#Medical Equipment Cooling Market Size

Text

Global top 24 companies accounted for 45% of total Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves market(qyresearch, 2021)

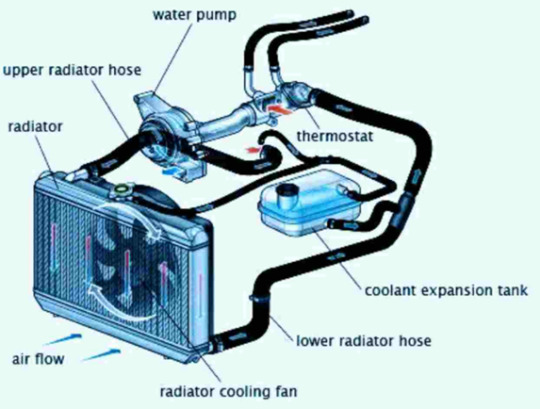

The engine-cooling system serves not just to keep the engine cool, but to also keep its temperature warm enough to ensure efficient, clean operation. System components include a radiator to dissipate heat, a fan or fans to ensure adequate airflow for radiator cooling, a thermostat valve that opens when the desired operating temperature is reached and a water pump (or coolant pump) to circulate coolant through the engine, hoses and other components.

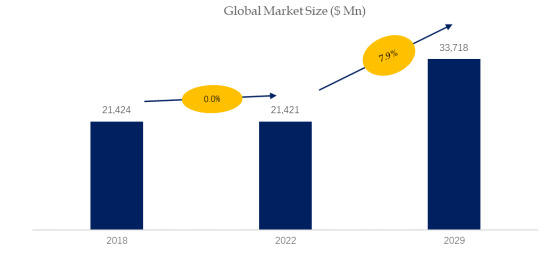

According to the new market research report “Global Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves Market Report 2023-2029”, published by QYResearch, the global Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves market size is projected to reach USD 33.72 billion by 2029, at a CAGR of 7.9% during the forecast period.

Figure. Global Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves Market Size (US$ Mn), 2018-2029

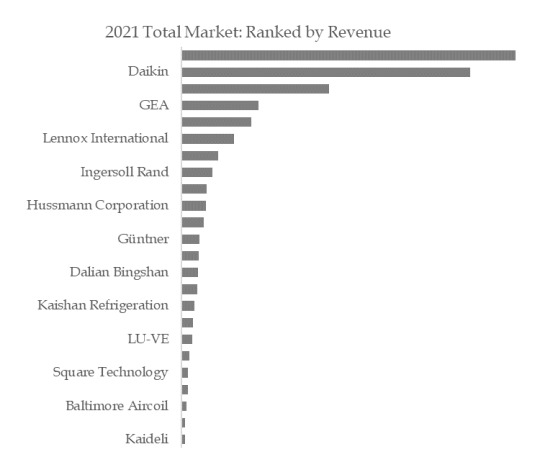

Figure. Global Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves Top 24 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves include Kaideli, FRIGEL, Baltimore Aircoil, Star Refrigeration, Square Technology, Zhejiang Gaoxiang, LU-VE, Evapco, Johnson Controls, Hussmann Corporation, etc. In 2021, the global top five players had a share approximately 45.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Korea Centrifugation Market Future Trends to Look Out | Bis Research

Centrifugation techniques used in Korea or developed by Korean scientists, would involve the separation of substances using centrifugal force, a method commonly used in various fields such as biology, chemistry, and medicine.

Centrifugation involves spinning a mixture at high speeds, causing the components to separate based on their density, size, and shape. This process finds applications in purifying biological samples, separating components of blood, isolating cellular organelles, and various other laboratory procedures.

The Korea centrifugation market was valued at $46.1 million in 2023 and is expected to reach $80.6 million by 2033, growing at a CAGR of 5.75% between 2023 and 2033

Korea Centrifugation Market Overview

Centrifugation is a fundamental laboratory technique used for separating components of heterogeneous mixtures based on their density, size, and shape differences. It involves spinning samples at high speeds, generating centrifugal forces that cause particles to move radially outward or inward according to their mass and buoyant density.

Centrifugation exploits the principle of sedimentation, where denser particles sediment faster under centrifugal force.

Types of Centrifugation

Differential Centrifugation

Density Gradient Centrifugation

Ultracentrifugation

Korea Centrifugation Market Drivers

Biotechnology and Life Sciences Research

Clinical Diagnostics and Healthcare

Industrial Applications

Technological Innovations

Korea's centrifugation market is driven by factors such as research and innovation, healthcare demand, industrial applications, environmental considerations, and global competitiveness, shaping the dynamics of the industry and driving technological advancements and market growth.

Have an understanding of our report Click Here !

Market Segmentation

Based on Product

Based on Model Type

Based on Application

Key Market Players

Agilent Technologies, Inc.

Andreas Hettich GmbH & Co. KG

ARI Medical Technology Co., Ltd.

Biolab Scientific

Bioneer Corporation

And many others

Download our sample page to have a better understanding click here !

Types of Korea Centrifugation Market

Ultracentrifugation

Differential Centrifugation

Density Gradient Centrifugation

Preparative Centrifugation

Analytical Centrifugation

Recent Developments in the Korea Centrifugation Market

• In April 2023, Eppendorf, a prominent life science company, unveiled the Centrifuge 5427 R, marking the introduction of Eppendorf's inaugural microcentrifuge equipped with hydrocarbon cooling. This innovation contributes to fostering a more sustainable laboratory environment. Through this advancement, users had the capability to conduct a diverse range of molecular and cell biology applications using a refrigerated device that incorporated a natural cooling agent boasting a nearly zero Global Warming Potential (GWP). The primary goal was to safeguard both samples and the planet.

•In February 2022, Beckman Coulter Life Sciences introduced its most versatile 3-liter benchtop centrifuge to date, the Allegra V-15R refrigerated centrifuge. It featured 10 rotor configurations and 50 programmable runs, along with a comprehensive array of adapters, allowing for a wide range of workflows and applications. These capabilities extended from cell and blood separation to high-throughput screening.

Visit our LifeSciences and Biopharma page click here !

Key Question Answers

Q What is the regulatory framework in the Korea centrifugation market?

Q What are the key trends and the impact of COVID-19 on the Korea centrifugation market?

Q What are the major market drivers, challenges, and opportunities in the Korea centrifugation market?

Q How is each product segment of the Korea centrifugation market expected to grow during the forecast period 2023-2033, and what is the anticipated revenue generated by each of the segments by the end of 2033?

Conclusion

In conclusion, the centrifugation market in Korea presents a dynamic landscape shaped by various factors driving demand, innovation, and growth. With a robust scientific research community, thriving industrial sectors, and a commitment to technological advancement, Korea stands as a key player in the global centrifugation market.

0 notes

Link

#3d#3Dultrasound#3d/4d#4d#4DUltrasound#4dultrasoundtraining#business#ElectiveUltrasound#opena4dultrasoundbusiness#opena4dultrasoundstudio#openahdultrasoundbusiness#openahdultrasoundstudio#training#ultrasoundbusiness#ultrasoundtraining

0 notes

Text

Cryogenic Equipment Market Dynamics: Size, Share, Trends, Growth And Forecast

Increasing demand for LNG and rising need for clean energy sources are likely to drive the market in the forecast period

According to TechSci Research report, “Cryogenic Equipment Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2029”, the Global Cryogenic Equipment Market is experiencing a surge in demand in the forecast period. One primary driver propelling the global cryogenic equipment market is the escalating demand for Liquefied Natural Gas (LNG). As the world transitions towards cleaner energy sources, LNG has emerged as a pivotal component in the global energy mix. Cryogenic equipment, such as LNG storage tanks and vaporization systems, plays a critical role in the liquefaction, transportation, and regasification of natural gas.

The rise in demand for LNG is attributed to its environmental benefits, as it produces fewer greenhouse gas emissions compared to traditional fossil fuels. This shift towards LNG is particularly notable in the transportation and power generation sectors. The construction of new LNG terminals, coupled with expansion projects, is fueling the need for advanced cryogenic equipment. As countries invest in enhancing their LNG infrastructure to meet growing energy demands, the cryogenic equipment market is experiencing a substantial boost, reflecting the industry's integral role in supporting the global adoption of cleaner energy alternatives.

Significant driver steering the global cryogenic equipment market is the expanding range of applications in healthcare and biotechnology. Cryogenic equipment, including cryogenic storage tanks and freezers, is instrumental in preserving and storing biological materials, pharmaceuticals, and medical gases at ultra-low temperatures.

In the healthcare sector, cryogenic applications are indispensable for the storage of stem cells, tissues, and organs, facilitating advancements in regenerative medicine and organ transplantation. Also, the biotechnology industry relies heavily on cryogenic solutions for the preservation of research materials, vaccines, and biomolecules. As medical and biotechnological research and development continue to advance, the demand for cryogenic equipment is witnessing a surge.

The precision and reliability of cryogenic systems in maintaining the integrity of biological samples make them indispensable in laboratories, hospitals, and biorepositories. Consequently, the expansion of healthcare infrastructure and ongoing developments in biotechnology drive the growth of the cryogenic equipment market, positioning it as a critical enabler of breakthroughs in medical science and biopharmaceutical innovation.

Browse over XX Market data Figures spread through XX Pages and an in-depth TOC on "Global Cryogenic Equipment Market.”

https://www.techsciresearch.com/report/cryogenic-equipment-market/20008.html

The Global Cryogenic Equipment Market is segmented into product type, cryogen type, end user and region.

Based on end user, The Energy & Power segment held the largest Market share in 2023. The Energy & Power sector, particularly the LNG industry, is a major consumer of cryogenic equipment. LNG, which is natural gas cooled to cryogenic temperatures for storage and transportation, is becoming increasingly important as a cleaner and more versatile energy source.

The demand for LNG is growing globally, driven by factors such as the transition to cleaner fuels, increased energy consumption, and the rise in international LNG trade.

Cryogenic storage tanks and transportation systems are integral components of the LNG supply chain. Cryogenic conditions are necessary to keep natural gas in a liquid state, reducing its volume for more efficient storage and transport.

The construction and expansion of LNG infrastructure, including liquefaction plants, storage terminals, and LNG carriers, contribute significantly to the demand for cryogenic equipment.

The Energy & Power sector is undergoing a transition toward cleaner energy alternatives, and LNG is positioned as a key player in this shift. LNG is considered a cleaner-burning fuel compared to traditional fossil fuels, contributing to reduced greenhouse gas emissions.

Governments and industries worldwide are increasingly adopting LNG as a cleaner energy source for power generation, industrial processes, and transportation, further driving the demand for cryogenic equipment.

Cryogenic technologies are essential for the production and storage of hydrogen, which is gaining prominence as a clean and sustainable energy carrier. Cryogenic storage is particularly effective in maintaining hydrogen at extremely low temperatures, allowing for denser storage.

The increasing focus on green hydrogen and the development of hydrogen-based energy systems contribute to the demand for cryogenic equipment in the Energy & Power sector.

Cryogenic technologies play a crucial role in enhancing the efficiency and reliability of power plants. For example, cryogenic air separation units are used to produce industrial gases like oxygen and nitrogen, which find applications in combustion processes for power generation.

The overall growth in global energy demand, coupled with the need for cleaner and more efficient energy sources, drives investments in energy infrastructure. Cryogenic equipment supports the development and operation of advanced energy systems.

The strategic importance of LNG in global energy trade makes the Energy & Power sector a key driver of the cryogenic equipment market. LNG terminals and facilities, equipped with cryogenic technology, facilitate international energy trade and distribution.

Major companies operating in the Global Cryogenic Equipment Market are:

Air Liquide S.A.

Linde Plc

Emerson Electric Co.

Chart Industries Inc.

Baker Hughes Company

IHI Corporation

Kawasaki Heavy Industries Ltd

Mitsubishi Heavy Industries Ltd

Howden Broking Group Limited

Burckhardt Compression AG

Download Free Sample Report:

https://www.techsciresearch.com/sample-report.aspx?cid=20008

Customers can also request for 10% free customization on this report.

“The Global Cryogenic Equipment Market is expected to rise in the upcoming years and register a significant CAGR during the forecast period. This growth is being driven by a number of factors, including the increasing demand for liquefied natural gas (LNG), the rising need for clean energy sources, and the growing use of cryogenic equipment in the healthcare, food processing, and electronics industries. For instance, LNG is a clean and efficient energy source that is becoming increasingly popular around the world. This is leading to an increase in demand for cryogenic equipment, which is used to store and transport LNG.

Additionally, The world is moving away from fossil fuels and towards cleaner energy sources such as solar, wind, and geothermal power. Cryogenic equipment is used to store and transport these renewable energy sources. Therefore, the Market of Cryogenic Equipment is expected to boost in the upcoming years.,” said Mr. Karan Chechi, Research Director of TechSci Research, a research-based management consulting firm.

“Cryogenic Equipment Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, 2019-2029 Segmented By Product Type (Valve, Tank, Vaporizer, Pump, and Others), By Cryogen Type (Nitrogen, Oxygen, Argon, Liquefied Natural Gas, and Others), By End User (Energy & Power, Chemical, Electronics, Shipping, Metallurgical, and Others), By Region, By Competition”, has evaluated the future growth potential of Global Cryogenic Equipment Market and provides statistics & information on Market size, structure and future Market growth. The report intends to provide cutting-edge Market intelligence and help decision-makers make sound investment decisions., The report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in the Global Cryogenic Equipment Market.

Browse Related Reports:

Saudi Arabia Solar Assisted Heat Pump Market:

https://www.techsciresearch.com/report/saudi-arabia-solar-assisted-heat-pump-market/21690.html

Saudi Arabia Wind Power Generator Market

https://www.techsciresearch.com/report/saudi-arabia-wind-power-generator-market/21832.html

Saudi Arabia LNG Engine Market

https://www.techsciresearch.com/report/saudi-arabia-lng-engine-market/21276.html

Saudi Arabia Onshore Floating Solar Market

https://www.techsciresearch.com/report/saudi-arabia-onshore-floating-solar-market/21291.html

Contact

Techsci Research LLC

420 Lexington Avenue,

Suite 300, New York,

United States- 10170

Tel: +13322586602

Email: [email protected]

Website: www.techsciresearch.com

#Cryogenic Equipment Market#Cryogenic Equipment Market Size#Cryogenic Equipment Market Share#Cryogenic Equipment Market Trends#Cryogenic Equipment Market Growth

0 notes

Text

Commercial Refrigeration Equipment Market Share, Size, Industry Growth and Forecast By 2030

The Commercial Refrigeration Equipment market research report offers an in-depth analysis of the industry as well as critical insights to assist businesses and key players in developing effective strategies. The study also takes into account advancements in market technology and product development. According to the report, the market is expected to grow significantly over the forecasted time period. Using historical data, the study examines key segments and sub-segments, revenue, industrial chain analysis, and demand and supply statistics.

Book Your Free Sample Report @ https://www.snsinsider.com/sample-request/1135

Top Keyplayers:

AHT Cooling Systems GmbH, Ali Group S.r.l. a Socio Unico, Carrier, Daikin Industries Ltd, Dover Corporation, Electrolux AB, Hussmann Corporation, Illinois Tool Works Inc., Johnson Control, Lennox International Inc., Panasonic Corporation, Whirlpool Corporation and Other Players

Market Segmentation View

By Product Type

Deep Freezers

Bottle Coolers

Storage Water Coolers

Commercial Kitchen Refrigeration

Medical Refrigeration

Chest Refrigeration

Others

By End User

Full-Service Restaurant & Hotels

Food Processing Industry

Hospitals

Retail Pharmacies

Supermarket/Hypermarket

Convenience Stores

Quick Service Restaurants

Others

By System type

Self-contained

Remotely Operated

The report covers the growth process, as well as macroeconomic and microeconomic factors, raw material source studies, and other technical data. The study includes both downstream and upstream market fundamentals for a complete value chain analysis. In the study, the Commercial Refrigeration Equipment market is further segmented by type, application, and region, with information on the segments with the highest penetration and profit margins, as well as current regional trends.

COVID-19 Impact Analysis

This research report examines the impact of the epidemic on demand and patterns, as well as the significant market challenges it has caused. This aspect of the research will aid market participants in preparing for future pandemics. The impact of the COVID-19 pandemic on the Commercial Refrigeration Equipment market, as well as important trends, are investigated during the market study. This report thoroughly examines the impact of the COVID-19 pandemic on market growth in the present and future. This critical information will assist market participants in preparing for a pandemic.

Competitive Scenario

Price analyses, revenue estimates, gross profit margins, corporate expansion strategies, and other critical factors are included in the research, providing readers with a comprehensive understanding of each company in the market. In the Commercial Refrigeration Equipment industry, mergers and acquisitions, joint ventures, product launches, brand promotions, partnerships, corporate and government agreements, and other activities are all investigated.

Reasons to Purchase the Commercial Refrigeration Equipment Market Report

An in-depth segmentation research with detailed statistics, as well as a thorough examination of the Commercial Refrigeration Equipment market.

An in-depth examination of the competitive landscape to provide businesses with a competitive advantage.

A snapshot of the market's ever-changing dynamics that will have a significant impact on the market during the forecast period.

Get Exclusive Discount this Report: https://www.snsinsider.com/discount/1135

Report Conclusion

Thank you for taking the time to read our report. Our team will make certain that the report is tailored to your specific requirements. Please contact us if you have any further questions or would like to learn more about report customization.

About US:

SNS Insider is a frontrunner in global market research and consulting. We empower clients with the insights they need to navigate evolving landscapes.

Our team leverages a global network to deliver cutting-edge market data, consumer trends, and actionable insights. Through surveys, focus groups, and video discussions, we provide the information you need to make confident decisions.

We are committed to delivering reliable data across a wide range of industries. Recognized as a global leader, we have the expertise to design and implement tailored research programs, from surveys to focus groups, catering to virtually any sector.

Key improvements:

Stronger verbs and adjectives: uses words like "frontrunner," "empower," "navigate," "cutting-edge," to create a more dynamic and confident tone.

Focus on benefits: emphasizes how SNS Insider helps clients make confident decisions and navigate change.

Conciseness: streamlines the text while maintaining key information.

Actionable language: highlights the "tailored" research programs offered by SNS Insider.

Contact Us:

Akash Anand – Head of Business Development & Strategy

[email protected]

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

What Are Most-Significant Applications of Industrial Refrigeration Systems?

The ongoing COVID-19 pandemic has put the spotlight on the global healthcare ecosystem, as many of the myths about how advanced the medical infrastructure around the world is were busted. With the case and death counts rising, the industry was caught gasping for breath (metaphorically), while the patients were literally gasping for breath (COVID is a lung infection). During this time, the number of research studies being conducted in the pharmaceutical and healthcare sectors on virology skyrocketed, as a vaccine was to be the leader of the charge against the pandemic.

Therefore, the number of clinical trials being conducted for viral vaccines rose massively, as did the worldwide trade of vaccines, aided by several such products getting regulatory approvals. With the healthcare and pharmaceutical sectors expected to not drop their guard for many years to come, the industrial refrigeration systems market size, as calculated by P&S Intelligence, is predicted to increase to $41.1 billion in 2030 from $26.8 billion in 2019, at a 5.0% CAGR between 2020 and 2030.

This is because an efficient, unbroken cold chain is essential for drug development and trade. Refrigerators are not only used to store and transport the final pharmaceutical products but also for the storage and transportation of the raw materials. Pharmaceuticals, biosimilars, excipients, active ingredients, tissues, and blood products are extremely sensitive to heat; therefore, effective cooling is necessary to protect them from damage and make them viable for use over a long time.

Another sector where refrigeration is important for the same reason is food and beverage. Most agricultural products spoil in the heat, which is why keeping them in cool conditions is paramount. Several of the processed food packages carry the directions “store in a cool and dry place”. In food processing factories, the ingredients, intermediate goods, and final products must be refrigerated to increase their shelf life. Thus, with the rising disposable income allowing people in developing countries to purchase processed food, the demand for industrial-grade refrigerators among food and beverage companies is surging.

Other industries where refrigeration is vital are oil and gas, construction, and manufacturing. Since, the food and beverage sector has been the largest user of such systems, their sales have been the highest in Asia-Pacific (APAC). Home to the largest number of people in the world, APAC has the most-productive food and beverage industry. India is already home to the fifth-largest processed food industry, which continues to garner extensive government support. “…the food processing sector in India has received around US$ 7.54 billion worth of Foreign Direct Investment (FDI) during the period April 2000-March 2017.”, says the India Brand Equity Foundation (IBEF).

Moreover, recently, the Indian government announced plans to establish 40 mega food parks, which are essentially integrated manufacturing districts for the food and beverage sector. With this, the industrial refrigeration systems market is poised for strong growth, with such equipment being important in this industry. Moreover, Invest India expects the country’s food processing sector to value more than $500 billion by 2025, which reflects a consistently growing demand for processing equipment.

Hence, with the pharmaceutical and food and beverage production growing, the procurement of industrial-grade refrigerators will escalate too.

#Industrial Refrigeration Systems Market Share#Industrial Refrigeration Systems Market Size#Industrial Refrigeration Systems Market Growth#Industrial Refrigeration Systems Market Applications#Industrial Refrigeration Systems Market Trends

1 note

·

View note

Text

What’s the Difference Between Thermoforming and Injection Molding

Often, customers in their own hands of the product in the thermoforming process or injection molding process can not tell the difference, or their own design in the end should be used in the injection molding process or thermoforming process?

In the market, the most common plastic parts in the market are thermoforming products or injection molded product. and thermoforming and injection molding are popular manufacturing processes. In fact, for many products, both can vacuum form and also can be plastic injection molding,. That specifically. In which way, do different users have different choices, exactly how is good? Cost, efficiency, and quality are often the most important considerations.

Of course, they are not opposites but complementary. In this blog, we will introduce the Difference Between Thermoforming and Injection Molding in detail.

Different Manufacturing Process

Thermoforming processing

The principle of thermoforming technology is also called the vacuum forming molding process. It is a thermoforming processing method, the use of the thermoplastic sheet, the manufacture of open plastic shell products the method, is the plastic sheet is cut to a certain size after heating and softening, with the help of the heated plastic sheet on both sides of the difference in air pressure and mechanical pressure, so that the deformation of a specific mold profile, after cooling and shaping, and cutting and trimming to complete the thermoforming products process!

Injection molding process

Injection molding is a process in which thermoplastic plastic pellets are heated and molten liquid polymers are, and then the molten plastic is injected into the injection molds through the injection molding machine with high pressure, after a certain cooling time, the plastic is solidified and shaped in the injection molding tooling.

Different materials used

The most significant difference between thermoforming and injection molding is the different materials used. The commonly used materials are PP, PE, ABS, PVC, PET, PS, and other thermoplastic pellets and sheets, while injection molding uses more thermosetting plastics, such as PP, PA, PC, ABS, POM, PE, and other granular raw materials.

Thermoforming uses plates and sheets, so the raw materials will be more expensive compared to injection molding granular materials.

Different design structure of products

Injection molded products are more accurate and can produce complex shapes and structures, while thermoforming products generally produce simpler shapes.

The shape obtained by injection molding is often the final product, and no further processing is required before it is installed or used as a final product. Many details, such as projections, ribs, and threads, can be molded in a single step in injection molding.

Thermoforming products can be produced in simple shapes, with smooth surfaces, are easy to process and assemble, and require post-processing to make holes and remove excess material after the product has been molded. The products mainly include packaging boxes, handicrafts, cards, and so on. Thermoforming products are also widely used in electronics, home appliances, medical and toys.

Different product usage

Due to the different materials and processes, there are some differences between the products made of thermoforming and injection molding. Thermoforming products usually have strong flexibility, impact resistance, and wear resistance, especially suitable for the production of curved and arched products, such as blister packaging boxes, three-dimensional billboards, and so on.

While injection molding products usually have the characteristics of high precision, high strength, good dimensional stability, etc., they are suitable for the production of electronic product shells, automobile parts, industrial equipment, and so on.

Different equipment and tools

Injection molding requires injection molding machines, molds, and other equipment and tools; injection molding machines are mainly divided into vertical injection molding machines, horizontal injection molding machines, two-colour injection molding machines, single-colour injection molding machines, high-speed injection molding machines and so on.

Thermoforming products require equipment and tools such as thermoforming machines and thermal processing devices. According to the different types of pressurization of thermoforming, the mainstream thermoforming equipment is mainly divided into the following three categories:

(1) Vacuum negative pressure forming machine, mainly through the negative pressure vacuum method, so that the plastic sheet is affixed to the mold;

(2) Positive pressure vacuum machine, through the air compressor on the front of the plastic sheet with atmospheric pressure, so that the softened plastic sheet is affixed to the mold;

(3) Positive and negative pressure vacuum molding machines, which form a strong pressure difference between the two sides of the plastic sheet by means of pressurization and vacuum, so that the softened plastic sheet is molded. These three kinds of equipment, each has its own advantages and disadvantages, need to be based on the characteristics of the product to choose the machine.

The parameters of temperature, pressure, and flow rate of injection molding equipment in the process of product processing can be precisely adjusted through the control system, which ensures the precision of product making. At the same time, injection molding equipment consumes less raw materials when processing high-precision products, which also reduces product costs.

In contrast, blister molding equipment is limited in the means of controlling parameters such as temperature, pressure, and flow rate, which is a limitation to the production of products requiring high precision.

Different production efficiency

Injection molding is a kind of high volume production runs plastic processing method. The general production efficiency of injection molding equipment can reach a production capacity of hundreds to thousands of pieces per hour.

At the same time, the degree of automation of injection molding equipment is also very high, and it can quickly complete the processing of products and improve production efficiency. In contrast, the production speed of thermoforming is slower compared to injection molding, and the processing time of the products usually takes several minutes to tens of minutes.

Different costs

A. Tooling Costs

Injection mold according to the complexity of the product, different precision, and mold material at different prices. The commonly used mold materials are S50C, P20, H13, 718H, NAK80, S136, etc., due to the complexity of the product is different, and involves a lot of complexity of the mold processing process than the thermoforming mold, the cost of the relative thermoforming molds are also higher than 5 to 10 times.

The molds used for thermoforming: The molds commonly used for blistering are gypsum molds, aluminum molds, copper molds, wood molds, and steel molds.

The materials used in plastic injection molds are relatively low, and the product structure is simple, so the molds are relatively simple, the materials are cheap, and there are lower tooling costs.

Gypsum mold: the material is gypsum powder, simple to manufacture and amend, usually a single piece of mold only needs 1~3 days, because it is brittle and difficult to dissipate heat, gypsum molds are usually used for the case of having samples handmade samples, not for production.

Aluminum mold: it is made of aluminum through machining and grinding. The aluminum mold has high precision, a smooth surface and is hard and durable, but the price is very expensive, generally used under strict requirements of the product, and ordinary molds can't achieve the precision effect of the use of such molds.

Copper mold: Copper mold should be made with plaster mold first, then take the sample to copper plating, and then fill with gypsum inside.

The copper mold has a better appearance and finish, strength can also reach the usual production requirements, and it is one of the widely used thermoforming molds.

Substitute wood mold: the material is substitute wood, the material cost is higher, needs CNC processing, the manufacturing cycle is short, usually a few hours, easy to sand and punch. The material is also brittle, suitable for sampling in the scene with 3D drawing files, not for production.

Steel mold: generally S45C, S50C, and P20 materials; generally thermoforming, use this type of steel mould.

B. Product costs

The cost of thermoforming vs injection molding is not the same. As the production process of injection molding is relatively simple, the cost advantage of injection molding is obvious when producing large quantities and high-cost products; while thermoforming molding is suitable for smaller production quantities, short production cycles, complex shape products, etc., which is relatively more economical.

The initial cost of injection molds is higher, but the cost per piece is lower when producing large quantities, and the start-up cost of thermoforming is lower, but the cost rises with the increase in production.

In injection molding equipment in the production process, recycling raw material loss will be much less than the vacuum forming molding equipment, especially in the production of larger batches of products, injection molding equipment in the cost savings have obvious advantages.

In addition, injection molding equipment has a higher degree of automation, which does not require much manual operation and also reduces production costs, it's more cost effective for high volume production.

Overall, injection molding is more efficient than blister molding is proven, although the investment in injection molding equipment is larger, in the long run, its production efficiency and production cost advantage will bring more profits and competitive advantage for enterprises.

Conclusion

To sum up, although both thermoforming and injection molding belong to the plastic molding process, there are obvious differences in their materials, production processes, uses, production precision, and product characteristics.

When choosing the molding process, you need to select the most suitable process according to the requirements and characteristics of the specific product. In the actual production and use need to choose the right type of product according to the specific needs.

0 notes

Text

Breathing Easy: Navigating the Unpredictable Terrain of the Medical Oxygen Market

In a world where respiratory diseases are as common as a Monday morning headache, the global market for medical oxygen concentrators and cylinders is growing faster than a pot of coffee in an early morning office. Let’s dive into the nitty-gritty of this market without unleashing the clichéd jargon of “unveiling” or “empowering.”

The Big Picture:

Picture this — the market size was a hefty USD 4.39 billion in 2022, a number that could make even Scrooge McDuck’s eyes widen. Fast forward to 2031, and we’re looking at a whopping USD 6.59 billion, thanks to a growth rate that even your favorite plant in the corner would envy (4.6% CAGR).

Market Dynamics —

Not Your Average Breath of Fresh Air: So, what’s causing this growth spurt? Well, besides the fact that respiratory diseases are spreading like gossip in a small town, the COVID-19 pandemic decided to crash the party and created a demand surge for medical oxygen equipment worldwide. Who knew a virus could be such a party planner?

The Players —

Not Your Average Poker Game: In the high-stakes game of medical oxygen, key players are dealing with challenges like regulatory compliance, reimbursement issues, and supply chain disruptions. But fear not, as they’re not just folding — they’re innovating. Strategic partnerships, product innovation, and expanding geographically are the cards they’re playing.

Market Snapshot —

Like a Selfie but for the Market: The market snapshot shows North America leading the charge, with the United States claiming the throne, probably with a crown made of oxygen cylinders. Home healthcare settings are growing faster than a teenager’s appetite, while hospitals remain the largest segment — because let’s face it, we all need a little extra oxygen when dealing with hospital bills.

Segmental Analysis —

Breaking Down the Oxygen Bubble: Portable and stationary oxygen concentrators are stealing the spotlight from traditional oxygen cylinders. The cool kids on the block are the portable ones, providing oxygen therapy with the convenience of a sidekick. Hospitals are the reigning champs, but home healthcare settings are the dark horses in this race.

Regional Insights —

From Hollywood to Bollywood: North America takes the lead, with the U.S. flaunting its developed healthcare system and a high rate of chronic respiratory illnesses. Latin America and the Asia-Pacific region are catching up like they just found out about this medical oxygen party, driven by a growing geriatric population, rapid economic expansion, and increased healthcare awareness.

For More Information: https://www.skyquestt.com/report/medical-oxygen-concentrators-and-oxygen-cylinders-market

Market Trends —

More Than Just Hot Air: The market is shifting towards portable and home-based solutions faster than you can say “breathe easy.” Technological advancements and innovation are not just buzzwords here; they’re making oxygen concentrators and cylinders more user-friendly, efficient, and portable. It’s like upgrading from a flip phone to the latest smartphone — but for your lungs.

Competitive Landscape —

The Real MVPs: Key players like Inogen, Philips Respironics, and DeVilbiss Healthcare are not just names; they’re the superheroes of the medical oxygen world. They’re in a fierce competition, not with capes, but with innovation, mergers, and strategic alliances. It’s like a Marvel movie, but for healthcare.

Recent Developments —

The Plot Thickens: In a plot twist worthy of an Oscar, Chart Industries Inc. acquires AirSep Corporation for a cool USD 1.1 billion, Inogen, Inc. snatches up Respironics, Inc. for USD 8 billion, and Longfian Scitech Co., Ltd. gets a new owner in Drive DeVilbiss Healthcare for a staggering US$ 1.3 billion. Move over Hollywood, we’ve got medical oxygen dramas!

Key Market Trends —

Breathing Life into the Market: The market is shifting towards portable and home-based solutions, and technological advancements are making oxygen concentrators and cylinders more user-friendly and efficient. It’s like upgrading from a rusty bicycle to a sleek electric scooter — but for your respiratory system.

Conclusion —

Breathing Easy in a Chaotic World: As the world grapples with respiratory challenges, the medical oxygen concentrators and cylinders market is on the rise. With key players innovating, regions catching up, and trends shifting towards convenience, it’s safe to say that breathing easy is not just a luxury — it’s a necessity.

So, buckle up and get ready for a breath-taking journey through the unpredictable terrain of the medical oxygen market. It’s not just hot air; it’s the oxygen we all need to survive — in style.

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

Breathing Easy: Navigating the Unpredictable Terrain of the Medical Oxygen Market

In a world where respiratory diseases are as common as a Monday morning headache, the global market for medical oxygen concentrators and cylinders is growing faster than a pot of coffee in an early morning office. Let’s dive into the nitty-gritty of this market without unleashing the clichéd jargon of “unveiling” or “empowering.”

The Big Picture:

Picture this — the market size was a hefty USD 4.39 billion in 2022, a number that could make even Scrooge McDuck’s eyes widen. Fast forward to 2031, and we’re looking at a whopping USD 6.59 billion, thanks to a growth rate that even your favorite plant in the corner would envy (4.6% CAGR).

Market Dynamics —

Not Your Average Breath of Fresh Air: So, what’s causing this growth spurt? Well, besides the fact that respiratory diseases are spreading like gossip in a small town, the COVID-19 pandemic decided to crash the party and created a demand surge for medical oxygen equipment worldwide. Who knew a virus could be such a party planner?

The Players —

Not Your Average Poker Game: In the high-stakes game of medical oxygen, key players are dealing with challenges like regulatory compliance, reimbursement issues, and supply chain disruptions. But fear not, as they’re not just folding — they’re innovating. Strategic partnerships, product innovation, and expanding geographically are the cards they’re playing.

Market Snapshot —

Like a Selfie but for the Market: The market snapshot shows North America leading the charge, with the United States claiming the throne, probably with a crown made of oxygen cylinders. Home healthcare settings are growing faster than a teenager’s appetite, while hospitals remain the largest segment — because let’s face it, we all need a little extra oxygen when dealing with hospital bills.

Segmental Analysis —

Breaking Down the Oxygen Bubble: Portable and stationary oxygen concentrators are stealing the spotlight from traditional oxygen cylinders. The cool kids on the block are the portable ones, providing oxygen therapy with the convenience of a sidekick. Hospitals are the reigning champs, but home healthcare settings are the dark horses in this race.

Regional Insights —

From Hollywood to Bollywood: North America takes the lead, with the U.S. flaunting its developed healthcare system and a high rate of chronic respiratory illnesses. Latin America and the Asia-Pacific region are catching up like they just found out about this medical oxygen party, driven by a growing geriatric population, rapid economic expansion, and increased healthcare awareness.

For More Information: https://www.skyquestt.com/report/medical-oxygen-concentrators-and-oxygen-cylinders-market

Market Trends —

More Than Just Hot Air: The market is shifting towards portable and home-based solutions faster than you can say “breathe easy.” Technological advancements and innovation are not just buzzwords here; they’re making oxygen concentrators and cylinders more user-friendly, efficient, and portable. It’s like upgrading from a flip phone to the latest smartphone — but for your lungs.

Competitive Landscape —

The Real MVPs: Key players like Inogen, Philips Respironics, and DeVilbiss Healthcare are not just names; they’re the superheroes of the medical oxygen world. They’re in a fierce competition, not with capes, but with innovation, mergers, and strategic alliances. It’s like a Marvel movie, but for healthcare.

Recent Developments —

The Plot Thickens: In a plot twist worthy of an Oscar, Chart Industries Inc. acquires AirSep Corporation for a cool USD 1.1 billion, Inogen, Inc. snatches up Respironics, Inc. for USD 8 billion, and Longfian Scitech Co., Ltd. gets a new owner in Drive DeVilbiss Healthcare for a staggering US$ 1.3 billion. Move over Hollywood, we’ve got medical oxygen dramas!

Key Market Trends —

Breathing Life into the Market: The market is shifting towards portable and home-based solutions, and technological advancements are making oxygen concentrators and cylinders more user-friendly and efficient. It’s like upgrading from a rusty bicycle to a sleek electric scooter — but for your respiratory system.

Conclusion —

Breathing Easy in a Chaotic World: As the world grapples with respiratory challenges, the medical oxygen concentrators and cylinders market is on the rise. With key players innovating, regions catching up, and trends shifting towards convenience, it’s safe to say that breathing easy is not just a luxury — it’s a necessity.

So, buckle up and get ready for a breath-taking journey through the unpredictable terrain of the medical oxygen market. It’s not just hot air; it’s the oxygen we all need to survive — in style.

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

Optical Coating Market: Trends, Challenges, and Opportunities

The global optical coating market size is expected to reach USD 37.58 billion by 2030, registering a CAGR of 9.2% from 2024 to 2030, according to a new report by Grand View Research, Inc. The market is estimated to be driven by the growing smart consumer electronics industry across the globe. The rising focus on electricity generation through clean sources is also expected to drive product demand. Consumer electronic devices include smartphones, tablets, phablets, smartwatches, and smart televisions. Rapid urbanization resulting in changes in consumer lifestyles is expected to create lucrative opportunities for smart consumer electronic devices. This is projected to lead to an increase in the utilization of optical coatings as they have a superior optical display and impact resistance properties.

Optical Coating Market Report Highlights

North America dominated the market and accounted for a revenue share of more than 37.0% in 2023

The anti-reflective coatings segment is the largest product segment and accounted for a revenue share of more than 29.0% in 2023. The growing demand for anti-reflective coatings from the solar industry is likely to fuel the market over the forecast period

The solar application segment is expected to witness significant growth over the forecast period. Rising demand for solar photovoltaic cells and emphasis on solar energy production in the Asia Pacific especially in countries including China, India, and Japan is anticipated to augment growth in market demand for optical coatings for the solar segment in the region

In April 2020, Alluxa, a US-based optical coatings and filters manufacturer, launched the Ultra Series qPCR filter for integration into medical equipment that performs COVID-19 testing of patient samples

For More Details or Sample Copy please visit link @: Optical Coating Market Report

The Asia Pacific is a major market for consumer electronics owing to the presence of a large number of key players. The demand in the region has shifted toward Southeast Asian countries, a trend that is likely to continue over the forecast period. However, the outbreak of highly contagious COVID-19 across the globe is severely affecting manufacturing industries, which, in turn, is anticipated to negatively impact the growth of the global optical coatings in various applications such as consumer electronics, automotive, and aerospace and defense, solar, and architecture. As COVID-19 continues to spread across the world, order cancellations and shipping complications are surging throughout the optical coatings industry.

The reflective coating segment is anticipated to progress at a substantial growth rate over the forecast period. A rise in the use of this product for roofing applications in the construction industry owing to factors such as prevention of direct exposure to sunlight on the roof and reduction in cooling cost is anticipated to propel the demand for reflective coating over the forecast period. There has been a rising demand for both commercial and passenger automobiles in emerging economies like South Africa, Mexico, Brazil, India, and China in light of improving standards of living and population growth. This is projected to benefit the automotive coatings industry, which in turn, is expected to propel the demand for optical coatings.

Furthermore, the increasing requirement for protection against dust, dirt, UV radiation, and harsh climate is anticipated to drive market growth in the coming years. Companies in the market experience fluctuating prices of raw materials, which are driven by factors such as changes in supplier feedstock costs, inventories, demand and supply factors, and government regulations. Therefore, manufacturers have been focusing on developing technologies for efficient coating at a low cost. In addition, key players are continuously engaged in the diversification of their existing product portfolio in order to cater to a large customer base, which ultimately enables a strong foothold in the global market.

#OpticalCoating#ThinFilmCoatings#CoatingTechnology#PrecisionOptics#Photonics#OpticalComponents#ReflectiveCoatings#AntireflectionCoatings#OpticalEngineering#CoatingIndustry#SurfaceEnhancement#SpectralOptics#CoatingApplications#OpticalInnovation#CoatingSolutions

0 notes

Text

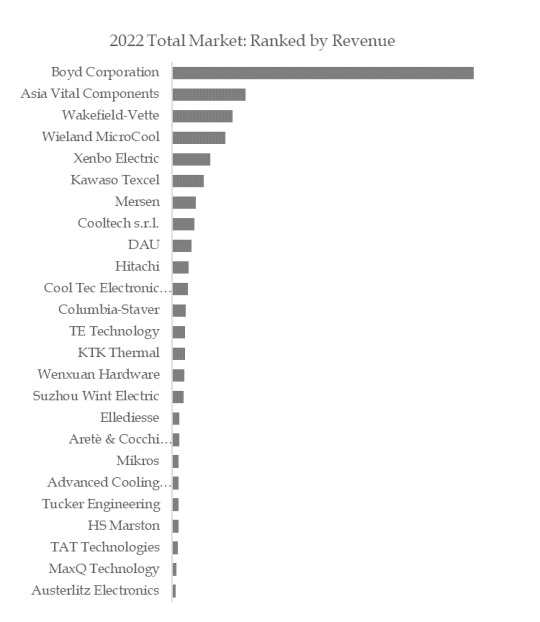

global top 25 companies accounted for 57% of total Specialty Aluminum Cold Plate market (qyresearch, 2021)

Liquid cold plates allow the cooling of the most of electronic components thanks to the circulation of liquid inside of a metal plate. The contact between the plate and the component extract calories and transmit them to the fluid circulating into the canals. The plate can integrate a system of turbulators in order to improve the thermal exchange and the homogeneity of the temperature under the component.

According to the new market research report “Global Aluminum Cold Plate Market Report 2023-2029”, published by QYResearch, the global Aluminum Cold Plate market size is projected to reach USD 0.41 billion by 2029, at a CAGR of 3.5% during the forecast period.

Figure. Aluminum Cold Plate Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Aluminum Cold Plate Market Report 2023-2029.

Figure. Aluminum Cold Plate Top 25 Players Ranking and Market Share(Continually updated)

Based on or includes research from QYResearch: Aluminum Cold Plate Market Report 2023-2029.

The global key manufacturers of Aluminum Cold Plate include Boyd Corporation, Wakefield-Vette, Wieland MicroCool, Asia Vital Components, Xenbo Electric, Kawaso Texcel, Mersen, Hitachi, Columbia-Staver, TE Technology, etc. In 2022, the global top five players had a share approximately 57.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Korea Centrifugation Market Future Trends to Look Out | Bis Research

Centrifugation techniques used in Korea or developed by Korean scientists, would involve the separation of substances using centrifugal force, a method commonly used in various fields such as biology, chemistry, and medicine.

Centrifugation involves spinning a mixture at high speeds, causing the components to separate based on their density, size, and shape. This process finds applications in purifying biological samples, separating components of blood, isolating cellular organelles, and various other laboratory procedures.

Korea Centrifugation Market Overview

Centrifugation is a fundamental laboratory technique used for separating components of heterogeneous mixtures based on their density, size, and shape differences. It involves spinning samples at high speeds, generating centrifugal forces that cause particles to move radially outward or inward according to their mass and buoyant density.

Centrifugation exploits the principle of sedimentation, where denser particles sediment faster under centrifugal force.

Types of Centrifugation

Differential Centrifugation

Density Gradient Centrifugation

Ultracentrifugation

Korea Centrifugation Market Drivers

Biotechnology and Life Sciences Research

Clinical Diagnostics and Healthcare

Industrial Applications

Technological Innovations

Korea's centrifugation market is driven by factors such as research and innovation, healthcare demand, industrial applications, environmental considerations, and global competitiveness, shaping the dynamics of the industry and driving technological advancements and market growth.

Have an understanding of our report Click Here !

Market Segmentation

Based on Product

Based on Model Type

Based on Application

Key Market Players

Agilent Technologies, Inc.

Andreas Hettich GmbH & Co. KG

ARI Medical Technology Co., Ltd.

Biolab Scientific

Bioneer Corporation

And many others

Download our sample page to have a better understanding click here !

Types of Korea Centrifugation Market

Ultracentrifugation

Differential Centrifugation

Density Gradient Centrifugation

Preparative Centrifugation

Analytical Centrifugation

Recent Developments in the Korea Centrifugation Market

• In April 2023, Eppendorf, a prominent life science company, unveiled the Centrifuge 5427 R, marking the introduction of Eppendorf's inaugural microcentrifuge equipped with hydrocarbon cooling. This innovation contributes to fostering a more sustainable laboratory environment. Through this advancement, users had the capability to conduct a diverse range of molecular and cell biology applications using a refrigerated device that incorporated a natural cooling agent boasting a nearly zero Global Warming Potential (GWP). The primary goal was to safeguard both samples and the planet.

•In February 2022, Beckman Coulter Life Sciences introduced its most versatile 3-liter benchtop centrifuge to date, the Allegra V-15R refrigerated centrifuge. It featured 10 rotor configurations and 50 programmable runs, along with a comprehensive array of adapters, allowing for a wide range of workflows and applications. These capabilities extended from cell and blood separation to high-throughput screening.

Visit our LifeSciences and Biopharma page click here !

Key Question Answers

Q What is the regulatory framework in the Korea centrifugation market?

Q What are the key trends and the impact of COVID-19 on the Korea centrifugation market?

Q What are the major market drivers, challenges, and opportunities in the Korea centrifugation market?

Q How is each product segment of the Korea centrifugation market expected to grow during the forecast period 2023-2033, and what is the anticipated revenue generated by each of the segments by the end of 2033?

Conclusion

In conclusion, the centrifugation market in Korea presents a dynamic landscape shaped by various factors driving demand, innovation, and growth. With a robust scientific research community, thriving industrial sectors, and a commitment to technological advancement, Korea stands as a key player in the global centrifugation market.

0 notes

Text

The Most Reliable Laboratory Supplies Company Ever!

An increase in biotechnology financing activities, together with the most recent advances in biological and chemical research, will provide enormous growth opportunities for the laboratory supply firm. The tools, apparatuses, and equipment used in diagnostic, research, and manufacturing applications are referred to as laboratory supplies.

The laboratory supplies company can be divided into two categories: disposables and equipment. Medical lab Equipment, instruments, utensils, and substances used in a laboratory setting to conduct experiments, tests, analyses, and scientific research.

These materials are specifically created and manufactured to fulfill the demands of scientists, researchers, and professionals working in laboratory supplies fields such as chemistry, biology, physics, and medicine, among others.

Biotechnology lab equipment research focuses on using biological approaches to solve issues and develop profitable goods, such as genetic engineering and cell culture. It includes genetic modification for improved traits, biopharmaceutical development, sustainable industrial production of biofuels and chemicals, agricultural advancements through crop enhancements, environmental solutions such as bioremediation, and the development of novel biological systems through synthetic biology.

Biotechnology Equipment This field contributes to the advancement of scientific knowledge and innovation in industries like healthcare, agriculture, energy, and the environment, with the goal of tackling global concerns and enhancing overall quality of life.

The expanding breadth of Medical laboratory supplies in pharmaceutical and biotechnology businesses, academic institutes, and diagnostic Laboratory Medical Supplies will provide huge potential prospects for the global market.

Equipment for Chromatography is a versatile analytical technique used in laboratories to separate, identify, and quantify individual components within complex mixtures of substances. It relies on the differential distribution of compounds between a stationary phase and a mobile phase, allowing for the separation of molecules based on their chemical properties, size, and affinity.

For Laboratory Equipment Supplies tasks requiring heating, cooling, agitation or mixing, and pumping, electrically powered equipment is regularly employed. Fluid and vacuum pumps, lasers, power supply, electrophoresis and electrochemical apparatus, x-ray equipment, stirrers, hot plates, heating mantles, microwave ovens, and ultrasonicators are examples of electrically driven Laboratory Chemical Supplies.

To obtain precise and detailed insights into the composition of substances, researchers and analysts use various chromatographic methods such as gas chromatography (GC), liquid chromatography (LC), and thin-layer chromatography (TLC), making it an essential tool for both qualitative and quantitative analysis in scientific research and quality control processes.

Water is commonly used as a coolant in laboratory condensers and other equipment. Although tap water is frequently used for these reasons, it should be avoided. In many areas, preserving water is crucial, making tap water unsuitable.

Furthermore, the likelihood of a flood is considerably increased. Refrigerated recirculators can be costly, but they are favored for cooling laboratory equipment in order to preserve water and reduce the impact of floods. To avoid freezing at the refrigeration coils, use a coolant mixture of water and ethylene glycol.

1 note

·

View note

Text

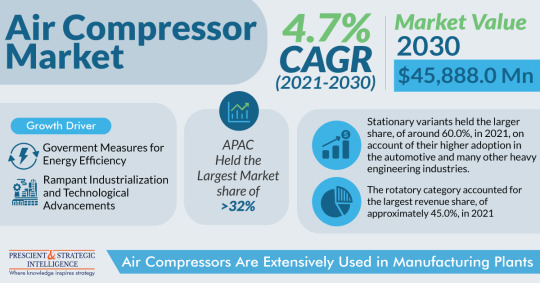

Air Compressor Market Analysis by Trends, Size, Share, Growth Opportunities, and Emerging Technologies

A diesel engine or electric motor powers an air compressor, a mechanical device that converts energy from one form to another and stores it in the pressured air. Powered machine tools, ventilation systems, HVAC control systems, and other industrial and non-industrial uses for powered air employ pressurized air.

Air compressors use the kinetic energy stored in the compressed air to deliver the required power to various machinery, tools, and equipment in different industrial verticals. Additionally, the continuous compression supports the transportation of gases and liquids, the production of goods connected to petrochemistry, and cooling applications.

It has various uses, including cleaning, vacuum packing, spray painting, and other things. Additionally, a wide range of end customers employs air compressors for dehydration, air blowing, cleaning, powering tools, and medical equipment.

Rapid industrialization in developing nations is a crucial element driving the demand for air compressors. The market is expanding because industries worldwide are increasing their need for energy-efficient air compressors.

Browse detailed report - Air Compressor Market Analysis and Demand Forecast Report

Which Category Lead Industry?

Historically, the rotatory category holds the most significant share of about 45.0% because of these types' excellent efficiency and durable construction. Additionally, the category's expansion is aided by the numerous standards issued by government organizations throughout the globe to improve the output energy and efficiency optimization of the rotatory type.

The sales potential is also increased by the rotatory compressor's numerous advantages, including its longer lifespan and significant battery energy savings. Additionally, it is anticipated that the equipment's costly installation and maintenance costs will slow expansion in the upcoming years.

But as technology has advanced, air compressors' compression capacities have increased, which is expected to increase the demand for air compressors. Developing portable and energy-efficient air compressor designs have been widely embraced by businesses worldwide.

0 notes

Text

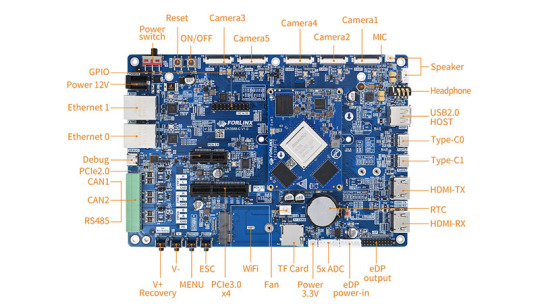

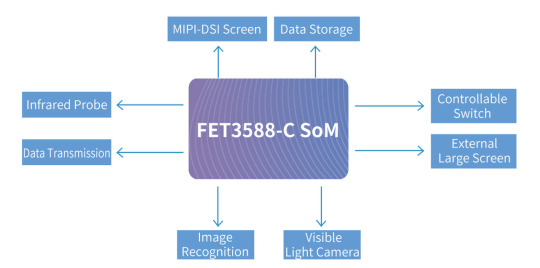

Forlinx FET3588-C SoM Facilitating the Intelligent Development of Infrared Thermal Imaging

According to Maxtech International data, the global civil infrared market size will exceed 7.6 billion US dollars in 2023, and in the past four years, the infrared industry has maintained a growth rate of over 11%. Moreover, according to data from Huajing Industrial Research Institute, the market size of China's infrared thermal imaging industry reached 65.534 billion yuan in 2021.

With the development of non-cooled infrared thermal imaging technology, infrared thermal imagers have been widely used in civil applications. This statement is attributed to Huajing Industrial Research Institute.

Against this backdrop, manufacturers and institutions that specialize in the research and production of infrared thermal imaging products have begun to lay out strategies for the civilian infrared thermal imaging market, which is a blue ocean market. The breast surgery research team from Peking Union Medical College Hospital in Beijing has applied their independently developed artificial intelligence-based infrared thermal imaging system (AI-IRT) to pre-screening for breast cancer.

The team has also developed a portable AI-IRT system, which includes an infrared miniature camera connected to a smartphone, AI software, and a real-time updated infrared thermal imaging database.

When using this system for pre-screening of breast cancer, the real-time captured infrared thermal images of the breasts are uploaded to the artificial intelligence software, which then provides a risk assessment rating. The system is non-invasive, radiation-free and easy to use, and can be used in families and community health service centers for screening.

Infrared thermal imaging can be used as an electrical equipment monitoring system, which is installed around the transformer, etc. Through optical fiber transmission, the monitoring of equipment can be completed in the monitoring room. 24 hours, all-weather, full coverage of all substation power equipment for real-time monitoring of thermal distribution field, real-time grasp of equipment operation status, found abnormal temperature rise immediately alarm.

In addition to equipment monitoring, it is also widely used in substation inspection, distribution inspection, transmission and distribution cable inspection industry, so that inspectors can grasp the temperature while helping the power industry inspection work become more efficient and easier.

In order to adapt to the development of infrared thermal imaging industry, Forlinx Embedded recommends FET3588-C System on Module(SoM) as the main control of highly integrated infrared thermal imager.

FET3588-C has 8K video codec + 8K display supporting 8K @ 60fps H.265 and VP9 decoders, 8K @ 30fps H.264 decoders and 4K @ 60fps AV1 decoders, supporting 8K @ 30fps H.264 and H.265 encoders. High quality JPEG encoder/decoder.

Optimization of 12V power supply can reduce losses, while PMIC dynamic frequency scaling can improve stability.

Powerful: Quad-core Cortex-A76 + Quad-core Cortex-A55, main frequency height of 2.4 GHZ, NPU with 6 TOPS

Support multi-channel video access and display output

Complete functional interfaces such as mipi-csi, mipi-dsi, USB, SATA, UART, CAN and Gigabit Ethernet

Originally published at www.forlinx.net.

0 notes

Text

The Middle East & Africa Antimicrobial Coatings Market is anticipated to grow at a CAGR of around 8% during the forecast period, i.e., 2021-26. The prime factors driving the market include the rapidly expanding healthcare & food & beverage industries and the increasing production of medical equipment in the Middle East & Africa. These aspects are leading to the continuous demand for antimicrobial coatings around the region. Besides, HVAC industries have also observed a decent accession in the market share due to the adoption of technologies, such as clean & germ-free cool air coming out of air conditioners.

#Middle East & Africa Antimicrobial Coatings Market#Middle East & Africa Antimicrobial Coatings Market News#Middle East & Africa Antimicrobial Coatings Market growth

0 notes