#PTFE LINED BALL VALVE

Explore tagged Tumblr posts

Text

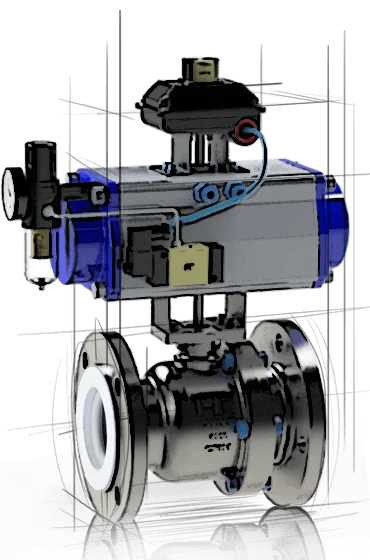

How PTFE Lined Ball Valves Enhance Chemical Processing Efficiency

Industrial processes rely on durable, corrosion-resistant components to handle aggressive chemicals. PTFE lined ball valves play a vital role in ensuring chemical processing efficiency, offering leak-proof operation, minimal friction, and enhanced durability. These properties make them ideal for applications where chemical purity, longevity, and operational safety are key concerns.

How PTFE Lining Improves Performance

Exceptional Chemical Compatibility: Prevents chemical breakdown and degradation.

Reduced Friction & Clogging: Ensures smooth flow and minimizes blockages.

Extended Valve Lifespan: Resists wear, reducing replacement and maintenance costs.

Key Benefits for Chemical Plants

PTFE lined ball valves are indispensable in chemical plants, where exposure to corrosive fluids poses operational risks. The protective PTFE barrier prevents leaks and ensures safe, contamination-free processing.

Leak-Proof Design: Minimizes hazardous spills and improves workplace safety.

High Temperature & Pressure Tolerance: Ideal for extreme processing conditions.

Long-Term Cost Savings: Reduced downtime and maintenance enhance plant efficiency.

The FDA-approved PTFE lining further supports industries requiring strict hygiene compliance, including pharmaceutical and food processing sectors. With versatile end connections and configurations, PTFE lined ball valves cater to diverse industrial needs, ensuring seamless integration into processing systems.

Investing in PTFE lined ball valves guarantees long-term operational efficiency, safety, and cost savings. Their non-stick, non-reactive properties make them a superior choice over conventional ball valves, particularly for industries dealing with highly aggressive fluids. With the ability to maintain purity, prevent contamination, and withstand extreme conditions, these valves continue to set the standard for chemical processing applications.

Choosing a trusted PTFE Lined ball valve manufacturer ensures high-quality solutions tailored to specific industry requirements, enabling businesses to optimize their operations and enhance overall system reliability.

#PTFE Lined Ball Valve#FEP Lined Ball Valve#Lined Ball Valves#manufacturers#suppliers#india#freturetechno

0 notes

Text

Solvent Weld vs Thermal Weld Ball Valves: Critical Differences

Welded ball valves provide permanent, leak-tight connections in critical piping systems. Understanding the fundamental distinction between solvent welding and thermal welding is essential for proper valve selection:ParameterSolvent Weld Ball ValvesThermal Weld Ball ValvesConnection MethodChemical fusion of thermoplasticsMetal melting (TIG/MIG welding)MaterialsPVC, CPVC, PP, PVDRStainless steel, carbon steelMax Temperature140°F (60°C)1200°F+ (650°C+)Pressure RatingClass 150Class 150-2500ApplicationsChemical transfer, water treatmentOil/gas, steam, high-pressure lines

Welded Ball Valve Types Explained

1. Fully Welded Ball Valves

– Structure: Monolithic body with no flanges/gaskets

– Advantages: Zero-leak guarantee, 30+ year service life

– Standards: ASME B16.34, API 6D

– Use Cases: Underground pipelines, subsea applications, LNG terminals

2. Semi Welded Ball Valves

– Hybrid Design: Welded body + bolted bonnet

– Maintenance: Seal replacement without pipe cutting

– Industries: Power generation, pharmaceutical processing

– Pressure: Class 600-1500

3. Stainless Steel Welded Ball Valves

– Grades: 316L, 304, duplex, super duplex

– Corrosion Resistance: Withstands chlorides, acids, H₂S

– Certifications: NACE MR0175 for sour service

– Sanitary Options: 3A compliant for food/pharma

Industrial Applications by Type

IndustryRecommended Valve TypeKey BenefitChemical ProcessingSolvent weld CPVC valvesSulfuric acid resistanceOil & GasFully welded SS316 valvesAPI 6FA fire-safe certificationDistrict HeatingSemi-welded carbon steel valvesThermal shock resistancePharmaSanitary stainless steel valvesElectropolished surfaces

NSW: Certified Weld Ball Valve Manufacturer

As an ISO 9001 & API 6D certified weld ball valve manufacturer, NSW delivers:

- Unmatched Range: ½” to 60″ valves (ANSI 150 – 2500)

– Specialized Welding:

– Orbital welding for nuclear applications

– Cryogenic treatment (-320°F/-196°C)

– Hot tapping capability

– Material Expertise:

– ASTM A351 CF8M stainless steel

– Alloy 20, Hastelloy, titanium

– Lined PTFE/PFA options

– Testing Protocol:

– 100% helium leak testing

– API 598 seat tests

– Fugitive emissions (ISO 15848-1)

0 notes

Text

Top 10 Control Valve Manufacturers in India (2025 Update)

India’s industrial sector is booming, and with it, the demand for reliable flow control systems. Whether it's oil & gas, power, pharmaceuticals, or water treatment — control valves play a crucial role in maintaining process efficiency and safety.

With rising infrastructure and exports, Indian manufacturers are now competing globally with high-quality, cost-effective control valves designed for demanding applications.

In this 2025 update, we explore the top 10 control valve manufacturers in India, based on product range, certifications, innovation, and customer trust.

MNC Valves

Location: Delhi- Gujarat India Specialty: Steam engineering & control instrumentation

MNC Valves offers high-performance control valves designed for accurate regulation of pressure, flow rate, and temperature across a wide range of industrial applications. Engineered with precision and built for durability, our control valves ensure optimal process efficiency and reliability in even the most demanding conditions.

Our control valves are available in various types including globe, angle, and diaphragm valves, and are compatible with both pneumatic and electric actuators. Each valve is manufactured using premium materials such as stainless steel, WCB, and alloy steels to provide superior resistance against corrosion, wear, and high-pressure media.

L&T Valves

Location: Chennai, Tamil Nadu Specialty: Critical service valves for oil & gas and power

A subsidiary of Larsen & Toubro, L&T Valves is a global player in flow-control solutions. Known for engineering excellence, they offer a wide range of control valves including globe, ball, butterfly, and plug valves for high-pressure and high-temperature applications.

KSB Limited

Location: Pune, Maharashtra Specialty: Globe control valves and energy-efficient systems

Part of the international KSB Group, KSB India offers high-precision control valves for water, wastewater, chemical, and energy applications. Their valves are known for durability, precision, and ease of maintenance.

BHEL (Bharat Heavy Electricals Limited)

Location: New Delhi (Plants in Haridwar, Hyderabad) Specialty: Control valves for power generation & nuclear sectors

A government-owned engineering giant, BHEL manufactures a broad range of control valves suited for power plants, hydroelectric stations, and defense applications. Their in-house R&D supports the development of indigenous valve technology for India’s strategic sectors.

Amtech Valves

Location: Ahmedabad, Gujarat Specialty: Industrial control and automation valves

Amtech Valves manufactures high-performance control valves designed for automation, including pneumatic and electric actuated valves. Their products serve the chemical, textile, and water industries with a strong domestic and international presence.

Flowserve India Controls

Location: Coimbatore, Tamil Nadu Specialty: Severe service control valves & smart diagnostics

Flowserve, a global brand with a strong manufacturing base in India, provides high-end control valve solutions for oil & gas, petrochemical, and marine sectors. Their smart valve diagnostics and performance monitoring tools offer real-time process insights.

CRI Pumps – Valves Division

Location: Coimbatore, Tamil Nadu Specialty: Automated control valves for water and irrigation systems

Well known for pumps, CRI also has a dedicated valves division manufacturing control valves for municipal water supply, irrigation, and infrastructure projects. They are widely trusted for reliability and cost-effective solutions.

SVR Valves

Location: Hyderabad, Telangana Specialty: PFA/PTFE lined control valves for corrosive media

SVR Valves specializes in PFA and PTFE lined control valves, widely used in chemical and pharmaceutical industries where corrosion resistance is critical. Their ISO-certified products conform to international standards like ASTM, DIN, and ASME.

Precision Control Valves

Location: Mumbai, Maharashtra Specialty: Custom-engineered control valves

A rapidly growing manufacturer offering customized solutions across diverse industries, Precision Control Valves caters to niche process applications. They’re known for tight shut-off designs and compatibility with automation systems like PLCs and SCADA.

Microfinish Valves

Location: Hubli, Karnataka Specialty: Globe and angle control valves

Microfinish is a major exporter of control valves with a strong presence in Europe, North America, and the Middle East. Their globe and angle control valves are precision-machined for tight control and long lifecycle.

✅ Choosing the Right Control Valve Manufacturer

When selecting a control valve supplier in India, consider the following:

Certifications: Look for ISO, API, CE, and ATEX certifications.

Material Capabilities: Choose manufacturers who offer a range of materials (SS, PFA, Hastelloy, etc.) for specific media.

After-Sales Support: A reliable service network for maintenance and spares is crucial.

Industry References: Check if the brand has experience in your industry (power, pharma, food, etc.).

🌍 India as a Global Valve Manufacturing Hub

With Make in India initiatives and rising export potential, India is becoming a preferred sourcing destination for industrial valves, including control, gate, globe, ball, and butterfly valves. Several Indian manufacturers now comply with international standards and offer custom solutions at competitive pricing.

Moreover, as green energy and water infrastructure projects grow, the demand for advanced control valves with automation compatibility is set to rise.

📌 Final Thoughts

Whether you're an OEM, EPC contractor, or procurement manager, finding the right control valve partner in India can boost efficiency, cut costs, and reduce downtime. The manufacturers listed above represent the best in quality, innovation, and customer satisfaction in 2025.

0 notes

Text

0 notes

Text

Plug Valve vs Ball Valve – Key Differences, Functions & Applications Explained

When selecting valves for industrial or commercial fluid handling systems, the choice between a plug valve and a ball valve is a common one. Though both are quarter-turn valves, they differ in design, sealing, application suitability, and maintenance.

As a leading plug and ball valve manufacturer and supplier in Delhi, Udhhyog provides high-performance solutions for a wide variety of industries including oil, gas, water treatment, chemical processing, and HVAC systems.

This article explores the key differences between plug and ball valves, their functions, advantages, applications, and how to select the right valve for your system.

What is a Plug Valve?

A plug valve uses a tapered or cylindrical plug inside the valve body to control flow. The plug has a hole that aligns with the pipe when open and blocks it when rotated 90°.

✅ Key Features:

Compact and simple design

Available in lubricated and non-lubricated forms

Often used for multi-port applications (3-way, 4-way)

Ideal for on/off and limited throttling service

✅ Common Types:

Lubricated Plug Valve

Non-Lubricated Plug Valve

Eccentric Plug Valve

Expanding Plug Valve

Multi-Port Plug Valve

What is a Ball Valve?

A ball valve uses a spherical disc with a central hole to regulate flow. Rotating the ball 90° allows or blocks flow. Ball valves offer tight shutoff with minimal pressure drop.

✅ Key Features:

Fast quarter-turn operation

Excellent for on/off control

Available in full bore and reduced bore types

Common in water, gas, and air applications

✅ Common Types:

Two-Piece Ball Valve

Three-Piece Ball Valve

Floating Ball Valve

Trunnion-Mounted Ball Valve

V-Port Ball Valve (for control applications)

Plug Valve vs Ball Valve – Detailed Comparison

FeaturePlug ValveBall ValveClosure TypeTapered or cylindrical plugSpherical ballOperationQuarter-turnQuarter-turnSealingLubricated or sleevedSoft seats (PTFE) or metalFlow ControlGood for isolation, limited throttleExcellent isolation, some throttlingSize RangeCompact for small to medium sizesAvailable in all sizesPressure HandlingExcellent in high-pressure systemsAlso excellent, especially trunnion-mountedApplicationsOil, gas, chemicals, wastewaterWater, air, HVAC, clean gasesMaintenancePeriodic lubrication (if lubricated)Low-maintenanceCostGenerally lower for basic modelsSlightly higher

✅ Use plug valves in abrasive, slurry, or chemical lines. ✅ Use ball valves in water, gas, and low-viscosity applications.

Applications of Plug Valves

🛢️ Oil and gas transmission

🧪 Chemical and petrochemical plants

🚰 Water treatment and wastewater management

🏭 Refinery and terminal piping

🔁 Flow diversion (multi-port plug valves)

Applications of Ball Valves

💧 Domestic and industrial water lines

🔥 HVAC systems

🌬️ Compressed air systems

🛠️ Machine tool lines and instrument panels

🧼 Food and pharma processing

Symbols – Plug Valve vs Ball Valve

Plug Valve Symbol: Square body with central plug icon; often shown with arrows and circular indicators.

Ball Valve Symbol: Circle with a horizontal line (ball) and an open or closed indication.

Both symbols are used in P&ID drawings to represent their specific function in fluid systems.

Materials Used

At Udhhyog, we manufacture both plug and ball valves using:

Cast Iron (CI)

Ductile Iron (DI)

Carbon Steel (WCB)

Stainless Steel (SS 304/316)

Bronze or Gunmetal

Pricing Overview – Plug & Ball Valves in Delhi

Valve TypeSize (mm)MaterialPrice Range (INR)Lubricated Plug Valve25–200CI/WCB₹1,800 – ₹12,000Non-Lubricated Plug15–100CI/SS₹1,200 – ₹6,000Multi-Port Plug Valve25–150Bronze/SS₹5,000 – ₹15,000Ball Valve (2-Piece)15–150CI/SS₹900 – ₹5,500Ball Valve (3-Piece)25–150SS 304/316₹2,500 – ₹12,000Trunnion Ball Valve50–200WCB/SS₹8,000 – ₹25,000

📌 Prices vary based on pressure rating, end connections, and seat type. Contact Udhhyog for bulk or custom rates.

Why Choose Udhhyog – Delhi’s Best Valve Manufacturer

🏭 Expertise in Both Plug and Ball Valves

Specialized solutions for oil, gas, steam, water, and chemical handling.

🛠️ Tested and Certified Products

Valves undergo pressure, leakage, and seat testing as per IS/API/ISO standards.

🚛 Supply Across North India

We supply to Delhi, Haryana, Punjab, UP, Rajasthan, Himachal Pradesh, and J&K.

📞 Dedicated Support Team

Technical assistance for selection, sizing, and installation.

💰 Affordable Pricing & Bulk Availability

Competitive rates with fast turnaround for all orders.

Conclusion

While both plug valves and ball valves serve as efficient shutoff solutions, understanding their construction, strengths, and limitations helps in choosing the right valve for your application.

If you're looking for reliable industrial valves in Delhi, trust Udhhyog – your dedicated manufacturer and supplier of plug and ball valves, offering consistent quality and dependable service.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed catalogs, pricing, and product specifications.

#PlugValve#BallValve#PlugVsBallValve#ValveComparison#ValveSupplierDelhi#Udhhyog#IndustrialValves#FlowControl#BallValvePrice#PlugValveApplications#pipefittings

1 note

·

View note

Text

Plug Valve vs Ball Valve – Key Differences, Functions & Applications Explained

When selecting valves for industrial or commercial fluid handling systems, the choice between a plug valve and a ball valve is a common one. Though both are quarter-turn valves, they differ in design, sealing, application suitability, and maintenance.

As a leading plug and ball valve manufacturer and supplier in Delhi, Udhhyog provides high-performance solutions for a wide variety of industries including oil, gas, water treatment, chemical processing, and HVAC systems.

This article explores the key differences between plug and ball valves, their functions, advantages, applications, and how to select the right valve for your system.

What is a Plug Valve?

A plug valve uses a tapered or cylindrical plug inside the valve body to control flow. The plug has a hole that aligns with the pipe when open and blocks it when rotated 90°.

✅ Key Features:

Compact and simple design

Available in lubricated and non-lubricated forms

Often used for multi-port applications (3-way, 4-way)

Ideal for on/off and limited throttling service

✅ Common Types:

Lubricated Plug Valve

Non-Lubricated Plug Valve

Eccentric Plug Valve

Expanding Plug Valve

Multi-Port Plug Valve

What is a Ball Valve?

A ball valve uses a spherical disc with a central hole to regulate flow. Rotating the ball 90° allows or blocks flow. Ball valves offer tight shutoff with minimal pressure drop.

✅ Key Features:

Fast quarter-turn operation

Excellent for on/off control

Available in full bore and reduced bore types

Common in water, gas, and air applications

✅ Common Types:

Two-Piece Ball Valve

Three-Piece Ball Valve

Floating Ball Valve

Trunnion-Mounted Ball Valve

V-Port Ball Valve (for control applications)

Plug Valve vs Ball Valve – Detailed Comparison

FeaturePlug ValveBall ValveClosure TypeTapered or cylindrical plugSpherical ballOperationQuarter-turnQuarter-turnSealingLubricated or sleevedSoft seats (PTFE) or metalFlow ControlGood for isolation, limited throttleExcellent isolation, some throttlingSize RangeCompact for small to medium sizesAvailable in all sizesPressure HandlingExcellent in high-pressure systemsAlso excellent, especially trunnion-mountedApplicationsOil, gas, chemicals, wastewaterWater, air, HVAC, clean gasesMaintenancePeriodic lubrication (if lubricated)Low-maintenanceCostGenerally lower for basic modelsSlightly higher

✅ Use plug valves in abrasive, slurry, or chemical lines. ✅ Use ball valves in water, gas, and low-viscosity applications.

Applications of Plug Valves

🛢️ Oil and gas transmission

🧪 Chemical and petrochemical plants

🚰 Water treatment and wastewater management

🏭 Refinery and terminal piping

🔁 Flow diversion (multi-port plug valves)

Applications of Ball Valves

💧 Domestic and industrial water lines

🔥 HVAC systems

🌬️ Compressed air systems

🛠️ Machine tool lines and instrument panels

🧼 Food and pharma processing

Symbols – Plug Valve vs Ball Valve

Plug Valve Symbol: Square body with central plug icon; often shown with arrows and circular indicators.

Ball Valve Symbol: Circle with a horizontal line (ball) and an open or closed indication.

Both symbols are used in P&ID drawings to represent their specific function in fluid systems.

Materials Used

At Udhhyog, we manufacture both plug and ball valves using:

Cast Iron (CI)

Ductile Iron (DI)

Carbon Steel (WCB)

Stainless Steel (SS 304/316)

Bronze or Gunmetal

Pricing Overview – Plug & Ball Valves in Delhi

Valve TypeSize (mm)MaterialPrice Range (INR)Lubricated Plug Valve25–200CI/WCB₹1,800 – ₹12,000Non-Lubricated Plug15–100CI/SS₹1,200 – ₹6,000Multi-Port Plug Valve25–150Bronze/SS₹5,000 – ₹15,000Ball Valve (2-Piece)15–150CI/SS₹900 – ₹5,500Ball Valve (3-Piece)25–150SS 304/316₹2,500 – ₹12,000Trunnion Ball Valve50–200WCB/SS₹8,000 – ₹25,000

📌 Prices vary based on pressure rating, end connections, and seat type. Contact Udhhyog for bulk or custom rates.

Why Choose Udhhyog – Delhi’s Best Valve Manufacturer

🏭 Expertise in Both Plug and Ball Valves

Specialized solutions for oil, gas, steam, water, and chemical handling.

🛠️ Tested and Certified Products

Valves undergo pressure, leakage, and seat testing as per IS/API/ISO standards.

🚛 Supply Across North India

We supply to Delhi, Haryana, Punjab, UP, Rajasthan, Himachal Pradesh, and J&K.

📞 Dedicated Support Team

Technical assistance for selection, sizing, and installation.

💰 Affordable Pricing & Bulk Availability

Competitive rates with fast turnaround for all orders.

Conclusion

While both plug valves and ball valves serve as efficient shutoff solutions, understanding their construction, strengths, and limitations helps in choosing the right valve for your application.

If you're looking for reliable industrial valves in Delhi, trust Udhhyog – your dedicated manufacturer and supplier of plug and ball valves, offering consistent quality and dependable service.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed catalogs, pricing, and product specifications.

#PlugValve#BallValve#PlugVsBallValve#ValveComparison#ValveSupplierDelhi#Udhhyog#IndustrialValves#FlowControl#BallValvePrice#PlugValveApplications

0 notes

Text

Plug Valve vs Ball Valve – Key Differences, Functions & Applications Explained

When selecting valves for industrial or commercial fluid handling systems, the choice between a plug valve and a ball valve is a common one. Though both are quarter-turn valves, they differ in design, sealing, application suitability, and maintenance.

As a leading plug and ball valve manufacturer and supplier in Delhi, Udhhyog provides high-performance solutions for a wide variety of industries including oil, gas, water treatment, chemical processing, and HVAC systems.

This article explores the key differences between plug and ball valves, their functions, advantages, applications, and how to select the right valve for your system.

What is a Plug Valve?

A plug valve uses a tapered or cylindrical plug inside the valve body to control flow. The plug has a hole that aligns with the pipe when open and blocks it when rotated 90°.

✅ Key Features:

Compact and simple design

Available in lubricated and non-lubricated forms

Often used for multi-port applications (3-way, 4-way)

Ideal for on/off and limited throttling service

✅ Common Types:

Lubricated Plug Valve

Non-Lubricated Plug Valve

Eccentric Plug Valve

Expanding Plug Valve

Multi-Port Plug Valve

What is a Ball Valve?

A ball valve uses a spherical disc with a central hole to regulate flow. Rotating the ball 90° allows or blocks flow. Ball valves offer tight shutoff with minimal pressure drop.

✅ Key Features:

Fast quarter-turn operation

Excellent for on/off control

Available in full bore and reduced bore types

Common in water, gas, and air applications

✅ Common Types:

Two-Piece Ball Valve

Three-Piece Ball Valve

Floating Ball Valve

Trunnion-Mounted Ball Valve

V-Port Ball Valve (for control applications)

Plug Valve vs Ball Valve – Detailed Comparison

FeaturePlug ValveBall ValveClosure TypeTapered or cylindrical plugSpherical ballOperationQuarter-turnQuarter-turnSealingLubricated or sleevedSoft seats (PTFE) or metalFlow ControlGood for isolation, limited throttleExcellent isolation, some throttlingSize RangeCompact for small to medium sizesAvailable in all sizesPressure HandlingExcellent in high-pressure systemsAlso excellent, especially trunnion-mountedApplicationsOil, gas, chemicals, wastewaterWater, air, HVAC, clean gasesMaintenancePeriodic lubrication (if lubricated)Low-maintenanceCostGenerally lower for basic modelsSlightly higher

✅ Use plug valves in abrasive, slurry, or chemical lines. ✅ Use ball valves in water, gas, and low-viscosity applications.

Applications of Plug Valves

🛢️ Oil and gas transmission

🧪 Chemical and petrochemical plants

🚰 Water treatment and wastewater management

🏭 Refinery and terminal piping

🔁 Flow diversion (multi-port plug valves)

Applications of Ball Valves

💧 Domestic and industrial water lines

🔥 HVAC systems

🌬️ Compressed air systems

🛠️ Machine tool lines and instrument panels

🧼 Food and pharma processing

Symbols – Plug Valve vs Ball Valve

Plug Valve Symbol: Square body with central plug icon; often shown with arrows and circular indicators.

Ball Valve Symbol: Circle with a horizontal line (ball) and an open or closed indication.

Both symbols are used in P&ID drawings to represent their specific function in fluid systems.

Materials Used

At Udhhyog, we manufacture both plug and ball valves using:

Cast Iron (CI)

Ductile Iron (DI)

Carbon Steel (WCB)

Stainless Steel (SS 304/316)

Bronze or Gunmetal

Pricing Overview – Plug & Ball Valves in Delhi

Valve TypeSize (mm)MaterialPrice Range (INR)Lubricated Plug Valve25–200CI/WCB₹1,800 – ₹12,000Non-Lubricated Plug15–100CI/SS₹1,200 – ₹6,000Multi-Port Plug Valve25–150Bronze/SS₹5,000 – ₹15,000Ball Valve (2-Piece)15–150CI/SS₹900 – ₹5,500Ball Valve (3-Piece)25–150SS 304/316₹2,500 – ₹12,000Trunnion Ball Valve50–200WCB/SS₹8,000 – ₹25,000

📌 Prices vary based on pressure rating, end connections, and seat type. Contact Udhhyog for bulk or custom rates.

Why Choose Udhhyog – Delhi’s Best Valve Manufacturer

🏭 Expertise in Both Plug and Ball Valves

Specialized solutions for oil, gas, steam, water, and chemical handling.

🛠️ Tested and Certified Products

Valves undergo pressure, leakage, and seat testing as per IS/API/ISO standards.

🚛 Supply Across North India

We supply to Delhi, Haryana, Punjab, UP, Rajasthan, Himachal Pradesh, and J&K.

📞 Dedicated Support Team

Technical assistance for selection, sizing, and installation.

💰 Affordable Pricing & Bulk Availability

Competitive rates with fast turnaround for all orders.

Conclusion

While both plug valves and ball valves serve as efficient shutoff solutions, understanding their construction, strengths, and limitations helps in choosing the right valve for your application.

If you're looking for reliable industrial valves in Delhi, trust Udhhyog – your dedicated manufacturer and supplier of plug and ball valves, offering consistent quality and dependable service.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed catalogs, pricing, and product specifications.

#PlugValve#BallValve#PlugVsBallValve#ValveComparison#ValveSupplierDelhi#Udhhyog#IndustrialValves#FlowControl#BallValvePrice#PlugValveApplications

0 notes

Text

Understanding Pneumatic Actuators: Working Principles, Types, And Key Components Explained

Pneumatic actuators are essential components in modern industrial automation and machinery. They convert compressed air energy into mechanical motion, enabling precise control of valves, grippers, and other mechanical systems. Widely used in manufacturing, robotics, and process industries, pneumatic actuators are valued for their reliability, simplicity, and cost-effectiveness. This article explores their working principles, common types, and key components.

1. Working Principles Of Pneumatic Actuators

Pneumatic actuators operate on the fundamental principle of pressure differential. When compressed air is introduced into the actuator, it creates a force that moves internal components, generating linear or rotary motion. Here’s a step-by-step breakdown:

Air Supply: Compressed air (typically 4–7 bar or 60–100 psi) is supplied from a pneumatic system or compressor.

Pressure Application: Air enters the actuator’s chamber, exerting pressure on a piston, diaphragm, or vane.

Motion Generation: The pressure differential across the piston/diaphragm creates linear or rotational movement.

Return Mechanism: In single-acting actuators, a spring returns the piston to its original position when air pressure is released. Double-acting actuators use compressed air to move in both directions.

Key advantages include rapid response times, high force-to-size ratios, and suitability for hazardous environments (no sparks or overheating).

2. Types Of Pneumatic Actuators

Pneumatic actuators are categorized based on their motion type and design:

A. Linear Actuators

Single-Acting: Compressed air moves the piston in one direction; a spring returns it. Ideal for simple on/off applications (e.g., clamping).

Double-Acting: Air pressure moves the piston in both directions, enabling precise bidirectional control. Common in industrial valves and automation.

B. Rotary Actuators

Rack-and-Pinion: A piston with a rack gear rotates a pinion gear, producing rotary motion. Used for quarter-turn valve control (e.g., ball valves).

Vane-Type: Compressed air pushes vanes in a circular chamber, generating torque. Suitable for continuous rotation applications.

Scotch Yoke: Converts linear piston motion into rotary motion via a slotted yoke mechanism. Offers high torque for heavy-duty valves.

C. Specialty Actuators

Diaphragm Actuators: Use a flexible diaphragm instead of a piston. Common in pressure control valves.

Rodless Actuators: Eliminate the piston rod, allowing for compact designs in confined spaces.

3. Key Components Of Pneumatic Actuators

Understanding the internal structure of pneumatic actuators is crucial for maintenance and selection:

Cylinder Body: Houses the piston and contains compressed air. Made of aluminum, stainless steel, or engineered plastics.

Piston: Converts air pressure into linear motion. Sealed with O-rings to prevent air leakage.

Piston Rod: Transmits motion to external mechanisms. Often chrome-plated for durability.

End Caps: Seal the cylinder and include ports for air inlet/outlet.

Seals and Gaskets: Ensure airtight operation. Common materials include nitrile rubber (NBR) or polytetrafluoroethylene (PTFE).

Spring (Single-Acting): Provides return force in single-acting designs.

Position Sensors (Optional): Detect piston position for feedback in automated systems.

4. Applications And Industry Use Cases

Pneumatic actuators are ubiquitous in industries requiring fast, reliable motion control:

Manufacturing: Operating conveyor belts, assembly line grippers.

Oil and Gas: Controlling pipeline valves in explosive environments.

Food and Beverage: Hygienic actuators for packaging and filling systems.

Automotive: Robotic welding and painting systems.

Conclusion

Pneumatic actuators remain a cornerstone of industrial automation due to their simplicity, safety, and adaptability. By leveraging compressed air, they provide efficient motion control for diverse applications. Engineers and technicians must consider factors like load requirements, operating environment, and cycle rates when selecting the right actuator type. As industries evolve, innovations in materials and smart pneumatics (e.g., IoT-enabled actuators) are enhancing their performance and integration with modern control systems.

This article provides a comprehensive overview of pneumatic actuators while maintaining readability for both technical and non-technical audiences.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

0 notes

Text

Can Ball Valves Be Used for Steam: A Comprehensive Guide

Ball valves are widely used in industrial applications, but their compatibility with steam systems often raises questions. This article explores whether ball valves can handle steam, their advantages, suitable types, and how to select reliable manufacturers.

What Is a Ball Valve

A ball valve is a quarter-turn valve that uses a hollow, perforated, rotating ball to control fluid flow. When the ball’s hole aligns with the pipeline, flow is allowed; rotating it 90 degrees blocks the flow. Known for durability and tight sealing, ball valves are popular in oil, gas, water, and chemical industries.

Characteristics of Steam

Steam is a high-energy gas generated by heating water. Its key properties include:

High temperature: Steam systems often operate at 100°C–400°C.

Pressure fluctuations: Steam lines may experience rapid pressure changes.

Corrosiveness: Impurities in water can create corrosive condensate.

These traits demand valves with robust materials, thermal stability, and reliable sealing.

Advantages of Ball Valves in Steam Systems

Quick Operation: The 90-degree turn enables fast shutoff, critical for emergency steam isolation.

Excellent Sealing: PTFE or graphite seats ensure leak-free performance under high pressure.

Durability: Stainless steel or alloy construction resists corrosion and thermal stress.

Low Maintenance: Simple design reduces wear and downtime.

Types of Ball Valves Suitable for Steam

Not all ball valves are steam-compatible. Key types include:

Full-Port Ball Valves: Minimize pressure drop in high-flow steam lines.

Floating Ball Valves: Ideal for low- to medium-pressure steam systems.

Trunnion-Mounted Ball Valves: Handle high-pressure steam with reduced operating torque.

High-Temperature Valves: Feature reinforced seats (e.g., metal-seated) and extended stems to protect seals.

Leading Steam Ball Valve Manufacturers

Reputable manufacturers include:

Spirax Sarco: Specializes in steam system components.

Velan: Offers high-pressure, high-temperature ball valves.

Swagelok: Known for precision-engineered valves.

Emerson (Fisher): Provides industrial-grade steam solutions.

Choosing a Steam Ball Valve Factory

When selecting a ball valve manufacturer, consider:

Certifications: ISO 9001, API 6D, or PED compliance.

Material Quality: Valves should use ASTM-grade stainless steel or alloys.

Testing Standards: Ensure valves undergo hydrostatic and thermal cycling tests.

Customization: Look for factories offering bespoke designs for unique steam applications.

After-Sales Support: Warranties and technical assistance are critical.

Conclusion

Ball valves can be used for steam systems when designed with high-temperature materials and robust sealing. Selecting the right type and a reputable manufacturer ensures safety, efficiency, and longevity in demanding steam environments. Always verify specifications with your supplier to match valve performance to your system’s requirements.

0 notes

Text

Comprehensive Guide to Valves in the Food & Pharma Industry

Valves are critical components in the food and pharmaceutical industries, playing an essential role in controlling the flow of liquids, gases, and semi-solid substances throughout processing. These industries adhere to strict hygiene, safety, and efficiency standards, making the selection of the right valve crucial for product integrity, compliance, and operational reliability. As global demand for high-quality food and pharmaceutical products increases, the need for robust, contamination-free, and precision-engineered valves has never been more significant. Indian manufacturers are at the forefront of supplying high-performance valves that meet international quality standards.

The Role of Valves in Food & Pharmaceutical Processing

Valves facilitate efficient and contamination-free processing in various stages, including ingredient mixing, sterilization, packaging, and distribution. They regulate pressure, temperature, and flow rates, ensuring smooth and controlled operations. In the pharmaceutical industry, valves play an essential role in sterile production processes, ensuring aseptic conditions that prevent microbial contamination. In food production, valves maintain hygiene by preventing bacterial growth and ensuring smooth operation in beverage, dairy, and processed food industries.

Types of Valves Used in Food & Pharma Industry

Butterfly Valves – These lightweight and compact valves are widely used due to their ease of cleaning and ability to facilitate quick shut-off and flow control. Their streamlined design minimizes dead space, reducing the risk of contamination and bacterial growth, making them ideal for hygienic applications.

Diaphragm Valves – Engineered to ensure sterility, diaphragm valves feature minimal dead space and a smooth flow path. These qualities make them particularly suitable for aseptic processes in pharmaceutical and food production, where strict contamination control is essential.

Ball Valves – Offering a robust sealing mechanism, ball valves provide excellent shut-off capabilities, preventing leaks and contamination. Their durability and ease of operation make them a preferred choice in high-pressure and high-purity applications.

Globe Valves – Designed for precision flow control, globe valves play a vital role in pharmaceutical processing, where accurate fluid regulation is required. Their ability to regulate flow rates efficiently makes them indispensable in processes that demand precision.

Control Valves – Automated control valves enhance processing consistency by regulating fluid flow with high accuracy. These valves integrate seamlessly with digital monitoring and control systems, ensuring optimal performance and process efficiency.

Key Features & Standards of Industrial Valves

Hygienic Design – Valves in food and pharmaceutical applications are designed with smooth, crevice-free surfaces that prevent bacterial buildup and allow for easy cleaning.

FDA & USP Class VI Compliance – Regulatory standards require materials used in valve manufacturing to be safe for food and pharma contact. Compliance ensures product integrity and consumer safety.

CIP/SIP Compatibility – Clean-in-Place (CIP) and Steam-in-Place (SIP) technologies allow automated cleaning and sterilization of valve systems without disassembly, ensuring consistent hygiene and reducing downtime.

How to Choose the Right Valve for Food & Pharma Applications

Material Selection – Stainless steel 316L and PTFE-lined surfaces offer excellent resistance to corrosion and chemical reactions, ensuring product purity and extended valve life.

Sealing Technology – Aseptic seals, minimal dead space designs, and leak-proof construction prevent bacterial growth and contamination.

Pressure & Temperature Ratings – Valves must withstand rigorous operating conditions, including high-pressure steam sterilization and extreme temperature fluctuations.

Ease of Maintenance – CIP/SIP-compatible valves reduce downtime and enhance process efficiency.

Automation & Control – Smart valve technology enables digital integration for precise fluid control, monitoring, and predictive maintenance.

Why Choose Freture Techno Valve Manufacturers?

We are leading Food and Pharmacutical valves manufacturers are recognized globally for producing high-quality valves that meet strict international regulatory standards, including ASME BPE, GMP, and EHEDG certifications. The advantages of sourcing valves from India include:

Cost-Effective Solutions – Competitive pricing without compromising on quality.

Customization – Tailored valve designs to meet specific industry needs.

Adherence to International Standards – Indian manufacturers comply with global safety and hygiene certifications.

Technological Advancements in Valve Manufacturing

The food and pharmaceutical industries are rapidly adopting advanced valve technologies, including:

Smart Valves – IoT-enabled valves provide real-time monitoring, predictive maintenance, and automated process adjustments.

Zero Dead-Leg Designs – Prevent product residue buildup, ensuring complete sterility and reducing contamination risks.

Self-Cleaning Mechanisms – Automated cleaning processes enhance operational efficiency and reduce downtime.

Applications of Valves in Food & Pharma Industry

Dairy Processing – Used in milk, yogurt, and cheese production to maintain product safety and quality.

Beverage Industry – Ensures contamination-free handling of soft drinks, juices, and alcohol.

Pharmaceutical Formulations – Used in sterile fluid processing, IV fluids, and vaccine production.

Fermentation & Bioprocessing – Helps regulate the flow of bioactive substances in drug manufacturing.

Cleanroom Operations – Supports high-purity environments by ensuring contamination-free operations.

Investing in high-quality pharmacutical and Food industrial valves is critical for food and pharmaceutical manufacturers to maintain efficiency, hygiene, and compliance with industry regulations. Indian manufacturers offer cutting-edge solutions tailored to global market demands, making them a preferred choice for businesses looking for reliability and innovation in industrial valve technology. Choosing the right valve ensures product integrity, operational efficiency, and regulatory compliance, making it a key factor in successful food and pharmaceutical production.

0 notes

Text

Lined Valve Market by Type (Ball Valve, Butterfly Valve, Globe Valve, Plug Valve, Gate Valve), Material (Polytetrafluoroethylene (PTFE), Perfluoroalkoxy (PFA), Polychlorotrifluoroethylene(PCTFE) ), Industry and Region

0 notes

Text

High quality ball valve manufacturer in Ahmedabad

Flowdo Valve is one of the premier ball valve manufacturers in Ahmedabad, recognized for its excellent quality and advanced products. Ball valves are widely used in oil and gas industry, chemical industry, water treatment industry and other industries because of their dependability and effectiveness in regulating the flow of the fluid.

Flowdo Valve is an eminent ball valve manufacturing company based in Ahmedabad, India that specializes in offering a wide assortment of ball valves for various applications. Our product lineup includes:

Ball Valve 3PC F/E: A three times body located full encapsulation valve which is highly reliable in terms of its construction and can also be easily maintained.

Ball Valve 2PC F/E: A two-piece full-encapsulation form valve made suitable for different applications in which it is necessary to ensure the tightness of the sealing.

Ball Valve 1PC F/E: This valve is half-circle full-encapsulation valves that consist of one body that makes it cheap and small in size.

Ball Valve 2PC F/E (High Pressure): Suitable for high pressure for instance in an organization so as to boost the performance and durability of a product.

Ball Valve 3PC & 1PC (S/E & S/W): These valves are available in screwed end (S/E) version and socket weld (S/W) and the buyer is free to choose according to the requirements.

PTFE Lined Ball Valve 2PC F/E: Including PTFE lining to give greater chemical endurance it is suitable for corrosive environment.

3 & 4 Way Ball Valve F/E: Valves that have multiple ports to permit regulation of directional flow to improve functionality.

Jacketed Type Ball Valve: It has a jacket for thermal management, perfect for operations that need to maintain or alter the temperature.

Flowdo Valve is an ISO 9001:2015 certified company as a sign or guarantee of the highest quality and reliability. It increases confidence that the quality management systems are being improved continuously and responsive to customer needs. Also, our products are API, ANSI, and DIN-coded qualities that are accepted internationally due to high set standards in the production of valves.

Flowdo Valve is one of the leading ball valve manufacturers based in Ahmedabad that offers reliable valves for various industries. Their products are durable and very accurate making them key in different industries and sectors.

Flow Regulation: Used in pipelines where the flow of the liquid or the gaseous commodity need to be regulated accurately and effectively.

Isolation Services: Employees get full isolation solutions to avoid accidents and control the fluid leakage.

Mixing and Diverting: Used in applications where it is necessary to combine various liqu ids or to change the route of the current.

Discover all our ball valve products and additional information about our manufacturing processes on

#ball valve manufacturer in Ahmedabad#ball valve manufacturer#valve manufacturer in Ahmedabad#valve manufacturer#ball valve

0 notes

Text

Gate Valve Exporter - Mayur Valves MVS

Mayur (Valves) System Private Limited is an ISO 9001 : 2015 Certified Company, Established in the year 1978, MVS Industrial Valves offers Diaphragm Valves, Ball Valves, Plug Valves, Butterfly Valves, Gate Valves, Globe Valves, Check Valves or Non Return Valves, Knife Gate Valves, Sight Flow Indicator or Sight Glass, Strainer or Filters, PTFE / FEP / PFA / PVDF Lined Valve, PTFE Lined Pipe, PTFE / FEP / PFA / PVDF Lined Pipe Fittings and Plastic / PP / PVDF Valves. Gate Valve Manufacturers Exporters in India MVS Industrial Valves have been exported to more than 40+ countries worldwide

Assurance of Quality: Mayur Valves MVS follows strict quality control procedures to guarantee that every gate valve satisfies global requirements. Every stage of the production process, from obtaining raw materials to inspecting the finished product, is cantered upon quality.

Wide Product Selection: To meet the needs of many applications and industries, Mayur Valves MVS provides a wide selection of gate valves. Mayur Valves MVS offers a solution for your needs, whether they are for industrial operations, oil and gas, or water supply valves.

Customization Options: Mayur Valves MVS offers customization options to fit gate valves to individual demands, acknowledging that every project has different requirements. Customers can request customized solutions, ranging from material selection to size and design alterations.

Reliable Performance: Mayur Valves MVS gate valves are built to provide constant performance even in the most demanding conditions, with a focus on durability and dependability. Thorough testing guarantees that every valve surpasses expectations and fulfils performance criteria.

Global Reach: Mayur Valves MVS reaches markets on all continents as an exporter, providing services to clients all over the world. Customers can count on prompt product delivery no matter where they are thanks to an efficient distribution system and effective logistics.

Conclusion

Go no further than Mayur Valves MVS for quality gate valves built for dependability and performance. Dedicated to quality and client satisfaction, Mayur Valves MVS is still a reliable partner for businesses worldwide. Get in touch with us right now to find out more about our offerings.

Contact Us: - +91 9898563969 [email protected]

Address: - Mayur (Valves) System Private Limited, SOBO Center, 421, Block B, 4th Floor, Gala Gymkhana Road, Near Sun City, South Bopal, Ahmedabad - 380058, Gujarat, India.

Visit for More Information: - https://mvsvalves.com/

#Gate Valve Exporter#Gate Valve Manufacturers Exporters in India#gate valve manufacturers exporters in gujarat#gate valve manufacturers exporters

0 notes

Text

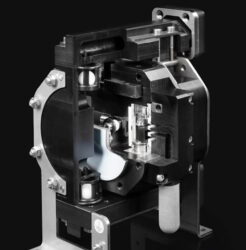

Double diaphragm pumps for greater reliability in chemical processes

Product Manager Stefan Anstöter knows the requirements of the chemical industry and knows what users value. "From the material to the design and the accessibility for repairs: Chemical pumps must function flawlessly in practical application," says Stefan Anstöter, Product Manager at Timmer GmbH. "We know: Here there is no room for error. That's why we have optimised our pumps so that they meet – and even exceed – all industry requirements. This starts with deliberate use of suitable pump materials. For example, stainless steel, which has proven to be effective in other industries, is often not suitable for chemical applications because it is subject to attack by alkalis and acids. Instead, the pumps in the ‘Tim Chem’ product line are equipped with a plastic housing. The polytetrafluoroethylene (PTFE) that we use is compatible with the chemicals that are used.” External influences such as significant temperature fluctuations change the shape of the material, and the housing then tends to leak at the connections. “We use a design for our pumps that connects the highly-resistant plastic components that are in contact with media, by means of tie rods. The force exerted by the tie rods is distributed by the large-area reinforcement plates – a measure that significantly minimises deformation of the plastic,” says Anstöter.

The Tim Chem series chemical pumps come factory-standard with a sensor that monitors the status of the pump and that can be integrated directly into the user's process control system. To ensure maximum protection, stainless steel sheets encompass the pump and provide stability for the entire construction. Metal does not come into contact with the medium. Plastic, and plastic only, which has been tested for resistance, completely encloses the processed medium. The material is FDA-compliant and thus it is food-safe. Optimal sealing of a pump is a major aspect of process reliability. It is a characteristic that plays a central role in product development at Timmer. In this regard, the design follows a simple rule: The fewer sealing surfaces, the fewer possibilities of a leak. Consequently, chemical pumps from Timmer have only four sealing points – and these pumps are Atex-compliant. Easy access for repairs

A look inside the pump shows the sealing concept, which significantly minimises the risk of leaks. The design enables easy access for repairs and fast on-site service. These double diaphragm pumps come factory-standard with an intelligent sensor for condition monitoring. The sensor can be integrated directly into the user's process control system. Integrated in a process control system the sensor shows the real-time status of the pump and by means of an additional system, immediately sounds an alarm should an error occur. The company decides how the pump should be integrated into the system and what data it should display. If an error message occurs and if repairs are required, service technicians benefit from the easy accessibility offered by the pumps. For example, valve balls and valve cages can be replaced without dismounting the side covers. Use of special tools is not necessary. The heart of the pump, a special, extremely low-wear, ceramic latching valve, ensures smooth operation. All of the valve's friction pairs are made of ceramics in conjunction with precision-ground, high-performance plastics. The result is minimum wear in the valve itself. The reduced stroke path provides long-term protection of the diaphragm. www.timmer.de Read the full article

0 notes

Photo

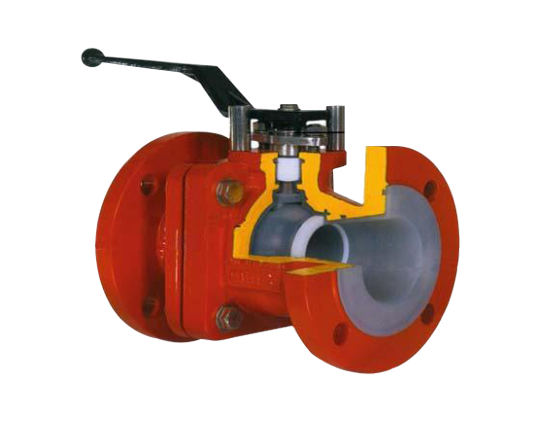

PTFE Lined Ball Valves Manufacturer in India

PTFE lined ball valves are devices designed to regulate the flow of fluids (including gases) by opening, closing, or moderately obstructing passageways in pipes. Lined ball valves have large- scale application over many various industries - for this reason they are vary widely in size, form and materials used depending on what they are going to be used for. They can be more or less simple, or they can be compound - in which case exceptional design is critical to how well they work.

Nowadays, PTFE lined ball valves have been the necessary products in all kinds of corrosive industrial applications. However, there are only a limited lined ball valve manufacturers who reach the international standard. So when company buy this valve, they must called for the seller to show the certifications for production. Through this way company can avoid purchasing the uncertified products.

The primary functions of lined ball valves are important guidelines based on exactly what the industry wants with regard to their machines and equipments. They are available on a number of designs and sizes, plus they are manufacture from different materials, which imply that they offer a model for just about any project.

Aira 4Matic Global Valves is an ISO 9001:2015 company, manufacturers and exporter of PTFE lined ball valves in India. Company’s manufacturing unit is established in Ahmedabad. We are offering Lined check valves for corrosive industrial applications. We have different size range of lined ball valves which are matched to all the industrial operations. We offer ball valves that are fire proof and also passed fugitive emissions testing standards.

1 note

·

View note

Text

The Guide to Small Ball Valves: Types, Applications, Tips.

When it comes to fluid control in compact systems, small ball valves, mini ball valves, and miniature ball valves are indispensable components. These valves are designed for precision, durability, and space efficiency, making them ideal for industries ranging from plumbing and HVAC to chemical processing and manufacturing. In this comprehensive guide, we’ll explore the key features, types, materials, and applications of small ball valves, along with tips for selecting the right valve for your needs.

—

What is a Small Ball Valve

A small ball valve is a quarter-turn valve that uses a hollow, perforated ball to control fluid flow. When the valve handle is turned 90 degrees, the ball rotates to align its bore with the pipeline (open position) or block it completely (closed position). These valves are characterized by their compact size, lightweight design, and ease of operation, making them perfect for tight spaces or applications requiring frequent adjustments.

Key advantages of small ball valves include:

- Leak-proof sealing for reliable performance. - Quick shutoff with minimal torque. - Versatility in handling liquids, gases, and corrosive media. - Low maintenance due to simple construction.

—

Types of Small Ball Valves

Small ball valves are available in various designs to suit specific applications. Below are the most common types:

1. Thread Ball Valve

A thread ball valve features threaded ends (NPT, BSPP, or BSPT) for easy installation in pipelines without welding. These valves are widely used in residential plumbing, compressed air systems, and low-pressure industrial setups.

2. Flange Ball Valve

Flange ball valves have flanged ends for bolted connections, ideal for high-pressure or large-diameter systems. They are common in oil and gas, water treatment, and chemical industries.

3. 2 PC Ball Valve vs. 3 PC Ball Valve

- 2 PC ball valves consist of two main body pieces, offering a balance between cost and serviceability. - 3 PC ball valves feature three separable body sections, enabling easy disassembly for cleaning or repair without removing the valve from the pipeline.

4. Floating Ball Valve

In a floating ball valve, the ball is held in place by compression from the valve seats. This design is cost-effective and suitable for low-to-medium pressure applications.

—

Material Choices for Small Ball Valves

The valve material impacts its durability, corrosion resistance, and compatibility with fluids. Popular options include:

1. Stainless Steel Ball Valve

Stainless steel ball valves (e.g., SS304, SS316) excel in corrosive environments, such as chemical processing, marine applications, or food-grade systems.

2. Carbon Steel Ball Valve

Carbon steel ball valves are robust and economical, ideal for high-temperature and high-pressure systems in oil refineries or power plants.

3. Forged Steel Ball Valve

Forged steel ball valves are manufactured through forging, resulting in superior strength and resistance to extreme conditions. They are commonly used in heavy-duty industrial applications.

—

Applications of Small Ball Valves

- Plumbing and HVAC: Regulating water flow in residential or commercial systems. - Chemical Processing: Handling aggressive fluids with stainless steel or PTFE-lined valves. - Automotive: Fuel and coolant control in compact engine systems. - Pharmaceuticals: Ensuring sterile fluid transfer with sanitary ball valves. - Agriculture: Irrigation and fertilizer distribution.

—

How to Choose the Right Small Ball Valve

1. Pressure and Temperature Ratings: Ensure the valve meets your system’s operational limits. 2. Connection Type: Select threaded, flanged, or welded ends based on installation requirements. 3. Material Compatibility: Match the valve body and seal materials to the fluid type (e.g., PTFE seals for chemicals). 4. Valve Size: Confirm the port size (e.g., ¼” to 2”) matches your pipeline dimensions. 5. Certifications: Look for industry standards like API, ANSI, or ISO for quality assurance.

—

FAQs About Small Ball Valves

Q: What’s the difference between a mini ball valve and a standard ball valve

A: Mini ball valves are smaller in size (typically under 1” diameter) and designed for low-flow or precision applications, whereas standard ball valves cater to larger systems.

Q: Can a stainless steel ball valve handle seawater

A: Yes, SS316 stainless steel valves offer excellent corrosion resistance in marine environments.

Q: When should I choose a 3 PC ball valve over a 2 PC design

A: Opt for a 3 PC ball valve if frequent maintenance or cleaning is required, as it allows easy access to internal components.

—

Conclusion

From thread ball valves in household plumbing to flange ball valves in industrial pipelines, small ball valves play a critical role in modern fluid control systems. By understanding the differences between floating ball valves, stainless steel ball valves, and forged steel ball valves, you can make informed decisions to optimize performance and longevity. Whether you need a miniature ball valve for a lab setup or a heavy-duty carbon steel ball valve for a refinery, prioritize quality materials, proper sizing, and compliance with industry standards.

Need a reliable small ball valve supplier, Contact Chinese NSW valve manufacturer experts today to find the perfect valve for your application.

#ball valve manufacturers in india#ball valve suppliers#ball valve#small ball valve#mini ball valve#china ball valve manufacturer#ball valve manufacturer#ball valve factory#ball valve supplier

0 notes