#modular PLC

Explore tagged Tumblr posts

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

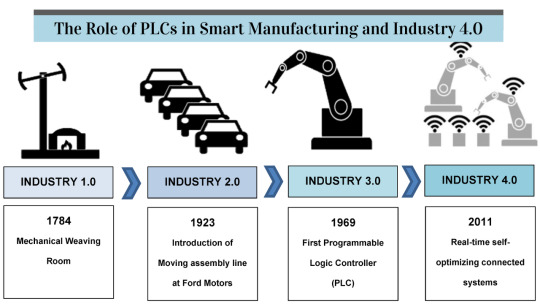

The Role of PLCs in Smart Manufacturing and Industry 4.0

Programmable Logic Controllers (PLCs) play a crucial role in the evolution of smart manufacturing and the implementation of Industry 4.0 principles. These advanced automation technologies are transforming traditional manufacturing processes into more connected, efficient, and intelligent systems.

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#automation#trending#tumblr trends#viral#trendingnow#bestdeals#allen bradley#rockwell automation#plc#viralpost#industry4.0#technology#companies#construction#manufacturing#modular plc

1 note

·

View note

Text

From Rolls to Retail: The Journey of Paper Bag Manufacturing

In an era increasingly defined by sustainability and eco-conscious choices, the humble paper bag has emerged as a symbol of responsible consumption. Behind this everyday product lies a marvel of modern manufacturing—the paper bag machine. Combining mechanical precision with environmental awareness, paper bag machines have become a critical tool in both industrial packaging and the global effort to reduce plastic waste.Get more news about paper bag machine,you can vist our website! Paper bag machines are highly automated systems designed to transform rolls of kraft paper or recycled paper into finished bags of various shapes and sizes. These machines can produce flat or square-bottom bags, with or without handles, depending on the configuration. As businesses and consumers alike shift toward greener packaging alternatives, demand for paper bags—and by extension, paper bag machinery—has soared across the globe. The process begins with feeding large rolls of paper into the machine’s unwinding system, which precisely aligns the material before it moves into the folding section. Here, the paper is shaped into the desired bag profile using a combination of rollers, creasing devices, and glue applicators. Advanced machines incorporate servo motors and programmable logic controllers (PLC) to ensure real-time adjustments and tight quality control. This high-speed automation enables manufacturers to produce thousands of bags per hour with minimal labor input and consistent output quality. One of the defining features of modern paper bag machines is their adaptability. Manufacturers can quickly switch between different bag sizes, thicknesses, and handle designs to meet custom client requirements. Integration with printing modules allows for brand logos, product information, or decorative patterns to be applied directly onto the bags during production—an especially valuable feature for the retail and food-service industries. The environmental benefits of paper bag machines are equally significant. With increasing bans on single-use plastics in many countries, paper bags have stepped in as a recyclable, biodegradable alternative. Machine producers have responded by offering systems that work efficiently with recycled paper and water-based adhesives, reducing energy consumption and minimizing environmental impact during the manufacturing process. Globally, regions like Asia, Europe, and North America have witnessed rapid growth in the paper bag machine market. In China and India, rising consumer awareness and government-led plastic reduction initiatives have spurred significant investment in domestic manufacturing. Meanwhile, European companies have focused on upgrading machine precision and efficiency, contributing to a competitive, innovation-driven industry. Despite their advantages, paper bag machines are not without challenges. The cost of raw paper, machine maintenance, and the need for skilled operators can impact profitability. Nevertheless, ongoing technological improvements—such as smart diagnostics, real-time monitoring, and modular machine design—are steadily addressing these issues and pushing the boundaries of what's possible. In conclusion, paper bag machines are more than just production equipment—they are enablers of a global movement toward sustainable packaging. By marrying mechanical engineering with environmental innovation, these machines stand at the crossroads of commerce and conscience, quietly supporting a greener tomorrow with every fold and seal.

0 notes

Text

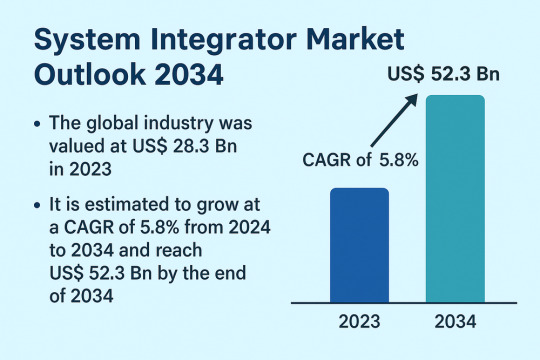

Automation and Integration Needs Power Robust Growth in System Integrator Market

The global System Integrator Market is poised for significant growth, projected to rise from US$ 28.3 Bn in 2023 to US$ 52.3 Bn by 2034, growing at a CAGR of 5.8% from 2024 to 2034. This growth is driven by the widespread adoption of industrial robots, technological advancements, and a pressing need among businesses to optimize operational efficiencies through connected systems.

System integrators play a pivotal role in designing, implementing, and maintaining integrated solutions that bring together hardware, software, and consulting services. These services support organizations in unifying internal and external systems, such as SCADA, HMI, MES, PLC, and IIoT, to enable seamless data flow and system interoperability.

Market Drivers & Trends: One of the primary market drivers is the rise in adoption of industrial robots. As industries accelerate automation, robotic system integrators have become vital in delivering customized, scalable, and high-performing solutions tailored to complex manufacturing needs.

Another major catalyst is the surge in technological advancements. Integrators are deploying cloud-based tools and platforms that provide real-time data insights, improve developer productivity, and support hybrid architectures. The increasing use of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) in integration solutions is fostering innovation and growth.

Latest Market Trends

Several emerging trends are shaping the system integrator landscape:

Cloud modernization platforms such as IBM’s Z and Cloud Modernization Center are enabling businesses to accelerate the transition to hybrid cloud environments.

Modular automation platforms are gaining popularity, allowing companies to rapidly deploy and scale integration solutions across multiple industry verticals.

Edge computing and cybersecurity solutions are increasingly being integrated to support secure, real-time decision-making on the production floor.

Digital hubs and scalable workflow engines are being adopted by integrators to support multi-specialty applications with high adaptability.

Key Players and Industry Leaders

The system integrator market is characterized by a strong mix of global leaders and regional specialists. Key players include:

ATS Corporation

Avanceon

Avid Solutions

Brock Solutions

JR Automation

MAVERICK Technologies, LLC

Burrow Global, LLC

BW Design Group

John Wood Group PLC

TESCO CONTROLS

These companies are actively investing in next-generation technologies, enhancing their product portfolios, and pursuing strategic acquisitions to strengthen market presence. For instance, in July 2023, ATS Corporation acquired Yazzoom BV, a Belgian AI and ML solutions provider, expanding their capabilities in smart manufacturing.

Recent Developments

Olympus Corporation launched the EASYSUITE ES-IP system in July 2023 in the U.S., offering advanced visualization and integration solutions for procedure rooms.

IBM introduced key updates in 2021 and 2022 to streamline mission-critical application modernization using cloud services and hybrid IT strategies.

Asia-Pacific companies have led the charge in deploying advanced integrated systems, reflecting the rapid industrial digitization in countries such as China, Japan, and South Korea.

Market Opportunities

Opportunities abound in both mature and emerging markets:

Smart factories and Industry 4.0 transformation offer immense potential for integrators to offer comprehensive solutions tailored to real-time analytics, predictive maintenance, and remote monitoring.

Government-led infrastructure modernization projects, particularly in Asia and the Middle East, are increasing demand for integrated control systems and plant asset management solutions.

The energy transition movement, including renewables and electrification of industrial processes, requires new types of integration across decentralized assets.

Future Outlook

As industries pursue digital transformation, the role of system integrators will evolve from traditional project implementers to long-term strategic partners. The future will see increasing demand for intelligent automation, cross-domain expertise, and real-time adaptive solutions. Vendors who can provide holistic, secure, and scalable services will dominate the landscape.

With continued advancements in AI, IoT, and robotics, the system integrator market will continue to thrive, transforming operations across diverse sectors, from automotive and food & beverages to oil & gas and pharmaceuticals.

Review critical insights and findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82550

Market Segmentation

The market is segmented based on offering, technology, and end-use industry.

By Offering:

Hardware

Software

Service (Consulting, Design, Installation)

By Technology:

Human-Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Manufacturing Execution System (MES)

Functional Safety System

Machine Vision

Industrial Robotics

Industrial PC

Industrial Internet of Things (IIoT)

Machine Condition Monitoring

Plant Asset Management

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

By End-use Industry:

Oil & Gas

Chemical & Petrochemical

Food & Beverages

Automotive

Energy & Power

Pharmaceutical

Pulp & Paper

Aerospace

Electronics

Metals & Mining

Others

Regional Insights

Asia Pacific leads the global system integrator market, holding the largest market share in 2023. This leadership is attributed to:

Rapid industrialization and digital transformation in China, Japan, and India.

Strong investments in smart manufacturing and Industry 4.0 initiatives.

Government support for infrastructure modernization, especially through Smart City programs and cybersecure IT frameworks.

North America and Europe also show strong demand, driven by the presence of established manufacturing facilities and a robust focus on sustainable operations and green automation.

Why Buy This Report?

Comprehensive Market Analysis: Deep insights into market size, share, and growth across all major segments and geographies.

Detailed Competitive Landscape: Profiles of leading companies with analysis of their strategy, product offerings, and key financials.

Actionable Intelligence: Understand technological trends, regulatory developments, and investment opportunities.

Forecast-Based Strategy: Develop long-term strategic plans using data-driven forecasts up to 2034.

Frequently Asked Questions (FAQs)

1. What is the projected value of the system integrator market by 2034? The global system integrator market is projected to reach US$ 52.3 Bn by 2034.

2. What is the current CAGR for the forecast period 2024–2034? The market is anticipated to grow at a CAGR of 5.8% during the forecast period.

3. Which region holds the largest market share? Asia Pacific dominated the global market in 2023 and is expected to continue leading due to rapid industrialization and technology adoption.

4. What are the key growth drivers? Key drivers include the rise in adoption of industrial robots and continuous advancements in integration technologies like IIoT, AI, and cloud platforms.

5. Who are the major players in the system integrator market? Prominent players include ATS Corporation, JR Automation, Brock Solutions, MAVERICK Technologies, and Control Associates, Inc.

6. Which industries are adopting system integrator services the most? High adoption is seen in industries such as automotive, oil & gas, food & beverages, pharmaceuticals, and electronics.

Explore Latest Research Reports by Transparency Market Research:

Multi-Mode Chipset Market: https://www.transparencymarketresearch.com/multi-mode-chipset-market.html

Accelerometer Market: https://www.transparencymarketresearch.com/accelerometer-market.html

Luminaire and Lighting Control Market: https://www.transparencymarketresearch.com/luminaire-lighting-control-market.html

Advanced Marine Power Supply Market: https://www.transparencymarketresearch.com/advanced-marine-power-supply-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Shape with Confidence – Advanced C Channel Roll Forming by Jugmug

In today’s age of industrial precision and structural performance, C channel profiles are more than just pieces of metal—they are the backbone of strong, dependable frameworks. At the heart of these robust profiles lies the C Post Channel Roll Forming Machine, and no one understands this better than Jugmug RollForming. With years of engineering expertise, Jugmug has become a name synonymous with precision forming, durability, and customer-focused innovation.

What Is a C Channel Roll Forming Machine?

A C Channel Roll Forming Machine, also known as a C Post Roll Former, is used to manufacture C-shaped steel sections from metal coils. These profiles are widely used in:

Construction (purlins, wall studs)

Industrial shelving

Cable tray supports

Solar panel mounting structures

Automotive and transportation frames

The forming process ensures accurate dimensions, clean edges, and consistent shapes, which are critical for structural stability and assembly efficiency.

Why Jugmug RollForming?

With a heritage of craftsmanship and a passion for innovation, Jugmug RollForming has revolutionized how industries view roll forming. Here's why Jugmug leads the pack in C Channel Roll Forming:

1. Precision Engineering

Jugmug’s machines are designed using advanced CAD/CAM systems and assembled with CNC-manufactured components. The result is ultra-precise forming even at high speeds, with tolerance control up to ±0.5mm.

2. Heavy-Duty Build Quality

Built with rugged structural frames, hardened rollers, and wear-resistant shafts, these machines are engineered for long-term, high-volume performance without breakdowns.

3. High-Speed Automation

Equipped with PLC control systems, servo motors, and hydraulic punching/cutting, Jugmug’s C Post machines reduce human error and improve productivity. The touchscreen HMI makes operation simple and intuitive.

4. Customization on Demand

Every business has unique needs. Jugmug provides tailor-made C channel forming machines, whether you require:

Variable sizes and gauges (1.2 mm to 3 mm)

Manual or fully automatic operation

In-line punching, embossing, or logo marking

Quick-change cassette design for multiple profiles

Applications of C Channel Profiles

The C profiles manufactured using Jugmug’s machines find applications in:

Construction

Used as wall studs, roof purlins, girts, and base plates due to their load-bearing capacity and resistance to warping.

Solar Panel Mounting

C channels are widely used to fabricate the structural framework for solar PV systems.

Automotive Chassis & Framework

Because of their strength-to-weight ratio, C channels are ideal for reinforcing vehicle bodies and cargo enclosures.

Racking & Storage Systems

Industrial shelving systems often rely on C profiles for their modular, load-bearing structure.

Customer Success Stories

Jugmug RollForming has delivered its C channel machines across India and globally. Many manufacturers in the solar, automotive, construction, and logistics sectors report:

30% increased output

Reduced material wastage

Quick ROI (within 12-18 months)

Minimal downtime

After-Sales Support & Training

Jugmug doesn’t stop at selling the machine—it partners with you throughout the journey. Their post-sale support includes:

Installation & operator training

Preventive maintenance plans

Spare parts availability

Remote troubleshooting support

Annual servicing packages

Their team of qualified engineers is just a call away, offering pan-India coverage and global service reach.

Green Manufacturing with Jugmug

In alignment with sustainability goals, Jugmug machines are designed to optimize energy usage and reduce raw material waste. The machines feature:

Servo-driven motors for low energy consumption

Smart sensors for real-time quality control

Eco-friendly hydraulic systems

By adopting Jugmug’s forming systems, manufacturers not only boost output but also reduce their carbon footprint.

Conclusion: Shape with Confidence

When strength, accuracy, and speed matter, Jugmug RollForming’s C Channel Roll Forming Machine delivers with unmatched precision. Whether you are scaling up production or entering new markets, Jugmug ensures your foundation is strong—both literally and technically.

Shape your future with confidence—partner with Jugmug RollForming.

#C channel roll forming machine#C post forming machine manufacturer#C profile making machine India#Jugmug RollForming machines#Structural roll forming equipment#Roll forming machine for solar structures#Best C channel machine in India

0 notes

Text

A10VSO Pump An In-Depth Overview

The A10VSO pump, developed by Bosch Rexroth, is a high-performance axial piston pump widely recognized for its reliability, efficiency, and versatility in hydraulic systems. Commonly used in industrial and mobile hydraulic applications, the A10VSO pump provides precise control of fluid flow and pressure. This article explores the design, features, working principle, benefits, and applications of the A10VSO pump, offering a comprehensive understanding for engineers, technicians, and industrial users alike.

What is an A10VSO Pump?

The A10VSO is an axial piston variable displacement pump designed for use in open-circuit hydraulic systems. It belongs to the axial piston swashplate design family, where pistons are arranged parallel to the drive shaft in a circular pattern. The swashplate mechanism controls the stroke of each piston, allowing the pump to adjust the volume of hydraulic fluid delivered based on system requirements.

The term “variable displacement” indicates the pump's ability to vary the flow output, which is crucial for energy savings and system flexibility. The A10VSO series is particularly popular in applications requiring fine speed and force control.

Design and Construction

The A10VSO pump features a robust and compact design suitable for demanding environments. Key design elements include:

Swashplate mechanism: This controls the piston stroke, and hence the flow rate, by altering the angle of the plate.

Cylinder block: Houses multiple pistons that rotate with the drive shaft.

Valve plate: Ensures that the suction and pressure sides of the pump are properly sealed.

Pressure and flow controllers: Integrated to manage output based on system demand.

Drive shaft: Connects the pump to the motor or engine that provides mechanical input.

Its modular construction allows for easy customization, maintenance, and integration with various control devices.

Working Principle

The A10VSO pump operates on the axial piston principle with a variable swashplate angle. Here's a step-by-step explanation of its working mechanism:

Drive input: The pump is connected to a motor that rotates the drive shaft.

Piston movement: As the shaft rotates, it causes the cylinder block and pistons to rotate. The pistons are forced to reciprocate due to the angled swashplate.

Intake stroke: During the downward stroke, pistons draw hydraulic fluid from the reservoir through the intake port.

Compression stroke: As the pistons move upward, they compress the fluid and discharge it through the outlet port at high pressure.

Flow control: The swashplate angle determines the length of the piston stroke, which in turn regulates the flow rate. A flatter angle results in less displacement and lower flow; a steeper angle increases both.

This ability to vary displacement makes the A10VSO ideal for applications needing dynamic flow control.

Control Options

A standout characteristic of the A10VSO pump is its versatile control options. These include:

Pressure compensator (DR): Automatically adjusts displacement to maintain constant pressure.

Load-sensing (DFE): Varies output according to system demand, ideal for mobile machinery.

Remote control (DRG): Enables pressure control from a remote location.

Electro-hydraulic controls (ED, EDR, etc.): Offers integration with programmable logic controllers (PLCs) for advanced automation.

These options provide designers with the flexibility to tailor system performance precisely to application requirements.

Applications of the A10VSO Pump

Due to its adaptability and performance, the A10VSO pump is used in a wide range of industries. In each of these applications, the pump provides consistent pressure, responsive control, and long-term durability.

Maintenance and Service

While the A10VSO pump is engineered for durability, proper maintenance ensures its longevity. Recommended practices include:

Regular inspection of hydraulic fluid: Contamination is a leading cause of wear.

Monitoring for leaks and noise that may indicate internal damage.

Following manufacturer-recommended service intervals

Replacing filters and seals periodically

Ensuring correct installation alignment and avoiding over-tightening during mounting

By adhering to preventive maintenance schedules, users can significantly extend pump life and reduce downtime.

Conclusion

The A10VSO pump is a cornerstone of modern hydraulic systems, offering a blend of performance, efficiency, and flexibility. Whether in high-demand industrial environments or rugged mobile machinery, its ability to adapt to varying pressure and flow needs makes it an invaluable asset.

With its proven design and wide range of displacement sizes and control types, the A10VSO pump continues to be a preferred choice for engineers and technicians seeking reliable and responsive hydraulic solutions. As automation and energy efficiency become increasingly important, pumps like the A10VSO are poised to play an even greater role in the evolution of hydraulic technology.

0 notes

Text

How Mechanical System Design Enhances Efficiency in Industrial Engineering

Introduction

Efficiency is a need, not just a goal, in the fast-paced field of industrial engineering. Retaining a competitive edge requires the capacity to optimize resource consumption, reduce downtime, and streamline processes. The design of mechanical systems is among the most important factors that contribute to this optimization. Mechanical systems are designed to increase overall productivity, decrease waste, and improve performance through clever planning, integration, and innovation.

Mechanical System Design: What Is It?

The process of organizing and developing mechanical systems and components that cooperate to carry out particular tasks in industrial settings is known as mechanical system design. It covers the design, dimensions, material choice, temperature and stress analysis, and incorporation of mechanical components such automated equipment, conveyors, gear mechanisms, HVAC systems, robotics, and gear mechanisms. Reliable operation under a variety of conditions is ensured by a well-crafted design, which is essential in industrial settings with high demand.

Essential Elements of an Energy-Efficient Mechanical System Design

Energy conservation is a key component of modern mechanical system design. Energy-efficient motors, regenerative braking systems, and intelligent load management are some of the methods used in systems designed to lower power usage.

Design Modularity

Without completely redesigning the system, modular components make it simple to upgrade, expand, or replace individual pieces. This method promotes ongoing development and increases adaptability.

Integration of Automation

Automation is becoming more and more important in today's industrial operations. In order to ensure accurate and reliable performance, mechanical systems are now made to seamlessly interface with sensors, robotic components, and programmable logic controllers (PLCs).

Compliance and Safety

Adherence to industry safety standards and regulations is a crucial factor in the design of mechanical systems. To safeguard employees and equipment, well-designed systems incorporate built-in safety features and fail-safes.

Efficiency via Optimization

Load capacity, temperature ranges, material durability, and anticipated wear and tear are all taken into account during the design process. Mechanical system design reduces unplanned failures and increases uptime by foreseeing operational issues and designing solutions prior to deployment. This prolongs the equipment's lives and increases productivity.

Industrial Engineering Case Applications

In industries such as heavy machinery, chemical processing, and automobile manufacture, customized mechanical system design guarantees optimal equipment performance. For instance, on an assembly line, specially made conveyor systems minimize manual handling, increasing productivity and reducing the possibility of mistakes or accidents. In a similar vein, well-designed HVAC systems in industrial facilities effectively control temperature, improving working conditions and reducing energy expenses.

Conclusion

To sum up, one of the key pillars of industrial engineering efficiency is mechanical system design. Automation, safety, adaptability, and energy-saving technology can all be included into a facility's mechanical infrastructure to increase production, decrease downtime, and ensure long-term sustainability. Investing in high-quality mechanical design is a business strategy that directly supports profitability and expansion, not just an engineering choice.

0 notes

Text

Water Filling Machine: The Ultimate Guide for Industrial and Commercial Use

What is a Water Filling Machine?

A water filling machine is an automated or semi-automated system used to fill water into bottles of various sizes. These machines are used in bottled water plants, beverage factories, and industrial packaging lines. They help ensure fast production, exact filling volumes, and sanitary operation, complying with industry standards such as BIS, ISI, FSSAI, FDA, and ISO 22000.

Types of Water Filling Machines

1. Automatic Water Filling Machines

These machines are fully automated, including bottle feeding, rinsing, filling, and capping systems. Ideal for high-volume production plants, they can process anywhere from 2,000 to over 24,000 bottles per hour (BPH).

2. Semi-Automatic Water Filling Machines

Perfect for small businesses or startups, these machines require some manual intervention. They offer great affordability while maintaining decent fill speeds and accuracy.

3. Rotary Water Filling Machines

These machines operate on a rotating base, filling multiple bottles simultaneously. High-speed and highly efficient, they are perfect for large-scale bottled water production.

4. Linear Water Filling Machines

Operate in a straight line and are suitable for mid-level production capacity. They are modular, easy to maintain, and can be integrated with other packaging systems.

Key Components of a Water Filling Machine

Rinsing Section: Ensures bottles are cleaned internally using sterile water or air-jet systems.

Filling Section: Dispenses the exact quantity of water without any spillage.

Capping Section: Automatically places and tightens caps.

Conveyor System: Moves bottles from one station to another seamlessly.

Control Panel: Touchscreen interface with PLC to monitor speed, fill levels, and errors.

Water Filling Machine Applications

1. Bottled Mineral Water Plants

Used for 200ml, 500ml, 1L, and 2L PET or glass bottles. Machines can be customized for various bottle neck sizes and shapes.

2. 20-Liter Jar Water Plants

These machines are used for large container packaging and generally include washing, sanitizing, and filling units integrated into one line.

3. Sparkling or Flavored Water Filling

Machines are modified to handle carbonated water, requiring pressure-resistant filling nozzles and foam control.

Advanced Features of Modern Water Filling Machines

1. PLC and HMI-Based Control

Allows real-time monitoring, quick troubleshooting, and batch-wise production tracking.

2. Automatic Bottle Detection

Ensures "no bottle – no fill" operation to prevent product loss.

3. HEPA Filters and UV Sterilization

Critical for maintaining hygiene, especially in pharmaceutical or baby water products.

4. Stainless Steel Construction (SS304/316L)

Non-corrosive, food-grade materials ensure long life and hygiene compliance.

5. Low Maintenance and CIP Systems

Machines now come with Clean-In-Place (CIP) systems to ensure regular, automated internal cleaning.

Benefits of Using a Water Filling Machine

High-Speed Production: Speeds of up to 400 bottles/min are possible with rotary models.

Precision and Accuracy: Digital flow meters ensure minimal variation in fill levels.

Labor Reduction: Fully automated systems require minimal operator intervention.

Consistency: All bottles are filled and capped identically, ensuring product standardization.

Scalability: Can be integrated with labeling, shrink tunnel, carton packing, and palletizing machines.

How to Choose the Right Water Filling Machine

1. Define Your Output Requirement

Are you producing 500 BPH or 10,000 BPH? Your choice of machine will depend on your volume.

2. Consider the Bottle Type and Size

Ensure the machine supports your bottle’s neck diameter, height, and shape.

3. Look for Hygiene Certifications

Machines must comply with BIS, FSSAI, or international norms depending on your target market.

4. Plan for Integration

Will your machine work as part of a full line (rinsing, capping, labeling, sealing)? If so, choose a modular or turnkey solution.

0 notes

Text

The Rising Demand for Mayonnaise Processing Equipment in the Food Industry

In recent years, the growing global appetite for sauces, dressings, and condiments has significantly driven the demand for mayonnaise processing equipment. As mayonnaise becomes a staple in both household and commercial kitchens, food manufacturers are actively investing in modern solutions to meet quality, hygiene, and production standards. The evolution of the industrial mayonnaise making machine has completely transformed traditional production practices, replacing manual labor with automated and continuous processes. This shift not only ensures consistency in taste and texture but also helps manufacturers scale up production to meet rising demand without compromising on safety.

Modern mayonnaise processing equipment is designed to ensure precise mixing, emulsification, and homogenization of ingredients such as oil, egg yolk, vinegar, and seasoning. Among the most critical parts of this setup is the automatic mayonnaise mixing system, which ensures a stable emulsion and uniform product consistency. Such systems have become a necessity for large-scale producers and commercial kitchens. With increasing focus on efficiency and hygiene, manufacturers now prefer stainless steel machinery, ensuring the equipment remains corrosion-resistant, durable, and easy to clean. In fact, many food processing units rely on a stainless steel mayonnaise mixer to uphold quality and food safety standards.

Technological Advancements in Mayonnaise Processing Equipment

The landscape of mayonnaise processing equipment has undergone a technological revolution. Older batch processing techniques have been replaced by more sophisticated and continuous production systems. The introduction of industrial mayonnaise making machines with high-shear mixing capabilities and vacuum systems allows manufacturers to produce smooth, lump-free mayonnaise with minimal air inclusion. This ensures longer shelf life and consistent quality. These advancements have significantly reduced the time and labor involved in traditional methods, allowing even medium-sized producers to compete with industry giants.

Additionally, automation in mayonnaise processing equipment enhances precision and control. With programmable logic controllers (PLCs), operators can adjust parameters like mixing speed, temperature, and emulsification time to fine-tune the final product. This is particularly beneficial in a commercial mayonnaise production line, where large batches must meet strict standards repeatedly. Machines equipped with smart sensors and touch-screen interfaces provide real-time monitoring and diagnostics, ensuring efficient and error-free operations. These improvements have made it easier to integrate automatic mayonnaise mixing systems into modern production workflows without the need for extensive training or complex maintenance.

Commercial Scale Production Using Mayonnaise Processing Equipment

As consumer preferences evolve, there’s a rising demand for customized and flavored varieties of mayonnaise, such as garlic, chipotle, or vegan versions. To cater to such diverse tastes, manufacturers need mayonnaise processing equipment that offers flexibility in recipe formulation without requiring frequent machine overhauls. Modern equipment supports rapid changeovers and automatic ingredient dosing, which is essential for a commercial mayonnaise production line that caters to multiple product SKUs. With precise control over the emulsification process, producers can create high-quality mayonnaise that meets varying customer expectations.

A well-designed stainless steel mayonnaise mixer plays a vital role in commercial scale production. Its robust construction allows it to handle viscous ingredients without clogging or overheating, while its hygienic design reduces contamination risks. Manufacturers in the foodservice and retail sectors now prefer modular systems that can be scaled up or down based on market demand. The ability to integrate industrial mayonnaise making machines with packaging systems has also enhanced production efficiency. From raw material input to final filling, today’s mayonnaise production setups are built to deliver quality at speed, proving the crucial role of advanced mayonnaise processing equipment.

The Future of Mayonnaise Processing Equipment in a Growing Market

The future of mayonnaise processing equipment lies in smarter, more sustainable, and energy-efficient solutions. As sustainability becomes a top priority across the food manufacturing industry, equipment manufacturers are focusing on reducing water, energy, and raw material wastage. Newer automatic mayonnaise mixing systems are being designed to minimize product loss during changeovers and clean-in-place (CIP) operations. Additionally, innovations in sensor-based technology and AI-driven process control are opening new possibilities for autonomous production lines, reducing human error and operational costs.

In this competitive landscape, investing in reliable mayonnaise processing equipment is not just a choice but a necessity for success. From a small artisan food business to a multinational condiment brand, the backbone of scalable production lies in high-performance machinery. As demand continues to grow globally, especially in emerging markets, manufacturers will increasingly depend on efficient industrial mayonnaise making machines and automated lines. Those leveraging a commercial mayonnaise production line that includes a stainless steel mayonnaise mixer will be better positioned to deliver consistent, high-quality products that meet the evolving preferences of today’s consumers. Tags: industrial mayonnaise making machine automatic mayonnaise mixing system commercial mayonnaise production line stainless steel mayonnaise mixer

0 notes

Text

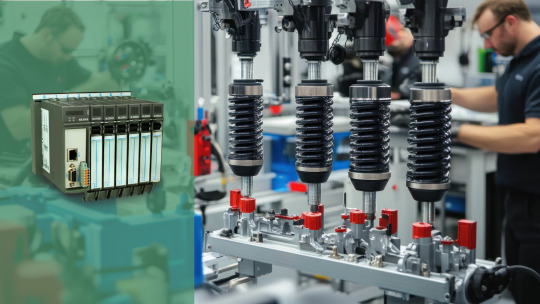

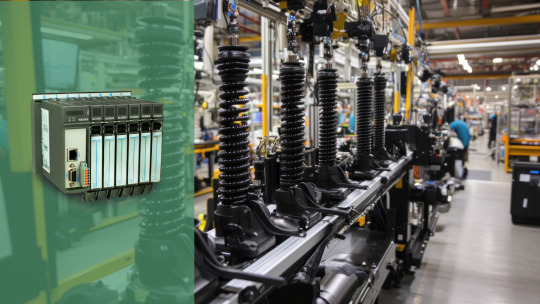

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

Stopping the Sand Crisis at Your Doorstep

09 June 2025

We began our journey with a simple idea: the world has plenty of sand, but little of it is clean, traceable, and mined without harming rivers. Sand taken from the sea or desert cannot be used in concrete because it carries chloride or is too fine in grain size.

By contrast, large volumes of construction debris, excavated material, quarry fines, dredged silt, mining overburden, and even lightly contaminated soil already hold the silica and aggregate now dredged from waterways.

The true barriers have always been cost effective processing, consistent quality, and a reliable route to market. CFlo solved the first two challenges with its technology, and its subsidiary, Doctor Sand, built the marketplace that completes the loop. This achievement remains unmatched in the global sand industry.

A technology that extracts value from most waste streams

CFlo’s patented modular units ship in standard containers but are powerful enough to treat the widest range of feedstocks in the sector. A demolition pile passes through a purpose-built wet processing system and emerges as graded sand, aggregate, or screened soil ready for unburnt bricks. Even lightly contaminated soil can be recycled and given a second life. Each processing module sits on a single chassis run by an intelligent PLC, so capital stays low, operations are eco-friendly, and deployment is measured in days rather than months.

A trading platform that turns output into revenue

Once the waste is processed and ready for sale, Doctor Sand steps in. The subsidiary registers every producer as a Cloudmill partner and certifies each load for grain size, silt content, moisture, and, most important, the royalty payment proof that confirms legal origin. Concrete plants, block yards, and infrastructure contractors log in, enter their demand and specifications, and place live orders. The platform assigns the nearest Cloudmill to fill each request. Doctor Sand pays the Cloudmill within eight working hours, a sharp contrast to the three or four months of credit that still dominate the trade. The platform raises the Cloudmill’s net price, cuts the builder’s landed cost, and removes middlemen from a market long known for opacity.

A circular loop, not a one-off sale

Traditional equipment vendors sell a plant and walk away. CFlo delivers usable products from recycling and an end-to-end solution that lifts the value of every tonne of waste. Through Doctor Sand, each Cloudmill gains reliable buyers, fair prices, and robust volumes, so plant utilisation rises dramatically. With higher throughput and fast, secure payments, most Cloudmills recover their equipment cost in two to three years.

Addressable market and first-mover moat

Global demand for construction aggregates is climbing to record levels, even as regulators from Amsterdam to Andhra Pradesh tighten licences for river extraction. No other company combines proprietary recycling hardware with a nationwide offtake platform. CFlo holds several granted patents covering material handling, water recovery, and modular assembly. Doctor Sand complements this with a network of more than one hundred Cloudmills in seventeen Indian states. The platform accepts material from any efficient and ethical source, whether or not the Cloudmill runs CFlo equipment. Recreating this ecosystem would take years of industry knowledge, supplier onboarding, and buyer trust.

Impact in numbers

A single CFlo line rated at 200 tonnes per hour diverts about one million tonnes of waste each year. This prevents hundreds of kilograms of CO₂ emissions compared with river sand and removes the need for acres of landfill. Over the past 18 years, Cloudmills running CFlo technology have the capacity to produce more than 50 million tonnes of alternative sand each year - about five percent of India’s total demand. CFlo has also enabled the recycling of almost 1.5 million tonnes of construction and demolition waste across 12 cities, including both India’s first and its largest recycling facilities. These achievements give CFlo a clear, measurable ESG profile and place the company at the forefront of sustainable, clean-environment solutions.

Path to scale with capital efficiency

The global sand crisis has created an $85 billion supply gap that conventional mining cannot fill without severe ecological damage. By pairing CFlo’s processing technology with the Doctor Sand managed marketplace, we turn an environmental liability into a bankable asset, keep downstream value in-house, and deliver a fast scaling circular economy solution. This is not a future promise; it is a proven cycle that already turns muck into margin. CFlo’s growth story offers worldwide reach for its proprietary technology, steady recurring revenue, and an ESG profile that regulators and investors now expect.

CFlo is not just building machines; it is rebuilding the raw material economy so that waste replaces depletion. For customers and investors, this is an invitation to back the first end-to-end circular supply chain for a resource the world cannot live -or build - without.

Source: https://medium.com/@mbhartia/stopping-the-sand-crisis-at-your-doorstep-d32b2c9e9c2f

Company Name : CFlo World Limited

Address : Ecospace Business Park Block 4A/Floor 6, Action Area II New Town, Rajarhat Kolkata 700 160, India

Official Email Address: [email protected]

Phone: +91 33 3029 3800

Fax: +91 33 3029 3802

Url : https://cfloworld.com/

0 notes

Text

Understanding Board-to-Board Connectors

In the world of electronic hardware, where space, speed, and signal integrity define performance, board-to-board connectors are critical components that quietly enable innovation. These specialized connectors join printed circuit boards (PCBs) directly without the need for cable assemblies, supporting compact, high-performance electronic designs used in everything from smartphones and laptops to industrial machinery and aerospace systems.Get more news about Board-to-board Connector,you can vist our website!

What Are Board-to-Board Connectors? Board-to-board connectors are designed to provide reliable electrical and mechanical connections between two or more PCBs within a device. Unlike wire-to-board or cable-based systems, these connectors allow signal and power transmission through directly mated interfaces, which helps reduce bulk and improve data integrity. They are essential for stackable or modular designs and are particularly favored in applications where internal space is limited.

Types and Configurations These connectors come in several configurations depending on the orientation and spacing needs:

Parallel (Mezzanine) Connectors: Used when two boards are stacked vertically. These are common in compact electronic devices and offer high-density signal transmission.

Coplanar Connectors: For side-by-side board connections, maintaining the same plane and allowing broader layout designs.

Right-Angle Connectors: Used when a 90-degree connection is required between boards, useful in folded or L-shaped PCB assemblies.

Pitch (the spacing between pins), stack height, current rating, and number of contacts are customizable depending on application requirements. High-speed data connectors often require shielding and controlled impedance to prevent signal loss and crosstalk.

Key Features and Advantages Modern board-to-board connectors are engineered for precision and durability. Key features include:

Miniaturization: Compact design supports smaller electronic devices.

High-Density Pin Configuration: Enables transmission of large volumes of data and signals.

Durability and Reliability: Designed for multiple mating cycles and resistance to shock and vibration.

High-Speed Signal Transmission: Particularly in designs requiring signal integrity for data communication or computing.

Manufacturers also offer versions with alignment guides, locking mechanisms, and surface-mount or through-hole mounting options, ensuring seamless assembly even in automated production lines.

Applications Across Industries Because of their versatility and performance, board-to-board connectors are used in a wide range of industries:

Consumer Electronics: Smartphones, tablets, laptops, and wearables.

Industrial Automation: PLCs, sensors, and motor controllers.

Medical Devices: Diagnostic imaging machines, patient monitors, and handheld tools.

Automotive: Advanced Driver Assistance Systems (ADAS), infotainment, and battery management systems in EVs.

Aerospace and Defense: Flight systems, navigation equipment, and satellite electronics.

As electronics become smarter and more integrated, the demand for connectors that balance power, data throughput, and mechanical integrity has never been higher.

Innovation and Market Outlook The global board-to-board connector market is expected to grow steadily, driven by trends such as miniaturization, 5G deployment, IoT integration, and automation. Emerging materials and manufacturing techniques—like laser welding and micro molding—are allowing for even smaller, faster, and more durable connectors.

Asian countries, particularly China, South Korea, and Taiwan, dominate production, but leading global manufacturers like Samtec, TE Connectivity, and Hirose Electric continue to drive innovation with proprietary designs optimized for high-speed and harsh-environment applications.

Conclusion Board-to-board connectors might not be visible to end users, but they are indispensable to modern technology. As we continue to demand more from our devices—in performance, portability, and connectivity—these small yet powerful components ensure that everything works as one cohesive system. Their evolution mirrors our own digital advancement: quietly essential, endlessly adaptable, and critical to progress.

0 notes

Text

Introduction to CODESYS PLC: A Comprehensive Overview

CODESYS (Controller Development System) is a leading software platform for industrial automation, widely used for programming and configuring Programmable Logic Controllers (PLCs). Developed by the German company 3S-Smart Software Solutions, CODESYS PLC is a versatile, hardware-independent development environment that supports a broad range of industrial applications, from factory automation to process control and motion control systems. This article explores the key features, benefits, programming capabilities, and applications of CODESYS PLC, highlighting its significance in modern industrial automation.

What is CODESYS?

CODESYS is an integrated development environment (IDE) that adheres to the international standard IEC 61131-3, which defines programming languages for PLCs. This standard ensures that CODESYS is compatible with a wide variety of hardware platforms from different manufacturers, making it a flexible and scalable solution. The platform supports all five IEC 61131-3 programming languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). Additionally, CODESYS extends support for object-oriented programming (OOP) with languages like Structured Text, enabling advanced programming techniques.

The CODESYS ecosystem includes not only the core IDE but also additional tools for visualization, simulation, debugging, and communication with field devices. It is used in industries such as manufacturing, energy, automotive, and building automation, offering a unified platform for developing complex automation solutions.

Key Features of CODESYS

IEC 61131-3 Compliance: CODESYS supports all standard PLC programming languages, allowing developers to choose the most suitable language for their application. This compliance ensures portability of code across different PLC hardware, reducing development time and costs.

Hardware Independence: CODESYS is compatible with over 1,000 devices from various manufacturers, including Siemens, Beckhoff, WAGO, and others. This flexibility allows engineers to write code once and deploy it on multiple platforms without significant modifications.

Integrated Visualization: CODESYS provides built-in tools for creating Human-Machine Interfaces (HMIs). Developers can design graphical user interfaces for operator panels, web-based visualizations, or mobile applications, all within the same environment.

Fieldbus and Communication Support: The platform supports a wide range of industrial communication protocols, such as Modbus, CANopen, EtherCAT, PROFINET, and OPC UA. This ensures seamless integration with sensors, actuators, and other devices in an automation system.

Simulation and Debugging: CODESYS includes a powerful simulation mode that allows developers to test their programs without physical hardware. The debugging tools enable real-time monitoring, breakpoints, and variable tracing, streamlining the development process.

Scalability and Modularity: From small embedded systems to large distributed control systems, CODESYS is highly scalable. Its modular architecture allows developers to add libraries, function blocks, and extensions as needed.

Safety and Security: CODESYS supports safety programming according to standards like IEC 61508 (SIL 2/3), making it suitable for safety-critical applications. It also includes features for secure communication and user authentication to protect against cyber threats.

Programming with CODESYS

CODESYS offers a flexible programming environment that caters to both novice and experienced developers. The five IEC 61131-3 languages provide diverse options:

Ladder Diagram (LD): Ideal for electrical engineers familiar with relay logic, LD resembles electrical circuit diagrams and is widely used for simple control tasks.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, making it intuitive for designing complex systems.

Structured Text (ST): A high-level, text-based language similar to Pascal or C, suitable for algorithmic and mathematical operations.

Instruction List (IL): A low-level, assembly-like language for precise control, though less commonly used today.

Sequential Function Chart (SFC): Used for sequential control processes, SFC is ideal for applications requiring step-by-step execution, such as batch processing.

In addition to these, CODESYS supports object-oriented programming, allowing developers to create reusable code through classes, methods, and inheritance. This is particularly useful for large-scale projects where modularity and maintainability are critical.

Benefits of Using CODESYS

Cost Efficiency: By supporting multiple hardware platforms, CODESYS eliminates the need for proprietary software tied to specific vendors, reducing licensing and development costs.

Flexibility: Developers can work in their preferred programming language and deploy code on various devices, enhancing project flexibility.

Community and Ecosystem: CODESYS has a large user base and an active community, with extensive documentation, libraries, and third-party tools available through the CODESYS Store.

Rapid Development: The integrated environment, combined with simulation and debugging tools, accelerates development and testing cycles.

Global Adoption: CODESYS is used worldwide, ensuring that skills learned in the platform are transferable across industries and regions.

Applications of CODESYS PLC

CODESYS is employed in a wide range of industries, including:

Manufacturing: Controlling assembly lines, robotic systems, and CNC machines.

Energy: Managing renewable energy systems, such as wind turbines and solar plants, as well as traditional power distribution networks.

Building Automation: Integrating HVAC, lighting, and security systems for smart buildings.

Automotive: Controlling production lines and testing equipment in automotive manufacturing.

Process Control: Managing chemical plants, water treatment facilities, and food processing systems.

Getting Started with CODESYS

To begin using CODESYS, developers can download the free CODESYS Development System from the official website. The software is compatible with Windows and supports a variety of PLC hardware. Beginners can start with the extensive documentation and tutorials available online, while advanced users can explore the CODESYS Store for additional libraries and add-ons.

A typical workflow involves:

Installing the CODESYS IDE.

Selecting a target PLC and configuring the hardware.

Writing the program using one or more IEC 61131-3 languages.

Simulating the program to test functionality.

Deploying the code to the PLC and monitoring its performance.

Challenges and Considerations

While CODESYS is a powerful platform, there are some considerations:

Learning Curve: For beginners, mastering all five programming languages and the IDE’s features can take time.

Hardware Dependency: Although CODESYS is hardware-independent, specific PLCs may require proprietary drivers or configurations.