#Modular Cold Storage

Explore tagged Tumblr posts

Text

Modular Cold Storage Rooms – What Are Their Benefits Over Traditional?

Cold storage is a critical component for industries like food processing, pharmaceuticals, and logistics. With advancements in technology, modular cold storage rooms have emerged as a superior alternative to traditional cold storage systems. At EPACK Prefab, we specialize in delivering state-of-the-art modular cold storage solutions that cater to diverse industry needs.

What Are Modular Cold Storage Rooms?

Modular cold storage rooms are prefabricated, insulated chambers designed for temperature-controlled environments. Unlike traditional cold storage, these modular systems are built using prefabricated panels and components that allow for easy assembly, customization, and scalability.

Benefits of Modular Cold Storage Rooms Over Traditional

1. Customization and Flexibility

Modular cold storage rooms are highly customizable, offering:

Tailored dimensions to fit specific space requirements.

Adaptable temperature zones for storing different products.

Scalability, allowing easy expansion as business needs grow.

Traditional cold storage lacks this level of flexibility, making modular systems a more versatile option.

2. Faster Installation

Modular cold storage rooms are prefabricated and delivered ready for assembly. This reduces installation time significantly compared to traditional systems, which often require lengthy on-site construction.

3. Energy Efficiency

Modular systems are designed with advanced insulation materials that minimize energy loss, ensuring consistent temperature control with lower energy consumption. This translates to reduced operational costs compared to traditional cold storage solutions.

4. Cost-Effective

The prefabricated nature of modular cold storage reduces labor and material waste, making it a more cost-efficient option. Additionally, the faster installation process lowers project timelines, further reducing costs.

5. Portability

Modular cold storage rooms can be disassembled, transported, and reassembled at a new location, offering unparalleled portability. This is particularly beneficial for industries that require temporary or mobile storage solutions.

6. Superior Quality and Durability

Constructed in controlled factory environments, modular cold storage systems maintain consistent quality standards. High-quality materials such as PUF (Polyurethane Foam) panels provide excellent thermal insulation and long-lasting performance.

7. Environmentally Friendly

Modular cold storage uses sustainable materials and energy-efficient technologies, reducing its environmental footprint. These systems are also recyclable, aligning with modern sustainability goals.

8. Easy Maintenance

The modular design simplifies maintenance, as individual components can be replaced or upgraded without disrupting the entire system, unlike traditional setups.

Applications of Modular Cold Storage Rooms

Modular cold storage rooms are used across various industries, including:

Food processing and storage (fruits, vegetables, dairy, meat).

Pharmaceuticals (medicines, vaccines, medical supplies).

Logistics and warehousing.

Retail (supermarkets, cold chain transportation).

Why Choose EPACK Prefab for Modular Cold Storage?

At EPACK Prefab, we offer modular cold storage solutions tailored to your specific needs. With advanced technology, superior materials, and energy-efficient designs, we ensure optimal performance and reliability.

Conclusion

Modular cold storage rooms provide unmatched advantages over traditional systems, offering flexibility, energy efficiency, and cost-effectiveness. Whether you’re looking to optimize space, reduce energy costs, or expand your storage capabilities, modular cold storage is the future of temperature-controlled environments.

Contact EPACK Prefab today to explore how our modular cold storage solutions can benefit your business.

Read to Know - Six Reasons why Cold Storage Industry should adopt Prefabrication

#Modular Cold Storage#Prefabricated Cold Rooms#Cold Storage Solutions#Energy Efficient Storage#Cold Chain Logistics#Temperature Controlled Rooms#Sustainable Storage Systems#PUF Panels#Industrial Cold Storage#EPACK Prefab Solutions

0 notes

Text

The Benefits of Modular Cold Rooms for Growing Businesses

As businesses expand and evolve, so do their requirements for efficient and dependable storage solutions. Temperature-controlled storage is one area that can have a considerable impact on a company’s operations, notably in the food and beverage, pharmaceutical, and biotechnology industries. Modular cold rooms have evolved as a versatile and affordable alternative for organizations of all sizes. This blog explores the many benefits of modular cold rooms and how they can help businesses develop and succeed.

What Are Modular Cold Rooms?

Modular cold rooms are temperature-controlled storage chambers that can be customized to meet specific environmental requirements. Unlike typical cold storage solutions, modular cold rooms are constructed from prefabricated panels that can be readily assembled, removed, and reconfigured to meet changing requirements. This adaptability makes them an excellent choice for expanding enterprises that demand scalable and adaptable storage solutions.

Key Benefits of Modular Cold Rooms

1. Scalability One of the most notable benefits of modular cold rooms is their scalability. As a firm expands, its storage requirements may change. Modular cold rooms can be expanded or changed to meet additional storage needs. As a result, firms do not need to invest in totally new cold storage facilities as they expand, saving both time and money.

2. Cost-Effectiveness Modular cold rooms are often more affordable than traditional cold storage systems. Their construction uses prefabricated panels that are built off-site, which reduces labor costs and building time. Furthermore, firms can begin with a smaller, more economical unit and grow as needed, avoiding the high initial expenses associated with constructing a big, permanent cold storage facility.

3. Energy Efficiency Modern modular cold rooms are designed to be energy efficient. They are made of high-quality insulating materials that reduce heat transfer and, hence, the energy required to maintain the optimum temperature. Many modular cold rooms also include efficient temperature control systems that optimize energy usage, cutting overall running expenses.

4. Flexibility and Customization Modular cold rooms provide a high level of flexibility and customization. Businesses can select from a range of sizes, shapes, and combinations to suit their specific requirements. This flexibility extends to the interior arrangement, which allows for the installation of shelves, racks, and other storage solutions specific to the objects being stored. Furthermore, modular cold rooms can be configured to maintain multiple temperature zones within the same unit, allowing for a diverse selection of products.

5. Quick Installation and Minimal Disruption Modular cold rooms are prefabricated, making installation quick and uncomplicated. Modular cold rooms can be erected on-site in a fraction of the time that typical cold storage construction takes. This reduces downtime and disruption to corporate operations, allowing businesses to begin utilizing their new storage facilities sooner.

Read more....

0 notes

Text

Choose the Right Cold Storage Room Manufacturer for Your Industry

Today’s fast-moving, quality-sensitive sectors require dependable temperature controlled environments, more than ever. If you are dairy, pharmaceutical, food or horticulture, when you select a vendor to work with on a cold storage room; you could decide on a vendor that will impact the integrity of your product, your compliance requirements, and the efficiency of your operations going forward. With numerous options available in the marketplace, it can be difficult and overwhelming to find the best fit among Cold Storage Room Vendors. This blog post will help you outline an overview for making the best decision to fulfill the needs of your industry.

Understanding the Importance of Cold Storage

Cold storage is the foundation of perishable management. Use it for anything from keeping dairy and meat fresh, to keeping life-saving pharmaceuticals in-tact for maximum potency, cold rooms have the best environmental conditions for various perishable products. Businesses rely on the best option when preserving their products for more attention and cost.

Not all cold storage rooms are equal. Each industry has its own temperature, humidity, and space specifications, and that's why it's important to find a manufacturer with industry-specific expertise. Some of the best Cold Storage Room Manufacturers provide a tailored solution based on these criteria.

Key Considerations When Choosing a Cold Storage Room Manufacturer

Industry Experience Select a manufacturer with demonstrable experience in your field. For example, a Pharmaceuticals Cold Room Manufacturers must be sufficiently knowledgeable of pharmaceutical storage regulations; GDP (Good Distribution Practice) and temperature mapping processes.

Customization Capabilities Each industry will have its own cold store requirements. Dairy Cold Room Manufacturers, for example, must ensure that their cold rooms can accommodate different volumes of milk and dairy products and are up to hygienic standards. In the same way, there are Modular Cold Room Manufacturers, who must provide an adaptable design that can increase in size as big as your business can get!

Quality of Materials and Technology Find manufacturers that construct cold rooms with good insulation and efficient refrigeration that are the two key components that will determine the lifespan and performance of your cold room.

Regulatory Compliance Make sure your manufacturer meets national and international standards when constructing your cold room. This is mainly critical for those that want to purchase from Pharma Cold Room Manufacturers because they must meet strict temperature requirements and record specifications.

Customer Support and Maintenance It is vital that there will be good after sales service from your supplier. Your after sales service should include from the initial set up, using them for planned maintenance, and sourcing help day or night if something goes wrong. Your manufacturer should support a range of services.

Why Modular Cold Room Manufacturers Are Gaining Popularity

Modular cold rooms have revolutionized the storage landscape by offering:

Flexibility: Easily expandable based on business growth.

Ease of Installation: Quick and hassle-free assembly.

Space Optimization: Customizable dimensions to suit different layouts.

Cost Efficiency: Lower upfront costs with reduced construction time.

Businesses with fluctuating storage needs, like food processing units and logistics hubs, benefit immensely from solutions offered by Modular Cold Room Manufacturers.

Sector-Specific Recommendations

Dairy Industry

Dairy products are especially vulnerable to fluctuations in temperature. A good cold room must hold its temperature accurately, prevent cross-contamination, and allow for easy cleaning.

Top Dairy Cold Room Manufacturers understand these requirements and offer units with:

High-grade stainless steel interiors

Advanced temperature monitoring systems

Proper airflow and humidity control

Pharmaceutical Industry

Pharmaceuticals usually involve storing products within a small temperature band. If the product is not stored at the right temperature, it can spoil and the user will have to deal with legal action and the impact of damage to their reputation.

Reputable Pharma Cold Room Manufacturers provide:

Precision cooling systems

Backup power solutions

Real-time temperature tracking

Data logging and alert systems

Banana Ripening

Banana ripening is a specialized process that requires specific conditions that need to be adhered to for good results, with poor control leading to the loss of the product and/or variation in ripening.

Banana Ripening Chamber Manufacturers design chambers that offer:

Controlled temperature and humidity

Ethylene gas control systems

Durable construction for long-term use

Multi-Purpose Cold Rooms

Some companies would require a more adaptable approach. Companies that specialize in modular systems would be appropriate in this case.

Leading Modular Cold Room Manufacturers provide:

Configurable layouts

Portable options

Compatibility with various refrigeration units

Questions to Ask Before Finalizing Your Manufacturer

Can you provide case studies or client references in my industry?

What insulation and refrigeration technologies do you use?

How scalable are your cold room solutions?

Do you offer preventive maintenance and emergency support?

Are your units energy-efficient and environmentally friendly?

How to Evaluate Cold Storage Room Manufacturers

Online Research

Begin by researching directories, discussion boards, and B2B sites / platforms, including Consumer Review sites. Look for feedback from customer reviews and ratings of Cold Storage Room Manufacturers.

Site Visits

If you can, visit the manufacturing plant of an organization you are interested in. This allows you to see their capabilities, any levels of technology used, quality control, etc.

Trial Installations

Some higher-end manufacturers will have a pilot installation, or demo unit, which will allow you to see the performance of the unit before committing to a long-term investment.

Cost vs. Value

Do not choose solely based on price. Look at the value you are getting; warranty, energy savings, unit life, service support are all equally important.

Conclusion

Choosing the best Cold Storage Room Manufacturer is more than making a purchase; it is an investment in the success of your business for the long term. Whether you need a banana ripening chamber, cold room for pharmaceuticals, or modular and flexible design, a knowledgeable expert is the best partner to work with.

Quality manufacturers like Modular Cold Room Manufacturers, have the experience, technology, and dedicated service support to ensure that you will be supplied with a well-designed, efficient, reliable and fit-for-purpose storage system.

So take your time, consider your options, ask the correct questions, and invest in a solution that will keep your business cool!

#Cold Storage Room Manufacturers#Modular Cold Room Manufacturers#Banana Ripening Chamber Manufacturers#Pharma Cold Room Manufacturers#Dairy Cold Room Manufacturers

0 notes

Text

Cold Room - Cold Storage Manufacturer | Acmas Technologies

Acmas Technologies is a leading Cold Storage Manufacturer, offering advanced Cold Room solutions designed to preserve temperature-sensitive products across industries. Our cold rooms are engineered with high-efficiency insulation, energy-saving refrigeration systems, and precise temperature control, making them ideal for pharmaceuticals, food processing, agriculture, and research facilities. Built to meet international standards, our modular cold storage units ensure durability, hygiene, and long-term performance. Whether you need walk-in cold rooms, blast freezers, or custom-built solutions, Acmas Technologies delivers reliable and cost-effective systems tailored to your specific requirements. Trust us for innovative cold storage solutions that ensure product integrity and operational efficiency. Partner with Acmas Technologies — your expert in cold chain solutions.

Visit: https://www.acmasindia.co.in/cold-room.html

#Cold Room#Cold Storage#Cold Room Manufacturer#Cold Storage Manufacturer#Cold Room Solutions#Cold Storage Room#Walk-In Cold Room#Modular Cold Room#Cold Storage for Food Industry#Cold Storage for Pharmaceuticals#Cold Storage System#Custom Cold Rooms#Blast Freezer Room#Industrial Cold Storage#Cold Chain Solutions

0 notes

Text

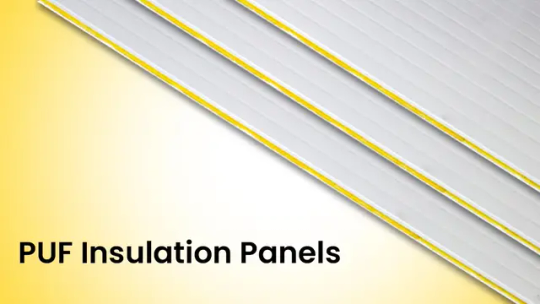

PUF Panel Applications in Cold Storage: From Clean Rooms to Modular Chambers

In India’s evolving industrial and food logistics landscape, PUF panels have quietly become the backbone of efficient cold storage infrastructure. These panels aren’t just a building component—they're a critical enabler of temperature-sensitive operations, from pharmaceuticals and food processing to precision-driven clean room environments.

Here’s a closer look at how PUF panels are being used across various cold storage and controlled-environment applications, and why industries are increasingly relying on them.

What Are PUF Panels?

PUF (Polyurethane Foam) panels are insulated sandwich panels made by injecting rigid polyurethane foam between two metal sheets—typically PPGI (Pre-Painted Galvanized Iron). The result is a lightweight yet sturdy panel with excellent thermal insulation, moisture resistance, and fire-retardant properties.

Why PUF Panels Are Ideal for Cold Storage in India

Thermal Conductivity: With a thermal conductivity of around 0.022 W/mK, PUF panels minimize heat transfer—vital for maintaining cold chain integrity.

Fast Installation: Prefabricated panels allow quick setup, reducing construction time by up to 60%.

Low Operating Costs: Proper insulation leads to lower energy bills and consistent temperature maintenance.

Hygienic and Compliant: Meets standards for food-grade and pharma-grade environments.

Applications of PUF Panels in Cold Storage

1. Modular Cold Rooms

From compact 5MT rooms to high-capacity storage chambers, PUF panels are widely used to create modular cold rooms with excellent air-tightness and insulation. They are especially useful for:

Dairy and meat processing

Frozen food storage

Floriculture units

Ice cream storage

2. Clean Rooms and Pharma Labs

In pharma, temperature and hygiene control are critical. PUF panels support dust-free, temperature-controlled environments that comply with GMP standards—ideal for:

Vaccine storage

R&D labs

Medical warehouses

3. Blast Freezers

Used in meat, seafood, and bakery processing units, PUF-insulated blast freezers help rapidly bring down temperatures while preserving the integrity of products.

4. Cold Storage Warehouses

Large-scale logistics parks and agri-storage facilities use PUF panels in roofing, walls, and flooring to maintain uniform temperatures while saving on long-term energy costs.

5. Modular Chambers and Portacabins

Temporary or scalable setups like mobile cold units or cold storage porta cabins are gaining traction across rural and semi-urban areas in India.

Why PUF Panels Are the Smart Choice in India

India faces extreme climates—from 45°C summers to monsoons with over 80% humidity. PUF panels address these challenges effectively by:

Reducing energy costs by up to 50%

Resisting corrosion and rust in coastal or humid zones

Offering fast scalability for businesses expanding into Tier 2 and Tier 3 cities

Supporting the national cold chain infrastructure push under schemes like PM-KUSUM and Operation Greens

A Trusted Name Behind the Panels

While this article shares a neutral overview, it’s worth noting that several industrial leaders have built their cold storage units using solutions from top PUF panel manufacturers like EPACK Prefab. With years of experience, they offer not just panels, but full-service support—from design to delivery and on-site assistance.

Whether you’re setting up a high-volume cold warehouse or a pharma-grade clean room, choosing the right insulated panels is essential for long-term operational success.

Related Post - What is a PUF Panel and Why Choose It Over Traditional Construction Materials?

0 notes

Text

Designing Your Dream: The Art of Custom Cold Room Design

When it comes to preserving perishable goods, one size certainly does not fit all. That's where custom cold room design steps in, offering tailored solutions to meet the unique needs of diverse industries and businesses. In this article, we'll delve into the world of Custom Cold Room Design, exploring its benefits, considerations, and the transformative impact it can have on your operations.

Unveiling the Essence of Custom Cold Room Design

Imagine a space that perfectly aligns with your needs: a cold room that seamlessly integrates into your workflow, maximizing efficiency and minimizing waste. Custom cold room design makes this vision a reality, offering bespoke solutions tailored to your specific requirements. Think of it as the difference between off-the-rack and made-to-measure: while both serve a purpose, custom design ensures a perfect fit, optimizing functionality and performance.

The Purpose of Custom Cold Room Design

At its core, custom cold room design is all about functionality and efficiency. Whether you're storing fresh produce, pharmaceuticals, or floral arrangements, the goal is the same: to create an environment that maintains optimal temperature and humidity levels, preserving the integrity of your goods. Customization allows you to design a cold room that aligns with your workflow, space constraints, and operational needs, maximizing productivity and minimizing costs.

The Components of Custom Cold Room Design

Custom cold room design involves careful consideration of various components, each playing a crucial role in the overall functionality and performance of the system:

Insulation Materials: Choosing the right insulation materials is essential for maintaining consistent temperatures and minimizing energy consumption. Custom designs allow you to select materials that offer the best combination of thermal efficiency and durability for your specific application.

Cooling Systems: From traditional refrigeration units to advanced HVAC technologies, custom cold room design offers flexibility in selecting the most suitable cooling system for your needs. Whether it's a split-system configuration or a centralized chiller plant, customization ensures optimal performance and energy efficiency.

Layout and Configuration: Custom designs allow you to optimize the layout and configuration of your cold room to maximize space utilization and accessibility. Whether you need a walk-in cooler, freezer, or combination unit, customization ensures that every square foot is utilized effectively.

Unlocking the Benefits: Why Choose Custom Cold Room Design?

But what sets custom cold room design apart from pre-fabricated options? Let's explore the benefits that make it a preferred choice for businesses across various industries:

Tailored Solutions

Custom cold room design offers tailored solutions that are specifically designed to meet your unique needs. Whether you require specialized shelving, custom door sizes, or specific temperature ranges, customization ensures that every aspect of your cold room is optimized for your requirements.

Enhanced Efficiency

By optimizing the design and layout of your cold room, custom solutions can significantly enhance efficiency and productivity. Streamlined workflows, optimized storage capacity, and energy-efficient components all contribute to reduced operating costs and increased profitability.

Future-Proofing

Custom cold room design allows for future-proofing your operations by accommodating potential growth and changes in your business needs. Whether you're expanding your product lines or scaling up your operations, a custom-designed cold room can adapt to meet your evolving requirements, minimizing the need for costly renovations or upgrades down the line.

Applications Across Industries: Where Custom Cold Room Design Shines

Custom cold room design finds applications across a wide range of industries, each benefiting from tailored solutions that meet their specific needs:

Food and Beverage: From restaurants and catering businesses to food processing facilities and cold chain logistics, custom cold room design ensures the freshness and safety of perishable goods throughout the supply chain.

Healthcare: Hospitals, clinics, and pharmaceutical manufacturers rely on custom cold room design to store medications, vaccines, and biological samples at precise temperatures, ensuring efficacy and compliance with regulatory requirements.

Floral Industry: Florists and floral wholesalers utilize custom cold room design to extend the shelf life of fresh flowers and plants, preserving their freshness and beauty until they reach the customer's hands.

Conclusion: Elevating Your Operations with Custom Cold Room Design

In today's competitive business landscape, efficiency, and flexibility are key to success. Custom cold room design offers a tailored solution that aligns with your unique needs, maximizing efficiency, and minimizing costs. So, whether you're in the food and beverage, healthcare, or floral industry, consider the transformative impact that custom cold room design can have on your operations, and take the first step toward designing your dream cold room today.

#Cold Room Temperature Monitoring#Floral Preservation Cold Rooms#Meat and Seafood Cold Storage#Emergency Cold Room Repairs#Modular Cold Room Extensions#Energy-Saving Refrigeration Techni

1 note

·

View note

Text

#Framing #cold with #zero #thermal #compromise #Aluminum #extruded #panel #frame provide airtight integration corrosion #resistance & dimensional #stability #essential for #building #efficient & #modular cold #storage #environment ❄️ Thermal break compatibility 📏 Tight-tolerance for insulated panels 🧱 Rust-proof and easy to clean #Built to frame #future of cold

📞 Beyond Lineals 🌐 www.beyondlineals.com | 📧 [email protected] | 📱 +91 9811088250

www.beyondlineals.com

www.instagram.com/beyondlineals/

www.x.com/Beyondlineals

www.facebook.com/beyondlineals/

www.youtube.com/@BeyondLineals

www.threads.net/@beyondlineals

www.in.pinterest.com/Beyondlineals/

#ColdStorageConstruction #AluminumExtrusion #PanelFraming #ModularColdRooms #IndustrialFreezer #ThermalEfficiency #CorrosionResistant #ColdRoomEngineering #SmartColdDesign

2 notes

·

View notes

Text

youtube

The Ultimate 2024 Guide to Sleeper Sofas: Style, Comfort & Space-Saving Magic

Let’s face it: not all of us have the luxury of a dedicated guest room. Whether you're in a cozy apartment, hosting guests for the weekend, or simply looking to get more function out of your living room, a sleeper sofa is the multitasking miracle you didn’t know you needed. Think of it as the Swiss Army knife of furniture—part sofa bed, part bed, 100% space-saving genius.

In this comprehensive guide, we’ll walk you through everything you need to know about sleeper sofas—from types, comfort levels, and designs, to choosing the right one for your lifestyle. Let's dive in and get comfy!

🛋️ What Is a Sleeper Sofa?

Definition and Functionality

A sleeper sofa, also known as a sofa bed, is a couch with a hidden mattress inside. It transforms into a bed, offering a convenient sleeping space without taking up permanent room.

Sleeper Sofa vs Sofa Bed

Though often used interchangeably, some distinguish sleeper sofas as pull-out types with full mattresses, while sofa beds often refer to futons or click-clacks that fold flat.

🛠️ Types of Sleeper Sofas

1. Pull-Out Sofa Sleeper

The classic. You remove the cushions and pull out a metal frame with a foldable mattress. Great for guests.

2. Futon-Style Sleeper

Simple mechanism: fold the back down to create a flat surface. Ideal for smaller spaces and budget buyers.

3. Click-Clack Mechanism

A modern twist on the futon, it "clicks" into different positions—upright, reclined, and flat. Fast and easy setup.

4. Sectional Sleeper Sofa

Big, comfy, and often with extra features like storage. Great for families or larger living rooms.

5. Loveseat Sleeper

Perfect for small rooms or studio apartments. Converts into a twin-sized bed.

6. Chair Sleeper

Yes, even a single seat can turn into a bed! Ideal for kids or solo guests.

📏 How to Choose the Right Sleeper Sofa

1. Measure Your Space

Before you fall in love with a design, grab your tape measure. Consider both the size as a sofa and when fully extended.

2. Determine Frequency of Use

Will it be used nightly or just for the occasional guest? Frequent sleepers should opt for higher-quality mattresses.

3. Consider Who’s Sleeping

Kids? Elderly relatives? Couples? Choose size and firmness accordingly.

4. Match Your Interior Style

Don't sacrifice aesthetics for functionality. Find one that blends with your decor—modern, traditional, industrial, etc.

💤 Mattress Types for Sleeper Sofas

1. Innerspring

Traditional coils. Affordable but may not be super comfy.

2. Memory Foam

Contours to your body. Great for long-term sleep quality.

3. Gel-Infused Foam

Regulates temperature while offering memory foam comfort.

4. Air-Over-Coil

Inflatable top with spring base—luxurious and supportive.

5. Latex

Eco-friendly, breathable, and durable. Higher cost, higher comfort.

🎨 Upholstery Options

1. Fabric

Soft and available in many colors/patterns. Can stain easily—treat with care.

2. Leather

Elegant and easy to clean. Might feel cold and firm.

3. Microfiber

Stain-resistant and affordable. A great family-friendly option.

4. Velvet

Luxurious texture and trendy. High-maintenance but visually stunning.

💡 Sleeper Sofa Features to Consider

1. Storage Compartments

Great for hiding extra linens or pillows.

2. USB Charging Ports

Because who doesn’t want to charge their phone in bed?

3. Reclining Features

Some sectional sleepers also recline—double duty furniture!

4. Modular Sections

Move pieces around for maximum versatility.

🏡 Best Uses for a Sleeper Sofa

1. Studio Apartments

Sleep, sit, lounge—all in one place.

2. Home Offices

Transform workspaces into guest rooms in seconds.

3. Guest Bedrooms

Save floor space while keeping your room functional.

4. Vacation Homes

Ideal for hosting unexpected visitors without extra beds.

🛠️ Sleeper Sofa Maintenance Tips

1. Vacuum Regularly

Dust and crumbs build up fast in the crevices.

2. Rotate the Mattress

Even wear extends mattress life.

3. Spot-Clean Spills Immediately

Especially on fabric and velvet models.

4. Lubricate Mechanisms

Keep the folding parts smooth and squeak-free.

📦 Top Sleeper Sofa Brands

1. IKEA

Affordable and stylish. Great for beginners.

2. Joybird

Customizable with trendy fabrics. Mid- to high-range pricing.

3. West Elm

Modern luxury. Expensive but elegant and durable.

4. Ashley Furniture

Reliable mid-range options. Variety of designs.

5. Burrow

Modular design and tool-free assembly. Ideal for urban dwellers.

💰 Budgeting for a Sleeper Sofa

1. Under $500

Futons, basic click-clacks, and IKEA specials.

2. $500–$1000

Mid-range pull-out sleepers with decent mattresses.

3. $1000+

High-quality materials, premium mattresses, and designer flair.

🛒 Where to Buy Sleeper Sofas

Online Retailers

Wayfair

Amazon

Burrow

Joybird

Article

Physical Stores

IKEA

Ashley HomeStore

Crate & Barrel

Local furniture outlets

🌱 Eco-Friendly Sleeper Sofa Options

1. Sustainable Materials

Look for FSC-certified wood frames and recycled fabrics.

2. Low-VOC Finishes

Avoid toxic chemicals in glue and finishes.

3. Organic Mattresses

Made without harsh chemicals—better for you and the planet.

👩🔧 Sleeper Sofa Troubleshooting

1. Mattress Feels Thin

Add a mattress topper for extra comfort.

2. Frame Squeaks

Tighten bolts and add lubricant to joints.

3. Difficult to Fold

Check for obstructions or bent frames.

🧰 DIY Sleeper Sofa Hacks

1. Add a Mattress Topper

Instant comfort upgrade!

2. Cover with Stylish Throws

Instant room makeover without buying a new couch.

3. Install Underneath Storage Bins

Perfect for small apartments.

🎯 Sleeper Sofa vs Alternatives

1. Murphy Bed

Folds into the wall. Great for space but expensive.

2. Air Mattress

Cheap and portable. Not ideal for long-term use.

3. Trundle Bed

Two beds in one. Takes more floor space but great for kids’ rooms.

📚 Real-Life Scenarios: When a Sleeper Sofa Saves the Day

Unexpected guests? Pull it out.

Movie night turns to sleepover? You’re ready.

Need to crash after a long workday? No judgment, just unfold.

🎉 Conclusion

A sleeper sofa isn’t just a couch with a party trick—it’s a space-saving, comfort-boosting, guest-friendly superhero of home design. With dozens of styles, features, and budgets available, there’s truly one out there for everyone. Whether you're buying your first apartment piece or upgrading your guest room, a sleeper sofa will serve you in ways a regular couch never could.

❓ FAQs

1. Are sleeper sofas comfortable to sleep on?

Yes, especially models with memory foam or upgraded mattresses. Add a topper for extra coziness.

2. Can you use a regular mattress in a sleeper sofa?

Nope. They require foldable, specially-sized mattresses.

3. How long do sleeper sofas last?

With regular use and proper care, around 7–15 years.

4. Are sleeper sofas good for everyday use?

Definitely—just invest in a durable frame and comfy mattress.

5. What size sleeper sofas are available?

Twin, Full, Queen, and even King sizes, depending on the model.

2 notes

·

View notes

Text

Cold Storage Construction in Bangalore

Cold Storage Construction

Cold Storage Manufacturers

Warehouse Cold Storage Construction

Cold Storage Warehouse Construction

Prefabricated Cold Storage Construction

Modular Cold Storage Construction

Cold Storage Building Construction

Prefab Cold Storage Construction

Steel Prefabricated Cold Storage Construction

Warehouse Cold Storage Manufacturers

Cold Storage Warehouse Manufacturers

Prefabricated Cold Storage Manufacturers

Modular Cold Storage Manufacturers

Cold Storage Building Manufacturers

Prefab Cold Storage Manufacturers

Steel Prefabricated Cold Storage Manufacturers

#coldstorageconstruction#coldstoragemanufacturers#prefabricatedcoldstorageconstruction#coldstoragebuildingconstruction#warehousecoldstorageconstruction#coldstorageconstructioncost#coldstorageinstallationcost#coldstoragewarehouseconstruction#modularcoldstorageconstruction#prefabcoldstorageconstruction#steelprefabricatedcoldstorageconstruction

2 notes

·

View notes

Text

Unlocking the Potential: Modular Cold Rooms in Kerala and Tamil Nadu

In the bustling agricultural landscapes of Kerala and Tamil Nadu, where the harvest season brings forth an abundance of fresh produce, the need for effective cold storage solutions has never been greater. This is where modular cold rooms step in, revolutionizing the way perishable goods are preserved and distributed. In this blog, we'll delve into the significance of modular cold rooms in these regions and how they are transforming the agricultural and food industries.

Understanding Modular Cold Rooms

Modular cold rooms are versatile refrigeration units that provide customizable storage solutions for perishable goods such as fruits, vegetables, dairy products, and pharmaceuticals. Unlike traditional cold storage facilities, modular cold rooms offer flexibility in size, design, and configuration, making them ideal for businesses of all scales.

Addressing the Challenges

Kerala and Tamil Nadu boast vibrant agricultural sectors, yielding an array of fresh produce year-round. However, the lack of efficient cold storage infrastructure has long been a challenge for farmers and distributors. Perishable goods often face spoilage due to inadequate preservation methods and limited storage capacity. This not only leads to financial losses for stakeholders but also impacts the availability and quality of produce in the market.

The Rise of Modular Cold Rooms

Enter modular cold rooms – the game-changer in cold storage solutions. These innovative units are rapidly gaining traction in Kerala and Tamil Nadu for several reasons:

Customization: Modular cold rooms can be tailored to suit the specific needs of businesses, whether it's a small-scale farmer looking for short-term storage or a large distributor in need of long-term preservation solutions.

Scalability: As the agricultural industry evolves, so do the storage requirements. Modular cold rooms offer scalability, allowing businesses to expand or downsize their storage capacity as per demand fluctuations.

Energy Efficiency: With advancements in refrigeration technology, modular cold rooms are designed to be energy-efficient, minimizing operating costs while maintaining optimal storage conditions.

Quick Installation: Traditional cold storage facilities often require extensive construction and lead time. In contrast, modular cold rooms can be installed swiftly, minimizing downtime and allowing businesses to start utilizing them at the earliest.

Transforming the Agricultural Landscape

The adoption of modular cold rooms in Kerala and Tamil Nadu is reshaping the agricultural landscape in several ways:

Reduced Food Wastage: By providing reliable cold storage facilities, modular cold rooms help minimize food wastage, ensuring that the surplus produce is preserved for future consumption or distribution.

Extended Shelf Life: Farmers and distributors can now extend the shelf life of their perishable goods, allowing them to explore new markets and improve profitability.

Quality Assurance: With precise temperature control and monitoring capabilities, modular cold rooms uphold the quality and freshness of the stored goods, enhancing consumer satisfaction and market competitiveness.

Conclusion

In conclusion, modular cold rooms are proving to be indispensable assets in the agricultural and food industries of Kerala and Tamil Nadu. By addressing the challenges of storage and preservation, these innovative solutions are fostering efficiency, sustainability, and growth in the sector. As the demand for reliable cold storage continues to rise, modular cold rooms are set to play an increasingly pivotal role in shaping the future of agriculture in these regions.

1 note

·

View note

Text

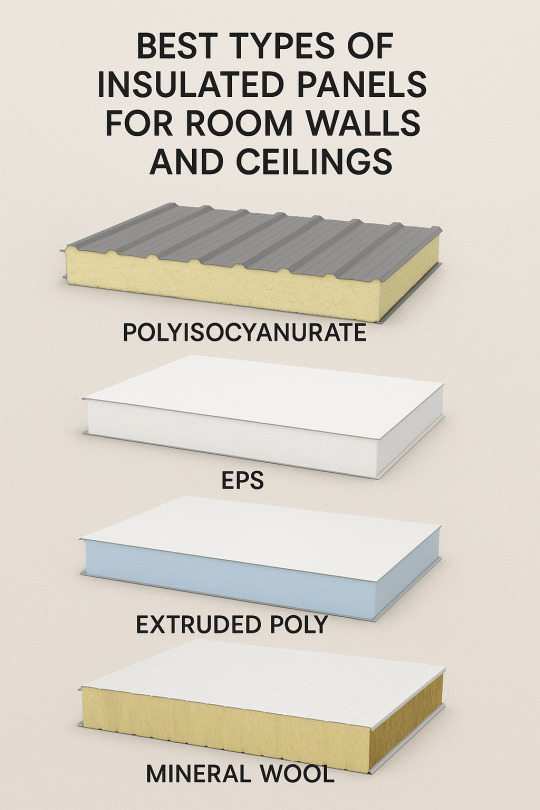

Best Types of Insulated Panels for Room Walls and Ceilings

In modern construction, energy efficiency, durability, and speed are more important than ever. Whether you're building a residential home, commercial office, warehouse, or prefab structure, choosing the right insulation for walls and ceilings is key to maintaining indoor comfort and reducing energy costs.

Insulated panels are prefabricated systems that combine insulation and structural support in a single solution. They’re ideal for temperature control, noise reduction, and structural strength. Here's a look at the best types of insulated panels for room walls and ceilings, each with its own advantages:

1. Polyisocyanurate (PIR) Panels

Polyisocyanurate, or PIR, is one of the highest-performing thermal insulation materials used in construction today. These panels consist of rigid foam sandwiched between two metal or board layers.

Key Benefits:

Superior thermal efficiency – high R-value per inch

Fire resistance – self-extinguishing properties

Lightweight and durable – easy to handle and install

Moisture resistance – ideal for both indoor and outdoor use

PIR panels are ideal for temperature-controlled spaces such as cold storage, server rooms, and industrial buildings.

2. Expanded Polystyrene (EPS) Panels

EPS panels are made from expanded polystyrene foam, known for its excellent insulating properties and cost-effectiveness. These panels are widely used in prefabricated and modular buildings.

Key Benefits:

Affordable insulation solution

Good thermal and acoustic performance

Lightweight and easy to cut or install

Environmentally friendly and recyclable

EPS panels are great for residential rooms, partitions, and standard prefab structures where cost and speed are priorities.

3. Extruded Polystyrene (XPS) Panels

Extruded polystyrene is a denser and stronger form of polystyrene insulation. XPS panels offer excellent thermal performance and resistance to moisture, making them ideal for high-humidity environments.

Key Benefits:

High compressive strength

Excellent moisture and water resistance

Smooth surface finish

Long-term durability

These panels are often used for roofs, ceilings, basements, and cold storage facilities.

4. Mineral Wool Panels

Mineral wool (or rock wool) panels are made from natural stone or slag fibers. Known for their fire resistance and soundproofing qualities, these panels are ideal for buildings where fire safety is a top priority.

Key Benefits:

Non-combustible and fire-resistant

Excellent sound insulation

Resistant to pests, mold, and rot

Eco-friendly and recyclable

They are commonly used in commercial and industrial spaces, especially in applications requiring acoustic control and fire safety.

Conclusion

The choice of insulated panels depends on your building's requirements—whether it’s superior thermal performance, moisture resistance, acoustic insulation, or fire safety.

Polyisocyanurate is best for energy efficiency, EPS offers an economical and lightweight option, XPS excels in moisture-prone areas, and Mineral Wool provides unbeatable fire and sound insulation.

Investing in the right insulation solution helps you reduce energy bills, enhance occupant comfort, and extend the life of your building.

Looking for high-quality insulated panel solutions? Partner with trusted manufacturers like Engko for expert guidance and top-grade materials tailored to your project.

#prefab#pre engineered building manufacturers#prefabricated#peb#prefabricated structure#warehouse#industrial

1 note

·

View note

Text

Understanding Cold Storage Types and Their Ideal Applications

In today’s world, where freshness, safety, and shelf life are more important than ever, cold storage systems have become a silent yet essential backbone of several industries, from food and pharmaceuticals to flowers and chemicals.

Whether you’re a farmer, retailer, manufacturer, or logistics provider, understanding the various types of cold storage and their ideal applications can help you make more informed business decisions.

Let’s dive into the world of cold storage in simple, practical terms.

What Is Cold Storage, Really?

At its core, cold storage is a temperature-controlled space designed to preserve perishable goods.

It slows down spoilage by reducing the growth of bacteria and other microorganisms.

The goal? Keep products safe, fresh, and usable for longer than they would be at room temperature.

But cold storage isn’t one-size-fits-all. Different products need different temperatures, humidity levels, and layouts, and that’s where various cold storage types come into play.

Types of Cold Storage and Where They Fit Best

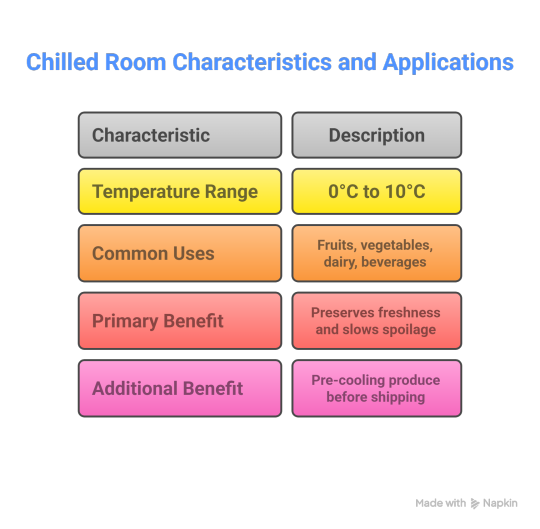

1. Chilled or Cool Rooms (0°C to 10°C)

Best for: Fruits, vegetables, dairy products, beverages, and flowers.

Chilled rooms are perhaps the most common type of cold storage. These are ideal for items that need to stay cool but not frozen.

Think of them as your walk-in refrigerator, just a lot bigger and more consistent.

Why use it? Cold rooms help preserve freshness, taste, and texture while slowing down spoilage.

They’re also great for pre-cooling freshly harvested produce before shipping or processing.

2. Freezer Rooms (-18°C and below)

Best for: Meat, poultry, seafood, frozen vegetables, and processed foods.

Freezer rooms are built to keep products well below freezing temperatures.

This is crucial when you need long-term storage without compromising food safety.

Why use it? Freezing stops microbial activity, extending the shelf life of food dramatically.

It's ideal for businesses that deal with bulk storage or seasonal inventory management.

3. Blast Freezers / Blast Chillers

Best for: Ice cream, cooked food, baked items, and sensitive pharmaceuticals.

Blast freezers are high-speed cooling units that bring down the temperature of products rapidly, sometimes from room temperature to -18°C in a few hours.

Why use it? Speed matters. The quicker you freeze, the smaller the ice crystals, which means better texture and quality when thawed.

It’s commonly used in food production, bakeries, and even in clinical trials for temperature-sensitive medicines.

4. Walk-in Cold Rooms

Best for: Restaurants, hotels, and medium-scale food businesses.

Walk-in cold rooms offer a balance of space, temperature control, and easy access.

They can be customised to suit specific product categories and storage volumes.

Why use it? They’re easy to operate, maintain, and organise. Perfect for businesses that need frequent access to stored items.

5. Modular Cold Storage

Best for: Startups, temporary storage, or changing product lines.

Modular cold rooms are prefabricated and can be assembled quickly. They offer flexibility in terms of location, size, and application.

Why use it? Think of them as plug-and-play cold storage. If your business is growing or changing fast, modular units are a cost-effective, scalable option.

6. Refrigerated Containers (Reefer Units)

Best for: Shipping and transporting perishable goods.

Reefer containers are portable cold storage units typically used in shipping and trucking. They maintain controlled temperatures during transit.

Why use it? They’re crucial for global trade and logistics. From fresh mangoes shipped overseas to temperature-sensitive vaccines, reefer units make safe delivery possible.

7. Pharma Cold Storage

Best for: Vaccines, biological samples, insulin, and certain medical equipment.

These cold rooms are designed with precision temperature and humidity control. They often include alarm systems, backup power, and data logging.

Why use it? Pharmaceutical products can lose their potency or become unsafe if stored improperly. Regulatory compliance is also a major concern here.

8. Ultra-Low Temperature Freezers (-40°C to -80°C)

Best for: Research labs, biotech firms, and specialized pharmaceutical products.

These freezers are typically used in scientific environments where biological samples, cell cultures, or enzymes need ultra-low temperatures to remain stable.

Why use it? Not your everyday cold storage. These units are built for precision and safety in highly sensitive use cases.

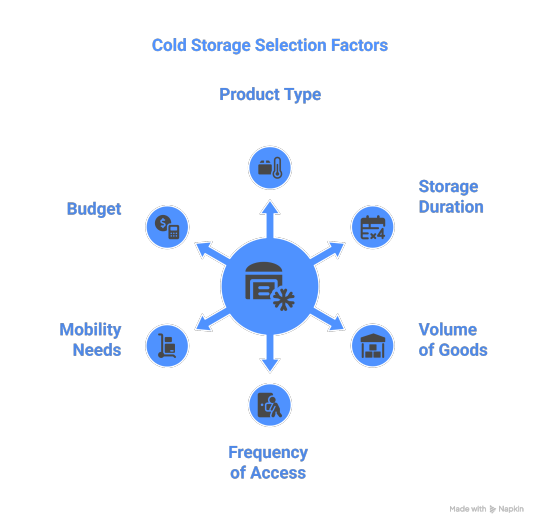

How to Choose the Right Cold Storage for Your Needs

Now that you know the types, how do you pick the right one for your business? Here are a few factors to consider:

Product Type: Fresh produce? Frozen meat? Medicines? Each category has its own temperature requirements.

Storage Duration: Are you storing for a few days or several months?

Volume of Goods: Will you need a small unit or a full warehouse?

Frequency of Access: Do staff need to walk in frequently, or is the storage more passive?

Mobility Needs: Will the cold storage remain at one site, or does it need to be portable?

Budget: Initial cost, operational costs, and maintenance should all be factored in.

Common Industries Using Cold Storage

Cold storage isn’t limited to food. Here’s a quick look at who benefits:

Agriculture: Farmers store seasonal fruits and vegetables to reduce waste and increase profits.

Retail and Supermarkets: To keep inventory fresh and safe for customers.

Pharmaceuticals: Ensuring drugs and vaccines remain effective.

Hospitality: Hotels and restaurants manage perishable items efficiently.

Floriculture: Flowers last longer with proper cold storage, improving export potential.

Chemical Industry: Certain substances require consistent cold temperatures to remain stable.

Final Thoughts

Understanding cold storage types isn’t just about refrigeration; it’s about protecting what matters.

Whether it's preserving food, maintaining medicine safety, or ensuring quality in transport, the right cold storage can make or break your operations.

With evolving technology, smart temperature controls, and energy-efficient models, cold storage solutions today are more reliable and customizable than ever before.

If you're planning to invest in one, think beyond just cooling; think about what you're protecting and how your business can benefit in the long run.

#cold storage manufacturer#cold storage room manufacturer#cold room manufacturer#cold room manufacturer in india#cold storage manufacturer in india#cold storage manufacturers#cold storage manufacturer in gujarat#cold room manufacturers in india

0 notes

Text

Top 5 PUF Panel Manufacturers in Noida: Leading the Way in Insulated Panel Solutions

In the rapidly evolving world of construction, PUF panels have emerged as a game-changer. Whether it is for cold storage, warehouse, clean rooms or prefabricated buildings, PUF (polyurethane foam) panels provide superior thermal insulation, energy efficiency and cost-effective solutions for modern construction. With the increasing demand for these panels, Noida has become the hub of reliable PUF panel manufacturers.

If you’re looking to invest in high-quality PUF panels for your next project, it’s important to partner with a reliable manufacturer that can deliver durability, performance, and cost savings. In this article, we will highlight the top 10 PUF panel manufacturers in Noida, known for their exceptional product offerings and customer satisfaction.

1. EPACK Prefab Technologies Limited

EPACK Prefab Technologies Ltd. is a well-established name in the PUF panel manufacturing industry. Known for its high-quality products, EPACK Prefab offers insulated panels designed to meet the energy efficiency and thermal insulation needs of modern construction projects. Their panels are used in cold storage, warehouses, industrial sheds and modular buildings.

With advanced manufacturing facilities and a focus on innovation, EPACK Prefab offers durable, fire-retardant, and energy-efficient panels that deliver long-term performance. Their PUF panels are customizable to meet specific project requirements, ensuring that customers get solutions that suit their needs.

2. Cactus Profiles Private Limited

Cactus Profiles Pvt Ltd is another leading PUF Panel Manufacturer in Noida. The company specializes in manufacturing high-performance insulated panels for a wide range of applications, including cold storage, pharmaceutical environments and industrial buildings. Cactus Profiles prides itself on delivering premium-quality panels that are both affordable and highly durable.

Their PUF panels are designed to provide excellent thermal insulation, moisture resistance and fire protection, making them the preferred choice for industries that require reliable, long-lasting building materials. With a reputation for superior customer service, Cactus Profiles remains a top choice for PUF Panels in Noida.

3. Vatsgroup India Private Limited

Vatsgroup India Pvt. Ltd. has been a trusted manufacturer of PUF Panels in Noida, providing high-quality products for various construction needs. They specialise in the production of thermal insulation panels used in cold storage, clean rooms, warehouses and prefabricated buildings.

The company is known for its commitment to precision engineering, using advanced manufacturing techniques to produce high-quality panels. Their PUF panels are designed with durability and energy efficiency in mind, making them a great solution for industries that require reliable insulation and low maintenance. Vatsgroup India is highly regarded for its customizable solutions and timely delivery.

4. Metal Tree Engineering Private Limited

Metal Tree Engineering Private Limited is a well-known manufacturer in the PUF panel market, providing a diverse range of insulated panel products for industrial and commercial use. The company focuses on high-quality, energy-efficient solutions that cater to industries in need of temperature-controlled environments.

With a strong presence in Noida, Metal Tree Engineering offers panels that are moisture-resistant, fire-retardant, and capable of maintaining optimal internal temperatures. Their PUF panels are engineered for strength, thermal insulation, and energy savings, making them suitable for a variety of projects, including cold storage and modular buildings.

5. Panjetani Buildwell Private Limited (PBPL)

Panjetani Buildwell Private Limited (PBPL) has been a reliable supplier of PUF insulated panels in Noida for several years. Known for their high-strength and energy-efficient panels, PBPL specializes in cold storage panels that help businesses maintain strict temperature controls.

Their PUF panels are designed to provide superior insulation, fire resistance, and moisture protection—key attributes for industries requiring reliable and long-lasting solutions. With a reputation for excellent craftsmanship and quick delivery, PBPL continues to be a trusted choice for businesses looking for energy-efficient, high-quality panels.

Read More: Top 4 Advantages of Having A Metal Building In The Winters

Conclusion: Why Choose PUF Panels for Your Construction Projects?

PUF panels have emerged as an industry standard for cold storage, clean rooms, industrial sheds, and warehouses due to their energy efficiency, cost-effectiveness, and durability. The top 5 manufacturers mentioned above, including EPACK Prefab, Cactus Profiles, Vatsgroup India, Metal Tree Engineering, and Panjetani Buildwell, have proven their ability to deliver premium-quality panels that meet the diverse needs of modern construction projects.

Choosing the right PUF panel manufacturer is crucial for ensuring that your building meets industry standards for thermal insulation, fire resistance, and moisture control. By partnering with trusted manufacturers like these, you can ensure that your project is built to last, is energy-efficient, and will provide long-term performance.

For more information or to discuss your next project, reach out to EPACK Prefab or any of the other leading PUF panel manufacturers in Noida.

#PUFPanelManufacturers#ColdStoragePanels#CleanRoomPanels#InsulatedPanels#PUFInsulation#IndustrialPanels#EnergyEfficientBuilding#ModularBuildings#PreEngineeredBuildings#NoidaManufacturers

0 notes

Text

Why Use HACCP-Approved Shelving Systems in Australia?

In Australia’s foodservice and healthcare industries, hygiene and safety are non-negotiable. That’s why using HACCP-approved shelving systems has become essential for businesses striving to meet high standards of cleanliness, food safety, and compliance. Whether you’re operating a commercial kitchen, cold storage room, food processing plant, or healthcare facility, the right shelving makes all the difference.

What is HACCP and Why Does it Matter?

HACCP stands for Hazard Analysis and Critical Control Points, a globally recognised system for managing food safety. In Australia, HACCP compliance ensures that businesses control potential hazards in food storage and preparation. Using HACCP-approved shelving means you’re taking the necessary steps to reduce the risk of contamination, improve hygiene practices, and pass audits with confidence.

Key Benefits of HACCP-Approved Shelving Systems

1. Optimised Hygiene

HACCP-certified shelving systems are made from materials that resist rust, mould, and bacteria. Many include removable polymer mats that can be run through dishwashers for regular cleaning, a crucial feature in high-risk areas like cool rooms and dry stores.

2. Compliance with Australian Food Safety Regulations

Using HACCP-compliant shelving helps businesses align with FSANZ (Food Standards Australia New Zealand) requirements. It’s not just best practice — it’s often a legal necessity in food and healthcare environments.

3. Durability in Harsh Conditions

These shelving units are built for tough conditions. Whether it’s a walk-in freezer or a hot commercial kitchen, HACCP-approved shelving systems withstand moisture, temperature fluctuations, and heavy loads without degrading over time.

4. Efficient Use of Space

Smart design allows for maximum storage capacity while promoting airflow — vital for food preservation and preventing bacterial growth.

Why Choose Mantova for HACCP Shelving?

Mantova, a trusted name in Australian shelving solutions, manufactures a wide range of HACCP-approved shelving systems that are engineered to meet the highest industry standards. Designed and made in Australia, Mantova shelving is built using premium-grade materials such as zinc-treated steel with antimicrobial coatings or fully polymer-based finishes.

Our shelving systems feature tool-free assembly, modular configurations, and fully removable shelves — all designed to make cleaning, setup, and reorganisation simple. Mantova’s commitment to safety and quality ensures your storage is always audit-ready.

Industries That Benefit from HACCP Shelving

· Commercial Kitchens & Restaurants

· Aged Care & Hospitals

· Food Manufacturing Plants

· Cold Storage & Distribution Warehouses

· Supermarkets & Butcheries

FAQs — HACCP-Approved Shelving Systems in Australia

Q1: What makes shelving HACCP-compliant? A: HACCP-compliant shelving must be easy to clean, non-corrosive, non-toxic, and resistant to moisture, mould, and bacteria. Designs often avoid sharp corners or hard-to-clean joints.

Q2: Is HACCP shelving required by law in Australia? A: While not always a direct legal requirement, HACCP principles are mandated by food safety regulators like FSANZ. Using HACCP shelving ensures your setup supports compliance.

Q3: How often should HACCP shelving be cleaned? A: Ideally, shelving should be cleaned weekly or more frequently depending on the usage environment. Mantova shelving makes cleaning easier with dishwasher-safe shelf inserts.

Q4: Can Mantova shelving be customised for specific spaces? A: Yes. Mantova offers custom configurations to suit any commercial space, ensuring you maximise both compliance and storage efficiency.

Q5: Is Mantova shelving suitable for cold storage environments? A: Absolutely. Mantova’s HACCP shelving systems are designed for extreme cold and moisture, making them perfect for cool rooms and freezers.

Final Thoughts

In fast-paced, hygiene-critical industries, you can’t afford to compromise on safety. HACCP-approved shelving systems offer peace of mind, improved workflow, and regulatory compliance. By choosing Mantova, you’re investing in a durable, food-safe solution made for Australian conditions.

For expert advice and tailored shelving solutions, contact Mantova today — and make safety your standard.

#shelving#mantova shelving#shelving australia#shelving system#haccp#haccp certification#haccp approve

0 notes

Text

Tin Shed Manufacturers in India: Enabling Fast, Durable, and Cost-Effective PEB Solutions

Introduction: As industrial and agricultural sectors grow across India, the demand for tin sheds—popular for their affordability and quick installation—has surged. These sheds, often used for warehouses, workshops, factories, and storage spaces, are integral to modern infrastructure. Today’s leading tin shed manufacturers in India are closely aligned with PEB manufacturers, delivering robust and scalable shed solutions that form a key part of pre-engineered structures.

What Is a Tin Shed in the Context of PEB? In the world of Pre-Engineered Buildings (PEBs), a tin shed refers to a lightweight, steel-structured shelter covered with galvanized or color-coated metal sheets (commonly referred to as “tin”). Despite the name, modern tin sheds use high-quality steel sheets that offer superior protection, aesthetics, and longevity. These sheds are modular, relocatable, and require minimal on-site fabrication—making them a go-to solution for fast-track projects.

Why Tin Shed Manufacturers Matter for PEB Construction:

PEB manufacturers rely on trusted tin shed suppliers for:

Quick Deployment – Ideal for urgent or temporary structures like site offices or warehouses.

Cost-Effective Construction – Lower material and labor costs.

Weather Resistance – Designed to withstand rain, heat, and wind.

Custom Design & Flexibility – Can be tailored in size, height, and layout.

Low Maintenance – Durable and long-lasting with minimal upkeep.

Key Applications of Tin Sheds in PEB Projects:

Industrial storage buildings

Agricultural warehouses and cold storages

Poultry farms and livestock shelters

Fabrication and manufacturing units

Parking sheds and utility shelters

What to Look for in a Tin Shed Manufacturer:

Quality of Steel Sheets – IS-standard, rust-proof, and UV-resistant.

Strong Structural Support – PEB-style frames for enhanced durability.

Design Expertise – Ability to meet unique industry or site-specific requirements.

On-Time Delivery – Coordinated with PEB project timelines.

Nationwide Service – Logistics and installation support across regions.

Tin Sheds: A Key Offering from PEB Manufacturers Many top PEB companies in India also manufacture or source tin sheds as part of their modular construction solutions. This integrated approach ensures that customers receive turnkey services—including structural design, fabrication, and installation—under one roof. Whether it's a temporary facility or a long-term industrial shed, the tin shed segment is an essential part of the broader PEB ecosystem.

Conclusion: With India's growing focus on speed, economy, and efficiency in construction, tin shed manufacturers are playing a crucial role in delivering value-driven building solutions. Backed by engineering excellence and strong partnerships with PEB manufacturers, these sheds provide the ideal blend of affordability, adaptability, and durability. For anyone planning an industrial, commercial, or agricultural setup, investing in quality tin sheds from a reliable source is a smart move toward success.

Visit:- https://www.pebmanufacturers.in/tin-shed.html

0 notes

Text

Breathing Life Into the Future: How a Hydrogen Power Plant Could Transform Our World

When we talk about renewable energy, wind turbines and solar panels usually dominate the conversation. But quietly gaining momentum—and fast—is a technological marvel that may define the next century: the hydrogen power plant.

Let’s not just dissect this concept with a cold lens of technical jargon. Let’s explore it through a more human story. Imagine a town where the factory chimneys no longer belch smoke, where school buses run silently, and where electricity doesn't just come from somewhere—but from clean molecules. That’s the kind of world hydrogen is building.

Why Hydrogen, and Why Now?

We’ve long depended on fossil fuels, not because we love pollution, but because we had few alternatives that were efficient, scalable, and affordable. But the tides are changing. Climate concerns, rising fuel costs, and technological advances have cracked open new doors—and hydrogen is standing right behind them, ready to walk in.

What makes hydrogen special is its versatility. It can be used in fuel cells, turbines, or combined with oxygen to produce electricity and water—that’s right, the only emission is water. In many cases, hydrogen can power what other renewables can’t: heavy industry, freight shipping, and even airplanes.

A hydrogen power plant uses this capability to convert hydrogen (produced through various methods like electrolysis or natural gas reforming) into electricity on a large scale, offering a clean, dispatchable, and increasingly cost-effective power option.

Real Stories: Communities on the Cusp

Let’s bring this home with a story.

In a small town in Spain, an aging coal-fired power plant was recently converted into a pilot hydrogen power plant. For years, the locals had relied on the coal facility not only for energy but for jobs and regional stability. When the plant shut down due to EU carbon policies, the town faced an uncertain future.

But the site was reborn. It now produces hydrogen using wind-powered electrolysis and converts it to electricity with zero carbon emissions. Young engineers, who once considered leaving for big cities, are now staying—and innovating. Children grow up without the haze of coal soot in their lungs. Farmers are testing hydrogen-powered tractors.

This isn’t a utopian dream. It’s happening.

Types of Hydrogen Power Plants

There are different architectures of hydrogen plants depending on the input and technology used. Here are the main ones:

1. Combustion-Based Plants

These operate much like traditional gas power plants, but instead of burning natural gas, they burn hydrogen. The main benefit? No CO₂ emissions.

2. Fuel Cell Plants

These are quieter and more efficient. Hydrogen is fed into fuel cells, which generate electricity through electrochemical reactions—again, the only byproduct is water.

3. Hybrid Plants

Some facilities integrate renewables and battery storage alongside hydrogen to ensure round-the-clock clean power.

The underlying technology might differ, but the goal is the same: reliable, scalable, and sustainable electricity.

Challenges Are Real—But So Is Progress

It would be naive to say this is all smooth sailing. The hydrogen power plant model faces real hurdles:

Storage and transport: Hydrogen is light and takes up a lot of space. Compressing or liquefying it adds cost and complexity.

Efficiency: Converting power to hydrogen (via electrolysis) and back to power isn’t as efficient as using power directly.

Cost: Electrolysers and infrastructure aren't cheap—yet.

But here’s the good news: with every passing month, those barriers are shrinking. Governments across the globe—from Japan to Germany to India—are investing billions in hydrogen infrastructure. Green hydrogen costs have dropped over 50% in five years. Innovations in solid-state storage, modular electrolyzers, and hybrid integration are turning yesterday’s limitations into today’s opportunities.

Not Just a Utility: A Catalyst for Economic Growth

There’s a fascinating secondary effect that’s worth mentioning: job creation.

A hydrogen economy isn't just about energy—it's about ecosystems. Engineers, chemists, mechanics, plant operators, technicians, data analysts—all become part of the equation. And unlike oil refineries or coal mines, these jobs align with sustainability goals.

In the U.S. alone, estimates suggest the hydrogen economy could support over 700,000 jobs by 2030. A single hydrogen power plant doesn’t just light up homes—it energizes careers.

Why It Feels Personal

Here’s something more human.

When a hydrogen power plant is installed in your community, it doesn’t feel abstract. People see new construction, attend public Q&As, get trained for new jobs, or watch trucks roll by with green hydrogen fuel tanks. This energy revolution isn’t just about carbon credits—it’s about real people and real lives.

Take Aditi, a 29-year-old electrical engineer from Maharashtra. She was working in a thermal power plant, increasingly worried about emissions. After retraining through a government-supported green energy program, she now oversees control systems at India’s first hydrogen-integrated grid project.

“I feel like I’m part of something bigger now,” she says. “We’re not just generating power—we’re redefining what it means to power the future.”

What’s Next?

Expect to see more hybrid plants that combine solar, wind, and hydrogen. Look out for gigawatt-scale hydrogen hubs. Even in aviation, aircraft manufacturers are exploring hydrogen combustion turbines and fuel cell systems for commercial flights.

The transition won’t happen overnight. But every hydrogen-powered bus, every electrolyzer farm, and every pilot hydrogen power plant gets us closer to a world where emissions are the exception—not the rule.

Conclusion: Time to Think Beyond the Flame

The 20th century was powered by combustion—of coal, gas, oil. The 21st will be powered by molecules. Clean ones. And the hydrogen power plant is at the center of that evolution.

It’s not just about switching fuels. It’s about rethinking how we live, how we grow, how we breathe. The future isn't waiting for someone else to build it. It’s being engineered right now—in labs, in plants, in communities like yours.

Maybe, just maybe, the future isn’t electric. It’s hydrogen.

0 notes