#Pharma Packaging Machine

Explore tagged Tumblr posts

Text

Reliable Semi-Auto Crimping Machine | NPM Machinery

Looking for a high-performance Crimping Machine? NPM Machinery offers a reliable Semi-Auto Crimper for precise cap sealing. Ideal for pharma & cosmetics.

Explore now at NPM Machinery.

#Crimping Machine#Semi Auto Crimper#Cap Sealing Machine#Pharma Packaging Machine#Cosmetic Packaging Equipment#NPM Machinery#Bottle Capping Machine#Packaging Automation#Industrial Crimping Equipment#Semi Automatic Capping Machine#Pharmaceutical Machinery#Cosmetic Machinery#Sealing Solutions#Crimping Solutions#Reliable Crimping Machine

0 notes

Text

Automatic Capsule Packaging Machine

In the heart of Bangladesh’s pharmaceutical industry, a revolution is quietly unfolding, and it begins with the humble capsule. With rising demand for high-volume capsule production and precision drug delivery, the choice between manual and automatic capsule packing is more than operational—it’s strategic.

#capsule packaging machine#packaging machine bangladesh#pharmaceutical packaging machine#pharmaceutical packaging machine manufacture#bangladesh pharmaceutical packaging machine#nichrome packagine machine bangladesh#pharma packaging

0 notes

Text

The Power of Stick Pack Machines for Modern Packaging

In today's fast-paced world, convenience and portability are king. From single-serve coffee and powdered supplements to liquid medications and granular snacks, consumers increasingly demand products that fit seamlessly into their on-the-go lifestyles. This demand has fueled the rise of innovative packaging solutions, and at the forefront of this revolution stands the stick pack machine.

But what exactly is a stick pack machine, and why is it becoming an indispensable asset for businesses across various industries? Simply put, a stick pack machine is a sophisticated piece of automated packaging equipment designed to fill and seal products into slender, single-serving pouches, commonly known as stick packs or sachets. These sleek, elongated packages offer a multitude of advantages over traditional packaging formats.

One of the primary benefits of utilizing a stick pack machine is the enhanced convenience it offers to end-users. Their slim and lightweight design makes stick packs incredibly portable, easily fitting into pockets, bags, and travel kits. This makes them ideal for single-dose applications where on-the-go consumption is prevalent. Imagine the ease of tearing open a stick pack of energy powder before a workout or adding a single-serving sweetener to your coffee without the need for bulky containers.

Beyond consumer convenience, stick pack machines offer significant advantages for manufacturers as well. The automated nature of these machines translates to increased efficiency and productivity. Compared to manual filling and sealing processes, stick pack machines can handle high volumes of product with remarkable speed and accuracy, reducing labor costs and minimizing errors. This streamlined operation allows businesses to meet growing demand and optimize their production workflows.

Furthermore, stick pack packaging offers excellent product protection. The sealed pouches safeguard the contents from moisture, oxygen, light, and other environmental factors that can compromise quality and shelf life. This is particularly crucial for sensitive products like pharmaceuticals, nutraceuticals, and certain food items. The precise sealing also minimizes the risk of leakage, ensuring a clean and mess-free experience for the consumer.

Another compelling reason to invest in a stick pack machine is the marketing and branding opportunities it presents. The elongated shape of the stick pack offers a unique canvas for eye-catching graphics, branding elements, and product information. This distinct packaging format can help products stand out on crowded shelves and create a memorable impression on consumers. Moreover, the single-serving format can encourage trial and repeat purchases.

The versatility of stick pack machines is also noteworthy. These machines can handle a wide range of product types, including powders, granules, liquids, and even pastes. They can be customized with various filling systems and sealing mechanisms to accommodate specific product characteristics and packaging requirements. This adaptability makes them a valuable investment for businesses with diverse product portfolios.

In conclusion, the stick pack machine is more than just a packaging solution; it's a strategic tool that empowers businesses to meet the evolving demands of modern consumers. By offering unparalleled convenience, boosting production efficiency, ensuring product integrity, and enhancing branding opportunities, stick pack machines are driving innovation and shaping the future of single-serve packaging across numerous industries. As the demand for portable and convenient products continues to grow, the power and potential of the stick pack machine will only become more pronounced.

0 notes

Text

Leading Packaging Machine Manufacturer

Nichrome is India's Leading Automated Packaging Machines Manufacturers, offering a wide range of Packaging Machines, Packaging Systems, Filling Machines for Solid, Liquid and Viscous products for Food, Pharma & Other Industries

#packaging machine manufacturers#integrated packaging solutions#automatic packaging machine#innovative packaging solutions#nichrome#automatic packaging machines#grains & seeds packaging machines#pharma packaging solutions

0 notes

Text

The Rise of Digital Health: France's Journey to Healthcare Innovation

More to the future of digital health in France , there is much hope. For the future with progressing and developing technologies France remains in strategic conditions to become one of leaders among digital health industries with great government backing, innovative effects and experienced staff.

#drug wholesale distributors#top 20 clinical research companies in India#pharma regulatory#pharmaceutical packaging machine#effervescent tablet manufacturers in India#pharmaceutical company website

1 note

·

View note

Text

blister packing machine -A valuable input on working

Working principle of automatic blister packing machine

Automatic blister packing machines are of 2 types

Cold-forming blister packing machine

Hot-forming blister packing machine

A blister packaging machine creates a cavity known as a blister. The blister resembles the shape of the product to be packed. The blister is produced in plastic or aluminum foil which is in roll form. The operations include ....... Read More

#pharmaindustry#pharma franchise company#pharma tablets manufacturers#pharmaceutical#packing machine#medicines#pcdpharmafranchise#pcd pharma franchise#blister packaging market

0 notes

Text

Discover the remarkable capabilities of the King Dispenser Rx! Witness how this semi-automatic tablet counting machine expertly counts a variety of essential products used in pharmaceutical, medical, and laboratory environments.

From Steri-Dropper Tips to Dropper Caps, Drop Plugs, and other similar items like dropper tip caps, caps for dropper bottle tips, and sterile dropper caps – the King Dispenser Rx handles them all with unmatched precision.

This machine is integral for ensuring accurate counting of products in pharmaceutical, medical, and laboratory settings. Its versatility and efficiency make it a vital asset for any operation prioritising precision and hygiene in product handling.

For more information don't hesitate to contact us at [email protected].

0 notes

Text

The Power of Automatic Packing Machines

In today's fast-paced world of manufacturing and logistics, efficiency and productivity are key factors in maintaining a competitive edge. One critical aspect of the production process that has undergone a remarkable transformation is packaging. Gone are the days of labor-intensive and time-consuming manual packing; the rise of automatic packing machines has revolutionized the industry. In this blog post, we will explore the capabilities and advantages of automatic packing machines, showcasing how they are revolutionizing the packaging landscape.

Streamlined Operations for Maximum Efficiency:

Automatic packing machines are a game-changer when it comes to optimizing operational efficiency. These machines are designed to perform packing tasks with lightning speed and unparalleled precision. With their advanced robotics and intelligent algorithms, they can handle a vast pharma packaging range of products and packaging materials, ensuring a seamless and consistent packing process. By automating this previously manual and error-prone task, businesses can significantly reduce production time and boost output without compromising quality.

Accurate and Consistent Packaging:

Manual packing processes are inherently prone to human errors, which can result in inconsistent packaging and customer dissatisfaction. Automatic packing machines eliminate such concerns by providing a level of accuracy and consistency that is unmatched. These machines are equipped with advanced sensors and computerized controls that ensure precise measurements, alignment of products, and application of packaging materials. As a result, each packaged item is uniform, presenting a professional and cohesive brand image while enhancing customer satisfaction.

Cost-Effectiveness and Resource Optimization:

Although the initial investment in automatic packing machines may seem substantial, the long-term cost savings and resource optimization they offer are undeniable. By automating the packaging process, businesses can reduce their reliance on manual labor, thereby minimizing labor costs, training expenses, and the risk of human error. Moreover, these machines are designed to minimize material waste by precisely utilizing packaging materials, which reduces costs and contributes to a sustainable approach to packaging.

Flexibility to Accommodate Diverse Needs:

The versatility of automatic packing machines is a key advantage for businesses operating in diverse industries. These machines can be easily programmed to handle various product sizes, shapes, and packaging formats, providing the flexibility needed to adapt to changing market demands. Whether it's fragile items, irregularly shaped products, or different packaging styles, automatic packing machines can be customized to meet specific requirements. This adaptability allows businesses to scale their operations, introduce new products, and cater to a wide range of customer preferences.

Enhanced Workplace Safety:

Another crucial aspect of automatic packing machines is their contribution to workplace safety. By automating repetitive and physically demanding tasks, these machines reduce the risk of injuries associated with manual packing. Employees can be reassigned to more complex and meaningful roles that require their expertise, creating a safer work environment and boosting overall employee morale. Additionally, ergonomic designs and safety features incorporated into these machines further enhance workplace safety and well-being.

Automatic packing machines have emerged as a transformative force in the packaging industry. With their remarkable speed, accuracy, and versatility, these here machines revolutionize the way products are packaged, increasing efficiency, reducing costs, and improving customer satisfaction. By leveraging the power of automation, businesses can unlock a world of opportunities, enabling them to stay ahead of the competition, scale their operations, and meet the ever-evolving needs of consumers. Embracing automatic packing machines is a strategic move that empowers businesses to streamline their packaging processes and focus on their core competencies, paving the way for long-term success in an increasingly dynamic market.

1 note

·

View note

Text

What I want to make

I'm a big fan of management and simulation-style games, especially those with automation elements. I'm hoping to create a game that fits into the same genre.

I should preface this all by saying that my goal isn't to create something I intend to sell on a storefront like Steam or itch.io - that would be a plesant 'bonus' outcome to this. I want to make sure this isn't my focus. Having commercial aspirations ends up being a twisty path that leads both to development pressure and a burden to fit within a specific kind of box that would appeal to consumers.

These aren't bad parameters, not really. But while they might add structure and purpose to development they aren't always the right fit for all projects and all people, myself especially.

A little bit of background

I've spent many years trying to make personal projects with commercial goals in mind. I find that, while inspirational and ambitious to begin with, the fact that you're banking on selling it and rewarding your time creates a bit of a false promise. The process of game development should be fun, and the moment it becomes burdensome is usually an indicator that some sort of external pressure has been acquired, and balancing your motivation with your pressures is something I've not been great with.

With that said, I'm approaching this project with an open mind and a simple goal: make something that I will find fun to play, and meets my own criteria alone.

What this game is

I play a bunch of management and automation games. Factorio, Satisfactory, Dyson Sphere Program, Factory Town, Astro Colony, Shapez, Production Line and many others. There is a running theme amongst these, and they all offer slightly different takes on the genre - which I love!

I'm hoping to create something very much in this vein, but more aligned with games like Big Pharma and Astro Colony, but probably nowhere near as ambitious as either (though being able to add greater depth to my initial idea would be nice).

The idea I've been toying with for a long time surrounds the mining of asteroids in the solar system. You've been give a small base of operations on a large asteroid, and your job is to take in samples from the asteroid and perform various operations on them in order to produce research and other products from it.

This could be as simple as taking in a raw mineral sample from the asteroid, running it through a machine to analyse it, and receiving a small bit of 'science' for it. As a kind of currency. This can then be used to purchase upgrades or improvements to your factory.

Other activities may involve taking those minerals and breaking them down, combining them with other minerals, and creating sample tubes to package up and send back to Earth for further research (via some kind of automated return cargo shuttle mechanism).

The ultimate goal here is to build a nice big automated factory that fulfils a large range of objectives. The player could choose to play this as a campaign mission - which may require building a factory to fulfil a certain range of objectives (gain a certain amount of science points, return a certain number of samples of something to Earth, and so on), or simply to just build-big and reach some kind of free-play achievement (much like Factorio's 'launch the rocket' soft completion requirement, which leaves the player free to carry on playing and accruing more resources).

With all that said, I'll end this post here and use the next post to explain how I'm planning to build all this, what I already know and can bring to the table, and what challenges I think I'm going to face.

2 notes

·

View notes

Text

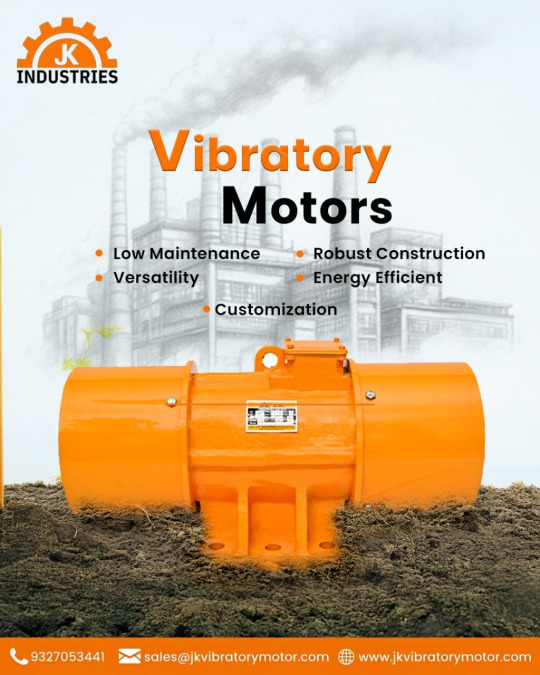

How Vibratory Motors Are Reshaping India’s Industrial Sector

India’s industrial journey is entering an exciting phase, fueled by innovation, infrastructure upgrades, and a renewed focus on automation. One of the most important yet often underestimated contributors to this progress is the vibratory motor—a compact machine that quietly powers essential operations across multiple industries.

Understanding the Purpose of Vibratory Motors

At their core, vibratory motors are devices engineered to create motion using rotational imbalance. This generated vibration helps move, compact, separate, or align materials without the need for manual effort. Their ability to deliver controlled vibrations makes them an invaluable asset in manufacturing, construction, mining, and beyond.

From feeding systems in food production lines to screening units in mining plants, these motors deliver consistent results with minimal intervention.

Where Vibratory Motors Make the Most Impact

Infrastructure & Building Projects

As India pushes forward with large-scale infrastructure development, the use of vibratory motors in compaction equipment, concrete forms, and other construction tools ensures uniform material density and improved structural strength.

Mining & Material Sorting

Mining operations—be it coal, iron ore, or stone—require reliable material handling systems. Vibratory motors installed in screening and feeding machinery make the sorting of raw material seamless, while standing up to tough operating conditions.

Food Production

Clean, precise, and safe material movement is a must in food facilities. These motors help sort, transport, and sift grains, powders, and other food items without contaminating the product.

Pharmaceuticals & Chemicals

Accuracy and hygiene are vital in pharma and chemical plants. Vibratory motors play a key role in sieving, drying, and conveying delicate ingredients under strict environmental conditions.

Recycling Facilities

With sustainability on the rise, recycling systems now rely heavily on vibratory motors for the efficient separation and sorting of reusable waste—boosting productivity while reducing human error.

Why Vibratory Motors Are Essential in Modern Industry

High Efficiency, Low Power

Despite their small size, these motors can handle large volumes of material with minimal power consumption—making them cost-effective and energy-conscious solutions.

Minimal Downtime

Their robust design allows for continuous operation with very little maintenance, keeping production lines moving and reducing unscheduled halts.

Highly Adaptable

Whether it’s a large factory floor or a compact production unit, vibratory motors can be tailored to fit any application, offering unmatched flexibility to industrial setups.

Helping Fuel India’s Manufacturing Momentum

The government’s strong focus on promoting domestic production under initiatives like “Make in India” has given rise to many local success stories. One such name is JK Industries, which designs and manufactures reliable, high-performance vibratory motors right here in India. Their innovations not only support local industries but also contribute to import substitution and job creation.

Success in Practice

A bottling plant in northern India recently upgraded its packaging lines with customized vibratory motors from JK Industries. The result? A 25% improvement in output and a notable drop in machine-related downtime—demonstrating how strategic equipment upgrades can deliver measurable gains.

Tips for Selecting the Ideal Vibratory Motor

To ensure you choose the right motor for your application, consider these points:

Know Your Load: Understand the material type, density, and volume.

Match Motor Rating to Need: Choose a power rating that suits the intensity of your process.

Factor in the Environment: Dust, moisture, and heat can affect motor performance—pick accordingly.

Work with Reliable Manufacturers: Brands like JK Industries offer durable options backed by technical support.

Final Words

Industrial efficiency isn’t just about automation—it’s about making smart choices in equipment. Vibratory motors, though small in size, have a powerful influence on how smoothly and cost-effectively operations run. Their quiet contribution to India’s booming industrial landscape deserves more recognition.

With trusted companies like JK Industries delivering top-quality vibratory motors, the path to industrial excellence becomes more achievable, sustainable, and future-ready.

0 notes

Text

Bottle Capping Machine: The Ultimate Guide to Efficient and Secure Bottling

What is a Bottle Cap Sealing Machine?

A bottle cap sealing machine (also known as a bottle capping machine) is designed to seal caps or closures onto bottles of various shapes and sizes. These machines ensure a consistent, tight seal that prevents leaks, contamination, or tampering. They are used in both manual and fully automated production lines, depending on the scale and speed required.

From screw caps to flip-tops and aluminum ROPP (Roll-on Pilfer Proof) caps, these machines handle them all with accuracy, speed, and repeatability.

Types of Bottle Cap Sealing Machines

1. Manual Bottle Capping Machines

Ideal for low-volume production

Simple hand-press or torque-based designs

Used by startups and small-scale operations

2. Semi-Automatic Cap Sealing Machines

Operator places the cap; machine seals it with consistent torque

Increases productivity and accuracy

Suitable for SMEs

3. Automatic Bottle Cap Sealing Machines

Fully automated cap placement and sealing

Integrated with bottle filling lines

Designed for high-speed mass production

4. ROPP Cap Sealing Machines

Specifically for aluminum roll-on caps

Common in wine, liquor, and pharmaceutical industries

5. Induction Cap Sealing Machines

Uses electromagnetic induction to heat and bond foil seals inside caps

Provides tamper-evident and leak-proof sealing

Essential in food, pharma, and chemical applications

6. Screw Capping Machines

Applies threaded screw caps

Compatible with plastic or metal caps

7. Lug Capping Machines

For twist-off caps, mainly used in food jars like pickles and sauces

Applications of Bottle Cap Sealing Machines

Pharmaceutical Industry

Air-tight, tamper-evident caps for syrups, tablets, and tonics

Ensures product safety and regulatory compliance

Food & Beverage

Bottling of juices, sauces, mineral water, milk, oils

Prevents spoilage and leakage

Cosmetics & Personal Care

Bottles for shampoos, lotions, perfumes

Demands aesthetic as well as secure seals

Chemical & Agrochemical

Bottling of detergents, cleaners, pesticides

Requires leak-proof and resistant sealing

Core Features of High-Performance Cap Sealing Machines

1. Adjustable Torque Control

Ensures caps are neither too tight nor too loose

Prevents spillage, breakage, or product damage

2. High-Speed Capping

Cap sealing rate from 30 to 300 bottles per minute, depending on machine type

3. Automatic Cap Feeding System

Vibratory bowl or cap elevator for continuous cap supply

4. PLC-Based Operation

Intuitive touch panel for setting speeds, torque, and diagnostics

5. Changeover Flexibility

Quick adjustments for different bottle shapes or cap sizes

6. Stainless Steel Construction

Rust-proof, durable, and compliant with hygiene regulations

Benefits of Using a Bottle Cap Sealing Machine

Leak-Proof Packaging: Prevents product loss during transport or storage

Tamper-Proof Seals: Especially critical in pharmaceuticals and food

Speed and Consistency: Uniform torque and sealing reduce rejection rates

Reduced Labor Costs: Automation cuts manual handling

High Production Output: Meets increasing market demands

Regulatory Compliance: Helps meet standards like FDA, ISO, FSSAI, WHO-GMP

0 notes

Text

Advanced Engineering That Delivers Packaging Perfection

At FAIR PACK MACHINERIES, we redefine packaging with cutting-edge engineering and precision-built machines that meet the demands of modern industries. From filling and sealing to labeling and conveying, our solutions ensure efficiency, reliability, and consistency—every time.

🌍 Trusted since 1998, FAIR PACK has become a global name in providing:

✅ High-speed packaging systems ✅ Custom-engineered filling & sealing machines ✅ Smart conveyor solutions ✅ Semi & fully automatic machinery for every scale

Whether you’re in food, pharma, chemicals, or consumer goods, we offer machines tailored to optimize your production line and improve product integrity.

🔧 Built with innovation. Backed by trust.

🔗 Visit us to learn more: https://www.fairpack.in/

📞 Ready to upgrade your packaging process? Contact us today!

0 notes

Text

Revolutionizing Packaging with Tray Forming Machines

In the fast-paced world of manufacturing and logistics, efficiency is king. And when it comes to packaging, the humble cardboard tray plays a vital role. From holding fresh produce in supermarkets to securing delicate components in warehouses, these trays are ubiquitous. But manually assembling them? That's a time-consuming and labor-intensive process, ripe for optimization. Enter the tray forming machine, a marvel of automation that's transforming how businesses handle their packaging needs.

These machines, often overlooked, are the unsung heroes of streamlined production lines. They take flat, pre-cut cardboard blanks and, with a combination of folding, gluing, and pressing, transform them into sturdy, ready-to-use trays. Imagine a continuous flow of perfectly formed trays, emerging at speeds that would make manual assembly pale in comparison. That's the power of automation.

The benefits extend beyond mere speed. Consistency is a major advantage. Every tray produced by a machine adheres to precise dimensions and specifications, ensuring uniformity and minimizing waste. This is crucial for industries where product presentation and secure transport are paramount. Think of the food and beverage sector, where perfectly aligned trays of fruits or bottles enhance shelf appeal and prevent damage during transit.

Furthermore, labor cost reduction is a significant driver for adopting tray forming machines. By automating the assembly process, businesses can free up valuable human resources for other tasks, optimizing overall productivity. This is particularly relevant in regions facing labor shortages or where labor costs are high.

The technology itself is diverse. Tray forming machines come in various configurations, catering to different tray sizes, shapes, and materials. Some are designed for high-volume production, while others are more flexible, accommodating smaller batches and customized designs. Advanced models incorporate features like automatic blank feeding, hot melt gluing systems, and integrated quality control mechanisms.

The versatility of these machines extends to the industries they serve. From food processing and pharmaceuticals to electronics and automotive, any business that relies on cardboard trays can benefit from automation. For instance, in the e-commerce sector, where packaging demands are constantly fluctuating, tray forming machines offer the flexibility to adapt to changing needs.

However, the initial investment in a tray forming machine can be a barrier for some businesses. It's essential to conduct a thorough cost-benefit analysis, considering factors like production volume, labor costs, and potential for increased efficiency. The long-term savings and increased throughput often outweigh the upfront expense.

Looking ahead, the future of tray forming machines is likely to be driven by advancements in robotics and artificial intelligence. We can expect to see more sophisticated machines capable of handling complex tray designs, integrating with other automation systems, and even self-adjusting to changing production parameters.

In conclusion, the tray forming machine is more than just a piece of equipment; it's a strategic investment in efficiency, consistency, and cost-effectiveness. By automating a critical aspect of packaging, businesses can unlock significant productivity gains and stay competitive in today's demanding market. It's a testament to how even seemingly simple processes can be revolutionized through smart automation.

0 notes

Text

#pharma packaging#pharmaceutical packaging#integrated packaging solutions#automatic packaging machine#innovative packaging solutions#packaging machine manufacturers#pcd pharma franchise#nichrome blister packaging#blister packaging

0 notes

Text

OSD Machine Market Size, Industry Share and Growth till 2033

Global “OSD Machine Market” research report is a comprehensive analysis of the current status of the OSD Machine industry worldwide. The report categorizes the global OSD Machine market by top players/brands, region, type, and end-user. It also examines the competition landscape, market share, growth rate, future trends, market drivers, opportunities, and challenges in the global OSD Machine market. The report provides a professional and in-depth study of the industry to help understand its current state and future prospects. What Are The Prominent Key Player Of the OSD Machine Market?

WESTEAM

Nama Group

Delex Pharma International Inc.

Bosch Packaging Technology

Ethical Pharma, Inc

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for OSD Machine

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals.

Regional Segment of OSD Machine Market:

Geographically, the report includes research on production, consumption, revenue, market share, and growth rate of the following regions:

United States

Europe (Germany, UK, France, Italy, Spain, Russia, Poland)

China

Japan

India

Southeast Asia (Malaysia, Singapore, Philippines, Indonesia, Thailand, Vietnam)

Latin America (Brazil, Mexico, Colombia)

Middle East and Africa (Saudi Arabia, United Arab Emirates, Turkey, Egypt, South Africa, Nigeria)

The global OSD Machine Market report answers the following questions:

What are the main drivers of the global OSD Machine market? How big will the OSD Machine market and growth rate in upcoming years?

What are the major market trends that affecting the growth of the global OSD Machine market?

Key trend factors affect market share in the world's top regions?

Who are the most important market participants and what strategies being they pursuing in the global OSD Machine market?

What are the market opportunities and threats to which players are exposed in the global OSD Machine market?

Which industry trends, drivers and challenges are driving that growth?

Browse More Details On This Report at - https://www.businessresearchinsights.com/market-reports/osd-machine-market-104439

Contact Us:

Business Research Insights

Phone:

US: (+1) 424 253 0807

UK: (+44) 203 239 8187

Email: [email protected]

Web: https://www.businessresearchinsights.com

Other Reports Here:

Line Proportioner Market

Interactive Smartboards Market

Fiberglass Swimming Pools Market

Intelligent Irrigation System Market

Racket Sweatband Market

Scarifier Drums Market

Endometrial Biopsy Cannulae Market

Wet Tissues and Wipes Market

Automotive Domain Control Unit (DCU) Market

Virtualized Radio Access Network (vRAN) Market

Other Reports Here:

Fish Counters Market

Infrared Lens (IR Lens) Market

Storage Pressure Vessel Market

Maternal and Infant Toiletries Market

Ferromagnetic Detectors Market

Internet Service Market

Fax Server Software Market

Ion Indicators Market

Erosion and Sediment Control Market

Panel Fastener Market

0 notes

Text

youtube

Bestselling Product Counting Machine: Efficiently Counting & Filling Pills, Tablets, Capsules & More.

Explore our bestselling semi-automatic countertop tablet counting and filling device King Dispenser Rx from C.E.King Limited, a distinguished packaging machinery manufacturer.

Tailored for precision and efficiency, this versatile machine seamlessly counts and fills pills, tablets, capsules and more, ensuring accuracy and reliability in your pharmaceutical packaging processes.

Navigate through a world where technology meets practicality with the King Dispenser Rx, and elevate your production capabilities with a machine designed to optimize your packaging operations.

#bestseller #counting #filling #bottling #packing #equipment #manufacturing #pharmaceutical

0 notes