#ptfe lined ball valves

Text

How to differentiate between PTFE lined valve and PFA lined valve?

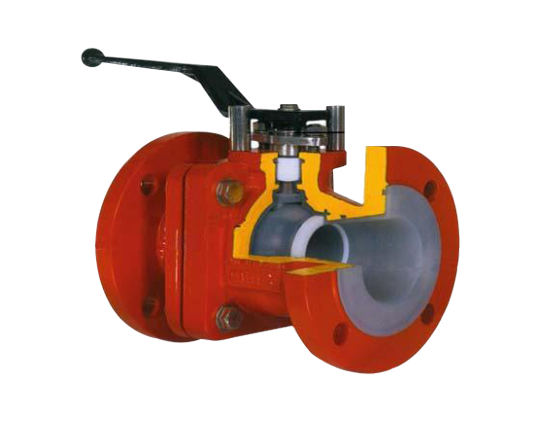

The components of a lined ball valve include the body, stem, ball, seat, and lining.

High-quality PFA or PTFE is used to line the interior, and this provides good protection against chemical corrosion. This makes these valves suitable for particularly unpleasant tasks.

These valves are widely popular as "Shut Off" because some kinds are manufactured with a free-floating design of the ball that favours Positive shut-off over the operating pressure range. As a result, these valves can be used in a variety of applications.

Lined Ball Valve v/s Unlined Ball Valve:

Similar in appearance to their unlined counterparts, lined ball valves are an economical choice for applications requiring long-term sealing and durability in harsh corrosive or chemical environments. They are suitable for use in control and shutdown applications due to their longevity, dependability, and performance even after repeated cycling.

They are suitable for automation since the ISO 5211 certified comprehensive mounting pad makes it simple to automate the valve while it is still in the pipeline, and they may be installed regardless of the direction of flow. Each lined ball valve is outfitted with its own anti-static mechanism, which safeguards against potentially harmful electrostatic discharges, and the stem design features an anti-blow-out function that offers improved safety. Are you looking for the best PTFE Lined Ball Valves manufacturer in Vadodara? Get in touch with Noble Glass Works today to get the best quality ball valves for your industrial applications.

How to differentiate between PTFE lined valve and PFA lined valve?

Lined valves offer a foolproof method of controlling the flow of chemicals while preventing corrosion at any concentration. The fittings as well as valves are coated so that they are resistant to chemicals and last a long time. PTFE lined valves and PFA-lined valves are frequently used as low-cost substitutes for high-grade alloys that are used in corrosive applications by various industries such as pharmaceutical, chemical, fertiliser, petrochemical, metallurgical as well as pulp and paper. Knowing the material distinctions between PFA and PTFE is essential for understanding their distinction.

Most people are familiar with PTFE, but PFA is also a common Teflon variety. PFA and PTFE share the same chemical characteristics, making both extremely strong and resistant to stress cracking in mechanical applications. Moulding, extrusion, injection, transfer moulding, and other forms of moulding are all possible thanks to the material's malleability and versatility; this means it can be used to create everything from high-frequency insulation parts to special spare pieces for machinery to the corrosion-resistant lining for pipes, valves, and pumps.

Excellent corrosion resistance, chemical stability, electrical insulation, high lubrication and non-viscosity, sealing, as well as good ageing resistance for media like strong acid, strong alkali, and strong oxidant characterise PTFE (Teflon), a polymer compound formed by the polymerization of tetrafluoroethylene. The chemical, electric equipment, pharmaceutical, petrochemical, fertiliser, pulp and paper, and metallurgical sectors are just some of the harsh environments where PTFE-lined valves can be put to good use.

Place bulk orders for PTFE Lined Ball Valves with the most distinguished as well as reputed PTFE Lined Ball Valves manufacturer in India, Noble Glass Works.

Polyfluoroalkoxy, or PFA, is an advanced thermoplastic polymer modified from PTFE that features higher performance and lower viscosity. The performance of PFA is comparable to that of PTFE, the more well-known type of Teflon, but PFA is more flexible. The ability to melt process PFA sets it apart from PTFE resins. Temperatures between -250 and 260°C may be maintained in service. It is inert to flames and is resistant to acids, bases, and alkalis as well as grease and oil. It also has a long lifespan, is not affected by heat or cold, and is impervious to ageing. Over 23 MPa of tensile strength and over 250% elongation.

Together, PFA-lined valves function substantially better than PTFE-lined valves. While PTFE valves enjoy widespread use due to their low cost, PFA valves and tubing are typically found in industrial settings. High sealing performance is ensured by the PFA lining of the valve, making it ideal for use with liquid and gas media in a wide variety of industrial pipelines, including those carrying hydrofluoric acid, sulfuric acid, nitric acid, hydrochloric acid, as well as other extremely corrosive compounds.

An excellent PTFE Lined Ball Valves manufacturer in India, Noble Glass Works provides leak-free, low-cost to operate and maintain lined ball valves, gate valves, as well as plug valves. If you are looking for anti-static PFA lining along with the normal PTFE lining, connect with Noble Glass Works, the most prominent industrial components manufacturer in India.

#best PTFE Lined Ball Valves manufacturer#PTFE Lined Ball Valves manufacturer in India#nobleglassworks

1 note

·

View note

Text

0 notes

Text

Gate Valve Exporter - Mayur Valves MVS

Mayur (Valves) System Private Limited is an ISO 9001 : 2015 Certified Company, Established in the year 1978, MVS Industrial Valves offers Diaphragm Valves, Ball Valves, Plug Valves, Butterfly Valves, Gate Valves, Globe Valves, Check Valves or Non Return Valves, Knife Gate Valves, Sight Flow Indicator or Sight Glass, Strainer or Filters, PTFE / FEP / PFA / PVDF Lined Valve, PTFE Lined Pipe, PTFE / FEP / PFA / PVDF Lined Pipe Fittings and Plastic / PP / PVDF Valves. Gate Valve Manufacturers Exporters in India MVS Industrial Valves have been exported to more than 40+ countries worldwide

Assurance of Quality: Mayur Valves MVS follows strict quality control procedures to guarantee that every gate valve satisfies global requirements. Every stage of the production process, from obtaining raw materials to inspecting the finished product, is cantered upon quality.

Wide Product Selection: To meet the needs of many applications and industries, Mayur Valves MVS provides a wide selection of gate valves. Mayur Valves MVS offers a solution for your needs, whether they are for industrial operations, oil and gas, or water supply valves.

Customization Options: Mayur Valves MVS offers customization options to fit gate valves to individual demands, acknowledging that every project has different requirements. Customers can request customized solutions, ranging from material selection to size and design alterations.

Reliable Performance: Mayur Valves MVS gate valves are built to provide constant performance even in the most demanding conditions, with a focus on durability and dependability. Thorough testing guarantees that every valve surpasses expectations and fulfils performance criteria.

Global Reach: Mayur Valves MVS reaches markets on all continents as an exporter, providing services to clients all over the world. Customers can count on prompt product delivery no matter where they are thanks to an efficient distribution system and effective logistics.

Conclusion

Go no further than Mayur Valves MVS for quality gate valves built for dependability and performance. Dedicated to quality and client satisfaction, Mayur Valves MVS is still a reliable partner for businesses worldwide. Get in touch with us right now to find out more about our offerings.

Contact Us: - +91 9898563969 [email protected]

Address: - Mayur (Valves) System Private Limited, SOBO Center, 421, Block B, 4th Floor, Gala Gymkhana Road, Near Sun City, South Bopal, Ahmedabad - 380058, Gujarat, India.

Visit for More Information: - https://mvsvalves.com/

#Gate Valve Exporter#Gate Valve Manufacturers Exporters in India#gate valve manufacturers exporters in gujarat#gate valve manufacturers exporters

0 notes

Text

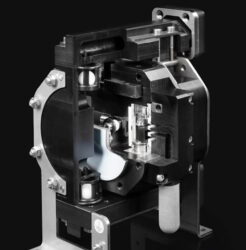

Double diaphragm pumps for greater reliability in chemical processes

Product Manager Stefan Anstöter knows the requirements of the chemical industry and knows what users value.

"From the material to the design and the accessibility for repairs: Chemical pumps must function flawlessly in practical application," says Stefan Anstöter, Product Manager at Timmer GmbH. "We know: Here there is no room for error. That's why we have optimised our pumps so that they meet – and even exceed – all industry requirements. This starts with deliberate use of suitable pump materials. For example, stainless steel, which has proven to be effective in other industries, is often not suitable for chemical applications because it is subject to attack by alkalis and acids. Instead, the pumps in the ‘Tim Chem’ product line are equipped with a plastic housing. The polytetrafluoroethylene (PTFE) that we use is compatible with the chemicals that are used.”

External influences such as significant temperature fluctuations change the shape of the material, and the housing then tends to leak at the connections. “We use a design for our pumps that connects the highly-resistant plastic components that are in contact with media, by means of tie rods. The force exerted by the tie rods is distributed by the large-area reinforcement plates – a measure that significantly minimises deformation of the plastic,” says Anstöter.

The Tim Chem series chemical pumps come factory-standard with a sensor that monitors the status of the pump and that can be integrated directly into the user's process control system.

To ensure maximum protection, stainless steel sheets encompass the pump and provide stability for the entire construction. Metal does not come into contact with the medium. Plastic, and plastic only, which has been tested for resistance, completely encloses the processed medium. The material is FDA-compliant and thus it is food-safe.

Optimal sealing of a pump is a major aspect of process reliability. It is a characteristic that plays a central role in product development at Timmer. In this regard, the design follows a simple rule: The fewer sealing surfaces, the fewer possibilities of a leak. Consequently, chemical pumps from Timmer have only four sealing points – and these pumps are Atex-compliant.

Easy access for repairs

A look inside the pump shows the sealing concept, which significantly minimises the risk of leaks. The design enables easy access for repairs and fast on-site service.

These double diaphragm pumps come factory-standard with an intelligent sensor for condition monitoring. The sensor can be integrated directly into the user's process control system. Integrated in a process control system the sensor shows the real-time status of the pump and by means of an additional system, immediately sounds an alarm should an error occur. The company decides how the pump should be integrated into the system and what data it should display. If an error message occurs and if repairs are required, service technicians benefit from the easy accessibility offered by the pumps. For example, valve balls and valve cages can be replaced without dismounting the side covers. Use of special tools is not necessary.

The heart of the pump, a special, extremely low-wear, ceramic latching valve, ensures smooth operation. All of the valve's friction pairs are made of ceramics in conjunction with precision-ground, high-performance plastics. The result is minimum wear in the valve itself. The reduced stroke path provides long-term protection of the diaphragm.

www.timmer.de

Read the full article

0 notes

Text

Ball Valve Selection for Chemical Processing: Corrosion Resistance and Compatibility

Ball valves are a crucial component in various industries, especially in chemical processing plants, where the safe and efficient handling of corrosive fluids is paramount. Selecting the right ball valve for chemical applications involves a deep understanding of materials and sealing mechanisms. In this article, we will delve into the complexities of choosing ball valves that offer optimal corrosion resistance and compatibility with chemicals, ensuring the reliability and safety of your operations.

The Challenge of Corrosive Chemicals: Chemical processing environments often deal with aggressive and corrosive substances that can wreak havoc on standard valves. Corrosion can compromise the integrity of the valve, leading to leaks, safety hazards, and costly downtime. Therefore, when it comes to ball valve selection for chemical applications, several key considerations must be taken into account.

Material Selection: One of the most critical factors in choosing a ball valve for chemical processing is the material used in its construction. The right material can withstand the corrosive effects of chemicals and extend the valve's service life. Common materials used for ball valves in chemical applications include:

Stainless Steel (316 or 316L): Known for its excellent resistance to a wide range of chemicals, stainless steel is a popular choice in chemical processing.

Hastelloy: This high-performance alloy offers superior resistance to highly corrosive chemicals, making it suitable for extreme conditions.

Teflon (PTFE): PTFE-lined ball valves are ideal for applications involving strong acids and bases, as they provide a non-reactive, chemically resistant surface.

Alloy 20: Often used in applications involving sulfuric acid and other aggressive chemicals due to its excellent corrosion resistance.

Duplex Stainless Steel: Combines the benefits of stainless steel and increased strength, making it suitable for challenging chemical environments.

Sealing Mechanisms: The choice of sealing mechanism is equally crucial. Ball valves can have soft-seated or metal-seated designs, each with its advantages:

Soft-Seated Valves: These ball valves use resilient materials such as PTFE to create a tight seal. They are well-suited for applications involving moderate pressures and a wide range of chemicals.

Metal-Seated Valves: Metal-seated ball valves are designed for high-pressure and high-temperature applications. They offer increased durability and resistance to abrasive chemicals but may require more precise alignment.

Considerations for Compatibility: Selecting the appropriate material and sealing mechanism also depends on the specific chemicals being handled. Before choosing a ball valve, consider the following compatibility factors:

Chemical Resistance: Review the chemical resistance chart for the chosen material to ensure it is compatible with the chemicals in your process.

Temperature and Pressure: Take into account the operating temperature and pressure conditions, as some materials may perform differently under extreme conditions.

Flow Control Requirements: Determine if your application requires precise flow control or if on/off functionality is sufficient.

Conclusion: In the world of chemical processing, the selection of ball valves is not a one-size-fits-all endeavor. It requires a deep understanding of the corrosive nature of the chemicals involved, as well as the materials and sealing mechanisms that offer optimal resistance. Choosing the right ball valve can prevent safety hazards, reduce maintenance costs, and ensure the smooth operation of your chemical processes. By emphasizing corrosion resistance and compatibility, you can make an informed decision that will benefit your operations in the long run.

#ball valves#ball valves manufacturers#ball valve suppliers#freture techno#freturetechno#valve muanufacturers#india

0 notes

Text

What Is PTFE Ball Valve?

What Is PTFE Ball Valve?

A PTFE ball valve is a crucial component of many industrial processes, allowing fluid or gas to flow through a valve that rotates 90 degrees and is sealed at both ends with solid sides. The durable design of this valve ensures that no leaks occur, and the material used is PTFE, which is the same as Teflon. In this article, we will discuss the manufacturing process and applications of a PTFE ball valve in various industries.

Manufacturing of PTFE Ball Valve

A PTFE ball valve manufacturer produces the valve body using a wide range of stainless steel and cast ductile iron materials. This material is commonly used in high-pressure and corrosive environments, serving as an alternative to metal valves. The PTFE-coated ball valve is used in petrochemical plants for flow control and transfer of chemicals. Apart from petrochemical processes, PTFE-coated ball valves can also be found in the manufacturing of fertilizers, pesticides, dyes, and pulp and paper processing plants.

Applications of PTFE Ball Valve

The PTFE ball valve is highly versatile, making it suitable for various industrial applications, including the pharmaceutical and food industries. For cryogenic applications, a PTFE ball valve is the preferred choice because of its high sealing capability and quick action. Its standard size and high strength make it an excellent choice for cryogenic applications.

PTFE is a versatile material that is resistant to chemicals and has no reaction with them. It is also an excellent choice for cookware, as metals like aluminum corrode easily when they come in contact with acids. Additionally, PTFE is not electrically conducting. Thus, PTFE is an excellent choice for hose linings, machine parts, and other components.

Advantages of PTFE Ball Valve

The advantages of PTFE are the high chemical resistance, low friction, and wide temperature range. These qualities make PTFE ideal for many industrial applications, including petrochemical, pharmaceutical, food processing, and cryogenic applications. Some PTFE ball valves are filled with glass fiber, carbon fiber, graphite, bronze, or glass, making them more durable and reliable.

In conclusion, the PTFE ball valve is an essential component of many industrial processes, and its reliability, durability, and ease of maintenance contribute to its popularity. The PTFE ball valve is versatile, making it suitable for various industrial applications, including the pharmaceutical and food industries. Its high chemical resistance, low friction, and wide temperature range make it an ideal choice for many applications.

MAN 7S35MC-MK7 Cylinder Liner from Decho Marine Services

Decho Marine Services (China) Tingting

+86 159-6706-1188

[email protected]

from Decho Marine Services

Decho Marine Services (China) Tingting

+86 159-6706-1188

[email protected]

0 notes

Text

The Ultimate Guide to Pp Ball Valves With Electrical Actuators

An overview of PP ball valves with electrical actuators

PP (polypropylene) ball valves with electrical actuators are valves that use a ball to control the flow of fluids. The ball is rotated by an electric actuator, which can open or close the valve to allow or restrict the flow of the fluid. PP is a thermoplastic polymer that is commonly used in the manufacturing of valves due to its chemical resistance, durability, and low cost. These valves are commonly used in industrial and commercial applications such as water treatment, chemical processing, and HVAC systems. They are available in a variety of sizes and pressure ratings and can be controlled by a variety of electrical actuator types such as pneumatic, hydraulic, and electric.

The benefits of using PP ball valves with electrical actuators

There are several benefits to using PP ball valves with electrical actuators:

Durability: PP is a strong and durable material that is resistant to many chemicals, making it well suited for use in harsh industrial environments.

Chemical resistance: PP is resistant to a wide range of chemicals, including acids, bases, and organic solvents, making it ideal for use in chemical processing and other industrial applications.

Low cost: Compared to other types of valves, PP ball valves are relatively inexpensive, making them a cost-effective choice for many applications.

Easy to operate: Electrical actuators make it easy to open and close the valve remotely, allowing for precise control of fluid flow.

Low maintenance: PP ball valves with electrical actuators require minimal maintenance, making them a reliable choice for long-term use.

Variety of control options: The electrical actuator can be controlled by different systems such as PLC, DCS, SCADA and other control systems

High-temperature resistance: PP can withstand high temperatures and maintain its strength, making it suitable for high-temperature applications.

Lightweight: PP ball valves are lightweight and easy to handle, making them easy to install and maintain.

Suitable for both liquid and gas: PP ball valves are suitable for both liquid and gas applications and can be used in a wide range of industries such as HVAC, Water treatment, and chemical processing.

The different types of PP ball valves with electrical actuators

There are several types of PP ball valves with electrical actuators, including:

Full-port PP ball valves: These valves have a large flow passage and a full-size ball, allowing for minimal pressure drop and maximum flow through the valve.

Reduced-port PP ball valves: These valves have a smaller flow passage and a smaller ball, which can be useful for applications where flow control is more important than flow rate.

Three-way PP ball valves: These valves have three ports and are used to direct the flow of fluid between two different paths. They are commonly used in HVAC systems and other applications where the flow of fluid needs to be directed to multiple locations.

PTFE/FEP Lined PP ball valves: These valves have an inner lining made of PTFE or FEP, which provides excellent chemical resistance, making them suitable for use in harsh chemical environments.

Flanged PP ball valves: These valves have flanges on the ends, which allows for easy installation and secure connection to pipes and other fittings.

Threaded PP ball valves: These valves have threads on the ends, which allows for easy installation and secure connection to pipes and other fittings.

Actuator PP ball valves: These valves have an actuator attached to the valve stem, which is used to open and close the valve. Actuators can be pneumatic, electric, or hydraulic.

High-pressure PP ball valves: These valves are designed to handle high-pressure applications and are available in a variety of pressure ratings.

Cryogenic PP ball valves: These valves are designed to handle low temperatures and are suitable for use in cryogenic applications such as LNG storage and transportation.

The installation process of PP ball valves with electrical actuators

The installation process of PP ball valves with electrical actuators typically includes the following steps:

Planning: Before installing the valve, it is important to plan the location of the valve and ensure that it is easily accessible for maintenance and operation. It is also important to confirm that the valve is the correct size and type for the application and that the necessary connections and accessories are available.

Preparation: Before installing the valve, the pipe or fitting should be cleaned and checked for any damage or debris. The valve should also be checked to ensure that it is free from damage and that all parts are present and in good condition.

Installation: The valve should be installed in the pipe or fitting, making sure that it is properly aligned and that the gasket or sealing ring is in place. The valve should then be tightened using the appropriate tools, making sure not to overtighten.

Connection: The electrical actuator should be connected to the valve according to the manufacturer's instructions, making sure that the correct wiring and voltage are used.

Testing: The valve should be tested to ensure that it is functioning properly and that there are no leaks or other issues. This can be done by running water or other fluid through the valve and observing the flow.

Maintenance: Regular maintenance should be performed on the valve and actuator to ensure proper functioning and longevity. This may include cleaning, lubrication, and replacement of parts as needed.

It is important to follow the manufacturer's instructions and any local codes and regulations when installing a PP ball valve with electric actuator. It is also important to have trained personnel with relevant knowledge and experience to do the installation.

How to maintain PP ball valves with electrical actuators

Proper maintenance is crucial to ensure the longevity and proper functioning of PP ball valves with electrical actuators. Here are some steps for maintaining these valves:

Regular Inspection: Inspect the valve and actuator regularly for any signs of wear, damage, or leakage. This can be done by visually inspecting the valve and actuator, as well as by running fluid through the valve and observing the flow.

Cleaning: Keep the valve and actuator clean to prevent build-up of debris or corrosion. This can be done by wiping down the valve and actuator with a clean, dry cloth.

Lubrication: Lubricate the valve and actuator as needed to ensure smooth operation. This should be done according to the manufacturer's instructions, using the recommended lubricant.

Tightening: Check the valve and actuator connections for proper tightness and retighten if necessary. Overtightening can cause damage so it is important to use the appropriate tools and to follow the manufacturer's instructions.

Actuator maintenance: Check the actuator for proper operation and lubrication, as well as for proper voltage and amperage. Actuator's manual and instructions should be followed for proper maintenance.

Replace worn parts: Replace any worn or damaged parts, such as gaskets, seals, or O-rings, to ensure proper functioning and to prevent leaks.

Storing: If the valve is not in use for an extended period of time, it should be stored in a clean and dry place, protected from extreme temperatures and humidity.

It's important to follow the manufacturer's instructions for maintenance and to have trained personnel with relevant knowledge and experience to do the maintenance. It's also important to follow the safety guidelines and regulations while performing the maintenance.

0 notes

Text

Best PTFE Lined Ball Valves manufacturer | Nobleglassworks

Nobel Glass Works is the Best PTFE Lined Ball Valves manufacturer in India. We introduce ourselves as a reputed manufacturer of Industrial Glass equipment like borosilicate glass tube, PTFE , FEP, PFA products, sight glass, heat exchanger, flask, valves, solar tube, well glass & pipe line components etc.

If you are looking for the PTFE Lined Ball Valves manufacturer in India, Nobel Glass Works is a trusted name in the market.

0 notes

Text

How do we Choose Right a Ball Valve Manufacturer?

When it comes to choosing a ball valve manufacturer, there are several factors to consider. Here are some reasons why it's important to choose the right manufacturer for your needs:

Quality: Quality is crucial when it comes to ball valves, as they are an essential component in many industrial and commercial applications. A reputable manufacturer will have a track record of producing high-quality products that meet industry standards and customer expectations.

Innovation: In an ever-evolving industry, it's important to choose a manufacturer that is constantly innovating and improving their products. This can lead to more efficient and effective valves, which can save you time and money in the long run.

Customization: If you have specific requirements or needs for your valves, choose a manufacturer that can customize their products to meet your needs. This can ensure that you get the exact product you need, rather than having to compromise on features or functionality.

Price: While price is certainly a factor to consider, it's important not to sacrifice quality for cost. Look for a manufacturer that offers competitive pricing while still producing high-quality products.

Lead time: If you have a project deadline, it's important to make sure the manufacturer can deliver the valves in a timely manner. Choose a manufacturer with a proven track record of meeting lead times to ensure that your project stays on track.

Customer service: Good customer service and support are essential when it comes to any product, and ball valves are no exception. Choose a manufacturer with a reputation for providing excellent customer service, as this can be important if you have any questions or issues with your valves.

Certification: To ensure that a manufacturer meets industry standards, look for certifications such as ISO 9001. This can give you peace of mind that the manufacturer follows best practices and produces high-quality products.

Warranty: Consider the manufacturer's warranty policy and whether they offer any guarantees on their products. This can provide added protection and give you confidence in the quality of the valves.

Overall, it's important to do your research and choose a ball valve manufacturer that meets your needs and has a strong reputation in the industry. By considering these factors, you can be confident that you're getting the best product for your application."

The different types of ball valves available in marrket

There are several different types of ball valves available, including:

Full port ball valves: These valves have a large opening that allows for maximum flow and minimal pressure drop.

Reduced port ball valves: These valves have a smaller opening than full port valves, which reduces flow and increases pressure drop. They are typically used in applications where precise flow control is necessary.

V-port ball valves: These valves have a V-shaped opening that allows for precise flow control. They are commonly used in flow metering applications.

Three-way ball valves: These valves have three openings and are used to redirect flow from one port to another. They are commonly used in applications where multiple flow paths are needed.

Floating ball valves: These valves have a ball that is not attached to the stem and is free to move within the valve body. They are typically used in high-pressure applications.

Trunnion mounted ball valves: These valves have a ball that is mounted on trunnions, which allows for precise control of the ball's movement. They are commonly used in high-pressure, high-temperature applications.

Metal seated ball valves: These valves have a metal seat and are used in high-pressure, high-temperature applications where a tight seal is required.

PTFE seated ball valves: These valves have a PTFE seat and are used in applications where a chemical-resistant seal is required.

Lined ball valves: These valves have an inner lining of a corrosion-resistant material, such as PTFE or ceramic, and are used in corrosive or abrasive environments.

Actuated ball valves: These valves are equipped with an actuator, such as a pneumatic cylinder or an electric motor, which allows them to be remotely controlled. They are commonly used in automation systems.

Why ball valves are the preferred choice for many applications

Ball valves are the preferred choice for many applications due to their versatility, reliability, and ease of use. Some specific benefits of ball valves include:

Simple design: Ball valves have a simple design that consists of a ball with a hole through the center that is rotated to open or close the valve. This simple design makes them easy to operate and maintain.

Quick opening and closing: Ball valves can be opened and closed quickly, making them suitable for applications that require rapid on/off control.

Low pressure drop: The ball in a ball valve has a small surface area in contact with the valve body, which reduces the pressure drop across the valve. This makes them ideal for applications where minimizing pressure drop is important.

Wide range of sizes and materials: Ball valves are available in a wide range of sizes and materials, making them suitable for a variety of applications.

Durability: Ball valves are known for their durability and can handle high pressure and temperature extremes, making them suitable for use in harsh environments.

Versatility: Ball valves can be used in a variety of applications, including on/off control, flow regulation, and pressure regulation. They can also be used in a wide range of industries, including oil and gas, chemical processing, water treatment, and more.

Overall, the simple design, quick opening and closing, low pressure drop, and versatility of ball valves make them a popular choice for many applications.

0 notes

Text

1 note

·

View note

Text

FEP and UPVC Ball Valve

What is UPVC 3-Way Ball Valve? What is a Valve?

Taking a look at the humble pipe is a good place to start. It could be a pipe transporting water in your bathroom or a pipe carrying gas to your kitchen stove. A mechanism that controls how much liquid or gas flows through these liquid and gas pipes is required to function efficiently; this mechanism can be used to increase, decrease, or even stop the flow of fluid or gas. A valve is a mechanism that performs this function. They are mechanical switches that can turn pipes on and off as well as increase or decrease the flow of fluid/gas through them.

Now let's take a look at a few more examples from everyday life. To brush your teeth, you open a valve that lets pressurized water flow out of the pipe when you turn on the tap. Turning the tap more to one side typically reduces, stops, or increases the amount of water coming out (depending on the valve).

FEP Ball Valves:

The best type of ball valve to use for paper and pulp industries is the FEP-lined ball valve. At 10kg/cm2 pressure and 180°C operating temperature, it is capable of withstanding a pressure of 180°C. FEP-lined Ball Valves are ideal for slurries and viscous materials since they are non-sticky. Its unique properties make it superior to alloys.

In terms of its effects, FEP is similar to PTFE except for its soften-processed performance. Despite this, FEP can be quickly processed, welded, and re-molded into complex shapes. Welding and remodeling prospects, chemical and UV resistance, biocompatibility, and clear color are some of the unique properties of FEP.

PFA Ball Valve:

Many oil and gas industries utilize PFA-lined ball valves. PFA-lined valves can withstand temperatures up to 230°C at 10kg/cm2. PFA-lined valves have similar properties and qualities to FEP, but PFA is more temperature-resistant than FEP. In addition to their thermoplastic properties, PFA-lined valves offer a wide range of benefits. A thermoplastic material with the highest working temperature capacity is PFA. There is no fluoroplastic that can work continuously at a temperature higher than +260°C. It is possible to weld and re-mold it, with good permeability and outstanding chemical resistance. We are the PFA lined ball valve manufacturers in India.

What is UPVC 3-Way Ball Valve?

UPVC Ball Valve Manufacturers: The two ports of the PVC union ball valve are made up of two unions that can be disassembled and replaced at any time, making them easier to check and replace than common ball valves. An adjustable tightness, a low friction coefficient, ease of maintenance, and no leaks are some of the characteristics of a union ball valve. Furthermore, since the joints can be purchased separately, you can choose between threaded, socket, and standard joints. Although its single cost is higher than that of common ball valves, its replacement cost is lower.

Aira Euro Automation is the leading ball valve manufacturer in India. We offer various types of industrial valves like ball valves, butterfly valves, control valves, and many more.

0 notes

Text

What Exactly Are Alloy Steel Valves?

What Exactly Are Alloy Steel Valves?

When compared to bidirectional valves, which can control flow in both directions, unidirectional valves only enable fluids to flow in one direction. Rather than a gate or ball to control the flow, the Alloy Steel Valves plug valve uses a plug. When the seat is closed, the plug is seated there. To activate the valve, the plug must be pulled away from the seat. PTFE may be coated on the plug, which is frequently constructed of more ductile materials. Following the prescribed specifications, valve sizes and pressure ratings range from 12 inches up to 150 pounds.

Applications Of Alloy Steel Valve

Water lines, oil and gas transmission lines, chemical and petrochemical plants, food processing, and power production plants are just a few of the uses for alloy steel valves. Due to variations in their chemical compositions, alloys exhibit a range of mechanical and physical properties. Fewer alloys are used to create the low alloy steel valves. These alloys are constrained by their temperature ranges, corrosion resistance, and strength values even if they have better mechanical qualities than regular stainless steel. High alloy materials with better mechanical qualities include Monel and Inconel. They are also more expensive. A gate valve made of alloy steel is employed in situations where regular steel would not hold up.

Features And Design Of An Alloy Steel Valve

resistant to oxidation and scaling

heat treatment to harden

Excellent weldability

powerful and hardy

superior ductility

Uses for Alloy Steel Valves

pipes under pressure

pressure tanks

Applications for welded tubing

Various Forms of Alloy Steel Valves

Valve made of low-alloy steel

Metal alloy gate valve

Steel Alloy Butterfly Valves

Reducing Valves Made of Cast Alloy Steel

Ball Valves Made of Chrome Alloy Steel

Alloy Steel Diaphragm Valves, Forged

0 notes

Text

How did the Ball Valves come into Existence?

Nowadays, the once-inconspicuous ball valve is recognised as a separate valve category from linear and rotary valves. A spherical plug valve was initially used in the 1950s, however, a different name was in use at the time of its introduction.

Since the 1950s, ball valves have become increasingly common due to the availability of various ball and seat materials, as well as the development of machinery capable of accurately producing the ball's spherical polished surface. The use of these valves has been broadened in recent years due to the development of new seat materials and the introduction of metal seats fabricated from low-wear materials, which have proven particularly useful in applications involving abrasive and high-temperature media.

Manufacturing of Ball Valves:

Ball Valves can have a variety of connection types, including flanged, socket welded, butt welded, and screwed.

Applications of the Ball Valves:

Ball valves' widespread adoption can be attributed to their adaptability; they can be used for a wide range of services, from the relatively mild (water, solvents, acids, and natural gas) to the quite harsh (oxygen, hydrogen peroxide, and other gases). PTFE Lined Ball Valves manufactured by the most popular as well as reliable PTFE Lined Ball Valves manufacturer, are used in a variety of heavy Industrial applications.

Materials used to manufacture Ball Valves:

Ball valves are often made with a body made of carbon steel (WCB or LCB) and a ball and shaft made of stainless steel (316 or CF8M). The body can be constructed out of stainless alloys for use in low/high-temperature environments or when corrosion is a concern.

Because of it being chemically inert to various fluids and having a low coefficient of friction (less than 0.1), PTFE (Polytetrafluoroethylene) is typically used as the seat material in ball valves.

PTFE Lined Ball Valves manufacturer in India will typically include a pressure/temperature curve to indicate the maximum safe operating temperature and pressure for the valve given that PTFE softens when heated.

Special Nylons, Polyetheretherketone (PEEK), and powder-filled PTFEs are utilised to increase stiffness over the seating face and maximum service temperature beyond what is possible with regular PTFE. Ball valves with metal seats are mandatory above 280°C.

Floating Design Ball Valve:

By pressing the ball seats together, the ball is kept in place in this configuration between two ball seats. A shaft that is attached to a slot on the top of the ball drives the ball in order to turn it 90° or quarter turns. Due to the effect of upstream line pressure, the ball can slide a little to the side in the slot. According to the floating ball valve design principle, the downstream seat is always thought of as the principal seat because it is loaded by line pressure. If the upstream seat design includes pre-loading or spring, it may occasionally additionally provide a secondary seal.

Trunnion Mounted Design Ball Valve:

The ball in this design is held in place by a trunnion rather than the valve seats, resulting in much-increased pressure and temperature ratings. The idea is to have the trunnion and shaft function as a single unit. To keep the ball from bouncing off the downstream seat, the shaft and trunnion are kept in bearings. The major seat in a trunnion-mounted ball valve is located on the upstream side because this is where the seat is most easily loaded, as it can slide forward against the ball. A spring mechanism is incorporated behind both seats to create a supplementary seal on the downstream side and to provide even seat loading even at low pressures. Trunnion-mounted ball valves have the same bidirectional shutoff capabilities as floating ball valve designs. Trunnion-mounted ball valves offer several advantages over their floating counterparts, the most notable of which being a reduction in operating torque and, by extension, actuation costs.

Other Designs of the Body of the Ball Valve:

One Piece Design

The ball is inserted into the body via an opening in one of the pipe flanges and sealed with a gasket that is integral to the upper face. This maximises resistance and prevents weak points.

Split Body Design:

The body of this valve is split in one or two places along the same plane as the valve flanges, giving it the alternate names of 2-piece and 3-piece ball valves. The ball is then secured to the body with bolts. Due to the lighter weight of the components, trunnion-mounted ball valves are more frequent in smaller sizes than their one-piece counterparts, and three-piece ball valves are widely used for these applications. The biggest benefit of split body ball valves is how simple they are to maintain.

Top Entry Design:

An unusual feature of this valve is that the ball enters the valve via a bonnet located above the valve's opening. The key benefit is that the valve may be maintained without having to remove it from the pipeline. It is frequently utilised in piping systems that include welding.

Fully Welded Design:

The valve body in this case is of welded construction and cannot be serviced in any way. These are commonly utilised in gas transmission lines.

#PTFE Lined ball Valves manufacturers#PTFE lined ball Valves manufacturers in vadodara#Nobleglassworks

1 note

·

View note

Photo

PTFE Lined Ball Valves Manufacturer in India

PTFE lined ball valves are devices designed to regulate the flow of fluids (including gases) by opening, closing, or moderately obstructing passageways in pipes. Lined ball valves have large- scale application over many various industries - for this reason they are vary widely in size, form and materials used depending on what they are going to be used for. They can be more or less simple, or they can be compound - in which case exceptional design is critical to how well they work.

Nowadays, PTFE lined ball valves have been the necessary products in all kinds of corrosive industrial applications. However, there are only a limited lined ball valve manufacturers who reach the international standard. So when company buy this valve, they must called for the seller to show the certifications for production. Through this way company can avoid purchasing the uncertified products.

The primary functions of lined ball valves are important guidelines based on exactly what the industry wants with regard to their machines and equipments. They are available on a number of designs and sizes, plus they are manufacture from different materials, which imply that they offer a model for just about any project.

Aira 4Matic Global Valves is an ISO 9001:2015 company, manufacturers and exporter of PTFE lined ball valves in India. Company’s manufacturing unit is established in Ahmedabad. We are offering Lined check valves for corrosive industrial applications. We have different size range of lined ball valves which are matched to all the industrial operations. We offer ball valves that are fire proof and also passed fugitive emissions testing standards.

1 note

·

View note

Link

Lined Ball Valves - We offer Lined Ball Valve at affordable rates ... 1" to 6" Flanged. Ball with Shaft. WCB / SS 304. Seals. PTFE. Temprature FEP.

0 notes