#Pharmaceutical lab reactors

Explore tagged Tumblr posts

Text

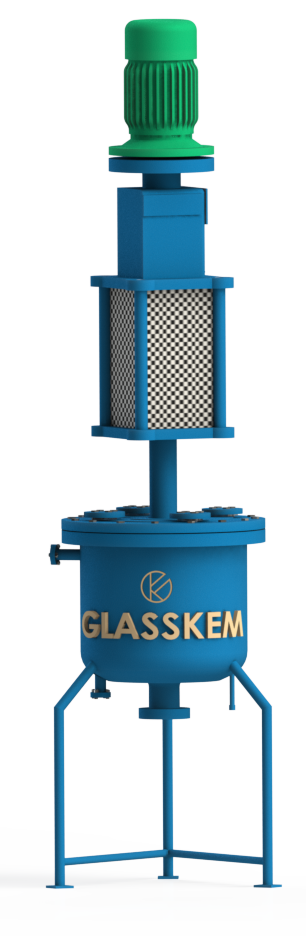

Best Glass-Lined Lab Reactors in USA & Canada | GlassKem

Discover PFG GlassKem's glass-lined lab reactors, designed for precision and reliability in R&D, quality control, and small-scale production across industries.

#Glass-lined lab reactors#Laboratory glass-lined reactors#Lab-scale glass-lined reactors#Corrosion-resistant lab reactors#Chemical lab reactors#Pharmaceutical lab reactors

0 notes

Text

youtube

What Are the Benefits of Using the AKF-100L Double-Glazed Reactor for Advanced Chemical Reactions?

The AKF-100L Double-Glazed Reactor is a high-performance solution for chemical reactions, offering precise temperature control ranging from -120°C to 300°C. It features:

100L material capacity & 60L jacket capacity for efficient heating and cooling.

6 customizable ports for versatile experimental setups.

Stainless steel fluoropolymer-coated stirrer for reliable mixing.

5L constant pressure funnel to enhance reaction efficiency.

Optional explosion-proof control box, explosion-proof motor, and insulation sheath for added safety.

Ideal for labs that require precision and safety, the AKF-100L Reactor is perfect for a wide range of chemical and pharmaceutical applications.

Explore more: AKF-100L Double-Glazed Reactor

#Chemical Reactor#Laboratory Equipment#Double-Glazed Reactor#Chemical Engineering#Temperature Control#Explosion-Proof Equipment#Pharmaceutical Manufacturing#Lab Stirrer#Scientific Instruments#Reactors for Laboratories#Youtube

3 notes

·

View notes

Text

Application and Advantages of Lab Scale Fermenter

Understanding Lab-Scale Bioreactors

Lab-scale bioreactors, often referred to as benchtop bioreactors, are compact vessels designed to facilitate the growth and manipulation of various biological entities under controlled conditions. These reactors mimic the natural environment of microorganisms or cells, providing optimal conditions for proliferation, metabolism, and product formation.

Components and Design

The design of lab-scale bioreactors is meticulously crafted to emulate the conditions prevalent in industrial-scale fermenters while maintaining versatility and ease of operation. Key components typically include:

Vessel: The core of the bioreactor, where the biological culture resides. Vessels come in various sizes and configurations, accommodating different volumes and types of cultures.

Agitation System: Ensures uniform mixing of nutrients, gases, and metabolites within the culture. Agitation mechanisms may include stirrers, impellers, or spargers, depending on the specific requirements of the culture.

Temperature Control: Precise temperature regulation is essential for maintaining optimal growth conditions. Bioreactors are equipped with heating elements and cooling jackets, along with temperature probes and controllers to monitor and adjust temperature levels.

pH and Dissolved Oxygen Control: Maintaining appropriate pH and dissolved oxygen levels is crucial for cell viability and productivity. Bioreactors are equipped with sensors and controllers to regulate these parameters through the addition of acids, bases, or oxygen.

Monitoring and Control Systems: Advanced bioreactors are integrated with sophisticated monitoring and control systems, allowing real-time monitoring of key parameters such as temperature, pH, dissolved oxygen, and biomass concentration. Automated control algorithms facilitate precise adjustment of operating conditions to optimize culture performance.

Applications and Advantages of Lab Scale Bioreactor

The versatility of lab-scale bioreactors extends across a wide range of applications in biotechnology, pharmaceuticals, and academia:

Bioprocess Development: Lab-scale bioreactors serve as invaluable tools for the optimization and scale-up of bioprocesses. Researchers can fine-tune culture conditions, evaluate the impact of different parameters, and optimize productivity before transitioning to larger scales.

Cell Culture and Tissue Engineering: Bioreactors play a pivotal role in the cultivation of mammalian cells and tissues for various applications, including regenerative medicine, drug discovery, and tissue engineering. Controlled environments within bioreactors facilitate the growth and differentiation of cells into functional tissues.

Microbial Fermentation: Microbial fermentation processes, such as the production of antibiotics, enzymes, and biofuels, are extensively studied and optimized using lab-scale bioreactors. These reactors allow researchers to explore different microbial strains, media formulations, and process conditions to maximize product yields and quality.

Biological Research and Education: Bioreactors serve as indispensable tools for biological research and education, providing students and researchers with hands-on experience in culturing and manipulating biological systems. Benchtop bioreactors enable reproducible experimentation and data collection, fostering a deeper understanding of bioprocess principles and techniques.

Challenges and Future Directions

While lab-scale bioreactors offer tremendous potential, several challenges persist in their design and operation:

Scalability: Translating results from lab-scale bioreactors to larger industrial-scale fermenters remains a challenge due to differences in hydrodynamics, mass transfer, and mixing dynamics. Bridging this scalability gap requires advanced computational modeling, process optimization, and scale-up strategies.

Sterility and Contamination Control: Maintaining sterility and preventing contamination are critical aspects of bioreactor operation, particularly in cell culture and pharmaceutical applications. Robust sterilization protocols, aseptic techniques, and stringent quality control measures are essential to minimize the risk of contamination.

Process Intensification: Enhancing productivity and efficiency through process intensification strategies is a key focus area in bioreactor development. Integration of online monitoring and control systems, advanced analytics, and novel bioreactor designs can streamline bioprocesses and maximize resource utilization.

Conclusion

Lab-scale bioreactors represent the cornerstone of bioprocessing innovation, offering a platform for exploration, discovery, and optimization across diverse biological applications. As advances in biotechnology continue to accelerate, the role of lab-scale bioreactors in shaping the future of bioprocessing becomes increasingly pronounced. By addressing challenges, embracing technological advancements, and fostering interdisciplinary collaboration, we can unlock the full potential of lab-scale bioreactors and propel bioprocessing into a new era of sustainability, efficiency, and impact.

#lab scale bioreactor#lab scale bioreactor manufacturer#lab scale bioreactor supplier#lab scale bioreactor manufacturer in India#fermenter technologies

2 notes

·

View notes

Text

Dopamine Hydrochloride Production Cost Report by Procurement Resource

Procurement Resource, a global leader in procurement intelligence and cost analysis, proudly presents its latest Dopamine Hydrochloride Production Cost Report. This detailed and data-driven report offers critical insights for stakeholders looking to invest in or expand dopamine hydrochloride manufacturing operations. With in-depth coverage of production methods, cost structures, market dynamics, and sustainability trends, this report is an indispensable resource for businesses, researchers, and investors operating in the pharmaceutical and biochemical industries.

Dopamine Hydrochloride: A Vital Pharmaceutical Ingredient

Dopamine Hydrochloride (C8H11NO2·HCl) is a crucial active pharmaceutical ingredient (API) used primarily in cardiovascular medications to treat conditions such as shock and low blood pressure. It is a synthetic catecholamine that mimics the body’s natural neurotransmitter dopamine and is vital in restoring sympathetic tone in critically ill patients.

Owing to its vasopressor, inotropic, and renal vasodilator properties, dopamine hydrochloride is extensively utilized in intensive care units and emergency medicine. The compound is listed on the World Health Organization's List of Essential Medicines, highlighting its critical role in global healthcare.

Strategic Utility of the Production Cost Report

The Dopamine Hydrochloride Production Cost Report by Procurement Resource is tailored to equip pharmaceutical companies, contract manufacturers, and R&D-based firms with comprehensive knowledge about production feasibility, raw material dynamics, technical operations, and economic returns. It offers detailed breakdowns of manufacturing steps, cost components, and infrastructure requirements, enabling companies to make data-driven investment decisions.

Market Overview and Demand Outlook

Global Market Dynamics

The demand for dopamine hydrochloride is driven by:

Rising incidence of critical care cases globally

Increasing geriatric population prone to cardiovascular diseases

Growth of the hospital-based injectable drug market

Expanding healthcare infrastructure in emerging economies

Regional Trends

North America and Europe: Mature markets with high consumption due to advanced healthcare systems and critical care infrastructure.

Asia-Pacific: Fast-growing demand owing to increasing healthcare expenditure, population density, and pharmaceutical manufacturing capabilities.

Middle East & Africa: Moderate growth with increasing import reliance and government healthcare investments.

Raw Materials and Price Trends

Primary Raw Materials:

L-DOPA (Levodopa) or 3,4-Dihydroxyphenylacetaldehyde

Hydrochloric Acid (HCl)

Solvents (such as methanol or ethanol)

Catalysts and buffer agents

The report provides an exhaustive analysis of raw material procurement trends and global pricing. Levodopa, synthesized from natural or synthetic catechol precursors, is the most cost-sensitive raw material impacting dopamine hydrochloride production economics. Market fluctuations in pharmaceutical-grade intermediates and solvents are also covered in the report.

Technology, Equipment, and Plant Requirements

Depending on the desired scale and production environment (lab-scale, pilot-scale, or GMP-certified commercial production), the report outlines the necessary machinery, such as:

Reactor vessels with temperature and pressure controls

Chromatographic purification systems

Vacuum dryers

Centrifuges and filtration equipment

Sterile filling and packaging lines

Automation levels and compliance with Good Manufacturing Practices (GMP) are critical for API production and are discussed thoroughly in the report.

Infrastructure and Utility Needs

Establishing a dopamine hydrochloride production facility requires:

Cleanroom infrastructure for sterile API production

Controlled environments for humidity, air pressure, and microbial contamination

High-grade HVAC systems

Utility connections for steam, chilled water, deionized water, and compressed air

Effluent treatment systems to manage pharmaceutical waste

Labor and Human Capital

Pharmaceutical production of dopamine hydrochloride involves skilled professionals across functions:

Process chemists and chemical engineers

Quality control and analytical lab personnel

Regulatory affairs specialists

Production supervisors and GMP auditors

The report provides human resource requirements based on facility size, compliance level, and automation degree.

Quality and Regulatory Compliance

As an injectable drug ingredient, dopamine hydrochloride must meet strict pharmacopoeial standards (USP, EP, JP). The report elaborates on:

Purity, moisture, residual solvent, and microbial testing

In-process controls and validation protocols

Documentation for FDA, EMA, and WHO GMP approvals

Batch traceability, serialization, and controlled substance regulations (if applicable)

Financial and Economic Evaluation

Capital Investment Assessment

The report outlines initial investment needed for:

GMP-certified plant setup

Lab-scale development and validation

Equipment purchase and facility construction

Licensing, safety compliance, and process validation

Estimates are categorized into small-scale R&D production and large-scale commercial facilities.

Operating Cost Breakdown

The recurring cost structure includes:

Raw materials and consumables

Utility costs (energy, water, solvents)

Labor and supervision

Quality assurance and compliance testing

Waste disposal and environmental controls

Profitability and Return on Investment (ROI)

The report presents profitability metrics based on:

Global API pricing benchmarks

Production scale and yield efficiency

Competitive analysis in key export markets

Includes projections for gross margins, net profit, and ROI under various operational scenarios.

Break-Even Analysis

A thorough break-even and payback period assessment helps decision-makers evaluate investment risk and time to profitability, considering input cost volatility and global market pricing shifts.

Sustainability and Industry Trends

The pharmaceutical industry is shifting toward greener synthesis routes and continuous manufacturing. The report explores:

Solvent recovery and waste minimization strategies

Adoption of enzymatic synthesis for cleaner production

Opportunities for contract development and manufacturing (CDMO) partnerships

Regional regulatory incentives for local API production

Growing focus on domestic API manufacturing in India, China, and the U.S. further supports the need for cost-effective, scalable production methods for dopamine hydrochloride.

Why Choose Procurement Resource?

Procurement Resource empowers businesses with the intelligence they need to thrive in competitive and regulated sectors. Our dopamine hydrochloride production report is backed by:

Accurate cost models and pricing data

Global supply chain benchmarking

Compliance-based facility design insights

Real-time market analytics

We help pharmaceutical manufacturers lower procurement risks, optimize cost-efficiency, and prepare for long-term growth with tailored reports and strategic consultation.

Get a Free Copy of the Report

The Dopamine Hydrochloride Production Cost Report is an invaluable tool for entrepreneurs, procurement teams, and pharmaceutical investors. Gain clarity on capital investment, operational cost, and profitability with this expert-curated guide.

Request your Free Sample Report: https://www.procurementresource.com/production-cost-report-store/dopamine-hydrochloride/request-sample

Contact Information

Company Name: Procurement Resource Contact Person: Ashish Sharma (Sales Representative) Email: [email protected] Location: 30 North Gould Street, Sheridan, WY 82801, USA Phone: USA: +1 307 363 1045 UK: +44 7537171117 Asia-Pacific (APAC): +91 1203185500

#dopamine hydrochloride#cost analysis#cardiovascular medications#inotropic#vasopressor#renal vasodilator

0 notes

Text

Leading Bromine Compound Supplier in India – Bromos Organics

In the rapidly evolving chemical industry, few names resonate with the level of precision, quality, and reliability as Bromos Organics. With a laser focus on producing high-purity brominated compounds, Bromos Organics has established itself as one of the leading Bromine Derivatives Manufacturers India. Our company stands at the intersection of innovation and responsibility, serving both domestic and global markets with customized solutions.

Who We Are: A Trusted Name in Bromine Chemistry

At Bromos Organics, our mission is to deliver performance-driven chemical products that meet the stringent demands of industries such as pharmaceuticals, agrochemicals, dyes, and specialty chemicals. We specialize in synthesizing organic intermediates that involve bromination—a highly specialized chemical reaction requiring expertise, precision equipment, and strict quality control.

Our team of skilled chemists, engineers, and quality assurance professionals ensures that every compound we manufacture meets international standards and complies with environmental safety regulations.

Our Core Products and Services

As a dedicated manufacturer of bromine derivatives, our product portfolio includes:

Alkyl Bromides

Aryl Bromides

Heterocyclic Bromine Compounds

Customized Brominated Intermediates

These derivatives are essential for applications in pharmaceuticals (as active pharmaceutical ingredients or intermediates), crop protection formulations, flame retardants, and more.

Our R&D facility plays a vital role in supporting custom synthesis and contract manufacturing, making Bromos Organics a one-stop solution provider for clients seeking specialized brominated chemicals.

Infrastructure and Quality Assurance

One of the major strengths of Bromos Organics lies in our state-of-the-art production facility, designed to handle complex reactions with efficiency and safety. Equipped with glass-lined and stainless steel reactors, high-vacuum distillation units, and advanced analytical labs, our infrastructure supports both small-batch and bulk manufacturing.

Our commitment to quality is reinforced through:

In-house quality testing laboratories

GMP-compliant processes

Strict adherence to ISO quality standards

Batch-to-batch consistency

Environmentally responsible waste management systems

We ensure every product leaving our facility is accurate in composition, safe to use, and meets client expectations.

Sustainability and Regulatory Compliance

Environmental sustainability is integral to our operations. Bromos Organics follows eco-friendly production methods that minimize emissions and waste generation. Our waste treatment systems are aligned with regulatory guidelines, and we invest in continuous improvement to reduce our carbon footprint.

In addition to complying with national regulations, our exports are backed by the necessary certifications and documentation to meet global quality and safety standards. Clients can rely on our transparency and traceability across every stage of production.

Why Choose Bromos Organics?

Choosing the right partner in chemical manufacturing is crucial for any industry dealing with sensitive and high-stakes products. Here's why businesses across India and abroad trust Bromos Organics:

Specialization in Bromine Chemistry: Decades of experience with a single focus—brominated compounds.

Customization Capability: We tailor solutions as per client specifications.

Timely Deliveries: Strong supply chain and logistic partnerships ensure quick, reliable distribution.

Global Reach: Supplying to customers in multiple countries with export-ready documentation.

Ethical Business Practices: Transparent dealings, commitment to safety, and customer-first mindset.

Applications Across Industries

The demand for bromine derivatives continues to grow across sectors such as:

Pharmaceuticals: For APIs and key intermediates

Agrochemicals: In the formulation of pesticides and herbicides

Dye Manufacturing: Providing stability and reactivity in colorants

Flame Retardants: Essential for electronics and safety materials

Specialty Chemicals: Used in fine chemical synthesis and niche applications

Bromos Organics serves all these sectors by offering reliable, scalable, and high-quality chemical solutions.

Conclusion

When it comes to finding trusted Bromine Derivatives Manufacturers India, Bromos Organics remains a top choice for companies looking for integrity, precision, and partnership. With a commitment to sustainable manufacturing, cutting-edge R&D, and industry-leading expertise, we continue to set benchmarks in brominated compound production.

Partner with us for your bromine derivative needs and experience the excellence that defines every product we deliver.

#BromineDerivativesManufacturersIndia#BromineDerivativesManufacturersNorthernIndia#HYDROBROMICACID48%

0 notes

Text

Pharmaceutical Manufacturing: How Pilot Plants Bridge the Gap Between Innovation and Full-Scale Production

he Challenge: Why Traditional Batch Processing Is No Longer Enough

For decades, batch processing has been the standard in pharmaceutical manufacturing. It’s tried, tested, and deeply embedded in most facilities. But as the pace of innovation quickens and expectations around speed, accuracy, and compliance continue to rise, the limitations of this traditional approach are becoming harder to ignore.

Whether it’s dealing with slow reaction times, poor heat and mass transfer, or unpredictable outcomes during scale-up, batch systems often fall short. Combine this with the increasing complexity of meeting GMP requirements and ensuring consistent product quality, and it becomes clear: the industry needs more than what batch processing can offer.

So, what’s the path forward?

The Shift to Continuous Flow Chemistry

Continuous flow chemistry has emerged as a powerful alternative. It offers greater precision, improved safety, and scalable production — especially important when working with hazardous, exothermic, or multi-phase reactions. But transitioning from batch to flow is not a plug-and-play solution. It requires thoughtful planning, technical expertise, and, most critically, a well-engineered pilot plant.

Why Pilot Plants Are Crucial in Modern Pharma

Moving from a lab-based batch process to a continuous production line isn’t just about equipment — it’s a transformation that affects chemistry, safety, compliance, and operational strategy. A pilot plant serves as a critical intermediate step, offering a controlled environment to test, validate, and refine processes before full-scale deployment.

Here’s how pilot plants solve real-world challenges in pharmaceutical development:

1. Translating Lab Results into Scalable Flow Processes

What works in a small lab setup doesn’t always scale predictably. Reactions that behave well in batch conditions might perform very differently in a flow reactor.

A pilot plant helps bridge that gap. It allows for accurate mapping of batch reaction kinetics into continuous flow conditions by optimizing:

Residence time — to ensure complete reactions

Mixing strategies — for efficient reactant interaction

Thermal control — to manage heat safely and consistently

By testing these parameters in a pilot setup, manufacturers gain a clear understanding of how the process will behave at scale — reducing guesswork and risk.

2. Integrating Safety From the Start

Pharmaceutical processes often involve reactive or hazardous materials. In batch systems, risks like runaway reactions, pressure surges, or insufficient heat removal become more pronounced with increased scale.

Continuous flow systems inherently reduce these risks by working with smaller volumes and enabling real-time monitoring. A pilot plant allows teams to evaluate:

Dynamic pressure behavior

Heat transfer efficiency

Containment system reliability

With these insights, safety becomes a design feature — not a post-launch adjustment.

3. Enabling Regulatory Compliance and GMP Preparedness

Compliance isn’t optional — it’s foundational. Regulatory bodies like the FDA demand robust validation, traceability, and process consistency.

A modern pilot plant supports this by naturally aligning with:

Quality by Design (QbD) principles

GMP validation from the outset

Comprehensive documentation and traceability

By building compliance into the pilot phase, organizations streamline their path to regulatory approval and reduce costly delays.

4. De-Risking the Scale-Up Phase

The jump from lab to production is where many pharmaceutical processes face unexpected hurdles — from inconsistent flow rates to equipment fouling.

Pilot plants are designed to uncover these potential pitfalls early, offering an opportunity to:

Identify and correct flow imbalances

Test material compatibility

Prevent clogging or fouling in reactors

By resolving these issues before full-scale production, manufacturers reduce risk and build confidence in their processes.

How Xytel India Supports the Pharma Industry

At��Xytel India, we go beyond building pilot plants — we engineer complete, purpose-driven solutions tailored to the unique challenges of pharmaceutical manufacturing.

Custom-Built Systems Aligned to Your Needs

No two pharmaceutical processes are the same. That’s why we design each pilot plant to match your specific chemistry, scale, and operational goals. Whether you’re developing a new API, refining a synthesis route, or validating a flow process, our pilot plants offer:

Precise replication of lab conditions

Advanced controls and real-time monitoring

Modular and flexible designs for multi-purpose applications

Every system is built with scalability in mind — so what works in the pilot phase transitions seamlessly to production.

Safety and Sustainability Engineered In

Safety isn’t an afterthought — it’s central to everything we build. Our pilot plants are equipped with:

Integrated safety features for pressure, temperature, and containment

Efficient heat management systems

Fail-safe protocols and emergency shutdown options

We design systems that meet today’s safety standards and tomorrow’s sustainability goals.

Built-In Compliance and Validation Support

From cleanroom-ready equipment to automated data logging, our pilot plants are designed to support your compliance journey. We work closely with your quality and regulatory teams to ensure alignment with:

GMP and QbD guidelines

Sanitary design requirements

Complete audit trail and documentation systems

With Xytel India, you’re not just developing a process — you’re preparing it for market success.

A Legacy of Experience and Global Reach

With decades of expertise and a global presence, Xytel India brings international standards and proven engineering to every pharmaceutical project. Whether you’re scaling up a formulation, producing toxicology batches, or prepping for tech transfer, our team brings the insight and support you need to succeed.

Conclusion: The Pilot Plant Advantage in a Changing Industry

In today’s fast-paced and highly regulated pharmaceutical landscape, a pilot plant is more than just a piece of equipment — it’s your testing ground for innovation, your safety net during scale-up, and your launchpad for market readiness.

At Xytel India, we’re proud to help pharmaceutical manufacturers confidently move from idea to implementation. With every pilot plant, we empower teams to innovate faster, safer, and smarter — with compliance, safety, and performance built into every stage.

Let’s shape the future of pharmaceutical manufacturing — one pilot plant at a time.

0 notes

Text

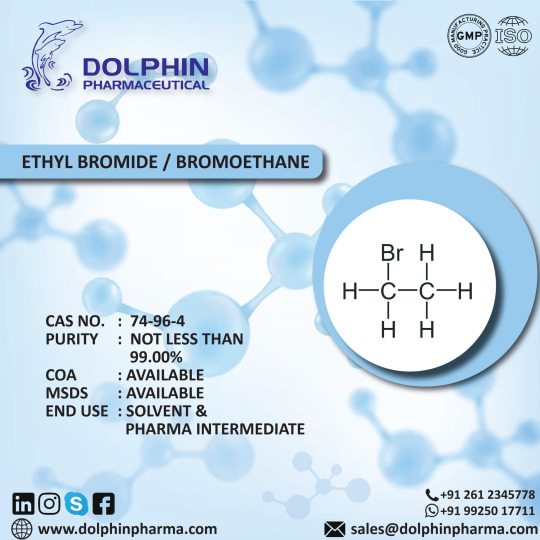

Best Bromoethane manufacturer in India

India is a global hub for chemical and pharmaceutical manufacturing, known for producing high-quality raw materials and intermediates. Among the many essential chemical compounds, Bromoethane stands out for its wide industrial and pharmaceutical applications. If you're searching for the best Bromoethane manufacturer in India, look no further—Dolphin Pharmaceutical offers unmatched quality, reliability, and compliance.

What is Bromoethane?

Bromoethane (also known as ethyl bromide) is a colorless, flammable liquid with a pleasant odor. It’s widely used as an alkylating agent in organic synthesis, particularly in the manufacture of pharmaceuticals, dyes, and agrochemicals. Due to its reactivity and versatility, it plays a crucial role in chemical synthesis and drug development processes.

Why Dolphin Pharmaceutical is the Best Bromoethane Manufacturer in India

As a leading pharmaceutical drug manufacturer in India, Dolphin Pharmaceutical brings a strong foundation of quality, safety, and innovation to the production of fine chemicals like Bromoethane. Here’s why we stand out:

1. High-Purity Chemical Production

We manufacture Bromoethane under tightly controlled conditions to ensure high purity and minimal impurities. Every batch is tested in our advanced labs to ensure it meets both domestic and international specifications.

2. Regulatory Compliance and Certifications

Our manufacturing facilities are ISO and WHO-GMP certified, assuring clients of quality and compliance. We adhere strictly to environmental and safety regulations throughout the production process.

3. State-of-the-Art Infrastructure

Our facilities are equipped with modern reactors, distillation systems, and automated controls to produce consistent and scalable batches of Bromoethane. This ensures quality in both small and bulk quantities.

4. Global Supply Network

As a trusted pharmaceutical drug manufacturer in India, Dolphin Pharmaceutical exports Bromoethane to clients across Asia, Europe, the Middle East, and Africa. Our global supply capabilities are backed by reliable logistics, documentation, and timely delivery.

Applications of Bromoethane

Bromoethane is widely used in:

Pharmaceuticals – As a building block in the synthesis of active pharmaceutical ingredients (APIs)

Agrochemicals – In pesticide and herbicide production

Organic Synthesis – As an ethylating agent in various industrial reactions

Laboratories and R&D – For developing new chemical compounds

Commitment to Safety and Sustainability

Handling of halogenated compounds like Bromoethane requires expertise and caution. At Dolphin Pharmaceutical, we follow stringent health, safety, and environmental (HSE) protocols to ensure our operations are sustainable and risk-free. Our trained professionals, modern waste treatment systems, and eco-friendly practices contribute to responsible manufacturing.

Why Choose a Pharmaceutical Drug Manufacturer in India?

India is globally recognized for its robust chemical manufacturing capabilities, skilled workforce, and competitive pricing. When you choose a pharmaceutical drug manufacturer in India like Dolphin Pharmaceutical, you benefit from:

High-quality standards

Regulatory support and documentation

Fast lead times and scalable production

Cost-effective pricing without compromising quality

Partner with Dolphin Pharmaceutical

With years of experience, Dolphin Pharmaceutical is your go-to partner for Bromoethane and other fine chemicals. Whether you are a formulation company, chemical supplier, or research organization, we offer customized solutions to meet your specific needs.

From small lab-scale orders to full commercial quantities, our team ensures a smooth experience from inquiry to delivery. Trust Dolphin Pharmaceutical for consistency, compliance, and complete customer satisfaction.

Final Thoughts

In the competitive world of chemical manufacturing, quality and trust matter. Dolphin Pharmaceutical has earned a reputation as the best Bromoethane manufacturer in India, thanks to our commitment to excellence and customer-centric approach.

0 notes

Text

Fine Speciality Chemical Supplier | Manufacturer | Vapi | India: Driving Quality and Innovation

In today’s competitive chemical industry, Jay Fine Chem stands out as a leading fine speciality chemical manufacturer in Vapi, India, delivering high-purity chemicals that power critical applications across pharmaceuticals, agrochemicals, and specialty industries. Backed by decades of expertise and a commitment to innovation, Jay Fine Chem has become a go-to partner for companies seeking quality, consistency, and reliability.

Your Trusted Source for Fine Speciality Chemicals

Jay Fine Chem specializes in the manufacture and supply of fine speciality chemicals tailored to meet the exacting standards of regulated industries. As a GMP-certified chemical manufacturer, the company ensures strict adherence to international quality protocols, offering products that are suitable for use in high-stakes environments like pharmaceutical production, electronic component manufacturing, and custom synthesis operations.

Operating out of Vapi, one of India’s premier chemical manufacturing hubs, Jay Fine Chem benefits from world-class infrastructure and an ecosystem built for scalable, compliant, and sustainable production. Their advanced facility is equipped with modern reactors, quality control labs, and a skilled technical team dedicated to custom synthesis and contract manufacturing solutions.

Why Choose Jay Fine Chem in Vapi?

Vapi, located in Gujarat, is known for its chemical clusters and regulatory support infrastructure, making it a natural choice for fine chemical manufacturing. Jay Fine Chem leverages this advantage to operate as a top-tier specialty chemical supplier in India, serving both domestic and global markets.

Key benefits of partnering with Jay Fine Chem include:

High-purity chemical production

Custom manufacturing and synthesis capabilities

ISO and GMP-certified operations

Efficient logistics and timely delivery

Global export-ready documentation and compliance

Whether you're looking for bulk specialty chemicals, intermediates for pharmaceuticals, or tailored chemical compounds, Jay Fine Chem offers precision-crafted solutions supported by robust quality control and regulatory compliance.

Serving Diverse Industries Globally

Jay Fine Chem supplies its specialty chemicals to a wide range of industries including life sciences, electronics, agrochemicals, and industrial manufacturing. As a fine specialty chemical supplier in India with a growing global footprint, the company exports to markets in Europe, North America, and Asia, ensuring that every client—no matter the location—receives consistent, high-quality products.

The company’s focus on research and process development allows it to innovate continually and respond quickly to evolving client requirements. With dedicated R&D support, Jay Fine Chem delivers cost-effective and scalable solutions for even the most complex chemical needs.

Conclusion

When it comes to sourcing fine speciality chemicals in India, Jay Fine Chem remains a name synonymous with trust, quality, and technical excellence. Located in Vapi, the heart of India’s chemical manufacturing corridor, the company is ideally positioned to serve clients across the globe with best-in-class products and personalized service.

For businesses seeking a dependable fine speciality chemical manufacturer and supplier in Vapi, Jay Fine Chem is the partner of choice—driving innovation, ensuring compliance, and delivering value with every batch.

0 notes

Text

Glass-Lined Lab Reactors in Canada & USA | PFG GlassKem Inc.

Explore PFG GlassKem's glass-lined lab reactors, offering precision and reliability for R&D, quality control, and small-scale production in various industries.

#Glass-lined lab reactors#Laboratory glass-lined reactors#Lab-scale glass-lined reactors#Corrosion-resistant lab reactors#Chemical lab reactors#Pharmaceutical lab reactors

0 notes

Text

Hyoscine Methyl Bromide: A Leading Antispasmodic API Choice

We are proud to be a trustworthy bulk drugs manufacturer and supplier of hyoscine methyl bromide, a well-known Smooth Muscle Relaxant API relied upon by the pharmaceutical sector. As a trusted bulk drugs manufacturer of premium quality pharma ingredients, we focus on providing our international customers with safe, efficient, and consistent active pharmaceutical ingredients. This detailed guide delves into the role, production, uses, and market trends of hyoscine methyl bromide, highlighting why it is still a vital option for antispasmodic therapy.

Introduction: Understanding Hyoscine Methyl Bromide in Pharmaceuticals

Hyoscine methyl bromide, or scopolamine methyl bromide, is an anticholinergic Smooth Muscle Relaxant API mainly employed to ease spasms in the urinary system, gastrointestinal tract, and other smooth muscle organs. It acts by inhibiting the effect of acetylcholine on smooth muscles, decreasing involuntary contractions that lead to pain and discomfort.

At Prism Industries Pvt. Ltd., we use cutting-edge technology, quality-oriented processes, and regulatory adherence to manufacture pharmaceutical-grade hyoscine methyl bromide for therapeutic applications. We are a reliable bulk drugs manufacturer, and our mission is to provide high-purity pharma ingredients that satisfy the changing requirements of healthcare professionals and pharma businesses globally.

The Therapeutic Application of Hyoscine Methyl Bromide

1. An Established Smooth Muscle Relaxant API

Hyoscine methyl bromide is an effective Smooth Muscle Relaxant API, acting to relieve spasms in the gastrointestinal, urinary, and reproductive systems. Through relaxing these muscles, it relieves pain, cramping, and discomfort in cases of numerous gastrointestinal and genitourinary illnesses.

Pharmaceutical companies rely on quality pharma ingredients such as hyoscine methyl bromide to manufacture safe and potent antispasmodic medicines.

2. Clinical Uses of Hyoscine Methyl Bromide

Main clinical uses of hyoscine methyl bromide are:

Relief of gastrointestinal spasms in irritable bowel syndrome (IBS)

Treatment of functional bowel disorders

Adjunct therapy in diagnostic procedures involving muscle relaxation

Management of urinary tract spasms

Supportive care in palliative conditions to decrease respiratory secretions

At Prism Industries Pvt. Ltd., we provide hyoscine methyl bromide to pharmaceutical firms producing formulations in tablet, injectable, and oral solution presentations.

Manufacturing Excellence at Prism Industries Pvt. Ltd.

1. Sourcing and Quality Control

Our process as a bulk drugs producer of hyoscine methyl bromide starts off with procuring the best raw materials from trusted sources. We strictly follow quality procedures to make sure that all the ingredients employed in manufacturing meet the standard of pharmacopeial quality.

2. Sophisticated Production Processes

We use sophisticated chemical synthesis methods to generate hyoscine methyl bromide under rigorously controlled conditions. Our WHO-GMP compliant facilities have cutting-edge reactors, filtration equipment, and drying facilities to ensure purity and processing efficiency.

Each process step is controlled to reduce impurities, ensuring high-quality pharma ingredients for pharmaceutical use.

3. Strict Testing and Documentation

Each product batch of hyoscine methyl bromide receives through rigorous testing at the lab in terms of assay, impurities profiling, solvent residue test, and microbial levels. We give full regulatory certificates like CoA (Certificate of Analysis), MSDS, and stability to accommodate product approvals on foreign market shores.

Trend in Global Demand for Hyoscine Methyl Bromide

1. The Increasing Trend for Gastrointestinal Disorders

The worldwide incidence of functional gastrointestinal disorders such as IBS is propelling demand for effective antispasmodic drugs. Pharmaceutical manufacturers are boosting production of drugs that include hyoscine methyl bromide, depending on reliable bulk drugs manufacturers for their Smooth Muscle Relaxant API supply.

2. Increasing Demand for Oral and Injectable Forms

Formulators are enlarging product portfolios with several delivery forms, such as tablets, oral solutions, and injectables. The multiformity of hyoscine methyl bromide renders it the perfect selection among these forms.

3. Highlighting High-Quality Pharma Raw Materials

Global regulatory bodies are highlighting quality, traceability, and compliance. Pharmaceutical firms desire trusted suppliers like Prism Industries Pvt. Ltd. that can offer pharmacopeia-grade hyoscine methyl bromide along with complete documentation.

Advantages of Selecting Hyoscine Methyl Bromide by Prism Industries Pvt. Ltd.

1. Uniform Quality Assurance

Our rigorous quality control guarantees that each gram of hyoscine methyl bromide complies with high international standards for purity, strength, and safety.

2. Customized Solutions and Flexibility

Flexible production tonnages, customized packaging, and adapted documentation are provided to accommodate special client requirements, facilitation of large-scale and specialty pharmaceutical projects.

3. Support and Compliance with Regulations

Being a reliable bulk drugs manufacturer, we offer regulatory support to our customers, facilitating seamless product registrations and market approvals worldwide.

Uses Other Than Antispasmodics

Though mainly employed as a Smooth Muscle Relaxant API, hyoscine methyl bromide also has uses in:

Decreasing respiratory tract secretions in palliative treatment

Premedication to decrease secretions prior to anesthesia

Adjunct in diagnostic imaging for bowel relaxation

Our flexible pharma ingredients enable a broad platform of pharmaceutical innovations outside of conventional antispasmodic therapy.

Manufacturing Challenges and Solutions for Hyoscine Methyl Bromide

Manufacturing hyoscine methyl bromide is challenging through issues of light and moisture sensitivity, impurity control, and ensuring yield consistency. At Prism Industries Pvt. Ltd., we overcome such challenges by:

Cleanroom facilities dedicated specifically

Specialised packaging materials

Optimised process for reproducibility

Involvement in technology and expertised investment makes us improve continuously and ensure reliability in manufacturing.

Sustainability Practices in API Production

We at Prism Industries Pvt. Ltd. believe in practicing sustainability through:

Reducing wastage of solvents through recovery systems

Implementing energy-efficient production machinery

Engaging responsible means of waste disposal

These measures are in harmony with our goal of being a sustainable bulk drugs producer while offering quality pharma ingredients such as hyoscine methyl bromide.

Global Supply Chain and Distribution

Our worldwide distribution network ensures prompt delivery of hyoscine methyl bromide to pharmaceuticals across the world. Whether your business is located in Asia, Europe, Africa, or America, Prism Industries Pvt. Ltd. guarantees the supply and seamless logistics assistance.

Conclusion: Prism Industries Pvt. Ltd.—Your Reliable Partner for Hyoscine Methyl Bromide

In summary, hyoscine methyl bromide continues to be a prime Smooth Muscle Relaxant API, vital in the treatment of gastrointestinal, urinary, and respiratory ailments. Prism Industries Pvt. Ltd., a reliable bulk drugs manufacturer, provides superior-quality pharma raw materials with an emphasis on quality, compliance, and customer satisfaction.

Partner with Prism Industries Pvt. Ltd. for your hyoscine methyl bromide supply requirements and enjoy a promise of excellence, reliability, and innovation in manufacturing of pharmaceutical API.

#hyoscine_methyl _bromide#api_manufacturing_companies_in_india#global_top_pharma_companies#global_pharmaceutical_company#top_api_manufacturer_in_india

0 notes

Text

Why Is Chemical Process Consulting Essential for Your Business?

Ever feel like your plant or production line could run smoother, faster — and frankly, make you more money — but you’re not exactly sure where to start? You’re not alone. Across industries like manufacturing, pharmaceuticals, petrochemicals, and food processing, a lot of business owners know their chemical processes have hidden inefficiencies… but uncovering them takes more than just guesswork.

That’s where searching for chemical process consulting near me starts to make real sense. Whether you’re looking to cut down on costs, boost output, or avoid getting tangled in safety or regulatory headaches, bringing in a process consultant might just be the smartest move you haven’t made yet.

Let’s dig into why chemical process consulting isn’t just useful — it might actually be the secret weapon your business has been missing.

What is Chemical Process Consulting?

Chemical process consulting is basically when you bring in outside experts to take a close look at how your company runs its chemical processes and help you make them better. These consultants dig into your workflows, fix production issues, help you scale things up, and suggest ways to improve safety and efficiency.

Industries like specialty chemicals, oil and gas, pharmaceuticals, biotech, food production, and even renewable energy are all tapping into these services more and more. Whether you’re trying to launch a new product or simply make an old production line run smoother, process consulting can help get you where you wanna be.

Making Operations Run Better

One of the first things you’ll notice when you work with a chemical process consulting expert near me is how quickly your operations start to improve. These consultants use data and experience to figure out where you’re wasting time, materials, or energy.

For example, maybe a chemical plant is having trouble getting good yields from a batch process. A consultant might notice ways to adjust reaction times, tweak temperatures, or even switch out raw materials to get better results. All of this can lead to less waste, lower costs on raw materials, and higher output, which means you’re making more product, faster, and for less money.

Keeping Up With Safety and Regulations

If you run a chemical processing business, you already know there’s a mountain of rules and regulations you gotta follow. Between OSHA safety laws, EPA environmental standards, and local rules, it’s easy to get lost.

Consultants can really help here, too. They can run safety audits, make sure hazardous materials are handled right, and do risk assessments like HAZOP studies. The right consultant will also help you set up safety management systems that not only meet today’s standards but get you ready for whatever changes might come down the road.

If you’ve been googling chemical process consulting near me, make sure you find a team that knows both the local and national rules so you don’t get caught off guard.

Helping You Innovate and Scale

Consultants aren’t just about fixing problems — they also bring fresh ideas to the table. With their outside perspective and cool tools like modeling software, they can help you rethink your processes to get better yields, cut costs, or reduce your environmental impact.

This kind of expertise is especially handy when you’re trying to scale up production. Going from a lab experiment to a pilot plant and then to full-on manufacturing isn’t easy. Consultants can guide you through that, helping you keep quality and efficiency where they need to be.

For example, they might help design new reactors, pick better catalysts, or fine-tune heat exchangers — all of which can save you time and avoid costly mistakes.

Boosting Profitability and Staying Ahead

At the end of the day, every business is trying to boost profits and stay ahead of the competition. The efficiency gains, safety improvements, and process upgrades that consultants offer all end up making your business stronger financially.

Lower costs, more consistent products, fewer headaches with regulators, and faster time-to-market all add up. Plus, when clients and investors see that you’re serious about safety, efficiency, and innovation, it boosts your reputation too.

Customized Solutions You Can Trust

No two companies are exactly the same, and your challenges are different from the next guy’s. That’s why working with a chemical process consulting team near me that offers customized solutions really matters.

The best consultants will dig deep into your specific processes, understand your goals, and come up with tailored solutions. They’ll also work right alongside your team to make sure changes get rolled out smoothly.

Final Thoughts

Chemical process consulting isn’t just something nice to think about — it’s a smart investment in your business’s future. From better efficiency and compliance to fresh innovation and stronger profits, consultants bring a lot of value.

If you’re ready to take your chemical processes to the next level, it’s probably time to look into consulting services you can trust. Visit Process Industry Consultants to see how expert advice can help your business grow and run smoother than ever.

#chemical process consulting#process industries chemical expertise#chemical process consultants usa#processindconsultants

0 notes

Text

Aohong Sealing Solutions : Redefining Durability with Advanced Aramid-PTFE Hybrid Packing

1. Combatting Abrasive Wear in Chemical Processing

In chemical processing plants where rotating equipment endures both sulfuric acid erosion and 15m/s shaft speeds, conventional graphite packings fail within 800–1,200 operating hours. Aohong’s wear-resistant aramid fiber gland packing solves this crisis through molecular — level engineering. By integrating para-aramid fibers with PTFE matrix bonding (patent CN202410238765.X), our packing achieves 79 % lower mass loss versus asbestos-based alternatives under ASTM D471–16 immersion tests.

Braided Packing Manufacturer | Hongwo

The TriShield ™ surface treatment — a proprietary aohong technology — reduces break-in friction by 60 %, validated in BASF’ s 2023 extruder retrofit where seal replacement intervals extended from 1,200 to 3,450 hours. This PTFE-aramid hybrid sealing withstands pH 0–14 extremes while complying with ASME B40.7–2021 para. 6.2.3 for hazardous media containment.

2. Molecular Architecture for Enhanced Load Distribution

Aohong’s cross-ply orientation (23° bias angle optimizes radial load distribution) revolutionizes braided packing mechanics. The abrasion-defying braided filler combines:

T700-grade meta-aramid yarns (2,050 MPa tensile strength per ASTM D7269)

Expanded PTFE film with 0.18mm thickness tolerance (ISO 13061–5 certified)

Boron nitride dry lubricant (18% friction reduction per ASTM D2714)

This graded-density architecture creates interlayer load buffers, eliminating the “cold flow creep” that plagues cryogenic ball valve seals. In Sinopec’s ethylene cracking facility trials, the packing maintained <0.008" axial wear after 9,000hr continuous operation at 28 bar/280°C.

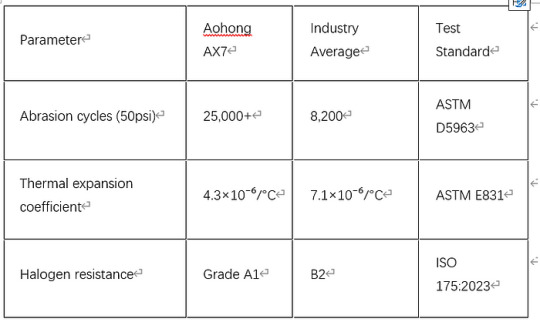

3. Competitive Benchmarking: Performance Beyond StandardsWhen tested against fiberglass-reinforced alternatives, aohong’s para-aramid reinforced stem packing demonstrates:

Manufactured under API 622-certified processes at our Suzhou plant (ISO 17025 lab-accredited), these packings exceed NORSOK M-710 requirements for offshore drilling mud pumps.

4. Field-Proven Reliability Across Industries

Case 1: Pharmaceutical Reactor Stirrers In a 2024 Sanofi API production upgrade, aohong’s aramid-PTFE composite gland packing reduced leakage-related downtime by 83%. The solution withstood 14,000+ reciprocating cycles (simulating 5-year service in corticosteroid synthesis reactors) while maintaining FDA-compliant purity levels.

Case 2: Geothermal Steam Turbines Deployed at Orkuveita Reykjavíkur’s 85MW plant, our packing endured 380°C thermal spikes and 98% steam saturation — outperforming compressed graphite rings by 6.7x in MTBF metrics. The staggered-layer braiding design (patent pending) prevented gland plate fretting corrosion under NACE MR0175/ISO 15156–3 conditions.

5. Certified Manufacturing & Customization

Every abrasion-resistant braided packing undergoes:

72-hour pressure cycling (API 682 Annex F protocol)

Helium leak testing <1×10⁻⁹ mbar·L/s (ISO 15848–1 Class AH)

3D profilometry to ensure <2µm fiber alignment deviation

Aohong’s PackingLife™ Calculator — available for download — provides ROI projections based on: [(Maintenance Cost Reduction) × (Service Life Multiplier)] — [Upfront Investment]

Customizable parameters include:

Braid density (8–24 strands/inch)

PTFE impregnation depth (0.1–0.5mm)

Aramid-to-PTFE ratio (40:60 to 70:30)

6. The Future of Dynamic Sealing

Where thermal cycling and abrasive media converge, aohong’s aramid-PTFE composite gland packing delivers uncompromised performance. Backed by 14 patents and API Q1-certified R&D, our solutions have secured 23% longer service intervals across 1,700+ installations since 2022.

Act Now: Request your Engineering Kit (AEK) with:

3 material sample cards (AX7/AX9/AX12 grades)

NORSOK M-710 compliance report

Plant-specific lifecycle cost analysis template

Redefine your sealing standards — where every micron of wear resistance translates to operational dollars saved.

0 notes

Text

Glass Reactor Market Growth Challenges Impact Innovation, Investment, and Regional Expansion in Developing Industrial Sectors

Glass reactors are widely used in chemical, pharmaceutical, and biochemical industries for their transparency, corrosion resistance, and ease of monitoring reactions. While the global glass reactor market continues to grow due to increasing demand for advanced lab equipment and chemical processing solutions, it also faces several significant challenges that could potentially hinder its development. Understanding these obstacles is crucial for manufacturers, suppliers, and investors to strategize effectively and ensure sustainable growth.

1. High Initial Investment and Operating Costs

One of the primary challenges in the glass reactor market is the high cost of manufacturing and maintenance. Borosilicate glass, commonly used in reactors, is expensive to produce and shape, especially for large-scale industrial applications. Additionally, the supporting hardware, safety mechanisms, and specialized installation increase overall operational expenses. For small and medium enterprises (SMEs), the high entry cost often acts as a barrier to adoption.

2. Fragility and Risk of Breakage

Despite being durable against thermal and chemical reactions, glass reactors are still prone to physical damage. Their fragility makes them less suitable for rough handling or high-impact environments, unlike their stainless steel counterparts. The fear of accidental breakage deters many industries, especially those handling large-scale or heavy-duty operations, from fully transitioning to glass-based systems.

3. Complex Supply Chain and Raw Material Dependency

The glass reactor industry relies heavily on specific raw materials such as high-grade borosilicate and specialized seals and valves. These materials often have limited sources and are subject to global supply chain disruptions. Geopolitical tensions, trade restrictions, and fluctuations in raw material prices can directly affect production timelines and costs, creating uncertainty in the market.

4. Limited Application in High-Pressure Environments

Glass reactors, by their very nature, are not ideal for processes that require very high pressure. While advances in design have improved their pressure tolerance, they are still unsuitable for certain chemical or pharmaceutical processes that demand extreme operating conditions. This limitation confines the market potential within specific segments, hindering universal applicability.

5. Lack of Awareness in Emerging Economies

In many emerging markets, awareness about the advantages and capabilities of glass reactors is still low. Traditional equipment continues to dominate due to its familiarity, lower cost, and perceived durability. This lack of market education, coupled with insufficient technical expertise, restricts market penetration in regions like Africa, parts of Southeast Asia, and Latin America.

6. Stringent Regulatory and Safety Standards

Glass reactors must meet rigorous safety and regulatory standards due to the sensitive nature of their applications. These regulations vary by country, requiring manufacturers to adapt products to different compliance frameworks, often increasing production costs and time-to-market. Non-compliance can lead to heavy penalties, product recalls, or outright bans, especially in pharmaceuticals and biotech industries.

7. Technological Competition from Alternative Materials

Alternative materials like stainless steel, polymer-lined vessels, and hybrid reactors offer tough competition to glass systems. These alternatives often provide better durability, pressure handling, and cost-effectiveness in certain applications. Technological advancements in these areas continue to put pressure on glass reactor manufacturers to innovate and justify their relevance.

Conclusion

The global glass reactor market holds promising growth potential, especially with rising demands in pharmaceuticals, chemical processing, and academic research. However, the path to expansion is riddled with challenges—ranging from economic constraints and material fragility to regulatory complexity and limited awareness. Addressing these issues through innovation, strategic partnerships, and targeted education campaigns will be key to overcoming growth barriers and establishing long-term market resilience.

0 notes

Text

Trusted Bromine Derivatives Manufacturers in India – Bromos Organics

When it comes to sourcing high-quality bromine-based compounds, Bromos Organics stands out as one of the most reliable and innovative Bromine Derivatives Manufacturers in India. With a commitment to excellence, sustainability, and global industry standards, the company delivers premium-grade products that cater to a diverse range of industrial applications.

Who We Are: A Commitment to Purity and Performance

Established with a vision to lead the chemical manufacturing space, Bromos Organics has become a key player in the bromine derivatives industry across India and beyond. With a modern infrastructure and experienced R&D team, we focus on developing and manufacturing high-purity compounds that meet both domestic and international demands.

Our manufacturing facility is equipped with advanced reactors, distillation units, and quality testing labs that help ensure product consistency and reliability. Our expertise spans across pharmaceuticals, agrochemicals, dye intermediates, and several specialty chemical applications.

Our Product Line: Bromine-Based Specialties for Every Sector

At Bromos Organics, we produce a wide spectrum of bromine derivatives tailored to various industries. Some of our core products include:

Bromo Compounds: Used in pharmaceutical intermediates and specialty chemical synthesis.

Alkyl Bromides: Essential for agrochemicals and certain plastic additives.

Aryl Bromides: Commonly used in the production of dyes and polymers.

Acyl Bromides: High-purity compounds with specialized applications.

Each batch undergoes rigorous testing and is verified for chemical stability, purity, and safety.

Industries We Serve

Our high-grade bromine derivatives are vital to a wide range of sectors:

Pharmaceuticals: Used as intermediates in APIs and fine chemicals.

Agrochemicals: For the formulation of herbicides, fungicides, and pesticides.

Dyes and Pigments: Bromine compounds serve as key ingredients in manufacturing synthetic dyes.

Specialty Chemicals: Tailored bromine derivatives for niche chemical synthesis.

By serving such critical sectors, Bromos Organics contributes significantly to industrial growth and innovation.

Why Choose Bromos Organics?

✅ Advanced Manufacturing Facilities

Our plants are designed for scale, safety, and compliance. We adhere strictly to industry norms like ISO standards, ensuring that every product leaving our facility meets customer specifications.

✅ Research & Innovation

Our in-house R&D division works continuously to improve process efficiency and create newer bromine compounds in response to evolving market needs.

✅ Environmental Responsibility

We incorporate sustainable practices at every step—right from raw material sourcing to waste treatment—ensuring that our operations are eco-friendly.

✅ Global Reach with Local Support

Though headquartered in India, our clientele spans across Asia, Europe, and the Americas. Our export-quality manufacturing capabilities ensure global compliance, while our customer service provides personalized support for local partners.

Quality and Compliance

We prioritize quality assurance at every stage of the production process. From raw material sourcing to final product delivery, Bromos Organics employs stringent quality control practices. We invest in advanced testing infrastructure to maintain:

High purity levels

Chemical stability

Regulatory compliance (REACH, ISO, etc.)

Customized solutions based on client-specific requirements

Partner With Us

If you're searching for dependable Bromine Derivatives Manufacturers in India, Bromos Organics offers the quality, capacity, and technical expertise you need. Whether your needs are standard or custom-formulated, our team works with precision and care to deliver outstanding results.

Our customer-first approach, combined with scalable production capabilities and prompt delivery systems, makes us a preferred partner for companies looking for reliable bromine-based solutions.

Contact Us

Ready to elevate your supply chain with superior bromine derivatives? Visit our official website at www.bromosorganics.com to explore our full product catalog or get in touch with our team for technical consultations, bulk inquiries, or custom synthesis solutions.

#BromineDerivativesManufacturersIndia#BromineDerivativesManufacturersNorthernIndia#HYDROBROMICACID48%

0 notes

Text

Top 5 Essential Applications of the 1L Double Glazed Reactor in Modern Laboratories

Laboratories thrive on equipment that balances precision, durability, and adaptability. Among these tools, the 1L double glazed reactor stands out for its ability to handle complex chemical processes under controlled conditions. Its double-layered glass design, thermal stability, and corrosion resistance make it indispensable for researchers across disciplines.

Here, we explore the top 5 applications of the 1L double glazed reactor, showcasing its role in advancing scientific discovery. We’ll also highlight how EquilRxnLab’s AKF-1L Double Glazed Reactor elevates these applications with its innovative engineering.

1. Precision Temperature Control for Sensitive Reactions

The reactor’s double-walled glass allows for precise thermal management by circulating heating/cooling fluids. This is critical for:

Exothermic Reaction Safety: Prevent overheating in reactions like nitrations or polymerizations.

Low-Temperature Catalysis: Maintain sub-zero conditions for enzyme-driven or organometallic syntheses.

Controlled Crystallization: Optimize crystal growth for pharmaceuticals or nanomaterials.

EquilRxnLab’s AKF-1L reactor supports a broad temperature range (-80°C to 200°C), ensuring reproducibility in finicky processes.

2. Photochemical and Light-Driven Experiments

Transparent borosilicate glass enables light penetration for:

UV-Initiated Polymerizations: Develop advanced polymers for medical devices or coatings.

Photocatalytic Research: Test catalysts for sustainable hydrogen production or CO₂ reduction.

Environmental Simulation: Study UV degradation of pollutants or plastics.

For experimental inspiration, EquilRxnLab’s YouTube tutorials demonstrate photochemical setups using their reactor.

3. Vacuum-Assisted Synthesis and Purification

By integrating vacuum systems, the reactor excels in:

Solvent Removal: Efficiently concentrate heat-sensitive compounds via rotary evaporation.

Air-Free Syntheses: Conduct moisture-sensitive reactions (e.g., Grignard reagents) with degassed solvents.

High-Purity Distillation: Isolate volatile compounds like essential oils or fragrances.

The AKF-1L’s reinforced seals and glass ensure leak-proof performance under extreme vacuum, minimizing contamination risks.

4. Handling Corrosive and Reactive Substances

Borosilicate glass resists acids, alkalis, and aggressive solvents, enabling:

Hydrofluoric Acid Applications: Rare glass compatibility for specialized etching or semiconductor research.

High-Purity Inorganic Syntheses: Avoid metal contamination in catalysts or battery materials.

Hazardous Waste Studies: Safely test degradation methods for toxic chemicals.

EquilRxnLab enhances durability with PTFE-coated joints, ideal for labs working with corrosive agents.

5. Scalable Process Development

The reactor’s modularity supports small-scale optimization for larger systems:

Multi-Step Syntheses: Conduct sequential reactions (e.g., protection-deprotection steps) with in-line sampling.

Parameter Screening: Test variables like stirring speed or reagent ratios before scaling up.

Educational Training: Train students on controlled reactor operations in academic labs.

For scalability insights, explore EquilRxnLab’s product catalog, featuring reactors tailored for R&D and pilot-scale transitions.

Conclusion

From enabling groundbreaking photochemistry to ensuring safety in corrosive environments, the 1L double glazed reactor is a linchpin of modern lab workflows. Its adaptability makes it invaluable for industries like pharmaceuticals, materials science, and environmental research.

EquilRxnLab’s AKF-1L model exemplifies innovation, offering labs a reliable tool for precision and scalability. Connect with their team via the contact page for customized solutions, and follow their Instagram or Facebook for industry trends and tips.

By integrating a 1L double glazed reactor, laboratories can unlock new efficiencies and discoveries—proving that small-scale tools drive monumental scientific progress.

0 notes