#PUF Sandwich Panels

Text

What are the considerations for installing PUF sandwich panels in different climates and environments?

Comprehensive Guide to Installing PUF Sandwich Panels in Various Climates and Environments

When it comes to building and construction, PUF (Polyurethane Foam) sandwich panels have emerged as a popular choice for insulation and cladding. Their excellent thermal performance, durability, and versatility make them ideal for various applications. However, the effectiveness of PUF sandwich panels can be significantly influenced by the climate and environment where they are installed.

This blog post will explore the key considerations for installing PUF sandwich panels in different climates and environments to help you make informed decisions for your projects. As one of the leadingPUF Sandwich Panels Manufacturers, Isoflex is committed to providing insights and solutions that ensure your installations are successful and efficient.

Understanding PUF Sandwich Panels

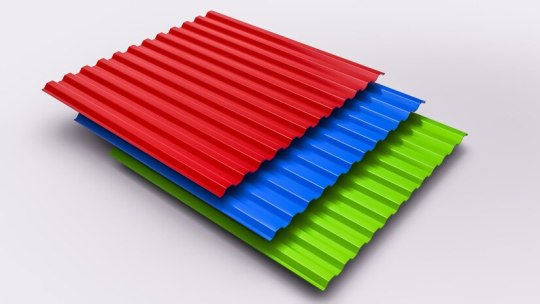

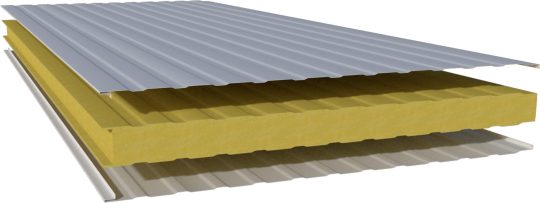

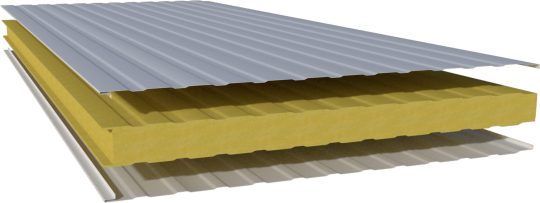

Before delving into climate-specific considerations, let’s briefly revisit what PUF sandwich panels are. These panels consist of two outer layers of metal (usually steel or aluminium) with a core of polyurethane foam in between. The foam provides excellent thermal insulation, making PUF sandwich panels popular for residential and commercial buildings.

Key Considerations for Different Climates and Environments

Hot and Humid Climates

The primary concerns in hot and humid climates are heat resistance, moisture control, and ventilation.

Heat Resistance: PUF sandwich panels offer high thermal resistance, which helps in keeping the indoor environment cool. However, for extremely hot climates, ensure that the panels are rated for high thermal resistance. Check with PUF Sandwich Panels Manufacturers to select panels with appropriate R-values (thermal resistance values).

Moisture Control: Humidity can lead to condensation issues. To prevent moisture ingress, which can compromise the insulation performance of the panels, it is crucial to install vapor barriers and ensure proper joint sealing. Look for manufacturers that offer panels with advanced sealing technologies to address these concerns.

Ventilation: Proper ventilation is essential to manage humidity levels and prevent condensation. Incorporate ventilation systems in the design to allow air circulation and moisture management.

Cold Climates

In cold climates, the focus shifts to heat retention and panel durability.

Heat Retention: PUF sandwich panels are excellent at retaining heat. However, to enhance thermal insulation, choose panels with a high R-value for very cold environments. Consult with PUF Sandwich Panel Manufacturers to find panels specifically designed for extreme cold conditions.

Durability: Cold climates can cause materials to become brittle. Opt for high-quality panels with a durable outer layer that withstand low temperatures without cracking or degrading. Also, the installation techniques must be appropriate for the cold environment to maintain panel integrity.

Snow Load: Consider the potential snow load on the roof or walls. Ensure that the panels and supporting structures are designed to handle the weight of snow accumulation.

Coastal Environments

Coastal environments present unique challenges, such as salt corrosion and high winds.

Salt Corrosion: Saltwater can cause significant corrosion issues. Choose PUF sandwich panels with coatings that resist saltwater corrosion. Manufacturers often offer panels with protective coatings or treatments suitable for coastal conditions.

High Winds: Coastal areas can experience strong winds. To prevent damage from wind forces, ensure that the panels are installed with reinforced structures and consider additional fastening solutions.

Industrial Environments

Industrial environments often involve chemical exposure, high temperatures, and heavy use.

Chemical Exposure: Choose PUF sandwich panels with chemical-resistant coatings for environments with potential chemical exposure. Consult with manufacturers to select panels that can withstand specific chemicals present in the environment.

High Temperatures: Industrial environments may involve high temperatures from machinery or processes. Ensure that the panels can handle the expected temperature ranges without losing their insulating properties.

Heavy Usage: The durability of the panels is crucial in areas subject to heavy use, such as warehouses or factories. Opt for panels with reinforced outer layers and high structural strength.

Arid and Desert Environments

Arid environments have extreme temperature variations and intense sunlight.

Temperature Fluctuations: Desert environments experience large temperature swings between day and night. Ensure that the panels have high thermal insulation properties to manage these extremes. Consult with PUF Sandwich Panels Manufacturers for panels with enhanced insulation features suitable for desert conditions.

UV Exposure: Intense sunlight can degrade some materials over time. Choose PUF sandwich panels with UV-resistant coatings to prolong their lifespan and maintain their performance.

Choosing the Right PUF Sandwich Panels Manufacturer

Selecting the right PUF Sandwich Panels Manufacturer is crucial for ensuring you get high-quality panels suited to your specific climate and environmental needs. Here are a few tips for choosing a manufacturer:

Reputation and Experience: Look for manufacturers with a strong track record and experience producing panels for various climates and applications. Isoflex, as a leading PUF Sandwich Panels Manufacturer, has extensive experience in providing solutions for diverse environments.

Product Range: Ensure the manufacturer offers various panels with different specifications. This lets you find the most suitable panels for your climate and environmental conditions.

Technical Support: Choose a manufacturer that offers technical support and advice. Isoflex provides expert guidance to help you select the right panels and ensure proper installation.

Certifications: Check for industry certifications and standards. This ensures that the panels meet quality standards and are reliable for your construction needs.

Conclusion

Installing PUF sandwich panels involves more than choosing the right product; it requires a thorough understanding of the environmental conditions where the panels will be used. Whether you are dealing with hot and humid climates, cold environments, coastal areas, industrial settings, or arid deserts, there are specific considerations to ensure the panels perform effectively and last long.

By partnering with experienced PUF Sandwich Panels Manufacturers like Isoflex, you can access high-quality products and expert advice tailored to your project’s needs. Understanding these considerations will help you make informed decisions and achieve the best results for your construction projects.

For more information on PUF sandwich panels and to explore our product offerings, visit the Isoflex website or contact our team of experts today!

0 notes

Text

No. 1 Puf Sandwich Panels Manufacturer In India

Learn About MacTech’s PUF Sandwich Panels’ Superiority

In the modern building sector, sustainability, durability, and efficiency are critical. MacTech, a front-runner in the industry, is raising the bar with its superior Puf Sandwich Panels Manufacturer. These panels are changing the way we think about construction materials because of their remarkable insulating qualities and wide range of applications.

PUF Sandwich Panels from MacTech are expertly made by fusing robust outer layers with stiff polyurethane foam (PUF). Because of their special composition, which guarantees excellent thermal insulation, they are perfect for regulating temperature in a variety of settings. With their unparalleled energy efficiency, solar panels drastically lower heating and cooling expenses, whether they are installed in residential projects, commercial buildings, or cold storage facilities.

The lightweight yet durable design of MacTech’s PUF Sandwich Panels is one of their best qualities. They are therefore simple to install, cutting down on labor expenses and construction time. The panels can be made to fit individual project requirements in a variety of sizes and thicknesses, offering a great degree of customization. In addition to adding to their attractiveness, their superior fire protection and acoustic insulation qualities guarantee the safety and comfort of their residents.

MacTech’s PUF Sandwich Panels are a testament to their commitment to sustainability. Because the panels are manufactured with environmentally friendly materials and techniques, they help cut carbon emissions and qualify as green buildings. Customers who choose MacTech are investing in a sustainable future in addition to premium construction solutions.

MacTech is still at the forefront of the construction business, having established a reputation for quality and innovation. Their PUF Sandwich Panels, which provide architects and builders dependable, high-performance solutions that last throughout time, are evidence of their dedication to quality.

With MacTech’s PUF Sandwich Panels, the possibilities are virtually limitless. Take your next project to new heights of sustainability and efficiency.

0 notes

Text

How PUF Sandwich Panels Enhance Energy Efficiency in Buildings

In the quest for sustainable building materials, PUF (Polyurethane Foam) Sandwich Panels stand out as a remarkable innovation. These panels are revolutionizing the construction industry by offering unmatched energy efficiency, durability, and versatility. As PUF Sandwich panels manufacturers continue to refine their products, it's crucial to understand how these panels contribute to enhancing energy efficiency in buildings.

Understanding PUF Sandwich Panels

Before delving into their energy-efficient properties, let's grasp what PUF Sandwich Panels entail. These panels consist of three layers: two external layers typically made of metal such as steel or aluminium, and a core layer composed of polyurethane foam. The unique construction of these panels provides exceptional thermal insulation properties, making them ideal for walls, roofs, and floors in both residential and commercial buildings.

Thermal Insulation: The Key to Energy Efficiency

One of the most significant advantages of PUF Sandwich Panels is their exceptional thermal insulation capability. The polyurethane foam core acts as a highly efficient thermal barrier, significantly reducing heat transfer between the interior and exterior of the building. This insulation not only keeps the interior spaces comfortable year-round but also minimizes the need for excessive heating or cooling, thereby reducing energy consumption and utility costs.

Reduced Energy Consumption

By installing PUF Sandwich Panels, buildings can achieve substantial energy savings. The superior insulation properties of these panels help maintain consistent indoor temperatures regardless of external weather conditions. As a result, heating and cooling systems operate more efficiently, consuming less energy to maintain comfort levels. This translates to lower electricity bills and reduced carbon emissions, contributing to a greener and more sustainable environment.

Enhanced Air Tightness

In addition to thermal insulation, PUF Sandwich Panels also offer excellent air tightness, further improving energy efficiency. The tightly sealed joints between panels prevent air leakage, minimizing heat loss or gain through infiltration. This ensures that conditioned air remains inside the building, reducing the workload on HVAC systems and optimizing energy performance.

Sustainable Construction Solution

PUF Sandwich Panels are not only energy-efficient but also contribute to sustainable construction practices. The manufacturing process of these panels involves minimal waste generation, and they are often fabricated using recycled materials. Additionally, their lightweight nature reduces transportation costs and carbon emissions associated with shipping, making them an eco-friendly choice for builders and developers.

Versatility and Design Flexibility

Beyond energy efficiency, PUF Sandwich Panels offer unparalleled versatility and design flexibility. They can be customized to meet various architectural requirements, allowing architects and designers to create innovative and aesthetically pleasing structures. Whether used in residential homes, commercial buildings, or industrial facilities, these panels provide endless design possibilities without compromising on performance or sustainability.

Long-Term Durability

Another notable benefit of PUF Sandwich Panels is their long-term durability. These panels are engineered to withstand harsh weather conditions, corrosion, and fire, ensuring the longevity of the building envelope. By choosing PUF Sandwich Panels, property owners can enjoy peace of mind knowing that their investment is protected against damage and deterioration, resulting in lower maintenance costs over time. In conclusion, PUF Sandwich Panels are a game-changer in the construction industry, offering a comprehensive solution for enhancing energy efficiency in buildings. As leading PUF Sandwich panels manufacturers continue to innovate and refine their products, the adoption of these panels is expected to rise, driving sustainability and resilience in the built environment. By incorporating PUF Sandwich Panels into construction projects, builders, developers, and property owners can achieve significant energy savings, reduce environmental impact, and create healthier and more comfortable living and working spaces for generations to come.

0 notes

Text

How PUF Sandwich Panels Enhance Energy Efficiency in Buildings

In the quest for sustainable building materials, PUF (Polyurethane Foam) Sandwich Panels stand out as a remarkable innovation. These panels are revolutionizing the construction industry by offering unmatched energy efficiency, durability, and versatility. As PUF Sandwich panels manufacturers continue to refine their products, it's crucial to understand how these panels contribute to enhancing energy efficiency in buildings.

Understanding PUF Sandwich Panels

Before delving into their energy-efficient properties, let's grasp what PUF Sandwich Panels entail. These panels consist of three layers: two external layers typically made of metal such as steel or aluminum, and a core layer composed of polyurethane foam. The unique construction of these panels provides exceptional thermal insulation properties, making them ideal for walls, roofs, and floors in both residential and commercial buildings.

Thermal Insulation: The Key to Energy Efficiency

One of the most significant advantages of PUF Sandwich Panels is their exceptional thermal insulation capability. The polyurethane foam core acts as a highly efficient thermal barrier, significantly reducing heat transfer between the interior and exterior of the building. This insulation not only keeps the interior spaces comfortable year-round but also minimizes the need for excessive heating or cooling, thereby reducing energy consumption and utility costs.

Reduced Energy Consumption

By installing PUF Sandwich Panels, buildings can achieve substantial energy savings. The superior insulation properties of these panels help maintain consistent indoor temperatures regardless of external weather conditions. As a result, heating and cooling systems operate more efficiently, consuming less energy to maintain comfort levels. This translates to lower electricity bills and reduced carbon emissions, contributing to a greener and more sustainable environment.

Enhanced Air Tightness

In addition to thermal insulation, PUF Sandwich Panels also offer excellent air tightness, further improving energy efficiency. The tightly sealed joints between panels prevent air leakage, minimizing heat loss or gain through infiltration. This ensures that conditioned air remains inside the building, reducing the workload on HVAC systems and optimizing energy performance.

Sustainable Construction Solution

PUF Sandwich Panels are not only energy-efficient but also contribute to sustainable construction practices. The manufacturing process of these panels involves minimal waste generation, and they are often fabricated using recycled materials. Additionally, their lightweight nature reduces transportation costs and carbon emissions associated with shipping, making them an eco-friendly choice for builders and developers.

Versatility and Design Flexibility

Beyond energy efficiency, PUF Sandwich Panels offer unparalleled versatility and design flexibility. They can be customized to meet various architectural requirements, allowing architects and designers to create innovative and aesthetically pleasing structures. Whether used in residential homes, commercial buildings, or industrial facilities, these panels provide endless design possibilities without compromising on performance or sustainability.

Long-Term Durability

Another notable benefit of PUF Sandwich Panels is their long-term durability. These panels are engineered to withstand harsh weather conditions, corrosion, and fire, ensuring the longevity of the building envelope. By choosing PUF Sandwich Panels, property owners can enjoy peace of mind knowing that their investment is protected against damage and deterioration, resulting in lower maintenance costs over time. In conclusion, PUF Sandwich Panels are a game-changer in the construction industry, offering a comprehensive solution for enhancing energy efficiency in buildings. As leading PUF Sandwich panels manufacturers continue to innovate and refine their products, the adoption of these panels is expected to rise, driving sustainability and resilience in the built environment. By incorporating PUF Sandwich Panels into construction projects, builders, developers, and property owners can achieve significant energy savings, reduce environmental impact, and create healthier and more comfortable living and working spaces for generations to come.

0 notes

Text

Enhancing Fire Safety in Commercial Buildings with Fireproof Rockwool Panels

Fire safety is a significant concern in commercial buildings today as it can be influenced to a large extent by the choice of construction materials. One such fireproof material is Rockwool panels, known for their exceptional resistance to fire and additional advantages that guarantee security and sustainability.

Understanding Fireproof Rockwool wall Panels

These panels are made from rock fibers and are known for not igniting under high temperatures. In a process called spinning, molten volcanic rock is converted into fibers. They are then combined into varying densities and thicknesses of panels. It produces a substance that cannot burn on itself but can act as an effective fire barrier.

Key Benefits of Fireproof Rockwool Panels

Non-Combustible Nature: These types of panels don’t burn or fuel fires; hence they are designed to contain fires within limited spaces in commercial outlets thus minimizing losses from blazes while safeguarding people’ lives.

High Temperature Resistance: These panels remain strong even when exposed to very high temperatures, meaning that they provide reliable barriers against burning fires.

Minimal Smoke and Toxic Gas Emissions: A fire outbreak is a great catastrophe that Fireproof Rockwool panels contribute to by emitting very little smoke and no toxic gases. This increases visibility during evacuation in the building and mitigates health issues brought about by inhaling smoke.

Thermal and Acoustic Insulation: The Fireproof Rockwool panels have excellent thermal insulation qualities as well as being resistant to fire. They help control room temperatures, reduce energy usage, besides affording occupants of such structures comfort. Moreover, these boards provide superiorinsulating characteristics, which assist in the reduction of noise across rooms while enhancing acoustic qualities within commercial spaces.

Durability and Sustainability: Being durable, moisture- Mold- pest-resistant products for Fireproof Rockwool panels require little maintenance over long periods of operation. They are also made from renewable and natural resources hence are aligned with sustainable construction methods resulting into minimum environmental degradation.

Applications in Commercial Buildings

Fireproof Rockwool panels find versatile applications in various areas of commercial building construction:

Exterior Cladding: Used to enhance fire protection against building facades

Interior Partitions: Made for separating different sections of the building;

The versatile application of Fireproof Rockwool panels in various areas of commercial building construction is notable:

Additionally, Fireproof Rockwool panels may be used for exterior cladding to improve fire protection and thermal insulation on building facades.

Also, Fireproof Rockwool panel can be employed as interior partitions that divide the building into several sections to promote compartmentalization and safety.

Furthermore, fire can also resistant roofing made from rock wool has the advantage of being energy efficient and having excellent thermal insulation capacity among others.

Again, rock wool is used for insulating HVAC ducts in order to enhance energy efficiency while ensuring fire safety points are met.

In conclusion

In conclusion, there is no doubt that, the use of Fireproof panels go a long way in improving fire safety standards within commercial buildings. Their high resistance to fires alongside other features such as ability to insulate against heat or sound makes them an attractive option for architects, engineers and property owners interested in observing strict safety codes while emphasizing sustainability concerns.

building projects, stakeholders can effectively address fire risks and improve overall building performance thereby prioritizing occupants’ safety and health. These panels do not only ensure compliance with fire safety regulations but also help create safer and more sustainable environments within commercial space thus benefiting everyone.

0 notes

Text

How Do Cold Room Doors Manufacturers Ensure Optimal Insulation and Temperature Control?

When preserving perishable goods, be it in the food industry, pharmaceuticals, or any sector where maintaining a specific temperature is crucial, cold room doors are at the forefront of this critical task. As one of the leading Cold Room Doors Manufacturers, Isoflex takes pride in delivering top-notch products that meet the highest insulation and temperature control standards. But what goes into making a cold room door truly effective? Let's delve into the intricate process that ensures our doors are second to none.

Isoflex: Leading the Way in Cold Room Door Manufacturing

At Isoflex, we have perfected the art of manufacturing cold room doors through years of research, innovation, and a deep understanding of our customers' needs. Our doors are engineered to provide superior insulation, robust durability, and seamless operation, ensuring your cold rooms perform at their best.

Isoflex manufactures cold room doors through a meticulous process that combines cutting-edge technology with skilled craftsmanship. Here's how we ensure our doors meet the highest quality and performance standards.

Design and Engineering

Every Isoflex cold room door starts with a detailed design phase. Our engineers use advanced computer-aided design (CAD) software to create precise specifications for each door. This includes determining the optimal insulation thickness, selecting the appropriate materials, and designing the door frame and sealing mechanisms. Our design process is guided by industry standards and best practices, ensuring that each door meets rigorous performance criteria.

Material Selection

We source high-quality stainless steel, galvanized steel, and polyurethane foam from trusted suppliers. Each material undergoes stringent quality checks to ensure it meets our strength, thermal resistance, and longevity standards.

Foam Injection

This is done using state-of-the-art machinery that ensures the foam is evenly distributed and fully expanded within the panel. The foam is then allowed to cure, forming a rigid core that provides excellent thermal insulation.

Assembly

Once the insulation is in place, the door panels are assembled with the outer and inner metal surfaces. This step involves precision welding and riveting to create a seamless and robust structure. The door frames are attached, and the entire assembly is inspected for structural integrity and alignment.

Sealing and Gasket Installation

The next step involves installing high-performance gaskets around the edges of the door. These gaskets are carefully fitted to ensure a tight seal when the door is closed. We also incorporate a unique interlocking system that enhances the sealing effectiveness, preventing air leakage and maintaining the internal temperature.

Quality Control

Each Isoflex cold room door undergoes rigorous tests to ensure it meets our standards for insulation, durability, and performance. These include thermal imaging tests to detect potential insulation gaps, pressure tests to check for air leakage, and durability tests to assess the door's resistance to wear and tear.

Customization and Finishing

The final step in the manufacturing process involves customizing the door to meet our customers' specific requirements. This can include adding features such as viewing windows, automated opening systems, or heated door frames.

Why Choose Isoflex?

Choosing Isoflex as your Cold Room Doors Manufacturer means partnering with a company that prioritizes quality, innovation, and customer satisfaction.

Customized Solutions

We understand that every customer has unique needs. We offer customizable options to tailor our cold room doors to your requirements. Whether you need a particular size, colour, or special features, we can provide a solution that fits your needs.

Commitment to Quality

At Isoflex, quality is our top priority. We use only the best materials and adhere to strict manufacturing processes to ensure the highest quality of our cold room doors. Our rigorous quality control measures ensure that every door we produce meets our exacting standards.

Excellent Customer Service

We pride ourselves on providing exceptional customer service. From the initial consultation to the installation and beyond, our team is dedicated to ensuring your satisfaction. We are always available to answer your questions and provide support whenever needed.

Competitive Pricing

We offer competitive pricing without compromising on quality. Our efficient manufacturing processes and strong supplier relationships allow us to provide high-quality cold room doors at affordable prices.

Conclusion

As one of the leading Cold Room Doors Manufacturers, Isoflex is committed to providing superior products that ensure optimal insulation and temperature control. Our cold room doors are designed and manufactured with precision, using high-quality materials and advanced technology to meet the diverse needs of various industries. With a focus on quality, innovation, and customer satisfaction, Isoflex is your trusted partner for all cold room door needs. Choose Isoflex for reliable, energy-efficient, and durable cold room doors that keep your products at their best.

0 notes

Text

What Are the Latest Trends in Cold Room Panels Manufacturing?

Cold room panels are at the forefront of innovation and efficiency in the ever-evolving landscape of cold storage solutions. As a leading name in the industry, Isoflex is proud to be at the cutting edge of these advancements, ensuring that our products not only meet but exceed our clients' expectations. In this blog post, we delve into the latest trends in cold room panel manufacturing and highlight why Isoflex is the best choice among cold room panels manufacturers.

Understanding Cold Room Panels

Cold room panels are essential components in the construction of cold storage facilities. These panels provide the necessary insulation to maintain low temperatures, crucial for preserving perishable goods, pharmaceuticals, and other temperature-sensitive items. Isoflex produces high-quality cold room panels that offer superior thermal insulation, durability, and energy efficiency.

Trend 1: Enhanced Insulation Materials

One of the most significant trends in cold room panel manufacturing is the development and use of advanced insulation materials. Traditional materials like polyurethane (PU) and polystyrene (EPS) are now being supplemented or replaced by more efficient options such as polyisocyanurate (PIR) and vacuum-insulated panels (VIPs).

Polyisocyanurate (PIR): PIR offers better fire resistance and thermal performance than PU.

Vacuum Insulated Panels (VIPs): VIPs consist of a core material enclosed in a vacuum-sealed barrier, providing exceptional insulation properties.

At Isoflex, we incorporate these advanced materials into our cold room panels, ensuring that our products deliver top-tier performance in terms of insulation and safety.

Trend 2: Sustainable and Eco-Friendly Solutions

With growing environmental concerns, sustainability has become a key focus in cold room panels manufacturing. Manufacturers increasingly adopt eco-friendly practices and materials to reduce their carbon footprint and promote energy efficiency.

Isoflex is committed to sustainability. We produce our cold room panels using recyclable materials and eco-friendly manufacturing processes. Our panels are designed to reduce energy consumption, lowering our clients' greenhouse gas emissions and operational costs.

Trend 3: Smart Technology Integration

The integration of smart technology into cold room panels is revolutionizing the industry. Smart panels have sensors and IoT (Internet of Things) devices that monitor and control real-time temperature, humidity, and other environmental factors. This technology ensures optimal storage conditions, reduces energy consumption, and minimizes the risk of spoilage.

At Isoflex, we leverage the latest advancements in smart technology to offer intelligent cold room solutions. Our panels can be integrated with advanced monitoring systems that provide real-time data and alerts, helping clients maintain precise control over their storage environments.

Trend 4: Modular and Flexible Designs

Flexibility and modularity are increasingly important in designing and manufacturing cold room panels. Modular panels allow for easy and quick assembly, disassembly, and reconfiguration, providing greater adaptability to changing storage needs and facility expansions.

Isoflex's cold room panels are designed with modularity in mind. They are easy to install and can be customized to fit any space, making them ideal for a wide range of applications, from small storage rooms to large industrial cold storage facilities.

Trend 5: Enhanced Durability and Longevity

Durability is critical in cold room panels, as these structures must withstand extreme temperatures, moisture, and physical wear and tear. Recent advancements in materials and manufacturing techniques have significantly improved the durability and longevity of cold room panels.

Isoflex uses state-of-the-art materials and manufacturing processes to ensure our panels are robust and long-lasting. Our panels feature corrosion-resistant coatings and reinforced structures, providing exceptional durability and reliability even in the harshest conditions.

Why Isoflex is the Best Among Cold Room Panels Manufacturers?

At Isoflex, we pride ourselves on being at the forefront of innovation in cold room panels manufacturing. Here's why we stand out as the best choice among cold room panels manufacturers:

Superior Quality

Quality is our top priority. We use the finest materials and employ stringent quality control measures to ensure our cold room panels meet the highest performance and reliability standards. Our commitment to quality ensures that our clients receive products that deliver unmatched insulation and durability.

Customization and Flexibility

We understand that every client has unique requirements. That's why we offer various customization options for our cold room panels. Whether you need specific dimensions, insulation materials, or integrated smart technology, Isoflex can tailor our panels to meet your needs.

Sustainability

As a responsible manufacturer, we are dedicated to sustainability. Our eco-friendly manufacturing practices and energy-efficient products help reduce environmental impact and operational costs.

Innovation

Our innovative approach ensures that our clients benefit from the latest advancements in cold room panel technology.

Expert Support

We offer comprehensive support services, including installation, maintenance, and technical assistance. Our team of experts is always ready to provide guidance and support to ensure our clients get the most out of their cold room panels.

Conclusion

The world of cold room panel manufacturing is rapidly evolving, driven by advancements in materials, technology, and sustainability. As a leading name in the industry, Isoflex is committed to staying at the forefront of these trends and providing our clients with top-quality, innovative, eco-friendly cold room panels.

Whether you are looking to build a new cold storage facility or upgrade an existing one, Isoflex has the expertise, technology, and commitment to deliver the best solutions. As the best cold room panels manufacturers, we ensure that our products meet the highest performance, durability, and sustainability standards. Trust Isoflex to provide you with the cutting-edge cold storage solutions you need to stay ahead in a competitive market.

0 notes

Text

What Are the Key Factors to Consider When Choosing Clean Room Doors Manufacturers?

Maintaining a clean and contaminant-free atmosphere is crucial in highly controlled environments like laboratories, pharmaceutical production areas, and high-tech manufacturing plants. The effectiveness of these environments often hinges on the quality of their infrastructure, especially the doors. Clean room doors serve as vital barriers, preventing the entry of contaminants and maintaining the required level of cleanliness.

Therefore, selecting the rightclean room doors manufacturers is a critical decision.

At Isoflex, we pride ourselves on being the best in the industry, providing top-tier clean room doors that meet the highest quality and performance standards. In this blog, we'll delve into the essential factors to consider when choosing clean room doors manufacturers and explain why Isoflex stands out as the leading choice.

Understanding the Importance of Clean Room Doors

Clean room doors are not just simple entry points but sophisticated components designed to maintain strict environmental control. Given their critical role, it is imperative to choose manufacturers who understand these requirements and can deliver products that meet stringent standards.

Key factors-

Quality and Compliance

The primary consideration when selecting clean room doors manufacturers is the quality of their products. High-quality doors ensure long-term reliability and effective contamination control. Look for manufacturers who adhere to international standards and certifications such as ISO, GMP (Good Manufacturing Practices), and FDA guidelines. These certifications indicate that the manufacturer meets rigorous quality and safety standards.

Customization Options

Clean rooms vary significantly in their design and requirements. Hence, it is crucial to choose a manufacturer that offers customizable solutions. This includes customizing door sizes, materials, finishes, and additional features like automated operation, interlocking systems, and vision panels. Customization ensures that the doors perfectly fit the specific needs of your clean room.

Material Selection

The materials used to construct clean room doors significantly affect their performance. Common materials include stainless steel, aluminium, and high-grade plastics, each offering different benefits. For instance, stainless steel is highly durable and corrosion-resistant, making it ideal for environments with stringent hygiene requirements. Evaluate the manufacturer's material options and ensure they align with your clean room's needs.

Installation and Maintenance Services

A reliable manufacturer should supply high-quality doors and offer professional installation and maintenance services. Proper installation is crucial to ensure the doors function correctly and maintain the clean room's integrity. Additionally, regular maintenance and prompt repair services are essential to extend the lifespan of the doors and prevent any operational disruptions.

Technological Advancements

Incorporation of advanced technologies in clean room doors can enhance their functionality and user convenience. Features such as automatic sliding or swing mechanisms, touchless operation, and integration with access control systems can significantly improve efficiency and hygiene. Choose manufacturers who stay abreast of technological advancements and incorporate them into their products.

Reputation and Experience

A manufacturer's reputation and experience in the industry are strong indicators of their reliability. Research the manufacturer's history, customer reviews, and case studies to gauge their credibility and expertise. Experienced manufacturers will likely better understand clean room requirements and can provide more reliable and innovative solutions.

Cost-Effectiveness

While quality should never be compromised, it is also essential to consider the cost-effectiveness of the products. Evaluate the manufacturer's overall value, considering factors such as product quality, customization options, warranty, and after-sales service. Opt for manufacturers who provide a good balance between quality and affordability.

Why Isoflex is the Best Choice for Clean Room Doors?

At Isoflex, we excel in all the factors mentioned above, making us the industry's best clean room doors manufacturers. Here's why:

Unmatched Quality and Compliance

Isoflex is committed to delivering the highest quality clean room doors. Our products meet and exceed international standards, including ISO and GMP certifications. We use premium materials and state-of-the-art manufacturing processes to ensure that our doors provide superior performance and longevity.

Comprehensive Customization Options

That's why we offer extensive customization options. Whether you need specific door sizes, materials, finishes, or advanced features, we can tailor our products to meet your needs. Our expert team works closely with clients to design and manufacture doors perfectly fitting their clean room environments.

High-Quality Materials

Isoflex clean room doors are made from the finest materials, including stainless steel, aluminium, and high-grade plastics. These materials are selected for their durability, corrosion resistance, and ability to withstand rigorous cleaning protocols. Our doors are designed to maintain integrity and appearance even in the most demanding environments.

Professional Installation and Maintenance

We provide comprehensive installation services to ensure our clean room doors are correctly fitted and fully operational. Our team of skilled technicians has extensive experience installing clean room doors and adheres to the highest standards of workmanship. Additionally, we offer ongoing maintenance services to keep your doors in optimal condition and address any issues promptly.

Innovative Technological Features

Isoflex integrates the latest technological advancements into our clean room doors. From automatic sliding mechanisms to touchless operation and advanced access control systems, our doors are designed to enhance convenience, efficiency, and hygiene. We continuously invest in research and development to bring cutting-edge solutions to our clients.

Proven Reputation and Experience

With years of experience in the industry, Isoflex has built a solid reputation for excellence. We have completed numerous projects for leading companies in various sectors, including pharmaceuticals, biotechnology, electronics, and more. Our record of delivering high-quality products and exceptional customer service speaks for itself.

Cost-Effective Solutions

At Isoflex, we believe in providing the best value to our clients. Our clean room doors are competitively priced without compromising on quality. We offer comprehensive warranties and after-sales support to ensure our clients get the most out of their investment. With Isoflex, you get premium quality at a reasonable price.

Conclusion

Choosing the right clean room doors manufacturer is a crucial decision that can significantly impact your clean room's performance and reliability. Consider factors such as quality, customization options, material selection, installation and maintenance services, technological advancements, reputation, and cost-effectiveness to make an informed choice.

Isoflex stands out as the leading manufacturer of clean room doors, offering unparalleled quality, comprehensive customization, high-quality materials, professional installation and maintenance, innovative features, a proven reputation, and cost-effective solutions. Trust Isoflex for your cleanroom door needs and experience the difference that comes with partnering with the best in the industry.

Contact us today to learn more about our products and services and how we can help you maintain the highest cleanliness and efficiency standards in your clean room environment.

0 notes

Text

How PUF Sandwich Panels Manufacturers Ensure High Thermal Efficiency and Insulation?

In today's rapidly evolving construction industry, thermal efficiency and insulation are paramount. As energy costs rise and environmental concerns intensify, the demand for advanced building materials that offer sustainability and performance has never been higher. This is where PUF (Polyurethane Foam) sandwich panels come into play, setting a new benchmark for insulation and energy efficiency.

At Isoflex, we pride ourselves on being the industry's best PUF sandwich panel manufacturers. In this blog post, we will delve into how we ensure the highest thermal efficiency and insulation in our PUF sandwich panels, highlighting the features and benefits that make our products the best choice for your construction needs.

Understanding PUF Sandwich Panels

PUF sandwich panels are composite building materials consisting of two outer layers and a rigid polyurethane foam core. The outer layers can be made of various materials, such as galvanized steel, aluminium, or other durable materials, providing structural strength and protection. The core, made of polyurethane foam, offers excellent thermal insulation properties.

Polyurethane foam is known for its low thermal conductivity, which means it can effectively reduce heat transfer and maintain a stable indoor temperature regardless of external weather conditions. This unique composition makes PUF sandwich panels ideal for various applications, including cold storage facilities, industrial buildings, residential homes, and commercial establishments.

The Isoflex Advantage

As a leadingPUF sandwich panels manufacturers, Isoflex stands out due to several key factors:

Advanced Manufacturing Techniques: At Isoflex, we utilize state-of-the-art manufacturing processes to ensure the highest quality and consistency of our products. Our production facilities are equipped with the latest technology, allowing us to produce panels with precise dimensions and uniform properties.

High-Quality Raw Materials: This includes top-grade polyurethane foam with excellent insulating properties and durable outer layers that provide strength and longevity. Our strict quality control measures ensure that every panel meets our high standards.

Our dedicated research and development team continuously works to improve our products, incorporating the latest advancements in material science and insulation technology. This commitment to innovation ensures that our PUF sandwich panels are always at the forefront of the industry.

Sustainability: We are committed to environmental sustainability. Our PUF sandwich panels are designed to be energy-efficient, reducing the need for heating and cooling and thereby lowering carbon emissions. Additionally, we implement eco-friendly practices in our manufacturing processes, minimizing waste and using recyclable materials wherever possible.

Ensuring Thermal Efficiency and Insulation

To ensure superior thermal efficiency and insulation in our PUF sandwich panels, we focus on several critical aspects:

Low Thermal Conductivity: The core of our sandwich panels is made from rigid polyurethane foam, which has one of the lowest thermal conductivity values among insulating materials. This means that our panels can effectively prevent heat transfer, keeping indoor spaces cool in the summer and warm in the winter.

Precision Engineering: Our manufacturing process involves precise engineering to ensure that each panel has a uniform thickness and density. This uniformity is crucial for maintaining consistent thermal performance across the panel's entire surface.

Thermal Bridging Prevention: Thermal bridging occurs when heat bypasses the insulation through conductive paths, such as metal fasteners or structural elements. We design our PUF sandwich panels to minimize thermal bridging, using advanced techniques to reduce heat transfer through the panel joints and connections.

Seamless Integration: Our panels are designed for easy and seamless integration into various building structures. The interlocking design of the panels ensures a tight fit, reducing gaps and air leakage, which can compromise thermal efficiency.

Weather Resistance: The outer layers of our PUF sandwich panels are made from weather-resistant materials, protecting the core from moisture, UV radiation, and other environmental factors.

Applications of PUF Sandwich Panels

The versatility and superior insulation properties of our PUF sandwich panels make them suitable for a wide range of applications:

Cold Storage Facilities: Maintaining a consistent temperature is crucial in cold storage facilities. Our PUF sandwich panels provide the necessary insulation to stabilize these environments, ensuring the quality and safety of perishable goods.

Industrial Buildings: In industrial settings, energy efficiency can significantly impact operational costs. Our panels help regulate indoor temperatures, reducing the need for heating and cooling and leading to substantial energy savings.

Residential Homes: Homeowners can benefit from the enhanced comfort and reduced energy bills that come with our PUF sandwich panels. These panels can be used in walls, roofs, and floors to create a well-insulated living space.

Commercial Establishments: From shopping malls to office buildings, our panels provide the thermal efficiency needed to create comfortable indoor environments for customers and employees.

Modular Buildings: Our PUF sandwich panels' lightweight nature makes them ideal for modular construction.

Conclusion

As the best PUF sandwich panels manufacturers, Isoflex is dedicated to delivering products that combine superior thermal efficiency, durability, and sustainability. Our commitment to quality and innovation ensures that our panels meet the highest standards, providing effective insulation solutions for various applications.

By choosing Isoflex PUF sandwich panels, you invest in a product that offers exceptional performance and long-term energy savings. Whether you are constructing a cold storage facility, an industrial building, a residential home, or a commercial establishment, our panels will provide the insulation you need to maintain a comfortable and energy-efficient environment.

Experience the Isoflex difference and discover why we are the preferred choice for PUF sandwich panels manufacturers. Contact us today to learn more about our products and how we can help you achieve your construction and insulation goals.

0 notes

Text

Energy Efficiency and Clean Room Doors: Saving Costs Without Compromising Quality

In today's competitive marketplace, businesses are constantly searching for ways to reduce operational costs while maintaining high standards of quality and efficiency. One critical area where companies can achieve significant savings is in their energy consumption. Investing in high-quality clean room doors is a smart move for industries that rely on controlled environments, such as pharmaceuticals, biotechnology, food processing, and electronics manufacturing. Isoflex, a reputable Clean Room Doors Manufacturers, offers solutions that enhance energy efficiency and uphold the stringent standards required in these environments.

The Importance of Clean Room Doors in Controlled Environments

Clean rooms are specialized environments that minimize contamination from airborne particles, microorganisms, and other pollutants. They are essential in various industries where even the smallest contamination can lead to significant product defects, health risks, or regulatory non-compliance. Clean room doors play a vital role in maintaining these controlled conditions by providing a barrier that prevents the ingress of contaminants and helps regulate internal environments.

Energy Efficiency: A Key Consideration

Energy consumption is one of the most pressing concerns for businesses operating clean rooms. Clean rooms typically require extensive HVAC systems to maintain specific temperature, humidity, and particulate levels. These systems can be energy-intensive, leading to high operational costs. However, by investing in high-quality clean room doors from reputable manufacturers like Isoflex, businesses can significantly enhance their energy efficiency and reduce costs.

How Isoflex Clean Room Doors Enhance Energy Efficiency

Isoflex clean room doors are engineered with energy efficiency in mind. Here are several ways in which our doors contribute to energy savings:

Superior Insulation

Isoflex clean room doors are constructed using advanced materials that provide superior insulation. This insulation minimizes heat transfer between the clean room and adjacent areas, reducing the load on HVAC systems. As a result, less energy is required to maintain the desired environmental conditions within the clean room.

Airtight Seals

Our clean room doors are designed with high-performance seals that ensure airtight closure. These seals prevent the leakage of conditioned air, maintaining consistent temperature and humidity levels inside the clean room. Isoflex doors reduce the energy required to compensate for temperature fluctuations by preventing air exchange with the outside environment.

Durable and Reliable Construction

Isoflex doors are built to withstand the demanding conditions of clean room environments. Their durability ensures long-term performance with minimal maintenance. Reliable doors that maintain their integrity over time reduce the need for frequent replacements or repairs, further contributing to cost savings and energy efficiency.

Cost Savings Without Compromising Quality

While the primary focus is often on energy savings, these savings mustn't come at the expense of quality. Isoflex clean room doors offer the perfect balance between cost-effectiveness and uncompromised quality.

Compliance with Standards

Isoflex clean room doors are designed to meet or exceed industry cleanliness and environmental control standards. They comply with regulations such as ISO 14644, which specifies the requirements for clean rooms and associated controlled environments. Investing in doors that meet these standards ensures that your cleanroom operations remain compliant and efficient.

Enhanced Operational Efficiency

High-quality clean room doors from Isoflex enhance overall operational efficiency. With features such as smooth and reliable opening mechanisms, our doors facilitate easy access while maintaining the integrity of the controlled environment. This ease of use reduces downtime and increases productivity, leading to cost savings over time.

Customization for Specific Needs

Every clean room has unique requirements, and Isoflex understands the importance of providing customized solutions. Our clean room doors can be tailored to fit specific dimensions, configurations, and operational needs. This customization ensures you get a product that perfectly suits your application, maximizing efficiency and cost-effectiveness.

Why Choose Isoflex?

When it comes to clean room doors manufacturers, Isoflex stands out for several reasons:

Expertise and Experience

With years of experience in the industry, Isoflex has developed a deep understanding of the needs and challenges faced by cleanroom operators. Our expertise allows us to design and manufacture doors that meet the highest performance and reliability standards.

Commitment to Quality

Quality is at the core of everything we do at Isoflex. From the selection of materials to the manufacturing process and final inspection, we maintain stringent quality control measures to ensure that our products exceed customer expectations.

Comprehensive Support

Isoflex offers comprehensive support to our customers, from initial consultation and design to installation and maintenance. Our team of experts is always available to provide guidance and assistance, ensuring you get the most out of your investment.

Conclusion

Investing in high-quality, clean room doors is a strategic decision that can lead to significant energy savings and cost reductions without compromising the quality of your controlled environment. Isoflex, a reputable manufacturer of clean room doors, offers solutions that provide superior insulation, airtight seals, and durable construction. Our doors are designed to enhance operational efficiency, comply with industry standards, and can be customized to meet your specific needs.

By choosing Isoflex clean room doors, you are making a smart investment in your business's future. Our commitment to quality, expertise, and comprehensive support ensures you receive a product that meets and exceeds your expectations. Make the switch to Isoflex clean room doors today and start saving on energy costs while maintaining the highest standards of quality and efficiency.

For more information about our products and how they can benefit your operations, please visit our website or contact our sales team. Isoflex is here to help you achieve your energy efficiency goals and ensure the success of your cleanroom operations.

0 notes

Text

Cost-Effectiveness of PUF Sandwich Panels in Construction Projects

The construction industry continually evolves, with new materials and techniques being developed to improve efficiency, sustainability, and cost-effectiveness. One such innovation that has gained significant traction is using PUF (Polyurethane Foam) sandwich panels. These panels, produced byIsoflex, a reputable PUF Sandwich Panels Manufacturer, offer many benefits that make them a preferred choice for modern construction projects. This blog will delve into the cost-effectiveness of PUF sandwich panels and explore why they are becoming an integral part of contemporary construction practices.

Understanding PUF Sandwich Panels

PUF sandwich panels are composite materials of a lightweight core material, typically polyurethane foam, sandwiched between two layers of durable facing materials such as galvanized steel, aluminium, or other metal sheets. This configuration provides an excellent combination of strength, thermal insulation, and lightweight properties, making them ideal for various applications in the construction industry.

Key Benefits of PUF Sandwich Panels

Before diving into their cost-effectiveness, it's essential to understand the key benefits that PUF sandwich panels offer:

Thermal Insulation: PUF sandwich panels have superior thermal insulation properties, which can significantly reduce heating and cooling costs in buildings.

Lightweight: Despite their strength, these panels are lightweight, reducing the structural load on buildings and simplifying transportation and installation.

Durability: The materials used in PUF sandwich panels are highly durable and resistant to weathering, corrosion, and other environmental factors.

Quick Installation: These panels' modular nature allows for rapid installation,

reducing Labour costs and construction timelines.

Fire Resistance: Many PUF sandwich panels are designed with fire-resistant properties, enhancing the safety of buildings.

Cost-Effectiveness of PUF Sandwich Panels

When evaluating the cost-effectiveness of any construction material, it's crucial to consider both the initial investment and the long-term savings. PUF Sandwich panels excel in both areas, making them a financially savvy choice for construction projects.

Initial Investment

While the upfront cost of PUF sandwich panels might be higher than some traditional materials, their overall value becomes evident when considering the following factors:

Reduced Structural Costs: The lightweight nature of PUF sandwich panels means that buildings require less structural support, leading to savings on foundational materials and labour.

Lower Transportation Costs: Due to their lightweight, transportation costs are significantly lower compared to traditional building materials.

Simplified Installation: The ease of installation reduces labour costs and shortens the construction timeline, leading to faster project completion and earlier occupancy.

Long-Term Savings

The long-term savings associated with PUF sandwich panels are substantial and contribute to their overall cost-effectiveness:

Energy Efficiency: The superior thermal insulation properties of PUF sandwich panels result in significant energy savings.

Maintenance Costs: The durability and resistance to environmental factors mean that buildings constructed with PUF sandwich panels require less maintenance and have a longer lifespan.

Sustainability: Many PUF sandwich panels are made with eco-friendly materials and processes, which can contribute to green building certifications and potential tax incentives.

Applications of PUF Sandwich Panels

The versatility of PUF sandwich panels allows them to be used in various construction projects. Some common applications include:

Commercial Buildings: Office complexes, shopping centers, and warehouses benefit from the energy efficiency and quick installation of PUF sandwich panels.

Residential Buildings: Homes and apartment complexes can achieve better insulation and reduced energy costs with these panels.

Cold Storage: The excellent thermal properties make PUF sandwich panels ideal for cold storage facilities and refrigeration units.

Industrial Buildings: Factories and industrial units require durable and low-maintenance materials, making PUF sandwich panels a suitable choice.

Conclusion

PUF Sandwich panels represent a cost-effective, efficient, and sustainable solution for modern construction projects. Their superior thermal insulation, durability, and lightweight properties make them a valuable addition to any building, offering both initial cost savings and long-term financial benefits. By partnering with Isoflex, a reputable PUF Sandwich Panels Manufacturer, construction companies can use high-quality materials that enhance their projects' overall performance and cost-effectiveness.

The adoption of PUF sandwich panels is not just a trend but a smart investment towards building a more sustainable and economically viable future. Whether for commercial, residential, or industrial applications, these panels offer unmatched benefits that make them a cornerstone of modern construction practices. As the industry continues to evolve, the role of innovative materials like PUF sandwich panels will only become more prominent, driving the construction sector towards greater efficiency and sustainability.

0 notes

Text

Cost-Effectiveness of PUF Sandwich Panels in Construction Projects

The construction industry continually evolves, with new materials and techniques being developed to improve efficiency, sustainability, and cost-effectiveness. One such innovation that has gained significant traction is using PUF (Polyurethane Foam) sandwich panels. These panels, produced by Isoflex, a reputable PUF Sandwich Panels Manufacturer, offer many benefits that make them a preferred choice for modern construction projects. This blog will delve into the cost-effectiveness of PUF sandwich panels and explore why they are becoming an integral part of contemporary construction practices.

Understanding PUF Sandwich Panels

PUF sandwich panels are composite materials of a lightweight core material, typically polyurethane foam, sandwiched between two layers of durable facing materials such as galvanized steel, aluminium, or other metal sheets. This configuration provides an excellent combination of strength, thermal insulation, and lightweight properties, making them ideal for various applications in the construction industry.

Key Benefits of PUF Sandwich Panels

Before diving into their cost-effectiveness, it's essential to understand the key benefits that PUF sandwich panels offer:

Thermal Insulation: PUF sandwich panels have superior thermal insulation properties, which can significantly reduce heating and cooling costs in buildings.

Lightweight: Despite their strength, these panels are lightweight, reducing the structural load on buildings and simplifying transportation and installation.

Durability: The materials used in PUF sandwich panels are highly durable and resistant to weathering, corrosion, and other environmental factors.

Quick Installation: These panels' modular nature allows for rapid installation,

reducing Labour costs and construction timelines.

Fire Resistance: Many PUF sandwich panels are designed with fire-resistant properties, enhancing the safety of buildings.

Cost-Effectiveness of PUF Sandwich Panels

When evaluating the cost-effectiveness of any construction material, it's crucial to consider both the initial investment and the long-term savings. PUF Sandwich panels excel in both areas, making them a financially savvy choice for construction projects.

Initial Investment

While the upfront cost of PUF sandwich panels might be higher than some traditional materials, their overall value becomes evident when considering the following factors:

Reduced Structural Costs: The lightweight nature of PUF sandwich panels means that buildings require less structural support, leading to savings on foundational materials and labour.

Lower Transportation Costs: Due to their lightweight, transportation costs are significantly lower compared to traditional building materials.

Simplified Installation: The ease of installation reduces labour costs and shortens the construction timeline, leading to faster project completion and earlier occupancy.

Long-Term Savings

The long-term savings associated with PUF sandwich panels are substantial and contribute to their overall cost-effectiveness:

Energy Efficiency: The superior thermal insulation properties of PUF sandwich panels result in significant energy savings.

Maintenance Costs: The durability and resistance to environmental factors mean that buildings constructed with PUF sandwich panels require less maintenance and have a longer lifespan.

Sustainability: Many PUF sandwich panels are made with eco-friendly materials and processes, which can contribute to green building certifications and potential tax incentives.

Applications of PUF Sandwich Panels

The versatility of PUF sandwich panels allows them to be used in various construction projects. Some common applications include:

Commercial Buildings: Office complexes, shopping centers, and warehouses benefit from the energy efficiency and quick installation of PUF sandwich panels.

Residential Buildings: Homes and apartment complexes can achieve better insulation and reduced energy costs with these panels.

Cold Storage: The excellent thermal properties make PUF sandwich panels ideal for cold storage facilities and refrigeration units.

Industrial Buildings: Factories and industrial units require durable and low-maintenance materials, making PUF sandwich panels a suitable choice.

Conclusion

PUF Sandwich panels represent a cost-effective, efficient, and sustainable solution for modern construction projects. Their superior thermal insulation, durability, and lightweight properties make them a valuable addition to any building, offering both initial cost savings and long-term financial benefits. By partnering with Isoflex, a reputable PUF Sandwich Panels Manufacturer, construction companies can use high-quality materials that enhance their projects' overall performance and cost-effectiveness.

The adoption of PUF sandwich panels is not just a trend but a smart investment towards building a more sustainable and economically viable future. Whether for commercial, residential, or industrial applications, these panels offer unmatched benefits that make them a cornerstone of modern construction practices. As the industry continues to evolve, the role of innovative materials like PUF sandwich panels will only become more prominent, driving the construction sector towards greater efficiency and sustainability.

0 notes

Text

Top 10 Quality Puf Sandwich Panels Manufacturer

Searching for a Top PUF Sandwich Panels Manufacturer.Mactec provides high-quality PUF sandwich panels designed for excellent insulation and durability. Ideal for construction and industrial use, our panels offer superior thermal performance and strength. As a leading PUF sandwich panels manufacturer, we focus on delivering top-notch products and outstanding service. Explore our range and experience the benefits of our reliable PUF sandwich panels. Visit mactec.in for more details!Adress : Khasra No. 536, Sikhera, Road, Industrial Area, Modinagar, Uttar Pradesh 201204

0 notes

Text

PUF Panels and Sandwich Panels: Applications Across Industries

Efficiency, durability, and versatility are essential in the realms of construction and industrial design. One innovation that has revolutionized these aspects is the introduction of Polyurethane Foam (PUF) panels and sandwich panels. These composite materials, consisting of a core sandwiched between two outer layers, offer numerous advantages and are widely used across various industries. In this text, we will explore the different areas where PUF panels and sandwich panels are commonly applied.

Cold Storage and Refrigeration: PUF panels excel in thermal insulation properties, making them ideal for cold storage facilities and refrigeration units. These panels create an efficient barrier against temperature fluctuations, helping to maintain the desired temperature inside the storage area. From food processing plants to pharmaceutical storage facilities, PUF panels ensure the integrity and freshness of perishable goods.

Commercial and Industrial Buildings: The versatility of PUF panels and sandwich panels extends to the realm of commercial and prefab construction. These panels are widely used for roofing, wall cladding, and partitioning in warehouse manufacturers, factories, workshops, and offices. Their lightweight nature facilitates quick installation, reducing construction time and costs. Moreover, their excellent insulation properties contribute to energy efficiency, leading to reduced heating and cooling expenses.

Modular Construction: The modular construction industry heavily relies on PUF panels and sandwich panels for their prefabricated structures. Whether it's modular homes, portable cabins, or temporary shelters, these panels offer a convenient solution for rapid assembly and disassembly. The modular nature of PUF panels allows for easy customization, enabling architects and designers to create versatile spaces tailored to specific needs.

Transportation Sector: PUF panels play a vital role in the transportation sector, particularly in the construction of refrigerated trucks, vans, and containers. These panels help to create insulated compartments that safeguard perishable goods during transit. Additionally, sandwich panels find applications in the aerospace industry for aircraft interiors, providing lightweight yet robust solutions for cabin walls and partitions.

Clean Rooms and Laboratories: Precision-controlled environments such as clean rooms and laboratories require stringent temperature and contamination control. PUF panels offer an ideal solution due to their ability to create airtight enclosures with superior insulation properties. These panels help maintain stable environmental conditions necessary for sensitive manufacturing processes, research, and testing activities.

Agricultural Sector: In agriculture, PUF panels are utilized for constructing storage facilities, cold rooms, and greenhouses. These panels help farmers and growers extend the shelf life of their produce by providing an insulated environment conducive to preservation. Additionally, sandwich panels are employed in livestock housing, offering comfortable and hygienic shelters for animals.

Conclusion: PUF panels and sandwich panels have emerged as indispensable materials across a myriad of industries, thanks to their exceptional thermal insulation, structural strength, and versatility. From cold storage facilities to commercial buildings, from transportation to clean room environments, the applications of these panels are diverse and far-reaching. As technology continues to advance, we can expect further innovations in the design and utilization of PUF panels, driving efficiency, sustainability, and performance across various sectors.

1 note

·

View note

Text

How PUF Sandwich Panels Enhance Energy Efficiency in Buildings

In the quest for sustainable building materials, PUF (Polyurethane Foam) Sandwich Panels stand out as a remarkable innovation. These panels are revolutionizing the construction industry by offering unmatched energy efficiency, durability, and versatility. As PUF Sandwich panels manufacturers continue to refine their products, it's crucial to understand how these panels contribute to enhancing energy efficiency in buildings.

Understanding PUF Sandwich Panels

Before delving into their energy-efficient properties, let's grasp what PUF Sandwich Panels entail. These panels consist of three layers: two external layers typically made of metal such as steel or aluminium, and a core layer composed of polyurethane foam. The unique construction of these panels provides exceptional thermal insulation properties, making them ideal for walls, roofs, and floors in both residential and commercial buildings.

Thermal Insulation: The Key to Energy Efficiency

One of the most significant advantages of PUF Sandwich Panels is their exceptional thermal insulation capability. The polyurethane foam core acts as a highly efficient thermal barrier, significantly reducing heat transfer between the interior and exterior of the building. This insulation not only keeps the interior spaces comfortable year-round but also minimizes the need for excessive heating or cooling, thereby reducing energy consumption and utility costs.

Reduced Energy Consumption

By installing PUF Sandwich Panels, buildings can achieve substantial energy savings. The superior insulation properties of these panels help maintain consistent indoor temperatures regardless of external weather conditions. As a result, heating and cooling systems operate more efficiently, consuming less energy to maintain comfort levels. This translates to lower electricity bills and reduced carbon emissions, contributing to a greener and more sustainable environment.

Enhanced Air Tightness

In addition to thermal insulation, PUF Sandwich Panels also offer excellent air tightness, further improving energy efficiency. The tightly sealed joints between panels prevent air leakage, minimizing heat loss or gain through infiltration. This ensures that conditioned air remains inside the building, reducing the workload on HVAC systems and optimizing energy performance.

Sustainable Construction Solution

PUF Sandwich Panels are not only energy-efficient but also contribute to sustainable construction practices. The manufacturing process of these panels involves minimal waste generation, and they are often fabricated using recycled materials. Additionally, their lightweight nature reduces transportation costs and carbon emissions associated with shipping, making them an eco-friendly choice for builders and developers.

Versatility and Design Flexibility

Beyond energy efficiency, PUF Sandwich Panels offer unparalleled versatility and design flexibility. They can be customized to meet various architectural requirements, allowing architects and designers to create innovative and aesthetically pleasing structures. Whether used in residential homes, commercial buildings, or industrial facilities, these panels provide endless design possibilities without compromising on performance or sustainability.

Long-Term Durability

Another notable benefit of PUF Sandwich Panels is their long-term durability. These panels are engineered to withstand harsh weather conditions, corrosion, and fire, ensuring the longevity of the building envelope. By choosing PUF Sandwich Panels, property owners can enjoy peace of mind knowing that their investment is protected against damage and deterioration, resulting in lower maintenance costs over time.

In conclusion, PUF Sandwich Panels are a game-changer in the construction industry, offering a comprehensive solution for enhancing energy efficiency in buildings. As leading PUF Sandwich panels manufacturers continue to innovate and refine their products, the adoption of these panels is expected to rise, driving sustainability and resilience in the built environment. By incorporating PUF Sandwich Panels into construction projects, builders, developers, and property owners can achieve significant energy savings, reduce environmental impact, and create healthier and more comfortable living and working spaces for generations to come.

0 notes

Text

1 note

·

View note