#Monel 400 Pipe Fittings Exporters In India

Text

#Monel 400 Pipe Fittings Manufacturers In India#Monel 400 Pipe Fittings Suppliers In India#Monel 400 Pipe Fittings Stockists In India#Monel 400 Pipe Fittings Exporters In India

0 notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Forged Threaded Fittings Exporters in India

Forged Threaded Fittings, Forged Threaded Fittings Manufacturers, Forged Threaded Fittings Suppliers, Forged Threaded Fittings Exporters, Forged Threaded Fittings Stockists.

Forged Threaded Fittings in Mumbai, Forged Threaded Fittings Manufacturers in Mumbai, Forged Threaded Fittings Suppliers in Mumbai, Forged Threaded Fittings Exporters in Mumbai, Forged Threaded Fittings Stockists in Mumbai.

Forged Threaded Fittings in India, Forged Threaded Fittings Manufacturers in India, Forged Threaded Fittings Suppliers in India, Forged Threaded Fittings Exporters in India, Forged Threaded Fittings Stockists in India.

https://www.chhajedpipefittings.com/img/forged-threaded-fittings-manufacturers-suppliers-exporters-stockists.jpg

FORGED THREADED FITTINGS

We supply and fare manufactured strung fittings that display predominant working. These strung channel fittings are composed and created to meet different working conditions. These strung fittings give lasting welded associations with basic applications.DNNominal Pipe SizeCenter-to

-End

Elbows,

Tees,

Crosses, ACenter-to-

End 45

deg Elbow, COutside

Diameter

of Band, HMin.

Wall

Thickness, GMin

Length

of

Thread [Note (1)]200030006000200030006000200030006000200030006000BL261/82121251717192222253.183.186.356.46.781/42125281719222225333.183.306.608.110.2103/82528331922252533383.183.516.989.110.4151/22833382225283338463.184.098.1510.913.6203/43338442528333846563.184.328.5312.713.92513844512833354656623.684.989.9314.717.3321 1/44451603335435662753.895.2810.5917.018.0401 1/25160643543446275844.015.5611.0717.818.450260648343445275841024.277.1412.0919.019.2652 1/2768395525264921021215.617.6515.2923.628.980386951066464791091211465.998.8416.6425.930.510041061141147979791461521526.5511.1818.6727.733.0

SPECIFICATION

Grades :

Nickel Alloy:

ASTM / ASME SB 564 UNS 2200 ( NICKEL 200 ), UNS 4400 (MONEL 400 ), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) ASTM / ASME SB 160 UNS 2201 (NICKEL 201 ) ASTM / ASME SB 472 UNS 8020 ( ALLOY 20 / 20 CB 3 )

Copper Alloy:

ASTM / ASME SB 61 UNS NO. C 92200 & ASTM / ASME SB 62 UNS NO. C 83600. ASTM / ASME SB 151 UNS NO. 70600, 71500, C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30), ASTM / ASME SB 152 UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200.

Stainless Steel :

ASTM / ASME SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel :

ASTM / ASME SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61.

Carbon Steel:

ASTM / ASME A 105. ASTM / ASME A 350 LF 2.

Alloy Steel:

ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91.

0 notes

Text

Monel Fasteners: Strength and Durability in Industrial Construction

Fasteners are of paramount importance when it comes to industrial construction. These seemingly small components play a crucial role in holding structures together. Among the myriad choices available, Monel fasteners stand out for their exceptional strength and durability. Jay Steel Corporation, we take pride in being a leading Monel fasteners manufacturer and supplier, offering unparalleled strength and durability for a wide range of industrial applications. Our commitment to quality extends to our diverse range of Monel alloy products, including Monel 400 Products and Monel K500 Products, available in various forms such as Monel Wire Mesh, Monel Round Bar, Monel Strips Sheet & Plats, Monel Tube & Pipe, Monel Fittings, Monel Flanges, and welding rods so that our customers can choose the one that will perfectly suit their project requirements!

In this blog post, we will explore the remarkable qualities of Monel fasteners and why they are considered a preferred choice in industrial construction.

Understanding Monel:

Monel is a nickel-copper alloy known for its corrosion resistance, high strength, and durability. The alloy primarily consists of nickel (approximately 67-70%) and copper (about 28-34%), with small amounts of iron, manganese, carbon, and silicon. The unique combination of these elements results in a material with superior properties that make it ideal for challenging industrial environments.

Strength Beyond Compare:

Monel fasteners are renowned for their remarkable strength, making them a reliable choice for heavy-duty applications in industrial construction. The high nickel content in Monel contributes to its exceptional tensile strength and resistance to deformation under extreme loads. This characteristic ensures that structures secured with Monel fasteners maintain their integrity even in the face of intense pressure and stress.

Corrosion Resistance:

One of the primary challenges in industrial construction is the corrosive nature of various environments. Monel fasteners excel in this regard, as they exhibit outstanding resistance to corrosion, particularly in harsh conditions such as exposure to saltwater, acids, and alkalis. This corrosion resistance significantly extends the lifespan of structures and reduces maintenance costs over time.

Durability in Diverse Environments:

Monel fasteners are versatile and well-suited for use in diverse industrial environments. Whether in chemical processing plants, marine applications, or oil and gas facilities, Monel's durability remains unwavering. The alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking further enhances its suitability for challenging construction scenarios.

Temperature Stability:

Industrial construction often involves exposure to extreme temperatures, and Monel fasteners are designed to withstand such conditions. The alloy maintains its strength and structural integrity across a wide temperature range, making it a reliable choice for projects that face temperature fluctuations, whether in cold or scorching heat.

Ease of Fabrication and Installation:

Despite its impressive strength, Monel is also known for its malleability, which makes it relatively easy to fabricate into various fastener shapes. This characteristic simplifies the manufacturing process and contributes to the ease of installation, saving both time and resources in construction projects.

Final Words!

With a strong focus on quality Monel fasteners and alloy products, Jay Steel Corporation emerges as a leader in industrial construction. With a comprehensive range of Monel offerings and a global presence, we continue to contribute to the success of diverse industrial projects. Recognizing the global demand for top-notch Monel alloy products, Jay Steel Corporation serves as a reliable exporter to various countries, including Thailand, Singapore, Malaysia, India, Germany, Russia, France, Nigeria, USA, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordan, Bahrain, the United Kingdom, and Italy. Our commitment to quality and competitive pricing has established us as a trusted partner in international markets. Choose us for your Monel Alloys Solutions that go beyond expectations, ensuring the resilience and longevity of your constructions.

#Monel Wire Mesh#Monel fasteners 400#Monel fasteners K500#Monel fasteners 400 Supplier#Monel fasteners K500 Exporters

0 notes

Text

Top Air Header Manufacturer in India - Arcellor Controls India

When it comes to precision engineering and top-tier quality in air header systems, Arcellor Controls India stands as the unrivaled leader in the industry. We specialize in crafting instrument air header solutions, and our commitment to excellence has earned us the reputation of being the foremost Air Header Manufacturer in India. Offering an extensive range of air headers in various sizes, specifications, standards, materials, grades, and types, we cater to diverse project needs, ensuring the highest standards for instrument air. Our global presence as an Air Header Exporter further sets us apart in the international market, making us your go-to source for superior quality and reliability in header air solutions.

Air Header

An air header refers to a component in industrial processes that is responsible for distributing compressed air to various pneumatic devices within a system. It typically consists of a manifold or a pipe system that collects and regulates the flow of compressed air from a centralized source, such as a compressor. The instrument air header ensures uniform pressure distribution and controls the direction of airflow to different branches or lines connected to it. This centralized distribution system facilitates efficient operation and control of pneumatic tools, valves, and other devices in industrial settings, contributing to the overall functionality and reliability of pneumatic systems.

Diverse Range of Air Headers:

At Arcellor Controls India, we understand that one size does not fit all. Hence, we bring forth a comprehensive range of Air Headers in various sizes, specifications, standards, materials, grades, and types. Our product line includes:

4-Way Air Header: Designed for efficiency and precision, our 4-Way Air Header is ideal for applications requiring controlled air distribution.

5-Way Air Header: With an extra outlet for enhanced versatility, our 5-Way Air Header ensures optimal performance in diverse industrial settings.

Air Header Distributor: Offering seamless distribution of air in your systems, our Air Header Distributor is a testament to reliability and durability.

12-Way Air Header With Stand: Engineered for projects demanding multiple outlets, our 12-Way Air Header with Stand provides a robust solution with added stability.

Pressure Air Header: Built to withstand varying pressure conditions, our Pressure Air Header ensures consistent performance under challenging environments.

Materials and Grades We offer - Air Header

With us, we construct the air header in various materials and grades including the following

Materials

Grades

Stainless Steel ASME B16.5

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel ASME

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel ASME B16.5

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60

Low-Temperature Carbon Steel

ASTM A350, LF2, LF3

Alloy Steel ASME 16.5

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel ASME B16.5

ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30)

Nickel Alloy ASME B16.5

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201),

Monel

Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500)

Inconel

Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600)

Hastelloy

Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

We also offer Instrument Air Header Made from other materials like aluminum, MS (Mild Steel Grades), and more, to our customers all across the globe!

Applications of Air Header

Air Header Plays a crucial role in maintaining proper pressure and flow control within the system. Here are some applications of air headers:

Instrumentation and Control Systems

Process Control

Pneumatic Tools

Safety Systems

HVAC Systems

Laboratory Equipment

Pneumatic Conveying Systems

Automated Manufacturing

Aerospace Industry

Clean Room Environments

Other Applications

Final Words!

Selecting the optimal Air Header is paramount for the triumph of your industrial ventures, and Arcellor Controls India stands out as the premier choice for astute customers. Boasting a diverse array of top-notch Air Headers, a global presence, and an unwavering dedication to customer contentment, we consistently lead the industry. We transcend the confines of the Indian market; we have positioned ourselves as a prominent Air Header Exporter on the global stage. Our products span the globe, reaching countries including Oman, Qatar, the USA, Germany, the UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia. We take immense pride in delivering quality solutions adhering to international standards, ensuring that industries worldwide benefit from our expertise in instrument air and header air manufacturing. Connect with us today at [email protected] to encounter excellence in Air Header production and exportation. Your success is our paramount concern!

0 notes

Text

All you need to know about Butt Weld Fittings

Butt weld fittings are essential components used in various industries to join and connect pipes or tubes seamlessly. These fittings play a crucial role in creating a robust and leak-free piping system. As a leading butt weld fittings manufacturer and supplier, stockist, and exporter in India. Bullion Pipes & Tubes LLP offers an extensive range to suit various project needs. Our fittings are available in different sizes, specifications, material grades, and types, ensuring you find the perfect fit for your specific application.

In this comprehensive guide, we will delve into all you need to know about butt weld fittings and how they cater to the needs of different applications.

What Are Butt Weld Fittings?

Butt weld fittings are designed to have smooth inner surfaces, ensuring minimal friction and pressure drop in the flow of fluids. This characteristic makes them ideal for applications where flow velocity and efficiency are critical factors. Additionally, the absence of crevices or threads in butt weld fittings prevents the accumulation of debris, reducing the chances of contamination and facilitating easy cleaning and maintenance.

Comprehensive Range of Butt Weld Fittings

We take pride in offering a comprehensive range of buttweld pipe fittings, including

Butt Weld Elbows: Available in 45-degree, 90-degree, and 180-degree angles, providing flexibility in directing the flow of fluids.

Butt Weld Crosses: Ideal for intersecting pipelines, ensuring smooth fluid flow in multiple directions.

Butt Weld Caps: Used to seal the end of a pipe, protecting it from contaminants and preventing leakage.

Butt Weld Tees: Available as equal and unequal tees, facilitating even or uneven flow distribution.

Butt Weld Reducers: Both concentric and eccentric reducers for smooth transitions between pipes of different diameters.

Butt Weld Stub Ends: Facilitating easy flange connections without welding.

Advantages of Butt Weld Fittings

Excellent Structural Integrity: Butt weld fittings create a continuous and strong joint that enhances the structural integrity of the entire piping system. This is especially important in applications where safety and reliability are paramount.

Smooth Inner Surface: The absence of internal disruptions such as threads or flanges ensures a smooth inner surface, minimizing turbulence and pressure loss during fluid flow.

Strong and Reliable Joints: The welding process used to join the pipes ensures a permanent and robust connection, reducing the risk of leaks or failures.

Suitable for High-Pressure and High-Temperature Applications: Butt weld fittings are capable of withstanding extreme pressures and temperatures, making them suitable for critical and demanding industries.

Disadvantages of Butt Weld Fittings

Skilled Labor for Welding: Proper welding requires skilled labor, which may increase the installation cost compared to other types of fittings that do not require welding.

Slightly More Expensive: Butt weld fittings can be slightly more expensive than other fittings due to the welding process and the need for precision manufacturing.

Materials & Grades we offer - Buttweld Fittings

Stainless Steel Buttweld Fittings

SS 904L

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347, 446

Titanium Buttweld Fittings

Titanium Alloy Gr 2

Titanium Alloy Gr 5

Monel Buttweld Fittings

Monel K500

Monel 400

Carbon Steel Buttweld Fittings

Inconel Buttweld Fittings

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel Buttweld Fittings

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium Buttweld Fittings

Nickel Buttweld Fittings

Nickel Alloy 200/201

SMO 254 Buttweld Fittings

Duplex Steel Buttweld Fittings

Duplex UNS S32205

Duplex UNS S31803

Hastelloy Buttweld Fittings

Hastelloy C22, Hastelloy B2

Hastelloy C276

Super Duplex Steel Buttweld Fittings

Super Duplex Steel S32750

Super Duplex Steel S32760

Incoloy Buttweld Fittings

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld fittings are a type of pipe fittings used to connect pipes or tubes with a butt welding process. They are widely used in various industries for a range of applications due to their structural integrity and reliability. Some of the common applications of buttweld fittings include:

Plumbing and Water Supply

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Power Generation

Pharmaceutical Industry

Food and Beverage Industry

HVAC Systems

Shipbuilding

Construction

Nuclear Power Plants

Other Application

How to Select the Right Butt Weld Fitting?

Choosing the right butt weld fitting is essential to achieve an efficient and reliable piping system. Consider the following factors during selection:

Project Requirements: Understand the specific needs of your project, such as fluid type, pressure, temperature, and flow rate.

Material Compatibility: Ensure that the material of the fitting is compatible with the material of the pipes to prevent corrosion and ensure longevity.

Fitting Dimensions: Select fittings with dimensions that match the pipe size to achieve a secure and leak-free joint.

Industry Standards and Codes: Adhere to industry-specific standards and codes to maintain the quality and safety of the piping system.

Installation and Welding Process of Buttweld Fittings

Proper installation and welding are critical to ensuring the effectiveness of buttweld pipe fittings. Follow these steps for a successful installation:

Preparation: Clean the pipe ends and fittings thoroughly to remove any dirt, grease, or debris that could affect the quality of the weld.

Alignment: Ensure precise alignment of the pipes and fittings before welding to create a strong and reliable connection.

Welding: Employ the appropriate welding method, such as TIG or MIG, to create a robust and leak-proof joint.

Inspection: Thoroughly inspect the welds for defects using non-destructive testing methods to ensure the integrity of the joints.

Leak Testing: Before putting the system into service, conduct a leak test to verify the integrity of the joints and prevent potential leaks.

Final Thoughts!..

Butt weld fittings are vital components in creating strong and reliable connections within piping systems. Bullion Pipes & Tubes LLP stands at the forefront as the leading butt weld fitting supplier, manufacturer, stockist, and exporter in India. With an extensive range of fittings and a commitment to quality, we cater to diverse industrial needs across India and various countries as well including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. Our buttweld pipe fittings offer exceptional strength, leak resistance, and versatility, making them the ideal choice for critical applications. When selecting the right fitting, consider the specific project requirements, material compatibility, and adherence to industry standards.

Choose Bullion Pipes & Tubes LLP for all your butt weld fitting needs, and experience excellence in quality and service. Contact us today to explore our vast range of fittings and find the perfect solution for your piping requirements.

0 notes

Text

Exploring the Superior Performance of Monel 400: Flanges and Pipes Introduced

Monel 400 is a popular and versatile nickel-copper alloy known for its exceptional performance in various industrial applications. This alloy offers superior resistance to corrosion, high strength, and excellent mechanical properties. Monel 400 flanges and pipes are widely used in industries such as oil and gas, chemical processing, marine, aerospace, and so on. At Metal Forge India, we take pride in being the leading Monel 400 Alloy Manufacturer, Supplier, Stockist, and Exporter in India. With a strong commitment to delivering high-quality products, we offer a wide range of Monel 400 components, including Monel 400 Pipes, Monel 400 Flanges, Monel 400 Pipe Fittings, Alloy 400 Elbows, Monel 400 Butt weld Pipe Fittings, and Monel 400 Welding Rods and also we do offer them in various sizes, specifications & standards and more so that our customers can choose the one that perfectly suits their project requirements.

In this article, we will explore the key characteristics and advantages of Monel 400 flanges and pipes, highlighting their superior performance and why they are the preferred choice for many critical applications.

Understanding Monel 400

Monel 400 is a solid-solution alloy that consists of approximately 67% nickel and 23% copper, with small amounts of iron, manganese, carbon, and silicon. The unique combination of nickel and copper provides Monel 400 with outstanding resistance to various corrosive environments, including seawater, sulfuric acid, hydrofluoric acid, and alkaline solutions. Additionally, Monel 400 exhibits excellent mechanical properties even at elevated temperatures, making it suitable for high-stress applications.

Exploring the Superior performance of Monel 400 - Pipe - Flanges

Corrosion Resistance

One of the key advantages of Monel 400 flanges and pipes is their exceptional resistance to corrosion. Whether exposed to saltwater, acids, alkaline solutions, or harsh chemicals, Monel 400 remains highly resistant. This property makes it suitable for offshore and marine applications, as well as industries dealing with corrosive substances.

High Strength and Toughness:

Monel 400 offers remarkable strength and toughness, making it ideal for applications that require durability and reliability. It maintains its mechanical properties even at extremely low or high temperatures, ensuring consistent performance in various operating conditions. This strength and toughness make Monel 400 flanges and pipes a preferred choice for critical industrial processes.

Heat and Pressure Resistance:

With its excellent heat and pressure resistance, Monel 400 proves its mettle in high-temperature environments. It can withstand elevated temperatures without losing its structural integrity. Additionally, it maintains its performance under high-pressure conditions, making it suitable for applications that involve fluid transportation and containment.

Excellent Ductility:

Monel 400 exhibits excellent ductility, allowing it to be easily formed and fabricated into different shapes and sizes. This ductility makes it an ideal material for flanges and pipes, enabling easy installation and connection in various industrial systems. Its malleability ensures a secure and leak-free joint, enhancing the overall efficiency of the system.

Wide Range of Applications

The exceptional properties of Monel 400 flanges and pipes make them versatile and applicable in various industries. They are commonly used in chemical processing plants, oil and gas refineries, marine equipment, heat exchangers, seawater systems, and more. Their broad range of applications is a testament to their reliability and performance.

Easy Machinability:

Another noteworthy feature of the Monel 400 is its excellent machinability. Despite its high strength and resistance, this alloy can be easily machined into intricate shapes and parts. The ease of machining simplifies the manufacturing process, reducing production time and costs. This aspect makes Monel 400 a preferred choice for industries that require complex and precise components.

Cost-Effectiveness:

Considering the long lifespan and durability of Monel 400 flanges and pipes, they offer excellent cost-effectiveness in the long run. While the initial investment may be higher compared to other materials, Monel 400's resistance to corrosion and wear minimizes the need for frequent replacements or repairs. This leads to significant cost savings over the equipment's lifespan.

Longevity and Low Maintenance:

Monel 400 flanges and pipes are known for their longevity and low maintenance requirements. They can withstand harsh conditions and continue to perform reliably for an extended period. With minimal maintenance, such as routine inspections and cleaning, Monel 400 components can remain in service for many years, ensuring uninterrupted operations.

Equivalent Material of Alloy 400 Pipe-Flanges

STANDARD

WERKOFF NR.

UNS

JIS

BS

GOST

AFNOR

EN

Monel 400

2.4360

N04400

NW4400

NA13

МНЖМц 28-2,5-1,5

NU-30M

NiCu30Fe

Chemical Equation of Monel DIN 2.4360 Flanges - Pipes

Grade

C

Mn

Si

S

Cu

Fe

Ni

Monel 400

0.30 max

2.00 max

0.50 max

0.024 max

28.00 - 34.00

2.50 max

63.00 min

Mechanical Characteristics of N04400 Flanges - Pipes

Element

Density

Melting Point

Tensile Strength

Yield Strength (0.2%Offset)

Elongation

Monel 400

8.8 g/cm3

1350 °C (2460 °F)

Psi – 80,000 , MPa – 550

Psi – 35,000 , MPa – 240

40 %

Applications of Monel 400 - Flanges and Pipes

Monel 400 is a nickel-copper alloy known for its excellent corrosion resistance, high strength, and good thermal conductivity. It is often used in various industries for its unique properties. When it comes to flanges and pipes, Monel 400 finds applications in several areas:

Marine and Offshore Industry

Chemical Processing Industry

Oil and Gas Industry

Power Generation Industry

Aerospace Industry

Pharmaceutical Industry

Food Processing Industry and so on

Final Thoughts!..

Monel 400 Flanges and Pipes are renowned for their exceptional performance and durability, making them the top choice for demanding industrial applications. With their impressive strength, corrosion resistance, and versatility, they are widely preferred across a range of industries, including marine, chemical processing, oil and gas, and aerospace. As the foremost Monel 400 Alloy manufacturer, supplier, stockist, and exporter in India, we offer an extensive selection to cater to the unique needs of every project.

In addition to their superior qualities, our Monel 400 Flanges and Pipes are accompanied by Material Test Certificates (MTC) compliant with EN 10204 3.1 and EN 10204 3.2 standards. These certificates, along with Test Certificates confirming NACE MR0103 and NACE MR0175 compliance, ensure the highest levels of quality and traceability. We take pride in our expansive export capabilities and widespread customer base, including countries such as the United Arab Emirates, the USA, Germany, South Korea, Russia, Singapore, France, Thailand, Turkey, Vietnam, and Indonesia. Metal Forge India has built a strong reputation for delivering top-notch Monel 400 products worldwide.

To explore our extensive range of Monel 400 products and find the perfect solution for your project needs, visit our website or contact our knowledgeable team today.

0 notes

Text

Overview of Monel alloy k 500

Monel K500 is a nickel-copper alloy that has the corrosion resistance of Alloy 400 and high-strength corrosion fatigue and erosion resistance. At MV Super Alloys, we take pride in being the leading Monel K500 Alloy stockist, trader, importer, supplier, and exporter in India. With a vast range of Monel K500 Alloy forms available, including pipes, tubes, round bars, coils, shims, strips, wires, sheets, and plates, we cater to diverse project requirements.

Monel K500

In this comprehensive article, we delve into the intricacies of Monel Alloy K500, highlighting its exceptional properties, its uses, applications, and the reasons why it outperforms other materials in the industry.

Overview of Monel K500 Alloys

Monel K-500 (UNS N05500) is an alloy consisting of nickel and copper, which has been age-hardened to achieve superior strength compared to Monel 400. Remarkably, it maintains these impressive mechanical properties even in high temperatures up to approximately 650 degrees Celsius. Furthermore, its exceptional corrosion resistance allows it to withstand harsh environments containing both chemicals and chlorides. With its unique combination of physical and mechanical characteristics, it is extensively employed in multiple challenging applications.

Properties of Monel k500 Alloys

Monel K500 is a nickel-copper alloy that offers excellent corrosion resistance and high strength. Here are some of the properties of Monel 2,4375 alloys:

Excellent corrosion resistance in various environments (seawater, acids, alkalis)

High strength and mechanical properties at room and elevated temperatures

Non-magnetic, suitable for applications requiring low magnetic interference

Good ductility, easily formed and fabricated

Resistant to wear and abrasion

Low coefficient of thermal expansion for dimensional stability

High fatigue strength for dynamic loading applications

Weldable using standard techniques

Limited temperature range (up to approximately 650°C or 1200°F)

Forged Monel K500 Equivalent

Standard - Monel K500

UNS - N05500

WNR. - 2,4375

Monel K500 Alloy Chemical Composition

The Monel alloy k 500 chemical composition typically includes the following elements:

Grade - Monel K500 Alloy

AI - 2.30 - 3.15

C - 25 max

Cu - 27.0-33.00

Fe - 2.0

Mn - 1.5 max

Ni - 63.0

Ti - 35 -85

S - 0.1 max

Si - 5 max

Physical Properties of Monel K500 Alloys

The UNS N05500 alloy exhibits exceptional strength at elevated temperatures, thereby rendering it a highly suitable material for deployment in high-temperature application domains such as boilers or furnace components. Furthermore, its non-magnetic nature renders it highly compatible with the use of electromagnetic equipment or electronic devices. Its low thermal expansion coefficient also exemplifies its utility in precision parts requiring constricted tolerances when exposed to temperature fluctuations.

Physical Properties - Metric

Density - 8.45g/cm

Melting - 1338°C

Physical Properties - Imperial

Density - 0.305 Ib/in3

Melting - 2440°F

Mechanical Properties of Monel K500 Alloys

Understanding the Monel K 500 mechanical properties is essential for assessing its suitability for specific applications.

Here are some key mechanical properties of Monel K500:

Monel K500 possesses exceptional tensile strength and flexibility, making it an ideal material for engineering applications, including but not limited to pipe fittings or valves that require both strength and flexibility. Additionally, it exhibits remarkable resistance to fatigue, which grants it superior performance when compared to other materials subjected to repeated loading cycles or stress fatigue conditions.

Hardness (HB)- 27-35 HRC

Ultimate Tensile Strength (N/mm2) - 970-1000

Proof Stress - 690-760

Monel k500 specification & Standards

Product Forms - Sheet, Plate

ASTM - B575

ASME - SB 575

DIN - 17744

Product Forms - Strips

ASTM - B575

ASME - B 575

DIN - 17744

Product Forms - Rod, bar, Forging

ASTM - B 574, B 564

ASME - B 574, B 564

DIN - B 574 , B 564

Product Forms - Wire

ASTM -

ASME -

DIN - 17744, 17753

Monel K500 Uses

Monel K500, a nickel and copper alloy, is renowned for its remarkable strength, resistance to corrosion, and ability to withstand extreme temperatures. It is a favored material in diverse industrial settings, including desalinization systems, oil refining operations, and the manufacturing of valves, pumps, shafts, and fasteners. Its application in these industries is particularly valuable because of its durability and reliability.

Additionally, Monel K500 exhibits exceptional resistance to loss of strength even when exposed to high temperatures up to 1200°F, which makes it an indispensable component in airplane manufacturing, among other applications. Its unparalleled strength and versatility have made it a crucial material for the production of long-lasting and reliable products across many industries.

Applications of Monel K500 Alloys

Monel K500 is a nickel-copper alloy that offers excellent corrosion resistance, high strength, and good mechanical properties at both room and elevated temperatures. There are numerous industries in which it is used.

Here are some common applications of Monel K500 alloys:

Marine and Offshore Industry

Oil and Gas Industry

Chemical Processing

Pump Shafts and Impellers

Doctor Blades and Scrapers

Oil-well drill Collars and Instruments

Electronic Components

Springs

Valve trim

Aerospace Industry

Electronics and Electrical Industry

Medical Equipment

Heat Exchangers and so on.

Final Thoughts!..

Monel Alloy K500 is a superior choice for high-performance applications, thanks to its well-balanced chemical composition, impressive mechanical properties, and adherence to industry specifications. The Monel K500 specification ensures that this alloy meets stringent standards, making it suitable for a wide range of demanding projects. As the leading Monel 2,4375 alloys supplier in India, MV Super Alloys is committed to providing you with the highest quality products that meet your project requirements. Whether you need Monel K500 Round Bars, sheets, plates, or any other form, we have a comprehensive inventory to cater to your needs. As a leading Monel K500 Alloy importer & Stockist in India, we supply the raw material with Material Test Certificate (MTC). In addition to providing high-quality products, MV Super Alloys also offers exceptional customer service and competitive pricing.

For more information on Monel Alloy K500 and how it can benefit your projects, feel free to visit our website or contact our knowledgeable team. Our team is here to help you every step of the way.

#Monel alloy k 500 chemical composition#Monel k500 round bar#Monel k 500 mechanical properties#Monel k500 specification

0 notes

Text

Prominent Manufacturer and Exporter of Monel Alloy 400 Fasteners, Monel 400 Fasteners. We offer Premium quality Monel 400 Fasteners at best price. We have Wide range of Fasteners such as Stud Bolts, Nuts, Fasteners etc. Contact Us and Book Now. JFE is the best manufacturer of buttweld and forged pipe fittings, flanges, fasteners, bars, pipes and tubes of high quality of various grades and materials in Mumbai, India

#Monel Alloy 400 Fasteners#UNS N04400 Monel Fasteners#Alloy 400 Monel Fasteners#Monel 400 Stud Bolts#Monel Werkstoff Nr. 2.4360 Fasteners#Monel UNS N04400 Fasteners#Monel Alloy 400 Stud Bolts Manufacture in India.

0 notes

Text

Monel K500 Socket Weld Flange

Kobs India has built a strong reputation in the industry with its amazing product line and outstanding customer service. We give preference to quality and reliability of our products. We make use of premium resources and machinery in the manufacturing process to make sure that all our products meet international standards. We are manufacturers, suppliers and exporters of Monel Weld Neck Flanges that are made with caution and care, to offer you the most precision made flanges.

Kobs India offers a wide range of Monel Flanges, As one of the pioneering manufactures and distributors, this company uses high-quality products and offers them at competitive prices to its customers in order to satisfy their specific needs. Monel is of two types; Monel 400 ( 2.4360) and Monel K500. ASME SB564 Monel UNS N04400 Weld Neck Flanges are utilised in pharmaceutical equipment, heat exchangers, condensers, power generation, etc. ANSI B 16.47 Monel DIN 2.4375 Threaded Flanges are welded to a pipe or fitting with a single full penetration.

For More Information

Visit Our Website - http://www.kobsindia.in/monel-socket-weld-flange.html

Contact Us -9819523999

Email Id [email protected]

1 note

·

View note

Text

Hig Hub Flange

What is a high Hub blind flange?

high hub flange is a kind of round plate with no center hold but with all the proper bolt holes. It is used to close ends of piping systems. It is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles.

Material & Grades of High Hub Flanges :

Stainless Steel High Hub Flanges : ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L High Hub Flanges

Duplex & Super Duplex Steel High Hub Flanges : ASTM A182 / ASME SA182 F44, F 45, F51, F 53, F 55, F 60, F 61 High Hub Flanges

Carbon Steel High Hub Flanges : ASTM A105 / ASME SA105 ASTM / ASME A 350 , ASTM A181 LF2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 High Hub Flanges

Low Temperature Carbon Steel High Hub Flange: ASTM A350, LF2, LF3 High Hub Flanges

Alloy Steel High Hub Flanges : ASTM A182 / ASME SA182 & A387 F1, F5, F9, F11, F12, F22, F91 High Hub Flanges

Copper Alloy Steel High Hub Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy High Hub Flanges : ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) High Hub Flanges

Application of High Hub Flange

ANSI B16.5 Class 150 High Hub Flanges uses in Industrial Boilers Industry

ASTM A182 Stainless Steel High Hub Flanges uses in Power Plants Industry

ASME B16.47 Series A and B High Hub Flanges uses in Nuclear Plants Industry

Stainless Steel High Hub Flanges uses in Oil & Gas Industry

Super Duplex Steel High Hub Flanges uses in Refineries Industry

Industrial High Hub Flanges uses in Ship Building Industry

Super Duplex Steel High Hub Flange Forged Flanges uses in Heat Exchanger Industry

Carbon Steel Industrial High Hub Flanges uses in Condensers Industry

Alloy Steel Industrial High Hub Flanges uses in Paper & Pulp Industry

Duplex Steel Industrial High Hub Flanges uses in Marine Applications

Stainless Steel Industrial High Hub Flanges uses in Nuclear Power Industry

Industrial High Hub Flange / Fittings System uses in Fossil Fuel Power Plants Industry

About Flanges And Nuts

Flanges nuts Is An ISO 9001:2015 licensed enterprise And Has A song file Of providing A wide variety Of Piping solution At Very competitive prices. In a totally brief time period, we've gained An tremendous national And international popularity.

Headed through Mr. Ronak Bhansali (Director) And Supported by way of Our committed, expert team, we are able to fulfill The needs Of Our customers In A timely And Systematic manner. The Profound know-how And wealthy experience Of our crew within the Respective arena Of metal merchandise Has Assisted The business enterprise To gather outstanding role Amidst The reliable chrome steel, Pipe fitting In India.

we're Counted most of the nice manufacturer, Exporter Stockist & provider. We Export 60% Of Our range Of Flanges, shops, Pipe Fittings And solid Fittings To many nations Like u.s.a., united kingdom, Italy, Malaysia, Gulf and so on. we'd admire To Get Your Esteemed Enquires And look ahead to The delight Receiving Your precious response. we're often supplying these objects To Many main industrial gadgets inclusive of : ship constructing, Petrochemical flora, metallic flowers, Refineries, chemical substances, Fertilizers, electricity Plant, Pharmaceutical, Ports, Oil & gas, Railway, Mining, Cement vegetation, Paper mills, Sugar generators, Fabrication units and so on.

TO KNOW MORE ABOUT OUR PRODUCTS YOU CAN VISIT OUR WESITE

www.flangesnuts.com

Used in different industries by

Refineries Gas Processing Off-Shore Oil Drilling Companies Petrochemicals Hydro-Carbon Fertilizers Paper & Pulp Companies Power Generation Specialty Chemicals Pharmaceuticals Drugs Steel Cement Water Pipe Line Pesticides General Piping Construction Engineering Nuclear Food Processing & Dairy boiler & heatexchangers

0 notes

Text

Monel 400 Pipe Fittings Exporters in India

0 notes

Photo

Nufit Piping Solutions - Manufacturer, exporter & supplier of Stainless Steel 316 Instrumentation Tube Fittings - Male Connector, Female Connector, Union, Tee, Cross, Tube End, Front Ferrule, Back Ferrule with end connection Male Threaded, Female Threaded, Tube End Available in SS 304, 304L, 316, 316L, Duplex Steel 2205 (UNS S31803, S32205), Super Duplex Steel S32750, S32760, Inconel 600, 625 (N06600, N06625) Monel 400 (N04400), Hastelloy C276 (N10276), Brass, Copper Alloy, Aluminium Bronze For more details, visit us at Https://fittingsmanufacturer.com For your requirement, mail us at [email protected] #ssInstrumentationfittings #instrumentationfittings #Tubefittings #sstubefittings #maleconnector #femaleconnector #unionfitting #uniontee #tubing #oilngas #oilngasindustry #manufacturer #exporter #tubefittingsmanufacturer #tubefittingsexporter #nufit #nufitpipingsolutions #india #instagood #instadaily #instalike #follow #newpost (at Singapore, Singapore) https://www.instagram.com/p/CjvM8Y6o3AB/?igshid=NGJjMDIxMWI=

#ssinstrumentationfittings#instrumentationfittings#tubefittings#sstubefittings#maleconnector#femaleconnector#unionfitting#uniontee#tubing#oilngas#oilngasindustry#manufacturer#exporter#tubefittingsmanufacturer#tubefittingsexporter#nufit#nufitpipingsolutions#india#instagood#instadaily#instalike#follow#newpost

0 notes

Text

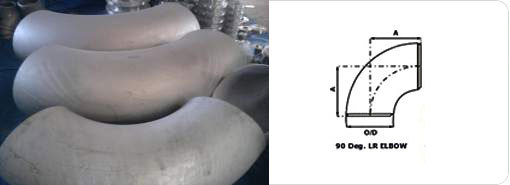

Elbow 90 Manufacturers

Elbow 90 Degree Buttweld Pipe Fittings, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers, Elbow 90 Degree Buttweld Pipe Fittings Suppliers, Elbow 90 Degree Buttweld Pipe Fittings Exporters, Elbow 90 Degree Buttweld Pipe Fittings Stockists.

Elbow 90 Degree Buttweld Pipe Fittings in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Exporters in Mumbai, Elbow 90 Degree Buttweld Pipe Fittings Stockists in Mumbai.

Elbow 90 Degree Buttweld Pipe Fittings in India, Elbow 90 Degree Buttweld Pipe Fittings Manufacturers in India, Elbow 90 Degree Buttweld Pipe Fittings Suppliers in India, Elbow 90 Degree Buttweld Pipe Fittings Exporters in India, Elbow 90 Degree Buttweld Pipe Fittings Stockists in India.

90° ELBOW

We have earned presumed name in making of Elbow (90°) which is developed with the best of the materials accessible in the business sector. Stainless steel, composite steel and carbon steel and so forth are utilized for manufacturing this elbow. We give these funnel fittings at business sector driving ratesSPECIFICATION

Size:

1/2"NB TO 48"NB IN

Schedule:

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type:

Seamless

ERW

Welded

Fabricated.

Material Type:

Stainless Steel

Alloy Steel

Carbon Steel

Nickel Alloys

Duplex

Grades :

Nickel Alloy:

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel:

ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel :

ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

Alloy Steel :

ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Carbon Steel:

ASTM / ASME A 234 WPB, WPC

ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

0 notes

Text

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

When it comes to industrial piping systems, the choice of flange material plays a pivotal role in ensuring peak performance and long-lasting functionality. Among the myriad materials available, Monel stands out as one of the most popular and reliable options. As the leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, we take pride in offering a wide range of options to cater to diverse project requirements. Our Monel Flanges come in various sizes, specifications, standards, and grades, including the popular Monel 400 Flanges and Monel K500 Flanges.

Moreover, we offer different types of flanges, such as Slip On Flanges, Weld Neck Flanges, Socket Weld Flanges, Blind Flanges, Orifice Flanges, Reducing Flanges, Ring Type Joint Flange, Spectacle Blind Flanges, and Lap Joint Flanges, ensuring that you find the perfect fit for your projects. With our expertise and dedication as suppliers of Monel 400 Flanges and other products, we strive to meet the highest industry standards and be your preferred partner for all your Monel Flange needs in India and beyond.

In this blog post, we will explore the unique advantages of Monel Flanges over other flange materials, demonstrating why they are the preferred choice for critical applications across various industries.

Understanding Flanges and Their Role in Industrial Piping

Before we dive into the comparison, let's briefly understand what flanges are and why they are vital in industrial piping systems. Flanges are flat, circular discs with evenly spaced bolt holes used to connect pipes, valves, and other equipment in a piping network. Their primary functions include providing support, facilitating alignment, and allowing for easy assembly and disassembly of components.

Exploring Monel Flanges

Monel Flanges are a class of nickel-copper alloy flanges renowned for their exceptional properties. The composition primarily consists of nickel and copper, with additions of small amounts of iron, manganese, and other elements. This alloy's chemical composition results in a combination of impressive characteristics, including excellent corrosion resistance, high tensile strength, and exceptional temperature stability.

The corrosion resistance of Monel Flanges is particularly noteworthy, making them suitable for use in harsh and corrosive environments. They perform exceptionally well in marine applications, offshore drilling, and chemical processing industries where exposure to seawater, acids, and alkalis is common. The resistance to localized corrosion, such as pitting and crevice corrosion, adds to their popularity.

Comparing Monel Flanges with Other Flange Materials

To make an informed decision, it is essential to compare Monel Flanges with other commonly used flange materials, such as stainless steel, carbon steel, Inconel, and Alloy 20.

Stainless Steel Flanges

Stainless steel flanges are widely used due to their general corrosion resistance and cost-effectiveness. However, when compared to Monel Flanges, they may fall short in highly corrosive environments. Monel Flanges, with their higher nickel content, exhibit superior resistance to chloride-induced stress corrosion cracking, a common concern in stainless steel.

Carbon Steel Flanges

Carbon steel flanges are widely used in various industries due to their affordability and mechanical properties. However, they lack the corrosion resistance required for aggressive environments. Monel Flanges outshine carbon steel in corrosive atmospheres, making them the preferred choice for applications where durability and longevity are crucial.

Inconel Flanges

Inconel is another popular nickel-based alloy known for its high-temperature strength. While Inconel Flanges offer excellent performance in extreme heat, they may not provide the same level of corrosion resistance as Monel Flanges. For applications where both heat and corrosion resistance are essential, they prove to be the optimal choice.

Alloy 20 Flanges

Alloy 20, also known as Carpenter 20, is a nickel-chromium-molybdenum stainless steel alloy that offers excellent resistance to corrosion and pitting. While Alloy 20 is suitable for many corrosive environments, it may not match the overall corrosion resistance and mechanical properties of Monel Flanges.

Advantages of Monel Flanges

The advantages of using Monel Flanges extend far beyond their corrosion resistance. Let's explore the various reasons why they are a preferred choice in different industries and applications.

High Tensile Strength and Temperature Stability

Monel Flanges are known for their high tensile strength, which ensures they can withstand significant mechanical stress without deformation. This property makes them suitable for applications where the flanges are exposed to high-pressure conditions, such as in oil and gas pipelines, chemical reactors, and high-temperature environments.

Durability and Longevity

Monel Flanges exhibit exceptional durability and longevity, even in the most demanding conditions. Their ability to withstand extreme weather conditions, abrasive elements, and frequent exposure to corrosive substances makes them a reliable choice for critical applications with long operational lifespans.

Resistance to Biofouling and Microbial Corrosion

In marine and offshore industries, biofouling and microbial corrosion can pose significant challenges. Monel Flanges possess inherent resistance to these issues, making them ideal for use in seawater desalination plants, offshore platforms, and shipbuilding.

Excellent Weldability and Formability

Monel Flanges are known for their excellent weldability and formability. They can be easily welded, machined, and formed into complex shapes, allowing for greater design flexibility and ease of installation.

Low Risk of Contamination

For industries dealing with sensitive materials such as pharmaceuticals and food processing, Monel Flanges offer a low risk of contamination. Their non-reactive nature ensures that they do not leach any harmful substances into the conveyed fluids or products.

Key Considerations for Choosing Flange Materials

Selecting the appropriate flange material is crucial to ensuring the success and safety of your projects. Here are some key considerations to keep in mind when choosing flange materials:

Operating Conditions

Evaluate the temperature and pressure conditions under which the flanges will operate. Monel Flanges, with their excellent high-temperature and pressure capabilities, are an ideal choice for applications where these factors are critical.

Corrosive Environment

Consider the nature of the fluid being transported and the corrosive environment in which the flanges will operate. Monel Flanges excel in corrosive atmospheres, providing reliable performance and extended service life.

Industry Standards and Certifications

Ensure that the chosen flange materials meet industry standards and certifications. At Jay Steel Corporation, we take pride in adhering to global standards, providing our customers with the assurance of top-quality products.

Cost-Effectiveness

While Monel Flanges may have a higher initial cost compared to some other materials, their long-term durability and low maintenance costs make them a cost-effective choice in the long run.

Expert Guidance

Seek expert guidance from professionals who can analyze your project requirements and recommend the most suitable flange material. At Jay Steel Corporation, our team of experts is always ready to assist you in making the right choice.

Applications of Monel Flanges

Monel flanges are essential components used in various industries due to their unique properties and corrosion-resistant nature. Monel is a group of nickel-copper alloys known for their excellent resistance to seawater, acids, alkalis, and various corrosive environments. Here are some of the common applications:

Marine industry

Oil and Gas industry

Chemical processing

Aerospace industry

Power generation

Seawater desalination

Food processing

Pharmaceutical industry

Water treatment

Nuclear industry

Other Application

Final Thoughts!..

Monel Flanges emerge as the ideal choice for critical applications where corrosion resistance, high strength, and temperature stability are paramount. Their exceptional properties and performance set them apart from other flange materials, making them the preferred option for industries such as marine, offshore, chemical processing, aerospace, and so on.

As India's leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, Jay Steel Corporation is committed to delivering top-notch products that cater to your specific project requirements. Our Monel Flanges are not only highly regarded in India but are also in demand across the globe, with exports to countries such as Singapore, Malaysia, Nigeria, the USA, France, Saudi Arabia, Kuwait, Tunisia, Qatar, and more. Our products have gained international acceptance due to their unmatched quality, reliability, and adherence to global standards and certifications.

0 notes

Text

PIPE SPOOLS MANUFACTURE AND EXPORTER

Superior Steel Overseas India always believes in serving their customers with utmost Quality Products. Superior Steel Overseas offers Complete Piping Solution i.e. From Pipes, and Plates to a Wide Range of Pipe Fittings & Piping Spools in almost all Ferrous and Non-Ferrous Material. Pre-Fabricated Piping Spools are made as per Client Requirements. We have a dedicated Designing, Engineering & Manufacturing Team that offers best in class Piping Spools. We do our best to fulfill all Piping Requirements of our Customer as a One Stop Solution Provider. we also offers Seamless/ERW Pipes in various materials like Alloy Steel, Stainless Steel, Duplex, Monel, Inconel etc. We maintain ready stock of 400 MT of Alloy Steel pipes that can be offered Ex-Stock.

https://superiorsteel.co.in/pipe-spools-manufacture-and-exporter/

0 notes