#pushbutton

Explore tagged Tumblr posts

Text

Pushbutton Spring 2019

#runway#runway fashion#fashion#fashion week#rtw#ready to wear#alternative#alternative style#alternative fashion#pushbutton#spring 2019

13 notes

·

View notes

Text

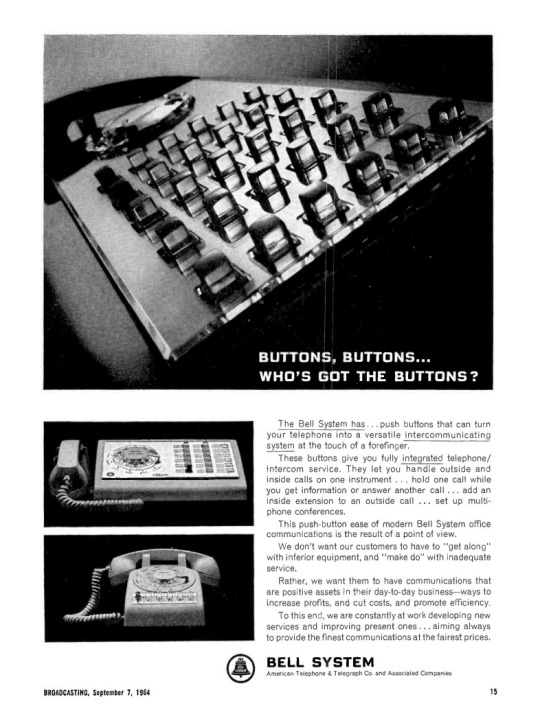

"The Bell System has push buttons that can turn your telephone into a versatile intercommunicating system at the touch of a forefinger." (1964)

#vintage#retro#advertising#vintage ad#black and white#old ad#1960s#bell system#telephone#vintage telephone#pushbutton#1960s ad

35 notes

·

View notes

Text

Pushbutton Spring 2025

#pushbutton#spring 2025#minimalism#minimal fashion#ready-to-wear#rtw 2025#fashion#style#rtw#ss25 rtw#spring rtw#rtw25#runway

9 notes

·

View notes

Text

Metal Push Button Switches: Metal shell, Dustproof and Waterproof, Tight and Durable, Exquisite Appearance, Long service life

2 notes

·

View notes

Text

Pushbutton Seoul Fall 2017

2 notes

·

View notes

Text

Wide Temperature Range Design Strategies for Pushbutton Switches: Materials and Structural Optimization from -40°C to +125°C

In modern electronic and industrial applications, pushbutton switches are increasingly required to operate reliably under extreme environmental conditions. From aerospace equipment operating at high altitudes to automotive systems exposed to cold winters and scorching summers, the ability of pushbutton switches to function stably within a temperature range of -40°C to +125°C is a critical technical requirement. This article explores in depth the design strategies of pushbutton switches for wide temperature range applications, focusing on material selection, structural adaptation, and sealing reliability, especially in addressing problems caused by thermal expansion and contraction.

1. Material Selection Strategy for Wide Temperature Ranges

The first step in achieving wide temperature resistance is choosing materials with suitable thermal properties. Key considerations include:

a. Housing Material:

The housing of pushbutton switches must maintain dimensional stability across extreme temperatures. Glass-filled thermoplastics such as PBT (polybutylene terephthalate) or PPS (polyphenylene sulfide) are commonly used due to their:

Low thermal expansion coefficient

High heat resistance

Dimensional stability at low temperatures

In certain high-reliability applications, aluminum or stainless steel enclosures are used, especially when mechanical strength and thermal resistance are both critical.

b. Actuator and Spring Materials:

Springs are typically made of stainless steel or beryllium copper (BeCu) alloys, which offer consistent elasticity and minimal mechanical fatigue even under wide thermal fluctuations.

The actuator component often uses high-performance engineering plastics or silicone rubber, ensuring flexibility at low temperatures and stability under heat.

c. Contact Materials:

Gold-plated or silver-nickel alloy contact points are preferred in wide temperature environments for their corrosion resistance and stable conductivity under thermal cycling.

2. Structural Design to Accommodate Thermal Expansion and Contraction

When the temperature changes drastically, different materials in the switch assembly may expand or contract at different rates, potentially affecting the device’s performance or integrity. Key design countermeasures include:

a. Floating Structures:

Introduce floating contact mechanisms or flexible internal structures that allow micro-movements to absorb the differential expansion between parts without compromising contact reliability.

b. Dual-Layer Shell Design:

A dual-layer structure (inner rigid core + outer flexible layer) allows the inner core to maintain structural stability while the outer layer absorbs deformation, preventing shell cracking or deformation due to thermal stress.

c. Compensation Grooves:

Incorporating compensation grooves or expansion gaps in the housing design helps absorb material displacement during extreme heat or cold, avoiding permanent deformation.

3. Sealing Reliability Under Thermal Cycling: Common Failures and Solutions

One major challenge in wide temperature applications is maintaining airtight sealing. The repeated expansion and contraction of materials under temperature cycling can lead to:

Gasket hardening and loss of elasticity

Cracking or loosening of interface bonding areas

Water or dust ingress, causing short circuits or corrosion

Case Example: Outdoor Industrial Control System

An outdoor pushbutton switch used in an industrial control box in Northern Europe experienced IP67 seal failure in winter. Investigations showed that the silicone O-ring seal lost elasticity below -30°C, creating micro-gaps where moisture later penetrated during thaw cycles.

Solutions:

Use low-temperature-resistant fluorosilicone or EPDM gaskets that maintain elasticity from -50°C to +150°C.

Employ ultrasonic welding or laser welding on enclosure joints to prevent mechanical seal failure.

Consider sealing gel or conformal coatings to supplement traditional O-rings in high-risk applications.

4. Reliability Testing and Qualification Standards

To verify wide temperature performance, manufacturers must implement comprehensive environmental testing:

Thermal Cycling Test: -40°C to +125°C, multiple cycles over 1000 hours

High-Temperature Aging: +125°C for 240–500 hours to test contact resistance and elasticity degradation

Cold Impact Test: Immediate exposure to -40°C followed by function test

Ingress Protection (IP) Test: To confirm sealing effectiveness under thermal stress

Compliance with standards such as IEC 61058, MIL-STD-202, and automotive AEC-Q200 is crucial for product qualification.

5. Future Development: Smart Temperature Compensation Designs

With IoT and smart device integration, next-generation pushbutton switches may incorporate temperature sensors or embedded micro-actuators to dynamically adjust response force or detect abnormal thermal drift, ensuring safer and smarter switch operation in extreme environments.

Conclusion

Designing pushbutton switches for operation across -40°C to +125°C demands an integrated strategy that combines advanced materials, adaptive structural design, and rigorous testing. With industries increasingly requiring reliability under harsh environments, wide-temperature pushbutton switch designs will continue to evolve toward smarter, safer, and more durable solutions.

en.dghongju.com

0 notes

Photo

Random Old Comic: Make Buttons Great Again! https://www.toyboxcomix.com/2018/01/03/make-buttons-great-again/

0 notes

Text

ootd: ITS GONNA BE A GREAT DAY BC I HAVE HAPPY99 AND PUSHBUTTON ANIME CUTIE BY MY SIDE 🙂↕️🤑⭐️🤸💖^_−☆

0 notes

Text

Imperial 35717 Pushbutton Micro Roller Switch W/3-Terminals, 125A ,15/250/480VAC | PartsFe

The Imperial 35717 Pushbutton Micro Roller Switch is a reliable replacement part for commercial kitchen equipment. Featuring 3 terminals, it is designed to handle up to 125A and supports voltage ratings of 15/250/480VAC. This durable micro switch ensures precise and consistent operation, making it essential for high-performance applications.

#Imperial35717#35717#Pushbutton#MicroRoller#Switch#Terminals#partsfe#partsfebuzz#restaurantowner#restaurantequipmentparts#kitchenequipmentparts#foodserviceparts#commercialkitchenequipmentparts#ovenparts#icemachineparts#dishwasherparts#griddleparts

0 notes

Text

youtube

Welcome to E-Switch

https://www.futureelectronics.com/m/e-switch . E-Switch offers tactile, anti-vandal, pushbutton, rocker, toggle, slide, DIP, rotary, keylock, snap action, power, illuminated switches, and more. E-Switch has been delivering quality electromechanical switches to the telecom, technology, medical, electronics, instrumentation, industrial, audio/visual, appliance, and consumer markets since 1979. https://youtu.be/PUC36XflVt8

#E-Switch#anti-vandal#pushbutton#rocker#toggle#snap action#illuminated switches#electromechanical switches#future#electronics#wt#future electronics#tech#electric#technology#instrumentation#switch#Youtube

0 notes

Text

Pushbutton Fall 2016

#runway#runway fashion#fashion#fashion week#rtw#ready to wear#alternative#alternative style#alternative fashion#pushbutton#fall 2016

10 notes

·

View notes

Text

Empowering your infrastructure with Aluminum Conductors.

#neelkanthcables#electriccable#cable#cat#electrical#energy#streetlight#power#flexiblecable#electricwire#signal#signalelectricals#light#tanzania#equipment#electricalsupply#pushbutton#vatan#cables#fire#alarm#africabless#metal#powercable#powercables#daressalaam#poles#streetlightpoles#contractor#electriccables

0 notes

Text

Buy Breter RM165R

0 notes

Text

Pushbutton Seoul Fall 2017

4 notes

·

View notes

Text

Thermal Expansion-Induced Sealing Failure in Pushbutton Switches: Causes, Case Studies, and Design Solutions

Pushbutton switches used in outdoor, automotive, and industrial settings must maintain long-term sealing integrity to ensure safety and reliability. However, one of the most common failure mechanisms under wide temperature variations is sealing failure caused by thermal expansion and contraction. This article analyzes the causes of such failures, presents real-world case studies, and discusses design strategies to prevent leakage, cracking, or loss of protection rating (IP67/IP68) due to temperature stress.

1. Understanding Thermal Expansion in Pushbutton Switches

All materials expand or contract when subjected to temperature changes. In a pushbutton switch, components made from plastics, rubber, and metals each have different coefficients of thermal expansion (CTE). This mismatch results in mechanical stress at interfaces and joints, especially during rapid thermal cycling (e.g., from -40°C to +125°C), potentially leading to:

Gaps between mating surfaces

Permanent deformation of parts

Loss of sealing pressure

Cracks in housings or sealing gaskets

2. Common Scenarios of Sealing Failure

a. Static Gasket Shrinkage:

At low temperatures, gaskets (e.g., silicone O-rings) can shrink and harden, reducing compression force and creating micro-gaps that allow water vapor ingress.

b. Material Mismatch at Interfaces:

When plastic housings are combined with metal buttons or bezels, differential expansion during heating can deform sealing interfaces or dislodge adhesive-bonded seals.

c. Repeated Stress Fatigue:

Daily thermal cycling leads to repetitive stress fatigue in glued seams or molded joints, eventually causing leaks or mechanical failures.

3. Case Study: IP68 Pushbutton Switch in High-Altitude Application

A manufacturer deployed IP68-rated pushbutton switches in a telecommunications tower operating at 3000 meters altitude. During summer, enclosure temperature reached 60°C under sunlight; at night, it dropped below freezing. After six months, internal condensation was found, and insulation resistance dropped significantly.

Root Cause Analysis:

The sealing ring hardened due to UV and cold exposure.

The plastic housing expanded during heat but contracted sharply at night, creating negative pressure that drew moist air inside.

Over time, cycles of condensation and evaporation corroded the contact terminals.

4. Solutions: Design Improvements Against Thermal Expansion Stress

a. Material Matching:

Use materials with similar CTEs in contacting components to reduce interface stress. For example, pairing PPS housing with fluorosilicone gaskets ensures minimal differential movement.

b. Dynamic Sealing Elements:

Instead of static gaskets, use spring-loaded sealing rings or bellows-type seals that can accommodate movement while maintaining compression.

c. Venting Solutions:

Integrate breathable membrane vents (e.g., ePTFE) in sealed switch housings to balance internal pressure and prevent vacuum-induced suction of moisture.

d. Overmolding Technology:

Overmolding the sealing layer (e.g., TPE over PBT) ensures no gaps and maintains integrity even under thermal expansion. This is increasingly used in automotive-grade switches.

5. Testing for Thermal-Induced Failure Risk

Switches should undergo rigorous thermal stress validation, including:

Thermal Shock Testing: Rapid cycling between extreme temperatures (e.g., -40°C to +125°C) to simulate real-world expansion-contraction

Ingress Test after Thermal Cycling: Ensures IP67/IP68 rating remains effective post-cycling

Humidity-Condensation Test: Evaluates risk of internal moisture after temperature fluctuation

Conclusion

Sealing failure caused by thermal expansion and contraction is a hidden but critical reliability risk in pushbutton switch design. By understanding the material behaviors, using structural compensation techniques, and adopting advanced sealing technologies, manufacturers can ensure long-term reliability of switches even in the most challenging temperature environments. With proper testing and innovation, it is possible to maintain both functionality and sealing performance from freezing tundras to desert heat.

en.dghongju.com

0 notes