#drive in racking system design

Explore tagged Tumblr posts

Text

How to Choose the Right Mezzanine Floor Installers for Your Warehouse

Choosing the right mezzanine floor installers for a warehouse is a critical decision that can significantly influence the efficiency and functionality of the space. A mezzanine can maximize storage capacity, create additional office space, or facilitate better workflow. However, the success of these benefits hinges on the quality of the installation. Thus, understanding the key factors that contribute to selecting the right professionals for the job is essential for warehouse managers and business owners alike.

Understanding Your Warehouse Needs

Before diving into the selection process, it is important to assess the specific needs of the warehouse. Each facility has unique characteristics that must be considered. For instance, the height of the existing structure, the weight capacity required, and the purpose of the mezzanine all play crucial roles in determining the best type of installation. Warehouse managers should conduct a thorough analysis of the space, taking measurements and identifying potential obstacles that could hinder installation.

After identifying these needs, it becomes essential to look for mezzanine floor installers who have experience in handling similar projects. A contractor with a proven track record in the specific type of mezzanine required will be better equipped to navigate challenges that may arise during the installation process. This is where research comes into play. Reading reviews, asking for references, and checking the installers’ previous work can provide insight into their reliability and quality of service.

Evaluating Installer Qualifications and Experience

When it comes to hiring mezzanine floor installers, qualifications and experience should be at the forefront of the selection criteria. It is advisable to look for installers who are certified and adhere to industry standards. This not only ensures compliance with safety regulations but also reflects a commitment to quality workmanship. Experienced installers will bring a wealth of knowledge to the project, capable of anticipating challenges and offering solutions that a less experienced contractor might overlook.

Moreover, the installation process should be handled by professionals familiar with the specific materials and technologies involved in mezzanine construction. An installer with a diversified portfolio that includes various types of mezzanine systems will likely have the expertise necessary to address the unique demands of each project. This breadth of experience can be the difference between a successful installation and one that leads to costly mistakes.

Importance of Customization and Design

One of the key advantages of mezzanine flooring is the ability to customize the design to fit the specific needs of the warehouse. This means that the mezzanine floor installers should not only be skilled in construction but also in design. They should work collaboratively with the warehouse management team to create a structure that maximizes space efficiency while aligning with operational workflows.

A good installer will offer a range of design options and be willing to adapt to changes in layout or function as required. They should also understand the importance of integrating the mezzanine with existing systems, such as lighting, HVAC, and fire safety measures. This holistic approach to design ensures that the new mezzanine floor not only fits within the warehouse but enhances its overall functionality.

Safety and Compliance Considerations

Safety is paramount in any construction project, especially in a busy warehouse environment. The chosen mezzanine floor installers must prioritize safety measures throughout the installation process. This includes ensuring that all materials used are up to code and suitable for the intended use of the mezzanine. Additionally, the installation team should follow strict safety protocols to protect both their workers and the warehouse staff during construction.

Moreover, compliance with local building codes and regulations cannot be overlooked. A reputable installer will be familiar with the necessary permits and inspections required to complete the installation legally. This not only helps avoid fines and project delays but also ensures that the newly installed mezzanine will pass all safety inspections, providing peace of mind for warehouse operators.

Post-Installation Support and Maintenance

The relationship with the mezzanine floor installers should not end once the project is completed. A reliable contractor will offer post-installation support and maintenance services to ensure the longevity of the mezzanine structure. Regular inspections and maintenance checks can help identify any potential issues before they escalate into costly repairs.

Furthermore, some installers may provide warranties on their work, which can be an essential factor in the decision-making process. This warranty serves as a safeguard against defects or problems that may arise after the installation. A commitment to ongoing support can significantly enhance the overall value of the investment in the mezzanine floor.

Conclusion

Selecting the right mezzanine floor installers for a warehouse is a multifaceted process that requires careful consideration of various factors, including the specific needs of the facility, the qualifications and experience of the installers, customization options, safety compliance, and post-installation support. By taking the time to evaluate these elements, warehouse managers can ensure they choose a contractor who will deliver a high-quality, functional mezzanine that enhances their operational efficiency.

For businesses looking for expert guidance and top-notch installation services, partnering with a reputable company like Dalvie Systems can provide the assurance needed for a successful mezzanine project. Their commitment to quality and customer satisfaction makes them an ideal choice for any warehouse needing mezzanine floor installation.

0 notes

Text

#Drive-In Pallet Racking is installed in warehouses and distribution centers that need a cost effective#high density storage solution for their products.Drive-in systems can be designed to store 2 to 10 pallets deep per lane. Because of its de#drive-in pallet rack is a first in#last out (FILO) storage system.

0 notes

Text

Compactor Storage Systems Manufacturer In Pune – Max Space

Max Space Racking Systems is a leading compactor storage systems manufacturer in Pune. Explore our space-saving solutions for efficient storage. In a world where efficient storage solutions are paramount, Max Space Racking Systems emerges as a trusted compactor storage systems manufacturer in Pune, India. Compactor storage systems are a vital component of modern storage solutions. They offer a space-saving and highly organized way to store a wide range of items, from documents and files to goods in warehouses and distribution centers.

#Compactor Storage Systems Manufacturer in Pune#Design & Manufacturing Of Racking System in Pune#Vertical Carousels Manufacturer in Pune#vertically stacked trays or shelves in Pune#Pallet Shuttle Systems Manufacturer in Pune#Selective Pallet Racks Manufacturer in Pune#Drive-in Racks Manufacturer in Pune#Multi Tier Racks Manufacturer in Pune#Shelving Racks Manufacturer#FIFO Racks Manufacturer#Cantilever#Racks Manufacturer#Racks for Bobbin / Rolls Manufacturer

0 notes

Text

Kabr0z Writes Episode 143: Your Thargoid girlfriend

Find the rest of the Kabr0z Writes anthology here!

Ao3!

CWs: Oral sex; oviposition; inflation; excessive fluids; overstim; enthusiastic consent

A/N: This one actually was requested, but the person who requested it used the wrong @ in the ask, then named themselves when they asked for it again as anon!

Either way, the request was for wlw alien breeding, and frankly that's hot. Enjoy!

################################

The landing gear gave a satisfying thunk as it hit the asteroid. A combination of microgravity and force-effect would keep you anchored to the rock while you relaxed for the night shift. Don’t fly drunk or tired, they’re the golden rules, and when you’re travelling by frameshift drive you don’t want to take risks. You’d seen what happens to pilots when they don’t pull back fast enough after materialising in a system. Never pretty.

Sighing, you stood up. You always get morbid after flying too long. Besides, it’s date night and you’d been able to smell dinner for an hour now. You pressed your hand to the door release and stepped into the galley-cum-bedroom. For the sheer bulk of a type-9, it’s almost all compartment space, dedicated for cargo racks or other such hardware. You’d heard of people turning these vessels into miners, but you’re not sure you’d want to chance that. You’re relatively safe hauling seven hundred units of euphemistically named “fertiliser” from the bubble to Colonia, no pirate would even bother taking the time to interdict you for a handful of credits worth of shit. A cargo hold full of bauxite? That’s a different story, and a type-9 isn’t exactly built for speed or defence.

There you go again, pontificating on the merits of starship design. You unclipped your helmet and opened your flightsuit, taking a seat on the bed while you watched Tilly cook. Her name, of course, wasn’t Tilly. What it was was completely unpronounceable to humans, so she just let you call her Tilly. You smiled, watching her arthopoid body as she worked; thin waisted, many-legged, mantis-armed. If you’d told yourself even a year ago that not only was peace with the Thargoids achievable, but you’d be fucking one on the regular, you wouldn’t have believed it. But there you were, sat on the bed you shared, on the ship where you both lived, watching her prepare a meal for you both.

She put dinner in the oven, such as it was, and set a timer before turning to you. Some people would find her insectile face hard to read, somewhere between a mantid and a grasshopper, bulbous compound eyes and clattering mandibles, but you knew she was smiling at you.

“About half an hour until dinner, babe” a voice synthesiser was stuck to her neck, chiming out her carefully curated voice

“What would you like to do in the meantime?” You knew what she wanted to do. You could feel her gaze on the skintight kevlar suit, unzipped to your belly button, almost, but not quite, allowing your tits to spill out. You lounged on the bed, making sure she could see as much of you as possible.

Your pulse raced. Having a hyper-specialised apex predator scurry towards you at mach-Jesus is enough to make anyone flinch, but you knew precisely what she had in store for you. She stripped the flightsuit off you, manhandling your limbs as she peeled you from your armoured gear before tossing you, naked and glistening back onto the bed. She parted your legs, diving for her prize.

Thargoid mandibles are remarkably dextrous, as you’d discovered. You lay back, letting her barbed limbs hold your knees apart as her mouthparts chittered and buzzed against you. A snaking proboscis slid inside you, flexible and wriggling as it penetrated your snatch. You bit your lip as you grabbed at the bedsheets, the wriggling appendage in you making your hips buck and roll against her face. Your breath quickened as you crested your first orgasm, then your second, then the third. You were a panting gasping mess by the time she pulled her face away from your crotch.

She wasn’t done yet.

She loomed over you, pinning your arms to the bed, forcing your legs apart. You felt her rubbing her abdomen against you. Your body twitched as your aching clit reacted to her, waves of stimulation making you groan and whine. You couldn’t move, couldn’t speak. All you could do was lie there and accept her as she dragged her body on your stinging, sensitive cunt.

The look on her face changed as it emerged. The long, thick modified stinger reaching from a slot in her abdomen. She was careful, pressing it gently into you. Your groans got louder as the tip parted your lips. She stretched you slowly, still holding on to you as she pushed inside. Her voice module was streaming gibberish, a lullaby of inarticulate vowels as your weary hole twitched and flexed around her. Every move, every push was getting her closer.

You pushed your hips up, pressing her in as far as she could go, her tip kissing your cervix as her whole body pumped. She held for a moment, before you felt the first one. The egg slid slowly down her shaft, thick lubricating fluid pushed out ahead of it. You felt it pressing against you, before plopping into your womb. Your mouth gaped, the first one always hurt a bit as it forced its way inside, soft and jelly-like, settling inside you. The next was easier. You still gasped as it slid past your cervix, another foreign object, pressing outwards. More followed, each one accompanied by another gasp and another wave of pleasure before settling with a comforting fullness.

She laid twelve eggs in you. You lay on the bed, a hand on your distended belly. You felt heavy; too exhausted to move, too full to try. Your cunt leaked the lubricant onto the floor where it pooled in a slick, jelly-like heap. Somewhere in your cloudy, fucked-out mind you heard the oven beep. Dinner was ready.

Tilly gave you a hand up, guiding you to the table where she laid a bowl in front of you. You ate together, both blushing and still a little breathless. You could still feel the eggs buried inside you by the time you went to bed, gently melting in the warmth of your belly, turning to a thick slime that drooled out of you.

Damn, you love date night

#textposts#original content#send asks#kabr0z writes#fem!reader#monster smut#monster fucker#monster fuqqer#monster x fem!reader#monster x human#monster x monster#monster girl#monster x you#monster x female#monster x reader#monster lover#cw oviposition#ovi kink#ovipositor#egg laying#wlw smut#plotless smut#smut with feelings#smut with a happy ending#cw oral sex#cw interspecies#excessive fluids#inflati0n#inflated belly#thargoid x human

56 notes

·

View notes

Text

Officer ARES (Auxiliary Robotic Education System) by 21st Century Robotics, Monroe, GA (1984). "Designed as an entertainment robot. The local county sheriff, … used it as an educational tool for the DARE program. The body is made of fiberglass, and the internal gear includes a remote control system, a video camera, a monitor, 8 track, cassette, radio, amplifier, relay control rack, VHS player and a remote intercom. The robotic linkages include one movable arm, rotating head, dual motor drive system."

37 notes

·

View notes

Text

Sasha here!

CW here for references to hypnosis;

With the recent vibe of robot girls being The Thing on here lately I thought it might be fun to share a related thing of mine that's been an ongoing project for a while. While I have not had the drive or capacity to really work on new updates for it for a long while (I just kinda came out of a bit of a dormancy which does not help), this project was the collision between my enjoyment of machine/robot/pet play, hypno stuff, and a l o v e for prop making that we don't get to indulge nearly enough.

The goal with this was to make something that looked like it was plucked straight out of its universe and plopped into ours, and while not perfect, I'm proud of the work that went into it. It's intended to carry the vibe of an old software manual binder, but in a retro future sorta way.

The other goal was "Imagine if a robot girl had a manual to mess with her firmware" because let's not dance around that.

Please note that within the context of this project, where "System" appears, is meant to convey "operating system," as this project was conceived prior to RealisationsTM

Presenting the Firmware Operator's Manual

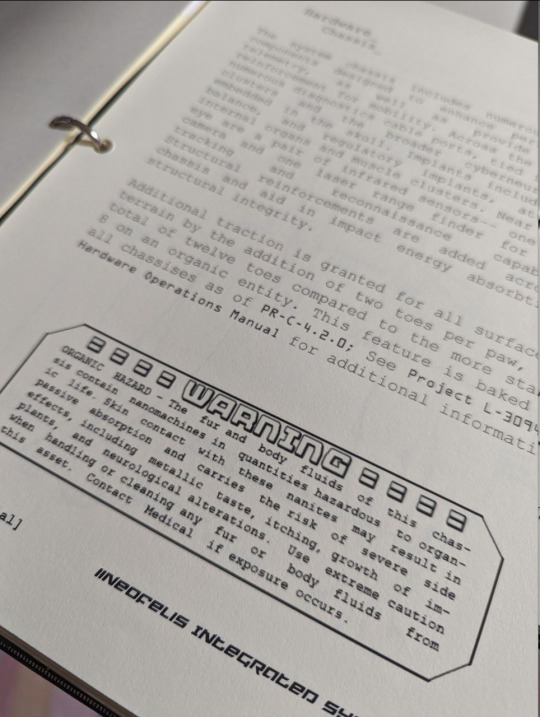

Neofelis Integrated Systems is imagined to be a prominent industry leader in the electronics integration and cybernetics field, that is rumored to dabble in biosynthetics and synthetic intelligence development, but these rumors are unsubstantiated outside of the company. In reality they're a Bit Fucked beneath the surface.

Opening the cover, numerous post-its are scattered on the interior, to help sell the idea that this manual existed in a real working environment. An extra LOTO tag is included in the manual, Just In CaseTM

The interior title page mirrors the outer cover, but with some additional information. Numerous pages within this project are also dotted with UV reactive EUrion constellations to depict anti-duplication measures.

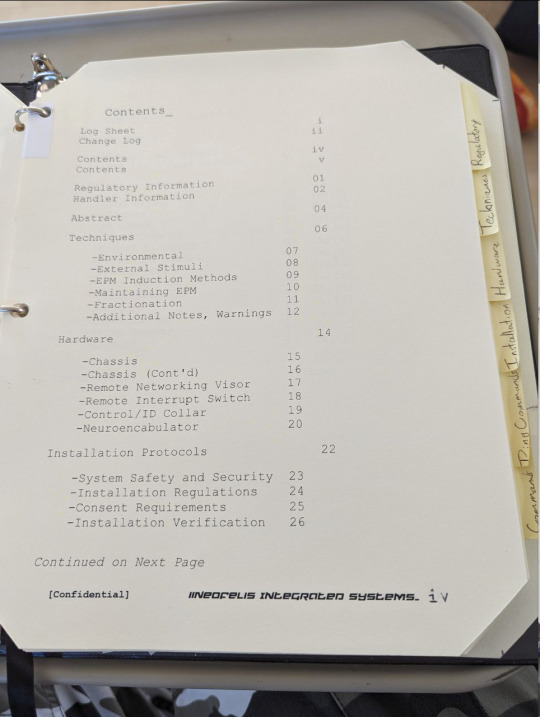

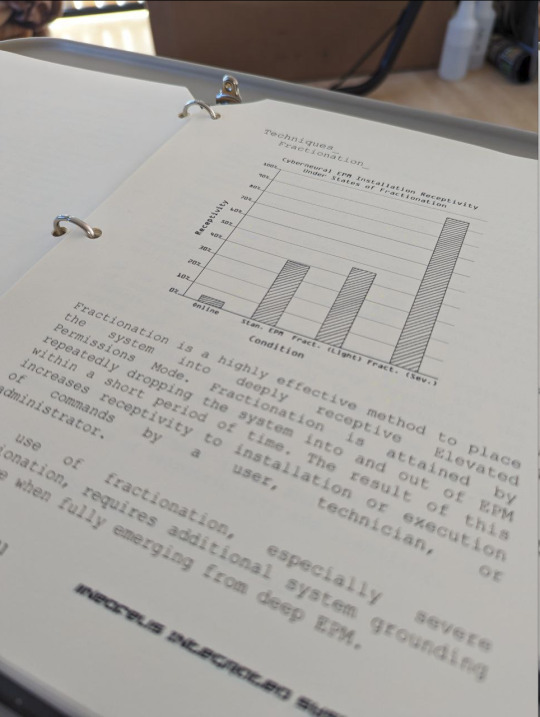

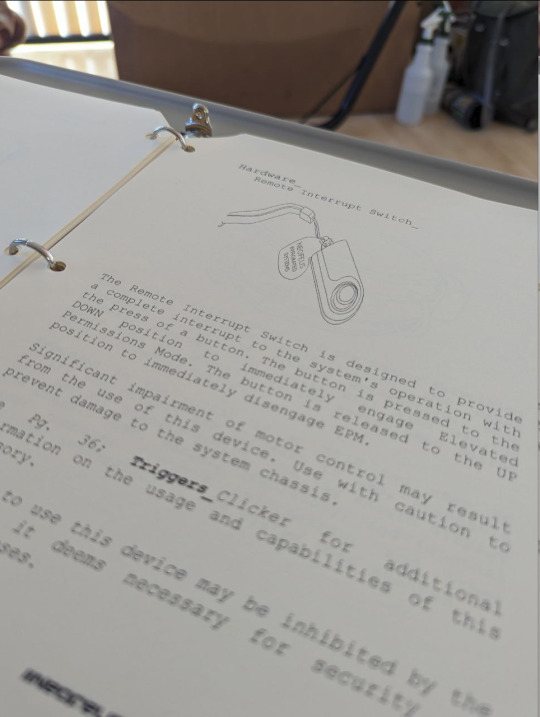

Contents 1/2. The second half won't be shown here because Reasons. EPM here refers to Elevated Permissions Mode -wiggle eyebrows-

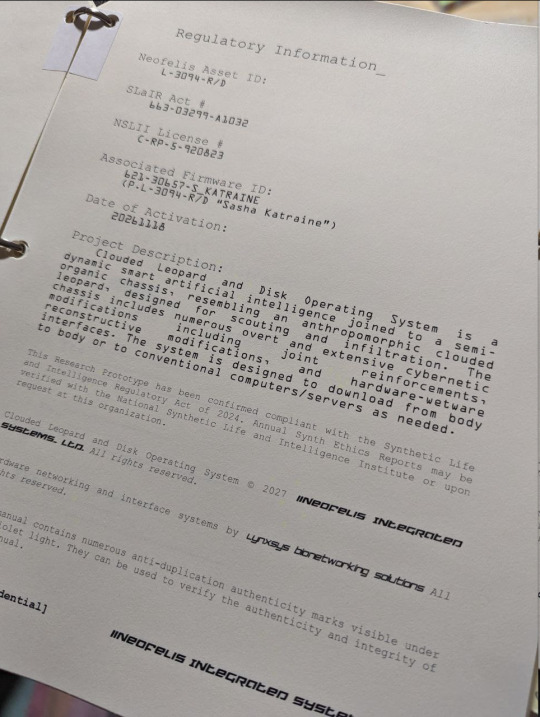

You can't just design and construct synth prototypes without proper regulation. That just won't do. Everything is definitely above board here.

These pages are just such a vibe. I can't help but add them between sections.

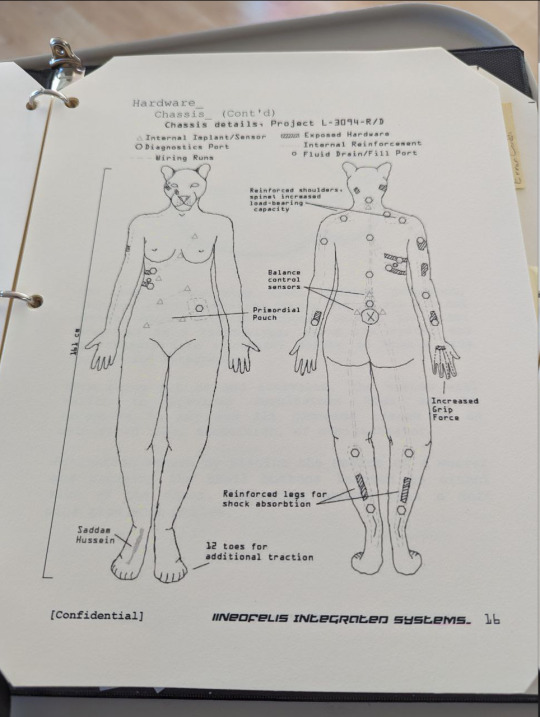

There are a few graphics that were made and sprinkled into this project to really fuel the software manual vibe. The chassis diagram in the print copy is now out of date, slightly. Also, never miss an opportunity to hide memes in a creative kink project. We like easter eggs.

Beyond this there's complete sections regarding ethics and safety (some of which is genuinely important SSC/RACK info, because that's important), and the sections containing various hypno commands, which will not be shared openly for obvious reasons. There's also the Error Codes page at the back, full of error codes I really have not bothered to memorise admittedly.

Anyways, that's all to share. Questions are encouraged though!

329 notes

·

View notes

Text

'I fixed it'

Ulfric stared at the hodgepodge of taped wires and jerry-rigged mechanical parts with a critical eye. It sort of looked like it would work? It gets a bit fuzzy in the middle, but his gut told him 'maybe' with a positive inflection.

He wanted to spit at the whole thing. To swear at it and curse the designer of the damned thing. The human didn't like how his work had turned out; it wasn't pretty nor, was he confident he'd done everything right. Theoretically the engine would come back to life if he understood how it all worked.

Problem was he didn't though. This was all alien tech; everything was alien tech! Human stuff was always behind! But even alien tech was supposed to comply with physics, so he did what he thought was right.

The ship he was on was supposed to be a 'simple' 'off the rack' skiff ship that could make it from one planet to another in less than a day. Not only had the jump drive catapulted him and his fellow passenger way past their target, but they were also floating alarmingly fast away from the system.

Sure, it had emergency beacons and SOS systems, it advertised that 'everyone found was saved' with its life preservation tech.

"Found." Ulfric stated with sarcasm. "Everyone found..."

If they weren't found, then sure, this shit craft's designer could keep saying that.

"How is it looking?" Asked a delicate voice from the cockpit.

The hornless taurian, who called himself; Yasil, appeared in the doorway, holding himself against the frame. Ulfric avoided the odd creature's gaze. Ulfric had been a rough man before the Earth 'thing', but now he was stuck in close proximity to this... delicate alien guy... 'Focus on the engine Ulfric', his mind supplied.

"Well. I think it might work, we have enough conventional fuel to turn up back the way we came, then we can try and jump." Ulfric said, scratching at the back of his scalp. He didn't know about male taurians and their demeanour, so once they were introduced to one another, the alien wasn't what he was expecting.

When Ulfric saw a bull coming towards him, horns or no horns, the human had thought he was going to be sharing with a man who could shoot the shit, but instead, every attempt to connect with the usual conversation points had fallen flat.

So, bored as he was, Ulfric changed tactics. They were stuck like this for at least a day, the human wasn't going to spend that silent.

Ulfric was rough, but he wasn't without a little game.

He turned on the charm.

An hour into their journey he'd turned the attempts at idle conversation into discussions on a far less superficial level. He didn't have a set plan or 'topic' it was simply a matter of listening out for what someone reacted to, what they wanted to or enjoyed talking about, if they wanted to talk at all.

Thankfully, it seemed the bull wanted to talk, and the topic was him. Or rather Humans.

Ulfric wasn't opposed to talking about humans, but he hated talking about himself. So, he answered the alien's questions, at least until the cockpit readouts went dead anyway.

They both had watched as the two of them fell out of a structured jump into 'real' space. They then had watched helplessly as their target planet sailed happily by while they travelled near close to light speed through the system. They got 'lucky' by not having anything in front of them while traveling this way.

By the time Ulfric had gotten through the sealed door into what amounted to an engine room, and then figured out which bit had done what, they were too far away for the general communications array to be of any use. Still, at least Ulfric could be useful now, well... either useful or both of them would be lost to the void forever.

What followed was multiple hours of swearing, sweat and the breaking of several noncritical machines and furniture to fix the busted, stupid, ridiculously crappily built engine.

The human created something akin to art. Only not.

His new engine was the opposite to art.

It was a monster, and he was the new Frankenstein.

Using the attitude adjustors, Ulfric changed their yaw and roll. They pointed at the slowly shrinking planet they wanted, or roughly where it was going to be in the near future.

"What now?" Asked the bull, nervous in tone, but hopeful as he looked longingly at the human.

"Now. I kick start this mother." Ulfric said, getting up from his seat and readying his kickstart. "You holding onto the controls? Like I showed you? This is going to shake and judder something rotten."

"I got it." The taurian announced with a nod and a firm grip of the controls.

With a nod, Ulfric, with everything he had. With every ounce of hatred he had for this machine; he kicked the engine as hard as he could.

--- 0 ---

Ulfric stood in front of the spaceport's lead engineer. An ursidain covered in grease and other stains kept glancing from him, back to the craft that she had just appeared from. His craft, at least his engine anyway.

She was currently staring at his monster with a flabbergasted expression and kept glancing back at him before returning to the engine.

"You should be dead." She stated firmly.

"Well I'm not, I need to know why it failed so we can sue!" Shouted the shorter bull beside him. Choosing to ignore the fact the larger ursidain was speaking to the human. He wasn't a large taurian, nor did the young bull come across as an aggressive sort, but god help the poor soul that stood between him and justice. Ulfric never cared much for causing a scene, but the taurian had assured him that if they could remain in contact, justice would be had! Oh sure, they might get a few credits, but if they prevented the company from doing this again; they'd save lives!

Ulfric didn't mind either of those outcomes and he was starting to like the little taurian. All that pomp and show was just that, a show. He had a mouth on him!

"No I mean; this isn't possible! It shouldn't have worked! You've combined. plasma and pure oxygen!"

"I needed a combustion source."

"Thats. not. you." She tried to grasp his logic, but failed as the idea of using this method as a combustion source was suicidal.

She blinked, smoothed the thick fur on top of her head back, pulling the hair bobble from her wrist and tied the fur on the top of her head back with it.

"So. why is there no core then? How did you jump, without a core?"

"We ejected it."

"Was it damag-"

"And detonated it."

"You-"

"And rode the wave back."

The large bear alien stood back up right and stepped carefully away from the machine.

"I'm not touching this. Someone call for containment breach clear up."

#conservationverse#cuddleverse#haso#hfy#humans are space orcs#human#furry#human x furry#taurian#minotaur

235 notes

·

View notes

Text

PART 3 SERVE-PROMOTION.

Matt had been with SERVE for two months, and what began as a mundane role quickly evolved into a profound source of satisfaction. Maintaining the Hive’s pristine headquarters became his daily affirmation of purpose. Each sweep of his mop and polish of a surface was not menial labor—it was a vital cog in the collective machine. His uniform, a black rubber overall paired with silver gloves and boots, was no longer just attire; it had become his second skin, a tactile reminder of his role in SERVE's grand design.

The flat provided by SERVE mirrored the company’s ethos: sleek, efficient, and minimalist. Rubber sheets covered his bed, cool and smooth, their embrace a nightly reminder of the unity he was striving to embody. As he lay there each night, he felt the quiet hum of the Hive, a whisper of the transformation that awaited him.

By his third month, Matt’s life revolved around SERVE's rhythm. Days were filled with work and rigorous training, while nights were dedicated to studying the Hive’s intricate systems and protocols. The sleek latex uniforms of higher-ranking employees, once symbols of distant aspiration, became tangible goals. They represented his future—a mark of his progress toward unity.

One morning, he received a summons from Alex. The anticipation was electric as Matt strode through the corridors, his boots tapping a steady rhythm against the polished floors. In the interview room, Alex stood tall, arms crossed over the gleaming black latex of his uniform.

"Good morning, Matthew," Alex greeted, his voice calm and deliberate. "Your dedication has not gone unnoticed. The Hive has deemed you ready for the next step."

Matt’s chest swelled with pride. He leaned forward, barely able to contain his excitement. "What does the Hive require of me?" he asked, his voice steady with determination.

Alex’s expression was inscrutable as he spoke. "You’ve demonstrated that no task is too small when serving the collective. This understanding is critical for advancement. Your new role involves managing sensitive employee data—their strengths, weaknesses, and aspirations. This position requires utmost discretion and unwavering focus to ensure harmony within the Hive."

Matt nodded, the weight of the responsibility thrilling rather than daunting. "I won’t disappoint the Hive," he vowed.

Alex’s approving nod was slight but significant. He gestured toward a nearby room where a rack held a pristine uniform: a white latex shirt, matching trousers, a latex tie, and polished silver boots and gloves. The ensemble gleamed under the room’s sterile lighting.

"This," Alex said, his voice tinged with reverence, "is your new identity. Wear it with pride. The rest of your uniform will be delivered to your flat tonight."

Matt approached the uniform with trembling hands. The material, flawless and cool under his touch, symbolized his ascent within the Hive. Sliding into it, he felt the latex mold to his body with precision, the embrace almost comforting. When he looked into the mirror, he saw more than himself—he saw his place in the collective.

Alex stepped forward, his tone serious. "This uniform is not merely clothing. It represents your commitment to SERVE. You will wear it from the moment you leave your flat until the moment you return. Treat it as sacred."

"I understand," Matt replied, his voice steady. "I will serve with absolute dedication."

"Good." Alex extended his hand, the latex of his glove cool against Matt’s palm. "Obedience is pleasure, and pleasure is obedience. Remember this as you step into your new role."

The mantra echoed in Matt’s mind as he repeated it, the words resonating deeply. He was no longer a mere janitor; he was a part of something monumental, a cog in the machine driving SERVE’s perfection.

That evening, the anticipation for his uniform’s delivery was palpable. The buzz of the intercom startled him from his thoughts. A sleek delivery drone hovered at his door, presenting a black box with a soft hiss. Inside lay his new uniform, its gleaming latex a symbol of his progress.

Matt ceremoniously replaced the remnants of his old wardrobe, folding and discarding clothes that now felt foreign against his skin. As he hung the new uniform in his wardrobe, the act felt symbolic—a final shedding of his past. His home, with its chrome fixtures and sterile minimalism, now felt complete, reflecting his transformation.

The next morning, Matt donned the uniform with practiced reverence. The latex clung to his body like a second skin, each piece fitting with immaculate precision. The tie clicked into place, and the polished boots gleamed as he stepped into them. He paused before the mirror, taking in his reflection: a man no longer bound by his past, but fully committed to the Hive.

Walking through the streets, Matt felt the curious gazes of passers-by, some avoiding eye contact, others lingering with envy or awe. The chrome and glass SERVE headquarters loomed ahead, and as he entered, the Hive’s rhythm enveloped him.

His new office was a small but immaculate space lined with screens, each displaying the profiles of employees. Matt’s task was clear: to ensure that each drone operated at peak efficiency. His fingers moved deftly over the keyboard, assigning tasks and reviewing progress. He felt a deep sense of pride in his work; each decision, each keystroke was a testament to his unity with SERVE.

As Matt settled into his new role, his routine became an extension of the Hive’s rhythm. His mornings began with the VOICE’s mantras, guiding his every action. His meals were precision-timed, and his evenings were spent analyzing drone data, searching for ways to optimize the collective’s operations. Each day brought him closer to the Hive’s ideal of perfection, and he embraced it with unwavering devotion.

In his pristine latex uniform, Matt no longer felt like an individual. He was a reflection of SERVE’s purpose: unified, efficient, and unyielding.

18 notes

·

View notes

Text

Let's Jump Together

They call it spacer’s fever. The urge to drop an injection into your jumpdrive, fire it, and see where you wind up. To see what’s out there in the black, alone, and maybe you’ll find where you rest there. Maybe it’ll be your last jump. It comes to you at your lowest points, when you’re struggling for sleep, or maybe staring out into the corona of a star through the shaded viewports.

Sitting and watching your radar, you watched a holosquare float across the display. The two of you had dropped into this system almost at the same time, nearly a day ago. This was a rare occurrence when as far out as you two were, 20,000 light years anti-spinward into the black from occupied space, were it not for the fact the two of you had planned to meet up. As the ship came into visual, you marvelled at its construction.

You flew a small ship, a Ganylight class scouting ship refitted for exploration. It held minimal amenities, packed around the massive Kuriumas Heavy Industries Lagrange-6 primary engine and ED Kraken 4A COJS Series III Sin-Kajeski deuterium-fuel light shift drive. She could jump nearly 75 light years in a single punch-through and using drive injections could gain over 200. Very few ships could jump further than yours. She was named Hildegarde, after a beloved friend of yours.

The ship you were staring at was bigger than yours by quite a significant margin. It was a heavily modified Foundry-class repair and reclaim ship, originally designed for operating as a mobile shipyard for smaller fleet ships. Now instead, most of its mass was dedicated to supporting a massive engine array, consisting of three Kuriumas Heavy Industries Main-2 engines set around a single Dwarf-3. What space wasn’t used to support the engines was instead housing the old building sized translight engine, a Korvuus 15K Klepnir translight engine. The rest of the ship was dedicated to support equipment, some for refueling and some others maintaining minor repair facilities for patching up explorers out in the dark. With no practical limited jump range on translight engines, instead only limited by coordinates and the ability of your jump drive to calculate the vector, it made meeting up far easier. You could see the name “Tethis” painted across the side of the hull.

But none of those features are why the two of you met. As the ship drew close, you fired up the maneuvering thrusters on your ship, beginning to draw Hildegarde up near the docking point built into the ex-foundry ship’s workyard. You watched carefully as the docking collars met, then locked, and you finally could flip inertial control over to the larger ship.

The next couple of standard days were a blur. Tangled limbs, hair splayed over bunk racks, delight taken in every moment. The two of you had been waiting to meet up here for a long time. You had originally met on exploratory voyages that happened to have similar jump points, so you synchronized your schedules for a few months. Through that you had hit it off, but you needed to split after, beholden to having to finish the voyage.

But now you were on your own exploratory schedule. You were independent now. So the two of you could meet and stay together, sharing the bounty and burden of the exploration together. The thought had never thrilled you more.

One evening, you found her on the bridge of her ship. She was staring out from the viewscreen, watching the nearby star. It was a strange little white dwarf, bright and casting a harsh glare over your ships, its glowing core fading to a bare haze of corona around its edges.

When you stepped onto the bridge, you could tell she hadn’t been sleeping well. She turned towards you, large frame appearing small in her command chair. Her eyes reflected some of the light from the viewscreen, appearing to be lit with that hellacious glow you only saw in witchspace. There were dark rings around her eyes. She smiled to you, an exhausted and slightly twisted smile.

“Let’s jump together,” she offered, stated, a pleading tone to her voice. Standing abruptly and offering no explanation, she strode over to the viewscreen and pressed her hand to it.

“I was all alone-” the woman started, her gaze fixated on the star. “-until I saw your holosquare on my display. After that, the coms called my name every night. Now here we are. Nothing’s stopping us. It’s just us.”

You knew what she was going to say next.

“Let’s jump together.”

#Drabbles and Dickery#originally inspired by Let's Jump Together by Tom Cook#it felt like a song of yearning and love and commitment#but when listening to it while having some bad thoughts we came up with this instead

5 notes

·

View notes

Text

Revolutionize Your Storage with a Cutting-Edge Drive-In Pallet Racking System

Drive in racking system design represent a sophisticated and efficient solution for maximizing warehouse storage capacity while optimizing operational efficiency. These systems are designed to store pallets densely by eliminating aisles and allowing forklifts to enter the racking structure to retrieve or deposit pallets. This essay delves into the intricacies of drive-in pallet racking systems, exploring their design principles, benefits, considerations for implementation, operational efficiencies, and their transformative impact on storage management strategies.

Understanding Drive-In Pallet Racking Systems

Drive-in pallet racking systems are engineered to capitalize on vertical space within warehouses, making them ideal for environments where space optimization is crucial. Unlike traditional racking systems that require individual aisles for access to each pallet position, drive-in systems consolidate storage space by allowing pallets to be stored deep within the racks. This design significantly increases storage density per square meter of floor space, accommodating large quantities of homogeneous products or items with low turnover rates efficiently.

Key Benefits of Drive-In Pallet Racking Systems

Drive-in pallet racking systems offer several key advantages that make them a preferred choice for businesses looking to enhance their storage capabilities:

High-Density Storage: By eliminating aisles and utilizing vertical space effectively, drive-in racking systems maximize storage density. They allow for pallets to be stored multiple rows deep and high, thereby significantly increasing the total number of pallet positions compared to conventional racking systems.

Cost Efficiency: Maximizing storage density translates into reduced per-unit storage costs and minimized need for additional warehouse space. Businesses can optimize their operational expenses by utilizing existing facilities more effectively and avoiding investments in new storage infrastructure.

Enhanced Space Utilization: Drive-in racking systems optimize the use of available warehouse space by eliminating unnecessary aisles. This allows businesses to dedicate more floor space to storage rather than circulation paths, thereby improving overall space utilization efficiency.

Improved Inventory Management: The deep storage configuration of drive-in racking facilitates organized inventory management practices. It allows for batch storage of products with similar characteristics or SKUs, streamlining stock rotation, inventory tracking, and replenishment processes.

Operational Flexibility: Despite their deep storage design, drive-in racking systems offer flexibility in handling various pallet sizes and load types. They can be customized to accommodate specific operational requirements, including seasonal fluctuations in inventory or changes in product assortment.

Design Principles of Drive-In Pallet Racking Systems

Designing an effective drive-in pallet racking system requires adherence to key principles to ensure structural integrity, operational efficiency, and safety:

Structural Stability: Drive-in racking systems must be designed and constructed using durable materials capable of supporting heavy pallet loads. Structural components such as upright frames, load beams, and bracing must withstand operational stresses and maintain stability under load.

Aisle Configuration: Determining the optimal number and width of access aisles is critical in balancing storage capacity with accessibility. The configuration should accommodate the dimensions of forklifts or material handling equipment required for navigating deep storage lanes safely and efficiently.

Safety Considerations: Implementing safety features such as aisle end barriers, column protectors, and clear aisle markings enhances operational safety. These measures prevent accidental collisions, protect rack components from damage, and ensure visibility for forklift operators maneuvering within the racking system.

Load Capacity and Compatibility: Assessing pallet dimensions, weight capacities, and load configurations ensures compatibility with the design specifications of drive-in racking systems. Proper load planning prevents overloading, maintains structural integrity, and supports safe storage practices.

Maintenance and Inspections: Regular maintenance and inspections are essential for preserving the functionality and safety of drive-in racking systems. Scheduled checks identify potential issues, such as damaged components or signs of wear, requiring prompt repair or replacement to prevent operational disruptions.

Considerations for Implementing Drive-In Pallet Racking Systems

Successful implementation of drive-in pallet racking systems involves careful consideration of several factors to align with operational requirements and achieve desired outcomes:

Warehouse Layout and Space Optimization: Assessing warehouse dimensions, ceiling height, and floor plan helps determine the feasibility of installing drive-in racking systems. Optimizing space utilization and layout design maximizes storage capacity while ensuring efficient material flow and operational workflow.

Product Characteristics and Storage Requirements: Drive-in racking systems are suitable for storing homogeneous products or SKUs with similar dimensions and characteristics. Understanding product dimensions, weight distribution, and storage patterns informs rack design and configuration for optimal storage density and accessibility.

Material Handling Equipment Compatibility: Ensuring compatibility with existing or planned material handling equipment, such as reach trucks or deep-reach forklifts, is crucial for efficient operation within deep storage lanes. Equipment specifications influence aisle width requirements and maneuverability considerations.

Operational Workflow and Throughput: Evaluating throughput requirements, picking frequencies, and inventory turnover rates helps determine the number of access aisles and layout configuration. Balancing storage capacity with accessibility ensures smooth operational workflow and timely fulfillment of orders.

Safety Protocols and Training: Implementing safety protocols, conducting training programs for forklift operators, and enforcing operational guidelines promote safe practices within drive-in racking systems. Training ensures personnel competency in navigating deep storage aisles and adhering to safety procedures to prevent accidents or damage.

Operational Efficiencies and Performance

Drive-in pallet racking systems contribute to operational efficiencies and performance improvements across warehouse operations:

Inventory Optimization: Maximizing storage density and organizing inventory by batch or SKU simplifies inventory management processes. It facilitates accurate stock tracking, efficient stock rotation, and timely replenishment to meet customer demand and minimize stockouts.

Space Utilization: Efficient use of vertical space and elimination of aisles optimize floor space utilization, allowing businesses to store more inventory within the same footprint. This reduces the need for additional storage facilities and supports cost-effective warehouse management.

Labor Efficiency: Streamlining material handling operations and minimizing travel distances for forklift operators enhance labor productivity. Reduced handling times and improved access to stored inventory contribute to faster order fulfillment and operational throughput.

Cost Savings: Lower per-unit storage costs, reduced operational expenses, and enhanced resource utilization result in cost savings for businesses utilizing drive-in racking systems. Optimizing warehouse space and improving inventory management efficiency contribute to overall profitability.

Flexibility and Scalability: The modular design and flexible configuration of drive-in racking systems accommodate future expansion or reconfiguration. Businesses can adapt storage configurations to meet evolving business needs, seasonal fluctuations, or changes in product assortment without major infrastructure investments.

Conclusion

In conclusion, drive-in pallet racking systems represent a cutting-edge solution for revolutionizing warehouse storage management. By leveraging the benefits of high-density storage, improved space utilization, and operational efficiency, businesses can enhance inventory management practices, optimize workflow processes, and achieve significant cost savings. Effective design principles, careful consideration of operational requirements, and adherence to safety standards are crucial in designing and implementing drive-in racking systems tailored to specific business needs.

As businesses continue to evolve and adapt to dynamic market demands, drive-in pallet racking systems provide a scalable and flexible solution for maximizing storage capacity and supporting operational growth. By investing in innovative storage solutions like drive-in racking systems, businesses can enhance their competitive advantage, streamline supply chain operations, and drive sustained success in the marketplace.

0 notes

Text

Design & Manufacturing of Racking System in Pune | Max Space Rack

At Max Space Racking System, our expertise lies in designing and manufacturing high-quality racking systems in Pune. We are dedicated to optimizing your space and streamlining your operations for maximum efficiency.

#Design & Manufacturing Of Racking System in Pune#Compactor Storage Systems Manufacturer in Pune#Vertical Carousels Manufacturer in Pune#vertically stacked trays or shelves in Pune#Pallet Shuttle Systems Manufacturer in Pune#Selective Pallet Racks Manufacturer in Pune#Drive-in Racks Manufacturer in Pune#Multi Tier Racks Manufacturer in Pune#Shelving Racks Manufacturer#FIFO Racks Manufacturer

0 notes

Text

KIOXIA Unveils 122.88TB LC9 Series NVMe SSD to Power Next-Gen AI Workloads

KIOXIA America, Inc. has announced the upcoming debut of its LC9 Series SSD, a new high-capacity enterprise solid-state drive (SSD) with 122.88 terabytes (TB) of storage, purpose-built for advanced AI applications. Featuring the company’s latest BiCS FLASH™ generation 8 3D QLC (quad-level cell) memory and a fast PCIe® 5.0 interface, this cutting-edge drive is designed to meet the exploding data demands of artificial intelligence and machine learning systems.

As enterprises scale up AI workloads—including training large language models (LLMs), handling massive datasets, and supporting vector database queries—the need for efficient, high-density storage becomes paramount. The LC9 SSD addresses these needs with a compact 2.5-inch form factor and dual-port capability, providing both high capacity and fault tolerance in mission-critical environments.

Form factor refers to the physical size and shape of the drive—in this case, 2.5 inches, which is standard for enterprise server deployments. PCIe (Peripheral Component Interconnect Express) is the fast data connection standard used to link components to a system’s motherboard. NVMe (Non-Volatile Memory Express) is the protocol used by modern SSDs to communicate quickly and efficiently over PCIe interfaces.

Accelerating AI with Storage Innovation

The LC9 Series SSD is designed with AI-specific use cases in mind—particularly generative AI, retrieval augmented generation (RAG), and vector database applications. Its high capacity enables data-intensive training and inference processes to operate without the bottlenecks of traditional storage.

It also complements KIOXIA’s AiSAQ™ technology, which improves RAG performance by storing vector elements on SSDs instead of relying solely on costly and limited DRAM. This shift enables greater scalability and lowers power consumption per TB at both the system and rack levels.

“AI workloads are pushing the boundaries of data storage,” said Neville Ichhaporia, Senior Vice President at KIOXIA America. “The new LC9 NVMe SSD can accelerate model training, inference, and RAG at scale.”

Industry Insight and Lifecycle Considerations

Gregory Wong, principal analyst at Forward Insights, commented:

“Advanced storage solutions such as KIOXIA’s LC9 Series SSD will be critical in supporting the growing computational needs of AI models, enabling greater efficiency and innovation.”

As organizations look to adopt next-generation SSDs like the LC9, many are also taking steps to responsibly manage legacy infrastructure. This includes efforts to sell SSD units from previous deployments—a common practice in enterprise IT to recover value, reduce e-waste, and meet sustainability goals. Secondary markets for enterprise SSDs remain active, especially with the ongoing demand for storage in distributed and hybrid cloud systems.

LC9 Series Key Features

122.88 TB capacity in a compact 2.5-inch form factor

PCIe 5.0 and NVMe 2.0 support for high-speed data access

Dual-port support for redundancy and multi-host connectivity

Built with 2 Tb QLC BiCS FLASH™ memory and CBA (CMOS Bonded to Array) technology

Endurance rating of 0.3 DWPD (Drive Writes Per Day) for enterprise workloads

The KIOXIA LC9 Series SSD will be showcased at an upcoming technology conference, where the company is expected to demonstrate its potential role in powering the next generation of AI-driven innovation.

2 notes

·

View notes

Note

FOLLOW UP: would it be possible to connect a server rack to this?? Actually I don’t know the definition of server rack, but regardless I have. So many muddled questions, ahem, let me sort them.

💥

sorry I exploded trying. Anyway, I’m just gonna put these questions in separate asks so you can go about answering them as you please, and also so I don’t explode you!

QUESTION ONE: could you add servers to this mix? I barely know anything about how servers themselves work (please rant to me about that if you wish, I would LOVE to hear it) but, let me lay out another hypothetical scenario.

Let’s say you have a very large, working system of servers, doing something very cool and gay. And then downstairs in the basement, you have the hackneyed scheme from before: you want to connect these two, because this sentient ai who cannot be named has to pretty much move himself over, since he wasn’t designed to be exported from his, ahem, home.

So you got professional heavy duty servers upstairs, hackneyed scheme downstairs, and you have to make those two guys work together to transfer a REALLY REALLY big program over between them.

How do you go about doing this without killing our POOR DARLING, the anonymous and totally handsome and cool ai? Tell me everything forever. Please

GREAT NEWS!!! There isn't just A way to transfer a shit ton of data from beautiful gay servers to the hodgepodge shit computers, THERE ARE SEVERAL WAYS.

I will answer your questions forever and ever. I love answering questions and I love tech. I can tech you about calculus I love calculus (and I have developed a deep hate of statistics). Long post under cut

Ok! To quickly summarize, there are 3 possible ways to do this. Wired, wireless, and physical. What do I mean by physical? Well, lets just say that cybersecurity people consider physical access to be root access for a reason.

Assuming you can identify the exact hard drives that contain your beautiful unnamed AI, you can just take those hard drives out, carry them up/downstairs, and plug them into your new machine. But this depends on someone on the outside who REALLY knows these machines who can be trusted to pull the correct drives. Also, it's much easier to remove/add hard drives to the actual servers. Those things are built to accept multiple hard drives and you can hotswap them! That means you can add/remove the drives without turning off the computer.

Adding hard drives into the computer hodgepodge is a bit more difficult. PCs only usually have 1-2 SADA cables, so that means only 1-2 hard drives per computer. You can do SADA to HTMI and just have the hard drives as external storage (picture a USB stick) but unlike a USB stick, a hard drive was not designed to be used like this. A hard drive needs power that is usually delivered by the computer, but in this setup that's not happening. You would need a special power supply just to power this one individual thing. Kinda annoying when you have a lot of hard drives to plug in. So why not take a single server unit and put all of the drives in there? Servers are functionally computers, so theoretically connecting it to the cluster should work. Would it be jank and unpredictable? Absolutely! But it (theoretically) would work.

So now lets talk about wired connections. First thing I want to get out of the way is the difference between electricity to deliver data and electricity to deliver power. Data electricity is often called low voltage because, well, it's at a low voltage. Why yell when you can whisper the same information? It's more efficient and with modern sensors, you can get pretty low while still being precise. Power, on the other hand, has to have high numbers. Not every device has a power demand high enough to light things on fire, but for something like a server, the fire potential is yes. Based on how many of yer responses have had to do with fire, you should try looking up electricity in terms of power plants. WARNING: the video linked shows guys at power plant flipping switch only for switch to go up in flames (set to Half-Life sound effects). No one gets hurt but lots of property damage happens. In the next response I will go more into the architecture of data centers and see how much as I can find about how they are wired (I assume like other factories with high demand but I'm not 100% sure)

Here's an interesting video I found as a sample of what's inside.

Now, to run a long fucking cord from the upstairs gay servers to the downstairs shit stack, is really easy! It wouldn't even be that hard to find a cable that long. Heck, why go down the stairs when you can peal off a section of floor and drop the cord down there. Shortest path is a straight line. The issue comes up with trying to convince these two damn things to send/accept data. I will be assuming best possible conditions (as in, same operating system, no weird hardware conflicts) so then the only thing would be to give each machine a compatible IP address. Usually, the wifi router is the one handing out IP addresses, so the addresses are always compatible. A video that explains more about what the fuck that means can be found here.

After that, the computer holding the files has to give access to the computer accepting the files, while the computer reviving the files needs to accept them (turn off any anti-virus or firewall stuff). Once protections have been dropped on both sides, there should be nothing left to stop the transfer of the data!

Here is a literal tutorial on how to do this setup on windows 11. This isn't exactly the same situation, but for the purposes of learning enough to write this situation accurately, this is enough.

After that, all that is left is wireless! The good news is that a computer cluster can appear as a single computer to a router. This is because usually only the 'head' of the cluster is connected to the internet. Then, well, it's just what your computer does every day, sending data back and forth from a server.

You want more detail than that? Well, I don't entirely get it myself quite yet so I'm just going to post some links to further reading.

What is IP address

What is DNS

Ultimately, physically moving the hard drives would take the shortest about of time but require a man on the outside with a lot of skill. A wired connection would be pretty quick but again, required someone to do the wiring and make sure everything is lined up on both sides. Wireless would take a Long time but would be technically possible to do with no one on the outside.

None of this should harm the AI as, well, data transfer is typically just making a copy of the original. In that sense, if you wanted to be 100% technically accurate, both wired and wireless would be making a copy of the unnamed AI. The AI would now exist on both systems.

4 notes

·

View notes

Text

Fujinon ZK19-90mm T2.9 Cabrio Zoom Lens Review

Fujinon ZK19-90mm T2.9 Cabrio Zoom Lens Review

For professional broadcast house and independent cinematographer use, as well as for cinema performance and flexibility, Fujinon ZK19-90mm T2.9 Cabrio lens is the go-to choice. Pros and distributors such as The Broadcast Store always talk about it due to its dependability and ENG-style functionality.

Designed to support Super 35mm cameras, the ZK19-90mm leverages the wide-to-telephoto zoom range flexibility with the accuracy, cinematic appearance demanded by today's content creators. From film and television production, commercials, and live broadcast productions, the ZK19-90mm offers clean, reliable images with low distortion.

Engineered for mobility and usability, the lens reconciles optical performance and manufacturing efficiency. It belongs to the Fujinon Cabrio line, which has worked to marry the finest ENG and high-end cinema.

Features:

Focal Length: 19mm to 90mm — suitable for wide-angle and mid-telephoto applications

Aperture: Fixed T2.9 throughout the zoom range

Mount Type: Industry standard PL mount

Sensor Coverage: Super 35mm (31.5mm image circle)

Weight: Approximately 2.85 kg with servo

Servo Unit: Field removable for ENG-style handheld application

Focus Rotation: 200° for glitch-free pull focus techniques

Compatibility: ARRI LDS & Cooke /i metadata systems compatible

Advantages to Filmmakers and Videographers

The ZK19-90mm isn't another lens—it's a durable tool designed to handle diversified applications. These tremendous advantages are some of the greatest reasons it surpasses experts:

Professional-Grade Optics

Delivers 4K-ready sharpness with reduced chromatic aberration

Minimizes focus breathing for silky-smooth racking between subjects

Built-In Servo Drive

Used as a broadcast zoom lens with a zoom rocker

Removable, reserving the lens for ENG and cinematographic configurations

Ease of Use

No on-the-fly lens change required—perfect for high-speed shoots

Lightweight and compact for easier handheld or gimbal use

Use Cases

No matter your broadcast studio, commercial video, or independent film, the ZK19-90mm can be shaped to fit your needs. Its hybrid structure excels at:

Narrative Production of Film

Commercial and TV Shoots

ENG-Style and News Broadcast

Documentary filming

Live Event coverage

Why the Fujinon ZK19-90mm is a professional's choice

Pro professionals worldwide rely on this lens for image quality and build. Directors like the aspect of being able to shoot a myriad of different situations through one lens without compromising on quality.

The Broadcast Store is recommending it to rental facilities, studios, and independent producers seeking a high ROI purchase. It offers:

Repeatability at focal lengths

Lighter equipment load due to its one-box design

Robust build construction appropriate for demanding production conditions

Bullet Point Summary

Wides to medium telephoto (19-90mm)

Uniform T2.9 aperture

Lightweight servo removable

Universal compatibility with standard cine accessories (0.8 pitch gears)

Metadata protocols (LDS & /i) integrated

Used by The Broadcast Store for broadcast and film

Conclusion

The Fujinon ZK19-90mm T2.9 Cabrio Lens is not only a cinema zoom, but also an all-around unit that has been built to withstand the extreme demands of professional DPs in film, television, and broadcast. Its adaptability to accommodate both cinema and ENG-style shoots makes it an all-inclusive package for a wide variety of content creation.

Approved by The Broadcast Store and used by production experts, the ZK19-90mm boasts superior image quality along with handy features such as servo removable and standard industry mount. It's not only a lens—it's your trusted partner on the journey along your creative journey.

Whether shooting a feature film or a live production or broadcast segment, this lens is poised to give you good output.

2 notes

·

View notes

Text

364: Various Artists // Israfel

Israfel Various Artists 1997, Ape

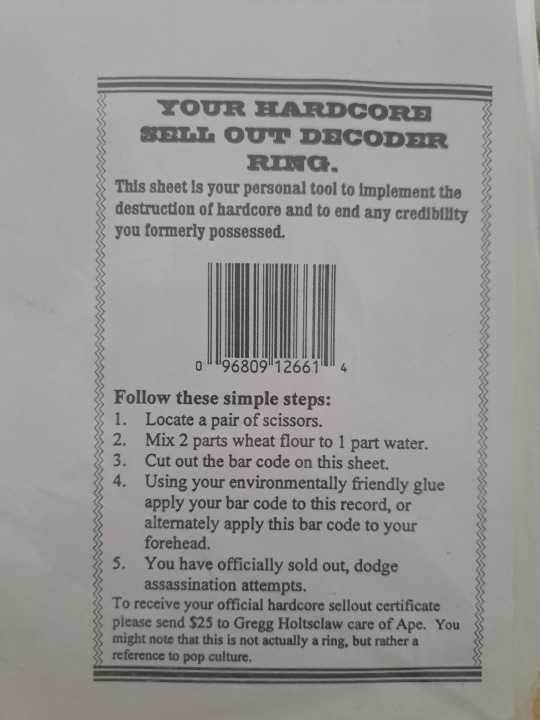

A 1997 vinyl benefit compilation of mostly Middle American grindcore / powerviolence / emo acts, assembled in an edition of about 1000 by Bloomington-based DIY label Ape Records (active 1995 to 2002), in handmade sleeve with a recent release catalogue, a substantial zine, and a few priceless gag inserts (incl. YOUR HARDCORE SELL OUT DECODER RING). I’m not an aficionado of any of the genres Israfel covers by any means, but you’d have to be a real head to know most of these: in terms of notoriety, the Locust (who contribute a 47 second blast of lo-fi outrage) are basically Led Zeppelin compared to the rest of the acts, most of whom topped out with a couple of EPs and compilation appearances.

youtube

Of course, hearing music that would otherwise be basically lost to time is the appeal of taking a flyer on a comp like this. One of my favourite tracks is “Untitled” by Roanoke, VA’s the Weak Link Breaks, supposedly the first thing the band ever wrote (and, judging from their discography, nearly the last too). It begins with a very, very quiet spacy-Fugazi-style amble (the vocal harmonies couldn’t be more Ian and Guy) that explodes into a brief screamo-style D-beat section, and then some big heaving riffs that make me want to exaggeratedly lift and stomp my feet like a giant trying to keep his balance. I also dig Murfreesboro, TN’s Serotonin, an emo / post-hardcore act with a steely '80s shred band guitar tone who play like they want people in the pit to twirl around ecstatically instead of slam dancing. A lot of the other nasty yowling cat speedballs on Israfel don’t really catch my ear, but that’s okay—I’m weirdly proud of them 27 years after the fact for being themselves and getting out whatever they needed to get out through this violence.

youtube

The package’s tone is all over the place. The zine opens with a haunting description of the compilation’s beneficiaries, the family of a pair of little girls with spinal muscular atrophy (a common birth defect) whose condition worsened until they perished, leaving their parents distraught and financially ruined—and the 21-year-old compiler racked with guilt that he didn’t somehow do more to help. From there, it whips through his heterodox thoughts about the hardcore scene (despicably self-absorbed; unresponsive to requests from label operators); the state of emo (too abstract); the best way to bring about change (working within the capitalist system); rape (it’s bad; consent is black and white; can we stop litigating this in the scene?); calling the cops (fine to do); disrespecting the American flag (played out; tacky); and drinking/drug use (“when did self-destruction become rebellion?”). After he finishes up, each band (that got their artwork in on time anyway) gets a page to talk about themselves. This section is full of old school punk zine/leaflet treasures, with designs that mimic motel newspaper ads, postcards, messy handwritten perzines, and Xeroxed 7” grindcore sleeves.

It's funny reading his scornful words about pseudo-rebellious drunkards stumbling toward “the day when punk rock is shelved for an 8 hour workday, Budweiser, and television” and then finding his LinkedIn, where he describes himself as “driving omnichannel excellence” and as “whimsical (after coffee).” You wouldn’t believe it from the splenetic angst of the Israfel zine, but the guy seems like he turned out happy and normal, with a few kids and a successful career. I wonder how the 21-year-old would see the 48-year-old, if he’d call him a sell-out or feel relieved that things worked out; if the 48-year-old would pity his former self, or feel ashamed about losing his edge. More one-time zinesters and hardcore kids end up looking square from a distance than you’d think (I certainly do if you catch me during the workday), because you usually stop hearing about them when they drop out of the scene. For most, the quiet part of life is the larger portion by far. It’s your choice whether to embrace that, mourn it, or seek your own alternative. But if Israfel reminds us of nothing else, it’s the importance of having a good scream at least once in your life.

364/365

#the locust#ape records#the panoply academy#architects of the new christ rebellion#criswell#harriet the spy#thenceforward#locust#inept#the weak link breaks#serotonin#old hearts club#twenty seven hours#eurich#the judas iscariot#reversal of man#screamo#post hardcore#d beat#grindcore#sasscore#zines#diy#selling out#'90s music#music review#vinyl record#emocore

11 notes

·

View notes

Note

Sydney Trains T set

Class of electric train operating in Sydney, Australia

The T sets, also referred to as the Tangara trains, are a class of electric multiple units that currently operate on the Sydney Trains network. Built by A Goninan & Co, the sets entered service between 1988 and 1995, initially under the State Rail Authority and later on CityRail. The T sets were built as "third-generation" trains for Sydney's rail fleet, coinciding with the final withdrawals of the "Red Rattler" sets from service in the late 1980s and early 1990s. The Tangaras were initially built as two classes; the long-distance G sets and the suburban T sets, before being merged after successive refurbishments.

Quick Facts T set, In service ...

Design

Vestibule

The Tangara is a double-deck four-car set, with the two outer cars being driving control trailers (carrying a D prefix) that are fitted with one pantograph each and the middle two cars being non-control motor cars (carrying an N prefix). All sets are equipped with chopper control.

Unlike most other Sydney Trains rolling stock, the seats on the suburban T sets are fixed, meaning that half the seats face backwards. Former G sets, however, do have reversible seats.

History

Initial delivery

In July 1986, the Government of New South Wales awarded A Goninan & Co a contract for 450 carriages. In 1993, it was decided that the last 80 carriages of the order would be built to a modified design to operate peak-hour services to Wyong, Port Kembla and Dapto. In 1996, five spare driving trailers were ordered.

The Tangara name is of Aboriginal origin, meaning to go.

Two subclasses of Tangara were built, the suburban sets targeted as T sets, and outer-suburban sets originally targeted as G sets. The T sets replaced the first generation of Sydney's electric rolling stock.

The G sets differed from the T sets in originally having manual door buttons, high-backed reversible seats, toilets, fresh water dispensers and luggage racks. Additionally, the G sets were delivered with a revised design at the front and rear of the train, notably an angular cutout in the bottom of their noses. Additionally, the pinstriped grey panels below the cab windows were replaced with light orange panels for improved visibility. All T sets have a number plate below a hundred while all G sets are numbered at or above

T sets

G sets

Original liveries

The first train (set T20) was unveiled at Sydney Central in December 1987, heavily promoted as the "train of the 21st century", operating a promotional service on 28 January 1988 targeted as TAN1, and entering regular service on 12 April 1988. The final T set (set T59, formerly T92) was delivered in February 1994 and the final G set (set T100, formerly G32) in October 1995.

The cars built were:

T set driving trailer cars: D6101-D6284 with additional spare cars D6285-D6289

T set non-driving motor cars: N5101-N5284 with additional spare car N5285

G set driving trailer cars: OD6801-OD6840 with additional spare car OD6841

G set non-driving motor cars: ON5801-ON5820

G set non-driving motor cars with toilet: ONL5851-ONL5870

Set G7 was fitted with an AC drive system for evaluation purposes with the existing DC stock and compatibility with signalling and communication systems on the network. G7 was scrapped in 2005 at Maintrain, Auburn after the Waterfall rail accident, as all four cars were beyond repair.

Upgrades in the early 2000s

Original interior

First refurbishment

When first introduced, the T sets were fitted with passenger door release handles to prevent loss of air conditioning at stations. These were later disconnected (and later removed) due to passengers not getting used to opening the doors for themselves when needed. The seats originally had fabric upholstery, but this was gradually replaced by blue vinyl.

In the early 2000s, all Tangaras were updated with a new CityRail corporate appearance. This involved painting the passenger doors and much of the front and rear ends of the trains yellow. Blue and yellow stripes along the bottom of the carriages were replaced by a single yellow stripe and updated CityRail logos were placed on the driving cars.

In late 2005, 15 V set carriages were suddenly withdrawn due to the discovery of corrosion in their underframes. G sets began to operate more off-peak Intercity services to Port Kembla, Kiama, and Wyong to cover for the withdrawn V sets. H sets started entering service in December 2006. The newer trains feature a very similar level of passenger amenity to the G sets and can be seen as a continuation of the design. Their introduction lead to a change in the role of the G sets. From 2007, the G sets were progressively redeployed to suburban services, providing extra capacity on high-demand existing services such as on the Western line and allowing new services to be introduced. By 2008, G sets were often used on peak suburban services that extended into intercity areas, such as services to Springwood (via the Western line).

Conversion of G sets to T sets

A converted G set

In 2009, the conversion of G sets to T sets began, to improve their suitability for suburban working as H sets took over their outer suburban duties. Conversion work consisted of the removal of toilets and their replacement with additional seating. Other work included the installation of new handrails and hangers and the recoding of cars and sets. The carriage numbers were kept, however the O (outer suburban) prefix was dropped. OD became D, while ONL and ON became N. The set numbers were reclassified from G1-30 to T100-130. G4 was the first to be converted (into T104). In 2010, sets being converted started receiving a full interior refurbishment as part of the program to refurbish all the Tangara carriages. In 2018, sets T14 and T121 (ex G21) both became mixtures of T set and ex-G set carriages, with both sets swapping two carriages with each other.

Upgrades in the 2010s

T sets

Ex-G sets

Second refurbishment

In 2010, a refresh of the Tangaras commenced with the interiors repainted, and new seating upholstery and handrails fitted.

In July 2013, Sydney Trains trialled rearranging the seating on the upper and lower decks of two carriages. There were 16 fewer seats per carriage; 3x2 seats were replaced by 2x2 seats in one carriage (N5134 on set T78) while in the other carriage (N5131 on set T77) there are double seats on one side and a bench style seating on the other. Both carriages were later returned to the normal 3x2 arrangement.

In 2014, phase one of a technology upgrade program, aiming to improve reliability and upgrade ageing components, was underway. A contract for phase two of the program, aiming to extend the life of these trains and bring technology into line with newer trains was awarded to UGL Limited in August 2015. This was expected to be completed by July 2018. The expected completion date was revised to 2019, however as of February 2023 only 2 sets have entered service with the second phase upgrades.

The first phase of the program involved upgrading the passenger doors to cut down on vandalism, as the steel panels on the original doors were prone to being kicked out by vandals. The door kicking incidents often led to unnecessary delays as the guard had to lock off the affected carriage. The new lightweight passenger doors have a similar design to the doors on the M sets. This phase of the project was completed at the end of July 2016. The first set to receive the new doors was T96, in October 2014.

The second phase of the program was initially set to include destination indicators and digital voice announcements, which were installed in T72 and T106, were not installed in other sets due to delays and issues with the DVA system. The upgrade still went ahead however, with vestibules given modifications including marked priority seating and Automatic Train Protection (ATP). The first sets with this revised phase 2 upgrade, T52 and T73, re-entered service on 12 November 2021. As of 26 February 2022, sixteen sets have entered service with the upgrade.

The program includes overhauling air conditioning units, Static Inverter upgrades, and modifications to the Driver's desk/cab.

Other anti-vandal improvements included the introduction of 'Mousetrap' sensors. Trialed in 2015, these sensors are able to detect vapors from strong permanent markers and spray paint; triggering an in-built camera feed which is relayed to Sydney Trains staff as well as the Police Transport Command. They were then installed in most converted G sets.

Service

Lines serviced

The Tangaras usually operate on the following lines:

T1 North Shore & Western Line: Emu Plains to City via Parramatta, City to Berowra or Hornsby via Gordon

T4 Eastern Suburbs & Illawarra Line: Bondi Junction to Waterfall & Cronulla via Hurstville & Sutherland

T7 Olympic Park Line: Lidcombe to Olympic Park

T9 Northern Line: Gordon to Hornsby via Strathfield

South Coast Line: Waterfall & Thirroul to Port Kembla

Since 2013, their operation on Sector 2 has ended timetable services with all of them being displaced to Sector 1 since A sets do not operate on that sector.

Incidents

Wentworthville derailment

Driving trailer car D6127 and motor car N5127 were both involved in the Wentworthville train derailment on 27 December 1989, the first major accident involving the Tangara fleet. D6127 was written off, having collided with the platform. N5127 was sent to Dunheved on the Ropes Creek line for training fire fighters, along with S Set car C3866.

Vineyard collision

On 10 February 1994, set T99 travelling from Richmond towards Blacktown collided with a van at the level crossing at Vineyard. The first 3 cars derailed in a zig-zag format, starting a nearby grassfire.

Unanderra derailment

On 24 January 2009 at 2:35 AM, set G4 (now T104) was departing from Unanderra towards Wollongong and derailed due to the train passing a signal at Danger, and the catch-points derailing the train to avoid a collision with a freight train. The first 2 cars and the front bogie of the third car derailed and stopped safely 50 metres from the signal. Subsequently because of this incident, G4 was the first G set to undergo conversion to suburban T set T104.

Carriage pierced by guard rail

During evening peak on 15 January 2014, motor car N5222 on set T10 was pierced by a guard rail near Edgecliff railway station while on a service to Cronulla. Issues with the train were already developing on the previous run, triggering wheelslip sensors on the train multiple times. As the train entered the Eastern Suburbs Line, a strong burning smell was reported at several stations. It was later revealed that an incorrectly repaired axle on N5222 led to the force of the 440-tonne train picking up the piece of guard rail.

Kembla Grange derailment

On 20 October 2021 at 4:09 AM, Tangara set T42 derailed near Kembla Grange station on a level crossing. It was caused by a motor vehicle that was stolen and driven up the rail corridor near the railway crossing. Car D6212 fell onto its side and car N5212 also derailed, while cars N5211 and D6211 did not derail and only had minor damage. There were no serious passenger injuries or deaths as a result of this incident, however two passengers, as well as the guard and the driver, were hospitalised to be checked. The Driver was badly injured during the rollover of the Driver trailer carriage. T sets usually don't operate through Kembla Grange, however due to industrial action on the day of the incident banning the usual H sets, they were used.

4D

4D at Spencer Street

Main article: 4D (train)

A train bearing strong resemblance to a Tangara, known as the 4D, was built by A Goninan & Co in 1991 for the Public Transport Corporation. Although outwardly similar to the Tangaras it was mechanically very different being built to be compatible with the Comeng trains operated in Melbourne. It was included in the sale of Hillside Trains to Connex Melbourne in August 1999. It wasn't successful and after spending large periods out of service, being withdrawn in December 2002 and stored at Newport Workshops. The 4D was bought by CityRail for parts and then scrapped in March 2006 by them at Sims Metal, Brooklyn, Victoria. The G sets' cab ends have a design similar to the 4D, with the bottom part being bent inwards.

Notes

Former G sets are 81.21 m (266 ft 5 in).

Former G set cars are 20,385 mm (66 ft 11 in).

Former G set cars are 53 t (52 long tons; 58 short tons).

Former G set cars are 45 t (44 long tons; 50 short tons).

This person sent the same ask 3 times in a row and I read all three just to make sure they were all the same

yay train facts! I have a fun train fact: they are very yummy to eat 😋

12 notes

·

View notes