#NDT Equipment Supply Services

Text

Titanium Alloys

RVS Quality Certifications Pvt. Ltd. is a leading company specializing in Titanium Alloys. Renowned for its commitment to excellence, It is at the forefront of providing high-quality titanium alloy solutions for diverse industries. With a focus on precision engineering and advanced metallurgy, the company ensures superior strength, corrosion resistance, and lightweight properties in its alloys. They dedicated to meeting stringent quality standards, offering innovative solutions, and fostering client satisfaction. As a trusted name in the industry, RVS Quality Certifications Pvt. Ltd. continues to be a reliable partner for those seeking top-notch titanium alloy products for various applications.

#Titanium Alloys#Third-Party Inspection Services#Eddy Current Training Courses#Rebound Hammer Testing Services#Non Destructive Testing Services#NDT Equipment Supply Services#Forging Consultants

1 note

·

View note

Text

STAINLESS STEEL FLANGES MANUFACTURER & EXPORTER IN ABU DHABI

Abu Dhabi, the capital of the United Arab Emirates, is known not only for its oil wealth but also for its growing industrial sector. Among the industries thriving in this dynamic city is the manufacturing and export of stainless steel flanges, which play a significant role in the local economy and the global supply chain.

Why Stainless Steel Flanges?

Stainless steel flanges are essential components used to connect pipes, valves, pumps, and other equipment in a piping system. They provide a reliable means for disassembly and maintenance, ensuring the integrity and efficiency of fluid and gas transport systems. The key advantages of stainless steel flanges include:

Corrosion Resistance: Stainless steel offers excellent resistance to rust and corrosion, making it ideal for harsh environments, including those with high levels of moisture, chemicals, and salinity.

Strength and Durability: Stainless steel flanges are known for their high tensile strength and durability, ensuring a long service life even under high-pressure and high-temperature conditions.

Versatility: Available in various grades and specifications, stainless steel flanges can be customized to meet the specific requirements of different industries, from oil and gas to chemical processing and water treatment.

Leading Manufacturer & Exporter in Abu Dhabi

Abu Dhabi is home to several leading manufacturers and exporters of stainless steel flanges, known for their commitment to quality, innovation, and customer satisfaction. Among these, Metalloys International stands out for its dedication to excellence. The company leverages advanced manufacturing technologies, stringent quality control measures, and a deep understanding of industry standards to produce flanges that meet and exceed client expectations.

Advanced Manufacturing Facilities

Manufacturers like Metalloys International invest in state-of-the-art production facilities equipped with the latest machinery and technology. This enables them to produce a wide range of flanges, including:

Weld Neck Flanges: Designed for high-pressure applications and seamless welding to the pipe.

Slip-On Flanges: Easy to install and suitable for low-pressure applications.

Blind Flanges: Used to seal off the ends of pipes or valve openings.

Socket Weld Flanges: Ideal for small-diameter, high-pressure pipelines.

Threaded Flanges: Used in systems where welding is not feasible.

For more information on advanced manufacturing facilities, visit here.

Quality Assurance

Quality is paramount in the manufacturing of stainless steel flanges. Leading manufacturers like Metalloys International adhere to international standards such as ASTM, ANSI, DIN, and JIS, ensuring their products meet the highest quality benchmarks. Rigorous testing procedures, including non-destructive testing (NDT), hydrostatic testing, and dimensional inspections, are employed to verify the integrity and performance of each flange.

Learn more about quality assurance practices here.

Innovation and Customization

Recognizing the diverse needs of their global clientele, Abu Dhabi-based manufacturers like Metalloys International offer customized solutions tailored to specific project requirements. Whether it's a unique design, a special alloy composition, or a specific surface finish, these manufacturers work closely with clients to deliver flanges that precisely match their needs.

Explore innovation and customization options here.

Global Reach

Abu Dhabi's strategic location and excellent logistical infrastructure make it a hub for international trade. Leading stainless steel flange manufacturers like Metalloys International leverage this advantage to export their products to markets worldwide, including the Middle East, Asia, Europe, and the Americas. They maintain robust supply chains and partnerships with global distributors, ensuring timely delivery and reliable service.

Read more about their global reach here.

Commitment to Sustainability

In line with global trends towards sustainability, manufacturers in Abu Dhabi are also focusing on eco-friendly practices. From sourcing raw materials responsibly to implementing energy-efficient manufacturing processes and recycling waste, these companies are committed to reducing their environmental footprint.

Conclusion

Abu Dhabi's stainless steel flange manufacturers and exporters, including Metalloys International, are at the forefront of delivering high-quality, reliable, and innovative solutions to the global market. With their advanced manufacturing capabilities, stringent quality assurance practices, and commitment to customer satisfaction, they continue to play a vital role in various industries worldwide. As the demand for stainless steel flanges grows, these manufacturers are well-positioned to meet the challenges and opportunities of an evolving market.

By choosing a reputable stainless steel flange manufacturer in Abu Dhabi, businesses can ensure they receive products that not only meet their technical requirements but also contribute to the overall efficiency and success of their operations. For more information, visit Metalloys International.

#SS FLANGES MANUFACTURER IN ABU DHABI#SS 304 / 304L FLANGES SUPPLIER IN ABU DHABI#SS 310 / 310S FLANGES STOCKIST IN ABU DHABI#SS 316 / 316L FLANGES WHOLESALER IN ABU DHABI#SS 316TI FLANGES EXPORTER IN ABU DHABI#SS 317 / 317L FLANGES LEADING MANUFACTURER IN ABU DHABI#SS 321 / 321H FLANGES MANUFACTURER IN ABU DHABI#SS 347 / 347H FLANGES SUPPLIER IN ABU DHABI#SS 446 FLANGES STOCKIST IN ABU DHABI#904L FLANGES STOCKIST IN ABU DHABI#SMO 254 FLANGES STOCKIST IN ABU DHABI#SS FLANGES MANUFACTURER & EXPORTER IN ABU DHABI

0 notes

Text

Role of third-party inspection in non-destructive testing

Nondestructive testing (NDT) is a vital aspect of ensuring the safety and reliability of critical infrastructure, such as oil and gas pipelines, aircraft, and bridges. NDT is a technique used to evaluate the integrity of a material or structure without damaging it. The effectiveness of NDT is dependent on the accuracy and reliability of the inspection process, which is why third-party involvement is crucial in the lifting equipment inspection.

The third-party inspection involves a neutral and independent inspection performed by a qualified inspection agency not affiliated with the manufacturer, supplier, or customer. Dutest is one of the best agencies providing third-party inspection services in the UAE. Third-party inspections are essential in ensuring the quality of materials, products, and processes by verifying that they meet the specified requirements and regulations. The role of third-party inspection in NDT is to provide an unbiased assessment of the accuracy and reliability of the inspection process, the quality of the equipment used, and the expertise of the personnel involved.

Benefits of third-party inspection in NDT

Reduction of error risks

The lower probability of mistakes and inaccuracies throughout the inspection process is one of the key advantages of third-party inspection in NDT. Inspectors hired by a third party are trained to spot and repair mistakes that could provide inaccurate results and have a wealth of knowledge and expertise in NDT. They can also offer an unbiased evaluation of the caliber of the tools and supplies used in the inspection procedure, verifying that they adhere to the appropriate criteria.

Reduced costs

Third-party inspection in NDT can also help to reduce costs by identifying potential problems before they become major issues. Early identification of problems can prevent costly repairs and downtime, ensuring that the infrastructure remains operational and safe. In the long run, this can result in significant financial savings for businesses.

Ensure compliance.

Additionally, independent inspection in NDT can support ensuring adherence to rules and specifications. Assuring that the inspection procedure complies with the appropriate requirements, third-party inspectors are educated to comprehend and follow the pertinent regulations and standards. This can assist businesses in avoiding exorbitant fines and legal problems that may result from non-compliance.

Third-party inspection is essential to NDT because it offers a neutral and unbiased evaluation of the process’ precision and dependability, the caliber of the tools utilized, and the personnel’s level of experience. As a result, it is crucial for businesses to spend money on third-party inspection services to guarantee the security, dependability, and compliance of their vital infrastructure.

0 notes

Text

1 note

·

View note

Text

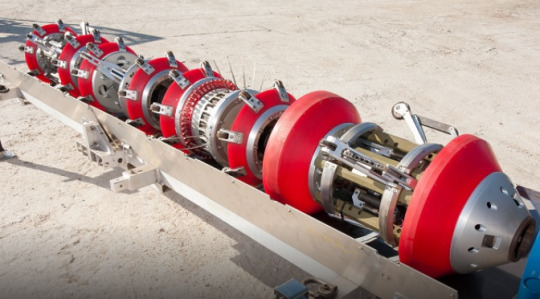

Intelligent Pigging Market: Analyzing Market Size, Share, and Forecast

The intelligent pigging market involves the inspection of pipelines using intelligent pigs also known as inline inspection tools, crawlers or smart pigs. Intelligent pigs make use of magnetic flux leakage or ultrasonic testing techniques to detect corrosion, cracks, dents and other irregularities in pipeline walls. Pipelines transporting oil, gas and other chemicals over long distances require periodic inspection to ensure integrity and avoid leakages. Intelligent pigs allow inspecting pipelines internally without disrupting product flow. This reduces downtime and helps operate pipelines safely for extended periods. The growing concerns around corrosion monitoring and leakage detection are driving the need for intelligent pigging solutions globally.

The Global intelligent pigging market is estimated to be valued at US$ 1,408.3 Bn in 2024 and is expected to exhibit a CAGR of 6.5% over the forecast period 2023 to 2030.

Key Takeaways

Key players operating in the intelligent pigging market are LIN SCAN, T.D. Williamson, Inc., Baker Hughes Incorporated, GE Oil and Gas, NDT Global, Enduro Pipeline Services, Inc., Petrobras, OMV Group, ConocoPhillips, and Royal Dutch Shell PLC. These players are focusing on new product launches and partnerships to expand their global footprint.

Growing inter-country and offshore oil and gas trade are increasing the number of pipeline projects globally. This is driving the demand for advanced inspection technologies like intelligent pigging to ensure pipeline integrity and safety.

Technological advancements including magnetic flux leakage tools with high resolution, new ultrasonic inspection solutions, and combo tools with dual inspection modes are improving intelligent pig accuracy and coverage. This is supporting condition-based maintenance approaches for pipelines.

Market Trends

One of the key trends in the intelligent pigging market is the growing adoption of intelligent pigs for midstream pipeline inspection. Several midstream operators are recognizing their pipeline inspection needs to ensure operational safety. This is expected to support market growth over the forecast period.

Another major trend includes the development of intelligent pigs for complex pipeline routes like subsea oil and gas pipelines. Vendors are focusing on tools capable of navigating tight bends and providing high resolution inspection of offshore pipelines transporting oil and gas over long distances.

Market Opportunities

Rising investments in pipeline infrastructure development and rehabilitation worldwide present significant growth opportunities. The market is expected to particularly benefit from projects lined up under natural gas and crude oil pipeline networks expansion.

Advancements in robotic and remote technology are enabling development of autonomous intelligent pigs. These tools can perform inspections without the need for launchers and receivers, saving costs. Such autonomous tools are expected to gain popularity going forward.

Impact of COVID-19 on Intelligent Pigging Market Growth

The COVID-19 pandemic has drastically impacted the growth of the intelligent pigging market. Nationwide lockdowns across major countries resulted in suspension of industrial activities and decline in oil & gas demand. This decreased the investments in pipeline maintenance and inspection activities globally. The disruption in supply chains further constrained the procurement of necessary equipment and technology required for pipeline inspection projects.

However, with easing of restrictions and restart of economies, the demand for oil & gas is recovering steadily. This is driving the revival of projects in the intelligent pigging market. The oil companies are now focusing more on integrity management and condition monitoring of pipelines to prevent failures. This provides growth opportunities for vendors providing advanced inspection technologies like MFL tools, ultrasonic tools, and combination tools. The providers of intelligent pigs, launchers, and receivers are strengthening their service offerings and offering customized solutions as per project needs. They are also investing more on R&D to develop innovative solutions for inspection of complex pipeline infrastructure and production facilities.

The market is projected to witness faster growth in coming years on back of increasing pipeline network and rising focus on operational safety. The service providers will need to invest in digital technologies and predictive analytics solutions to improve inspection capabilities. Collaboration with oil majors for complex integrity issues will also be crucial for future growth. Overall, while the pandemic impacted short term sales, the long term outlook remains positive with increasing investments in pipeline infrastructure globally.

Geographical Regions with Highest Intelligent Pigging Market Value

North America accounts for the largest share of the global intelligent pigging market in terms of value. This is mainly attributed to extensive pipeline network and aging oil & gas infrastructure in countries like the US and Canada. According to reports, over 66% of the pipelines in these regions are aged between 30-50 years demanding frequent condition assessments. This drives the demand for internal line inspections using intelligent pigs. Moreover, presence of major oilfield service vendors along with technology advancements in pipeline inspection supports market growth.

Asia Pacific displays tremendous growth opportunities with emerging economies vastly investing in development of oil & gas pipeline infrastructure. China being the largest importer and consumer of oil & gas worldwide is significantly expanding its domestic pipeline network. Other Asian countries like India are also undertaking major pipeline projects and retrofitting existing networks which will drive intelligent pigging demand over the forecast period.

0 notes

Text

Conducting Effective Oil Well Inspections with Javier Daniel Salcido

Javier Daniel Salcido

Conducting Effective Oil Well Inspections with Javier Daniel Salcido

Oil Well servicing helps identify potential issues like leaky valves or sand accumulation before they become significant obstacles to production while finding ways to optimize operations by lubricating moving parts to minimize wear and tear and increase operational efficiencies.

Safety inspections and audits are an integral component of oil and gas operations. Regular audits should be conducted to ensure compliance and ensure maximum safety.

Preparing for Inspections

Oil and gas industries adhere to some of the strictest safety protocols worldwide, making adherence paramount for protecting employee health and wellbeing, minimizing environmental incidents, avoiding costly equipment damage and structure damage, and protecting equipment assets.

Javier Daniel Salcido highlights that conducting inspections is crucial to oil well operations, yet adequate inspections require meticulous preparation. This involves selecting qualified inspectors for different inspection types, reviewing existing documentation, and setting clear expectations regarding the conduct of an inspection.

An oil well can undergo numerous tests to assess its productivity and integrity, such as daily production tests that provide valuable insights into productivity issues, such as pressure drops or changes to its oil-to-gas ratio. Furthermore, these tests can also be used to estimate pump lifespan, forecast production, and anticipate expenses in the future.

Other inspections include a visual examination to check for corrosion, poor welding, or signs of wear; radiography tests using x-rays to assess internal equipment; and thermography inspections, which detect leaks by measuring differences in pipeline and insulation temperature - these should all help ensure maximum oil healthy production efficiency.

Performing Inspections

Javier Daniel Salcido mentions that oil and gas industries operate under stringent standards to keep equipment running efficiently while upholding workplace safety. Unfortunately, adhering to these guidelines may prove challenging due to their complex nature and many moving parts, so frequent and thorough inspections are vital in this industry.

Visual inspections are a popular and cost-effective method used in oil and gas to detect corrosion, cracks, and other defects. Corrosion, cracks, and other flaws may often be identified through visual examination; however, there are limits to what a human eye and borescope can see. Therefore, other NDT methods must also be utilized to identify internal flaws.

Javier Daniel Salcido points out that ultrasonic testing (UT), another widespread nondestructive testing (NDT) technique in the oil and gas industry, provides another NDT method. While radiography requires specific preventive measures that slow inspection times, ultrasonic testing offers an image of an object's interior without exposing personnel to radiation exposure and identifying surface-breaking anomalies. Furthermore, operators can quickly spot potential problems before they lead to severe damage or failure.

Private well owners must conduct regular water testing to ensure their home water supply meets all necessary regulations and requirements. This includes inspecting the well and its system's equipment annually and keeping the area around your well clear of harmful materials such as fertilizer, paint, and motor oil that could contaminate it with potentially toxic compounds. Keeping a logbook to record each inspection, any odor, taste, or appearance changes, and flow tests to determine whether your well meets household demands would be best.

Documenting Inspections

Javier Daniel Salcido emphasizes that oil and gas industries operate according to stringent safety standards, prioritizing worker and public well-being while promoting efficient operations and protecting equipment against potential failures that could cause accidents.

Unfortunately, state agencies charged with enforcement, such as New Mexico's Office of the Commissioner of Oil and Gas (OCD), often lack adequate funds and staff. As reported by Grist in 2018, OCD penalties for abandoned oil wells with many unused pipes remain low and infrequent.

Inspectors conduct numerous tests on wells to assess their health. This includes daily production, the oil-to-gas ratio, and radiography and thermography, which help determine whether they meet regulatory standards.

Field inspectors must record their findings during an inspection, providing a report detailing everything found, from any significant problems or observations, through photos and documentation (such as maps) of the healthy site. This data helps identify potential issues at that location and inform future inspections at that site; furthermore, this process identifies areas that require repair or replacement and saves organizations both time and money by pinpointing any areas that need extra focus shortly.

Reporting Inspections

Due to the delicate nature of oil and gas production, this industry's regulations are incredibly stringent. Faulty equipment or poor quality control can result in severe damages that require expensive repairs; regular inspections are integral to maintaining high standards throughout production processes.

The Railroad Commission aims to reduce the percentage of wells not inspected to below one percent over five-year cycles through improved staffing and enforcement efforts. More resources must be dedicated and enforced to achieve this goal, and activities must be enhanced.

Javier Daniel Salcido highlighted that monitoring inspection results are critical for companies and regulatory agencies; however, paper checklists can be time-consuming and error-prone.

Oil and gas companies that rely on the integrity of infrastructure and assets for success depend on regular inspections of vital systems to maximize profits while protecting the environment. Low failure rates are essential to maximize profits while protecting the environment - whether it's offshore oil rigs, onshore pipelines, or storage tanks; frequent inspections are crucial in keeping them functional while increasing productivity and efficiency. When combined with an effective quality management system, you can ensure compliance and safety, rove productivity efficiency, and increase productivity levels while enhancing profits and efficiency.

0 notes

Text

Ultrasonic Testing Market Size, Share & COVID-19 Impact Analysis

The global ultrasonic testing market size is projected to reach USD 3,671.9 million by 2027, exhibiting a CAGR of 9.43% during the forecast period. The burgeoning startup culture in the non-destructive testing (NDT) domain will play a central role in fueling this market, postulates Fortune Business Insights™in its report, titled “Ultrasonic Testing Market Size, Share & COVID-19 Impact Analysis, By Type (Time-Of-Flight Diffraction, Phased Array, Immersion Testing, Guided-Wave Testing, Acoustography, and Others) By Equipment (Flaw Detectors, Thickness Gauges, Transducers & Probes, Industrial Scanners, Tube Inspection Systems, Bond Testers, Imaging Systems, and Others), By Service (Inspection Services, Equipment Rental Services, Calibration Services, and Training Services), By Vertical (Manufacturing, Oil & Gas, Aerospace, Public Infrastructure, Automotive, Power Generation, and Others) and Regional Forecast, 2020-2027”. Testing and inspection are critical functions that operators and owners of capital have to perform to ensure the safety and reliability of equipment, machinery, and other assets. Startups have been steadily emerging over the past few years to fulfill these functions using NDT and ultrasonic testing (UT) technologies. For example, the Indian startup AAVRTTI has developed RUDI (Radar for Utility Detection and Imaging) to detect, identify, and map buried utilities. The company also offers other services, such as the localized detection of cable faults and underground pipe leakages. Inductosense, a startup domiciled in the UK, has been engaged in developing NDT solutions using ultrasonic testing. The company manufactures ultrasonic sensors to facilitate accurate monitoring of internal corrosion & erosion in pipelines and vessels. These advancements in asset testing technologies, heralded by fledgling startups, will create massive opportunities for this market.

The report states that the value of the market was estimated to be USD 2,297.2 million in 2019 and also shares the following:

Holistic evaluation of the various market drivers and trends;

Granular understanding of the challenges facing the market;

Unmatched segmentation of the market; and

Microscopic study of the competitive milieu and regional prospects of the market.

Browse Complete Report Summary:

Restraining Factor

Revenue Shortfalls amid the COVID-19 Crisis to Quell Market Growth

With the coronavirus-induced global economic and health crisis unfolding with increasing intensity, the aviation industry is set to experience unprecedented revenue shortfalls. According to the International Civil Aviation Organization (ICAO), in the first half of 2021, airlines are likely to face potential gross passenger operating revenues between USD 163 billion and USD 194 billion. This is in addition to the USD 391 billion worth of losses faced by airliners in 2020. The ultrasonic testing market growth is also expected to suffer setbacks as a result of these financial stresses as the pandemic has severely disrupted investment plans of aircraft manufacturers and aviation technology providers. Furthermore, travel restrictions and the cancelation of flights have delayed the adoption of advanced UT technologies. For example, a recent report by the Organization for Economic Cooperation and Development (OECD) points out that a combination of supply shocks and negative demand has created widespread uncertainty in the aviation industry, thus delaying the deployment of next-generation technologies, such as ultrasonic testing, by airline companies. As a result of these developments, this market will display a negative CAGR of -14.9% in 2019 and reach a value of USD 1,954.4 million in 2020.

Regional Insights

North America to Register Sterling Growth; Asia Pacific to Progress Promisingly

In 2019, the North America market size stood at USD 893.7 million, and the region is expected to bolster its growth trajectory during the forecast period on account of the rising employment of UT methods in the inspection of railway infrastructures. In addition, growing adoption of advanced testing technologies in the region’s robust aerospace industry will further boost the regional market.

Asia Pacific is anticipated to showcase the fastest growth in the ultrasonic testing market share in the forthcoming years owing to the huge investments in ramping up public infrastructure in India and the rapid expansion of the manufacturing industry in China. In Europe, the regional market growth will be aided by the increasing demand for these ultrasonic type of testing solutions in the automotive industry in Germany.

Competitive Landscape

Lucrative Collaborations to Characterize Market Competition

The competitive landscape of this market is experiencing a period of prolific dynamism due to the increasing number of lucrative partnerships between aviation industry giants and key players in the UT market. These collaborations are aimed at developing inventive testing solutions for aircraft components, which in turn will entrench the market position of the collaborating entities.

Industry Developments:

September 2020: Element Sheffield announced the bagging of approval from the aircraft engine maker, Safran, for destructive testing services. The agreement follows the recent clearance from Safran to Element to deploy ultrasonic testing techniques for Safran’s components and materials.

January 2020:Novosound, a Scottish startup, secured a USD 4.3 million investment to develop and launch its first flexible thin-film ultrasound sensor for inspecting curved surfaces in June. The startup will be targeting the field of inspection and maintenance of aircraft with the introduction of this device.

0 notes

Text

The #steelstructures fabricated for one of our clients have been packed properly ready for pick-up. all materials adopt Chinese GB standard Q235 and Q355, and the fabrication and quality control is according to EN1090-2 requirements. the scope of supply includes material, fabrication, NDT, trial assembly, painting as well as all fastening elements.

0 notes

Text

Among the most reputable suppliers of GPR equipment in Delhi is Shijay Project.

Introduction:

The efficient and secure completion of any construction or infrastructure development project relies on the accurate detection of buried structures and utilities. Shijay Project is a frontrunner among Delhi businesses that supply state-of-the-art ground penetrating radar (GPR) equipment. Shijay Project is a prominent provider of GPR equipment, having established itself via a dedication to technological innovation and client satisfaction.

GPR Instruments at the Cutting Edge of Technology Shijay Project is pleased to provide cutting-edge ground penetrating radar instruments. These devices use electromagnetic waves to create photographs of what's below the surface, including structures, utilities, and other subterranean things. The GPR devices used by Shijay Project are trustworthy and precise, whether they are being used to locate buried pipes, map geological features, or evaluate the state of concrete buildings.

In order to cater to its varied clientele, Shijay Project equips its GPR equipment with state-of-the-art technology and features. Keeping abreast of developments in the industry, the firm guarantees that its instruments have cutting-edge features. The tools made available by the Shijay Project range from high-frequency antennas that provide greater resolution to user-friendly software interfaces that allow for straightforward operation.

As a result of its versatility, Shijay Project's Ground penetrating radar instrument provider in Delhi is used in a wide variety of fields. To ensure the safety of employees and prevent expensive damages, these tools are indispensable in the construction industry for finding rebar, post-tension cables, and other subsurface structures prior to drilling or excavation. Non-destructive testing (NDT) of concrete structures is also made easier with the use of these tools, which can reveal any flaws or deterioration that may have been overlooked. Instruments from the Shijay Project are put to use in geological surveys, groundwater monitoring, and subsurface mapping in the geotechnical and environmental fields.

In addition to producing top-tier GPR equipment, Shijay Project stands out in the industry because of its unparalleled dedication to customer service. The organization has a staff of experts who help customers with every step of the process, from deciding which instrument is best for them to receiving training on how to use their new equipment and make sense of the data it produces. When working on a project, clients can rest assured that they will receive timely and helpful assistance from Shijay Project's customer service team.

Shijay Project is, without a doubt, the best option for purchasing high-quality, cutting-edge ground penetrating radar equipment in Delhi. Shijay Project has been a game-changer for several sectors thanks to their cutting-edge technology, adaptability, and dedication to client satisfaction with their subsurface detection solutions. Shijay Project's GPR instruments are reliable, high-quality equipment that boost security, productivity, and final results on any construction, geotechnical, or environmental endeavor.

#Ground penetrating radar instrument provider in Delhi#Geophysical instruments provider in India#ground penetrating radar survey in delhi#GPR instrument provider in Delhi

0 notes

Text

Ensuring Quality and Safety: The Importance of Inspection Services

Inspection service act as a critical quality control mechanism, helping organizations identify potential defects, deviations, and non-compliance issues in their operations. By conducting thorough inspections, businesses can ensure that their products, structures, and processes meet regulatory standards, industry best practices, and customer expectations. MIMC's inspection services encompass a broad spectrum of areas, including Non-Destructive Testing (NDT), Advanced Non-Destructive Testing (ANDT), third-party inspection, rig inspection, power generation inspection, and more.

Non-Destructive Testing (NDT):

One of the key inspection services offered by MIMC is Non-Destructive Testing (NDT). This technique allows for the assessment of materials, components, and structures without causing any damage or impairment. NDT employs various methods such as ultrasonic testing, radiographic testing, magnetic particle testing, and visual inspection. By utilizing these advanced techniques, MIMC's experts can identify flaws, cracks, corrosion, or structural weaknesses that may affect the safety and reliability of assets.

Advanced Non-Destructive Testing (ANDT):

In addition to traditional NDT methods, MIMC offers Advanced Non-Destructive Testing (ANDT) services. This entails utilizing cutting-edge technologies like phased array ultrasonics, computed radiography, eddy current array, and laser scanning. ANDT provides enhanced accuracy, efficiency, and depth of inspection, making it particularly valuable for complex and critical applications. MIMC's skilled professionals leverage their expertise in these advanced techniques to deliver precise and detailed inspection reports.

Third-Party Inspection:

Third-party inspection services offered by MIMC play a vital role in ensuring impartiality and objectivity in quality assessment. As an independent inspection body, MIMC acts as a neutral party, verifying compliance with industry standards, contractual requirements, and applicable regulations. This impartial evaluation adds credibility and transparency to the inspection process, providing clients with reliable information and fostering trust in their supply chains.

Rig Inspection:

For the oil and gas industry, rig inspection is an essential component of maintaining operational integrity and safety. MIMC's rig inspection services cover a comprehensive evaluation of drilling rigs, offshore platforms, and associated equipment. These inspections encompass structural integrity assessment, equipment functionality verification, safety system audits, and adherence to industry-specific standards. Through diligent rig inspections, MIMC helps organizations identify potential hazards, minimize downtime, and ensure the well-being of personnel.

Power Generation Inspection:

Power generation facilities require meticulous inspections to guarantee uninterrupted operations and minimize the risk of failures. MIMC's power generation inspection services encompass a thorough evaluation of power plants, including turbines, boilers, generators, and associated infrastructure. By utilizing advanced techniques and industry expertise, MIMC identifies any potential issues, ensuring compliance with safety standards and optimal performance of power generation equipment.

In today's quality-driven environment, inspection services have become indispensable for organizations across various industries. Maqlink International Management Consultants (MIMC) stands as a reliable partner in ensuring quality, safety, and compliance through their comprehensive range of inspection services. With a team of highly qualified professionals and state-of-the-art technology, MIMC delivers accurate and reliable inspection results. By leveraging these services, businesses can mitigate risks, enhance operational efficiency, and uphold their commitment to excellence.

0 notes

Video

undefined

tumblr

The company BEVALDIA welcomes the new video creation era with AI technology.

Herewith following is our presentation of our activities in the Mediterranean. https://bevaldia.com/mediterranean-underwater-services-ai/

Dear customers, BEVALDIA has successfully provided underwater services in the Mediterranean Sea for the last 45 years. Our clientele portfolio is proof of our success.

Our company uses the latest technology equipment which is manufactured in our own factories under our brand GAMSRO.

More than 560 shipping companies trust us worldwide to provide underwater services to their vessels.

In addition, more than 5700 underwater operations have been successfully completed.

Our teams are trained to the latest standards and are approved from all IACS classification societies.

Some of the services we provide include:

Diving services: underwater inspections, full hull cleaning, propeller polishing, IACS video surveys, underwater repairs.

Dry ship repairs: NDT inspections, welding & fabrications, vessel re naming services, repairs made by welding.

Agency services: Call entry formalities, greenlight, crew change, stores, provisions, supplies, launch boats.

Finally, we can assist your good company with any questions you may have regarding diving services for your good vessels.

BEVALDIA is a company you can trust because we operate 24/7, all days in a year, we provide our services always on schedule without unnecessary and costly delays to your vessels and are ISO certified for our quality, environmental, health and safety plus anti-bribery policy.

We will be happy to receive your requests and inquiries.

You can contact us 24/7 on our telephone numbers: (+30)2104001120, (+30)2104004470, (+30)2109582176 You may also send us an email at [email protected] Website: www.bevaldia.com

0 notes

Text

Skilled NDT Services in Michigan

Patriot Weld Inspections LLC supplies thorough NDT inspections in Michigan, and they have serviced the construction and manufacturing industries for over 40 years.

They have years of experience in testing and inspection services to many customers in various industries, and they take pride in playing a part in countless projects.

Patriot Weld Inspections LLC competes against national brands by participating in various weld quality programs which allows their employees to obtain a unique level of expertise. They are also equipped with top-notch tools for testing any material.

Certified To Do The Job Right

At Patriot Weld Inspections LLC, they are trained by necessary authorities, including ASNT Level III Inspector and AWS Certified Weld Inspector. This combination of skills and nationally recognized certifications helps them give high-quality Michigan NDT services tailored to their customers' needs.

The Services They Offer

The employees at Patriot Weld Inspections LLC present some of the best Michigan NDT services, including (MT) Magnetic Particle, (PT) Liquid Penetrant, (UT) Ultrasonic and (AE) Acoustic Emissions of Valves, Tanks and Piping. They also provide Visual Inspections, so you can count on them for thorough help.

Why Choose Patriot Weld Inspections LLC

Patriot Weld Inspections LLC utilizes different NDT inspection processes to give accurate results, and their appropriate techniques can locate materials, including those not visible to the unaided eye.

At Patriot Weld Inspections LLC, customers are the center of everything, and for this reason, they are committed to providing them with a first-rate level of service and professionalism. As part of their commitment, they are available around the clock to ensure their customers obtain top-notch services whenever they need them.

They also ensure all tasks they complete for their clients follow strict quality control guidelines and industry standards. They demand zero accidents and are dedicated to building a safe job environment for clients and customers. For further information about NDT inspections in Michigan, check out www.patriotweldinspections.com.

0 notes

Text

Building Material Testing Lab in India

KC India Test Lab - Building Material Testing Laboratory ( ISO , NABL accredited Certificate No. ) is one of the best laboratory providing reliable, accurate and defensible data in standardize and user-friendly format.

We have expertise in mechanical and chemical testing. We also provide geotechnical, civil engineering and construction inspection services.

Our goal is to achieve unique and unbeatable position in the field of testing and analysis of materials through our constant efforts, commitment of quality and customer satisfaction.

Let me tell you one thing, you have very bright idea of starting a material testing lab. Following are the few things you need to know before starting it:

It is must to have technical person with adequate qualification which means for soil testing you have to appoint a Geotech engineer, for structural testing you will be needing a structural engineer and for highways tastings such as. BBD you will need a highway engineer.

Material testing equipments are high in price so manage proper budget.

Get company ISO certified this will help you to attract more clients.

Make contacts with local bodies’ government and private companies

Have enough space and power supply there on

Don’t forget to buy NDT instruments they are more demanding Hope this will help you for Building Material Testing Labs

0 notes

Text

Blueprint reading

#Blueprint reading how to#

C32 – Parking and Highway Improvement Contractor.

C31 – Construction Zone Traffic Control Contractor.

C28 – Lock and Security Equipment Contractor.

C21 – Building Moving/Demolition Contractor.

C20 – Warm-Air Heating, Ventilating and Air-Conditioning Contractor.

C15 – Flooring and Floor Covering Contractors.

C6 – Cabinet, Millwork and Finish Carpentry Contractor.

C5 – Framing and Rough Carpentry Contractor.

C4 – Boiler, Hot Water Heating and Steam Fitting Contractor.

C2 – Insulation and Acoustical Contractor.

B2 - Residential Remodeling & Home Improvement.

Class “B2” - Residential Remodeling & Improvement.

Class “B” - General Building Contractor.

Class “A” - General Engineering Contractor.

Ability to weld with and trouble shoot welding processes such as SMAW, GMAW, FCAW, GTAW, SAW, etc. Familiar with NDT procedures and operations (UT, RT, PT, VT, MT and other similar methods of NDT). Preparing all projects reports such as usage reports, damage reports, and equipment acceptance reports, which are reviewed for accuracy and passed on for processing in our database. Work within defined parameters to make decisions, apply concepts to issues and resolve issues through immediate action or short-term planning. Provides direction and assistance to the team in order to meet assigned objectives. Analyze consigned inventory and review list of consumables and spares in order to provide inventory information to technicians in the field.Īs a Welding Technician with CRC-Evans Automatic Welding, I supervised and supported the Automatic Welding Equipment, Coordinate and planning maintenance of Equipment, Monitor the welding activity in accordance with welding specification and welding Engineering, Training welders and personnel, Support and assistance the Field Service Technician, Supply Technical Data, Organize Storage of spare parts to insure the maintenance of equipment, Organize rotation of Personnel. Preparing, monitoring and receiving all projects reports such as usage reports, damage reports, and equipment acceptance reports, which are reviewed for accuracy and passed on for processing in our database. Operations Support Specialist and Welding Technician since June 1992 to Current with CRC-Evans (Automatic Welding) Stanley Black & Decker Oil and Gas - Houston, TXĪs an Operations Support Specialist with CRC-Evans, my duties include identifying parts that will be needed to support pipeline welding projects, quoting and selling parts to customers, monitoring projects to determine the number of parts used per weld, and repair rates. Manage student learning outcomes assessment such that the results of the assessment lead to meaningful instructional development. Collaborate with an advisory committee of industry professionals to review programs that results in developing and maintaining curriculum that meets current industry standards. Day-to-day operations include assisting students toward successful program completion and fostering student achievement. Maintain accurate records of student enrollment, attendance, and academic progress. I teach a combination of Welding lecture and lab classes for SMAW, GMAW, FCAW, GTAW, Blueprint Reading for Welders, CWI seminar prep course and Advance Pipe Welding which may include evening and weekends.

#Blueprint reading how to#

Learn specific instructions on how to make the weldĪdjunct Welding Instructor since August 2012 to Current Local Community College - Houston, TX.Identify different parts of the welding symbol.As with all welding techniques, with some time and practice you will soon began to master the processes. But after you have gained some experience in reading blueprints it will become second nature. Reading welding blueprints can be very complicated and confusing on occasions. You will go over the basic lines which includes object line, hidden lines, center lines, extension lines, dimension lines, leader lines, cutting plane lines, section lines, short break lines, long break lines and phantom lines. These instructions often include which type of weld to be used, the size of the weld, how many similar welds need to be performed, and tell the welder which joint the weld should be made. At the end of the course, you will better understand the basic lines and views associated with blueprint reading and know how you supervisor want the weld to be accomplished. If you are just starting out in the welding world, odds are that at some point in your career you will be required to read welding blueprints in order to complete your job.

0 notes

Link

I am serving in calibration and inspection services (LEEA, NDT).My company name is INSPECTECH.

#Lahore#pk#Full Time#mdi-email#verified#Calibration of plant instruments and master equipment#Lifting equipment and accessories inspection#NDT services#PSV (pressure safety valves) testing#Supply of instruments

0 notes

Text

Global Non-Destructive Testing Market Revenue, Growth, Developments, Size, Share and Forecast 2027

Global Non-Destructive Testing Market: was valued at US$ 13.9 Bn. in 2020 and is expected to reach US$ 21.7 Bn. by 2027, at a CAGR of 6.6% during a forecast period.

Global Non-Destructive Testing Market Overview:

The main purpose of this report is to estimate the Global Non-Destructive Testing Market The MMR Global Non-Destructive Testing Market Research Report analyzes and quantitatively surveys world trade. It looks at the top key Global Non-Destructive Testing market momentum, constraints, opportunities, constraints for success, challenges, and key issues. Global Non-Destructive Testing market is further segmented and forecasts for major countries in each region such as Asia Pacific, North America, Europe and therefore other regions (ROW). By abusing secondary sources such as encyclopaedias, directories, and databases, we make the most of the data collected and edited by Maximize market research for this vast industrial research of the Global Non-Destructive Testing market. No relevant industry or supplier experts are involved as the primary source of information for collecting and validating important information for predicting the future outlook of the market.

Get Free Sample copy Link @ https://www.maximizemarketresearch.com/request-sample/10939

Global Non-Destructive Testing Market Scope:

During the forecast period 2021-2027, the Global Non-Destructive Testing market is expected to grow at the fastest rate. Maximize Market Research (MMR) findings include supply and demand trends, costs, prices, shares, volumes, sales, and gross margins. Based on this MMR data collection, each manufacturer is analyzed for its manufacturing unit, capacity, production, factory price, market price, and market share.

Global Non-Destructive Testing Market Segmentation:

Based on offering, the services category led the market in 2020, accounting for 74.8 % of total revenue, and is likely to continue to do so throughout the forecast period. The high upfront cost of non-destructive testing equipment, combined with the technical obstacles associated in its Verticals/installation, is the main reason why end-users outsource non-destructive testing. A shortage of competent workers to do non-destructive testing is another constraint limiting new non-destructive testing equipment installations around the world.

Global Non-Destructive Testing Market Key Players:

• Mistras Group Inc.

• Olympus Corporation

• GE Measurement & Control Solutions

• Nikon Corporations

• Ashtead Technology

• Magnaflux Corporation

• Zetec Inc.

• Sonatest Ltd.

• Sonotron NDT

• Bosello High Technology SRL

• Fischer Technology, Inc.

• Eddyfi

• JSR Ultrasonics

• Source Production & Equipment Co., Inc.

• Airstar Inc.

• AMDATA Products (WesDyne)

• Applus RTD

• AT-Automation Technolo.

• BALTEAU NDT

• Canadian Institute for NDE

• Controle Mesure Systemes

• Cygnus Instruments Ltd.

This MMR report provides complete information about the major players in the Global Non-Destructive Testing market. Annual Corporate Revenue, Global Non-Destructive Testing Corporate Market Share, Corporate Business Strategy, Corporate SWOT Analysis, PESTEL Analysis, and Latest Corporate Development.

Global Non-Destructive Testing Market Regional Analysis:

North America, Asia Pacific, Europe, Latin America, Middle East and Africa are all covered by the MMR Global Non-Destructive Testing Market Report. In this Global Non-Destructive Testing market report, MMR focuses on key market segments and sub segments, as well as key market sectors. Based on market share, volume, and market size, the MMR survey ranks innovative countries in district development. Indicators include volume, area, revenue, marketplace chain system, and trends.

COVID-19 Impact Analysis on Global Non-Destructive Testing Market:

Between 2020 and 2021, the significant impact of the COVID-19 Rule occurred in terms of global, industry and worker expectations. The COVID-19 threat poses a threat to society and living standards and requires rapid industrial support and innovation. Indian expatriates face many problems due to COVID-19. Millions of migrant workers have lost their jobs due to embargoes, food shortages and fears of the future.

In general, MMR research aims to provide a better understanding of the current economy, COVID-19, and its impact on the commercial market. COVID-19 is followed by MMR in most industries, sectors and disciplines. Maximize Market Research (MMR) can help you assess the impact of COVID-19 on your industry.

Will You Have Any Questions About This Report? Please Contact Us On link @ https://www.maximizemarketresearch.com/market-report/global-non-destructive-testing-market/10939/

Key Questions answered in the Global Non-Destructive Testing Market Report are:

Which product segment grabbed the largest share in the Global Non-Destructive Testing market?

How is the competitive scenario of the Global Non-Destructive Testing market?

Which are the key factors aiding the Global Non-Destructive Testing market growth?

Which region holds the maximum share in the Global Non-Destructive Testing market?

What will be the CAGR of the Global Non-Destructive Testing market during the forecast period?

Which application segment emerged as the leading segment in the Global Non-Destructive Testing market?

Which are the prominent players in the Global Non-Destructive Testing market?

What key trends are likely to emerge in the Global Non-Destructive Testing market in the forecast period?

What is the expected Global Non-Destructive Testing market size by 2027?

Which company held the largest share in the Global Non-Destructive Testing market?

About Maximize Market Research:

Maximize Market Research is a market research and consulting organisation that provides syndicated and custom-built research reports, as well as consulting. The company’s solutions are dedicated to helping companies make better business decisions by identifying, targeting and analysing changes in demographics and customer behaviour across the industry. To provide meaningful and fact-based research, the company conducts market research research across a wide range of categories such as healthcare, engineering equipment’s, chemicals, Power and energy. Maximize Market Research has a huge team of talented analysts with expertise in different disciplines. The company’s industry experience and ability to provide actionable solutions to all research issues give clients an edge over their competitors.

Contact Maximize Market Research:

3rd Floor, Navale IT Park, Phase 2

Pune Banglore Highway, Narhe,

Pune, Maharashtra 411041, India

Website: www.maximizemarketresearch.com

0 notes