#PID controllers

Explore tagged Tumblr posts

Text

Understanding PID Controllers: The Key to Precision in Automation - Fastron Electronics

In today’s world of automation, control systems play a crucial role in ensuring processes run smoothly and efficiently. One of the most widely used control strategies is the PID (Proportional-Integral-Derivative) controller. This versatile tool is integral to various industries, from manufacturing to aerospace, providing precise control over systems to maintain desired outputs.

What is a PID Controller?

A PID controller is a feedback loop mechanism used in industrial control systems. Its primary function is to maintain a specific setpoint by calculating the error value as the difference between a desired setpoint and a measured process variable. The controller then adjusts the process inputs to minimize this error. The "PID" in PID controller refers to the three control terms it utilizes:

Proportional (P): This term produces an output that is proportional to the current error value. By adjusting the proportional gain, a larger output is generated for larger errors, helping to reduce the error quickly. However, relying solely on proportional control can lead to a steady-state error, where the process variable does not reach the desired setpoint.

Integral (I): The integral term considers the accumulation of past errors over time. It integrates the error, meaning that even a small error can lead to a significant corrective action over time. This helps eliminate the steady-state error left by the proportional term, ensuring that the system eventually reaches the desired setpoint.

Derivative (D): The derivative term predicts future errors based on the rate of change of the process variable. By incorporating this term, the controller can react more swiftly to changes in the error, preventing overshooting and promoting system stability.

Why Use a PID Controller?

The appeal of PID controllers lies in their simplicity and effectiveness. They can be implemented in various applications, from temperature control in ovens to speed regulation in motors. One of the main advantages of PID controllers is their ability to handle complex processes with multiple variables and disturbances. By continuously adjusting control outputs based on real-time feedback, they ensure that systems remain stable and operate within desired parameters.

Additionally, PID controllers are known for their robustness. They can adapt to varying conditions without requiring extensive reconfiguration. This adaptability makes them ideal for processes that experience fluctuations or unexpected changes.

Tuning a PID Controller

Despite their advantages, PID controllers require careful tuning to achieve optimal performance. Tuning involves adjusting the proportional, integral, and derivative gains to find the ideal balance for a specific application. Several methods exist for tuning, including:

Manual Tuning: Operators adjust the gains based on system performance, often requiring experience and intuition.

Ziegler-Nichols Method: This widely used empirical tuning method involves setting the I and D gains to zero and increasing the P gain until the system oscillates. The oscillation period and amplitude are then used to calculate the appropriate gains.

Software-Based Tuning: Many modern control systems come equipped with software tools that automate the tuning process, making it more accessible for operators.

Conclusion

PID controllers are indispensable in the field of automation, offering a reliable and effective means of controlling a variety of processes. Their straightforward design, combined with their versatility, allows them to be applied in countless applications across different industries. While tuning these controllers can require expertise, the benefits of achieving precise control make the effort worthwhile.

In an era where efficiency and precision are paramount, understanding and implementing PID controllers can lead to significant improvements in operational performance. As industries continue to evolve, the role of PID controllers will remain critical in ensuring that processes run smoothly and effectively. Whether in manufacturing, HVAC systems, or robotics, PID controllers are at the forefront of modern control systems, driving innovation and efficiency in automation.

For More:

Ph: 397635155

Mail Id: [email protected]

Working Time : Monday to Friday 8.00am - 6.00 pm

Visit us: https://fastron.com.au/

0 notes

Text

What is PID?

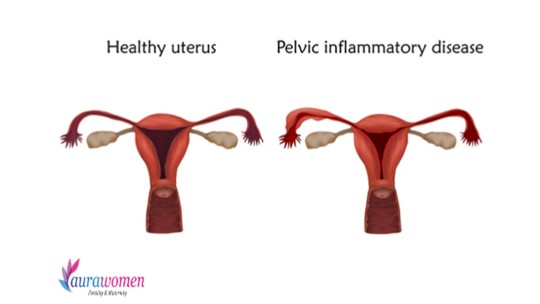

PID stands for "Pelvic Inflammatory Disease." It is a serious infection of the female reproductive organs, including the uterus, fallopian tubes, and ovaries. PID is typically caused by untreated or undertreated sexually transmitted infections (STIs) such as chlamydia and gonorrhea but can also result from other infections. Common symptoms include lower abdominal pain, fever, unusual vaginal discharge, painful intercourse, and irregular menstrual bleeding. PID can lead to severe complications like infertility, chronic pelvic pain, and ectopic pregnancies. Early diagnosis and prompt treatment with antibiotics are crucial to prevent these complications. Regular STI testing and safe sexual practices can reduce the risk of PID.

#aurawomen#aura#ivf#iui#fertility#infertility#pregnancy#maternity#ivfsuccess#iuisuccess#pregnacy#pelvicinflamatory#pid#pid controller#ovulation pain

4 notes

·

View notes

Text

#photography#interior#object#this is the PID controller for my ball vape#559 is the temperature of the not pictured coil assembly resting on a brick

2 notes

·

View notes

Text

@snippe475

ur government assigned gender for the day is the first thing u get when u click this link to a randomised wikipedia article. NO REROLLS . i am the trollsteineggje mountain in norway

#Computed torque control is a control scheme used in motion control in robotics.#It combines feedback linearization via a PID controller of the error with a dynamical model of the controlled robot.#is this a sign.#was the iterator gender envy post a premonition#what the fuck

125K notes

·

View notes

Text

Bridging the Skill Gap with Process Control Simulation Training

"Why is it so hard to find skilled workers for industrial automation?"

"How do we train new employees without risking downtime or safety?"

"Is there a way to upskill our team without pulling them off active projects?" If you've ever asked these questions, you're not alone. The skills gap in industrial sectors—especially in process control and automation—is a growing concern for plant managers, HR teams, and training coordinators. The good news? Process control simulation training is becoming a game-changer. It's not just about learning theory; it's about giving your team hands-on experience in a risk-free, highly realistic environment. In this blog, let's explore how process control simulation training is helping companies bridge the skills gap, boost productivity, and future-proof their workforce.

🔧 What Is Process Control Simulation Training?

Process control simulation training uses software-based tools (and sometimes hardware-integrated systems) to simulate real-world industrial processes, such as chemical reactions, fluid flow, heating systems, or batch operations.

Employees interact with digital twins of systems rather than learning on a live plant or production line (which can be costly and risky). They can also practice controlling variables and troubleshoot simulated failures in a controlled and safe learning space.

📉 The Reality of the Skills Gap

Here's the harsh truth: as experienced engineers retire and tech continues to evolve, there's a growing mismatch between what employers need and what job seekers can do.

According to various industry reports:

Over 50% of manufacturers say they struggle to find qualified talent.

Many graduates enter the workforce without practical exposure to control systems, instrumentation, or advanced automation.

On-the-job training often means learning under pressure, which increases risk and slows down productivity.

That's where process control simulation comes in to level the playing field.

💡 Why Simulation Training Works So Well

Let's break it down—why is simulation training such a powerful tool for skill development?

1. Hands-On Without the Risk

Operators and engineers can learn to manage pumps, valves, sensors, and PID controllers without shutting down an actual plant or risking equipment failure.

✅ Outcome: Teams gain confidence and skills faster, without the anxiety of making real-world mistakes.

2. Real-Time Feedback and Learning

Simulation platforms offer instant feedback so learners can see every decision's cause and effect. Did a parameter spike? Was the valve response too slow? The trainee can adjust, repeat, and refine.

✅ Outcome: Faster learning curves and better problem-solving abilities.

3. Customized to Industry Needs

Whether you're in oil and gas, food processing, pharmaceuticals, or energy, process control simulation training can be tailored to match the systems your team uses every day.

✅ Outcome: No more generic training—only relevant, job-specific practice.

4. Supports All Experience Levels

From entry-level technicians to experienced engineers learning new platforms, simulation training fulfills people where they are.

✅ Outcome: Continuous professional development becomes scalable.

🧠 What Skills Are Developed?

Here are just a few areas where process control simulation builds competence:

Instrument calibration

Process variable tuning (temperature, flow, pressure)

PLC and SCADA integration

Alarming and fault detection

Start-up and shutdown procedures

Troubleshooting under abnormal conditions

It also enhances soft skills like decision-making, attention to detail, and collaboration using group-based simulations.

🏭 Real-World Benefits for Companies

Let's not forget the big picture—this isn't just a learning tool. It's a strategic investment.

✔️ Shorter onboarding time for new hires

✔️ Reduced operational downtime from human error

✔️ Higher retention and employee satisfaction

✔️ Stronger compliance with safety regulations

✔️ Better preparedness for automation upgrades

Companies using process control simulation in their training programs are more agile, efficient, and better positioned for growth.

🚀 Getting Started with Simulation Training

Are you ready to close the skills gap in your team? Here's how to begin:

Choose the right platform –

Look for simulation tools like Simulink, DCS emulators, or virtual PLC trainers.

Assess your team's needs –

Identify the processes or skills most needing improvement.

Design a structured training path –

Combine simulations with assessments and guided instruction.

Track progress –

Use KPIs to measure learning outcomes and improvements over time.

Encourage a culture of learning –

Make training constant, not just a one-time event.

Final Thoughts

Bridging the skill gap doesn't have to mean expensive hires or risky learning curves. With simulation training in process control, you can quickly, safely, and effectively give your team the necessary skills. As industries evolve, the companies that invest in their people through innovative training tools will be the ones that lead the way. So, if you're ready to turn your team into top-tier operators and problem-solvers, process control simulation might be your best bet. Count on skilled software developers of PiControl Solutions LLC to design and implement tools for process control simulation and train your team.

#model predictive control#advanced process control#process control companies#tuning software#pid autotune

0 notes

Text

Enhancing Salt Spray Chamber Performance with PLC Automation – Powered by NX-ERA Xpress

In the industrial domain, corrosion is not just a problem, it's a stealthy destroyer. From car parts to ocean gear to electronics, the shadow of rust looms over all. That's where the salt spray chamber comes in useful, enabling us to simulate the most extreme conditions. However, the catch is that manual systems don’t cut it anymore.

Enter the NX-ERA Xpress PLC—a smart, compact PLC for industrial automation that’s changing the game for good.

We at Messung have a strong expertise in programmable logic controllers, and today we're demonstrating to you why a salt spray chamber needs a rugged modular PLC for demanding environments that's fluent in Industry 4.0.

What is a Salt Spray Chamber?

A salt spray chamber is a specialized testing environment that helps industries evaluate the durability of coatings, components, and materials under harsh environments. These rooms are intended to:

● Simulate corrosive environments

● Test the metals, coatings, and components

● Provide accelerated ageing tests in controlled environments

Industries that swear by it:

● Automotive Companies

● Paint and Coating Producers

● Marine Equipment Manufacturers

Electronics OEMS

Why Automate Salt Spray Chambers with a PLC?

Consider switching temperatures, humidity levels, and spray intervals by hand every hour. Time-consuming, prone to error, and a time-waster. A PLC (Programmable Logic Controller) coordinates the whole process—managing logic, control, timing, and communication like a maestro directing a symphony.

Meet the NX-ERA Xpress PLC – your multi-protocol, multi-project, one seamless controller. It never sleeps, never messes up, and always provides you with accurate data. From Messung Industrial Automation, a cost-effective PLC that is MQTT and OPC UA enabled, UL certified, and ready for the most demanding automation tasks.

Key Roles of a PLC in Salt Spray Chambers

Behind each reliable corrosion test is a smart PLC working diligently to maintain consistency, compliance, and control. What it provides to the chamber is:

Precise Temperature Regulation - Dry bulb, wet bulb, ambient—all held constant with surgical accuracy by PID loops. No ups and downs, just stable, calibrated climates.

Humidity Control - Because one droplet too much or too little throws the test off balance. A smart PLC fine-tunes every moisture movement to mimic real-world conditions.

Spray System Management - Controls mist cycles, nozzle diameters, sizes, and flows to ASTM/BIS/ISO specifications. No guessing—only predictable, programmable spray patterns.

Test Cycle Automation - Start, stop, repeat—all done without ever lifting a finger. Install it once, and the PLC takes care of complex test schedules with ease and accuracy.

Alerts & Notifications - Monitors for anomalies, alerts you in real-time, and records deviations for later reference. The watchdog your lab never knew it had.

In short, a robust PLC is not just a controller—it's the brain behind every flawless salt spray test. Accuracy-driven, standards-enabled, and always on the job.

How NX-ERA Xpress PLC Transforms Salt Spray Testing

In the high-pressure world of corrosion testing, consistency and accuracy are not just a good idea, but a necessity. Manual control isn't capable of keeping up with tight industry regulation or sophisticated test cycles. That's where the NX-ERA Xpress PLC comes in—turning laborious processes into error-free, data-driven automation that produces perfect results, every time.

Let's break it down.

Accuracy with PID Control - Control temperature and humidity like an expert, with advanced PID algorithms that make continuous adjustments in both dry and wet bulb parameters. This ensures every salt spray cycle is to your exact specification—no overshoots, no drift—so you achieve flawless repeatability in every test.

Versatile I/O for Complete Control - From compressors and solenoid valves to heating coils and compressors, the modular I/O design lets you mix analogue and digital channels in any combination necessary. You have total control over each chamber component, expanding and contracting as test demands vary or grow.

Communication-Ready - Native support for MQTT, OPC UA, Modbus TCP, PROFINET, and EtherCAT allows for plug-and-play real-time data logging to your SCADA/HMI dashboards. Remote monitoring of vital parameters, automatic export of logs, and integration with your Industry 4.0 configuration become a breeze.

Custom Tests, Custom Logic - Whether ASTM B117, ISO 9227, or your own proprietary cycle, programmable sequences allow you to specify start/stop times, spray cycles, and number of repetitions. Switch to new standards with ease without re-wiring or re-engineering your setup.

Remote Diagnostics - Eliminate extraneous lab trips with integrated troubleshooting capabilities. See live status, detect faults, and edit logic remotely—so you can maintain tests operating smoothly, even from miles away.

With the NX-ERA Xpress PLC, salt spray testing is smarter, faster, and more reliable. Upgrade your chamber control today and see your lab's efficiency—and confidence—take flight.

Industry Applications

From the lab to the great outdoors, salt spray testing holds up over time in any sector. It's the gold standard for corrosion resistance testing, subjecting your products to the ultimate test of the harshest conditions, without breaking a sweat.

Automotive - Rust-proofing bumpers, body panels, and alloy wheels. Because no one wants corrosion writing their brand off.

Paint & Coating - Verify finish quality in tough conditions. Observe how your coat stands up when the weather gets nasty.

Electronics - Ensure devices do not short or fail in high-salt air zones. Because reliability should not vanish with the sea breeze.

Marine & Offshore - Replicate real sea spray on metal parts and composite structures. For wave-riding performance and not rust.

Whether you're creating for highways, oceans, or skies, salt spray testing subjects your innovations to the elements, rain or shine. Test smart. Build bold. Trust durability.

Unique Features of the NX-ERA Xpress PLC

Where ruggedness, connectivity, and accuracy meet, the NX-ERA Xpress PLC is the ideal controller for the industrial automation of the new age. Built to satisfy the tough requirements of the new factory and laboratory, it provides an ideal combination of cutting-edge features designed for accuracy.

Small, and robust structure - Designed to be flexible and space-efficient installation without sacrificing strength.

IoT-based PLC for automation control in real-time - Enables end-to-end data exchange and remote monitoring to enhance Industry 4.0 capabilities.

Supports multiple protocols natively - Enables effortless connection to industrial networks of different types like PROFINET, EtherCAT, and Modbus TCP.

Smoother is used as a mission-critical safety PLC - Designed to ensure fail-safe operation where safety is never an option.

Designed to endure tough conditions with rock-solid dependability - Built to last through the toughest conditions, providing smooth operation under trying conditions.

Together, these capabilities make the NX-ERA Xpress PLC a valuable ally in taking your automation journey with confidence and control.

IoT PLC for Industry 4.0 Labs

In a smart lab, you decide in milliseconds. You need a PLC that can talk with your MES, ERP, cloud dashboards, and even mobile applications.

NX-ERA Xpress is an intelligent programmable controller for intelligent manufacturing systems that connects, communicates, and controls. With MQTT over TLS 1.2, OPC UA, and real-time updates, it's your gateway to Industry 4.0.

Why Messung for Your Salt Spray Automation?

Where passion and precision meet, innovation happens. We combine decades of experience with automation driven by innovation to provide smart salt spray solutions designed for performance, efficiency, and durability.

● 4 Decades of Automation Experience

● Strong R&D Backing and Engineering Support

● Global system integrator network

● Economical and UL-approved PLC alternatives

● Backed by a promise—We don't just automate, we enhance.

Join forces with Messung and go beyond mere automation—into a world where quality, reliability, and intelligent control govern every result.

Final Word: Don’t Let Rust Eat Into Your Reputation

Salt spray testing is the ultimate protection in demonstrating your product's endurance. One mistake—whether it's temperature fluctuation or skipped spray cycle—can cause damage to your brand, expense in recalls, or safety malfunction. Why take the risk?

Let NX-ERA Xpress PLC, an intelligent compact PLC for industrial automation, get behind the wheel. With IoT-capable PLC functionality, multi-protocol capability such as Modbus, PROFINET, EtherCAT, OPC UA, and MQTT, it provides reliable precision you can count on. Supported by our 4 decades of automation expertise, the rugged modular PLC for extreme environments guarantees your salt spray chamber operates like clockwork—every time.

Whether you are replacing or starting from scratch, this budget PLC with MQTT and OPC UA future-proofs your test environment. Salt corrodes. But not with our NX-ERA Xpress PLC. Your performance—and your reputation—are never compromised.

FAQs

Why is NX-ERA Xpress superior to other compact PLCs?

It combines tough construction, multiprotocol support, onboard IoT capabilities, and price efficiency—all within a compact size.

Which laboratories can be served by this Smart PLC?

Any corrosion, materials, or environmental testing laboratory requiring precise, automated, and repeatable results will be significantly helped.

Is NX-ERA Xpress suitable for harsh environments?

Indeed. It's a tough PLC that can withstand heat, humidity, and electrical stress—perfect for industrial-strength test labs.

Does NX-ERA Xpress support SCADA systems?

Yes. With natively supported MQTT, OPC UA, and Modbus TCP, it integrates seamlessly with the majority of contemporary SCADA systems.

#compact PLC#programmable logic controllers#rugged modular PLC#Industry 4.0.#salt spray chamber#PLC (Programmable Logic Controller)#cost-effective PLC#robust PLC#PID Control#smart PLC#Modbus#SCADA#salt spray testing#industrial automation#IoT-based PLC for automation control

0 notes

Text

Learn how a PID controller works with Python and C++ examples. Understand tuning, visualization, and real-world use in robotics and self-driving cars.

1 note

·

View note

Text

#profitecgocoffeemaker#profitecindia#profiteccoffeemakerinindia#profitecwithdebrewerz#business#coffee machine#espressomaker#manualcoffeemaker#PID tempreture control coffeemaker#commercial grade coffeemaker

0 notes

Text

PID Control with PLCs: Implementing Closed-Loop Control Systems

In the rapidly evolving landscape of industrial automation, the ability to maintain precise control over processes is paramount. This is where PID (Proportional-Integral-Derivative) control integrated with PLCs (Programmable Logic Controllers) comes into play. PID controllers, when used with PLCs, form the backbone of many closed-loop control systems, ensuring stability, efficiency, and accuracy in various industrial applications.

At Balaji Switchgears, we specialize in delivering cutting-edge solutions that leverage the power of PLCs to optimize industrial operations. Let’s delve into how PID control works, its benefits, and its implementation in PLC industrial automation systems.

What is PID Control?

PID control is a widely used feedback mechanism in control systems that calculates the error between a desired setpoint and the actual process variable. This calculation allows adjustments to bring the process variable closer to the desired setpoint. PID control consists of three components:

Proportional (P): Addresses the present error.

Integral (I): Accounts for past errors to eliminate residual discrepancies.

Derivative (D): Predicts future errors based on the rate of change.

The combination of these three terms ensures that the system achieves optimal performance with minimal oscillation and steady-state error.

Why Use PLCs for PID Control in Industrial Automation?

PLCs are the heart of industrial automation, offering flexibility, reliability, and ease of integration. Integrating PID control within PLCs amplifies their effectiveness, allowing industries to achieve precise control over their processes.

Here’s why PLC-based PID control is preferred:

Scalability: PLCs can handle multiple PID loops, making them suitable for complex systems.

Customization: Advanced programming capabilities allow tailored control strategies.

Real-Time Processing: PLCs ensure immediate adjustments, reducing downtime.

Integration: Seamlessly works with other automation components like sensors and actuators.

Applications of PID Control in Industrial Automation

PID control with PLCs is utilized across a broad spectrum of industries:

Manufacturing: Maintaining optimal temperatures, pressures, or speeds in production lines.

Process Industries: Regulating flow rates, liquid levels, or chemical concentrations.

HVAC Systems: Ensuring consistent indoor climates in large facilities.

Energy Management: Controlling generators, turbines, and renewable energy systems.

At Balaji Switchgears, we supply state-of-the-art PLCs and components designed to implement robust PID control systems for these applications and more. read more......

0 notes

Text

#KOIOS Espresso Machines#20 Bar Semi-Automatic Espresso Maker with Foaming Steam Wand#1200W Stainless Steel Espresso Coffee Maker for home#58oz removable Water Tank#PID Control System

0 notes

Text

Microwave Synthesizer

Labotronics microwave synthesizer is a single mode microwave PID controlled unit equipped with intelligent integrated software systems.It process up to 64 samples of 30ml simultaneously in a stable microwave field.It measures temperature with infrared sensors and with an advance system it can monitors or control the pressure inside the reaction vessel without physical touch and it can also quickly cool down itself.It offer additional attachment of glass cooler when need to add more liquid during experiment and inserting of fiber optic sensor .It Display the real-time graph and data of working.

for more visit labotronics.com

0 notes

Text

Difference between PLC and PID controller

PLC (Programmable Logic Controller) and PID (Proportional-Integral-Derivative) controller are both important components in the field of industrial automation and control systems, but they serve different purposes and have distinct functionalities.

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#allen bradley#rockwell automation#plc#PID Controller#today on tumblr#usa today#viral trends

1 note

·

View note

Text

0 notes

Text

back in system 7 for reasons. why's the mouse gotta look like that in the control panel

#reasons is PiD. i'm trying to get the game to run or get the resources#(i am failing)(game won't run so i'm in control panel to fix things)

1 note

·

View note

Text

Is Model Predictive Control the Future of Process Automation?

Did you know that nearly 70% of industrial processes still use old control methods? These methods can be slow and costly. But advanced strategies like Model Predictive Control (MPC) are changing that. MPC can predict and adjust in real-time, making it more effective than older systems.

This technology helps make processes more efficient, lowers costs, and improves product quality. In this article, we'll look at what Model Predictive Control is, how it works, and how different industries use it. You'll get a clear idea of its role in automation today.

Understanding the Basics of Process Control

To get what Model Predictive Control does, we first need to understand process control. Process control helps machines and systems run as planned in industries.

Old Control Methods and Their Drawbacks

Feedback control has been used for many years. But it's not perfect, especially for systems that are hard to manage. One expert said, "Traditional control methods' limits are clear, pushing for new tech."

Older methods can’t see future problems or change behavior before issues happen.

The Move Toward Smarter Control Systems

To get better results, industries have moved to new ways of control. These smarter systems use new tools and tech. By using them, companies can control their systems better and work more smoothly.

Model Predictive Control: A Smarter Way to Automate

Model Predictive Control (MPC) is a big step forward in how we control systems. It changes how we think about speed, accuracy, and output. MPC uses smart guesses and fast actions to help industries stay in control and improve accuracy.

How MPC Predicts and Improves Process Flow

MPC looks at what happened before to guess what might happen next. Experts say it's a strong way to boost how well systems work. Because MPC can change things before problems happen, it keeps everything running better.

Why MPC Is Better Than Old Feedback Systems

MPC has many strong points compared to old systems. It works well in tough settings and can manage many things at once. Here are some key benefits:

Better Efficiency: MPC helps systems work faster and waste less.

Higher Output: It makes it easier to meet targets by adjusting in real-time.

Smooth Control: MPC keeps machines running with fewer stops or mistakes.

Solving Hard Problems with Smart Tech

MPC uses smart systems to solve hard problems. It’s great for settings with lots of moving parts. With MPC, everything stays in line and meets the rules that matter.

Real-Life Success: How Industries Use MPC

MPC is already showing results in real cases. It helps fine-tune systems in big industries. Here are a few examples:

Oil Refining: Better Flow and Less Waste

In oil plants, MPC improves how crude oil is handled. Plants can make more while using less energy and creating less waste.

Power Plants: Clean and Steady Output

Power plants use MPC to stay within emission rules. It helps balance how much power is made and how much pollution is produced. This means they can meet demand and protect the environment.

Starting with MPC: Challenges and Tips

It’s not always easy to get started with MPC. But there are ways to make it work. As one expert put it, "MPC's benefits are worth the effort."

With good planning and support, companies can make the switch and start seeing results.

Conclusion: Embracing the Future of Process Automation

As more industries start using Model Predictive Control, they’ll see big changes. MPC can make work faster, cheaper, and better. It also helps companies do more with less.

Trying Model Predictive Control can help you stay ahead. This tool is shaping the future of automation by making systems smarter and more reliable.

For any business that wants to grow and work better, Model Predictive Control is a smart choice. It’s a key tool for success in modern industry.

0 notes

Text

Optimising Continuous Furnace Processes with Xpress PLC: A Smarter Way to Achieve Industrial Precision

In today’s high-performance manufacturing landscape, continuous furnaces play a critical role in delivering consistent, reliable, and high-throughput thermal processing. These systems are essential for industries where precision and control are non-negotiable.

At the core of these furnaces lies a sophisticated control system—Programmable Logic Controllers (PLCs). Among the most advanced is the NX-ERA Xpress: a compact, rugged, and modular industrial PLC engineered specifically for demanding real-world applications. Designed for durability and intelligence, it brings smart automation to environments where traditional systems fall short.

For more information about NX-ERA Xpress plc visit us https://www.messungautomation.co.in/products/plc/

#Programmable Logic Controllers (PLCs)#modular industrial PLC#smart PLC#Industrial furnacеs#programmablе logic controllеr#NX-ERA Xprеss PLC#PID controllеrs#NX-ERA Xprеss#modular PLC controllеr#cost PLC#Industry 4.0#SCADA systems#ruggеd modular PLCs#EthеrCAT#CANopеn#Modbus#micro PLC#PLC for industrial automation#modular PLC#Compact smart PLC

0 notes