#PCB Soldering Services in India

Link

Get high-grade PCB Soldering Services in India for superior Electronic Assembly and Electronics Manufacturing Service. Techno Advance System also providing EMS in Ahmedabad, Gandhinagar.

#PCB Soldering Services in India#PCB Soldering Service in Ahmedabad#PCB Soldering Services in Gandhinagar#EMS in Ahmedabad#Electronics Manufacturing Service

1 note

·

View note

Text

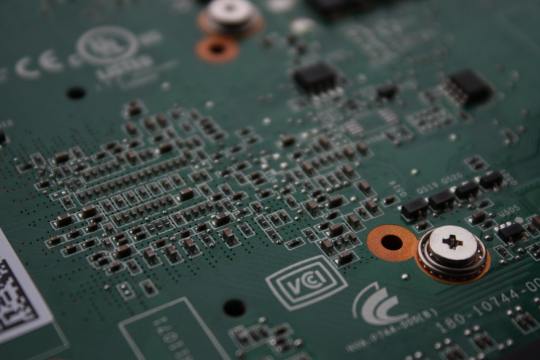

Factors driving the growth of SMT PCB assembly in India

The electronics manufacturing industry of INDIA has shown a lot of growth in the recent years. India is soon coming up as electronics manufacturing destination with strong supply chain and skilled manpower acting as the catalysts. SMT PCB assembly is a standout technique that can exceptionally engage in electronics manufacturing, typically in Printed Circuit Board assembly.

SMT PCB Assembly is the process of placing electronic components onto the surface of the printed circuit board (fused with PCB). This new technology does away with the through-hole process where parts are inserted directly into drilled holes. SMT also enables the Manufacture of smaller and lightweight components which go well with the current small electronic gadgets that require improved performance.

Components

Surface Mount Devices (SMDs): These are the components that are screwed onto the circuit board surface such as resistors, capacitors, diodes, and integrated circuits.

Solder Paste: A combination of powder solder and a flux which is needed to hold the SMDs in position while in the PCB.

Pick-and-Place Machines: Special machines that are capable of correctly positioning SMDs on the PCB that has solder paste on it.

Reflow Oven: Used to heat the PCB and melt the solder paste to give strong connection between the SMDs and the PCB.

Factors

The electronics industry in India has also benefited from enormous economic growth over the last few decades. The drastic increase of SMT PCB assembly in India can be attributed to several factors in its economical aspect. Some of the most important factors include the development of sound government policies and incentives aimed at enhancing electronics manufacturing within the country. Rising internal consumption towards electronics and related products has played a key role in the growth of SMT PCB assembly in India.

The most important strength of the country is the demography factor which offers a large number of youths and qualified technical workforce. This skilled labor force is a valuable benefit because it contributes to the rate of increase and improved effectiveness of SMT PCB assembly in India.

To improve the skills of this competent workforce, various training schemes and interventions have been developed. Various government initiatives like the Skill India Mission and the Electronics System Design and Manufacturing (ESDM) program ensures that people are skilled in modern electronics manufacturing processes.

Several educational institutions prepare talent for SMT PCB assembly in India and these institutions are crucial to its growth. Smt Pcb Assembly has special modules included in the engineering colleges and technical institutes that focus on manufacturing electronics with electronics manufacturing courses.

Epsilon electronics emerges as the industry leader of SMT PCB Assembly in India that relies on the best technology and on the strict fulfillment of the highest quality standards. Epsilon Electronics offered efficient SMT PCB assembly solutions which improved the value of its communication devices. Epsilon Electronics has a big share in the SMT PCB Assembly in India along with many successful project work and good vision.

#SMT PCB Assembly in India#ems solution provides#pcb assembly service provider#pcb assembly service provider in gujarat#pcb assembly service provider in india#pcb design company in gujarat#circuit design company in india#ems solution provider#pcb design company in india#ems supplier in gujarat#ems supplier in india

0 notes

Text

Find Reliable PCB Fabrication Providers in India

PCB fabrication is building the raw board as the foundation for the final printed circuit board assembly. After testing of fractions, electronic components are assembled on the board and soldered. When searching for PCB fabrication services near me, consider factors such as reputation, experience, and capabilities.

#PCBcircuit#pcbmanufacturing#pcb#electronics#circuit#manufacturing#manufacturer#pcbdesign#pcbassembly#pcbmanufacturer#pcbpune#ems

0 notes

Video

undefined

tumblr

best supplier of Introduction of BGA planting ball fixture

best supplier of Introduction of BGA planting ball fixture In this video, I'll show you best supplier of Introduction of BGA planting ball fixture. It's essential for every to understand how to best supplier of Introduction of BGA planting ball fixture. Enjoy and subscribe this video! Want more? Check out my https://www.dataifeng.com?tumblr=video2b Shenzhen Dataifeng Technology Co., Ltd. was established in March 2009. It is a professional manufacturer of electronic chip welding technology in the SMT production process, integrating R&D, production, sales and service. At present, the company has a number of senior technical engineers, as well as 2 R&D bases and multiple production lines. At the same time, we have applied for a number of national technology patents and professional inspection certificates in China. Now the company's business projects are diversified (BGA rework stations, BGA test tools, BGA ball planting equipment, BGA plant ball processing services, BGA consumables, BGA soldering rework services, and other PCB motherboard chip repair services), among which equipment products can be processed and customized . In addition to having a large domestic customer base, we also export to the United States, Canada, Australia, Singapore, Malaysia, India and other countries. We firmly believe that with the support of customers and the joint efforts of all employees, Dataifeng Company will strive to serve more customers through innovation and make customers have a better sense of experience. FOLLOW ME: Check my website: https://www.dataifeng.com?tumblr=video2b Twitter: https://twitter.com/DTFTonyQin Facebook: https://www.facebook.com/104772748916218 Youtube: https://www.youtube.com/channel/UCV5AMybaJrbSkaAkVlG843g Vimeo: https://vimeo.com/user168307180 Tiktok: https://www.tiktok.com/@tonyqin6 Tumblr: https://www.tumblr.com/blog/view/tonyqin Reddit: https://www.reddit.com/user/BGAreworkstation best supplier of Introduction of BGA planting ball fixture please contact us immediately if you are interested in. View more: Best Dataifeng Tin printing machine and reballing machine for BGA chips repair Factory Price : https://szdtf.tumblr.com/post/681407848252620800 Factory Customizing 80*80 mm bga Chips reballing plate for BGA Reballing Repair : https://youtu.be/oMbJY27cn7o Factory Customizing 80*80 mm bga Chips reballing plate for BGA Reballing Repair : https://www.facebook.com/396566665621135 Factory Customizing 80*80 mm bga Chips reballing plate for BGA Reballing Repair : https://vimeo.com/699392388 #best #supplier #Introduction #BGA #planting #ball #fixture #Dataifeng #Rework #Station #DataifengBGAReworkStation #ballonsleeves #350legendballisticgel #pajamaplanting #introductiontoaffecttheory #diylightfixture #KitchenFixture #ballcockchangingprocess #150wattledfloodlightfixture

0 notes

Text

A Comprehensive Guide to Choosing the Best Single Sided PCB Manufacturer in India: Shreeram Electronics

The electronics industry is rapidly evolving, demanding high-quality Printed Circuit Boards (PCBs) that can meet the demands of modern technology. When it comes to sourcing reliable single-sided PCBs in India, Shreeram Electronics stands out as a premier manufacturer. As an industry leader with years of expertise and cutting-edge technology, Shreeram Electronics has been a trusted partner for businesses seeking top-notch PCB solutions.

In this comprehensive guide, we will delve into the intricate world of single-sided PCBs, understanding their significance, manufacturing process, and the reasons why Shreeram Electronics is the ideal choice for your PCB needs.

Importance of Single Sided PCBs

Single-sided PCBs play a pivotal role in the electronics industry, serving as the foundation for a wide range of electronic devices. Their simplicity and cost-effectiveness make them a popular choice for various applications, including consumer electronics, automotive systems, and industrial equipment. With a single layer of substrate material, these PCBs facilitate easy design and installation, making them an essential component in numerous electronic devices.

Understanding the Manufacturing Process

The manufacturing process of single-sided PCB manufacturer in India requires meticulous attention to detail and adherence to industry standards. At Shreeram Electronics, the manufacturing process begins with a comprehensive design phase, where expert engineers meticulously plan the layout of the circuit. This is followed by the etching process, where the copper layer is carefully removed to create the desired circuitry.

The subsequent steps involve drilling, solder masking, and silk-screening, ensuring the precision and quality of the final product. Shreeram Electronics employs state-of-the-art technology and adheres to stringent quality control measures at every stage of production, guaranteeing superior single-sided PCBs that meet the highest industry standards.

Key Factors to Consider When Choosing a Manufacturer

Selecting the right manufacturer for your single-sided PCBs is crucial to the success of your electronic projects. Several factors must be taken into consideration to ensure that you partner with a reliable and competent manufacturer. Some of these factors include the manufacturer's experience and expertise, their adherence to quality standards, the use of advanced technology, and their ability to provide custom solutions tailored to your specific requirements.

Shreeram Electronics checks all these boxes, boasting a proven track record, a team of skilled professionals, and a commitment to delivering high-quality, customized single-sided PCBs that cater to diverse industry needs.

Advantages of Partnering with Shreeram Electronics

Collaborating with Shreeram Electronics offers numerous advantages that set them apart from other manufacturers in the industry. Their commitment to innovation and quality is evident in their efficient production process, ensuring quick turnaround times without compromising on the quality of the final product. Moreover, their competitive pricing and personalized customer service make them an ideal partner for businesses looking to streamline their production processes and reduce overall costs. With a strong emphasis on customer satisfaction and product excellence, Shreeram Electronics remains a reliable and trusted choice for all your single-sided PCB needs.

The Future of Single Sided PCBs in India

As India continues to witness rapid technological advancements and an increased demand for sophisticated electronic devices, the role of single-sided PCBs in the country's electronics industry is set to expand significantly. Shreeram Electronics, with its forward-thinking approach and unwavering dedication to excellence, is poised to remain at the forefront of this growth, catering to the evolving needs of various sectors and contributing to the development of cutting-edge electronic solutions across the nation.

Conclusion

In a competitive market where quality and reliability are paramount, choosing the right single-sided PCB manufacturer is crucial to the success of your electronic projects. Shreeram Electronics, with its unwavering commitment to excellence, cutting-edge technology, and customer-centric approach, stands out as a leading player in the Indian electronics industry.

By understanding the significance of single-sided PCBs and the factors that differentiate Shreeram Electronics from its competitors, you can make an informed decision and pave the way for the seamless integration of high-quality PCBs into your electronic applications. Trust Shreeram Electronics to be your strategic partner in fulfilling your single-sided PCB requirements and taking your business to new heights.

0 notes

Text

pcb cleaning chemicals

Streamlining PCB Assembly Processes with Cutting-Edge Equipment The electronics industry is constantly evolving, demanding high precision and efficiency in PCB (Printed Circuit Board) assembly. As technology advances, the components become smaller and more intricate, making it essential to employ sophisticated equipment and techniques to ensure flawless assembly. In this article, we will explore several essential tools and equipment used in the PCB assembly process, focusing on PCB cleaning machines, acrylic conformal coating, robotic dispensers, electric screwdrivers, and where to find top-quality PCB assembly equipment in Delhi. PCB Cleaning Machines PCB cleaning machines are vital in the assembly process to eliminate any contaminants and residues that may affect the functionality and reliability of the circuit board. These machines use various cleaning techniques, including ultrasonic cleaning, aqueous cleaning, and vapor phase cleaning. The choice of cleaning method depends on the specific needs of the assembly and the type of contaminants present on the PCB. Ultrasonic cleaning machines use high-frequency sound waves to dislodge contaminants from the surface of the PCB. This method is effective for removing particles, flux residues, and other contaminants that may be challenging to remove manually. Aqueous cleaning, on the other hand, involves the use of water-based cleaning agents, making it an environmentally friendly option. Vapor phase cleaning uses vaporized solvents to clean and remove residues from the PCB's surface, ensuring a residue-free board. Acrylic Conformal Coating Acrylic conformal coating is a protective layer applied to PCBs to safeguard them from environmental factors, such as moisture, dust, and chemicals, while also providing electrical insulation. This transparent, thin coating is essential to ensure the longevity and reliability of electronic devices. Acrylic conformal coating helps prevent corrosion and short circuits, extending the lifespan of the assembled PCB. Robotic dispensers are automated machines used to apply precise amounts of adhesive, solder paste, or other materials to PCBs. These machines ensure consistent and accurate dispensing, reducing the risk of errors that may occur with manual application. The use of robotic dispensers not only enhances the quality of PCB assembly but also significantly increases production efficiency. These dispensers are equipped with precise control systems that allow for the adjustment of dispensing volume, speed, and patterns, making them suitable for various assembly tasks. Additionally, robotic dispenser can handle a wide range of materials, from low-viscosity adhesives to high-viscosity sealants, ensuring versatility in the assembly process. PCB Assembly Equipment in Delhi Delhi, India, is home to a growing electronics manufacturing industry. To meet the demands of this expanding sector, numerous suppliers and manufacturers offer a wide range of PCB assembly equipment. When searching for high-quality equipment in Delhi, it is essential to consider the following factors: Reputation: Look for suppliers with a solid reputation in the industry, known for providing reliable and top-notch equipment. Support and Training: Opt for suppliers who provide technical support, training, and maintenance services to ensure that your equipment functions optimally. Price and Value: While cost is a significant factor, prioritize value over price, as investing in high-quality equipment can lead to better long-term results and fewer maintenance issues. For those in Delhi, it's essential to choose suppliers and manufacturers who offer top-quality PCB assembly equipment and provide the necessary support to streamline the production process. With the right equipment and a commitment to excellence, the electronics industry in Delhi can continue to thrive and contribute to technological advancements on a global scale. Read More...

0 notes

Text

Johnson Electric Job Openings in Chennai | Any Degree | Hardware Engineer Openings | Apply now

Johnson Electric Job Openings in Chennai | Any Degree | Hardware Engineer Openings | Apply now

Company Name: Johnson Electric

Company Details :

Caring for the world one person at a time motivates and brings Johnson & Johnson employees together.

We are open to new ideas, products, and services that will improve the health and well-being of people worldwide.

We believe in working together, which has led to breakthroughs, from medical miracles that have changed lives to simple consumer products that make every day a little better.

Job Openings in Chennai

Related Jobs :

- TATA Electronics Walk-in-Interview

- Foxconn Company Off-Campus Drive

- Motherson Automotive Technology Limited Walk-In Interview

- Maraimalai Nagar Area Walk-In Interview

- Hiring for Freshers Infosys Internship 2023

Royal Enfield Walk-In Interview | Fresher Candidates can attend the interview directly

Apply link: https://myemploymentjobs.com/royal-enfield-walk-in-interview-fresher-candidates-can-attend-the-interview-directly/

HCL Off Campus Drive 2023 | Madurai Location

Apply link:https://myemploymentjobs.com/hcl-of

Our Latest YOUTUBE Videos

Link : https://www.youtube.com/channel/UCZYt-jtPk975fMuI6tLpUEg

Our Telegram Channel

Link: https://t.me/employmentjobs

Latest Jobs By :

Chennai JobsClick HereCoimbatore JobsClick HereBangalore JobsClick HereHyderabad JobsClick HereAndra Pradesh JobsClick HereSalem JobsClick HereMadurai JobsClick HereTrichy JobsClick HerePondicherry JobsClick HereAcross India JobsClick HereOther Cities JobsClick Here

Designation: Hardware Engineer

Educational Qualifications: Any Degree

Role: Permanent

Year of Experience: Fresher

Job Location: Chennai, Tamilnadu

Salary Details: As per the Company Standard

Mechanical JobsClick HereELE / ECE JobsClick HereCivil JobsClick HereIT / Software JobsClick HereBPO / Call Centre JobsClick HereH/W & Networking JobsClick HereHuman Resource Jobs Click HereAcc/Fins JobsClick HereArts & Science JobsClick Here

Job Description :

Hardware Design, PCB Design and Hardware Testing for IPG & APG Projects.

PCB Testing of IPG and APG Projects

PCB Assembly Documentation Preparation

PCB assembly (Component Soldering & Desoldering and Assembly)

Prepare and Release the report to the engineering

How to Apply for this Job?

Details & Apply link :

Click Here

Production Planning Engineer Job Openings in TVS Company | B.E.Mechanical / Automobile | Hosur – Tamilnadu

Designation: Production Planning Engineer

Educational Qualifications: B.E. in Mechanical & Automobile

Role: Permanent

Year of Experience: Min Experience

Job Location: Hosur – Tamilnadu

APPLY LINK - https://myemploymentjobs.com/production-planning-engineer-job-openings-in-tvs-company-b-e-mechanical-automobile-hosur-tamilnadu/

Mahindra Company Hiring Fresher Graduate Apprentice Trainee Candidates Chennai | B.E.Mechanical & Automobile

Designation: Graduate Apprentice Trainee

Educational Qualifications: B.E.Mechanical & Automobile

Role: Permanent

Year of Experience: Fresh Graduates

Job Location: Chennai TN

Salary Details: As per the Company Standard

Apply link: https://myemploymentjobs.com/mahindra-company-hiring-fresher-graduate-apprentice-trainee-candidates-chennai/

For more Job info, subscribe to our website & and check our website daily.

Join Our Youtube ChannelClick HereJoin Our Telegram ChannelClick HereOur Linkedin PageClick HereOur Quora PageClick Here

Read the full article

#fresherjobopenings#jobopeningsinbangalore#jobopeningsinchennaiforfreshers#jobopeningsincoimbatore#JohnsonElectricJobOpeningsinChennai#mechanicalengineerjobschennai

0 notes

Text

Solder Paste for Electronic Products Market Statistics, Segment, Trends and Forecast to 2032

The solder paste for electronic products market refers to the global market for the materials used to create electronic circuits and components. Solder paste is a material that is applied to the surface of a printed circuit board (PCB) to connect the components to the circuit. The paste is composed of metal particles, flux, and other additives.

The market for solder paste is driven by the growing demand for electronic devices and the increasing use of printed circuit boards in various applications. The rise of the Internet of Things (IoT) and the increasing number of connected devices are also driving the demand for solder paste.

The Solder Paste for Electronic Products Market report is an excellent starting point for anyone seeking a thorough examination and analysis of the market. This report provides a wide range of research and data that will assist users in understanding niches and focusing on key market channels in the regional and worldwide Solder Paste for Electronic Products market. For the goal of understanding competition, the study provides market details such as size, share, current and projected market trends, supply chain information, trading concerns, competitive analysis, and prices, as well as vendor information.

Click Here, To Get Free Sample Report : https://stringentdatalytics.com/sample-request/solder-paste-for-electronic-products-market/316/

Market Segmentations:

Global Solder Paste for Electronic Products Market: By Company

• Senju

• MacDermid Alpha Electronics Solutions

• Heraeus

• Tamura

• Henkel

• Indium

• Shengmao

• Inventec

• KOKI

• AIM

• Nihon Superior

• KAWADA

• Yashida

• Tongfang Tech

• Yong An

• DS HiMetal

• Eunow Company Limited

Global Solder Paste for Electronic Products Market: By Type

• Rosin Based Pastes

• Water Soluble Pastes

• No-clean Pastes

Global Solder Paste for Electronic Products Market: By Application

• Consumer Electronics

• Vehicle Electronics

• Other

Global Solder Paste for Electronic Products Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Solder Paste for Electronic Products market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/solder-paste-for-electronic-products-market/316/

Reasons to Purchase Solder Paste for Electronic Products Market Report:

• To gain insights into market trends and dynamics: this reports provide valuable insights into industry trends and dynamics, including market size, growth rates, and key drivers and challenges.

• To identify key players and competitors: this research reports can help businesses identify key players and competitors in their industry, including their market share, strategies, and strengths and weaknesses.

• To understand consumer behavior: this research reports can provide valuable insights into consumer behavior, including their preferences, purchasing habits, and demographics.

• To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.

• To make informed business decisions: this research reports provide businesses with data-driven insights that can help them make informed business decisions, including strategic planning, product development, and marketing and advertising strategies.

Overall, market research reports provide businesses and organizations with valuable information that can help them make informed decisions and stay competitive in their industry. They can provide a solid foundation for business planning, strategy development, and decision-making.

More Reports:

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Contact US:

Stringent Datalytics

Contact No - 91-9763384149

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Solder Paste for Electronic Products Market Statistics#Segment#Trends and Forecast to 2032#market research report#marketing#investors#electronicmarketreport#marketresearchreport

0 notes

Text

Roots EMS

PCB Assembly & Electronics Manufacturing Services Company in India

Our Services

PCB Design and Engineering

PCB Assembly & SMT

Vapor phase soldering

Conformal Coating

Box Build Assembly

Our PCB Designing Services

Schematic capture

Layout

Fabrication

Testing

PCB Assembly & SMT

CAPABILITIES

Hi complex double-sided PCB assembly

High mix, medium volume assemblies

Fine Pitch SMT, Through-hole and Box Build Assemblies

Automated optical inspection

In-circuit test

X-ray inspection

Full functional testing, automatic testing equipment and End of Line (EOL) testing

Conformal coating

IPC 610 standards class 2 and class 3

Design for manufacturing (DFM), Design for Assembly (DFA) & Design for Test (DFT) analysis

End to End manufacturing traceability

Rapid prototyping

https://rootsems.com/

Group of Companies

ROOTS INUSTRIES INDIA LIMITED

ROOTS MULTICLEAN LIMITED

ROOTS AUTO PRODUCTS PRIVATE LIMITED

ROOTS CAST PRIVATE LIMITED

ROOTS POLYCRAFT

ROOTS PRECISION PRODUCTS PRIVATE LIMITED

SATCHIDANANDA JOTHI NIKETHAN INTERNATIONAL SCHOOL

RK NATURE CURE HOME

roohttps://rootsems.com/about-us/

#printedcircuitboard#roots#PCB Design and Engineering#PCB Assembly & SMT#Vapor phase soldering#Conformal Coating#Box Build Assembly

1 note

·

View note

Link

Techno Advance Systems offer Printed Circuit Board Assembly Services in India. We also providing through hole soldering services in Ahmedabad & Gandhinagar. The company is committed to delivering quality products, on time and within budget, and to building long-lasting partnerships with its customers. If you're looking for a reliable, experienced partner for your PCB assembly and box building needs, look no further than Techno Advance Systems.

#through hole soldering services in Ahmedabad#through hole soldering services in Gandhinagar#Printed Circuit Board Assembly Services in India#PCB Assembly Service in Ahmedabad#PCB Assembly Services in Gandhinagar#Box Building Service

0 notes

Text

Industrial X-Ray Inspection System Market - Global Opportunity Analysis and Industry Forecast (2021 - 2028)

Meticulous Research®—a leading global market research company, published a research report titled “Industrial X-ray Inspection System Market by Component (Hardware, Software), Imaging Technique (Digital, Film-Based), Dimension (2D X-ray Systems, 3D X-ray), Vertical (Electronics & Semiconductors, Oil & Gas), and Geography — Global Forecasts to 2028.”

The industrial X-ray inspection system market is expected to grow at a CAGR of 10.3% by value from 2021 to reach $1.03 billion by 2028. Stringent government regulations regarding the safety of assets, increasing consumer awareness regarding quality standards, and rising security concerns in strategic infrastructure installations are the factors driving the growth of the industrial X-ray inspection systems market.

Increasing automation in digital X-ray inspection systems, miniaturization of X-ray inspection systems for higher mobility, and increase in user-friendly interfaces due to technological advancements are projected to provide significant growth opportunities for vendors operating in this market.

However, the availability of substitute technologies and high equipment and maintenance costs are expected to restrain the growth of this market to some extent. Additionally, the lack of qualified personnel poses a major challenge for the growth of the industrial X-ray inspection systems market.

The market is segmented based on component, imaging techniques, dimension, vertical, and geography. The study also evaluates industry competitors and analyzes the market at the country level.

Download Sample of This Strategic Report: https://www.meticulousresearch.com/download-sample-report/cp_id=5148?

Scope of the Report:

Industrial X-ray Inspection System Market, by Component

Hardware

Software

Support Services

Consumables

Industrial X-ray Inspection System Market, by Imaging Technique

Digital Radiography

Computed Radiography

Computed Tomography

Industrial X-ray Inspection System Market, by Dimension

2D X-ray Systems

3D X-ray Systems

Industrial X-ray Inspection System Market, by Vertical

PCB Inspection

Solder Joint Inspection

Wafer Inspection

Automated Optical Inspection

Other Applications

Aircraft Maintenance

Composite Material Analysis

Airport Security

Railway Tracks

Bridges and Tunnels

Nuclear Power Plants

Renewable Energy Plants

Non-Renewable Energy Plants

Subsea Pipeline Monitoring

Transmission Pipeline Monitoring

Storage Tank Monitoring

Refinery Plant Monitoring

Product Quality Control

Additive Manufacturing

Plant Health Monitoring

Industrial X-ray Inspection System Market, by Geography

U.S.

Canada

China

Japan

India

Rest of Asia-Pacific

Germany

U.K.

France

Italy

Spain

Rest of Europe

Brazil

Mexico

Rest of Latin America

Saudi Arabia

UAE

Rest of the Middle East & Africa

Access full Report Description, TOC, Table of Figure, Chart, etc: https://www.meticulousresearch.com/product/industrial-x-ray-inspection-system-market-5148

Based on components, the industrial X-ray inspection system market is segmented into hardware, software, support services, and consumables. The hardware segment is estimated to account for the largest share of the industrial X-ray inspection systems market in 2021. The large market share of this segment is attributed to the increasing demand for high-quality X-ray detecting solutions and technological advancements.

Based on imaging techniques, the industrial X-ray inspection system market is segmented into digital imaging and film-based imaging. The digital imaging segment is estimated to account for the largest share of the industrial X-ray inspection systems market in 2021. The large market share of this segment is attributed to factors such as digitalization, rising industrial automation, and rising quality and safety standards. Additionally, this segment is expected to register the highest CAGR throughout the forecast period.

Based on type, the digital imaging market is segmented into direct radiography, computed radiography, and computed tomography. The direct radiography segment is estimated to account for the largest market share in 2021. Effective dynamic range, high contrast detectability, accurate image capture, less radiation exposure, high flexibility, and lower operational costs are the factors attributed to the large market share of this segment. These features contribute to the adoption of direct radiography in various industries.

Based on dimensions, the industrial X-ray inspection system market is segmented into 2D X-ray systems and 3D X-ray systems. The 2D X-ray system is estimated to account for the largest market share in 2021. The dominant position of this segment is attributed to its use in various automotive, aerospace, defense, and manufacturing industries to detect defects or faults in the final products. The increasing adoption of 2D X-ray systems across these industries drives the growth of this segment.

SPECIAL OFFER (Click Here): https://www.meticulousresearch.com/request-sample-report/cp_id=5148

Based on the vertical, the industrial X-ray inspection system market is segmented into electronics and semiconductors, aerospace, automotive, public infrastructure, power generation, oil & gas, food & beverages, manufacturing, and other verticals. Among these verticals, the electronics and semiconductors segment is estimated to account for the largest market share in 2021. The large market share of this segment is attributed to the rising usage of X-ray inspection for 3D packaging in electronics and integration of X-ray inspection in non-destructive testing of components, PCB assemblies, and solder joints. Additionally, this segment is slated to register the highest CAGR during the forecast period.

Based on geography, this market is segmented into five major regions: North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. North America is estimated to account for the largest share of the industrial X-ray inspection systems market in 2021. The large market share of this region is attributed to the rising demand for industrial X-ray systems in the oil & gas industry.

North America is followed by Asia-Pacific and Europe in terms of revenue share. Asia-Pacific is expected to register the highest CAGR during the forecast period.

The COVID-19 pandemic had a massive negative impact on the industrial X-ray inspection systems market in North America. Major oil & gas companies in the region decreased their investments in inspection-related activities due to low production and depressed oil prices.

Key Players

The key players operating in the industrial X-ray inspection system market are North Star Imaging Inc. (U.S.), Nikon Metrology, Inc. (U.S.), Nordson Corporation (U.S.), YXLON International GmbH (Germany), VJ Group, Inc. (U.S.), 3DX-RAY Ltd (U.K.), Visiconsult GmbH (Germany), Smiths Detection Group Ltd. (U.K.), Mettler Toledo International Inc. (U.S.), Maha X-ray Equipment Private Limited (India), Baker Hughes Company (U.S.), Ishida Co., Ltd. (Japan), Carl Zeiss AG (Germany), Ametek, Inc. (U.S.), and Thermo Fisher Scientific Inc. (U.S.).

Speak with Our Analyst: https://www.meticulousresearch.com/speak-to-analyst/cp_id=5148

Key Questions Answered in the Report-

Which are the high-growth market segments in terms of components, imaging techniques, dimensions, vertical, and geography?

What is the historical market size for the industrial X-ray inspection systems market?

What are the market forecasts and estimates for the period 2021–2028?

What are the major drivers, restraints, opportunities, and challenges in the industrial X-ray inspection systems market?

Who are the major players in the market, and what shares of the market do they hold?

How is the competitive landscape for the industrial X-ray inspection system market?

What are the recent developments in the industrial X-ray inspection system market?

What are the different strategies adopted by the major players in the market?

What are the key geographic trends, and which are the high-growth countries?

Who are the local emerging players in the industrial X-ray inspection system market, and how do they compete with the other players?

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

Connect with us on Twitter- https://twitter.com/MeticulousR123

#x ray inspection system Market#x ray inspection system#x ray inspection#x ray#healthcare#health#2D X ray#3D X ray#Electronics#Semiconductors#oil and gas#imaging#digital imaging#automotive#aerospace

0 notes

Text

Get the best electronics manufacturing services in India?

The electronics manufacturing industry has seen good growth in recent years and has become an important member of the global electronic industry. With the government's push like ‘Make in India’ and growing foreign investments, the industry has observed enhancements in both technology and infrastructure. This growth has seen fertile ground for electronics manufacturing services in India (EMS) with many companies from across the world investing in the country.

The strong growth of the Indian electronics sector has enhanced its global importance in terms of expansion. As per the latest statistics, it is forecast that the industry will hit $400 billion by 2025 due to domestic consumption as well as export sales. This growth is driven mainly by the necessity of electronics using devices like smart phones, laptops and IoT gadgets for modern life and business.

The government’s push for a digital economy has only served to grow the sector even more. Programs such as Digital India for enhancing usage and connections to the internet have further strengthened the need for electronic products hence fueling growth for electronics manufacturing services in India.

Key statistics are useful to point to this upward trend. For example, the electronics manufacturing industry in India rose to 23% in 2021 from 2020, with exports worth $11. 4 billion. The country is now among the five leading producers of mobile phones in the world, which underlines its aptitude for mass manufacturing and development.

What involves EMS?

EMS signifies a range of services that extend from the development to the manufacturing, testing and supply of electronic parts and systems.

Design

EMS providers work closely with clients to come up with comprehensive designs based on certain criteria. Schematics are designed and employments are made of the components including the printed circuit boards (PCBs).

Production

After the final decision on the design, there comes the production stage. This involves acquiring materials used to make PCBs and all other components, mounting and soldering these PCBs and finally installing all parts onto the circuit board. The production process involves the use of technology and automation to achieve accuracy and effectiveness.

Test

Various test methodologies are performed to ensure that the electronic assemblies are functional and reliable. This involves circuit testing, functional testing, and environmental testing to help detect any flaws that may be present.

Support

Good post production support is crucial in ensuring that the quality of the product and the satisfaction of the consumers are kept at an optimum level. To that end, EMS providers provide services like repairs, upgrades, and support logistics so that the products remain functional and satisfactory to end-users.

Epsilon Electronics provides end-to-end electronics manufacturing services in India that address the specific requirements of every customer. Epsilon Electronics has only one mission, deliver outstanding electronics manufacturing services that surpass client’s expectations. So don’t miss out on the opportunity to collaborate with the best EMS provider. Visit Epsilon Electronics to fulfill all your electronics manufacturing needs.

#electronics manufacturing services in India#electronics manufacturing services#electronics manufacturing service provider#ems solution provides

0 notes

Text

Best PCB Assembly Manufacturers & Services India

The PCB assembly process occurs after PCB manufacturing, where the board structure is completely formed according to client requirements. The PCB assembly covers actions from stencil preparation and solder paste printing to SMD parts placement, bonds formation in the curing oven, and final inspection of the PCB functionality.

#PCBcircuit#pcbmanufacturing#pcb#electronics#circuit#manufacturing#manufacturer#pcbdesign#pcbassembly#pcbmanufacturer#pcbpune#ems

0 notes

Text

Shreeram Electronics - Your One-Stop Solution for PCB Design and Fabrication in Delhi

In today's world, Printed Circuit Board (PCB) design and fabrication are crucial for almost all electronic devices, from simple toys to complex medical equipment. And when it comes to the national capital, Delhi, it's one of the largest hubs of electronics manufacturing in India. PCB design and fabrication in Delhi is essential to the local electronics industry, and Shreeram Electronics has been a leading provider of PCB design and fabrication in Delhi for over two decades.

At Shreeram Electronics, we offer end-to-end PCB design and fabrication services, including schematic design, board layout design, and fabrication. We work with a wide range of industries, including automotive, medical, telecommunications, and defense, and provide custom PCB design and fabrication solutions that meet the specific requirements of our clients.

Our team of experienced designers and engineers use the latest software tools to create PCB designs that are optimized for performance, reliability, and manufacturability. We ensure that our designs are compatible with the latest manufacturing processes and technologies to minimize cost and reduce lead times.

When it comes to PCB fabrication, we use state-of-the-art equipment and processes to ensure high-quality, reliable, and cost-effective PCBs. We work with a wide range of materials, including FR4, polyimide, and Rogers, and offer a range of surface finishes and solder masks to suit our clients' specific requirements.

At Shreeram Electronics, we understand the importance of timely delivery, and we strive to meet our clients' deadlines, no matter how tight. We also ensure that our PCBs meet the highest industry standards, including IPC-A-600 and IPC-6012.

If you're looking for a reliable, experienced, and customer-focused PCB design and fabrication service provider in Delhi, look no further than Shreeram Electronics. We pride ourselves on providing high-quality, cost-effective, and timely services that meet our clients' specific requirements. Contact us today to learn more about our services and how we can help you with your next project.

In addition to our comprehensive PCB design and fabrication services, Shreeram Electronics offers a range of value-added services, including component sourcing, assembly, and testing. We work closely with our clients to understand their specific requirements and provide customized solutions that meet their needs.

Our team of experienced engineers and technicians have the skills and expertise to provide full turnkey solutions for PCB assembly, including surface mount technology (SMT) and through-hole technology (THT) assembly, testing, and inspection. We use advanced equipment and processes to ensure high-quality, reliable, and cost-effective PCB assemblies.

At Shreeram Electronics, we are committed to providing our clients with exceptional customer service. We work closely with our clients throughout the design and fabrication process to ensure that their requirements are met and their expectations are exceeded. We also provide regular updates and progress reports to keep our clients informed about the status of their projects.

We take pride in our reputation for providing high-quality PCB design and fabrication services in Delhi. Our commitment to quality, reliability, and customer satisfaction has earned us the trust and loyalty of our clients, many of whom have been with us for years.

In conclusion, if you're looking for a reliable, experienced, and customer-focused PCB design and fabrication service provider in Delhi, Shreeram Electronics is the right choice. Contact us today to learn more about our services and how we can help you with your next project. Our team of experts is ready to assist you in achieving your goals and exceeding your expectations. Our Website- www.shreeramelectronic.com, Call us for more details:9810432675,8810665013, Email us at [email protected].

0 notes

Text

AC PCB technician India - Salary, How to find a job

The people that fix the air conditioning in homes, offices, schools, hospitals, and other buildings are AC PCB repairers and technicians. You may believe that they are just trained to operate cooling systems, but that is incorrect because they are also trained to operate ventilation and heating systems. These AC PCB technicians can work in the public or private sectors or even as self–employed and freelancers depending on their personal preferences. In order to become an AC PCB technician one should learn a proper AC PCB repairing course in Delhi where you will gain knowledge about the repairing of PCB. In this ac repairing course, you will learn all the essential skills required to start fixing printed circuit boards on your own. You will learn how to read schematics and PCB drawings, measure voltage and current use the necessary equipment and tools, solder an SMD component, and repair hot thermals on different kinds of SMD chips. This course covers every aspect of printed circuit board (PCB) repair, such as techniques for inspection and examination, maintenance, and troubleshooting. When we talk about the salary of an AC PCB technician there is a good salary package for the technician. The salary of a technician always depends upon his experience in the field. There are many HVAC companies that required AC PCB technicians in their companies according to their experience.

If a technician has 1 or 2 years of experience he can easily get a job in companies with a decent salary of 20k to 25k. The more experience he gains in a field the more salary he will get. There are technicians who get 40k per month with the most experience in this field. In India, an AC technician makes an average annual pay of 240,000 rupees or 96.15 rupees per hour. Most experienced workers can earn up to 475,000 per year, while entry-level roles start at 180,000. When we talk about how to find a job as an AC technician then there are several job opportunities for AC PCB technicians. If they work for themselves or as freelancers then they can ads about their services on Google, social media platforms, and more. If they want to get a job in this field then there are many job portals that have thousands of job opportunities for them. Register as a job seeker and submit your resume for the position of AC Technician. When you apply for a job in this field you see a qualification needed to apply so your first step towards it should be having an ac repairing course where you will get the desired knowledge and experience of the field thus it will be easy for you to find a job. There are some AC PCB repairing institutes in Delhi that provide job opportunities to their students. These institutes in Delhi arrange seminars that help them a lot in finding jobs. These AC PCB repairing institutes in Delhi also have placement facilities also which help students enter this industry.

1 note

·

View note

Text

Best PCBA Manufacturing Equipment Services in India

PCB is a Printed Circuit Board. It's a significant electronic part, which is a help for electronic parts and a transporter for electrical associations between electronic parts. As it is created by printing the expected picture on the substrate, it is known as a "printed" circuit board. It's most usually produced utilizing copper-clad epoxy sap/glass material compound.

The PCB is frequently comprised of various layers with 4 and 6 being the most normally utilized, depending on the necessary number of sign layers.

At the point when countless PCBs must be made, odds are parts will not be physically bound manually. This is where proficient gathering houses like Seeed will step in, to assist with manufacturing both the uncovered sheets and collect every one of the parts onto the Printed Circuit Boards, or PCBs.

Best PCBA Manufacturing Equipment Services in India - Syrma SGS

Yet, have you at any point thought about how your makers can stick that monstrous number of small parts onto your PCBs? I have, yet that was until I needed to drive through passages of specialized language online about the apparatus that takes care of business. While there's nothing provocative about PCBA producing, understanding how the cerebrums of all hardware are made most certainly gives pleasure and a feeling of achievement. Heaps of thought go into each phase of the gathering system to convey an entirely working board. Furthermore, with the gadgets getting increasingly progressed, the hardware used to make PCBs are steadily improving and more energizing than at any other time.

Best PCBA Manufacturing Equipment Services in India - Syrma SGS

In PCB gathering, there are 4 primary phases of SMT, or Surface Mount Technology get together utilizing the reflow strategy, which are glue application, mechanized part situation, binding, and review. The essential gear expected for PCB gathering incorporates:

Bind Paste Printing machine

Bind Paste Inspection (SPI) machine

Stick Dispensing machine

Pick-and-Place machine

Reflow Soldering machine

Wave Soldering machine (for through-opening parts)

Programmed Optical Inspection (AOI) machine

In-Circuit Test (ICT) Fixture

Practical Validation Test (FVT) Fixture

Best PCBA Manufacturing Equipment Services in India - Syrma SGS

Bind Paste Printing Machine

The initial phase in PCB gathering is the use of bind glue onto the board. Bind glue is a dim shaded goo produced using a combination of minuscule particles of metal compounds; normally of tin, lead, and silver. Consider it a paste that will keep your finished board intact. Without it, parts wouldn't adhere to your uncovered board.

Patch glue (left), PCB stencil laser-cut openings (right)

Before the glue is applied, a PCB stencil is set over the board. A PCB stencil is a tempered steel sheet that has little laser-cut openings that permit patch glue to be applied exclusively to the region of the board where the parts contacts will ultimately sit on the completed PCB, for example, the SMD cushions.

During the use of patch glue, the PCB stencil and the PCB are gotten into a place in the mechanized glue printer. A wiper then, at that point, applies without lead weld glue on the cushions in exact sums. The machine then hauls a cutting edge across the stencil, to spread and store the glue equitably in the ideal regions. After the stencil is taken out, the patch glue will be precisely where we maintain that it should be (ideally).

Best PCBA Manufacturing Equipment Services in India - Syrma SGS

Weld Paste Inspection (SPI) machine

Various industry studies have brought up that up to 70% of SMD binding issues are followed back to inappropriate or inadequate patch glue printing. Thus, the subsequent stage is to check to assume that the binding glue is printed appropriately onto the board. While utilizing great bind glue printing strategies are in many cases enough for PCBs in low volumes, SPI ought to be thought about while producing higher volumes of PCB to stay away from high modification costs.

0 notes