machine that does things backwards and out of order if it'll get you even a little speedup, as Mickens puts it in The Slow Winter:

I think that it used to be fun to be a hardware architect. Anything that you invented would be amazing, and the laws of physics were actively trying to help you succeed. Your friend would say, “I wish that we could predict branches more accurately,” and you’d think, “maybe we can leverage three bits of state per branch to implement a simple saturating counter,” and you’d laugh and declare that such a stupid scheme would never work, but then you’d test it and it would be 94% accurate, and the branches would wake up the next morning and read their newspapers and the headlines would say OUR WORLD HAS BEEN SET ON FIRE. You’d give your buddy a high-five and go celebrate at the bar, and then you’d think, “I wonder if we can make branch predictors even more accurate,” and the next day you’d start XOR’ing the branch’s PC address with a shift register containing the branch’s recent branching history, because in those days, you could XOR anything with anything and get something useful, and you test the new branch predictor, and now you’re up to 96% accuracy, and the branches call you on the phone and say OK, WE GET IT, YOU DO NOT LIKE BRANCHES, but the phone call goes to your voicemail because you’re too busy driving the speed boats and wearing the monocles that you purchased after your promotion at work. You go to work hung-over, and you realize that, during a drunken conference call, you told your boss that your processor has 32 registers when it only has 8, but then you realize THAT YOU CAN TOTALLY LIE ABOUT THE NUMBER OF PHYSICAL REGISTERS, and you invent a crazy hardware mapping scheme from virtual registers to physical ones, and at this point, you start seducing the spouses of the compiler team, because it’s pretty clear that compilers are a thing of the past, and the next generation of processors will run English-level pseudocode directly.

Die shot of a Ryzen 5 2600 core complex (2019)

Nowadays to meet performance parity you can't just be pin-compatible and run at the right frequency, you have to really do a ton of internal logical optimization that is extremely opaque to the reverse engineer. As mentioned, Via is making the Zhaoxin stuff, they are licensed, they have access to all the documentation needed to make an x86_64 processor, and their performance is still barely half of what Intel and AMD can do.

Companies still frequently clone each others simpler chips, charge controllers, sensor filters, etc. but the big stuff is just too complicated.

183 notes

·

View notes

Text

By: River Page

Published: Feb 2, 2024

"Companies also cannot take race-motivated actions to maintain a demographically 'balanced' workforce." — Commissioner at Equal Employment Opportunity Commission Andrea R. Lucas in Reuters, June 29, 2023

"An unlawful employment practice is established when the complaining party demonstrates that race, color, religion, sex, or national origin was a motivating factor for any employment practice, even though other factors also motivated the practice." — 42 USC § 2000e–2(m) of Title VII of the Civil Rights Act of 1964

---

In the wake of the George Floyd protests, tech companies promised to hire more minorities. One company that claims to help them do it is Gem, and although you might not have heard of it, you’ve probably heard of some of its 1,200-plus clients: Reddit, Dropbox, Robinhood, Discord, Zillow, Stripe, Affirm, and Grammarly, just to name a few. Although Gem’s software is primarily used for things like non-race- and gender-based recruiting, payroll, and benefits management, John, (not his real name) — who worked for Gem as a sales development representative through a B2B outsourcing firm from March to July of 2021, told us that the prospective corporate clients he talked to were most interested in Gem’s “diversity enhancing” capabilities. Essentially, they had race- and gender-based hiring quotas and wanted to use Gem’s software to meet them. He said one prospective client, an executive at the Bay Area-based AI and robotics research arm of one of the world’s leading car manufacturers, told him explicitly: “I need more black candidates this month.”

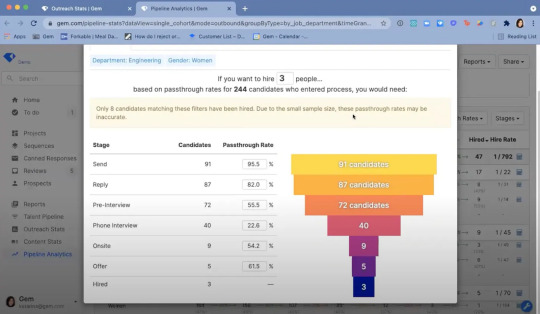

According to its website, Gem’s software allows recruiters to track “gender and race/ethnicity throughout the entire hiring funnel.” Essentially, it appears to include a comprehensive race and gender tracking system designed to help companies fill race- and gender-based quotas with precision. For example, in a 2021 diversity webinar posted on YouTube, a Gem employee seemed to explain how the software could show how many candidates a company would need to reach out to if it had three engineering positions open, but didn’t want to hire men for them (in her words: “wanted to give women a chance”). In the same video, she demonstrated how to break down each stage in the hiring funnel by race, and explained (but did not show, probably for privacy reasons) how companies could further track how their recruiters’ own efforts break down along the lines of the company’s race- and gender-based hiring quotas, so that the company may “hold them accountable.”

[ Screen capture from Gem’s diversity webinar ]

All this requires a lot of data. According to a recent LinkedIn post by Gem founder Steve Bartel, this data can come from three sources:

Self-ID: the demographic data collection on job applications

Manual override: the recruiter reports your race and gender based on visual cues such as your LinkedIn profile picture

Predicted: Gem’s proprietary AI determines a candidate's race and gender based on machine learning (Bartel notes this is only for aggregate/anonymized use, meaning that the UI doesn’t allow recruiters to see which race was assigned to individual candidates)

John told me that, of Gem’s features, its race- and gender-identifying AI was the biggest selling point. “A key part of the pitch was to tell clients that Gem uses AI and machine learning to determine race and gender.” (This is especially ironic, given the panic about “racist AI” that has consumed every discussion about artificial intelligence for years.)

“One thing that cracked me up was that recruiting/DEI buyers at companies would ask, ‘Is this legal?’” John told me. “Not because they were offended by how obviously racist the software was — they loved what they saw. The concern was pushback from their legal team.” He said this question was asked so frequently that Gem’s Chief Legal Counsel had a prewritten response to the question that would be passed along to clients who asked.

[ Source: Gem’s website, February 1, 2024 ]

The "Diversity Recruiting" section of Gem’s website offers a slate of what it calls “Case Studies” — essentially customer testimonials — where companies explain how they used Gem to hire based on race and gender.

In a case study for payroll firm Gusto, Gem seems to indicate the company used its “Candidate Rediscovery” tool to hire based on candidates’ race and gender. In Gem’s language, Gusto used the tool to “unearth talent who is vetted — and diverse — ultimately reducing time-to-hire.” In other words, companies could use Gem’s software to find people with specific racial and gender-based characteristics that meet the position’s requirements and hire them quickly, while weeding out similarly qualified candidates who are, presumably, white or male or both.

In a case study about the telecommunications company Twilio, Gem seems to describe how one of its senior recruiters was able to avoid hiring men with their tool:

Gem’s metrics have also helped [the recruiter] zero in on stages in the interview process where the team is falling short on equitable gender hiring. “For one division, we intuited that we were hiring more women than the average team—and we were! We were prepared to roll off our passive sourcing efforts for that division, but I don’t like to make a move without looking at all the data first. That’s where Gem came through.” [The recruiter] dug through the data in more detail and discovered that the proportion of male candidates was actually increasing quarter over quarter—so much so that, by Q3, they would have made significantly more male than female hires. “If we hadn’t had access to that data, we wouldn’t have been able to identify that trend and strategize on how to allocate our resources properly.”

This is easily interpretable as: We thought everything was fine until Gem showed us that by Q3 we might hire a disproportionate number of men in a division that a disproportionate number of men applied to work in. It's worth noting that when announcing massive job cuts in 2022, Twilio’s CEO bragged that the layoffs had been carried out through an “Anti-Racist/Anti-Oppression lens.”

In another testimonial from Chili Piper, an inbound conversion platform for B2B revenue teams, the company’s Talent Ops Manager says she used Gem to discover that URG (under-represented group) candidates were dropping off after the company stopped including a video submission in the application (itself seeming to indicate that a significant proportion “URGs” were being advanced through the hiring pipeline because of their race or gender). She successfully lobbied to bring the video submission back and modified the assignment. “Now it’s like, sell us a new smartphone: something that really levels the playing field and lets us see candidates’ creativity, communication, and approach in action. It’s not necessarily entrenched in experience in tech and SaaS sales.” Since then, the company has “seen a decisive shift in the demographics of candidates who make it to the interview stage of our process. We have seen a 54% increase in URG candidates and a 31% increase in female-identified candidates making it to the first round of interviews. Offers extended to, and offers accepted by URGs have increased.”

In other words, Chili Piper's testimonial seems to indicate that Gem showed the company that when it stopped asking applicants to submit a video that allowed them to see their race and gender, they stopped hiring more minorities. So they brought video back, and seemed to effectively lower their standards by changing the assignment to one in which industry experience was deprioritized.

Gem’s own hiring practices also raise red flags. An internal jobs board from June 2021 provided to Pirate Wires shows that under a field titled “Diversity Search,” positions are either listed as “Open,” “Women,” “URM,” or “Women & URM,” suggesting that certain positions were closed off to straight white males, or perhaps that women and minorities were being sought after in those positions. We sent the screenshot of the internal job board — with company name and other identifying information redacted — to a tech industry employment lawyer, who said:

Without knowing more about the company or getting clarification on what some of the designations mean on the chart, it looks a bit problematic. The law allows companies to set “targets” and “goals” as they relate to the hiring, retention, and promotion of women, veterans, and underrepresented minorities (those targets/goals must be temporary). But the law does not currently allow private companies to set aside or otherwise designate specific positions for such group members. There are some grey areas for certain types of federal contractors, but it’s the exception to the rule.

As a non-lawyer, I’ll not comment on the legality of Gem’s hiring practices. However, I will say the company seems to use unorthodox recruiting methods. In Gem’s diversity webinar I referred to earlier, one of the hosts said, “Here at Gem, each time we open a new req [position], we actually focus solely on sourcing URGs, and in conjunction [with that] we don’t post the job on the career site until other levers need to be pulled…”

The host then explained how she found candidates of specific races and genders at Gem, telling the audience: “Sourcing for URGs may require you to shift some fundamental ideas you have about what a quote-unquote good candidate looks like.” Next, she described how she would go through LinkedIn, searching for candidates with stereotypically minority names, who use neo-pronouns, or who went to minority-majority schools, among other tactics.

[ Slide from Gem’s diversity webinar]

When asked for comment, a representative from GEM told us “Our product provides interested customers with insights that help them build a diverse talent pipeline. We work closely with legal counsel to ensure our platform complies with all applicable laws and welcome potential customers looking to learn more to reach out to us."

Gem: a company that apparently doesn’t post some job announcements publicly without searching for specific races and genders on LinkedIn first. A company whose value proposition is to help companies hold their recruiters “accountable” for hiring too many of the wrong race and gender. A company that created an AI that predicts your race and gender. A company whose AI tracks race throughout the hiring pipeline so efficiently that, allegedly, even woke companies question its legality during sales calls. Gem is the company that vast swaths of the tech industry are using to hire.

So if you’re in the business, and you’re a Derrick O’Donnell or a John Chau, good luck out there. I think you’re gonna need it.

[ Via: https://archive.md/gxFMK ]

==

DEI is discrimination.

#River Page#Gem Software#discrimination#racial discrimination#Title VII#Civil Rights Act#Civil Rights#DEI bureaucracy#diversity equity and inclusion#diversity#equity#inclusion#DEI must die#wokeness#woke#cult of woke#wokeism#wokeness as religion#religion is a mental illness

7 notes

·

View notes

Text

Factory Management Software (F-VAPP) for Valves Maintenance & Manufacturing Factories and Workshops. 🖥

------

Revolutionize your valve production and maintenance with F-VAPP—a comprehensive factory management software designed by industry experts who understand the specific needs of the valves manufacturing world. F-VAPP is not just a tool, it's a fully integrated solution that enhances every aspect of your factory’s operations. 📈

------

Hosted securely on your internal server, F-VAPP provides role-based access for every department, ensuring seamless workflows. It’s more than just software—it’s a complete management system that knows how to prioritize and automate daily operations for each machine and section. F-VAPP deeply understands the intricate processes of valve manufacturing and maintenance, making sure every task is executed efficiently with priorities clearly in place.

----

Why F-VAPP?

----

1- Tailor-made for the valves industry, considering every detail in production and maintenance.

2- Automated daily operations for machines and departments, prioritizing workflows for maximum efficiency.

3- Real-time production line monitoring and machine load management to optimize operations.

4- Full control over inventory management and cost automation for smart financial planning.

5- User-friendly yet powerful interface that’s simple to navigate and efficient for everyday use.

6- Comprehensive reporting tools for actionable insights and informed decision-making.

7- Streamlined processes through custom roles and permissions, helping you build a clear organizational chart and strong operational workflows.

8- Enhanced collaboration between departments, improving overall productivity and quality management.

----

With F-VAPP, your factory’s operations aren’t just managed—they’re optimized. From inventory control to production management, every function is fine-tuned for efficiency and performance.

----

Key Benefits:

----

1- Boost productivity by ensuring smooth, prioritized workflows for machines and workers.

2- Gain real-time insights into machine performance, production schedules, and factory output.

3- Automate complex processes like costing, pricing, and inventory management.

4- Seamlessly integrate departments, improving quality control and production planning.

5- Build the perfect organizational structure with clear roles and responsibilities.

6- Generate detailed reports to guide smarter business decisions.

----

F-VAPP goes beyond software. It’s a full-scale factory management system built to meet the specific needs of the valves manufacturing and maintenance industry. Take your operations to the next level with a system designed by professionals, for professionals. 🛠

2 notes

·

View notes

Text

Global Engineering Services in pune | India

In accordance with the specifications, we are able to perform site surveys, create build proposals, and generate cost takeoffs. We are also able to offer thorough estimations. Our primary goal is making sure that our clients receive the caliber of service they anticipate within the set time frame. Our goal is to do this by offering top-notch services.

#Global Engineering Services Outsourcing Pune#Services India#Panel Design Electrical Pune#Eplan Electrical#Material handling systems Pune#Automation Systems India#MES Manufacturing Execution System Pune#System Software India#Solutions for OEMs

0 notes

Text

Key Insights on MES Market 2023-2033

Dive into the evolution of Manufacturing Execution Systems (MES) from 2023 to 2033. Uncover key insights and trends shaping the global landscape!

#industry 4.0 in manufacturing#manufacturing execution system software#manufacturing execution system

0 notes

Text

Global top 13 companies accounted for 66% of Total Frozen Spring Roll market(qyresearch, 2021)

The table below details the Discrete Manufacturing ERP revenue and market share of major players, from 2016 to 2021. The data for 2021 is an estimate, based on the historical figures and the data we interviewed this year.

Major players in the market are identified through secondary research and their market revenues are determined through primary and secondary research. Secondary research includes the research of the annual financial reports of the top companies; while primary research includes extensive interviews of key opinion leaders and industry experts such as experienced front-line staffs, directors, CEOs and marketing executives. The percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

According to the new market research report “Global Discrete Manufacturing ERP Market Report 2023-2029”, published by QYResearch, the global Discrete Manufacturing ERP market size is projected to reach USD 9.78 billion by 2029, at a CAGR of 10.6% during the forecast period.

Figure. Global Frozen Spring Roll Market Size (US$ Mn), 2018-2029

Figure. Global Frozen Spring Roll Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Discrete Manufacturing ERP include Visibility, Global Shop Solutions, SYSPRO, ECi Software Solutions, abas Software AG, IFS AB, QAD Inc, Infor, abas Software AG, ECi Software Solutions, etc. In 2021, the global top five players had a share approximately 66.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

2 notes

·

View notes

Text

Manufacturing Software (MES) for Metal Fabrication, Millwork and Furniture

HitechDigital provides manufacturing software MES solutions that help streamline production process for metal Fabrication, millwork and furniture manufacturers.

0 notes

Text

The Role of Scheme Management Software in Business

The corporate world has become more competitive recently, and with it, scheme management. If schemes are effectively managed, they play a crucial role in enhancing sales, customer satisfaction, and profits. The question then arises: Do sales executives need help coordinating their campaigns effectively, which poses challenges for maintaining customer satisfaction and profitability maximization? Does your company struggle with growth due to errors, delays, and inefficiencies caused by manual operations?

For those looking to streamline promotions and enhance efficiency, it's worth exploring scheme management software. This application is designed to streamline the process of managing offers and schemes for national distributors or manufacturers. It allows you to enter scheme parameters like validity period, scheme concept, terms and conditions, price involved, etc., into the system and share the information. Let's explore how it can drive business expansion.

What Makes Efficient Scheme Management So Important?

The scheme management platform helps manage promotional plans that involve developing, launching, and monitoring strategies to boost sales and revenue. Previously, errors, paperwork, and complex calculations were common while implementing schemes manually. Anticipated outcomes included inefficiencies and challenges in measuring program success.

Companies have shifted their approach to scheme administration by utilizing scheme management software. It streamlines various aspects of administration so businesses can effortlessly create, execute, and oversee schemes. It is recognized as workflow efficiency software because it enhances business productivity. Let’s explore how implementing this software can revolutionize your business operations and drive growth.

1. Adaptability in Defining Schemes

Scheme management software integrates supplier loyalty programs with defined regulations. Its dynamic system assists end-users in effectively planning, creating, and developing innovative strategies. Regarding channel sales management, field force automation, or sales tracking, software for managing schemes can be customized to fit specific client requirements.

2. Optimized Dealer Satisfaction

Supervisors can track project advancement through the scheme management app's enterprise resource planning (ERP) integration. It is structured and operates methodically, expediting the implementation of new projects. Additionally, it efficiently manages credit notes, boosting sales, customer trust, and overall profits.

3. Boosts Productivity

Once in auto mode, the scheme assessment speeds up and requires minimal human involvement. Scheme management software greatly enhances reclaiming schemes, which are known for their challenges and setbacks, resulting in lost opportunities. It improves productivity, generates leads, increases brand visibility, and fosters dealer confidence.

4. Emphasizing a Strong Sense of Responsibility

Operating scheme automation software involves significant responsibility, as it documents and displays all credit transactions, records, and deals. In addition, the software's report production feature simplifies generating reports on sales, events/promotions, costs, and costings.

Scheme management software enhances corporate operations, scheme performance, and sales. Streamlining design, validation, and monitoring processes enhances productivity and drives revenue growth.

Nural Schemes enables you to share schemes and evaluate their performance. It has benefited a wide range of sales professionals and retail outlets. Clients have experienced significant growth in human capital, revenue, and operational expense savings with various scheme combinations. Rely on Nural for optimizing business solutions and top-notch workflow efficiency software. Schedule a demo today.

2 notes

·

View notes