#Mezzanine System

Explore tagged Tumblr posts

Text

India Warehouse Show 2024 Kicks Off Today: Visit Sigma Racks at Booth B25B

The much-anticipated India Warehouse Show 2024 starts today, bringing together industry leaders, innovators, and professionals from around the globe. This year's event, held at the prestigious Yashobhoomi ICCC in Dwarka, New Delhi, promises to be a hotspot for the latest advancements in warehouse and storage solutions. Sigma Racks is thrilled to be a part of this grand event, showcasing our cutting-edge products at Booth B25B from July 11-13.

Discover Sigma Racks' Innovative Storage Solutions

At Sigma Racks, we pride ourselves on offering state-of-the-art storage solutions tailored to meet the diverse needs of our clients. Here's a glimpse of what we have in store for you at the India Warehouse Show 2024:

1. Pallet Racking

Our Pallet Racking systems are designed for high-density storage and easy accessibility. They are ideal for warehouses that require efficient use of vertical space, allowing you to store large quantities of goods securely and systematically.

2. Drive-In/Drive-Through Pallet Rack

Maximize your storage capacity with our Drive-In/Drive-Through Pallet Racks. These systems are perfect for storing homogenous products in large quantities, providing a high-density storage solution that allows forklifts to enter the rack structure for loading and unloading.

3. Longspan Shelving

Longspan Shelving is versatile and easy to assemble, making it an excellent choice for storing a wide variety of items. Whether you need to store small parts or large, bulky items, our Longspan Shelving can be customized to suit your requirements.

4. Mezzanine System

Optimize your warehouse space with our Mezzanine Systems. These systems create additional floorspace within your existing warehouse, offering a cost-effective way to expand your storage capacity without the need for building extensions.

5. Cantilever Racks and Cable Tray Systems

Our Cantilever Racks are ideal for storing long, bulky items such as pipes, lumber, and steel bars. Coupled with our Cable Tray Systems, they provide a comprehensive solution for managing and organizing your inventory efficiently.

6. Skeleton Racks

Skeleton Racks are designed for heavy-duty storage needs. Their robust structure ensures durability and reliability, making them suitable for storing large and heavy items safely.

7. ASR Racking

Automated Storage and Retrieval (ASR) Racking systems are the future of warehouse management. These systems enhance productivity by automating the storage and retrieval process, reducing human error, and increasing operational efficiency.

8. Box Conveyor Systems

Streamline your warehouse operations with our Box Conveyor Systems. These systems facilitate the efficient movement of goods within your warehouse, improving workflow and reducing handling time.

9. Autonomous Mobile Robots (AMRs)

Our AMRs are designed to revolutionize your warehouse operations. These robots can navigate autonomously, transporting goods throughout your warehouse with precision and efficiency, thereby reducing labor costs and increasing productivity.

10. Carton Flow Racking

Carton Flow Racking is perfect for first-in, first-out (FIFO) inventory management. These systems use inclined shelves equipped with rollers, ensuring that products are always accessible and efficiently rotated.

11. Shuttle System Tray Building

Enhance your storage density and efficiency with our Shuttle System Tray Building. This automated system uses shuttles to move trays within the rack structure, optimizing space utilization and speeding up the storage and retrieval process.

Visit Us at Booth B25B

We invite you to visit Sigma Racks at Booth B25B during the India Warehouse Show 2024. Our team of experts will be on hand to demonstrate our innovative products and discuss how they can be tailored to meet your specific needs. Don’t miss this opportunity to explore the latest advancements in warehouse technology and network with industry leaders.

Join us from July 11-13 at Yashobhoomi ICCC, Dwarka, New Delhi, and see how Sigma Racks can transform your warehouse operations. We look forward to meeting you and exploring new opportunities together. See you at the show!

#warehousing racks#slotted angle racks#HDR#mezzanine system#pallet racking#cantilever racking system#racks#industrial racking#storage solutions

0 notes

Text

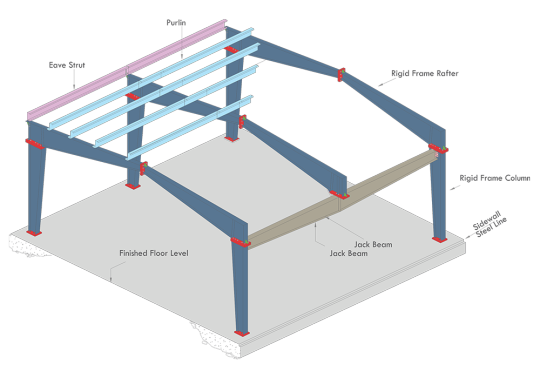

Smith Structure| Jack Beam Elevating Structural Support

Smith Structure introduces jack beams structural component used in construction for temporary or permanent support of floors, roofs, or load-bearing elements

#Jack Beam#Isometric Jack Beam at Sidewall#Isometric Jack Beam at Interior Column Location#Mezzanine System#mezzanine framing system#steel deck support#mezzanine beams#Mezzanine Plan#steel formwork#oncrete slab construction#Mezzanine Cross Section#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

Chemey is preferred Global Supplier of safety railing systems, Hard yet portable Barricades, fall protection solutions and safe access equipment for working at height.

#Chemey#Chemey Mechatronics#Chemey Mechatronics LLP#Industrial Solutions#Industrial Safety#Safety Solutions#Safety Products#Safety Equipments#Industrial Safety Solutions#Industrial Safety Products#Slip-On Fittings#Modular Guard Rail Solution#Tanker Access Platform#Aluminium Slip-On Fittings#Self-Closing Industrial Safety Gates#Osha Safety Gates#Rooftop Guardrails#Skylight Safety Cover#Tanker Truck Access Platform#Aluminium Industrial Floor Grating#Portable Work Platforms#Modular Safety Railing#Mezzanine Safety Barriers#Mobile Tanker Ladder#Self-Closing Safety Gates#Aluminum Structural Fittings#Mezzanine Pallet Gate#Modular Safety Rail Systems#Rooftop Walkway#Scaffold Mobile Tower

2 notes

·

View notes

Text

https://querykaro.com/maximize-vertical-space-how-mezzanine-racking-systems-transform-indian-warehouses-factories/

Wiremesh Cage Pallets – Secure & Versatile Storage for Indian Industries

Our Wiremesh Cage Pallets offer secure, ventilated, and stackable storage for loose parts, tools, and inventory. Used in automotive, pharmaceuticals, and logistics, these cages are rust-proof, durable, and forklift-compatible. Custom sizes and designs available—contact India’s trusted manufacturer!

0 notes

Text

Visit Sigma Racks at IWS 2025 – Booth C77, New Delhi

In a country where warehousing and logistics are growing at an unprecedented pace, events like the India Warehousing Show 2025 are becoming more than just exhibitions — they are becoming platforms where change can take place. Sigma Racks is proud to have been a part of this year's event.

Our company is thrilled to announce our participation in this historical event, which will take place at the India International Convention and Expo Centre (IICC) in Dwarka, New Delhi from June 26 to June 28. You can find us at Booth C77, where we'll be showcasing the newest innovations in industrial and warehouse shelving. Read full blog:- https://sigmastorage.com/blog/explore-the-future-of-storage-with-sigma-racks-at-iws-2025

#India Warehousing Show 2025#Sigma Racks Booth C77#Warehouse Racking Systems#Industrial Storage Racks#Mezzanine Floors#Heavy Duty Racks

1 note

·

View note

Text

Maximizing Space Efficiency with MEK STRUCTURAL ENGINEERING

As a trusted mezzanine floor manufacturer, MEK STRUCTURAL ENGINEERING specializes in designing and installing robust mezzanine systems. These structures not only enhance floor space but also provide an economical way to expand your operational area without the need for new construction. Read more at: https://shorturl.at/7UQZl

#Cantilever Racks Manufacturers and Suppliers#Storage System Designing Services#Industrial Storage Rack Solutions#Mezzanine Floor Manufacturer

0 notes

Text

#Mezzanine Floor Racking System supplier#Mezzanine Floor Racking System Manufacturer#Mezzanine Floor Racking System supplier in Pune#Mezzanine Floor Racking System Manufacturer in Pune#Mezzanine Floor Racking System supplier in Mumbai#Mezzanine Floor Racking System Manufacturer in Mumbai#Mezzanine Floor Racking System supplier in Nashik#Mezzanine Floor Racking System Manufacturer in Nashik#Mezzanine Floor Racking System supplier in Ahmednagar#Mezzanine Floor Racking System Manufacturer in Ahmednagar#Mezzanine Floor Racking System supplier in Gujarat#Mezzanine Floor Racking System Manufacturer in Gujarat#Mezzanine Floor Racking System supplier in Ahmedabad#Mezzanine Floor Racking System Manufacturer in Ahmedabad#Mezzanine Floor Racking System supplier in Delhi#Mezzanine Floor Racking System Manufacturer in Delhi#Mezzanine Floor Racking System supplier in Bengaluru#Mezzanine Floor Racking System Manufacturer in Bengaluru#Mezzanine Floor Racking System supplier in Karnataka#Mezzanine Floor Racking System Manufacturer in Karnataka#Mezzanine Floor Racking System supplier in Hyderabad#Mezzanine Floor Racking System Manufacturer in Hyderabad#Mezzanine Floor Racking System supplier in Chennai#Mezzanine Floor Racking System Manufacturer in Chennai#Mezzanine Floor Racking System supplier in Kolkata#Mezzanine Floor Racking System Manufacturer in Kolkata#Mezzanine Floor Racking System supplier in Indore#Mezzanine Floor Racking System Manufacturer in Indore

0 notes

Text

#warehouses#industrial storage racks in noida#industrial racks for warehouses#metalstorage#drive-in racking system#business#slotted angle racks manufacturers#modular mezzanine floor in pune#mezzanine floor structure manufacturers#driveinracking

0 notes

Text

How to Choose the Right Mezzanine Floor Installers for Your Warehouse

Choosing the right mezzanine floor installers for a warehouse is a critical decision that can significantly influence the efficiency and functionality of the space. A mezzanine can maximize storage capacity, create additional office space, or facilitate better workflow. However, the success of these benefits hinges on the quality of the installation. Thus, understanding the key factors that contribute to selecting the right professionals for the job is essential for warehouse managers and business owners alike.

Understanding Your Warehouse Needs

Before diving into the selection process, it is important to assess the specific needs of the warehouse. Each facility has unique characteristics that must be considered. For instance, the height of the existing structure, the weight capacity required, and the purpose of the mezzanine all play crucial roles in determining the best type of installation. Warehouse managers should conduct a thorough analysis of the space, taking measurements and identifying potential obstacles that could hinder installation.

After identifying these needs, it becomes essential to look for mezzanine floor installers who have experience in handling similar projects. A contractor with a proven track record in the specific type of mezzanine required will be better equipped to navigate challenges that may arise during the installation process. This is where research comes into play. Reading reviews, asking for references, and checking the installers’ previous work can provide insight into their reliability and quality of service.

Evaluating Installer Qualifications and Experience

When it comes to hiring mezzanine floor installers, qualifications and experience should be at the forefront of the selection criteria. It is advisable to look for installers who are certified and adhere to industry standards. This not only ensures compliance with safety regulations but also reflects a commitment to quality workmanship. Experienced installers will bring a wealth of knowledge to the project, capable of anticipating challenges and offering solutions that a less experienced contractor might overlook.

Moreover, the installation process should be handled by professionals familiar with the specific materials and technologies involved in mezzanine construction. An installer with a diversified portfolio that includes various types of mezzanine systems will likely have the expertise necessary to address the unique demands of each project. This breadth of experience can be the difference between a successful installation and one that leads to costly mistakes.

Importance of Customization and Design

One of the key advantages of mezzanine flooring is the ability to customize the design to fit the specific needs of the warehouse. This means that the mezzanine floor installers should not only be skilled in construction but also in design. They should work collaboratively with the warehouse management team to create a structure that maximizes space efficiency while aligning with operational workflows.

A good installer will offer a range of design options and be willing to adapt to changes in layout or function as required. They should also understand the importance of integrating the mezzanine with existing systems, such as lighting, HVAC, and fire safety measures. This holistic approach to design ensures that the new mezzanine floor not only fits within the warehouse but enhances its overall functionality.

Safety and Compliance Considerations

Safety is paramount in any construction project, especially in a busy warehouse environment. The chosen mezzanine floor installers must prioritize safety measures throughout the installation process. This includes ensuring that all materials used are up to code and suitable for the intended use of the mezzanine. Additionally, the installation team should follow strict safety protocols to protect both their workers and the warehouse staff during construction.

Moreover, compliance with local building codes and regulations cannot be overlooked. A reputable installer will be familiar with the necessary permits and inspections required to complete the installation legally. This not only helps avoid fines and project delays but also ensures that the newly installed mezzanine will pass all safety inspections, providing peace of mind for warehouse operators.

Post-Installation Support and Maintenance

The relationship with the mezzanine floor installers should not end once the project is completed. A reliable contractor will offer post-installation support and maintenance services to ensure the longevity of the mezzanine structure. Regular inspections and maintenance checks can help identify any potential issues before they escalate into costly repairs.

Furthermore, some installers may provide warranties on their work, which can be an essential factor in the decision-making process. This warranty serves as a safeguard against defects or problems that may arise after the installation. A commitment to ongoing support can significantly enhance the overall value of the investment in the mezzanine floor.

Conclusion

Selecting the right mezzanine floor installers for a warehouse is a multifaceted process that requires careful consideration of various factors, including the specific needs of the facility, the qualifications and experience of the installers, customization options, safety compliance, and post-installation support. By taking the time to evaluate these elements, warehouse managers can ensure they choose a contractor who will deliver a high-quality, functional mezzanine that enhances their operational efficiency.

For businesses looking for expert guidance and top-notch installation services, partnering with a reputable company like Dalvie Systems can provide the assurance needed for a successful mezzanine project. Their commitment to quality and customer satisfaction makes them an ideal choice for any warehouse needing mezzanine floor installation.

0 notes

Text

Industrial Warehouse Racking Columbus OH

Industrial Warehouse Racking: The Backbone of Efficient Storage Solutions

Industrial Warehouse Racking Columbus OH play a critical role in modern logistics and storage operations. Designed to maximize space, improve organization, and streamline operations, these systems are essential for businesses handling large volumes of inventory. From retail warehouses to manufacturing facilities, racking solutions ensure optimal storage efficiency while prioritizing safety and accessibility.

What is Industrial Warehouse Racking?

Warehouse racking refers to the structured storage system used to stack materials and products in a warehouse. These systems typically consist of metal frameworks with multiple levels of shelves, allowing businesses to make the most of vertical space. They are designed to accommodate heavy loads while ensuring durability, flexibility, and accessibility.

Different industries employ a variety of racking systems, each tailored to specific storage needs. Choosing the right type of racking depends on factors like the size and weight of inventory, warehouse dimensions, and operational requirements.

Types of Warehouse Racking Systems

Selective Racking:

The most common and straightforward type, selective racking provides direct access to every pallet. This system is ideal for warehouses handling a variety of products with a high turnover rate. It’s versatile and cost-effective but may require more floor space.

Drive-In and Drive-Through Racking:

Designed for high-density storage, these systems allow forklifts to drive into the racking structure to place or retrieve pallets. Drive-in systems have one access point, while drive-through racking allows access from both ends, improving efficiency for warehouses with large quantities of similar items.

Pallet Flow Racking:

A dynamic solution, pallet flow racking uses inclined rollers to move pallets automatically from one end to the other. This system is ideal for first-in, first-out (FIFO) inventory management, commonly used in industries like food and beverage.

Cantilever Racking:

Perfect for long or bulky items like pipes, lumber, or steel, cantilever racking features horizontal arms extending from a single vertical column. Its open design ensures easy storage and retrieval of oversized products.

Push-Back Racking:

This high-density system allows pallets to be stored on carts that slide backward along inclined rails. Push-back racking is ideal for last-in, first-out (LIFO) inventory systems, optimizing space for products with low rotation.

Benefits of Warehouse Racking

Maximized Space: Racking systems utilize vertical space, freeing up floor space for other operations.

Improved Efficiency: Organized racking reduces the time required to locate and retrieve items.

Enhanced Safety: Durable materials and secure structures minimize risks in the warehouse environment.

Scalability: Modular designs make racking systems easy to expand or reconfigure as storage needs grow.

Conclusion

Industrial Warehouse Racking Columbus OH are indispensable in today’s fast-paced supply chain environment. By optimizing space, improving inventory management, and enhancing operational efficiency, these systems enable businesses to meet the demands of a competitive market. Investing in the right racking solution is not just a choice—it’s a necessity for streamlined and safe warehouse operations.

#pallet rack warehouse & supply#warehouse mezzanine systems cincinnati ohio#Industrial Warehouse Racking cincinnati ohio

0 notes

Text

Efficient Warehouse Storage Solutions for Supermarkets & Food Processing Equipment - Global Automation Ltd

Discover essential warehouse storage strategies, including pallet racking systems, mezzanine floors, and temperature-controlled storage. Optimize space and maintain product quality in supermarkets and food processing with Global Automation Ltd’s tailored solutions.

#Warehouse storage solutions#Pallet racking systems#Mezzanine floors warehouse#Temperature-controlled storage#Warehouse shelving systems#Supermarket storage strategies#Food processing equipment storage#Commercial refrigeration solutions#Inventory management software#Optimizing warehouse space

0 notes

Text

The Benefits of Investing in MS Slotted Angle Racks

Looking for reliable and versatile storage solutions? Discover the benefits of MS Slotted Angle Rack Manufacturers

Why Choose MS Slotted Angle Racks?

Customizable Design: Tailor the size and layout to fit your specific needs, whether for offices, warehouses, or retail spaces.

High Load Capacity: With load capacities ranging from 50 kg to over 400 kg per layer, these racks can handle heavy items efficiently.

Durable Material: Made from high-grade mild steel, these racks are built to last and withstand rough usage.

Versatile Applications: Ideal for storing tools, equipment, and supplies, they are perfect for various settings including industrial, commercial, and residential.

Easy Assembly: Designed for quick and straightforward assembly, making them user-friendly for all.

Key Features

Adjustable Shelves: Easily modify the height and number of shelves to accommodate different items.

Corrosion Resistance: Many manufacturers offer paint-coated or powder-coated finishes to enhance durability and aesthetics.

Space Efficient: Helps maximize storage space while keeping your environment organized.

Leading Manufacturers

Rolex India Engineering: Offers customizable racks with a load capacity of up to 100 kg per layer, perfect for office use.

Neelkamal Steel: Known for their six-shelf racks, designed for heavy-duty storage in warehouses.

Jaashvi Storage Solutions: Provides a range of display and storage racks, ensuring high quality and reliability.

Metal Storage Rack: Specializes in mobile shelving systems with a capacity of up to 1000 kg per layer.

Conclusion

Investing in MS Slotted Angle Racks is a smart choice for anyone looking to enhance their storage solutions. With their durability, customization options, and high load capacities, these racks are designed to meet diverse storage needs.Contact leading manufacturers today to find the perfect MS Slotted Angle Rack for your space!

#Mezzanine Floor Manufacturers#Fabric Storage Rack Manufacturers#Industrial Plastic Pallet Manufacturers#Storage Rack Manufacturers#Mobile Compactor Storage System Manufacturers#Storage Systems Manufacturers#Slotted Angle Racks Manufacturers#MS Slotted Angle Rack Manufacturers#Slotted Angle Storage Rack Manufacturers#Supermarket Display Rack Manufacturers#Mobile Compactor Manufacturers#Grocery Display Rack Manufacturers

0 notes

Text

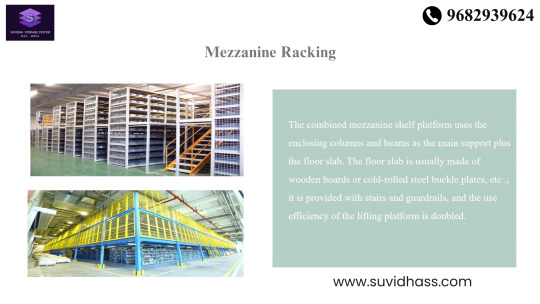

Mezzanine Racking | Efficient Storage Solutions - Suvidha Storage System | Premier Rack Manufacturer

Suvidha Storage System's Mezzanine Racking provides a practical and efficient solution for expanding storage capacity. As a top storage rack manufacturer in India, we are dedicated to delivering quality and innovation. Visit us at suvidhass.com for more information.

#suvidha storage system#High-Density Storage#Efficient Storage Solutions#Double Decker Mezzanine#Custom Racking Solutions#Top Storage Rack Manufacturer#Industrial Storage Rack#Warehouse Storage Rack#Storage Rack System#Heavy Duty Storage Rack#Rack Manufacturer

0 notes

Text

How Pallet Racking Systems Streamline Warehouse Logistics for Success?

Discover the game-changer in warehouse logistics: Pallet Racking Systems. Our latest blog delves into how these systems optimize storage, streamline operations, and boost productivity. Learn about the different types, benefits, and key considerations for implementation. Whether you're a logistics pro or a business owner, mastering pallet racking systems is crucial for success. Elevate your warehouse management with insights on maximizing space and enhancing efficiency. Stay ahead of the curve and unlock the potential of pallet racking systems to drive your business toward unparalleled success. Read now for expert tips and strategies in warehouse logistics.

#Indoff Canada#Roll Out Racks#roll out pallet ontario#industrial storage units#pallet racking#sheet metal rack#cantilever racking systems#cantilever metal racks#industrial racking systems#industrial shelving canada#mezzanines

0 notes

Text

Why Mezzanine Floors Are a Smart Way to Expand Warehouse Storage?

Modern warehouses are constantly under pressure to store more — but expanding physical space isn’t always an option. That’s where Mezzanine Floors come in as a smart, efficient solution.

Mezzanine systems allow businesses to make use of unused vertical height in their facilities. Instead of renting additional storage space or constructing new buildings, companies can add an extra level within the same footprint. This upper level can be used for storing inventory, packaging operations, or even light office setups.

Because Mezzanine Floors are modular, they can be custom-fitted to existing layouts and future storage needs. They’re also scalable — meaning as operations grow, so can the mezzanine structure. Many setups are designed using durable steel frames and grating, offering both strength and flexibility.

Whether it’s an industrial plant, e-commerce hub, or distribution center, mezzanines offer an ideal balance of space optimization and cost-efficiency. With minimal disruption during installation, they’re a fast, practical upgrade for growing businesses.

For businesses looking to maximize space without expanding their footprint, mezzanine flooring is a solution worth considering.

#industrial racking systems#mezzanine racking system#mezzanine floor systems#mezzanine floor warehouse system#heavy duty racks#industrial racking#mezzanine floor design#mezzanine warehouse system

1 note

·

View note

Text

Mezzanine Floors: A Comprehensive Guide by Addmore International

Optimising industrial and commercial spaces is of utmost importance for businesses that thrive. One space solution that stands out for its versatility and efficiency is mezzanine floors – which Addmore International UAE Sharjah explores through this comprehensive guide.

Understand Mezzanine Floors

Mezzanine Floors: A Brief Overview:

At Addmore International, we recognize that mezzanine floors present an undiscovered resource in space utilisation. A mezzanine serves an intermediary level between the main floors of a building, creating an additional platform. It empower businesses to maximise vertical space without incurring extensive construction costs.

Types of Mezzanine Floors

Our experts at Addmore International specialise in crafting diverse mezzanine floor designs. Whether your requirements involve additional storage, office space, or a showroom expansion, our team can customise the floor type to meet your specific needs. Prioritising the alignment of solutions with your business goals, we address structural considerations and incorporate aesthetic elements to deliver tailored results.

Advantages of Choosing Mezzanine Floors

Space Optimization and Expansion

We understand the importance of seamless expansion, and our mezzanine-floor solutions reflect this commitment.

Economical Solutions

Our clients frequently remark on how affordable mezzanine levels are. An cheap and expedient alternative to conventional construction procedures is the installation of a mezzanine level.

Mezzanine Floors in Action: Real-Life Applications

Warehouses and Industrial Spaces

Mezzanine floors play an indispensable part in Sharjah’s bustling industrial sector, where efficient storage solutions are paramount.

Retail locations and office spaces

Mezzanine floors can add value in both office environments and retail settings, providing valuable workspaces.

Conclusion: Elevate Your Space with Mezzanine Floors

In the bustling business landscape of Sharjah, maximising space efficiency becomes a strategic imperative. Addmore International UAE, Sharjah, provides mezzanine floors that serve as the key to unlocking untapped potential in your existing space. We design cost-effective and innovative, aiming to lift your business to new heights.

#Dismantling#Relocation and Re fixing of racking system in uae#Shelving and Storage Suppliers Sharjah#Warehouse Racking Accessories dubai#Mezzanine Floors Suppliers dubai

0 notes