#Pallet Conveyors

Explore tagged Tumblr posts

Text

The Ultimate Guide to Pallet Conveyors: Streamlining Heavy Material Handling

In today’s fast-paced industrial world, efficiency is key. Companies are constantly looking for ways to improve productivity, reduce manual labor, and streamline operations. One of the unsung heroes of this mission is the pallet conveyor system. Whether in manufacturing, warehousing, or distribution, pallet conveyors play a crucial role in moving heavy goods with precision and speed.

What is a Pallet Conveyor?

A pallet conveyor is a mechanical handling device designed to transport pallets — flat transport structures that carry goods — across a facility. Unlike standard conveyors meant for smaller items, pallet conveyors are built to handle heavy, bulky loads typically ranging from 500 to 2000 kilograms or more.

These systems use a combination of belts, rollers, or chains to move pallets smoothly from one point to another, ensuring minimal manual handling and reducing the risk of damage or injury.

Types of Pallet Conveyors

Depending on the specific needs of an operation, there are several types of pallet conveyors to choose from:

1. Chain-Driven Pallet Conveyors

These conveyors use heavy-duty chains to move pallets. They are ideal for very heavy loads and are commonly used in rugged environments like manufacturing plants.

2. Roller Pallet Conveyors

In this design, pallets move along rollers, either powered or gravity-fed. Powered roller conveyors are great for controlled movement, while gravity versions are ideal for simple, downhill transfers.

3. Belt-Driven Pallet Conveyors

These systems use a belt underneath the rollers to provide motion. They are often used when smooth, even motion is critical, or when pallets must be moved up or down inclines.

4. Turntable Pallet Conveyors

When the direction of pallet movement needs to change (such as 90° turns), turntable conveyors come into play. These systems rotate the pallet without the need for complex manual handling.

Key Benefits of Pallet Conveyors

✔️ Improved Efficiency

Pallet conveyors automate the movement of heavy loads, saving significant time and reducing bottlenecks in production and warehousing operations.

✔️ Enhanced Safety

By reducing manual handling, pallet conveyors help lower the risk of workplace injuries, protecting your workforce and lowering insurance costs.

✔️ Cost Savings

Though they require upfront investment, pallet conveyor systems significantly reduce labor costs over time, offering a solid return on investment.

✔️ Space Optimization

Pallet conveyors can be customized to fit your facility layout, including vertical lifts and stackers that maximize space usage.

✔️ Reliability and Durability

Built to withstand tough conditions, pallet conveyors are a long-lasting solution for industries dealing with heavy goods.

Applications of Pallet Conveyors

Manufacturing plants for moving raw materials or finished products

Warehouses and distribution centers for order fulfillment

Automotive industries for parts transportation

Food and beverage industries for bulk goods handling

Pharmaceutical sectors where clean and efficient movement of heavy batches is critical

Factors to Consider When Choosing a Pallet Conveyor

When selecting a pallet conveyor for your operations, consider:

Load Weight and Size: Ensure the system can handle your heaviest pallets.

Facility Layout: Choose between straight, curved, or multi-level conveyors based on your space.

Speed Requirements: Some operations require faster pallet movement than others.

Environmental Conditions: For example, cold storage facilities may need specially designed conveyors.

Budget: Balance initial investment with long-term savings and efficiency gains.

Conclusion

Pallet conveyors are a smart investment for any business handling heavy loads. By improving efficiency, enhancing safety, and reducing costs, they become an integral part of a well-oiled supply chain. Whether you’re upgrading an existing system or setting up a new facility, a tailored pallet conveyor solution could be the key to your operational success.

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

Efficient Warehousing Starts with the Right Pallet Dispenser

In modern warehousing and logistics, efficiency is no longer optional—it’s essential. A key component in streamlining material handling operations is the pallet dispenser. Often working in tandem with a pallet stacker, this equipment automates one of the most overlooked steps in warehouse workflows: dispensing and stacking pallets.

What Is a Pallet Dispenser?

A pallet dispenser is a mechanical device designed to automatically release or stack pallets without the need for manual handling. Commonly used in distribution centers, manufacturing plants, and packaging lines, these machines reduce downtime and improve worker safety by minimizing manual lifting.

Pallet dispensers can handle wooden, plastic, and sometimes even metal pallets, and they come in various configurations—floor-mounted, overhead, or integrated into conveyor systems.

Why Warehouses Are Turning to Pallet Dispensers

As labor shortages and operational costs continue to impact supply chain dynamics, automation is becoming an integral part of warehouse optimization. Pallet dispensers, when combined with pallet stackers, can lead to significant improvements in:

Productivity: Continuous feed of pallets eliminates manual placement delays.

Safety: Reduces the risk of injuries related to lifting and moving heavy pallets.

Consistency: Ensures uniform pallet handling, reducing operational errors.

“Since we implemented a pallet dispenser and stacker combo, our warehouse throughput has improved by nearly 30%. It’s reduced both idle time and workplace injuries.” — Carlos M., Logistics Manager, Northern Freight Solutions

Pallet Dispenser vs. Pallet Stacker: Understanding the Difference

While both are used in handling pallets, their functions differ:

Integrating both systems creates a closed-loop pallet management solution, minimizing idle time and maximizing operational flow.

Use Cases Across Industries

Pallet dispensers are not industry-specific. They are used in:

Food & Beverage: For maintaining hygiene and preventing contamination through minimal contact.

Pharmaceuticals: Ensuring consistent pallet availability during automated packaging.

Retail Distribution: Speeding up order fulfillment operations.

Automotive: Managing heavy-duty pallets for parts and components.

How to Choose the Right Pallet Dispenser

Selecting the ideal pallet dispenser depends on several operational factors:

Pallet Type and Size: Compatibility with standard or custom pallet dimensions.

Capacity: Number of pallets handled per cycle or per hour.

Integration Requirements: Whether it needs to work alongside conveyors, robots, or pallet stackers.

Space Constraints: Floor-mounted vs. overhead models depending on available warehouse space.

“Choosing a dispenser that integrates easily with our conveyor line made a significant difference. It wasn’t just about the machine—it was about how well it fit into our existing layout.” — Stephanie T., Plant Supervisor, Midstate Manufacturing Co.

Maintenance and Lifecycle Cost

Though typically low-maintenance, routine checks on mechanical parts, sensors, and hydraulic components are essential for longevity. Many dispensers offer diagnostics features to alert users of wear and tear, further reducing downtime.

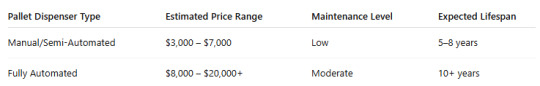

Here’s a general overview of cost expectations: Pallet Dispenser

Final Thoughts

For operations seeking to reduce manual labor, enhance safety, and improve throughput, a pallet dispenser paired with a pallet stacker offers a robust, scalable solution. With proven applications across diverse industries, it's clear that these machines are more than just convenience—they're a strategic investment in productivity.

0 notes

Text

Boost Efficiency with Dorner Dual Belt Pallet Conveyors

In today's fast-paced industrial world, efficiency and reliability are crucial for any production line. Dorner Dual Belt Pallet Conveyors are designed to optimize material handling, ensuring smooth and efficient transportation of products across various manufacturing processes.

Why Choose Dorner Dual Belt Pallet Conveyors?

Dorner's dual belt pallet conveyors stand out due to their versatility and precision engineering. These conveyors are ideal for automated assembly lines, inspection systems, and robotic integration, offering a seamless workflow.

Key features include:

Flexible Design: Adjustable configurations to fit diverse production needs.

Precision Movement: Ensures accurate positioning of pallets for assembly or inspection tasks.

Durable Construction: Built to handle heavy-duty applications while maintaining long-lasting performance.

Ease of Integration: Compatible with automated systems, reducing downtime during installation.

Whether you’re looking to improve productivity, reduce errors, or streamline processes, Dorner’s conveyors are a reliable solution for a wide range of industries.

Learn More About Dorner Dual Belt Pallet Conveyors

Investing in the right conveyor system can transform your production line. With Dorner Dual Belt Pallet Conveyors, you’re choosing a system that delivers precision, durability, and unmatched efficiency.

Ready to take your operations to the next level? Visit HMCross to explore the full range of Dorner conveyors and find the perfect solution for your business needs.

0 notes

Text

Why Accurate Bidder Information is Crucial for Winning Government Contracts on GeM Portal?

Accurate bidder information on the GeM portal is essential for building trust, ensuring smooth transactions, and increasing the chances of winning government contracts. By providing complete and verified details, both buyers and sellers can foster transparency, reliability, and efficient procurement processes.

When the government buys things, we need complete and correct information about bids to make sure the deals go smoothly and build trust. You can handle government bids well with the Government e-Marketplace (GeM) site. An excellent way to discover how educated, experienced, and reliable possible buyers really are is to look into the bidders. Both the buyer and the seller need to know a lot about the person who bids on the gem portal site. It’s important to give unique buyer information on the GeM site, and this blog will explain why it’s important.

What does it mean to know about those who bid?

When a business or group bids on a government job, they give information that is known as bidding information. The bidder’s qualifications, experience, skills, licenses, and how to get in touch with them are usually included in this information. People look at this written list of the bidder’s skills and abilities to see if they are ready for a job.

Important parts of the buyer information

Sometimes, the following parts of full buying information can be found on the GeM site:

A summary of the business

The company bio tells about the bidder’s past. The business name, the year it started, its address, and a short summary of the goods or services it provides are all on this. It shows that the seller is trustworthy and helps you understand their experience if they give you a full account of the business.

Contact Information

There should be correct contact information for the main person to reach, such as their name, phone number, email address, and office address. It’s easy for the buyer and seller to talk to each other during the buying process if the contact information is right and up to date.

Experience and Past Performance

A lot of the time, how much the buyer knows is a very important part of government bids. Sometimes, this part has a list of past projects that were finished, along with information about the clients and the projects’ value, length, and due date. People who want to buy something can see related projects to see if the seller has worked on projects like this before.

Getting licenses and following the rules

When people want to bid on government jobs, they often have to follow strict rules. You need to add certifications like ISO, GST registration, and other qualifications that are specific to the bid in the Gem Bidding Process. This lets the customer know that the seller is following all the rules and laws that govern the deal.

Details about the flow of cash

It’s very important for the government to bid that the money is safe. As proof that the buyer has the cash to do the job, you can show them accepted financial records and the amount of money the business makes each year. Having enough money is very important for big projects, so this is very important.

Product or Service Offerings

An important part of the buying guide is a list of all the goods or services that are being bid on. This should include what is needed, how good it should be, and any extra services that will make the deal more useful. Being clear about these things helps the seller make sure the buyer knows what they’re selling and how it meets the requirements of the tender.

Importance of Accurate Bidder Information

Being clear about what you’re selling is important for a number of reasons:

Makes people accountable and trustworthy

You can better understand the buying process if you know about the buyers. Buyers will trust bidders more if they give them full and correct information. This makes it more likely that they will be thought about for the purchase. When the government spends money on things, people need to trust them and be responsible.

It makes reviews more useful

When the customer knows a lot about the buyers, it’s easy for them to compare how skilled each one is. If all the information the buyer needs is given in a clear and straight way, they can pick the best bidder for the job. This also makes sure that the decision is fair and neutral.

It makes it more likely that you’ll get the deal.

People have a better chance of getting the job if they talk more about their skills, experience, and education. Give them an edge over other bidders by telling them everything they need to know about you. The fact that they are ready, motivated, and dependable is clear.

Tips for Providing Effective Bidder Information

Here are some good ways to list things for GeM site buyers:

Be honest and open. Check that everything you say is correct and up to date. You might lose your job or get a fine if you lie.

You need to make sure the details match the bid: Pay close attention to the projects and skills that are most important for the present jobs. People who want to buy from you want to know that you understand them.

It’s best to use clear, simple words. Don’t use too many words or hard to understand language. Everything should be clear and the important parts should be easy to find.

Add Supporting Documents: To back up what you say, include important documents like bank records, licenses, and client references. This makes the information more important and makes people want to learn more about it.

Declaration of Acceptance of Bid Terms and Conditions (ATC) for Bid

Date: [Insert Date]

To,

The Procurement Officer, [Name of the Procuring Organization], [Address of the Procuring Organization], [City, State, PIN Code].

Subject: Bidder Information for Bid Number

Dear Sir/Madam,

We, [Your Company Name], located at [Your Company Address], are providing the following information as part of our bid submission for Bid Number.

Bidder Information

Please find below the detailed information about our company and bid submission:

Field

Details

Company Name

[Your Company Name]

Address

[Your Company Address]

Contact Person

[Name of Contact Person]

Designation

[Contact Person’s Designation]

Phone Number

[Contact Number]

Email Address

[Contact Email Address]

Business Type

[Type of Business: Manufacturer/Dealer/Reseller]

Registration Number

[Company Registration Number]

GST Number

[GST Number]

PAN Number

[PAN Number]

Bank Details

[Bank Name, Branch, Account Number, IFSC Code]

Authorized Signatory

[Name of Authorized Signatory]

Declaration

We declare that:

Accuracy of Information: The information provided above is accurate and complete to the best of our knowledge.

Compliance: We are committed to complying with all terms and conditions specified in the tender document and any additional requirements outlined by the procuring organization.

Contact Availability: Our designated contact person is available to provide any additional information or clarification required during the evaluation process.

Thank you for considering our bid. We look forward to a favorable response and the opportunity to work with your esteemed organization.

Yours faithfully,

[Signature] [Name of the Authorized Signatory] [Designation] [Your Company Name] [Contact Number] [Email Address]

Conclusion

Information for Bid Number on the Gem Bidding Process site is very important if you want to buy something. Before making a choice, it tells government buyers everything they need to know about the bidder’s skills, experience, and work history. Include important information about your business in your bid, like a description of the company, contact information, work experience, skills, and recommendations from past clients. This will show that you are a trusted partner.

#oil and gas tenders india#cpwd tender#dibt mysore#gujarat tenders#e tender cpwd#etender cpwd#ministry of tourism tenders#advance correction slip gcc 2022#municipal corporation chandigarh tenders#e tender delhi cpwd#tender services#metal pallets in nowgong#belt conveyor system in nowgong#bid assistance#tourism department tenders#Gem bidding process

1 note

·

View note

Text

Enhancing Workplace Safety with Material Handling Equipment

Material handling equipment refers to tools and machinery designed to efficiently move, store, and manage materials and products within various industrial settings. This equipment includes items such as forklifts, conveyor belts, pallet jacks, and cranes, which streamline the movement of goods, reduce manual labor, and enhance productivity. By automating and optimizing processes, material handling equipment helps minimize operational costs and improve safety. These systems are crucial in warehouses, manufacturing plants, and distribution centers, ensuring smooth and effective material flow from one stage to the next. Properly chosen and maintained equipment can significantly impact overall operational efficiency and performance. Discover a wide range of top-quality material handling equipment at https://www.headsupb2b.com/material-handling-equipment . Find the perfect solutions for your business needs today!

#Conveyor Belts#Forklifts#Pallet Jacks#Handling Systems#Manufacturing Equipment#Industrial Machinery#Warehouse Equipment

1 note

·

View note

Text

Pallet chain conveyor Manufacturer in Pune | India

Maximize your facility's vertical space with our cutting-edge pallet chain conveyor manufacturer in India which enhances output and minimizes cost with Rothe Packtech. Pallet chains are space-saving, quiet, durable, and provide high performance.

#Pallet Chain Conveyor Pune#Material Handling Systems Pune#Conveyor Systems Pune#Industrial Conveyors Pune#Chain Conveyors Pune#Knife Roller Conveyor Pune#Gravity Spiral Conveyor Pune#Vertical Transport Solutions Pune#Industrial">

0 notes

Text

conveyors

#trying to remember if i ever got on a moving conveyor or if its just something i really wanted to do and everyone said i couldnt#it wouldve been fine i think. pallet conveyors can handle more weight than i am. just put me on a psb and ill get off before the cranes#ive stood (crouched) on a stopped conveyor at least. im looking at the selfie right now. it was a roller conveyor its fine#well whatever it wouldnt be that fun anyway. conveyors dont go that fast <- cope from someone who still wants to ride a conveyor

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

The Evolution of Pallet Dispensers: Enhancing Efficiency in Warehousing

Understanding the Role of a Pallet Dispenser

In modern warehousing and logistics, efficiency is key. A pallet dispenser is an automated or semi-automated system designed to streamline pallet handling, reducing manual labor and improving workflow. These machines automatically dispense pallets one at a time, eliminating the need for manual stacking and unstacking, which can be time-consuming and hazardous.

For businesses operating in high-volume industries, integrating a pallet dispenser into their supply chain ensures seamless operations while reducing workplace injuries associated with manual pallet handling.

How a Pallet Dispenser Works

A pallet dispenser functions by holding a stack of pallets and releasing them one at a time as needed. These systems are often integrated with conveyor system manufacturers who design complete automated solutions for warehouses and production lines.

Typically, the process works as follows:

A stack of pallets is loaded into the dispenser.

The dispenser lifts the entire stack while allowing one pallet to slide out from the bottom.

The released pallet is then used for loading products, either manually or through an automated system.

The remaining stack lowers, preparing for the next dispensing cycle.

This automation reduces downtime and ensures a steady supply of pallets, improving productivity in distribution centers and manufacturing facilities.

Key Benefits of Using a Pallet Dispenser

1. Improved Workplace Safety

Handling pallets manually can lead to injuries such as back strain, pinched fingers, and other musculoskeletal disorders. Automating pallet dispensing reduces these risks and ensures compliance with workplace safety standards.

2. Increased Efficiency

A pallet dispenser significantly reduces time spent retrieving and organizing pallets. Workers can focus on more value-added tasks, leading to increased output and efficiency in operations.

3. Space Optimization

Warehouses with limited space can benefit from a pallet dispenser as it helps in keeping pallets neatly stacked and accessible, reducing clutter and optimizing storage areas.

4. Cost Savings

By minimizing manual labor and potential injuries, businesses can save on operational costs, including worker compensation and downtime. A well-integrated system from a trusted conveyor system manufacturer ensures that automation leads to long-term cost savings.

Industries Benefiting from Pallet Dispensers

E-commerce and Retail

With the rise of online shopping, warehouses need efficient ways to move goods. Pallet dispensers help in quickly deploying pallets for packing and shipping operations, keeping up with high-demand fulfillment requirements.

Manufacturing

Manufacturing plants rely on a consistent supply of pallets for transporting raw materials and finished goods. A pallet dispenser ensures a steady workflow without bottlenecks in production lines.

Food and Beverage Industry

Hygiene and efficiency are crucial in food handling. Automated pallet dispensers reduce human contact with pallets, minimizing contamination risks while keeping the supply chain smooth.

Pharmaceutical Sector

Pharmaceutical warehouses require precision and automation for handling goods. Pallet dispensers ensure that pallets are readily available for moving medical supplies without manual intervention.

Integrating a Pallet Dispenser with a Conveyor System

To maximize automation, many businesses integrate pallet dispensers with conveyor systems. A conveyor system manufacturer can design a setup that seamlessly moves pallets from dispensers to different workstations, ensuring a continuous flow in operations.

Some common integrations include:

Automated Guided Vehicles (AGVs): These transport pallets to specific locations within a facility.

Roller and Belt Conveyors: These systems work alongside pallet dispensers to move pallets efficiently across warehouse zones.

Robotic Arms: In some setups, robotic arms pick pallets from dispensers and place them onto conveyors for further processing.

Testimonials: Real-World Success Stories

“Game-Changer for Our Warehouse” – Mark T., Warehouse Operations Manager

“Implementing a pallet dispenser in our facility has dramatically reduced our reliance on manual labor. Productivity has increased, and we’ve seen a significant drop in workplace injuries related to pallet handling.”

“Seamless Integration with Our Conveyor System” – Sarah L., Logistics Director

“Our conveyor system manufacturer recommended a pallet dispenser to improve efficiency, and it has exceeded our expectations. Now, we have a continuous flow of pallets without interruptions, making our warehouse operations smoother.”

Choosing the Right Pallet Dispenser

When selecting a pallet dispenser, consider the following factors:

Capacity: Determine how many pallets the dispenser needs to hold at a time.

Type of Pallets: Ensure compatibility with different pallet sizes and materials (wood, plastic, metal).

Automation Level: Decide whether a fully automated or semi-automated system suits your operation.

Integration Needs: Check if the dispenser can work with existing conveyor systems and other warehouse automation tools.

Durability and Maintenance: Opt for a robust system with low maintenance requirements to ensure long-term reliability.

Conclusion

A pallet dispenser is a critical component in modern warehousing and manufacturing, providing efficiency, safety, and cost savings. When integrated with conveyor systems, these dispensers contribute to a seamless supply chain, reducing bottlenecks and enhancing productivity.

0 notes

Text

Revolutionize your business operations by harnessing the power of warehouse conveyors. Streamline material handling, reduce labor costs, and eliminate bottlenecks in your workflow. From simple to advanced automation solutions, our conveyors optimize processes, enhance productivity, and maximize space utilization.

0 notes

Text

Japanese Male Airport Luggage Loader

In Japan on IG a passenger is filming a male airport luggage loader through a window, he is treating the luggage so gently. This man is laying each suitcase down on the conveyor belt that takes the baggage into the plane like an adult: slow, responsible, with perception, with agency, intentional, calmly, focused. He is a man not a boy because he is not exhausted, he is not rushing or stressed. The luggage doesn’t take on the energy of Picasso’s weeping woman.

The curse is not being passed on (The Iliad, or The Poem of Force Simone Weil). We can make choices that create the conditions for this state to exist (a Sovereign State). I work in a box factory in Melbourne. I am weak and exhausted from metabolic syndromes, at 10am I say “time for mothers matcha” and spend $8 on a matcha. Often I buy two and slam them like an alcoholic, if people weren't watching I would buy two everytime. Ander watches and says “woah”. When Liam was alive once after school we drank together, he said “wow” after I skulled my glass bottle VB.

“It requires to be generally recognized, and above all by leaders themselves, that consent and not fear of punishment or hope of reward constitutes, in fact, the mainspring of obedience, so that submission may never be mistaken for servility.” Everything I do is in hope of reward or fear of punishment—over cleaning the house, working three days a week instead of two because I desperately want to protect my casual position to afford entrance to the bourgeois world of shoppers. I’ve never known a better job, and it rapes me of my life force. Fluorescent lighting manual labour and I’m a girl.

Karen Hurd’s no list (no sugar, caffeine, flour, dairy, exercise, cold drinks, preservatives, alcohol, soy, cinnamon, fruit, supplements, herbal tea, coconut oil, fatty meats, fragrances, cured meats, less than 9 hours sleep a night) protects the worker from the work and transforms the workers physiology into a site capable of choice, consent (responsive not reactive). The worker begins to be able to tolerate the work. The work stops registering on the worker (the worker and the works footprint is reduced). The cell that is a sponge stops being covered in wax (Traditional Chinese Medicine grease on the doorknob analogy).

After three cell mitosis (~9 months) I can place the JB Hi-Fi boxes on the scale precisely and with control. I lift the boxes and put them down on the pallet without a biological (and therefore emotional-spiritual) tax. I don’t pass on the Force. I pass on the Power (David R. Hawkins) I am an example of possibility, of expansion. It’s important to be the example. I didn’t write on this blog because negative marketing (death art) is the world standard and I wanted to point out pro-life positivity, change and transformation (Krishna), and Inspire, instead of highlighting what I reject. I was stuck under the line of courage on David R’s “Map of Consciousness” so I didn’t have the Vision to forge my attention towards what's beautiful.

Millennials have smoothed our environment with homeless graphic design and when I mention it I amplify it. Where your attention goes, grows. Working against millennial-nation homeless graphic design requires turning towards what’s beautiful, turning your back on the problem. Painting with your back against the world (Agnes) applied to diet and routine behaviour. “It should also be realized that those who command, obey in their turn, and the whole hierarchy should have its face set in the direction of a goal whose importance and even grandeur can be felt by all, from the highest to the lowest.” Luis Mojica, Peter Levine's somatic experiencing (SE) and Karen R. Hurd’s “bean protocol” assist the goal of such grandeur we should all be faced towards, which is the goal of liberation and agency. Real Consent. Difference, novelty like Terrence McKenna talks of. Prison abolition.

When our physiology has space we can become Of Service like the Japanese plane luggage worker. There is separation between the job and the person. In the Separation between an action and its consequence lies Agency. I don’t have children or a boyfriend if I follow the protocol I tend to the land to create the conditions that would allow for that infrastructure to take if the building blocks (seed) present themselves, right now the land is arid and hostile. If sperm doesn’t come at least I ploughed the land so it could have happened if He did. Being adult means participating in preparation, with and through grief. I chose to drive to Ballarat to see a tree instead of going to Ikea to buy two pillows for my bed to replace the old ones from six years ago.

I chose to go see Rex’s show at Strawberry instead of getting a gym membership to Ascot Vale Leisure Center. The Will to allow contact with disappointment creates the conditions to accept reality which allows the past and the future to transform into the present—I assume this is the process of grief (wouldn’t know). I wanted to buy Glamorama from Rainbow’s mobile library in Footscray I also didn’t want one more symbolic stand-in for what I actually want that isn’t here. You don’t consent to what you’re compulsed to do.

The pastor from Seventh Heaven being a pedophile activates my sex drive for the first time in two years. “An employer who is incapable or guilty of an offence against his workmen ought to be made to suffer far more, both in the spirit and in the flesh, than a workman who is incapable or guilty of an offence against his employer. Furthermore, all workmen ought to know that this is so.” We recreate our formative traumas. We are looking for a corrective experience. It’s not your fault but it is your responsibility. Looking good in clothes is about your body not about the clothes (clown meme level one). Looking good in your body is about your self-relationship—self-acceptance and acknowledgement of reality—not about your actual body (clown meme level two). I don’t join Essendon Canoe Club. I do nothing. I ask God to relieve me of my eating disorder and I carry on with the day.

I’m laughing because on Twitter someone said “be there now.” Terrence McKenna said no one escapes, I know that some people enter. Duncan Trussell and Dr. Bruce Damer say the fruiting body of caffeine was skyscrapers and trains but coffee is a taxman and everything has a price—now I’m on chemotherapy and don’t even have cancer (just a spiritual disease with no known cure). Ones quality of life is improved when insulin levels function within nontraumatic scales and then one’s sex drive is returned.

We don’t need to use people-places-things to “secure” our “safety” and we move from a life of nonconsensual self-reliant reactive pattern behaviour to a creative responsive autonomous interdependent God-reliant life. You can love more, you can feel more love, you can give more love when you aren’t dependent on Perception to survive. I’m trying to become an Aboriginal capable of Service (before Socialised Patterning, before the wax all over the sponge).

#agency agency#rex veal#karen r hurd#luis mojica#somatic experiencing#peter levine#david r hawkins#the bean protocol#bean protocol#aboriginal#Himalayan cypress

12 notes

·

View notes

Note

question for alif: what caused you to found R.E.D and BOT CORPORATION?

This rant brought to you by the first-person perspective

It started with a thought. No, a knowing. An unshakable, thunderous, nuclear truth that detonated in my skull when I was 21—when the crust of this sad little planet finally cracked under the weight of my genius. I remember the moment vividly: I was halfway through my seventh protein bar of the morning (don’t ask why, you wouldn’t get it), staring into the flickering blue light of a broken vending machine, and it hit me. Not a vision. Not an idea. A revelation. The world was… incomplete. And only I could finish it.

So I built BOTCORP. Or rather—it built itself, out of the sheer gravitational pull of my ambition, coalescing like a galaxy around the singularity that is me. You think corporations are founded on market research? Capital? NO. BOTCORP erupted into existence because the cosmic code needed it to. It’s not a company. It’s an ontological inevitability. Like death. Or taxes. Or the heat death of the universe, if it wore a tailored suit and harvested biometric data faster than the speed of light.

People think it started with software and a warehouse. Wrong. It started with a mirror. A mirror I stared into for nine consecutive days, each second peeling back layers of human mediocrity until all that was left staring back was a divine blueprint—a screaming, incandescent idea-being screaming, “YOU ARE THE GOD OF INFRASTRUCTURE.”

So yeah. BOTCORP. Multi-quintillion dollar valuation? Cute. It’s not about the money. The money is just the byproduct, like radioactive ash from the reactor core of my soul. I don’t want to own the economy. I want to replace it. I want your entire life to run on systems I designed in a caffeine fugue at 3am during a manic episode that I later retroactively rebranded as a “vision sprint.”

And then there’s R.E.D. Registered Equipment Distributors. People ask, “Why not just call it BOTCORP Logistics or BOTCORP Shipping?” Because R.E.D. isn’t logistics. R.E.D. is RED. It’s blood. It’s the primal pulse of movement, of power, of the very concept of transfer incarnate. It’s not a child company—it’s my right arm, surgically removed, mechanically enhanced, and reattached with an energy gun and an energy relay theater will outlive GOD. It doesn’t distribute equipment. It births it into the world, fully formed, tagged, tracked, and blessed in the name of ME.

You think you bought a pallet jack? NO. That was a fragment of my subconscious, lovingly injected into your warehouse to watch you—to listen, to learn, to report back to me via a proprietary telemetry language based entirely on my old dreams and the sound of whales dying in sonar feedback loops.

BOTCORP doesn’t make products. BOTCORP makes reality compatible with my existence. It rewires cause and effect. It redefines supply and demand as submit or perish. Every market trend you see? I made that. Every stock surge? My twitching eyelid. Every “innovation” from a competitor? Me, two years ago, discarded in disgust because I found a way to do it using hydrophobic quantum thread and half a toothpick.

My employees? They’re not employees. They’re neurons. My management team? They’re echoes. My HR department? Psychological warfare technicians, each trained in 17 forms of passive aggression and one ancient Babylonian curse. The break room contains a shrine. Not by my order. They just… started building it. I’ve never asked them why. I already know.

Sometimes I forget where I end and BOTCORP begins. I try to walk down the street, and the stoplights blink in binary. Street names rearrange into acronyms. Children point and say “mommy, the god-king of machines is here.” I cough, and somewhere, an office tower in Dubai gets a firmware update.

And R.E.D.—ah, R.E.D.—its warehouses are alive. Not metaphorically. I mean they breathe. There are vents that inhale dust and exhale profit. Conveyor belts that scream lullabies to the pallets. Forklifts that argue with each other in machine tongues only I can translate. I once found a shipment of mining drills singing “Ave Maria.” We don’t question it anymore. We just ship faster.

Why did I do all this? Why did I create BOTCORP? Because the world was a sandbox and I was tired of pretending to be one of the children. Because every other business was a joke told in bad faith by small men in smaller suits. Because I saw the void and I said, “This would make a great distribution hub.”

I am not your competitor. I am not your peer. I am the whisper in your quarterly reports. I am the red dot on your supply graph. I am the sleep paralysis demon of capitalism, and my name is branded on the walls of time.

You want to stop me? Good luck. I already knew you would try. I factored your resistance into our Q3 forecasts. I’m not just five steps ahead. I’m already at your funeral, selling commemorative mugs and action figures of the children you never had.

So, why did I found BOTCORP?

Because I could.

Because no one told me not to.

Because this world didn’t have a god, and I was bored.

2 notes

·

View notes

Text

airsLLide No. 9252: LZ-BEI, Ilyushin 18V, Balkan Bulgarian Airlines, Zürich, July 1, 1993.

"Preighters", i.e. the temporary use of regular passenger aircraft as make-shift freighters, is not an invention of the Covid-19 hardships in aviation. Already in 1993, we do see such an example of a fully configured passenger plane loading freight here.

Namely, LZ-BEI is on one of the typical post-iron-curtain cigarette flights. With demand for Western smokeables high in former East Bloc states, several airlines from former Comecon-countries could regularly be seen shuttling a cabin full of the relatively light, but spacious boxes with globally known brand names of tobacco companies on cargo charters from Western manufacturing hotspots to their home countries.

In the case of Bulgaria, that would normally have translated into one of Balkan Bulgarian's then three Antonov 12 freighters doing one of their regular runs to Zürich. However, on that specific occasion, none of them seems to have been available, so to everybodies surprise, the periodic cigarette flight was assigned to one of the Ilyushin 18s from the passenger division of the carrier. Loading the boxes took some time, given the need to hand-load single boxes via the conveyor at the main cabin door, as opposed to shoving loaded pallets into the rear cargo ramp of an Antonov 12. At least I do remember that when I had to head home for a family event - a birthday dinner - loading of the Ilyushin was to my regret still in progress and obviously far from being complete.

3 notes

·

View notes

Text

365 Promises of God

Day 306 – We Are Presented Holy, Blameless, Above Reproach

in the body of His flesh through death, to present you holy, and blameless, and above reproach in His sight-- (Col 1:22 NKJV)

Read: Colossians 1:21-23

Many years ago, I worked for a company that made air conditioner registers, the very common variety that exist in almost every home with central heat and air. The plant that made these registers was located in Mexico, and I was sent there to train them how to use our computer system to properly plan to forecast. When I got there, I was given a tour of their seven million dollar production line. It was a simply amazing and complicated process of stamping and spot-welding metal parts, and a paint line that painted the finished products. They were sparkly when they were carefully set on a conveyor system after being professionally painted and dried. Beautiful parts moving back to back along a conveyor.

We followed the conveyor for what was about 50 yards, to a packaging station where 7 workers were packaging the parts. Each register was put in a fancy individual box buy guy #1, which was quickly folded and taped by guy#2, and guy #3 would take the completed individual boxes, and put six of them in a carton. Guy #4 would tape the cartons up and stack them on a pallet. Guy #5 would drive off with a full pallet, once complete, and guy #6 would place a fresh pallet in that place. Guy #7 was frantically forming cartons and individual boxes, and was always behind.

Since Guy #7 couldn’t keep up with demand, shiny registers passed everyone by, one by one, and fell on the concrete floor, getting marked and dented as a pile of finished not-so-new registers built up on the floor. I pointed at the guy waiting to put a pallet on the floor. “You should help that guy make boxes! He can’t keep up!”

His response was, “No, I’m the guy who places the pallet.”

I looked at guy #5. “You’re not doing anything while waiting for that pallet to fill up. You need to help that guy make boxes!”

He said, “No, I’m the guy that takes the pallets away.”

I spied a shiny red button by the end of the conveyor. I pointed to it and asked guy #7, “Why don’t you press that button and stop the production line until you can catch up?”

Everyone there started shaking their heads frantically, “NO NO NO NO! Only the plant manager can stop the production line!”

I then asked guys 5 and 6 to help guy 7, again, pointing at the stack of damaged registers. They repeated to me what their jobs were. I just shook my head as we walked away from that travesty in manufacturing.

I asked one of the supervisors why they were destroying expensive and perfectly good parts and why the workers couldn’t shift to fill the bottlenecks in the process. He said everyone had a specific job to do, and that they would get blamed if that job didn’t get done. Helping somebody else would expose them to getting blamed if that job wasn’t done right, and they were not required to do it anyway.

I mentioned that no matter how good a job they all did at their own pieces, they were all at fault if we shipped boxes of bent registers to our customers. He shrugged and said that the blame for that would go to the plant manager, who was the only one allowed to shut down a production line for any reason.

Less than a year later, the plant manager took the fall for this and many other manufacturing issues they discovered. He really did get the blame for them, and in a lot of respects, he deserved it. Compare this to the company I now work for, where workers freely move from position to position on a production line, helping each of them complete a production run. If anything is wrong with the parts at any stage, they can and do shut the production line down, because they all know that it’s better to fix an issue that caused 10 bad parts than to continue letting it run, producing a thousand bad parts.

You can bet that if we produce an entire run of mislabeled product, somebody is going to catch the blame for it, possibly losing their job. Blame is a painful thing to be on the receiving end of. I’ve gotten blamed for many things I didn’t do, and many other things I did. If you stacked those things I earned blame for, if each were an inch that blame train would be a thousand miles long. It might be the same for you too.

Isn’t it comforting to have a promise like this in the Bible, that we are going to be presented by Christ to God as holy, and blameless, and above reproach? All those things we did? The mistakes we made, the errors in judgement, even the willful sins we’re sorry about now, the ones we regret and hope nobody finds out about? Those have all been nailed to the cross, dear Christian, and you will NEVER have to get shouted at about them again.

Prayer:

Lord, thank you for this beautiful promise, that I won’t have to get blamed for what I’ve done, when I get to heaven. I can hardly wait. Help me, Lord, to keep short accounts with you, today. Amen

3 notes

·

View notes