#MotorizedLinearStage

Explore tagged Tumblr posts

Text

Linear electric motors for clients from Germany are under test

Linear electric motor is a type of electric motor that converts electrical energy into linear motion. It’s similar to a traditional rotary motor, but instead of producing a rotational motion, it generates linear movement.

Linear electric motors are commonly used in various industrial applications where precise and controlled linear motion is required. They offer several advantages over conventional mechanical systems, such as higher accuracy, faster response times, and increased reliability due to their simple design and absence of mechanical transmission elements like gears, belts, or screws. The basic construction of a linear servo motor consists of a stator and a mover. The stator contains a series of coils that are energized with electric current, creating a magnetic field. The mover, typically a permanent magnet or a set of magnets, is attracted or repelled by the magnetic field, resulting in linear motion along a track or guide. The movement of the mover is controlled by a feedback mechanism, usually involving position sensors such as encoders or linear scales. These sensors provide precise information about the position and speed of the mover, allowing for accurate control and positioning. Linear electric motors find applications in various industries, including robotics, CNC machining, packaging, semiconductor manufacturing, medical devices, etc. They are used in systems requiring precise linear motion, such as linear stages, pick-and-place machines, cutting machines, and inspection systems. It's worth noting that Linear electric motors are different from linear actuators, which are typically simpler devices that convert rotational motion into linear motion using mechanisms like lead screws or belts. While, Linear motors offer higher performance and are often preferred in applications where precise control and high-speed operation are critical. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#ChinaLinearMotionStage#ElectricLinearMotor#IronlessMotors#Linearinductionmotor#LinearMotors#MotorizedLinearStages

0 notes

Text

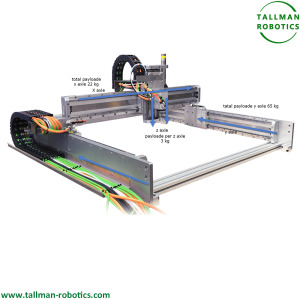

Industrial Linear Motion Modules Are Picked Up to Germany

Industrial Linear Motion Modules Are Picked up to Germany.

Industrial Linear Motion Modules are mechanical systems designed to provide linear motion to various industrial applications. They consist of a combination of linear guides, actuators, and other components that enable precise and controlled movement of a load along a straight line. These modules are widely used in various industries such as manufacturing, automation, robotics, and material handling. Some common types of industrial linear motion modules include: - Linear Guides: These are mechanical components that provide support and guidance to the moving parts of a linear motion system. Linear guides typically consist of a rail and a carriage, with the rail providing a smooth surface for the carriage to slide along. - Linear Actuators: These are electromechanical devices that convert rotational motion from a motor into linear motion. Linear actuators can be divided into several types, such as screw-driven, belt-driven, and direct-drive actuators. - Ball Screws: A ball screw is a type of mechanical actuator that translates rotational motion into linear motion. It consists of a screw shaft and a ball nut, with ball bearings positioned between them to reduce friction and increase efficiency. - Linear Motors: These are direct-drive motors that generate linear motion without the need for any mechanical transmission components like gears or belts. They use magnetic fields to produce force, which moves the load along a linear path. - Linear Bearings: These are mechanical components that provide low-friction movement for linear motion systems. Linear bearings can be divided into several types, such as ball bearings, roller bearings, and plain bearings. - Linear Slides: These are pre-assembled systems that combine linear guides, actuators, and other components to provide a ready-to-use linear motion solution. Linear slides can be customized to meet specific application requirements. When selecting an industrial linear motion module, it is essential to consider factors such as load capacity, speed, accuracy, repeatability, and environmental conditions to ensure the chosen system meets the requirements of the specific application. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#HighSpeedLinearModules#linearmodulesforprecisionmotionandindustrialautomationapplications#LinearMotionModules#LinearMotionProducts#LinearMotionSystems#MotorizedLinearStage

0 notes

Text

Linear Translation Stages are Finished for Germany Clients.

Linear Translation Stages have been Finished and will be delivered to Germany Clients.You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

How to adjust the preload of ball screw nut. Ball screw nut pair is a high-precision transmission device. It uses rolling friction screw instead of sliding friction screw, which has the advantages of small wear, high transmission efficiency, stable transmission, long service life, high accuracy and low temperature rise. Select high-quality screw to identify titanium Hao. Because the ball screw nut pair has the outstanding advantages of small motion friction and easy to eliminate transmission clearance, it brings great benefits to the performance improvement of electromechanical integration system. Pre tightening is to prevent the ball from slipping. The self-locking property of the ball screw nut pair is poor, which can be said to be absent. It is easy to fall off without pre tightening. https://youtube.com/shorts/ctaMxDnmOC8?feature=share There are four common methods for ball screw preloading: - Double nut gasket type pre tightening The mechanism of this method is simple and reliable. Good rigidity and most widely used. The form of adding gasket between the double nuts can be adjusted in advance by a professional manufacturer according to the user's requirements. It is very convenient to unload when using. - Double nut threaded pre tightening Use the external thread on one nut to adjust the relative axial position of the two nuts through the round nut to achieve pre tightening. - Double nut tooth difference pre tightening On the flanges of the two nuts, cut out the gears with a tooth number difference of 1. The two gears mesh with the corresponding internal gear rings at both ends. The internal gear rings are fastened on the nut seat with screws. By rotating one of the nuts, the mutual positions of the two nuts are changed to adjust the clearance and apply the preload. - Single nut variable lead self preloading The internal thread raceway of the nut will produce a lead sudden change on the middle circle, so that the balls at the left and right ends will be axially displaced after assembly to realize pre tightening. The purpose of eliminating the axial clearance of the ball screw nut pair is to increase the preload and reduce the empty stroke in the reverse direction, so that there is no reverse dead zone, and improve the transmission rigidity and transmission accuracy. Not all ball screws(in Linear Translation Stages) are pre tightened, mainly according to the accuracy requirements. Generally, the pre tightening accuracy is high and the load capacity is large. The pre tightening is graded. The selection is based on the use requirements. You can check the samples of different brands for details. Read the full article

#HighPrecisionPositioning#High-PrecisionLinearStages#LinearMotionStages#LinearRotaryStages#LinearTranslationStages#MiniatureLinearStages#MotorizedLinearStages#MotorizedXYLinearStage#PrecisionLinearStages#X-YStages

0 notes

Text

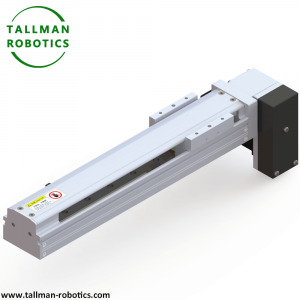

Industrial Linear Motion

Industrial Linear Motion As a professional Industrial Linear Motion, Tallman Robotics supplies wide range of TM linear motion actuators, including Screw and Belt driven linear modules by different driven solution, also Semi and fully closed linear modules for different use environment. Industrial Linear Motion, also named as Modular Linear Actuator, Linear Motion Module, Linear Actuator Bundle, Linear Modular Actuator, Single Axis Linear Actuator etc. Industrial Linear Motion can be in combination with range of brand motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 stepping motors in extruded base aluminum profile to get precise and speed target of various precision and common linear robot application. There is option of brake and no brake. TM Industrial Linear Motion of type TM65 with body with by 65mm have 4 series respectively by Ball Screw drive semi closed, Ball Screw drive fully closed, and Timing Belt drive semi closed, Timing Belt drive fully closed. These linear modules have strokes from 0mm to 800 mm, and payload from 2.5kg to 30kgs. It could applied in auto feeding before CCD visual inspection, components picked at the appointed position, flexible picking, gluing the sealant between the work piece, large-scale parts rack picking and placing, electronic components inspection etc.

Basic Specification of TM65 series Model No TMS65-CM TMS65-CR TMB65-CM TMB65-CR Drive solution Ball screw Ball screw Timing belt Timing belt Sealed or not Semi closed Fully closed Semi closed Fully closed Motor power AC (W) 50/100W Repeatability (mm) ±0.01/±0.005 ±0.04 Ball screw outer diameter (mm) 12 Reduction Ration: 1:1 lead (mm) 5 10 5 10 66 Fastest speed Motor speed 3000 (rpm) 250 500 250 500 3300 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 15/30 7.5/15 15/30 7.5/15 2/4 Vertical 0.3G 5/10 2.5/5 5/10 2.5/5 - Rate Thrust (N) 170/341 85/170 170/341 85/170 15/30 Linear guide (mm) 42*9.5-1 Origin sensor: Plug-in EE-SX674(NPN)EE-SX674P(PNP) Related knowledge: Laser marking machine for linear module application The word laser stands for "light amplification of stimulated radiation". Simply put, light particles (photons) excited by an electric current release energy in the form of light. The lamp was pointed at a bunch. The laser beam is formed in this way. Lasers are one of the most important inventions of human beings and they play an important role in our daily life; they are used in almost every field we can imagine, including electronics, modern medicine, defense and so on. With four basic characteristics of laser radiation: monochrome, high directivity, high consistency, and high energy density, lasers are used in many fields of modern material processing. Due to coherence, strength can be maintained for a long time, and can be further guided with the help of lenses. The laser beam engraves the surface of the material, is absorbed and heats the material. This heat generation causes the material to be removed or completely evaporated. This makes it possible to engrave, mark or cut various materials. In industry, lasers are used every day: engraving, marking, welding, cutting, drilling, cleaning, measuring, testing, etc. Laser has become one of our powerful production tools! Let's take a look at laser marking. As a modern processing method, it has great advantages compared with traditional processing methods such as printing, mechanical scribing, and EDM. Laser marking machine has maintenance-free, high flexibility, high reliability and other properties, especially suitable for areas with high requirements for fineness, depth and smoothness, so it is widely used in the hardware industry. Copper, stainless steel, gold, alloy, aluminum, silver and all metal oxides. The laser marking machine can mark various characters, serial numbers, product numbers, barcodes, QR codes, production dates, etc. on hardware products, and the time, date or serial number, product number can be automatically skipped. The laser-marked text and graphics are not only clear and fine, but also cannot be erased or modified, which is very beneficial to the tracking of product quality and channels, and can effectively prevent the sale of expired products, anti-counterfeiting and prevent cross-products. The hardware products engraved by the laser marking machine have fine patterns and long-lasting, beautiful and clear marks. The laser marking machine can meet the needs of printing large amounts of data on very small hardware products, and can print two-dimensional barcodes with higher resolution. Compared with the imprinting or jet marking methods, the powerful functional advantages allow the laser Standard machine has a broader market at home and abroad. As a new marking equipment, laser marking machine gradually shows better and better performance quality. The trend of using laser marking machine is increasing year by year, especially in the application of hardware products. Read the full article

#BeltDriveActuators#Beltdrivelinearactuator#BeltDriveLinearSystems#BeltDrivenActuators#BeltDrivenLinearStages#BeltDrivenLinearSystems#Beltdrivenmodularactuators#LinearBeltDriveActuators#Linearbeltdrivenactuators#MotorizedLinearStages#SealedBeltdrivenactuators#SingleAxisRobot#Timingbeltdrivenactuator#Timingbeltlinearactuators

0 notes