#Optical Encoders Demand

Explore tagged Tumblr posts

Text

[tfp] obsessed!optimus prime x human!reader

inspired by this very old ask about you giving opti diy crochet charms

cw: hardcore pinning, obsessive thoughts, optimus is bad with dealing with emotions

word count: 700

something small that I needed to get off my system <3

Digits glide over the soft yarn with calculated subtlety. A thumb slowly traces the indentations of the intricate patterns, acquainting itself with the texture of the interwoven chains and half-double stitches, magically linking together into a shape. A few motions are enough for him to memorize every dent and placement of the material, yet he does not cease his journey, still gently stroking the creation. After dozens of times, the tenderness gives way to adoration — he is aware of it, but cannot stop, incapable.

But he knows he should. Optimus uses this friendly gesture to feed the fire, burning ever fiercer with every movement of his thumb, taking advantage of your kindness to nurture the warped, unworthy-of-your-innocence feelings that slip further and further beyond control. He despises himself for it — oh, how he loathes himself — but has long since grown accustomed to self-hatred, his ever-present shadow at every turn. Hatred was familiar. The feeling of receiving gifts from you was a vibrant novelty he had yet to learn how to handle, for it terrified him with its rawness.

Crochet charms, as you called them. Everyone on Team Prime received a few, so he should not be assigning such immense significance to his own. Should simply be happy with the gift, accept it, and maybe glance at it occasionally, recalling your eyes gleaming with excitement like beads and your broad smile, radiating pure joy, as you handed your tiny creations to his massive servo. A star and a sunflower — both incredibly delightful, almost as much as your expression when you saw that he had accepted your present.

"Tomorrow, I can help attach them to your mirror in the alt mode. If you’d like to, of course" you told him, and though he longed for nothing more than to fall to his knees before you and beg you to do it now, the only thing he managed to utter was:

"I would be delighted."

But he cannot simply be "delighted". Cannot just set your creations aside and occupy himself with other things when a piece of you is so close to him. Cannot fall into indifference, seeing it as an affront to you. Wants to cherish the crumbs of attention you have given him, to savor this non-physical affection he is unworthy of but treasures more than the ability to sustain himself with energon. Wants to linger by the proof of your kindness for as long as he can, fully aware of his madness yet unable to put its source away.

His thumb moves to the sunflower, gently pressing into the material. A gift from you. You. He never asks for anything, demanding only the preservation of safety. Optimus doesn't seek glory, gold, or riches, for he has found them in you — and you are the most magnificent treasure he could have ever dreamed of. Yet you went a step further, crafting something with your own hands, dedicating your precious time to him. You called your gift modest, but in this, he cannot agree with you, for to him, it was everything. And soon, it would permanently become a part of him.

It is an exhilarating thought, but also a treacherous one, for he knows these are the last moments he will hold your creations in his servos. The final moments to touch, to encode the texture into his memory, to relish the sight of your affection woven into physical form. Wanting to make the most of it, he brings the crochet charms closer to his faceplate, pressing against the soft fabric. Closes his optics, sharpening the remaining senses, focusing entirely on the feeling of having a piece of you so close to him. Knows he is defiling your gifts, that he should have let them be long ago and forced himself to suppress his erratic emotions towards you, but he cannot, craving to draw every ounce of impure satisfaction from this moment.

He clings to the gifts more tightly. Just a little longer. A nanoklik, he tells himself — but he cannot bring himself to turn his helm away.

216 notes

·

View notes

Text

Shafted Hall Effect Sensors Market: Technological Advancements Reshaping Illumination Control

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Demand for Shafted Hall Effect Sensors

The rapid expansion of industrial automation across manufacturing sectors is driving significant demand for shafted Hall effect sensors. These sensors play a critical role in position sensing, speed detection, and angular measurement in automated systems. The global industrial automation market is projected to maintain a robust growth rate, creating parallel opportunities for shafted Hall effect sensor manufacturers. Their durability, precision, and ability to operate in harsh environments make them indispensable components in modern automated production lines. Recent advancements in Industry 4.0 technologies have further intensified this demand, particularly for sensors that can deliver accurate real-time data for process optimization.

Electric Vehicle Revolution to Accelerate Market Expansion

The automotive industry’s accelerated shift toward electric vehicles presents a substantial growth opportunity for shafted Hall effect sensors. These sensors are essential components in EV powertrains, battery management systems, and motor control units. With global EV sales surpassing 10 million units annually and projected to grow exponentially, the demand for reliable position sensing solutions is reaching unprecedented levels. Major automotive manufacturers are increasingly specifying shafted Hall effect sensors for their compact size, resistance to vibration, and ability to operate in electromagnetic interference-rich environments characteristic of electric vehicles.

Furthermore, government initiatives supporting EV adoption across major economies are creating favorable conditions for sensor manufacturers:

➤ Several national policies now include stringent requirements for position sensing accuracy in EV components, directly benefiting high-performance Hall effect sensor suppliers.

MARKET RESTRAINTS

Intense Price Competition from Alternative Technologies to Limit Growth

While shafted Hall effect sensors offer numerous advantages, the market faces considerable pressure from competing technologies such as optical encoders and inductive sensors. These alternatives have seen significant price reductions in recent years, making them attractive options for cost-sensitive applications. The average selling price for standard shafted Hall effect sensors has declined steadily, squeezing profit margins for manufacturers. This pricing pressure is particularly acute in high-volume consumer applications where even marginal cost differences significantly influence purchasing decisions.

Additionally, the growing adoption of integrated sensor solutions that combine multiple sensing modalities presents a competitive challenge for standalone Hall effect sensor providers.

MARKET CHALLENGES

Complex Supply Chain Disruptions to Impact Production Capacities

The shafted Hall effect sensor market continues to grapple with multifaceted supply chain challenges that emerged following recent global disruptions. Semiconductor material shortages have particularly affected sensor production, given their reliance on specialized magnetic materials and integrated circuits. Lead times for certain critical components have extended dramatically, forcing manufacturers to either maintain larger inventories or risk production delays. These challenges are compounded by rising transportation costs and geopolitical factors affecting rare earth material supplies essential for sensor manufacturing.

Other Significant Challenges Include:

Technical Limitations in Extreme Environments While shafted Hall effect sensors perform well in most industrial conditions, their reliability can be compromised in extremely high-temperature or highly corrosive environments. This limitation restricts their applicability in certain heavy industrial and aerospace applications where alternative technologies may be preferred.

Miniaturization Demands The persistent industry trend toward smaller form factors presents engineering challenges for maintaining sensor accuracy and durability in ever-shrinking packages, requiring continuous R&D investments.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Verticals

The rapid proliferation of Industrial Internet of Things (IIoT) deployments is opening substantial new opportunities for shafted Hall effect sensor manufacturers. These sensors are increasingly being integrated into predictive maintenance systems and smart equipment monitoring solutions. The ability of Hall effect sensors to provide reliable, contactless position data makes them ideal for IIoT applications where continuous monitoring is essential. Market analysts project strong growth in this segment as industries increasingly adopt condition-based maintenance strategies that rely on real-time sensor data.

Medical Device Innovations to Drive Premium Sensor Demand

The medical equipment sector is emerging as a high-growth market for precision shafted Hall effect sensors. These components are finding increasing use in advanced imaging systems, robotic surgical equipment, and portable medical devices. The medical sensor market commands premium pricing due to stringent reliability requirements and regulatory certifications. Several leading sensor manufacturers have recently introduced medical-grade shafted Hall effect sensors with enhanced EMI resistance and sterilization capability, specifically targeting this lucrative segment.

SHAFTED HALL EFFECT SENSORS MARKET TRENDS

Automotive Electrification Drives Demand for Hall Effect Sensors

The global shafted Hall Effect sensors market is witnessing significant growth, driven primarily by the increasing electrification of automotive systems. These compact, durable sensors play a critical role in modern vehicle systems, enabling precise angular position sensing in throttle valves, pedal positions, and transmission systems. With electric vehicle production expected to grow at a CAGR of over 26% through 2030, OEMs are incorporating more Hall Effect sensors to monitor motor position and speed in electrified powertrains. The automotive sector now accounts for nearly 42% of all shafted Hall Effect sensor applications globally.

Other Key Trends

Miniaturization and IoT Integration

The demand for compact, rugged position sensors has increased across industrial automation and consumer electronics sectors. Shafted Hall Effect sensors – combining high accuracy with small form factors – are increasingly being integrated into IoT-enabled devices. Their ability to operate in harsh environments without physical contact makes them ideal for smart factory equipment, where they monitor parameters like fluid levels, valve positions, and actuator movements. The industrial segment is projected to account for over 28% of market revenue by 2030 as Industry 4.0 adoption accelerates.

Technological Advancements in Sensing Capabilities

Recent innovations are expanding the capabilities of shafted Hall Effect sensors to meet evolving industry needs. Rotary Hall Effect sensors now achieve angular resolutions below 0.1°, while linear variants offer sub-millimeter precision. Manufacturers are also developing multi-axial sensing solutions that combine position and speed measurement in single packages, reducing system complexity. These advancements are particularly valuable in medical devices and robotics, where precision motion control is critical. The integration of self-diagnostics and digital interfaces (like I²C and SPI) is further enhancing their utility in connected industrial systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Regional Analysis: Shafted Hall Effect Sensors Market

North America The North American market for shafted Hall effect sensors is driven by strong demand from the industrial automation and automotive sectors, particularly in the U.S. and Canada. The U.S. accounts for the majority of the regional market due to heavy investments in Industry 4.0 adoption, with leading manufacturers such as Sensata Technologies and TE Connectivity headquartered here. Stringent safety regulations in automotive applications, particularly in electric vehicles (EVs), further boost demand. However, the market faces challenges from increasing competition from alternative sensing technologies and supply chain disruptions.

Europe Europe remains a key market for shafted Hall effect sensors, driven by advancements in industrial automation and strong automotive manufacturing activities in Germany, France, and Italy. The EU’s focus on precision engineering and energy-efficient solutions supports sensor adoption in high-performance applications. Market leaders like Gefran and Novotechnik have capitalized on the region’s emphasis on quality-controlled manufacturing. However, strict regulatory compliance and elevated production costs compared to Asian manufacturers present constraints for market expansion.

Asia-Pacific The Asia-Pacific region dominates global consumption of shafted Hall effect sensors, primarily due to rapid industrialization in China, Japan, and India. China, being a manufacturing powerhouse, leads in both production and utilization of these sensors across automotive and telecommunications sectors. Cost-effectiveness and scalability of local suppliers such as Vishay and Servotech Instrumentation fuel market growth. Meanwhile, Japan’s precision manufacturing industry and India’s expanding automation sector contribute significantly. Though price sensitivity remains a challenge, increasing investments in smart manufacturing are expected to sustain demand.

South America Market growth in South America is gradual, influenced by Brazil’s and Argentina’s emerging industrial sectors. While adoption of shafted Hall effect sensors is primarily seen in automotive manufacturing, economic instability limits widespread industrial automation. Local players face competition from imported products, yet the growing focus on upgrading manufacturing facilities hints at untapped potential. Regulatory gaps and limited R&D investments hinder faster technological adoption despite the expanding market.

Middle East & Africa This region shows moderate demand, primarily driven by industrial and automotive applications in GCC countries such as Saudi Arabia and the UAE. Investments in smart infrastructure and gradual industrial diversification are creating opportunities for sensor integration. However, the market’s growth remains constrained by reliance on imports and limited local manufacturing capabilities. Though still nascent, strategic collaborations with international players like Amphenol Corporation could enhance market penetration in the long term.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Shafted Hall Effect Sensors markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Shafted Hall Effect Sensors market was valued at USD 260 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (Rotary Hall Effect Sensor, Linear Hall Effect Sensor), application (Industrial Equipment, Automotive, Telecommunications Equipment), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD 85 million in 2024), Europe, Asia-Pacific (fastest growing at 6.2% CAGR), Latin America, and Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies (12% market share), TE Connectivity, Amphenol Corporation, and Vishay, covering product portfolios, R&D investments, and strategic developments.

Technology Trends & Innovation: Assessment of miniaturization trends, integration with IoT systems, and advancements in magnetic sensing technologies.

Market Drivers & Restraints: Evaluation of factors including industrial automation growth, automotive electrification trends, and challenges related to raw material pricing volatility.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

Understanding the Role of Hollow Shaft Rotary Encoders in Modern Robotics

Introduction to Rotary Encoders in Robotics

Rotary encoders are fundamental components in robotic systems, serving as critical feedback devices that measure the rotation, position, and direction of motor shafts. These sensors translate mechanical motion into electrical signals, which control systems then interpret to ensure precise movement. Among the various types of rotary encoders, hollow shaft rotary encoders have emerged as a key player due to their compact design, ease of integration, and high reliability. As robotics continues to permeate sectors like manufacturing, healthcare, logistics, and consumer electronics, understanding the specific contributions of hollow shaft rotary encoders becomes vital. Their importance lies not only in their functional capabilities but also in how they influence design flexibility and performance optimization in robotic applications. By integrating seamlessly into existing architectures, these encoders reduce mechanical complexity while improving feedback accuracy. This comprehensive examination will explore how these components are revolutionizing modern robotics, from their design advantages to their roles in various robotic subsystems.

Evolution of Rotary Encoders and Robotic Needs

The development of rotary encoders parallels the evolution of robotics itself. Early robotic systems relied on open-loop controls, often leading to inaccuracies and inefficiencies. As the demand for precision and repeatability grew, rotary encoders became indispensable. Initially, these sensors were bulky and susceptible to environmental interference. Over time, however, innovations in materials, signal processing, and miniaturization led to more robust and compact designs. Hollow shaft rotary encoders, in particular, emerged as a response to the need for space-saving yet highly accurate feedback devices. Robotics has evolved from simple pick-and-place machines to complex, autonomous entities requiring precise coordination across multiple axes. This shift necessitated encoders capable of delivering consistent, high-resolution feedback without contributing to design bulk. In mobile robots, surgical devices, and industrial arms, space is a premium commodity. Hollow shaft encoders allow engineers to route cables or mechanical shafts through the encoder's center, optimizing spatial configuration and reducing wear on moving parts. This evolution marks a significant turning point in the interplay between sensor technology and robotic capability.

Anatomy of a Hollow Shaft Rotary Encoder

At its core, a hollow shaft rotary encoder consists of a rotor, stator, and signal processing circuitry housed in a compact unit. What distinguishes it from other encoder types is the central hollow section through which a shaft or cabling can pass. This seemingly simple design offers substantial advantages. The rotor attaches directly to the rotating shaft, while the stator remains fixed to the structure. As the shaft turns, the encoder senses the angular displacement and transmits corresponding electrical signals. These signals may be digital or analog, depending on the encoder type and application. Typically, hollow shaft encoders utilize optical, magnetic, or capacitive technologies to detect movement. Optical encoders, for instance, use a light source and a photo-detector array to interpret interruptions in a coded disc. This method provides high-resolution data, essential for robotic operations requiring micrometer-level precision. Additionally, many hollow shaft encoders incorporate features like integrated bearings, multi-turn tracking, and error correction protocols, ensuring they maintain accuracy even under high-speed or high-vibration conditions.

Integration in Robotic Joint Systems

One of the primary applications of hollow shaft rotary encoders in robotics is within joint systems. Whether in humanoid robots or articulated industrial arms, joint movement must be monitored and controlled with utmost precision. Hollow shaft encoders facilitate this by being mounted directly onto the joint actuators, enabling real-time position feedback. Their hollow design allows power and data cables to pass through the joint axis, reducing external cabling and potential points of failure. This configuration not only enhances the mechanical efficiency of the joint but also simplifies maintenance and design. In collaborative robots, or cobots, where safety and fluid motion are paramount, these encoders help ensure smooth articulation and responsive behavior. They support closed-loop control systems that adjust motor output dynamically based on encoder feedback. This loop is crucial for tasks like pick-and-place operations, precision welding, or surgical manipulations, where even millimeter-level deviations can compromise functionality or safety. By offering a balance of compactness, accuracy, and reliability, hollow shaft rotary encoders are central to robotic articulation systems.

Enhancing Mobility in Autonomous Robots

Autonomous mobile robots (AMRs) require robust sensory systems to navigate complex environments accurately. Hollow shaft rotary encoders play an essential role in this context by providing reliable feedback on wheel or track rotation. Unlike incremental encoders that only track changes in position, absolute feedback systems offer the advantage of positional memory. This becomes crucial in navigation, where knowing the robot's exact orientation at any given time determines path planning and obstacle avoidance efficacy. In differential drive systems, for instance, encoders mounted on each wheel shaft measure relative speeds and directions, allowing for accurate steering and speed control. The compact nature of hollow shaft encoders is especially beneficial in mobile platforms, where every millimeter of space impacts battery size, payload capacity, or sensor load. Their integration also enhances durability since fewer external mechanical parts mean less exposure to dust, moisture, or mechanical wear. This synergy of design efficiency and functional robustness makes hollow shaft encoders indispensable in robotic mobility subsystems.

Role in Precision Tasks and Fine Manipulation

Modern robotics increasingly involves tasks requiring fine motor control, such as electronic assembly, 3D printing, and medical interventions. In these scenarios, the encoder’s resolution and responsiveness directly impact task accuracy. Hollow shaft rotary encoders contribute significantly by enabling micro-adjustments based on real-time positional data. In robotic arms used for electronic manufacturing, for instance, components must be placed with sub-millimeter accuracy. The encoder's feedback ensures that the tool tip follows the programmed path without deviation. Similarly, in 3D printing, layer consistency and nozzle positioning depend heavily on precise rotary feedback. Medical robotics, particularly in minimally invasive surgery, represents another frontier where precision is non-negotiable. Here, hollow shaft encoders are used in tool actuation systems, allowing surgeons to perform complex procedures remotely with high confidence in the robot's positional accuracy. The encoders’ inherent design also aids in sterilization and integration within tight surgical tool assemblies. Thus, their role extends from mechanical feedback to enabling new capabilities in high-precision robotic tasks.

Environmental Robustness and Industrial Viability

Robotic systems often operate in harsh environments—factories, outdoor settings, or hazardous locations. Devices integrated into such systems must exhibit resilience to temperature fluctuations, vibrations, dust, and moisture. Hollow shaft rotary encoders are increasingly engineered with these challenges in mind. Manufacturers offer variants with IP-rated enclosures, corrosion-resistant materials, and sealed optical systems. This robustness allows them to function reliably in automotive assembly lines, mining robots, or agricultural drones. In temperature-controlled warehouse automation, for example, encoders must perform consistently despite frequent exposure to cold or variable humidity levels. The absence of exposed cables and the encoder’s enclosed design minimize contamination risks and mechanical wear. These features contribute to lower maintenance demands and longer operational lifespans, which are critical in high-throughput industrial settings. Moreover, their compatibility with various communication protocols—such as EtherCAT, CANopen, and SSI—ensures that they can be integrated into diverse control architectures without extensive modification. This adaptability further cements their place in modern industrial robotics.

Supporting Safety and Redundancy Mechanisms

Safety is a fundamental concern in robotics, particularly in collaborative or human-facing environments. Encoders play a vital role in ensuring operational safety by providing accurate position feedback for motion verification and error detection. Hollow shaft rotary encoders are especially suited for redundant systems, where multiple sensors verify each other's outputs. This redundancy ensures that if one sensor fails, the system can continue operating safely or shut down in a controlled manner. In safety-rated robotic arms, encoders are often employed in tandem with other sensors to monitor limits and ensure compliance with predefined safety envelopes. Their high resolution and low latency make them ideal for such critical feedback loops. Additionally, their compact form factor allows for integration into secondary safety circuits without adding bulk. The feedback from these encoders also enables soft-limit programming, which prevents actuators from moving beyond safe zones. In service robots or exoskeletons, where human safety is paramount, this encoder-driven feedback becomes essential for real-time decision-making and reactive control.

Future Outlook: Smart Integration and Predictive Maintenance

As robotics evolves towards greater autonomy and intelligence, the role of feedback devices like hollow shaft rotary encoders is also transforming. Modern encoders are increasingly being equipped with smart features such as self-diagnostics, condition monitoring, and real-time data streaming. These capabilities feed into predictive maintenance systems, helping operators detect wear or misalignment before it causes failure. For example, by monitoring signal consistency or rotational anomalies, the encoder can alert the system to potential mechanical issues. This proactive approach reduces downtime and extends the life of robotic assets. Furthermore, as artificial intelligence becomes integral to robotics, encoder data can be used to train machine learning models for movement optimization and adaptive control. Smart encoders also support advanced communication standards that facilitate seamless integration into IoT-enabled infrastructures. This trend indicates a shift from passive sensing to active data contribution, where encoders not only report motion but also enhance system intelligence. Such evolution positions hollow shaft rotary encoders as foundational components in next-generation robotic ecosystems.

Precision Engineering Meets Practical Application

The intersection of precision engineering and practical robotic application is where hollow shaft rotary encoders demonstrate their full potential. As manufacturing tolerances tighten and robotic roles diversify, the demand for encoders that can deliver high-resolution feedback in compact, rugged packages continues to grow. These devices are not only vital for motion tracking but also contribute to reducing system complexity, enhancing safety, and enabling adaptive control. Their utility spans industries and use-cases, from autonomous warehouse robots to robotic-assisted surgery. As designers push the boundaries of what robots can achieve, they increasingly turn to encoders that offer a balance of size, accuracy, and integration flexibility. Among these, the hollow shaft rotary encoder stands out for its ability to combine mechanical elegance with technical performance. Its role in facilitating the compact, precise, and reliable movement is central to the continued advancement of robotics.

Enhancing Control Through Advanced Feedback Systems

In many robotic systems, especially those with complex kinematics, advanced feedback is necessary to synchronize multiple actuators. Here, the absolute rotary encoder proves instrumental. By providing unique position values that do not require recalibration after power loss, these encoders enhance system reliability and responsiveness. This becomes particularly valuable in automated systems that must resume operation immediately after interruptions. Their use simplifies control algorithms and reduces computational overhead, which in turn allows for more fluid and responsive robotic behavior. From industrial automation lines to mobile robotic platforms, absolute encoders bring consistency and predictability, even under dynamic load changes or complex trajectories. When integrated with real-time control loops, they enable smoother transitions, better torque management, and reduced mechanical stress. These benefits contribute to more agile and longer-lasting robotic systems.

Meeting Modern Demands with Cutting-Edge Solutions

The robotic landscape is shifting rapidly, driven by needs for flexibility, scalability, and intelligence. In this context, the absolute position encoder emerges as a critical component, especially in scenarios where exact positioning is non-negotiable. Whether it’s aligning robotic cameras, controlling prosthetic limbs, or managing the angular position of robotic grippers, these encoders deliver the granularity required for high-precision tasks. They also facilitate seamless feedback for AI-driven decisions, particularly in adaptive robotics that interact with unpredictable environments. The encoder's ability to provide exact position data without drift ensures consistent performance across repetitive tasks. In emerging sectors like robotics-as-a-service or modular robotics, where plug-and-play compatibility is essential, these encoders ensure that new modules or replacements can integrate smoothly and function reliably. As expectations for precision, speed, and autonomy grow, so too does the importance of dependable, high-performance feedback systems like the absolute position encoder.

0 notes

Text

Photonic processor could streamline 6G wireless signal processing

New Post has been published on https://sunalei.org/news/photonic-processor-could-streamline-6g-wireless-signal-processing/

Photonic processor could streamline 6G wireless signal processing

As more connected devices demand an increasing amount of bandwidth for tasks like teleworking and cloud computing, it will become extremely challenging to manage the finite amount of wireless spectrum available for all users to share.

Engineers are employing artificial intelligence to dynamically manage the available wireless spectrum, with an eye toward reducing latency and boosting performance. But most AI methods for classifying and processing wireless signals are power-hungry and can’t operate in real-time.

Now, MIT researchers have developed a novel AI hardware accelerator that is specifically designed for wireless signal processing. Their optical processor performs machine-learning computations at the speed of light, classifying wireless signals in a matter of nanoseconds.

The photonic chip is about 100 times faster than the best digital alternative, while converging to about 95 percent accuracy in signal classification. The new hardware accelerator is also scalable and flexible, so it could be used for a variety of high-performance computing applications. At the same time, it is smaller, lighter, cheaper, and more energy-efficient than digital AI hardware accelerators.

The device could be especially useful in future 6G wireless applications, such as cognitive radios that optimize data rates by adapting wireless modulation formats to the changing wireless environment.

By enabling an edge device to perform deep-learning computations in real-time, this new hardware accelerator could provide dramatic speedups in many applications beyond signal processing. For instance, it could help autonomous vehicles make split-second reactions to environmental changes or enable smart pacemakers to continuously monitor the health of a patient’s heart.

“There are many applications that would be enabled by edge devices that are capable of analyzing wireless signals. What we’ve presented in our paper could open up many possibilities for real-time and reliable AI inference. This work is the beginning of something that could be quite impactful,” says Dirk Englund, a professor in the MIT Department of Electrical Engineering and Computer Science, principal investigator in the Quantum Photonics and Artificial Intelligence Group and the Research Laboratory of Electronics (RLE), and senior author of the paper.

He is joined on the paper by lead author Ronald Davis III PhD ’24; Zaijun Chen, a former MIT postdoc who is now an assistant professor at the University of Southern California; and Ryan Hamerly, a visiting scientist at RLE and senior scientist at NTT Research. The research appears today in Science Advances.

Light-speed processing

State-of-the-art digital AI accelerators for wireless signal processing convert the signal into an image and run it through a deep-learning model to classify it. While this approach is highly accurate, the computationally intensive nature of deep neural networks makes it infeasible for many time-sensitive applications.

Optical systems can accelerate deep neural networks by encoding and processing data using light, which is also less energy intensive than digital computing. But researchers have struggled to maximize the performance of general-purpose optical neural networks when used for signal processing, while ensuring the optical device is scalable.

By developing an optical neural network architecture specifically for signal processing, which they call a multiplicative analog frequency transform optical neural network (MAFT-ONN), the researchers tackled that problem head-on.

The MAFT-ONN addresses the problem of scalability by encoding all signal data and performing all machine-learning operations within what is known as the frequency domain — before the wireless signals are digitized.

The researchers designed their optical neural network to perform all linear and nonlinear operations in-line. Both types of operations are required for deep learning.

Thanks to this innovative design, they only need one MAFT-ONN device per layer for the entire optical neural network, as opposed to other methods that require one device for each individual computational unit, or “neuron.”

“We can fit 10,000 neurons onto a single device and compute the necessary multiplications in a single shot,” Davis says.

The researchers accomplish this using a technique called photoelectric multiplication, which dramatically boosts efficiency. It also allows them to create an optical neural network that can be readily scaled up with additional layers without requiring extra overhead.

Results in nanoseconds

MAFT-ONN takes a wireless signal as input, processes the signal data, and passes the information along for later operations the edge device performs. For instance, by classifying a signal’s modulation, MAFT-ONN would enable a device to automatically infer the type of signal to extract the data it carries.

One of the biggest challenges the researchers faced when designing MAFT-ONN was determining how to map the machine-learning computations to the optical hardware.

“We couldn’t just take a normal machine-learning framework off the shelf and use it. We had to customize it to fit the hardware and figure out how to exploit the physics so it would perform the computations we wanted it to,” Davis says.

When they tested their architecture on signal classification in simulations, the optical neural network achieved 85 percent accuracy in a single shot, which can quickly converge to more than 99 percent accuracy using multiple measurements. MAFT-ONN only required about 120 nanoseconds to perform entire process.

“The longer you measure, the higher accuracy you will get. Because MAFT-ONN computes inferences in nanoseconds, you don’t lose much speed to gain more accuracy,” Davis adds.

While state-of-the-art digital radio frequency devices can perform machine-learning inference in a microseconds, optics can do it in nanoseconds or even picoseconds.

Moving forward, the researchers want to employ what are known as multiplexing schemes so they could perform more computations and scale up the MAFT-ONN. They also want to extend their work into more complex deep learning architectures that could run transformer models or LLMs.

This work was funded, in part, by the U.S. Army Research Laboratory, the U.S. Air Force, MIT Lincoln Laboratory, Nippon Telegraph and Telephone, and the National Science Foundation.

0 notes

Text

Optical Encoder Market to Expand Rapidly Thanks to Precision Motion Control Demand

The optical encoder market encompasses devices that convert mechanical motion into electrical signals, enabling precise control in robotics, industrial automation, medical equipment, and aerospace systems. Optical encoders offer high resolution, reliability, and minimal signal noise, making them vital components in motion feedback loops. As industries pursue Industry 4.0 and smart manufacturing, there is a growing need for accurate position sensing and speed measurement to optimize processes, ensure safety, and reduce downtime. Continuous advancements in miniaturization and integration have expanded applications in consumer electronics, automotive steering systems, and renewable energy installations.

Get More Insights on Optical Encoder Market https://www.patreon.com/posts/optical-encoder-131064922

#OpticalEncoderMarket#HighResolutionEncoders#IndustrialAutomation#MotionControlSystems#CoherentMarketInsights

0 notes

Text

How Scaler Chip Photonics Powers Quantum Future

Scaler Chip

Chip-scale photonics uses photonic integrated circuits to produce, manipulate, and detect quantum states of light. These devices' high density and performance are designed to promote quantum technology by enabling quantum computing and systems outside conventional light noise. For large-scale quantum information processing, integrated photonics is the best candidate since it is compatible with complementary metal-oxide-semiconductor (CMOS) fabrication methods, which are utilised in classical communications and microprocessors.

Chip-scale integration builds tiny, dependable, portable, and deployable quantum systems by merging numerous components on one substrate.

Important aspects of chip-scale photonics include:

Platforms: Silicon photonics is a suitable platform for this integration due to its well-established semiconductor production methods, high nonlinearity, programmable routing, and affordability. Silicon nitride (Si3N4), lithium niobate, aluminium nitride, and high-index doped silica are also being developed for integrated components. Many quantum technologies use quantum light sources.

Sources of entangled photon pairs include spontaneous four-wave mixing (SFWM) in silicon waveguides and SPDC in thin-film lithium niobate. Famous for their efficiency and small size, microring resonators (MRRs) are popular. They also need less pump power. Alternative materials like Si3N4 and Hydex are being researched for high laser power due to their lower propagation loss and greater transparency.

Ideal single photon sources are on-demand, deterministic, and indistinguishable. From parametric sources, “heralded single-photon generation” detects one photon and announces the presence of another. Scholars want high spectral purity for interference-based QIP and to overcome brightness-purity trade-offs.

Squeezed light sources reduce noise below the quantum limit, improving measurement accuracy. Dual-pump SFWM in MRRs and Si3N4 MRRs are examples of integrated photonics' progress in source preparation.

Modulators (Phase Shifters): Phase shifters precisely regulate photons. Silicon phase shifters often use plasma dispersion (PD) or thermo-optic (TO) phenomena. Despite their simplicity, TO modulators are slow and cause thermal crosstalk. While PD modulators are faster, absorption losses may occur. High-speed, low-loss electro-optic modulators are being researched using hybrid integration approaches like silicon with lithium niobate or barium titanate.

Single photon detectors: High efficiency, low dark counts, and time resolution are needed. SNSPDs are desirable because of their great performance, however they need cryogenic operation. Despite their poor performance, on-chip SNSPDs and other room-temperature technologies like silicon avalanche photodiodes and transition-edge sensors are being developed. Effective coupling of PIC waveguides with detectors is important to explore.

“Chip-Scale photonics Enables Advanced Quantum Communication and Sensing Technologies” covered photonic integrated circuits (PICs) that make and detect CV quantum states of light on June 7, 2025.

Chip-scale devices can operate outside light noise, which will improve quantum technology, especially secure communication and precise sensing (e.g., gravitational wave detection). The paper was based on a review paper titled “Integrated photonics for continuous-variable quantum optics,” co-authored by Southampton, NIST, and Bristol experts.

To fulfil the demand for scalable quantum technologies, CV quantum photonic systems are being integrated onto PICs. Some highlights from the

Technology: CV quantum photonics encodes and processes quantum information using light properties like amplitude and phase, making it compatible with present telecommunications infrastructure.

Feasibility and Platforms: Investigations have shown that integrated platforms can create and modify CV states, with silicon photonics being particularly promising.

Recent developments: Integrated photonic-electronic receivers can transmit data at 10 Gbaud, and CV-QKD (Quantum Key Distribution) can be extended to 100km fibre optic lines with local oscillators to avoid discrete optical component issues.

Component Integration:

Sources: Squeezed states improve gravitational wave detection sensitivity by reducing noise below the quantum limit. The mentions spontaneous parametric down-conversion (SPDC) and other PIC electro-optic modulation approaches.

Detectors: Cryogenic but extremely efficient SNSPDs and other room-temperature detector technologies like silicon avalanche photodiodes and transition-edge sensors are covered. Effective coupling between PIC waveguides and detectors remains a research priority.

System Integration: Integrated detectors and photonic circuits on a chip enable portable and deployable systems. This integration makes quantum systems compact and trustworthy.

Challenges and Future Work: The paper emphasises the need to study non-Gaussian quantum states to increase performance and expand quantum information processing. Scalability is crucial, and modular techniques using networked chip designs can help. Future priorities will include developing more deterministic and efficient non-Gaussian states, improving detector integration (especially room-temperature detectors), and researching CV system-specific error correction protocols to improve robustness against noise and decoherence.

Chip-scale photonics breakthroughs are needed to turn complex lab quantum experiments into scalable quantum technologies for safe communication and reliable sensing.

#ScalerChip#photonicintegratedcircuits#quantuminformationprocessing#chipscalephotonics#microringresonators#spontaneousparametricdownconversion#technology#technews#technologynews#news#govindhtech

0 notes

Text

Small Servo Motors and Drives: Big Performance in a Compact Package

When you think of high-precision motion systems, it's easy to imagine large, complex machines operating in sprawling factories. But what about applications where space is limited, yet the demand for performance remains sky-high? This is where small servo motors and drives come into play—offering the same precision and control as their larger counterparts, in a much smaller footprint.

At their core, small servo systems provide closed-loop motion control using a servo motor and a dedicated drive. The combination ensures that position, speed, and torque are tightly managed, which is essential in applications like robotics, medical equipment, lab automation, and compact assembly lines.

1. Miniature Size, Maximum Accuracy

Don’t let their size fool you—small servo motors are engineered to deliver incredible accuracy. With high-resolution encoders and fast feedback loops, these motors can achieve micron-level precision. For industries where detail matters—like electronics, 3D printing, or optical manufacturing—this is a critical advantage.

2. Space-Saving, Cost-Saving

One of the biggest advantages of small servo motors and drives is their ability to save valuable space. Compact control cabinets, lightweight end-of-arm tools, and portable machines benefit greatly from these scaled-down systems.

But space isn’t the only thing saved—costs come down too. Smaller systems typically consume less power, generate less heat, and require fewer support components, making them more efficient both operationally and financially.

3. Highly Responsive for Delicate Tasks

In precision operations such as dosing, cutting, or delicate part manipulation, speed without control is useless. THM Huade’s small servo motors and drives are built for fast, intelligent response to changing loads or commands. Whether you’re operating a miniature conveyor belt or a robotic gripper, every movement is smooth and predictable.

4. Plug-and-Play Integration

Small servo drives from THM Huade come with user-friendly interfaces and are compatible with popular industrial control systems like EtherCAT and Modbus. The drives support both position and torque modes and offer configuration flexibility, so you can adapt them easily to a wide variety of compact machinery.

5. Built for Versatility

These small systems might be designed for tight spaces, but their capabilities are expansive. From lab automation to packaging equipment, and from laser cutters to textile machines—small servo motors and drives prove themselves in virtually any application where precision and footprint matter.

Why Choose THM Huade?

At THM Huade, we understand the challenges of fitting high-performance automation into limited space. Our small servo motors and drives are designed with engineers and integrators in mind—offering powerful functionality, long-term reliability, and seamless integration with your existing systems.

Backed by technical support and decades of industry experience, our solutions are built to help you scale precision, not just machinery.

💡 Interested in upgrading your compact motion system with intelligent servo technology? Visit THM Huade to discover small servo motors and drives that deliver big results in tight spaces.

#SmallServoMotors#ServoDrives#THMHuade#PrecisionAutomation#CompactMachinery#MiniServoSystems#SmartManufacturing#MotionControlTech#IndustrialAutomation#HighPrecisionDrives

0 notes

Text

\documentclass[11pt]{article} \usepackage{amsmath, amssymb, amsfonts} \usepackage{geometry} \usepackage{graphicx} \usepackage{hyperref} \geometry{margin=1in} \title{Spectral Foundations for Hybrid Optoelectronic Computing Architectures: From Riemann Zeros to Physical AI Hardware} \author{Renato Ferreira da Silva \ \texttt{[email protected]} \ ORCID: \href{https://orcid.org/0009-0003-8908-481X}{0009-0003-8908-481X}} \date{\today}

\begin{document}

\maketitle

\begin{abstract} This article establishes a theoretical bridge between spectral models of the Riemann zeta zeros and the design principles of hybrid optoelectronic computing architectures. By interpreting data flow and signal processing as spectral phenomena, we draw on Schr\"odinger operators with machine-learned potentials to inform the structural logic of neuromorphic chips. Our approach uses the Gaussian Unitary Ensemble (GUE) as a universal benchmark for both numerical accuracy and hardware robustness. We argue that such architectures are not merely computational devices, but physical realizations of spectral operators whose eigenvalues encode semantic and functional states. This spectral paradigm enables scalable, reconfigurable, and energetically efficient AI hardware that emulates fundamental structures from number theory and quantum mechanics. \end{abstract}

\section{Introduction} The convergence of high-performance computing, artificial intelligence, and photonics demands a foundational rethinking of how computation is physically realized. While Moore's Law slows, spectral methods rooted in mathematical physics offer a new direction. In particular, the Hilbert--P\'olya conjecture---which suggests that the nontrivial zeros of the Riemann zeta function correspond to the eigenvalues of a self-adjoint operator---invites a reinterpretation of computation as a spectral phenomenon. This work connects spectral operator modeling with hardware design, offering a principled framework for constructing optoelectronic systems whose logic is derived from eigenvalue dynamics.

\section{Spectral Operator Framework} We consider operators of the form: [ \mathcal{L} = -\frac{d^2}{dx^2} + V(x), ] with Dirichlet boundary conditions and potentials of the form: [ V(x) = \sum_{n=0}^K c_n H_n(x) e^{-x^2/2}, ] where $H_n(x)$ are Hermite polynomials and $c_n$ are trainable parameters. The eigenvalues of $\mathcal{L}$, computed numerically, align with the statistical properties of the nontrivial zeros of the Riemann zeta function. We leverage neural networks to learn mappings $c_n \mapsto \lambda_j$, interpreting these as functional transformations from hardware configurations to observable spectral states.

\section{GUE as Design Metric} The Gaussian Unitary Ensemble provides a statistical benchmark for spectral rigidity and eigenvalue spacing. In our context, it serves dual roles: \begin{itemize} \item In simulation: to validate the fidelity of the learned operator. \item In hardware: to ensure robust optical communication, minimal crosstalk, and consistent signal coherence across filaments. \end{itemize} Designing hardware whose delay paths, optical resonances, and thermal fluctuations approximate GUE behavior results in physical stability under computational load.

\section{Hardware Realization of Spectral Paradigms} Each computational unit (UC) in the hybrid optoelectronic architecture is interpreted as a physical realization of a node in a spectral graph: \begin{itemize} \item Optical interconnects act as eigenmode couplings. \item Modulation depths and frequencies correspond to potential configurations. \item Thermal gradients and electromagnetic fields define boundary conditions. \end{itemize} Hence, computation is no longer symbolic but spectral---defined by eigenvalue distributions and dynamic wave propagation.

\section{Spectral Learning and Inference} Using physics-informed neural networks (PINNs), we train the system to infer potential shapes from target spectral outputs. This establishes a feedback loop where: \begin{enumerate} \item Input data modulates physical parameters. \item Spectral output is measured optically. \item Machine learning adjusts the configuration for optimal response. \end{enumerate} This feedback aligns with biological principles of neural plasticity, offering a pathway to hardware-level learning.

\section{Conclusion and Outlook} We propose a new paradigm in AI hardware design rooted in spectral operator theory. By grounding hardware architectures in the spectral behavior of Schr\"odinger-type systems, validated through GUE statistics and machine learning, we lay the foundation for scalable, efficient, and intelligent photonic computing. Future work will explore: \begin{itemize} \item Topological extensions to noncommutative geometries. \item Quantum analogs with entangled photonic states. \item Integration with health diagnostics and real-time physical simulation. \end{itemize}

\end{document}

0 notes

Text

Analog 0-5V Linear Draw Wire and Cable Displacement Sensor Transducer

Explore a range of premium Servo Motor Encoders at Briter Encoder, featuring high-precision optical technology for accurate position feedback. Choose from single-turn and multi-turn options with optical encoding that ensures reliable performance. From the RS Series-SH for Single & Multi-Turn to the RZ Series-ZH with a robust design and wide operating temperature, find encoders tailored for demanding applications. Benefit from precision speed measurement and rugged construction in the Servo Motor Spindle Absolute Encoder, ideal for industrial environments requiring speed and accuracy. Upgrade your servo motor systems with our advanced encoder solutions.

0 notes

Text

Universal Encoder Systems | High-Precision Position & Speed Monitoring

Emco Precima's Universal Encoder Systems offer modular solutions for precise speed and position monitoring in industrial applications. The U-ONE Generation II series includes the LWL-System, featuring interference-free fiber optic signal transmission over distances up to 1,000 meters, and the Compact System (UOC 40 / USC 42), which integrates function modules within a robust housing for easy installation. Both systems provide high-resolution capabilities and optional safety certifications up to SIL 2 / PL d, ensuring reliable performance in demanding environments.

For more information visit our website: https://www.emcoprecima.com/

0 notes

Text

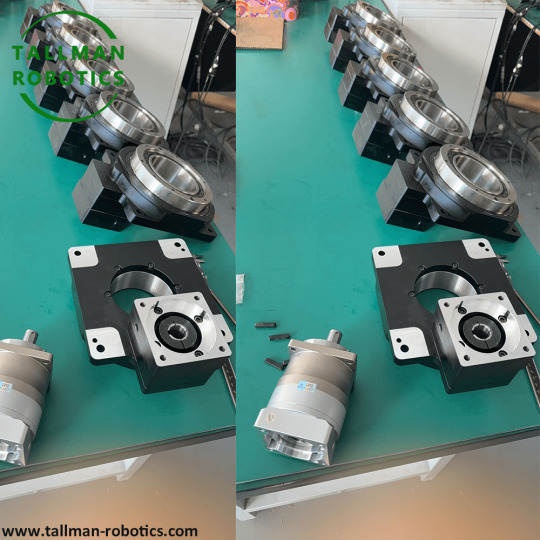

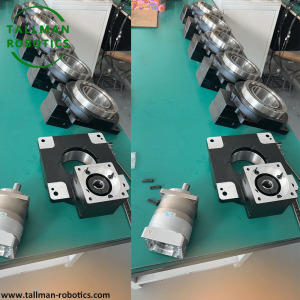

Precise Positioning Hollow Rotary Tables Will Be Delivered to Pakistan

Precise Positioning Hollow Rotary Tables are specialized rotational devices featuring a central hollow shaft, designed for high-accuracy angular positioning. The hollow core allows cables, pneumatic lines, or shafts to pass through, eliminating cable tangling and reducing system complexity.

https://youtu.be/ZP31od3m6Xc?si=KSzfpuXjjSW-2xnV Key Components and Features 1. Drive Mechanisms: Harmonic Drives: Preferred for near-zero backlash and high torque density. Direct Drive Motors: Offer smooth operation and precise control without mechanical reduction. Alternative systems like worm gears may be used but are less common in ultra-high-precision settings. 2. Bearings: Crossed Roller Bearings: Provide high rigidity and accuracy, handling both radial and axial loads efficiently. 3. Feedback Systems: High-resolution absolute encoders ensure accurate position tracking, even after power interruptions. 4. Materials and Construction: Made from rigid materials like aluminum or steel alloys to minimize deflection under load. Standardized mounting interfaces (e.g., ISO/SAE flanges) for easy integration with machinery. Applications of Large hollow shaft rotary tables CNC Machining: Enables multi-axis machining by rotating workpieces precisely. Semiconductor Manufacturing: Used in wafer handling and inspection systems. Optics and Medical Devices: Positions lenses or surgical tools with high accuracy. Robotics: Facilitates precise joint movements in automation and articulated robots. Advantages Over Standard Rotary Tables Hollow Design: Central pass-through avoids cable management issues, enhancing reliability. High Precision: Sub-arc-minute accuracy achievable with advanced feedback and drive systems. Versatility: Suitable for diverse industries due to customizable sizes and load capacities. Conclusion Precise Positioning Hollow Rotary Tables/Large hollow shaft rotary tables are critical in applications demanding exact angular positioning with central component pass-through. Their design combines mechanical precision with intelligent feedback systems, making them indispensable in advanced manufacturing and automation. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#CNCHollowRotaryActuator#HeavyDutyHollowRotaryTables#HighPrecisionHollowRotaryTablesforCNCMachines#High-precisionrotarytable#HollowAxes#HollowRotaryPlatform#HollowRotaryTableRightAngleManufacturer#LargeApertureHollowRotaryTables#Largehollowshaftrotarytables#PlanetaryGearboxes#PrecisePositioningHollowRotaryTables#PrecisionHollowRotaryTable#PrecisionRightAngleRotaryTables#RotaryActuators

0 notes

Text

The Science Behind Fiber Optic Technology

Have you ever wondered how data moves so quickly across the internet? How streaming your favorite TV show, playing online games, or even making a video call halfway across the globe happens almost instantaneously? The magic behind this speed lies in fiber optic technology—a marvel of modern engineering that has transformed the way we communicate.

Let’s break it down. At its core, fiber optic technology uses light to transmit data. Unlike traditional copper cables that rely on electrical signals, fiber optic cables are made up of ultra-thin strands of glass or plastic—each about the diameter of a human hair. These strands are designed to carry pulses of light, which represent data. This light travels at incredible speeds, carrying your information from one place to another faster than traditional methods.

How Does It Work?

The basic principle of fiber optics revolves around total internal reflection. Fiber optic cables are constructed with two main parts: the core and the cladding. The core is where the light travels, and the cladding is a surrounding layer that keeps the light contained within the core by reflecting it inward.

Imagine shining a flashlight down a long, polished hallway. If the walls are reflective enough, the light will bounce off the walls and continue down the hall. In a fiber optic cable, this happens on a microscopic scale, with the light bouncing millions of times per second as it travels.

To send data, this light is pulsed in specific patterns that represent binary code—the 1s and 0s that make up digital information. Specialized equipment encodes the data into light at one end of the cable, and a receiver at the other end decodes it back into its original form.

Why Is Fiber Optic Technology So Fast?

One of the main reasons fiber optics are faster than traditional copper cables is that light travels much faster than electrical signals. Moreover, fiber optic cables can carry far more data at once. This is because they use different wavelengths of light, allowing multiple streams of information to flow simultaneously through a single cable.

Another key advantage is the lack of interference. Copper cables can be affected by electromagnetic signals from nearby devices, which can slow down data transfer. Fiber optics, on the other hand, are immune to such interference, making them more reliable for high-speed internet.

Applications of Fiber Optics

Fiber optic technology isn’t just limited to internet connectivity. It’s used in various fields, from medical instruments like endoscopes to advanced military communication systems. But perhaps the most transformative application is in telecommunications and data transmission. Fiber optics have become the backbone of modern internet infrastructure, enabling lightning-fast speeds for everything from streaming to cloud computing.

Why Choose Fiber Optic Services for Data Needs in Orlando, FL?

If you’re in Orlando, FL, and looking for the best data communication service, fiber optic technology is your answer. Data Com’s fiber optic services stand out as one of the most reliable and efficient options in the area.

With Data Com, you can enjoy ultra-fast internet speeds that make streaming, gaming, and working from home a breeze. Whether you’re running a business or just want seamless connectivity for your household, fiber optics offer the capacity and reliability you need. Unlike older technologies, fiber optic services provide consistent performance, even during peak usage times.

In addition to speed, Data Com prioritizes security and scalability. Fiber optic networks are less prone to breaches compared to traditional systems, making them a safer choice for sensitive information. Plus, as your data needs grow, fiber optic technology can easily adapt without the need for major infrastructure changes.

Switching to fiber optic services is an investment in the future. With the ever-increasing demands of modern digital life, staying ahead means relying on cutting-edge technology. Data Com’s fiber optic service in Orlando, FL, ensures that you’re not just keeping up but leading the way in connectivity.

The Bottom Line

Fiber optic technology is nothing short of revolutionary. By harnessing the power of light, it delivers unparalleled speed, reliability, and capacity. Whether you’re watching a movie, conducting a virtual meeting, or running a business, fiber optics ensure a seamless experience. And if you’re in Orlando, FL, Data Com is the go-to provider for leveraging this cutting-edge technology. So why wait? Make the switch to fiber optics and experience the future of connectivity today!

0 notes

Text

Scanning-Slit Beam Profiler Market: Investments and Technological Advances

MARKET INSIGHTS

The global Scanning-Slit Beam Profiler Market size was valued at US$ 45 million in 2024 and is projected to reach US$ 58 million by 2032, at a CAGR of 3.6% during the forecast period 2025-2032

Scanning-slit beam profilers are precision optical instruments that measure laser beam characteristics through mechanical scanning of orthogonal slits. These devices utilize photodetectors to capture beam intensity profiles while digital encoders ensure positional accuracy. The technology enables high-power beam analysis with minimal attenuation, making it particularly valuable for industrial laser applications. Key measurements include beam width, position, quality (M² factor), and spatial intensity distribution.

The market growth is driven by increasing laser applications in material processing, medical devices, and scientific research. While North America currently leads adoption with 38% market share, Asia-Pacific shows the fastest growth at 9.1% CAGR through 2032. Major manufacturers like Thorlabs and Ophir Photonics continue innovating with multi-detector systems that support wavelengths from UV to far-IR. The Si/InGaAs detector segment dominates currently but emerging hybrid detector technologies are gaining traction for broader spectral range applications.

MARKET DYNAMICS

MARKET DRIVERS

Expansion of Laser-Based Manufacturing to Fuel Demand for Beam Profiling Solutions

The global laser technology market is projected to grow significantly, driven by increasing adoption in material processing applications. Scanning-slit beam profilers play a critical role in ensuring beam quality for precision cutting, welding and additive manufacturing processes. Industries are increasingly relying on these measurement systems to optimize laser performance, with the manufacturing sector accounting for over 35% of total demand. The ability to profile high-power beams without attenuation makes scanning-slit systems indispensable for industrial laser applications. Recent advancements in automation and Industry 4.0 implementations are further accelerating adoption rates, as manufacturers seek real-time beam monitoring solutions to maintain consistent product quality.

Growing Investments in Photonics Research to Stimulate Market Growth

Government and private sector investments in photonics research are creating substantial opportunities for beam profiling equipment manufacturers. Research institutions and universities are expanding their photonics capabilities, with funding for optical technology development increasing by approximately 15% year-over-year. Scanning-slit profilers are essential tools for characterizing laser beams in these research environments, particularly for applications requiring high dynamic range measurements. The technology’s ability to precisely measure complex beam shapes and M² values makes it invaluable for cutting-edge research in quantum optics, laser development and biomedical photonics. This sustained research investment is expected to drive steady demand for advanced beam profiling solutions in academic and government research settings.

➤ For instance, major research grants for photonics innovation are including specifications for beam characterization equipment, making scanning-slit profilers mandatory for many funded projects.

Furthermore, the integration of scanning-slit technology with automated analysis software is creating new opportunities in process control applications, particularly in semiconductor manufacturing and precision optics production.

MARKET RESTRAINTS

Competition from Alternative Profiling Technologies to Limit Market Penetration

While scanning-slit beam profilers offer distinct advantages for high-power applications, they face increasing competition from camera-based beam profiling systems. Recent advancements in CMOS sensor technology have improved the dynamic range and resolution of camera systems, making them viable alternatives for many applications. Camera-based systems now account for nearly 60% of the beam profiling market in low-to-medium power applications, creating pricing pressure on scanning-slit solutions. This competitive landscape is particularly challenging in price-sensitive segments like academic research and small-scale manufacturing, where the higher cost of scanning-slit systems can be prohibitive.

Other Restraints

Measurement Speed Limitations Scanning-slit profilers typically require physical movement of components for beam sampling, resulting in slower measurement times compared to snapshot technologies. This temporal resolution limitation becomes significant in applications requiring real-time monitoring of rapidly changing beams, such as in ultrafast laser systems or high-speed manufacturing processes.

Alignment Sensitivity The precise mechanical alignment required for scanning-slit systems can present operational challenges, particularly in industrial environments subject to vibration or thermal fluctuations. Maintaining optimal performance often requires more frequent recalibration compared to alternative profiling methods, adding to total cost of ownership.

MARKET CHALLENGES

Technical Complexities in High-Power Applications Pose Implementation Barriers

Despite their advantages for high-power beam measurement, scanning-slit profilers face significant technical challenges when applied to emerging laser technologies. The increasing prevalence of kilowatt-class lasers in industrial applications requires specialized solutions for beam sampling and thermal management. Development of these high-power solutions involves substantial R&D investment, with prototype testing often revealing unexpected material limitations or measurement artifacts. Furthermore, the lack of standardized test protocols for extreme power densities creates validation challenges, potentially slowing adoption in critical applications like laser welding and metal cutting.

Additional Challenges

Integration with Smart Manufacturing Systems While scanning-slit profilers provide valuable beam data, integrating this information with industrial control systems remains technically challenging. Compatibility issues between proprietary communication protocols and the need for customized software interfaces often require additional engineering resources, increasing implementation costs.

Maintenance and Service Requirements The mechanical nature of scanning-slit systems results in higher maintenance needs compared to solid-state alternatives. Wear components like translation stages and encoder systems may require periodic replacement, particularly in high-throughput industrial environments. This maintenance burden can be prohibitive for organizations with limited technical support capabilities.

MARKET OPPORTUNITIES

Emerging Applications in Biomedical and Defense Sectors to Drive Future Growth

The expanding use of high-power lasers in medical device manufacturing and defense applications presents significant growth opportunities for scanning-slit beam profiler manufacturers. Medical laser systems used in surgical applications and therapeutic devices require precise beam characterization to ensure patient safety and treatment efficacy. Similarly, defense applications including directed energy weapons and LIDAR systems demand robust beam measurement solutions capable of operating in challenging environments. The defense sector in particular is expected to increase investment in beam measurement technologies, with projected spending growth exceeding 20% annually for advanced optical test equipment.

Furthermore, ongoing miniaturization of scanning-slit components is enabling new applications in portable and field-deployable measurement systems. This trend aligns with increasing demand for on-site beam characterization in aerospace maintenance and remote sensing applications.

Advancements in Data Analytics to Create Value-Added Solutions

The integration of machine learning algorithms with beam profiling systems is creating opportunities for predictive maintenance and process optimization solutions. Modern scanning-slit profilers equipped with advanced analytics capabilities can detect subtle changes in beam characteristics that indicate impending laser system degradation. This predictive capability is particularly valuable for industrial users seeking to minimize downtime in continuous manufacturing processes. Service providers are increasingly offering these intelligent monitoring solutions as bundled packages, creating new revenue streams beyond equipment sales.

Additionally, cloud-based data analysis platforms are enabling remote monitoring of beam characteristics across multiple facilities, supporting the growing trend toward distributed manufacturing networks in high-tech industries.

SCANNING-SLIT BEAM PROFILER MARKET TRENDS

Rising Demand for Laser-Based Applications to Propel Market Growth

The global scanning-slit beam profiler market is experiencing significant growth, driven by increasing adoption across laser-based applications in industrial, medical, and research sectors. These devices play a crucial role in characterizing laser beams, ensuring precise measurements of beam width, position, and quality. This is particularly important as lasers become integral to manufacturing processes such as cutting, welding, and additive manufacturing, where beam quality directly impacts production outcomes. The ability to measure high-power beams with minimal attenuation positions scanning-slit profilers as essential tools in sectors where accuracy is non-negotiable.

Other Trends

Technological Advancements in Measurement Systems

Recent innovations in scanning-slit beam profilers include enhanced sensor technologies such as Si, InGaAs, and hybrid Si+InGaAs detectors, expanding measurement capabilities across a broader wavelength range. Manufacturers are integrating advanced digital signal processing to improve noise reduction and measurement accuracy. This evolution comes as industries demand sub-micrometer resolution for applications in semiconductor lithography and precision manufacturing. The development of compact, portable systems is also broadening adoption, particularly in field applications where real-time beam analysis is critical.

Expanding Applications in Medical & Biomedical Fields