#PCB surface protection

Explore tagged Tumblr posts

Text

Solder Mask vs PCB Solder Resist: Understanding the Differences

Understand the role of solder mask vs solder resist in PCB production. Learn how these coatings enhance electrical insulation, prevent solder bridging, and support UK manufacturing standards. Visit our site for advanced solder mask solutions tailored to your needs.

#solder mask#solder resist#PCB solder mask#PCB solder resist#LPI solder mask#solder mask vs solder resist#PCB surface protection#epoxy solder mask#dry film solder resist#UK PCB manufacturing#high-reliability A-Gas Electronic Materials#circuit board protective coatings

0 notes

Text

Prompt #17, Extra Credit: Blood

“Gun- Gun- Gunslinger- Hawk-” The static came in the middle of hysterical laughter. Raucous. Joyful. Pained.

Weaponsfire seared the air. Plasma scorched even the darkest pieces of the midnight alleys. Circuits and bone and artificial memories screamed in the arching shadows like neon. Copper wiring with magnetic spirals as plasma bolts in magnetic remnants spun by them, electricity in the air that coursed along her skin and down her fingertips. Gunshots. Gunshots. Gunshots. It had just rained. The puddles were evaporating. Water and mineral content changing. Not the acid-tinged rain. Not the runoff filled with particulate plastic and rubber. Iron. Blood. It reverberated with the screaming. With the gunfire. Her fingertips scrabbled as the night drowned out her voice, as the one currently fighting couldn’t turn away. There were so many after all. Where had they come from? No evidence on any network. No trace in the silicon. No touch could elevate her senses into finding them in footage or local magnetic effects. But here they were now, and here they were now. Bullets scraped the sheet metal wall as she finally found it. She tore off the access panel, the metal groaning and screaming in time with the combat. Could it be heard over it all? She could certainly feel it. She could feel the echo of it in every sensor even as they focused on tracking every projectile that rocketed by. How could she feel so powerless in all of this? Certainly she wasn’t made for being a combatant but she had some of the best military tech money could buy put into this body, not even speaking on software- No time, no time, milliseconds were screaming by and signals were closing in. Coming closer, gunfire louder, her combatant charge cursing as she fumbled for ammunition. And then it all went black.

Not for her, no. Far from it. For her? The world couldn’t be clearer. Her tail was jammed straight into the junction box. The entire sector’s power supply at her fingertips. Enough voltage to fry any human so insane, enough current to melt any synthetic that could ever hope to imagine. But for her? The mimicked taste of copper and ozone on her body’s sensors only let her know that her laughter had become laced with the high pitched scream of high voltage.

Fuses blew, breakers popped, lights went dark, machines fell dead, as all in that moment was hers. All in that moment was made to bend to her, to come to her, to feed her. “Gunslinger.” The AM-3S unit spoke. A voice of one, a chorus of more. “Watch.” And the city came to life under the weight of a mind. Pylons roared into brilliant plasma arcs, neon bulbs sparked and exploded, ancient machinery lost beneath the asphalt screamed through the surface. All of it her hands, all of it her fingertips, all of it bleeding her senses and bleeding her life. The datastream of multitudes as network and networked rose in tandem, as circuit and copper and old-world PCB responded to her just as the body of one did. Human-lethal pressure waves, human-lethal temperature, human-lethal particulate as blood and bone vaporized under the renewed life of a mind that had been confined from ten thousand senses down to one. And still the unit stood close to her gunslinger. A smile on its face. The cables trailing behind it still sparking and frying in the junction box. Further and further the blackout spread. And louder and louder the voltage laughed. Drive off these attackers, protect herself, protect this charge, follow her protocols to the letter and she could have it all. She could have her network, this body, her mind and all that it entailed, she could be free of it all and take what she wanted in this cesspool that she had been born into-

Blackout. Cut off. Her tail snapped back into her body, her mind pulled back as a cord which had stretched too far. Face down in the water. Iron percentage: 34%. Correction, as her last thought plugged through her remaining charge. Face down in the blood.

#/For Whom Sunlight Speaks/Recollections#/AU/Cyberpunk#FFXivWrite2023#that's right baby we're back to this#a continuation au day how garish of me#but i'm 30 minutes out of playing so much bg3 my brain fries#decided this was an appropriate part of that thought

8 notes

·

View notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

�� Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

【The ultimate guide to choosing the perfect Dry Ice Cleaning Machineand dry ice machine for your needs】

UNDERSTANDING YOUR REQUIREMENTS

1. Determine your application area:

Before diving into machine specifications, determine your primary application. Whether it’s industrial cleaning, food preservation, or special effects in the entertainment industry, understanding your specific use case will allow you to more accurately select the machine that’s best for you.Or you can tell us your needs and we will recommend the best solution for you.

2. Dry ice quantity issue:

Consider the amount of dry ice you need. Industrial applications may require high-capacity machines, while smaller equipment can meet smaller-scale needs. Understanding your production requirements is critical.You can refer to 【Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers】and 【How to set up your own dry ice manufacturing factory?】Learn more about dry ice in two articles.

TYPES OF DRY ICE CLEANERS AND DRY ICE PELLETIZERS

1. Dry ice cleaning machine(Dry ice blasting machine):

Compressed air is used to accelerate dry ice pellets to supersonic speeds and spray them onto the surface being cleaned. The high-speed ice particles hit the dirt, and through the freezing and mechanical action of the ice, the dirt is peeled off the surface.It is widely used for cleaning machinery and equipment, production lines, building surfaces, etc. It is especially suitable for the food and pharmaceutical industries because the cleaning process does not require water or chemicals.(Want to learn more about Dry Ice Cleaning?)

· P7X Dry ice cleaning machine: Very suitable for cleaning carbon deposits and oil stains in car engines. It can effectively complete cleaning without damaging engine parts etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· A625i Dry ice cleaning machine: Suitable for cleaning oily molds, motor windings, paint rust cleaning, and printing machine ink residues etc.. (Suitable for rubber factories, shoe factories, factory machine maintenance, etc.)Go to view product details

· P60 Dry ice cleaning machine: Used for car interior renovation and cleaning, car seat cushions, surface glue residue, and oil stain cleaning etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· T6 Dry ice cleaning machine: Used for PCB circuit board renovation and cleaning, soldering residue, surface glue residue, oil stains, PPS material deburring, etc. (Suitable for component factories, component maintenance, factory machine maintenance, etc.)Go to view product details

· B3+ Dry ice cleaning machine: Used for cleaning motor winding dust, printing machine ink, oil sludge, rust stains, heavy oily metal, etc.(Used to clean and maintain a variety of industrial equipment, including engines, pumps, valves, pipes, etc.)Go to view product details

Generally speaking, the dry ice cleaning machine is an efficient, environmentally friendly, and multi-purpose cleaning equipment. Its working principle is based on high-speed spraying of dry ice particles to clean the surface through freezing and mechanical impact. The advantages of this cleaning method include being water-free, leaving no chemical residue, being non-abrasive, suitable for a variety of surfaces and materials, and having a wide range of applications in a variety of industries.

For potential users, when choosing a dry ice cleaning machine suitable for specific needs, factors such as cleaning objectives, working environment, cleaning effect requirements, production capacity and budget need to be considered. Whether in industrial, food, medical or other industries, dry ice cleaning machines have demonstrated their excellent performance in improving cleaning efficiency and protecting equipment surfaces.You can also tell us your needs and our engineers will recommend the most suitable solution for you. Contact an engineer now >>

2. Dry ice pellet machine(Dry Ice Granulator Machine):

Dry ice pelletizer is a piece of equipment specially used to turn liquid carbon dioxide (CO2) into solid carbon dioxide (dry ice) pellets.

Dry ice pelletizers usually deliver liquid CO2 into the machine through a liquid carbon dioxide supply system. Liquid carbon dioxide undergoes a series of cooling and pressurization processes, causing its temperature and pressure to rise. The pressurized liquid carbon dioxide passes through the nozzle or spray head and enters a relatively low-pressure environment. In this environment, liquid CO2 rapidly relaxes and expands, lowering its temperature and turning into a solid state. Because the temperature drops sharply, liquid CO2 turns into a gaseous state and forms tiny CO2 particles, known as dry ice particles.

The Dry ice machine can efficiently convert liquid CO2 into a large number of evenly distributed dry ice pellets. The advanced control system can achieve precise control of parameters such as temperature, pressure and particle size to ensure the production of dry ice that meets requirements. Some Dry Ice Granulator have adjustable mechanisms that allow the user to select different sizes of dry ice pellets. There is no need to add any chemicals during the manufacturing process, and the waste material is CO2 gas, so the dry ice pelletizer is considered a relatively environmentally friendly production method. Most Dry Ice Pelletizer Making Machine are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

3. Dry Ice Block Machine(Dry ice briquetting machine):

A dry ice block press is a piece of equipment specifically designed to compress dry ice pellets or pieces into block form.

Dry ice block presses typically use previously produced dry ice pellets or chips as raw material. These pellets or chips are usually prepared through an overhead dry ice pelletizer or other means. Dry ice raw material is transported to the compression zone and heated to a certain level. The purpose of heating is to cause the dry ice pellets or blocks to begin to soften and melt. After heating, the softened dry ice is placed in a compression zone, where compression machinery or a hydraulic system exerts tremendous pressure to compress the dry ice into blocks. The compressed dry ice blocks pass through the cooling system, where they are quickly cooled and re-solidified to form solid dry ice blocks. The formed dry ice blocks enter the collector through the collection system, and then enter the packaging area through the conveyor system for final packaging.

Go to view product details >>

Main feature:

Efficient production: The dry ice block press can efficiently convert dry ice pellets or fragments into large, solid dry ice.

Uniformity of dry ice blocks: Compression machinery and control systems ensure uniform shape and size of dry ice blocks, suitable for different applications.

Save space: Dry ice in block form is easier to store and transport than in crushed or pellet form, thus saving space.

Energy savings: Previously produced dry ice pellets or crumbs are used as raw material, reducing the need for additional refrigeration and helping to save energy.

Automated operation: Most modern dry ice block presses are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

Application areas:

Food and pharmaceutical transportation: Dry ice blocks are widely used in cold chain transportation to keep food and pharmaceuticals at low temperatures.

Laboratory and scientific research: In laboratories and scientific research fields, dry ice blocks are used to prepare low-temperature environments, such as refrigeration reagents.

Special effects production: Dry ice cubes are often used in film productions and stage performances to create special smoke and cold fog effects.

Environmentally Friendly Cleaning: Dry ice cubes are also used in the cleaning industry for cleaning and removing dirt, especially for electrical equipment cleaning.

Overall, the dry ice block press provides a reliable production method for producing large blocks of dry ice, suitable for the different needs of multiple industries.

RODUCTION CAPACITY

Evaluate the machine's productivity in pounds per hour. Make sure it fits your needs without sacrificing quality. To meet high-volume demand, faster production may be required.

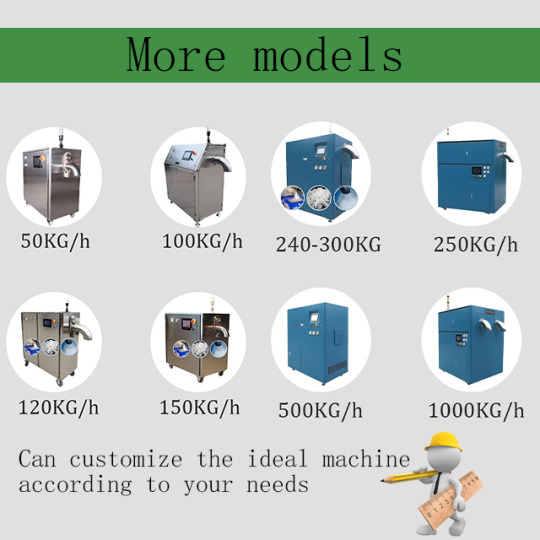

OLLITAL aims to provide customers with more choices in production capacity. Independently developed: 50KG/H (110 lbs/H), 100KG/H (220 lbs/H), 150KG/H (330 lbs/H), 250KG/H (551 lbs/H), 500KG/H (1102 lbs/H), and 1000KG/H (2204 lbs/H) dry ice pellet machine. Or you can tell us your needs and our engineers will customize the most suitable solution for you according to your needs. Contact an engineer immediately for customization >>

TECHNICAL SPECIFICATIONS

1. Size and portability:

Consider the physical size of the machine. A compact, portable unit may be better for versatility and ease of use, especially if you work from different locations or have limited space. If you need to move your cleaning equipment between job sites, choosing a dry ice blaster that is compact and portable may be key. This is important for tasks that require frequent movement or operation in limited spaces.

* Machine size: View the actual dimensions of your dry ice blaster, including length, width, and height. Make sure the machine is sized to fit your workplace and can be easily stored or carried.

* Weight: In addition to size, consider the weight of your dry ice blaster. The lightweight design can improve portability, reduce the burden of transportation, and make the device easier to carry and operate.

* Easy to carry design: Choose a machine with a user-friendly carrying design, such as handles, wheels, or other structures for easy movement. These designs make it easier for operators to move equipment from one location to another.

* Versatility: Some portable dry ice blasters are designed for versatility and can be used in a variety of applications. This flexibility increases the equipment's usefulness and makes it suitable for different types of cleaning tasks.

* Easy to store: Consider the storage needs of the machine when not in use. Some machines may have folding or removable parts to make it easier to store in limited spaces.

* Power and energy requirements: Consider the power and energy requirements of your dry ice blaster. Portable devices are often easier to connect to different types of power sources, such as batteries, generators, or standard electrical outlets.

When selecting a dry ice blaster, considering size and portability can ensure the equipment is better suited to your job requirements, increasing operational flexibility and efficiency.

2. Automation and control:

Automation and control are crucial considerations when selecting a dry ice pelletizer and cleaning machine. Look for user-friendly controls and automation features. An intuitive interface and automation streamline operation, making the machine easier for operators of all skill levels to use.

* Intuitive interface: Choose a dry ice granulator/cleaner with an intuitive interface. An intuitive control panel or touch screen makes it easier for operators to understand and operate the equipment, reducing training time.

* User-friendly controls: Consider choosing a machine with user-friendly controls. Simple buttons, knobs or digital controls allow operators to easily adjust and monitor cleaning parameters.

* Default program: Look for machines with preset cleaning programs. Preset programs improve operational consistency and efficiency, reducing manual setup and adjustments by the operator.

* Automation features: Understand whether the machine has automated functions, such as automatic nozzle adjustment, cleaning trajectory planning, etc. These features simplify the cleaning process and reduce operator intervention.

* Remote control and monitoring: If possible, choose machines that support remote control and monitoring. In this way, operators can monitor and adjust the cleaning process remotely, increasing the operational flexibility of the equipment.

* Fault diagnosis and alarm system: Look for machines with fault diagnosis and alarm systems. These systems can detect and report potential problems in a timely manner, helping to quickly resolve faults and improve equipment reliability.

* Data logging and reporting: Some advanced dry ice cleaning machines have data logging and reporting capabilities that can record key parameters during the cleaning process. This is very useful for quality control and traceability.

* Programmability: If you need to personalize it for a specific application, consider choosing a machine with some programmability to accommodate different cleaning needs.

By choosing a dry ice pelletizer/cleaner with an intuitive interface, automated features, and user-friendly controls, you can increase the ease of use of your equipment, reduce training costs, and ensure consistent cleaning results among operators of different skill levels .

Choosing the perfect dry ice machine requires a thorough understanding of your specific needs, technical specifications, and cost considerations. By carefully evaluating these factors, you will be able to make an informed decision that meets your application requirements and provides long-term value.

Whether you're venturing into a new business or upgrading an existing setup, investing the time in selecting the right dry ice machine is a critical step toward efficiency and success.

�� If you want to know more about Dry Ice Pellet Manufacturing Machinery or you want to build a dry ice production line, please refer to [Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers].

In this era of cleaning revolution, choose a dry ice cleaning machine to make cleaning easier, more efficient and more environmentally friendly! Thank you for reading our blog, if you have any questions or cooperation intentions, please feel free to contact us. Let us help the cleaning industry together and create a better future!

2 notes

·

View notes

Text

Rain Sensor: Advanced Automotive Safety Technology

What is a Rain Sensor?

A rain sensor is an electro-optical system that uses infrared technology to detect the presence and intensity of precipitation on the windshield. This system is designed according to ISO 11452-9 standards and operates as part of the automatic wiper system.

What is a Rain Sensor in Cars?

The rain sensor is installed behind the central rearview mirror and consists of three key components:

Infrared Light Source: LED with wavelength of 880-940 nanometers

Photodiode Receiver: Detects light reflection from the glass surface

Signal Processing Unit: Analyzes data at a rate of 100 samples/second

The most important capability of the rain and light sensor is its ability to detect raindrops as small as 0.5 millimeters.

How Does a Rain Sensor Work?

The rain sensor operates in four stages:

Emission of light pulses to the external glass surface

Measurement of reflection coefficient with photodiode

Calculation of precipitation intensity based on reflection changes

Sending commands to ECU for wiper speed adjustment

The rain sensor system can distinguish between rain, snow, and water spray from other vehicles.

Benefits of Rain Sensors

Key advantages of rain sensors in cars include:

40% reduction in accident probability during rainy conditions

Automatic wiper speed adjustment from 1 to 6 levels

15% savings in windshield washer fluid consumption

Increased lifespan of wiper blades

Rain Sensor Construction

Rain sensor construction is based on advanced optical and electronic principles. The sensor consists of a light-emitting diode (LED) for projecting infrared light onto the windshield surface and an optical sensor for measuring the amount of reflected light.

Under normal, dry conditions, infrared light is completely reflected from the glass surface. However, when water droplets are present, the light becomes scattered and the amount of reflected light decreases.

These changes are detected by the optical sensor and converted into electronic signals. These signals are then sent to the vehicle's Electronic Control Unit (ECU), which issues commands to activate the wipers.

Modern rain sensors are constructed from these materials:

Lens: Polycarbonate with anti-reflective coating

PCB: Printed circuit fiber with gold plating

Optical Adhesive: UV-Curable epoxy with refractive index of 1.52

Housing: ABS with IP69K protection rating

Rain Sensor Price

The cost of a rain sensor depends on various factors:

Number of optical channels (1 to 3 channels)

Operating temperature range (typically -40 to +85°C)

CAN Bus compatibility

Manufacturer brand (Bosch vs. Valeo)

The current price range for car rain sensors in the Iranian market in 2024 is between 1.2 to 5 million tomans.

Rain Sensor Installation

To install a car rain sensor, the installation location on the windshield is first determined, usually behind the center mirror. The glass surface in this area is then completely cleaned and dried to ensure proper sensor adhesion.

The rain sensor, which includes an electronic module and an optical gel layer, is attached to the glass using special adhesive. After installation, the sensor cables are connected to the vehicle's electronic system, and necessary software settings are performed through diagnostic equipment to properly synchronize the sensor with the wiper systems.

Finally, the sensor's performance is tested under various weather conditions to ensure its proper operation.

Rain Sensor Repair

Rain sensor repair typically involves checking and fixing problems related to its optical and electronic components. If the sensor doesn't work properly, electrical connections and related cables should first be examined.

Additionally, the windshield surface at the sensor installation location must be cleaned of any contamination and scratches. If there are problems with optical components, such as LED or optical sensor, replacement of these parts by experienced specialists is recommended.

In some cases, reprogramming the sensor software or vehicle ECU can resolve operational issues.

Rain Sensor: Integration of Optics and Electronics for Safety

Modern rain sensors with 99% accuracy and 50-millisecond response time have created new standards in active safety systems. Development of this technology is moving toward integration with more advanced systems such as fog detection and automatic headlight adjustment.

Proper maintenance, including periodic lens cleaning and connection inspection, can extend the system's useful life up to 10 years.

Source: http://galaxyturbo.co/blog/car-accessories/what-is-rain-sensor/

0 notes

Text

Insulink: Leading the Way as India's Best ESD Trays Manufacturer

In today’s high-tech world, where electronic components have become more compact and sensitive, protection against electrostatic discharge (ESD) is no longer optional—it’s essential. If your business involves the production, handling, or shipment of electronic devices, investing in high-quality ESD trays is a critical step to ensure product integrity. This is where Insulink steps in as one of the most trusted and advanced ESD trays manufacturers in India.

What Makes ESD Trays So Important?

ESD (Electrostatic Discharge) is a silent threat. A tiny spark, invisible to the eye, can destroy or degrade sensitive components such as microchips, circuit boards, and sensors. ESD trays help mitigate this risk by providing a secure, static-free environment for transportation and storage.

These trays are a must in industries such as:

Electronics manufacturing

Defense and aerospace

Medical technology

Semiconductor production

Automotive electronics

Insulink – Setting New Standards in ESD Tray Manufacturing

With years of manufacturing expertise and a customer-first approach, Insulink has established itself as a pioneer in anti-static solutions in India. The company is renowned for producing durable, customizable, and cost-effective ESD trays that meet the highest industry standards.

🛠️ Product Range at a Glance

Insulink offers a wide spectrum of ESD tray solutions including:

Conductive Trays – Designed for superior static protection

Anti-Static Stackable Trays – Great for space-saving and organized storage

Vacuum-Formed ESD Trays – Lightweight and customizable

Injection-Molded Trays – Known for strength and reusability

Custom Molded Trays – Tailored to your product specifications

Each product is engineered to offer maximum protection and efficiency.

🎯 Why Choose Insulink?

Here are the top reasons why Insulink stands out as a premier ESD trays manufacturer:

✅ Tailor-Made Designs

No two components are alike. That’s why Insulink offers bespoke tray solutions that are designed to precisely fit your parts, minimizing movement and reducing the risk of ESD damage.

✅ Top-Grade Materials

All ESD trays are made from premium-quality static-dissipative or conductive materials like ABS, PETG, and HIPS—ensuring both durability and safety.

✅ ESD Compliance

Insulink’s trays comply with international ESD protection standards, helping you maintain a safe environment throughout your supply chain and production floor.

✅ Reusable & Eco-Friendly

Built to last, Insulink trays are not only cost-effective in the long run but also recyclable, promoting a sustainable approach to industrial packaging.

🧪 Quality That Speaks for Itself

Every tray manufactured at Insulink undergoes stringent quality checks—from material testing to surface resistance measurement—to ensure optimal performance. With a robust quality control process, the company delivers consistently reliable solutions across industries.

🌍 Serving Diverse Industries

Insulink proudly caters to:

Consumer Electronics: Safe transport and handling of phones, laptops, PCBs, and more

Automotive: Protection for embedded electronic systems and chips

Medical Devices: For safely handling delicate diagnostic and monitoring equipment

Aerospace & Defense: High-precision packaging for mission-critical parts

No matter the size or scope of your requirement, Insulink delivers with precision and professionalism.

💼 Partner with the Experts

Whether you need a bulk order for mass production or a specialized solution for a high-value component, Insulink’s team of engineers and consultants are always ready to assist. Their end-to-end support—from design consultation to after-sales service—sets them apart from typical manufacturers.

📞 Get in Touch Today

Secure your electronic components with trusted anti-static protection from India’s top ESD trays manufacturer. Request a quote, explore custom designs, or simply talk to a product expert today.

📱 Phone: +91 92052 74027 🌐 Website: www.insulink.co.in

🏁 Final Thoughts

In a world where electronics are becoming increasingly complex and compact, static protection is a necessity—not a luxury. With its deep industry knowledge, innovative product range, and unwavering commitment to quality, Insulink is not just a manufacturer; it’s a long-term partner in your operational success.

Choose Insulink for reliable, efficient, and customized ESD tray solutions that truly make a difference.

0 notes

Text

Protect Your Workstations with a High-Quality ESD Mat in India

In the electronics industry, static electricity is a silent killer. It can damage sensitive electronic components, cause data corruption, and even pose fire hazards. That’s why using an ESD mat in India has become an essential practice in every electronics manufacturing and repair environment. At Ascomp Inc., we provide premium quality ESD mats that offer optimal protection, durability, and value for your investment.

An ESD (Electrostatic Discharge) mat is designed to safely ground static electricity before it can damage electronics or disrupt operations. Whether you're setting up an ESD-safe workstation in a factory, lab, or repair center, our mats provide the first line of defense against static build-up.

What Is an ESD Mat?

An ESD mat in India is a static-dissipative surface made from conductive materials that prevent electrostatic discharge. It works by safely channeling static charges away from components and operators to a grounding point. ESD mats are typically used on workbenches, floors, or shelves where electronics are handled, tested, or assembled.

Ascomp Inc.’s ESD mats are compliant with international standards and help organizations maintain a static-free work environment, ensuring product reliability and workplace safety.

Key Features of Ascomp Inc. ESD Mats

Multi-Layer Construction: Our mats come with dual or triple-layer structures combining anti-static and conductive materials.

Durable Material: Resistant to heat, chemicals, and abrasions, making them ideal for harsh industrial use.

Easy to Clean: Smooth, non-slip surface that is easy to maintain and long-lasting.

Grounding Kit Included: Each mat comes with a grounding wire and wrist strap to ensure complete protection.

Custom Sizes Available: Choose from standard sizes or request a custom cut to fit your specific workspace.

Applications of ESD Mat in India

The need for an ESD mat in India is rising rapidly across various sectors such as:

Electronics Manufacturing: For PCBs, semiconductors, and component assembly.

Service Centers and Labs: Protects components during diagnostics and repair.

Medical Device Assembly: Ensures static-safe assembly of sensitive equipment.

Defense and Aerospace: Protects mission-critical electronics from ESD.

Educational Institutions: Teaching ESD-safe handling in labs and workshops.

Why Choose Ascomp Inc.?

High Quality: We source premium materials and follow strict quality control.

Competitive Pricing: Our ESD mats are affordable without compromising performance.

Bulk Availability: Ready stock for bulk orders and fast shipping across India.

Expert Guidance: We help you choose the right mat type and size based on your operations.

After-Sales Support: Our team is always ready to assist with setup and maintenance.

#ESDMatIndia#AscompInc#StaticProtection#ElectronicsSafety#AntiStaticMat#ElectronicsManufacturing#LabSafety#WorkstationSetup#IndustrialMats#StaticControl

0 notes

Text

Trusted Laminar Airflow Manufacturers in India: Everything You Need to Know

In environments in which cleanliness is essential, laminar airflow structures make certain precision, protection, and contamination manipulate. Whether it’s a pharmaceutical cleanroom, a clinical facility, or an electronics lab, these structures offer a controlled, sterile quarter through channeling purified air in a uniform route. As industries demand greater stringent hygiene requirements, the role of experienced laminar airflow manufacturers turns into critical.

This complete guide explores how those systems work, their blessings, and the top manufacturers in India supplying excessive-performance laminar airflow solutions.

What is Laminar Airflow?

Laminar airflow is a way of controlling the motion of air inside a restrained workspace. Unlike turbulent airflow, laminar waft moves air in a clean, steady direction — either vertically or horizontally — via excessive-performance filters like HEPA or ULPA.

Vertical Flow Units: Push filtered air from the pinnacle down to the work surface, perfect for sterile packages.

Horizontal Flow Units: Deliver air from the again of the unit in the direction of the operator, decreasing overhead infection.

By making sure that easy air flows in a streamlined sample, those structures considerably lessen airborne contaminants and defend important approaches.

Importance of Laminar Flow in Sensitive Workspaces

Laminar airflow devices help protect product integrity and prevent contamination-related losses. These systems are normally utilized in:

Pharmaceutical manufacturing

Biotechnology labs

Semiconductor fabrication

Hospitals and working theaters

Food and beverage nice manipulate

Key benefits encompass:

Clean air environment for touchy responsibilities

Improved compliance with GMP, ISO, and FDA requirements

Lower threat of microbial or particulate contamination

Increased productivity with the aid of retaining a stable workspace

Core Features of Laminar Airflow Systems

When evaluating systems from main laminar airflow manufacturers, recollect the following preferred capabilities:

HEPA or ULPA filters that dispose of up to ninety nine.999% of debris

Non-turbulent airflow with steady speed

Silent operation to reduce noise in laboratory or clinical settings

Durable metallic or powder-coated production

Integrated UV lighting fixtures for floor sterilization

Custom sizes and mobility options

Who Uses Laminar Airflow Systems?

These systems are integral in sectors where even a hint of infection can compromise safety or effects. Some main industries encompass:

Healthcare: Used for IV preparation, surgical procedures, and pathology labs

Pharmaceuticals: Ensuring sterile environments all through drug components

Electronics: Protecting microchips and PCBs from dirt and static

Research & Development: Used in microbiology, tissue lifestyle, and genetic research

Food Tech: For keeping clean zones in the course of packaging or ingredient handling

Top Laminar Airflow Manufacturers in India

India hosts numerous reputable agencies generating world-class laminar go with the flow devices for numerous applications. Below are the main laminar airflow producers recognized for high-quality, customization, and compliance.

1. Clean Air India

Clean Air India is a nicely-mounted manufacturer of cleanroom system. Their variety includes both vertical and horizontal laminar float benches, designed to meet ISO Class five cleanliness tiers. Their structures are extensively utilized in labs, pharma production, and IVF centers.

2. Aeromech Equipments Pvt. Ltd.

Aeromech is thought for its modern easy air structures, offering ceiling-hooked up, vertical, and modular laminar waft systems. Their designs are built with excessive-grade stainless steel and incorporate capabilities like silent blowers and virtual airflow video display units.

3. Microflow Devices India Pvt. Ltd.

Microflow Devices is every other key player, supplying a number LAF systems that comply with international cleanroom requirements. They concentrate on products for biotechnology, medical research, and cleanroom-primarily based production.

4. TechAir India

TechAir has built a popularity for precision-constructed laminar airflow cabinets with person-pleasant controls and robust overall performance. Their gadgets come with HEPA filters, UV germicidal lighting fixtures, and sturdy systems tailored to various industries.

5. Pure Air Systems

Focused on IVF labs, biotech, and lab-scale easy environments, Pure Air Systems offers horizontal laminar airflow benches with superior airflow manage and compact designs. Their systems include pre-filters, quiet vehicles, and energy-saving options.

How to Choose the Right Laminar Airflow Manufacturer

Not all systems are constructed alike. Here’s how to pick the first-rate provider on your application:

Certification & Standards: Ensure merchandise meet ISO 14644-1, GMP, or FDA requirements.

Customization: Choose producers that offer size, airflow, and fabric customization.

Installation & Service: Look for complete guide, which includes installation, AMC, and guarantee.

Reputation: Read case studies or purchaser evaluations to assess the business enterprise’s track report.

Why Indian Laminar Airflow Manufacturers Stand Out

India has come to be a center for remarkable cleanroom technology, supplying value-effective solutions with worldwide compliance. Top laminar airflow manufacturers in India have:

In-house R&D abilties

Global export certifications

Flexible design and fabrication services

Access to advanced filtration and automation technologies

With a focus on innovation and affordability, Indian providers are meeting international call for for dependable, excessive-performance cleanroom device.

Final Thoughts

In managed environments, a well-designed laminar airflow unit is extra than simply an asset — it’s a need. Selecting the proper gadget and provider immediately impacts manner integrity, safety, and compliance. The main laminar airflow producers in India offer now not best superior fine however additionally the power and help required with the aid of today’s dynamic industries.

Whether you're setting up a brand new lab, increasing a production facility, or upgrading present cleanroom infrastructure, partnering with a depended on Indian manufacturer ensures reliability, affordability, and lengthy-term value.

0 notes

Text

Understanding MOVs: The Unsung Heroes of Surge Protection

The global Metal Oxide Varistors (MOV) market was valued at US$ 12.29 billion in 2024. Driven by the growing demand for robust surge protection across consumer electronics, industrial automation, and the burgeoning electric vehicle (EV) sector, the market is projected to expand at a CAGR of 10.61% from 2025 to 2035. By the end of 2035, the industry is expected to reach US$ 38.48 billion, reflecting a nearly threefold increase in market size over the forecast period.

MOVs, primarily composed of zinc oxide (ZnO) grains enhanced with metal oxides such as bismuth, cobalt, and manganese, function as voltage-dependent resistors. When voltages surpass their clamping thresholds, MOVs transition to a low-resistance state, diverting and absorbing high-energy transients to protect sensitive electronic components.

Market Drivers & Trends

Electronic Protection Demand: The proliferation of smartphones, laptops, IoT devices, and smart home appliances has intensified the need for surge protection. MOVs ensure operational reliability by guarding against voltage spikes, overloads, and short circuits, particularly in miniaturized circuit designs.

Industrial Automation & Industry 4.0: As factories deploy advanced robotics, control systems, and AI-driven analytics, safeguarding critical equipment from electrical disturbances is paramount. MOVs help minimize downtime and reduce maintenance costs in highly automated environments.

EV and Charging Infrastructure: Adoption of EVs continues to accelerate worldwide. MOVs play a vital role in protecting battery management systems (BMS) and charging stations from transient overvoltages, thereby enhancing vehicle safety and charging reliability.

Smart Grids & Renewable Energy: Integration of distributed energy resources and renewable power generators exposes grids to dynamic voltage fluctuations. MOVs provide essential transient suppression, supporting grid stability and protecting power electronics.

Latest Market Trends

R&D Investment: Leading manufacturers are channeling resources into developing MOVs with lower clamping voltages, higher surge handling capacities, and miniaturized footprints.

Customizable Solutions: Modular and surface-mount MOV variants are gaining traction, allowing OEMs to tailor surge protection to specific application requirements across consumer, automotive, and industrial segments.

Diversification of Applications: Beyond traditional roles, MOVs are finding use in healthcare devices, aerospace systems, and renewable energy inverters, unlocking new growth avenues.

Key Players and Industry Leaders

Bourns, Inc.

CEDICOM ELECTRONICS

Dongguan Tianrui Electronics Co., Ltd

Eaton Corporation PLC

Elpro International Ltd

Guangdong Uchi Electronics Co.,Ltd

INPAQ Technologies Co. Ltd

KEMET Corporation

KYOCERA AVX

Littelfuse, Inc.

Meritek Electronics Corporation

Nippon Chemi-Con Corporation

Panasonic Corporation

Synton-Tech Corporation

TDK Electronics AG

Vishay Intertechnology Inc.

Walsin Technology Corporation

Among Others

Recent Developments

July 2024: KOA Speer Electronics launched the NV73S series multilayer MOV capable of handling surge currents up to 6,000 A—five times the capacity of prior models—while retaining a compact form factor suitable for high-density PCB layouts.

January 2024: Littelfuse, Inc. introduced the SM10 Varistor Series, engineered for superior transient suppression in automotive electronics and EV charging systems, further cementing its position in the automotive MOV segment.

Download to explore critical insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=15548

Market Opportunities

Healthcare & Medical Devices: As medical imaging and telemedicine devices proliferate, demand for reliable surge protection in sensitive electronics is set to rise.

Aerospace & Defense: Avionics systems and ground support equipment require high-reliability MOVs capable of enduring harsh operational environments.

Renewable Energy Inverters: Solar and wind installations rely on power inverters, which benefit from advanced surge suppression to protect against grid disturbances and lightning strikes.

Future Outlook

Analyst projections indicate sustained double-digit growth through 2035, driven by:

Rapid EV adoption and expansion of global charging infrastructure.

Continued evolution of consumer electronics toward higher performance and miniaturization.

Growth of smart grid initiatives and renewable energy integration.

Market Segmentation

By Type

Single Chip (76.1% share in 2024)

Array

By Size

0402, 0603, 0805, 1206, Others

By Mounting Type

Surface Mount Technology (SMT)

Through Hole

By Voltage Range

18 V–50 V, 51 V–100 V, 101 V–200 V, 200 V–300 V, 301 V–400 V, Above 400 V

By Application

Automotive (Infotainment, Lighting, BMS, EV Chargers, ABS)

Consumer Electronics (Smartphones, Laptops, Home Appliances)

IT & Telecommunications (Networking, Telecom Towers, Power Supply)

Aerospace & Defense

Industrial (Motor Drives, Control Panels, Robotics)

Healthcare

Regional Insights

Asia Pacific leads the market with US$ 5.83 billion in 2024, driven by robust electronics manufacturing in China, Japan, and emerging hubs in India and Southeast Asia. Government initiatives such as China’s "Made in China 2025" and India’s "Atmanirbhar Bharat" are promoting local MOV production.

North America and Europe follow, where strong automotive and telecommunications sectors support steady demand. Latin America, Middle East & Africa are emerging markets, with infrastructure modernization and renewable energy projects creating growth prospects.

Why Buy This Report?

Comprehensive Analysis: Detailed market size, share, and forecast data across segments and regions.

Strategic Insights: In-depth coverage of drivers, restraints, opportunities, and Porter’s Five Forces.

Competitive Benchmarking: Profiles of leading players, their product portfolios, strategies, and recent developments.

Actionable Recommendations: Guidance on investment priorities, technology trends, and go-to-market strategies.

Ready-to-Use Format: Delivered in PDF and Excel formats for seamless integration into presentations and planning tools.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

pcb fuse types

PCB fuse types include cartridge, surface mount, resettable (PTC), and thermal fuses, each offering circuit protection for different applications. These fuses safeguard electronic components from overcurrent and short circuits. Their selection depends on voltage rating, current rating, and form factor. Surface-mount fuses are ideal for compact designs, while resettable fuses automatically restore function. Understanding these fuse types ensures optimal safety and reliability in PCB designs.

pcb fuse types

0 notes

Text

Failure Mode Analysis of Metal Push Button Switches and Field Case Reviews

Introduction

Metal push button switches, despite their robust design, are still subject to various failure modes in practical applications. These failures not only reduce product reliability but also lead to maintenance costs and safety issues in customer sites. This article analyzes common failure modes of metal push button switches—such as contact arcing, button jamming, LED failure, and seal degradation—and reviews real customer cases to provide targeted design optimization suggestions.

1. Common Failure Modes and Root Cause Analysis

1.1 Contact Arcing and Wear

Phenomenon: After long-term use, switch contact resistance increases, even resulting in failure to conduct.

Cause:

High inrush current without arc suppression.

Inadequate contact material (e.g., pure copper without plating).

High operating voltage or inductive load.

Optimization:

Use silver-nickel or gold-plated contacts for high current reliability.

Add arc suppression components (RC snubber or MOV).

Reinforce spring force to ensure contact pressure.

1.2 Button Jamming

Phenomenon: The button becomes stuck in the pressed position and does not rebound.

Cause:

Debris ingress due to poor sealing.

Deformation of spring plate.

Excessive wear on plastic guide sleeve.

Optimization:

Use dustproof and waterproof structures (e.g., IP67 design).

Reinforce spring plate material and shape (e.g., double-curvature dome).

Use self-lubricating plastic or metal guide sleeves.

1.3 LED or Light Ring Failure

Phenomenon: LED does not light up or flickers after a period of use.

Cause:

LED solder joint fracture due to vibration.

Electrostatic breakdown or surge.

Moisture ingress leading to corrosion.

Optimization:

Use flexible PCB and reinforcement glue for LED solder joints.

Add TVS protection to the LED circuit.

Improve potting and waterproof design of light ring.

1.4 Seal Failure (IP Degradation)

Phenomenon: Moisture ingress, fogging inside switch, corrosion.

Cause:

Poor sealing design (e.g., thin O-ring, low contact pressure).

Material aging (e.g., silicone rubber hardening).

Incorrect installation causing compression loss.

Optimization:

Use high-performance fluorosilicone O-rings.

Design mechanical structures that maintain sealing pressure under thermal expansion.

Add secondary sealing like glue filling or ultrasonic welding.

2. Case Studies from Customer Sites

Case A: Food Processing Machine Button Fails after 3 Months

Problem: Button became sticky and unreliable; LED flickered.

Analysis: High humidity and oil vapor caused internal corrosion and solder failure.

Solution: Upgraded to IP68 switch with epoxy-sealed LED and food-grade silicone sealing ring. After redesign, no failure in 6-month follow-up.

Case B: Elevator Call Panel Button Lost Tactile Feedback

Problem: Users reported button was soft and unresponsive.

Analysis: Long-term mechanical fatigue led to spring plate deformation.

Solution: Changed to double-spring structure (coil + dome), added fatigue life test in production. Mechanical cycles improved from 300,000 to 1.2 million.

Case C: Industrial Panel with Intermittent Contact

Problem: Switch signal occasionally failed.

Analysis: Contact surface oxidation due to prolonged storage and lack of current load.

Solution: Switched to gold-plated contacts, added low-current self-cleaning pulse during power-on to ensure reliability.

3. Proactive Design Recommendations

Reliability testing: Include high/low temperature cycling, salt spray, vibration test.

Redundancy: In critical environments, use redundant contacts or signal confirmation circuits.

Installation training: Guide customers to use correct torque and mounting methods to avoid sealing damage.

Conclusion

By thoroughly understanding the failure modes of metal push button switches and drawing lessons from field failures, we can implement targeted design optimizations to improve product reliability. This not only enhances user satisfaction but also reduces after-sales maintenance costs, building long-term trust with B2B clients.

en.dghongju.com

0 notes

Text

Surface Finishes for Multilayer PCBs and Their Impact

Multilayer PCBs are essential in modern electronic systems where high-density routing, signal integrity, and reliability are critical. While inner layers are encapsulated during lamination, the outer layers of a multilayer PCB are exposed for component assembly — making surface finish a key factor in performance and long-term reliability.

Surface finish not only protects the exposed copper but also directly influences soldering quality, component compatibility, and board lifespan, especially in complex multilayer designs.

Why Surface Finish Is Critical in Multilayer PCBs

In a multilayer PCB, especially those with 6, 8, or more layers, outer-layer copper traces and pads are often extremely dense and designed for fine-pitch SMT components such as BGAs, QFNs, or high-pin-count connectors.

A good surface finish must:

Ensure consistent solderability across dense pad arrays

Maintain flatness to support reliable assembly of micro-components

Provide oxidation protection during storage and processing

Be compatible with lead-free reflow profiles

Handle multiple reflow cycles without degradation

Multilayer PCBs often undergo more complex assembly and higher thermal stress, so the surface finish must meet higher standards than simple single- or double-layer boards.

Common Surface Finishes for Multilayer PCBs

1. ENIG (Electroless Nickel Immersion Gold)

The most popular surface finish for multilayer boards, especially in high-density and high-reliability applications.

Provides excellent flatness for fine-pitch components (e.g. BGAs)

Stable during multiple reflow cycles

Compatible with high-speed signals due to smooth surface

Long shelf life, ideal for staged assembly

Slightly higher cost but justified by performance

Widely used in servers, telecom equipment, and aerospace PCBs.

2. OSP (Organic Solderability Preservative)

Preferred for cost-sensitive multilayer boards with fine-pitch components.

Flat surface suitable for automated SMT

Environmentally friendly and lead-free

Lower cost than ENIG

Limited shelf life, requires controlled handling

Not ideal for boards requiring multiple assembly cycles

Often used in consumer electronics and automotive applications.

3. Immersion Silver

Used for multilayer boards requiring high signal integrity or RF performance.

Low surface roughness ensures good impedance control

Suitable for high-frequency multilayer PCBs

Sensitive to tarnishing and handling

Better electrical performance than ENIG in certain designs

Good choice for communication equipment and high-speed digital boards.

4. Lead-Free HASL

Sometimes used in low-cost multilayer boards, but not recommended for very dense designs.

Cost-effective, robust finish

Less flat surface can cause soldering issues on fine-pitch pads

May lead to solder bridging in dense layouts

Acceptable for through-hole or mixed technology boards

Usually applied to industrial control or power-related multilayer PCBs.

Surface Finish Considerations in Multilayer PCB Design

When choosing a surface finish for multilayer PCBs, consider:

Assembly method (SMT vs through-hole, single vs multiple reflows)

Pad density and component type (especially fine-pitch packages)

Signal performance needs (RF, impedance control, etc.)

Environmental factors (RoHS, storage conditions)

Budget vs reliability trade-offs

In many high-reliability or mission-critical multilayer designs, ENIG or Immersion Silver is preferred despite higher cost, due to their consistent performance.

Final Thoughts

The outer layers of a multilayer PCB may seem like a small part of a complex system, but the choice of surface finish can make or break the final product. Whether it's ensuring reliable solder joints for 0.4 mm pitch BGAs, withstanding multiple reflow cycles, or maintaining performance in high-frequency circuits — the right surface finish is critical.

Understanding the relationship between board complexity, material stack-up, and surface treatment is essential for delivering a reliable, high-performance multilayer PCB.

0 notes

Text

Insulink – Leading ESD Trays Manufacturer in India

In today’s rapidly advancing electronics industry, electrostatic discharge (ESD) is a silent destroyer. Sensitive components, circuit boards, and microchips can be permanently damaged by the slightest static charge. That’s why using high-quality ESD-safe packaging solutions is not just recommended—it’s essential.

When it comes to reliable and durable ESD trays, Insulink is a name trusted across industries for manufacturing high-performance, customizable, and cost-effective anti-static tray solutions in India.

Why ESD Trays Matter

ESD trays, also known as anti-static trays, are designed to safely store, handle, and transport static-sensitive electronic components. These trays are made from conductive or dissipative materials that prevent the buildup of static electricity and shield components from ESD damage.

Industries like:

Electronics Manufacturing

Semiconductors

Aerospace

Automotive

Telecommunications

Medical Devices

...all rely on ESD trays to ensure product integrity during assembly, storage, or shipping.

Without proper ESD protection, even a small spark can lead to:

Product failure

Increased rejection rates

Costly delays in production

Safety risks in critical applications

This is where Insulink steps in with cutting-edge ESD packaging solutions tailored to your needs.

Why Choose Insulink as Your ESD Tray Manufacturer?

At Insulink, we specialize in the design, development, and manufacturing of premium ESD trays that meet international quality standards. Here's why businesses across India trust us:

✅ 1. High-Quality Conductive & Anti-Static Materials

Our trays are made from conductive polymers and ESD-safe plastics, ensuring long-lasting electrostatic protection. Whether you need:

Thermoformed conductive trays

Injection-molded trays

Fabricated ESD-safe bins or pallets

...our materials deliver excellent surface resistance, durability, and environmental stability.

✅ 2. Custom-Made Tray Designs

We understand that each product has unique dimensions and sensitivity levels. That’s why Insulink offers fully customizable ESD tray solutions. You can specify:

Cavity shapes and sizes

Tray thickness and strength

Number of compartments

Stackability and ergonomic design

With our in-house design and tooling facilities, we can develop the exact tray configuration your operations demand.

✅ 3. Precision Manufacturing & Quality Assurance

Our manufacturing process is powered by:

Advanced machinery

Skilled engineers

Strict quality control systems

We follow ISO-compliant protocols and conduct surface resistivity testing to ensure every tray we manufacture meets the highest industry standards. You get precision, consistency, and reliability with every order.

✅ 4. Industries We Serve

Insulink has built long-term relationships with some of the biggest names in:

Electronics & PCB assembly

Automotive components manufacturing

Defense and aerospace supply chains

Consumer electronics and LED manufacturers

Whether you're a startup or a multinational, we have the scale and expertise to support your ESD packaging needs.

✅ 5. Sustainable & Reusable Solutions

We’re committed to eco-friendly manufacturing. Our ESD trays are designed to be:

Reusable and recyclable

Lightweight, reducing logistics costs

Durable enough to withstand repeated handling and stacking

With Insulink, you not only protect your products but also contribute to a greener supply chain.

Types of ESD Trays Offered by Insulink

We provide a wide range of anti-static trays, including:

🔹 Thermoformed ESD Trays 🔹 Conductive Component Trays 🔹 Custom Molded ESD Trays 🔹 PCB Handling Trays 🔹 Stackable ESD Workstation Trays 🔹 Injection Molded Storage Trays

From handling tiny microchips to larger PCBs, our tray solutions are designed for maximum efficiency and safety.

Customer Support That Goes the Extra Mile

Insulink is not just a manufacturer—we're a partner in your success. Our team provides:

Technical consultation

Rapid prototyping

Volume production capabilities

Nationwide delivery

We pride ourselves on quick turnaround times, competitive pricing, and exceptional after-sales support.

Hear from Our Clients

“We switched to Insulink’s ESD trays last year, and our rejection rate due to ESD damage dropped significantly. Their team is professional, and their trays are top-notch.” – R&D Head, Leading Electronics Firm – Noida

“Customization and quality were our top priorities. Insulink delivered exactly what we needed for our automotive component packaging.” – Procurement Manager, Automotive Supplier – Pune

Let’s Build Static-Safe Solutions Together

Whether you're upgrading your current packaging system or launching a new product line, Insulink is ready to be your trusted ESD tray manufacturing partner. Let us help you improve safety, reduce component damage, and optimize your handling process.

📞 Get in touch with us today:

📱 +91 92052 74027 🌐 Visit: www.insulink.co.in

Final Thoughts

Static electricity may be invisible—but its damage is very real. Don’t let ESD risks derail your quality and production goals. Choose Insulink, the best ESD trays manufacturer in India, and ensure your products stay safe, protected, and ready for the world.

0 notes

Text

Metal Surface Finish: Key Techniques for Protection and Aesthetic Enhancement

Introduction

A metal surface finish is essential for enhancing durability, performance, and appearance in metal components. Applied across industries such as aerospace, automotive, electronics, and medical equipment, surface finishing improves resistance against corrosion, wear, and environmental damage while achieving a polished or functional aesthetic.

Types of Metal Surface Finishes

1. Mechanical Finishing

Processes such as grinding, polishing, and sandblasting create a smoother, refined surface texture.

2. Chemical Treatment

Includes anodizing, passivation, and chemical etching, improving corrosion resistance and enhancing metal integrity.

3. Coatings & Plating

Techniques like electroplating, powder coating, and painting provide protective and decorative layers.

4. Thermal Treatments

Processes such as heat treatment and thermal spray coatings reinforce material strength and wear resistance.

5. Conversion Coatings

Chemical treatments such as phosphating and chromate conversion improve adhesion and surface protection.

Benefits of Metal Surface Finishing

Corrosion Resistance: Shields components from oxidation and environmental wear.

Enhanced Durability: Improves hardness and abrasion resistance for industrial applications.

Aesthetic Customization: Achieves polished, matte, or textured finishes for visual appeal.

Improved Electrical Conductivity: Essential for electronics and semiconductor components.

Eco-Friendly Protection: Reduces degradation caused by moisture, chemicals, and extreme temperatures.

Industries Utilizing Metal Surface Finishing

1. Automotive & Aerospace

Applied to vehicle bodies, engine components, aircraft structures, and precision-machined parts.

2. Electronics & Semiconductor Manufacturing

Used for PCB coatings, microchip protection, and conductive layers in circuits.

3. Medical & Healthcare Equipment

Essential for sterilization-resistant instruments, implants, and diagnostic devices.

4. Industrial Machinery & Tools

Enhances mechanical components, manufacturing tools, and high-stress industrial equipment.

Latest Innovations in Metal Surface Finishing

Nano-Coatings providing superior resistance and longer lifespan.

Environmentally-Friendly Finishing Solutions reducing hazardous waste.

Automated Surface Treatment Technologies improving efficiency and consistency.

Conclusion

Selecting the ideal metal surface finish optimizes functionality, durability, and aesthetic value across diverse applications. As finishing technologies evolve, industries continue to benefit from advanced solutions that improve product quality and longevity.

0 notes

Text

PCB Manufacturing: A Comprehensive Guide to Printed Circuit Board Production

Introduction to PCB Manufacturing

PCB manufacturing is the process of creating printed circuit boards, which are essential components in nearly all modern electronic devices. From smartphones to industrial machinery, PCBs provide the foundation for electrical connections and component mounting. This guide explores the PCB manufacturing process, materials, technologies, and applications.

The PCB Manufacturing Process

1. Design and Schematic Creation

Before production begins, engineers design the PCB using specialized software like Altium Designer, KiCad, or Eagle. The design includes:

Schematic diagrams (circuit connections)

Component placement

Trace routing (copper pathways)

Layer stack-up (for multi-layer PCBs)

Once the design is finalized, a Gerber file (standard PCB manufacturing file) is generated for fabrication.

2. Material Selection

The base material of a PCB is typically FR-4, a flame-resistant fiberglass epoxy laminate. Other materials include:

Flexible PCBs: Made from polyimide for bendable circuits.

High-frequency PCBs: Use Rogers material for RF applications.

Metal-core PCBs: Aluminum or copper for heat dissipation.

3. Printing the Circuit Pattern

The PCB design is transferred onto the board using one of these methods:

Photolithography: A UV-sensitive photoresist is applied, exposed to UV light, and developed to create the circuit pattern.

Direct Imaging: A laser directly etches the pattern onto the PCB.

4. Etching the Copper Layers

After the circuit pattern is printed, the unwanted copper is removed through chemical etching. The remaining copper forms the conductive traces.

5. Drilling Holes for Components

Precision CNC machines drill holes for through-hole components and vias (connections between layers).

6. Plating and Copper Deposition

The drilled holes are electroplated with copper to ensure conductivity between layers.

7. Solder Mask Application

A solder mask (usually green) is applied to protect the copper traces and prevent short circuits. Openings are left for soldering components.

8. Silkscreen Printing

Text, logos, and component labels are printed on the PCB using silkscreen ink for easy assembly and identification.

9. Surface Finish Application

A surface finish is applied to protect exposed copper and improve solderability. Common finishes include:

HASL (Hot Air Solder Leveling)

ENIG (Electroless Nickel Immersion Gold)

OSP (Organic Solderability Preservative)

10. Electrical Testing and Quality Control

Each PCB undergoes automated optical inspection (AOI) and electrical testing to ensure functionality. Defective boards are rejected.

Types of PCBs in Manufacturing

1. Single-Layer PCBs

Simplest and most cost-effective.

Used in basic electronics like calculators.

2. Double-Layer PCBs

Conductors on both sides.

Common in consumer electronics.

3. Multi-Layer PCBs

4+ layers for complex circuits (e.g., motherboards).

Requires precise PCB manufacturing techniques.

4. Flexible PCBs

Used in wearables and medical devices.

Made from bendable materials.

5. Rigid-Flex PCBs

Combines rigid and flexible sections.

Ideal for aerospace and military applications.

Advanced PCB Manufacturing Technologies

1. High-Density Interconnect (HDI) PCBs

Features microvias and finer traces.

Used in smartphones and compact devices.

2. Embedded Components

Passive components (resistors, capacitors) are embedded within the PCB.

Reduces size and improves performance.

3. 3D Printed Electronics

Emerging technology for rapid prototyping.

Combines additive manufacturing with conductive inks.

Applications of PCB Manufacturing

PCBs are used in nearly every industry, including:

Consumer Electronics (Smartphones, Laptops)

Automotive (ECUs, Infotainment Systems)

Medical Devices (Pacemakers, Imaging Systems)

Aerospace & Defense (Avionics, Radar Systems)

Industrial Automation (Robotics, Control Systems)

Challenges in PCB Manufacturing

Miniaturization: Shrinking component sizes demand precision.

High-Speed Signal Integrity: Ensuring minimal interference.